Development and Research of Biocompatible Composite Materials Based on Polyvinyl Alcohol and Hydroxyapatite Obtained by 3D Printing

Abstract

1. Introduction

- (i)

- Metal implants, for example, those made of titanium [12] and cobalt-chromium alloys [13], are valued for their high strength and are used for fracture fixation and total joint replacement. However, they have the potential to induce stress shielding, thereby weakening the surrounding bone and impeding active regeneration.

- (ii)

- Ceramic materials (e.g., hydroxyapatite, tricalcium phosphate) demonstrate high biocompatibility, osteoconductivity (i.e., the capacity to function as a matrix for bone growth) and chemical similarity to natural bone. These fillers are utilised in the treatment of bone defects, while their use as coatings for metal implants has also been demonstrated [14,15,16]. The primary disadvantages associated with these materials pertain to their fragility and the challenge of constructing intricate structures.

- (iii)

- Polymeric materials (for instance, polymethyl methacrylate, polyetheretherketone, and biodegradable polymers such as polylactic acid or polyglycolic acid) possess the advantageous qualities of flexibility, controllable degradation rates, and the capacity to generate porous structures. These materials find application in a variety of contexts, including bone cements, scaffolds for tissue engineering, and specific types of prostheses. However, it has been observed that their mechanical strength frequently falls short of the requirements necessary for load-bearing applications [17,18].

2. Materials and Methods

2.1. Synthesis of Composite Material

2.2. Three-Dimensional Printing Parameters

2.3. Characterization Methods

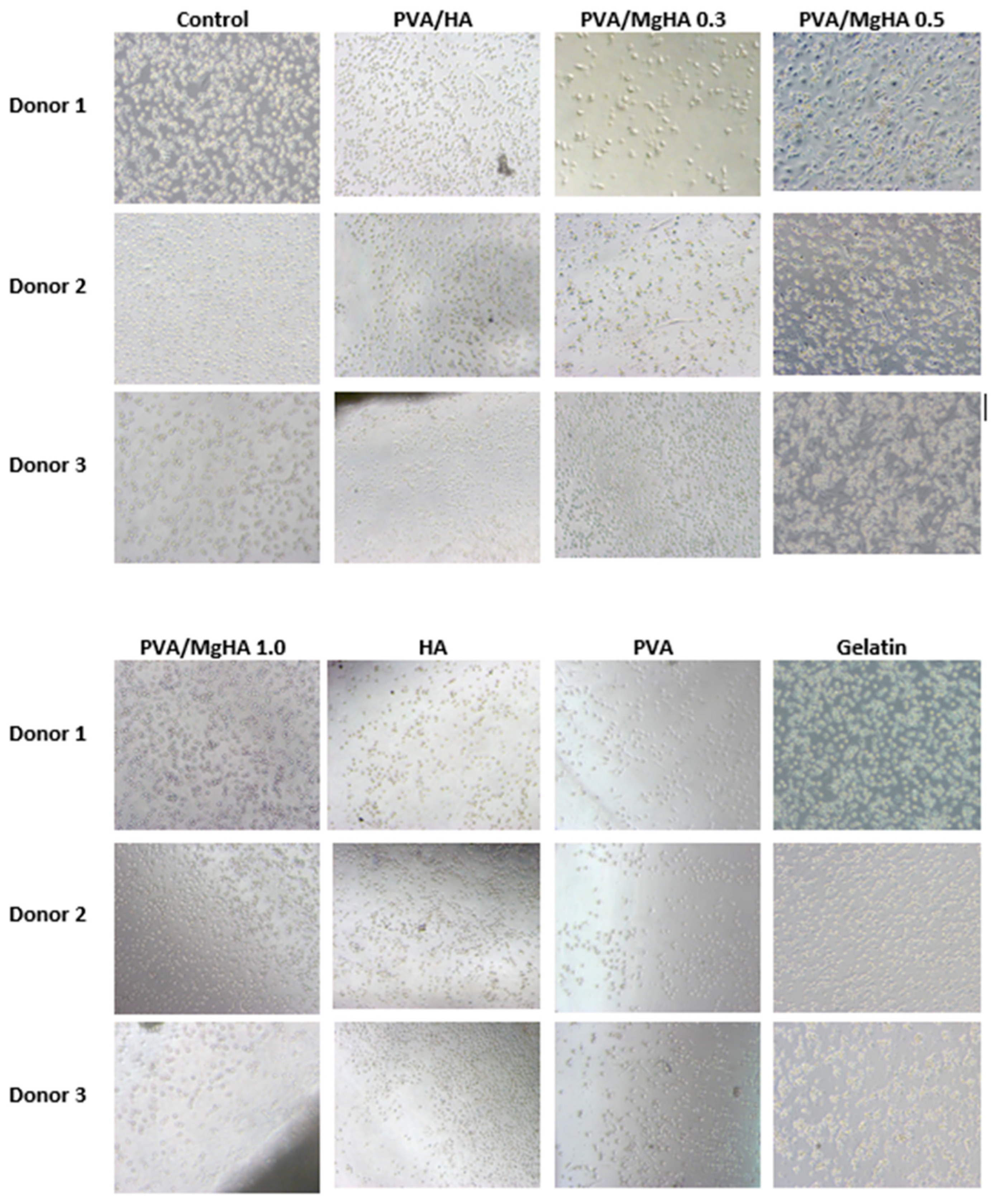

2.4. In Vitro Experiments

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Florencio-Silva, R.; da Silva Sasso, G.R.; Sasso-Cerri, E.; Simões, M.J.; Cerri, P.S. Biology of bone tissue: Structure, function, and factors that influence bone cells. BioMed Res. Int. 2015, 1, 421746. [Google Scholar] [CrossRef]

- Saul, D.; Menger, M.M.; Ehnert, S.; Nüssler, A.K.; Histing, T.; Laschke, M.W. Bone healing gone wrong: Pathological fracture healing and non-unions—Overview of basic and clinical aspects and systematic review of risk factors. Bioengineering 2023, 10, 85. [Google Scholar] [CrossRef]

- Khan, A.A.; Slart, R.H.J.A.; Ali, D.S.; Bock, O.; Carey, J.J.; Camacho, P.; Engelke, K.; Erba, P.A.; Harvey, N.C.; Lems, W.F.; et al. Osteoporotic fractures: Diagnosis, evaluation, and significance from the International Working Group on DXA Best Practices. Mayo Clin. Proc. 2024, 99, 1127–1141. [Google Scholar] [CrossRef] [PubMed]

- De Pace, R.; Molinari, S.; Mazzoni, E.; Perale, G. Bone regeneration: A review of current treatment strategies. J. Clin. Med. 2025, 14, 1838. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.-Y.; Song, W.; Wang, J.-B.; Lv, R.-Q.; Zhao, F.-H.; Yang, D.-W. Surgical vs. conservative treatment for hip osteoporotic fracture in maintenance hemodialysis patients: A retrospective analysis. Front. Surg. 2024, 11, 1471101. [Google Scholar] [CrossRef]

- Ehlen, Q.T.; Costello, J.P.; Mirsky, N.A.; Slavin, B.V.; Parra, M.; Ptashnik, A.; Nayak, V.V.; Coelho, P.G.; Witek, L. Treatment of bone defects and nonunion via novel delivery mechanisms, growth factors, and stem cells: A review. ACS Biomater. Sci. Eng. 2024, 10, 7314–7336. [Google Scholar] [CrossRef]

- Todd, E.A.; Mirsky, N.A.; Silva, B.L.G.; Shinde, A.R.; Arakelians, A.R.L.; Nayak, V.V.; Marcantonio, R.A.C.; Gupta, N.; Witek, L.; Coelho, P.G. Functional scaffolds for bone tissue regeneration: A comprehensive review of materials, methods, and future directions. J. Funct. Biomater. 2024, 15, 280. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y.; He, C.; Yang, W.; Qi, F.; Xie, D.; Shen, L.; Peng, S.; Shuai, C. Mg bone implant: Features, developments and perspectives. Mater. Des. 2020, 185, 108259. [Google Scholar] [CrossRef]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.S.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D bioprinting: An overview. Biomater. Sci. 2018, 5, 915–946. [Google Scholar] [CrossRef]

- Kačarević, Ž.P.; Rider, P.M.; Alkildani, S.; Retnasingh, S.; Smeets, R.; Jung, O.; Ivanišević, Z.; Barbeck, M. An introduction to 3D bioprinting: Possibilities, challenges and future aspects. Materials 2018, 11, 2199. [Google Scholar] [CrossRef]

- Fang, Y.; Guo, Y.; Liu, T.; Xu, R.; Mao, S.; Mo, X.; Zhang, T.; Ouyang, L.; Xiong, Z.; Sun, W. Advances in 3D bioprinting. Chin. J. Mech. Eng. 2022, 1, 100011. [Google Scholar] [CrossRef]

- Zhang, J.; Zhuang, Y.; Sheng, R.; Tomás, H.; Rodrigues, J.; Yuan, G.; Wang, X.; Lin, K. Smart stimuli-responsive strategies for titanium implant functionalization in bone regeneration and therapeutics. Mater. Horiz. 2024, 11, 12–36. [Google Scholar] [CrossRef] [PubMed]

- Mani, G.; Porter, D.; Collins, S.; Schatz, T.; Ornberg, A.; Shulfer, R. A review on manufacturing processes of cobalt-chromium alloy implants and its impact on corrosion resistance and biocompatibility. J. Biomed. Mater. Res. B Appl. Biomater. 2024, 6, e35431. [Google Scholar] [CrossRef]

- Baggio, A.M.P.; Sillmann, Y.M.; Eber, P.; Michallek, F.R.; Monteiro, J.L.; Bassi, A.P.; Guastaldi, F.P. How Does Ceramic-Based Scaffold Microarchitecture Impact Maxillofacial Bone Regeneration? A Systematic Review of Large Animal Models. Appl. Sci. 2025, 15, 6899. [Google Scholar] [CrossRef]

- Kucko, S.K.; Raeman, S.M.; Keenan, T.J. Current advances in hydroxyapatite-and β-tricalcium phosphate-based composites for biomedical applications: A review. Biomed. Mater. Devices 2023, 1, 49–65. [Google Scholar] [CrossRef]

- Somngam, C.; Samartkit, S.; Kanchanasurakit, S.; Strietzel, F.P.; Khongkhunthian, P. New bone formation of biphasic calcium phosphate bone substitute material: A systematic review and network meta-analysis of randomized controlled trials (RCTs). Int. J. Implant Dent. 2025, 11, 47. [Google Scholar] [CrossRef]

- Wachtman, J.B.; Cannon, W.R.; Matthewson, M.J. Mechanical Properties of Ceramics; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Elsayed, A.; Wille, S.; Al-Akhali, M.; Kern, M. Comparison of fracture strength and failure mode of different ceramic implant abutments. J. Prosthet. Dent. 2017, 4, 499–506. [Google Scholar] [CrossRef] [PubMed]

- Sadykov, R.; Lytkina, D.; Stepanova, K.; Kurzina, I. Synthesis of biocompatible composite material based on cryogels of polyvinyl alcohol and calcium phosphates. Polymers 2022, 16, 3420. [Google Scholar] [CrossRef]

- Shalygina, K.; Lytkina, D.; Sadykov, R.; Kurzina, I. Composite cryogels based on hydroxyapatite and polyvinyl alcohol and the study of physicochemical and mechanical properties. Materials 2024, 2, 403. [Google Scholar] [CrossRef]

- Stepanova, K.; Lytkina, D.; Sadykov, R.; Shalygina, K.; Khojazoda, T.; Mahmadbegov, R.; Kurzina, I. Composite cement materials based on β-tricalcium phosphate, calcium sulfate, and a mixture of polyvinyl alcohol and polyvinylpyrrolidone intended for osteanagenesis. Polymers 2022, 1, 210. [Google Scholar] [CrossRef]

- Lan, W.; Xu, M.; Qin, M.; Cheng, Y.; Zhao, Y.; Huang, D.; Wei, X.; Guo, Y.; Chen, W. Physicochemical properties and biocompatibility of the bi-layer polyvinyl alcohol-based hydrogel for osteochondral tissue engineering. Mater. Des. 2021, 204, 109652. [Google Scholar] [CrossRef]

- Yang, M.; Wang, Z.; Li, M.; Yin, Z.; Butt, H.A. The synthesis, mechanisms, and additives for bio-compatible polyvinyl alcohol hydrogels: A review on current advances, trends, and future outlook. J. Vinyl Addit. Technol. 2023, 6, 939–959. [Google Scholar] [CrossRef]

- Li, L.; Xu, X.; Liu, L.; Song, P.; Cao, Q.; Xu, Z.; Fang, Z.; Wang, H. Water governs the mechanical properties of poly (vinyl alcohol). Polymer 2021, 213, 123330. [Google Scholar] [CrossRef]

- Fumio, U.; Hiroshi, Y.; Kumiko, N.; Sachihiko, N.; Kenji, S.; Yasunori, M. Swelling and mechanical properties of poly (vinyl alcohol) hydrogels. Int. J. Pharm. 1990, 2, 135–142. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, Z.; Li, W.; Fan, Y.; Li, Z.; Wei, J. Hydroxyapatite based materials for bone tissue engineering: A brief and comprehensive introduction. Crystals 2021, 2, 149. [Google Scholar] [CrossRef]

- DileepKumar, V.G.; Sridhar, M.S.; Aramwit, P.; Krut’ko, V.K.; Musskaya, O.N.; Glazov, I.E.; Reddy, N. A review on the synthesis and properties of hydroxyapatite for biomedical applications. J. Biomater. Sci. Polym. Ed. 2022, 2, 229–261. [Google Scholar] [CrossRef]

- Alanis-Gómez, R.P.; Hernández-Rosas, F.; Olivares-Hernández, J.D.; Rivera-Muñoz, E.M.; Zapatero-Gutiérrez, A.; Méndez-Lozano, N.; Alanis-Gómez, J.R.; Velázquez-Castillo, R. Magnesium-Doped Hydroxyapatite Nanofibers for Medicine Applications: Characterization, Antimicrobial Activity, and Cytotoxicity Study. Int. J. Mol. Sci. 2024, 25, 12418. [Google Scholar] [CrossRef]

- Santos, G.G.; Nunes, V.L.C.; Marinho, S.M.O.C.; Santos, S.R.A.; Rossi, A.M.; Miguel, F.B. Biological behavior of magnesium-substituted hydroxyapatite during bone repair. Braz. J. Biol. 2020, 1, 53–61. [Google Scholar] [CrossRef]

- Predoi, D.; Ciobanu, S.C.; Iconaru, S.L.; Predoi, M.V. Influence of the biological medium on the properties of magnesium doped hydroxyapatite composite coatings. Coatings 2023, 2, 409. [Google Scholar] [CrossRef]

| Sample | Reaction Equation |

|---|---|

| PVA/HA | 10Ca(OH)2 + 6(NH)4HPO4 = Ca10(PO4)6(OH)2↓ + 12NH4OH + 6H2O |

| PVA/MgHA 0.3 | 9.7Ca(OH)2 + MgCl2 + 6(NH4)2HPO4 = Ca9.7Mg0.3(PO4)6(OH)2↓ + 2NH4Cl + 10NH4OH + 6H2O |

| PVA/MgHA 0.5 | 9.5Ca(OH)2 + MgCl2 + 6(NH4)2HPO4 = Ca9.5Mg0.5(PO4)6(OH)2↓ + 2NH4Cl + 10NH4OH + 6H2O |

| PVA/MgHA 1.0 | 9Ca(OH)2 + MgCl2 + 6(NH4)2HPO4 = Ca9Mg(PO4)6(OH)2↓ + 2NH4Cl + 10NH4OH + 6H2O |

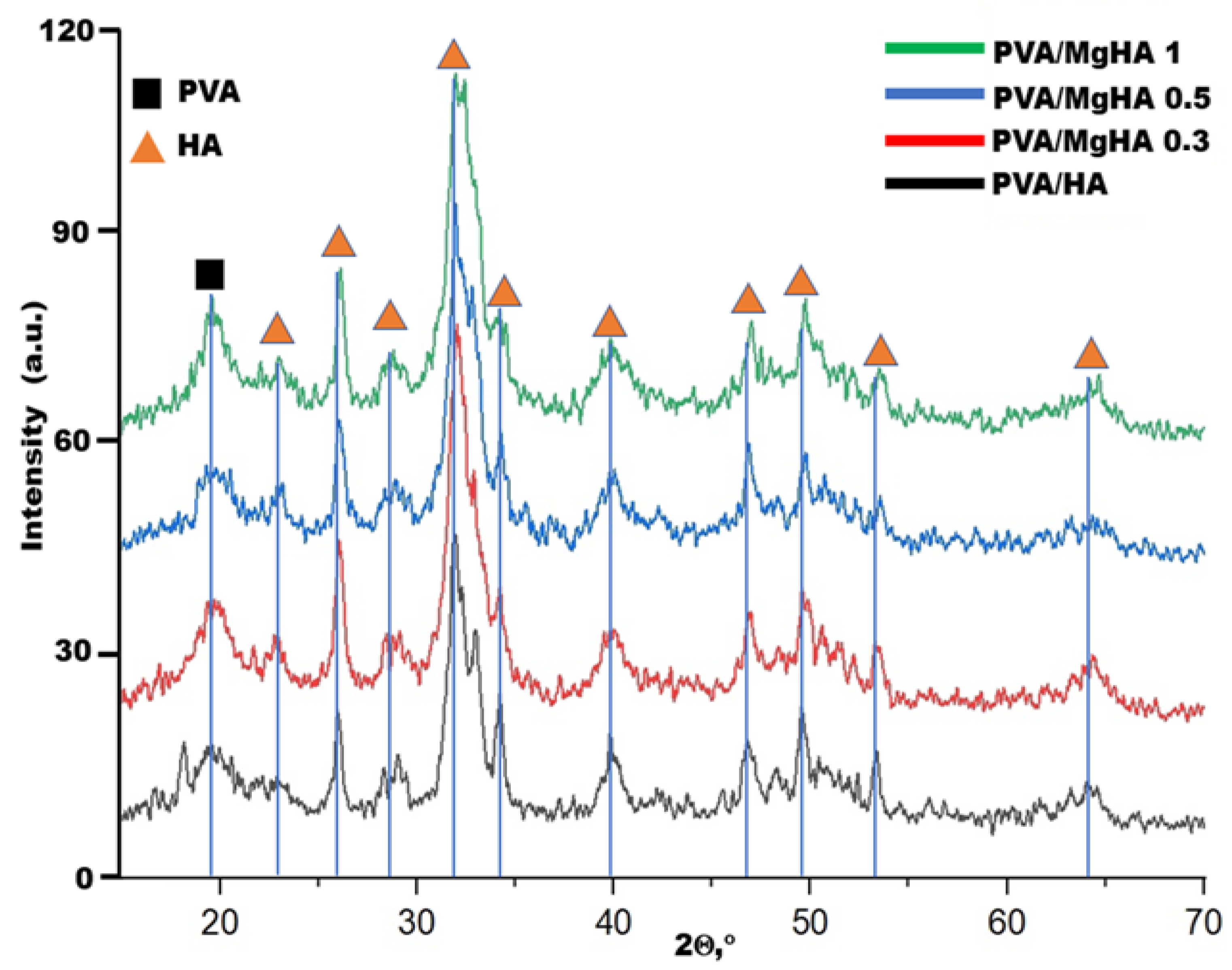

| Sample | Crystallite Size, nm | D, Å |

|---|---|---|

| PVA/HA | 13 | 2.5 |

| PVA/MgHA 0.3 | 10 | 2.1 |

| PVA/MgHA 0.5 | 10 | 2.1 |

| PVA/MgHA 1.0 | 10 | 2.1 |

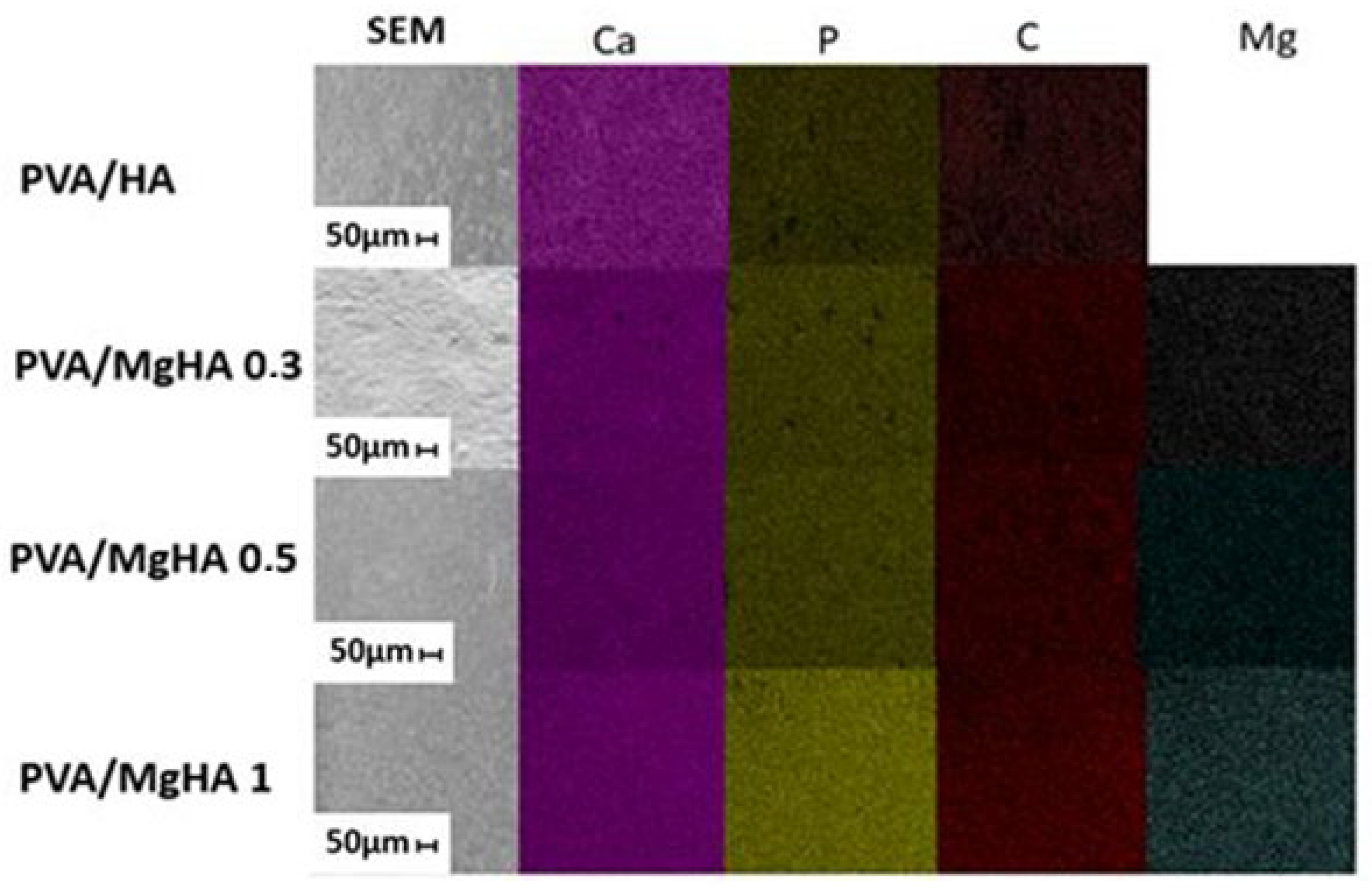

| Element | PVA/HA (at. %) | PVA/MgHA 0.3 (at. %) | PVA/MgHA 0.5 (at. %) | PVA/MgHA 1 (at. %) |

|---|---|---|---|---|

| C | 37.5 | 53.1 | 39.8 | 37.5 |

| P | 7.3 | 4.3 | 7.5 | 7.9 |

| Ca | 12.6 | 7.13 | 11.6 | 13.8 |

| Mg | - | 0.2 | 0.5 | 0.9 |

| Ca/P | 1.71 | 1.65 | 1.53 | 1.71 |

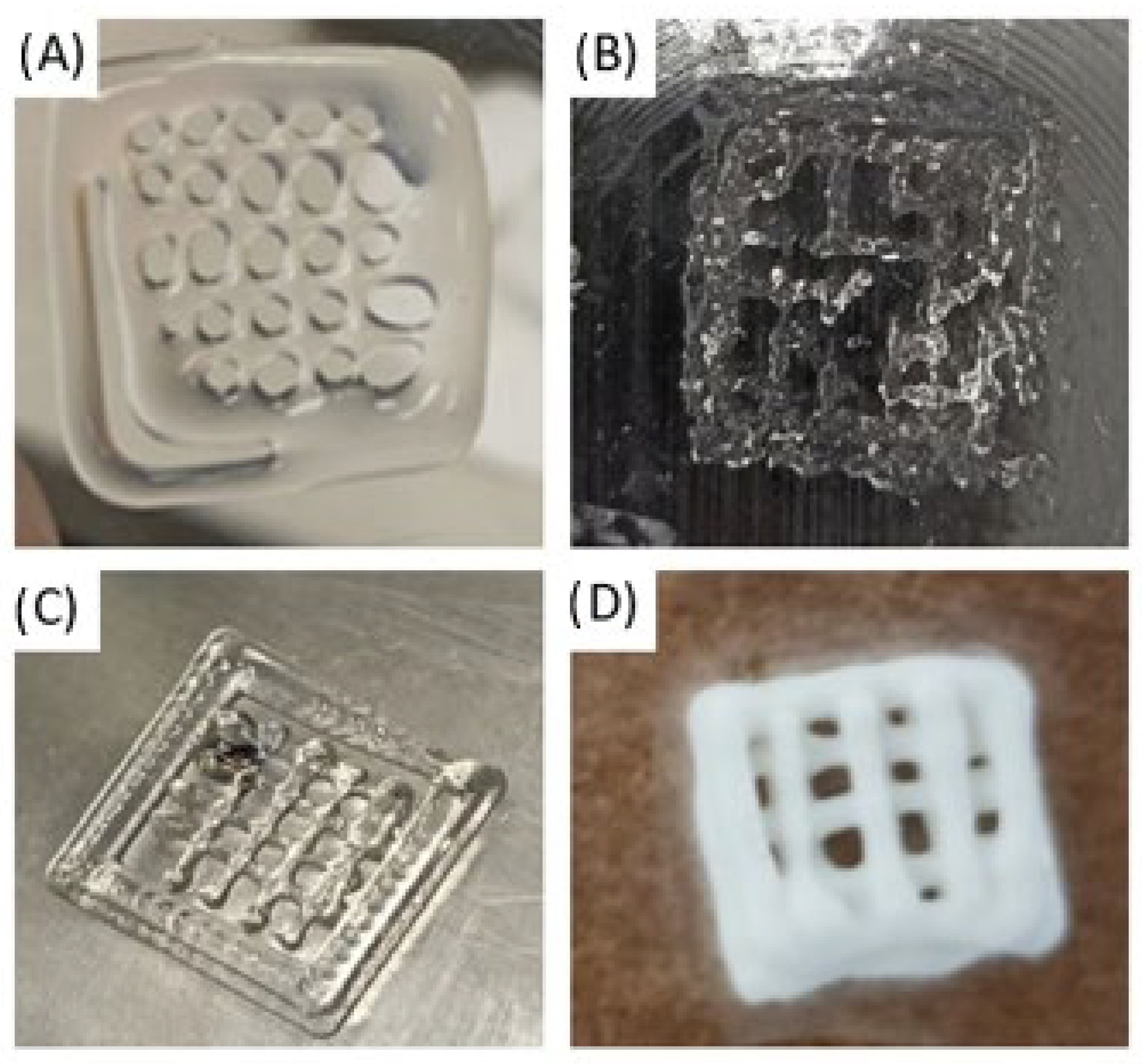

| PVA Solution wt.% | Pure Solution | Freezing (−15 °C) | Alginate (1–5 wt. %) | Gelatin (4 wt. %) |

|---|---|---|---|---|

| 1 | − | − | − | − |

| 3 | − | − | − | − |

| 5 | − | − | − | − |

| 7 | − | − | − | − |

| 9–10 | − | − | − | + |

| 12–13 | − | − | − | − |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadykov, R.; Musina, G.; Zhaslan, R.; Lytkina, D.; Khomutova, U.; Laput, O.; Domracheva, L.; Kurzina, I.; Takibayeva, A.; Rakhimberlinova, Z.; et al. Development and Research of Biocompatible Composite Materials Based on Polyvinyl Alcohol and Hydroxyapatite Obtained by 3D Printing. J. Compos. Sci. 2025, 9, 614. https://doi.org/10.3390/jcs9110614

Sadykov R, Musina G, Zhaslan R, Lytkina D, Khomutova U, Laput O, Domracheva L, Kurzina I, Takibayeva A, Rakhimberlinova Z, et al. Development and Research of Biocompatible Composite Materials Based on Polyvinyl Alcohol and Hydroxyapatite Obtained by 3D Printing. Journal of Composites Science. 2025; 9(11):614. https://doi.org/10.3390/jcs9110614

Chicago/Turabian StyleSadykov, Rustam, Gulnaz Musina, Rymgul Zhaslan, Daria Lytkina, Ulyana Khomutova, Olesya Laput, Lyubov Domracheva, Irina Kurzina, Altynaray Takibayeva, Zhanara Rakhimberlinova, and et al. 2025. "Development and Research of Biocompatible Composite Materials Based on Polyvinyl Alcohol and Hydroxyapatite Obtained by 3D Printing" Journal of Composites Science 9, no. 11: 614. https://doi.org/10.3390/jcs9110614

APA StyleSadykov, R., Musina, G., Zhaslan, R., Lytkina, D., Khomutova, U., Laput, O., Domracheva, L., Kurzina, I., Takibayeva, A., Rakhimberlinova, Z., & Seitkasymova, G. (2025). Development and Research of Biocompatible Composite Materials Based on Polyvinyl Alcohol and Hydroxyapatite Obtained by 3D Printing. Journal of Composites Science, 9(11), 614. https://doi.org/10.3390/jcs9110614