In Situ Polymerization as an Effective Method, Compared to Melt Mixing, for Synthesis of Flexible Poly(lactic acid) Nanocomposites Based on Metal Nanoparticles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PLA and PLA Nanocomposites Based on Ag via Ring-Opening Polymerization

2.3. Masterbatch Preparation via Solvent Casting

2.4. Preparation of PLA-Based Nanocomposites via Melt Mixing

Film Preparation

2.5. Characterization Techniques

2.5.1. Intrinsic Viscosity

2.5.2. Gel Permeation Chromatography (GPC)

2.5.3. Attenuated Total Reflectance Fourier-Transform Infrared Spectroscopy (ATR-FTIR)

2.5.4. Color Measurements

2.5.5. Differential Scanning Calorimetry (DSC)

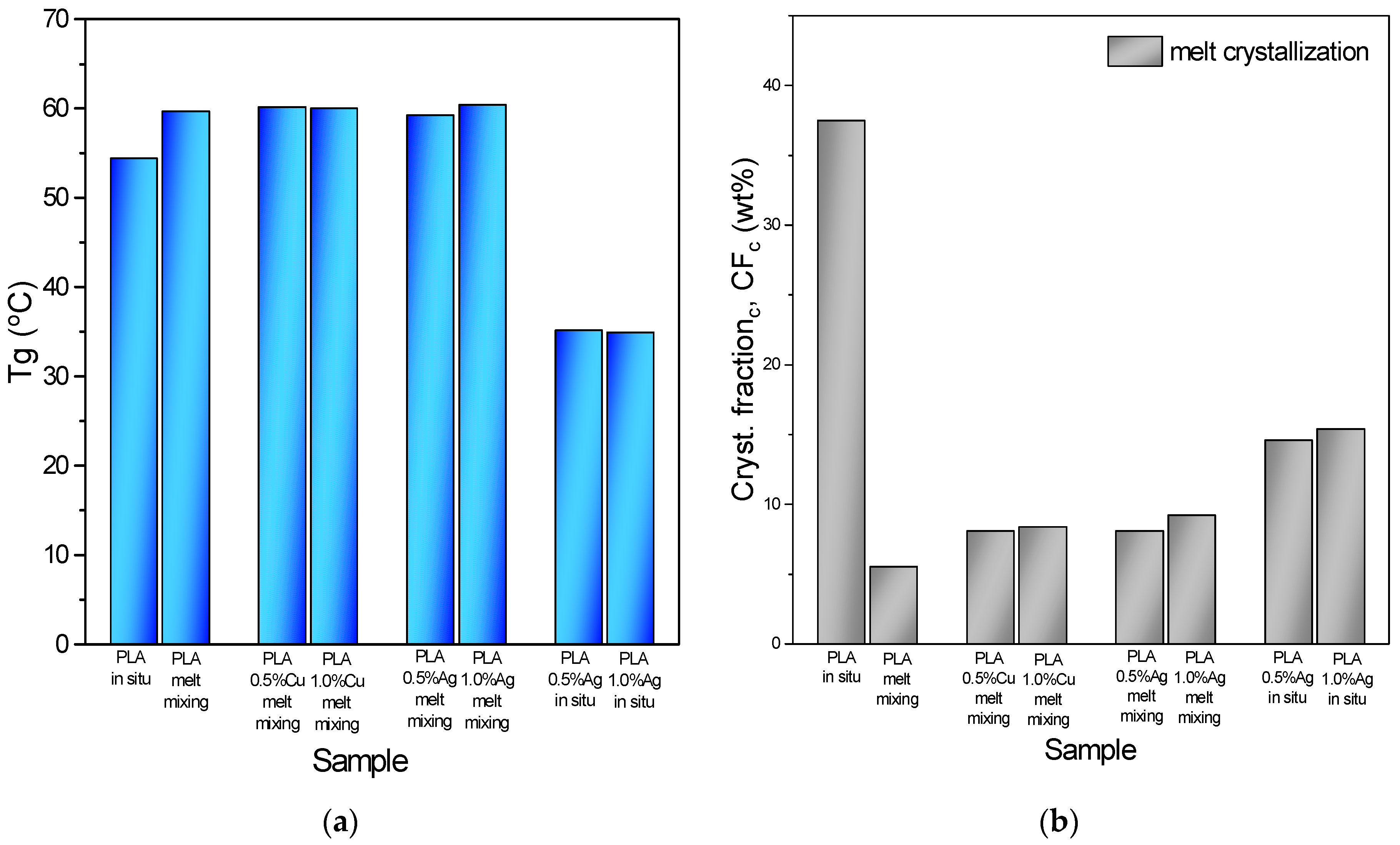

2.5.6. X-Ray Diffraction (XRD)

2.5.7. Tensile Properties

2.5.8. Flexural Properties

2.5.9. Water Contact Angle

3. Results and Discussion

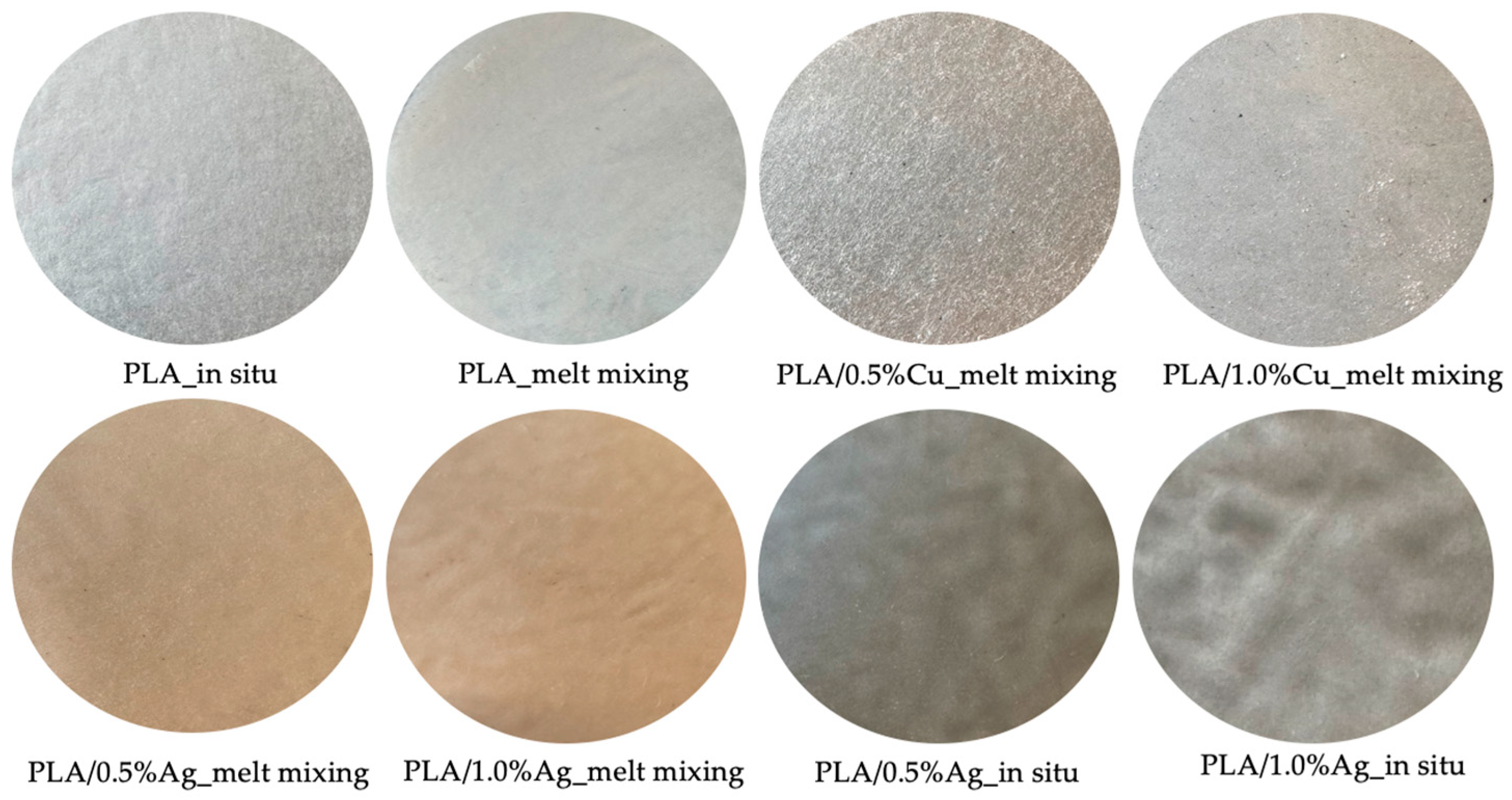

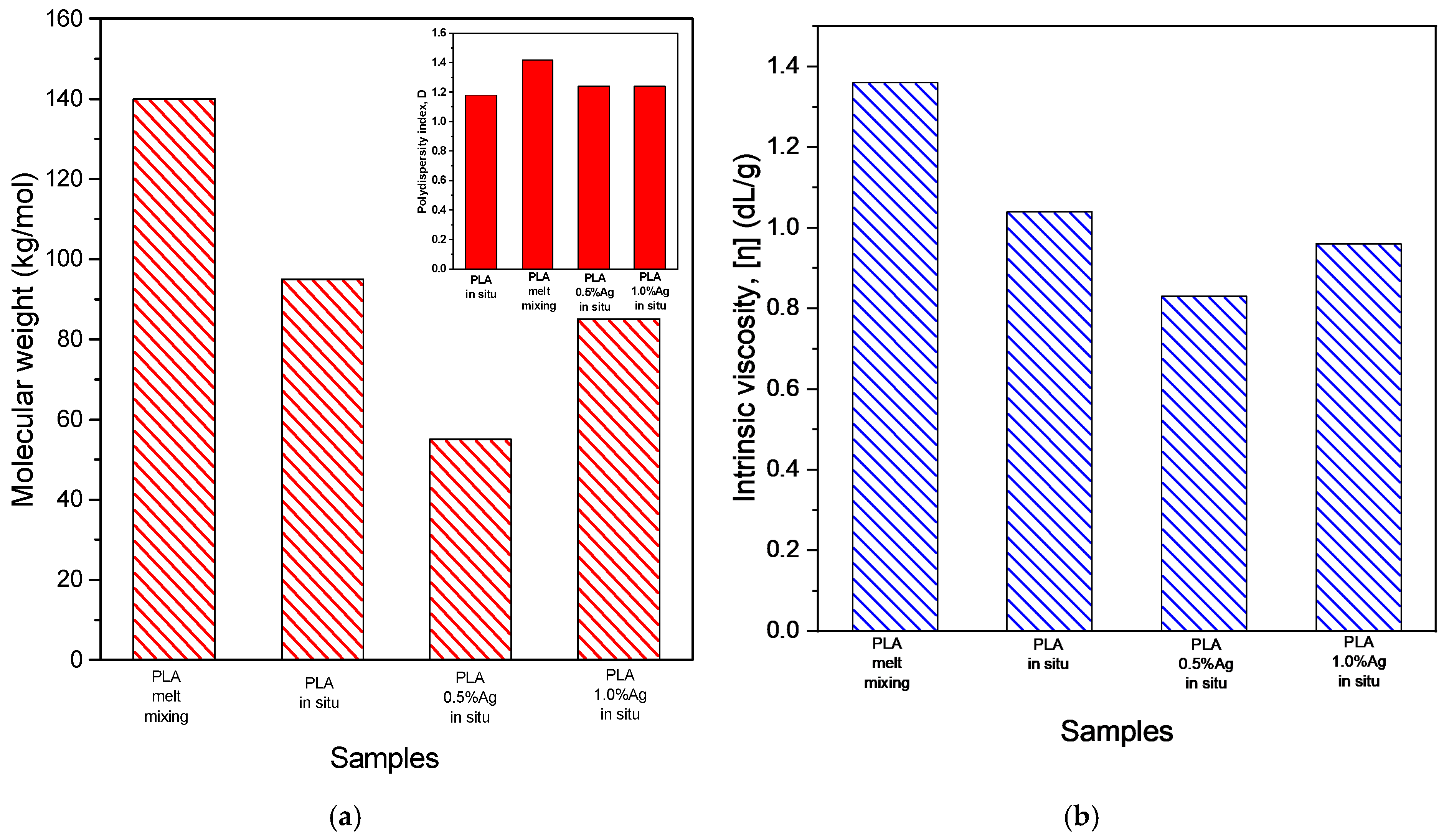

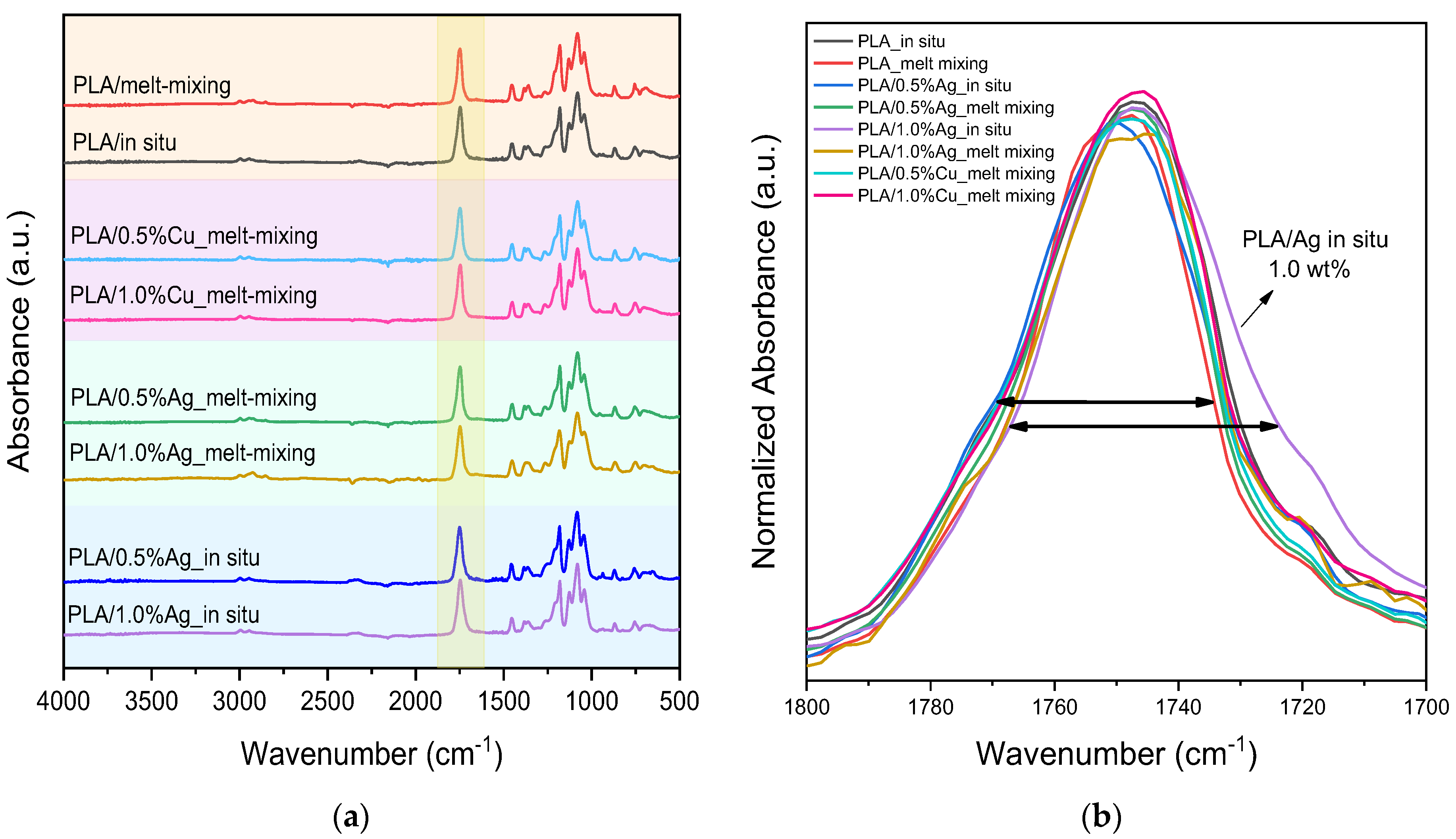

3.1. Synthesis and Structural Investigation of PLA and PLA/Ag-Cu Nanocomposites

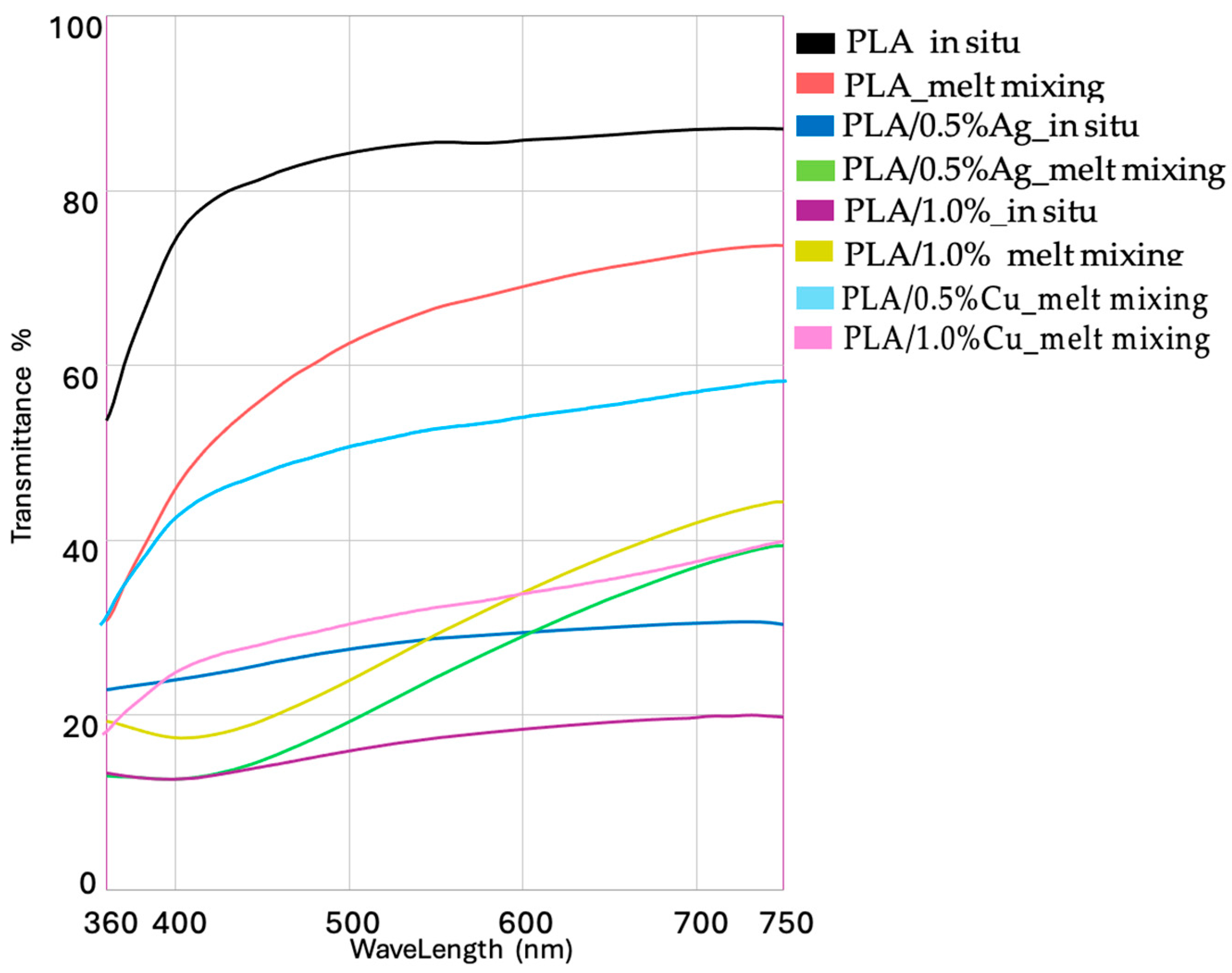

3.2. Optical Properties

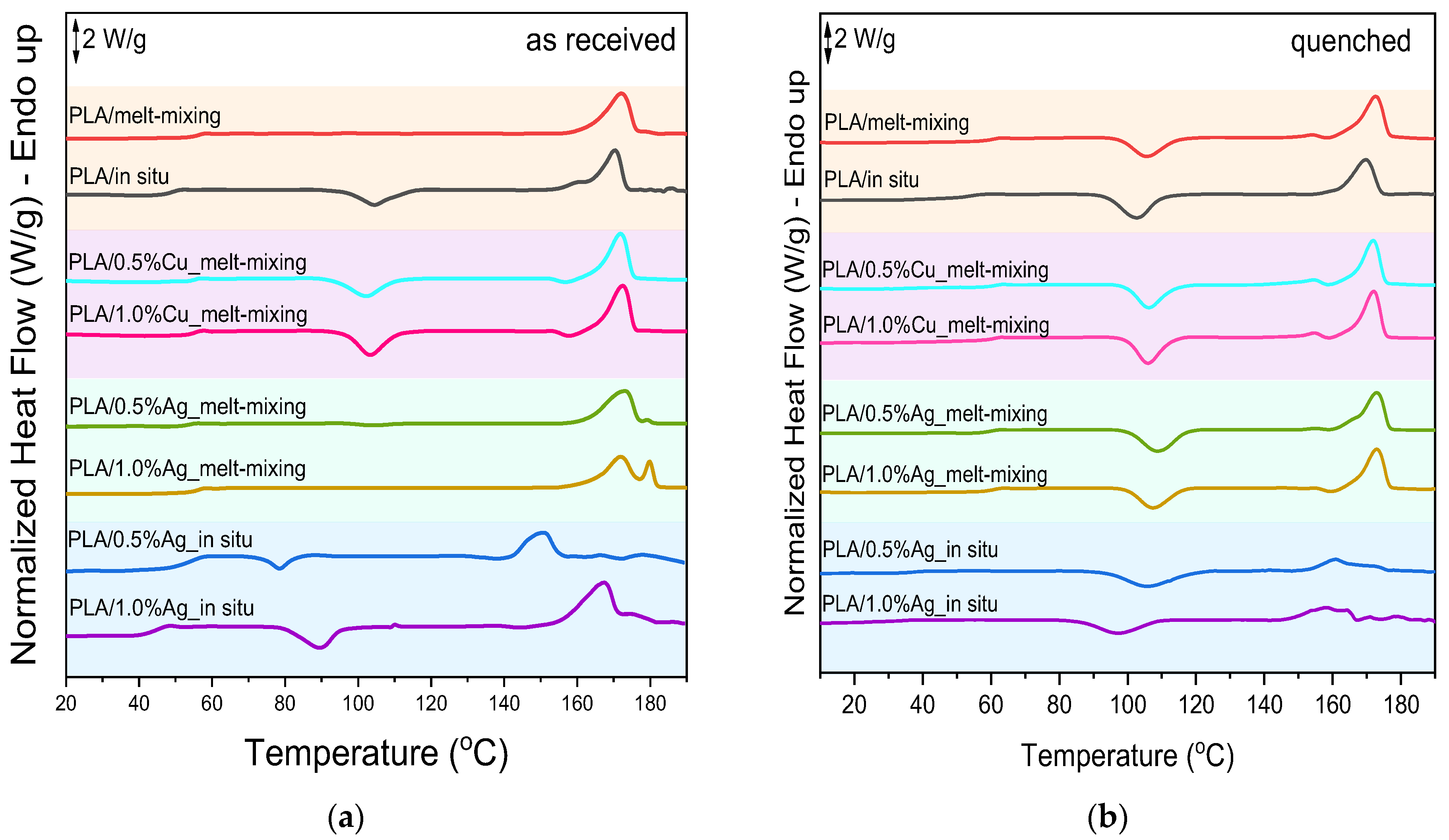

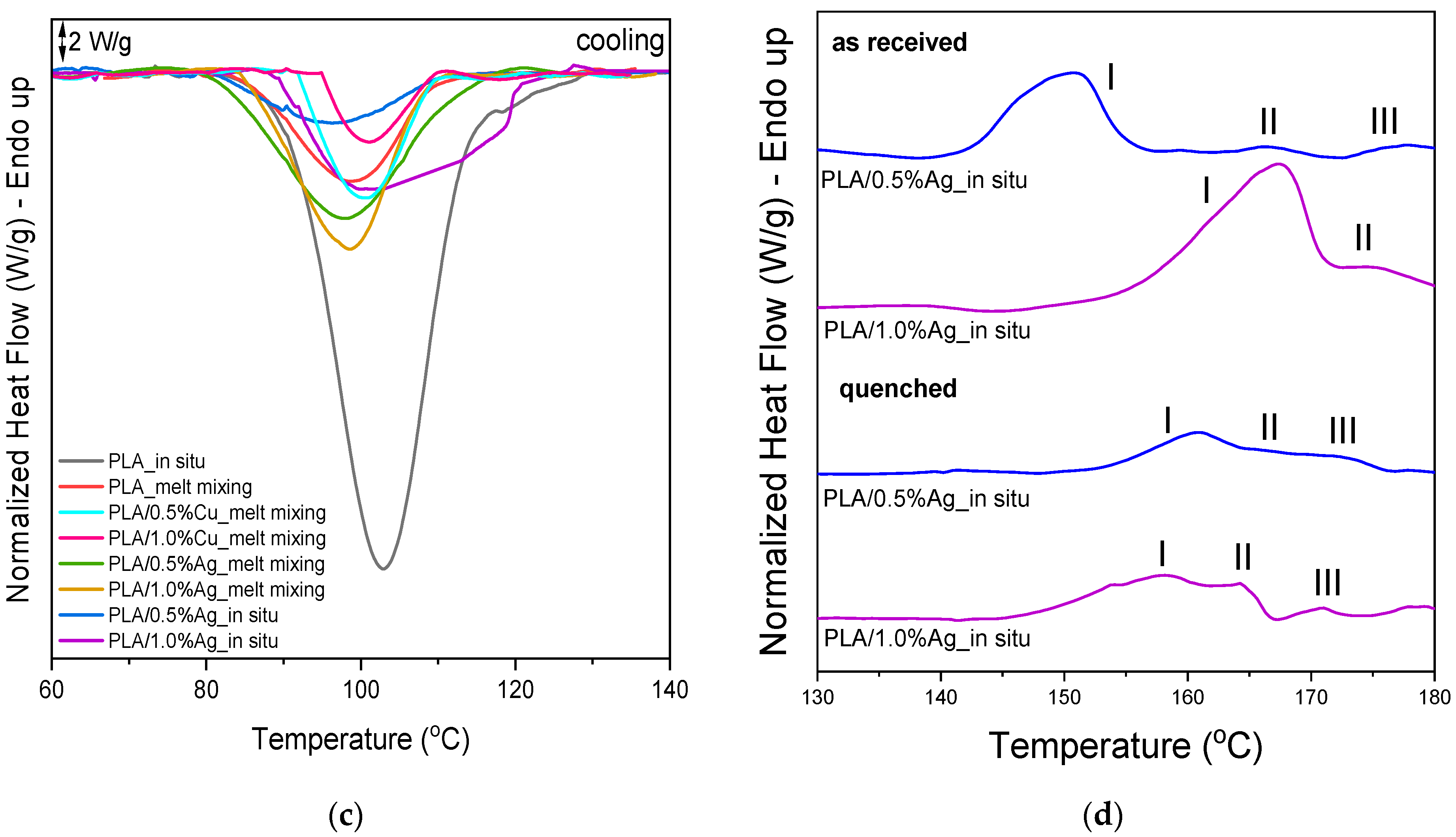

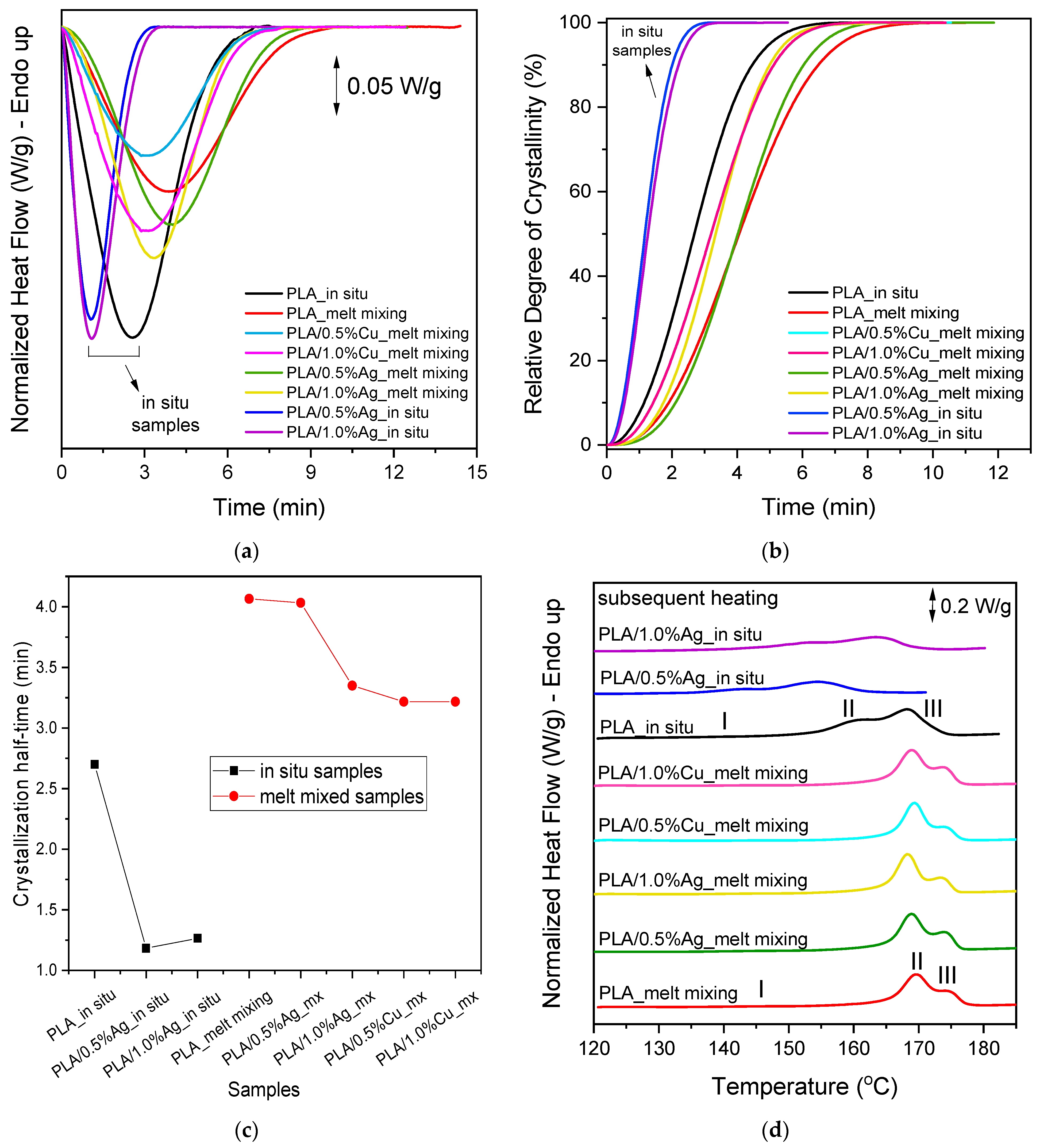

3.3. Thermal Properties, Crystallinine Behavior, and Isothermal Melt Crystallization

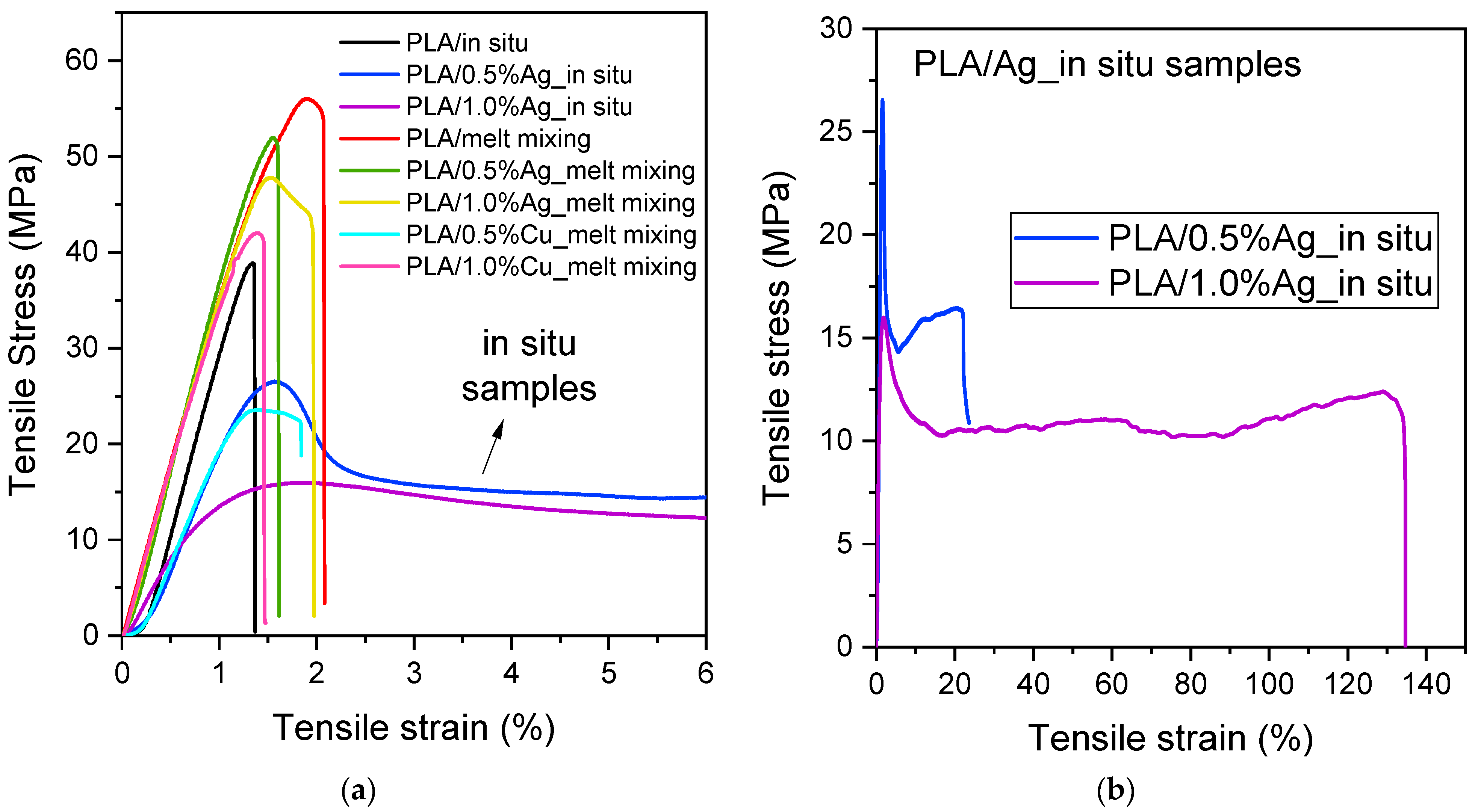

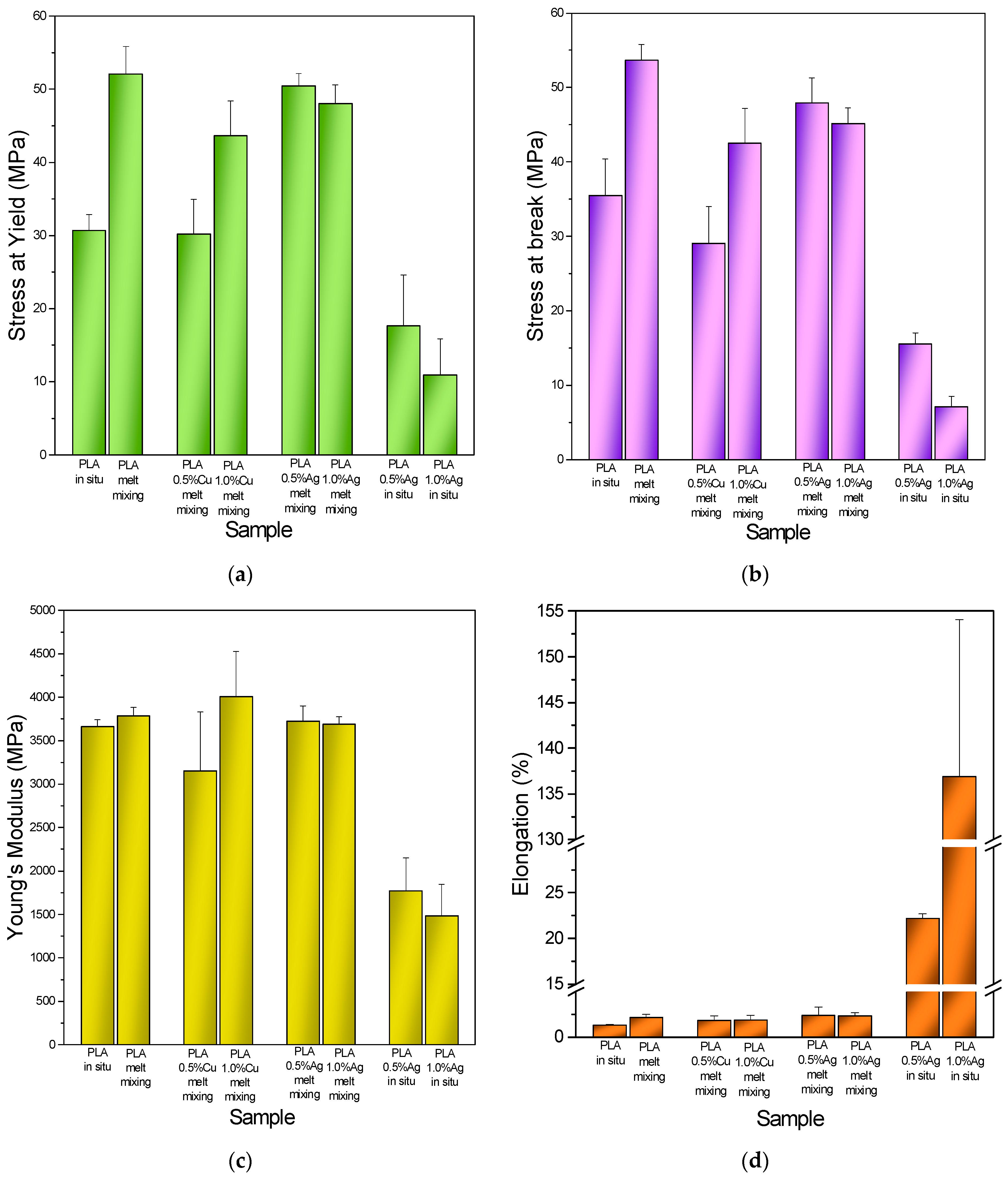

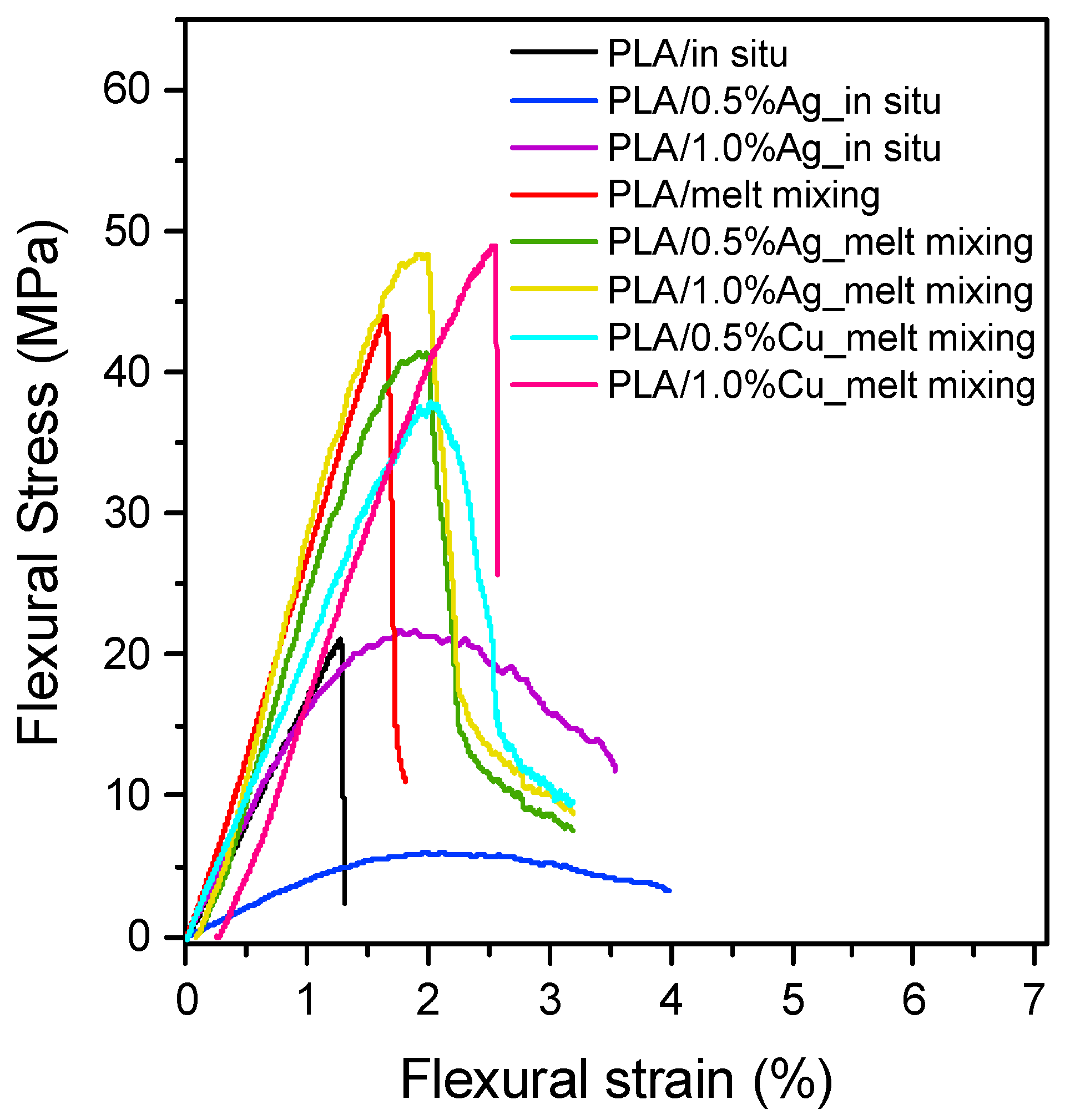

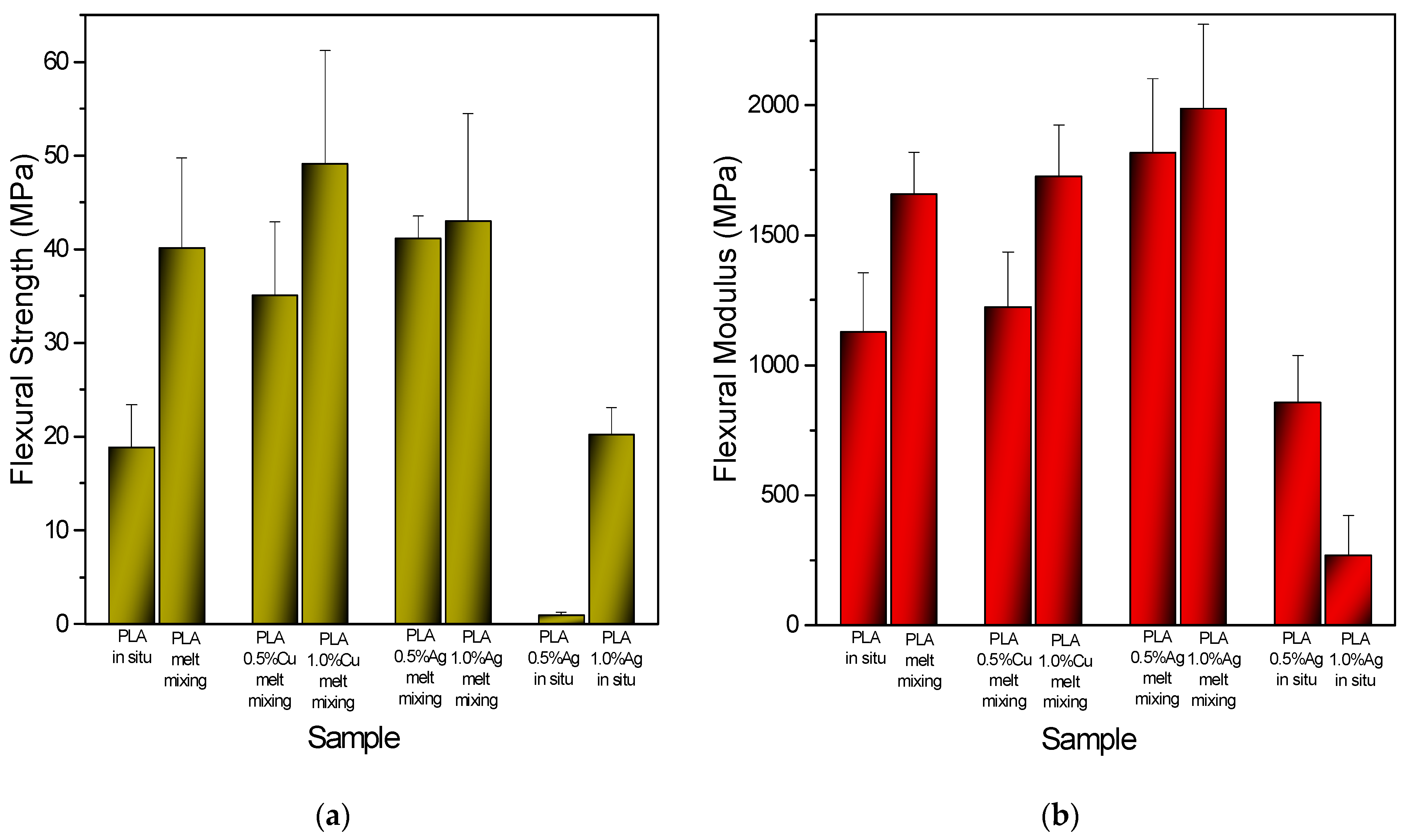

3.4. Mechanical Evaluation via Tensile and Three-Point Bending Tests

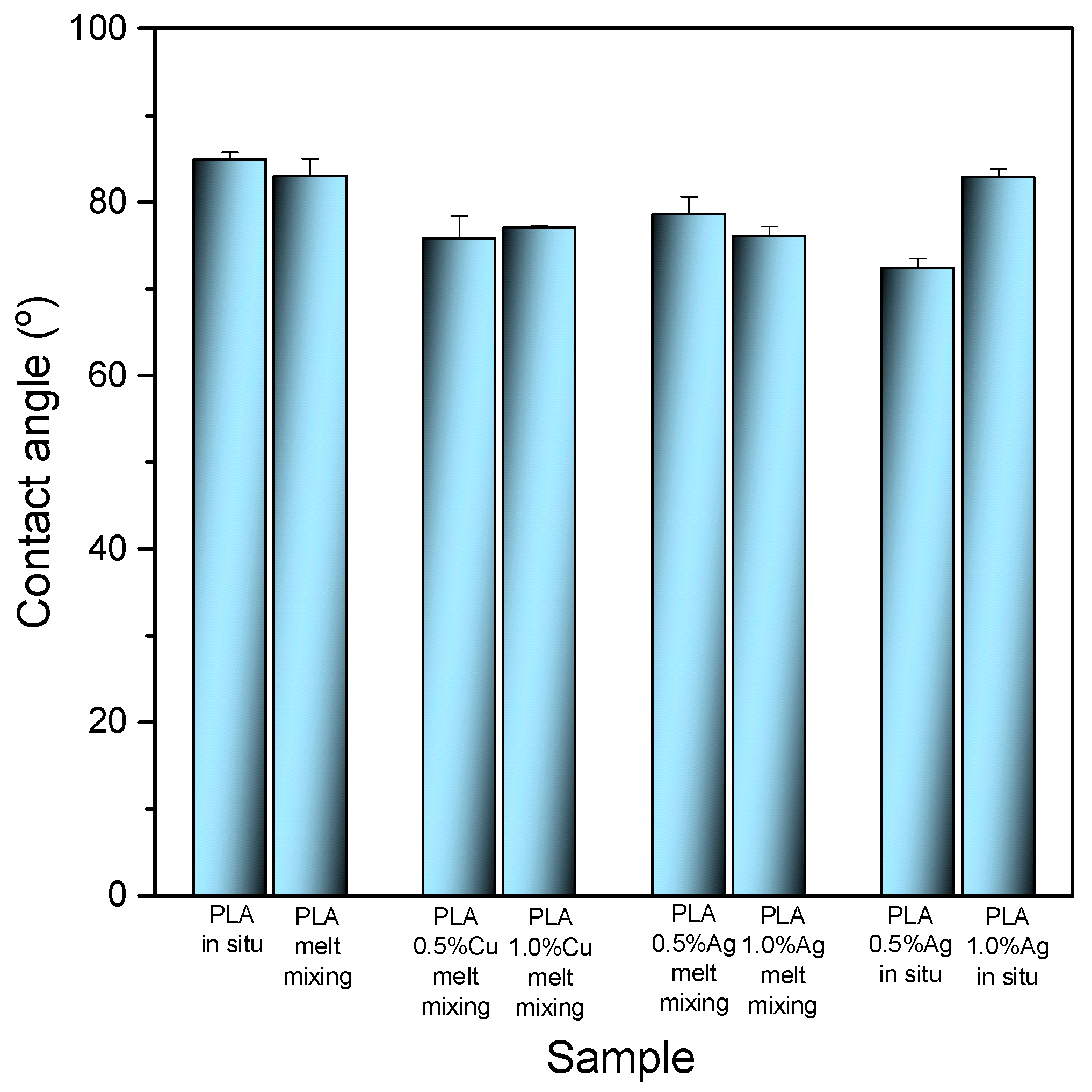

3.5. Surface Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ali, S.S.; Abdelkarim, E.A.; Elsamahy, T.; Altohamy, R.; Li, F.; Kornaros, M.; Zuorro, A.; Zuo, D.; Sun, J. Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environ. Sci. Ecotechnol. 2023, 19, 100254. [Google Scholar] [CrossRef] [PubMed]

- Mohammad, R.S.; Vivek Kumar, V. Impact of plastic pollution on ecosystems: A review of adverse effects and sustainable solutions. Environ. Monit. Assess. 2025, 197, 264. [Google Scholar] [CrossRef] [PubMed]

- Babaremu, K.; Oladijo, O.P.; Akinlabi, E. Biopolymers: A suitable replacement for plastics in product packaging. Adv. Ind. Eng. Polym. Res. 2023, 6, 333–340. [Google Scholar] [CrossRef]

- Chanda, M.; Roy, S.K. Industrial Polymers, Specialty Polymers, and Their Applications; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Terzopoulou, Ζ.; Bikiaris, D.N. Biobased plastics for the transition to a circular economy. Mater. Lett. 2024, 362, 136174. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2017, 546, 67–70. [Google Scholar] [CrossRef]

- Schneiderman, D.K.; Hillmyer, M.A. 50th Anniversary Perspective: There Is a Great Future in Sustainable Polymers. Macromolecules 2017, 50, 3733–3749. [Google Scholar] [CrossRef]

- Velasquez, S.T.R.; Hu, Q.; Kramm, J.; Santin, V.C.; Völker, C.; Wurm, F.R. Plastics of the Future? An Interdisciplinary Review on Biobased and Biodegradable Polymers: Progress in Chemistry, Societal Views, and Environmental Implications. Angew. Chem. Int. Ed. 2025, 64, e202423406. [Google Scholar] [CrossRef]

- Ali, W.; Ali, H.; Souissi, S.; Zinck, P. Are bioplastics an ecofriendly alternative to fossil fuel plastics? Environ. Chem. Lett. 2023, 21, 1991–2002. [Google Scholar] [CrossRef]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-Manchado, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic acid) a versatile biobased polymer of next decades with multifunctional properties. From monomer synthesis, polymerization techniques and molecular weight increase to PLA applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Liu, S.; Qin, S.; He, M.; Zhou, D.; Qin, Q.; Wang, H. Current applications of poly(lactic acid) composites in tissue engineering and drug delivery. Compos. Part B Eng. 2020, 199, 108238. [Google Scholar] [CrossRef]

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2020, 1, 76–87. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nquyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E.; Patel, M.K. Comparing life cycle energy and GHG emissions of bio-based PET, recycled PET, PLA, and man-made cellulosics. Biofuels Bioprod. Biorefin. 2012, 6, 625–639. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, J.; Li, J.; Liang, X.; Zhou, W.; Peng, S. Strategies and techniques for improving heat resistance and mechanical performances of poly(lactic acid) (PLA) biodegradable materials. Int. J. Biol. Macromol. 2022, 218, 115–134. [Google Scholar] [CrossRef]

- Bianchi, E.; Guidotti, G.; Soccio, M.; Siracusa, V.; Gazzano, M.; Salatelli, E.; Lotti, N. Biobased and Compostable Multiblock Copolymer of Poly(l-lactic acid) Containing 2,5-Furandicarboxylic Acid for Sustainable Food Packaging: The Role of Parent Homopolymers in the Composting Kinetics and Mechanism. Biomacromolecules 2023, 24, 2356–2368. [Google Scholar] [CrossRef]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Bikiaris, N.D.; Koumentakou, I.; Samiotaki, C.; Meimaroglou, D.; Varytimidou, D.; Karatza, A.; Kalantzis, Z.; Roussou, M.; Bikiaris, R.; Papageorgiou, G.Z. Recent Advances in the Investigation of Poly(lactic acid) (PLA) Nanocomposites: Incorporation of Various Nanofillers and their Properties and Applications. Polymers 2023, 15, 1196. [Google Scholar] [CrossRef]

- Mulla, M.Z.; Rahman, M.R.T.; Marcos, B.; Tiwari, B.; Pathania, S. Poly Lactic Acid (PLA) Nanocomposites: Effect of Inorganic Nanoparticles Reinforcement on Its Performance and Food Packaging Applications. Molecules 2021, 26, 1967. [Google Scholar] [CrossRef]

- Sha, L.; Chen, Z.; Chen, Z.; Zhang, A.; Yang, Z. Polylactic acid based nanocomposites: Promising safe and biodegradable materials in biomedical field. Int. J. Polym. Sci. 2016, 2016, 6869154. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Kickelbick, G. Hybrid Materials—Past, Present and Future. Hybrid Mater. 2014, 1, 39–51. [Google Scholar] [CrossRef]

- Sarma, S.; Rao, V.R. Emerging synthesis and characterization techniques for hybrid polymer nanocomposites. Nanotechnology 2023, 35, 012002. [Google Scholar] [CrossRef]

- Machiels, J.; Verma, A.; Appeltans, R.; Buntinx, M.; Ferraris, E.; Deferme, W. Printed Electronics (PE) as an enabling Technology to Realize Flexible Mass Customized Smart Applications. Proc. CIRP 2020, 96, 115–120. [Google Scholar] [CrossRef]

- Klonos, P.A.; Ioannidis, R.O.; Pitsavas, A.; Bikiaris, N.D.; Makri, S.P.; Koutsourea, S.; Grigoropoulos, A.; Deligkiozi, I.; Zoikis-Karathanasis, A.; Kyritsis, A.; et al. Segmental mobility, interfacial polymer, crystallization and conductivity study in polylactides filled with hybrid lignin-CNT particles. Nanomaterials 2025, 15, 660. [Google Scholar] [CrossRef] [PubMed]

- Nicolae-Maranciuc, A.; Chicea, D.; Chicea, L.M. Ag Nanoparticles for Biomedical Applications—Synthesis and Characterization—A Review. Int. J. Mol. Sci. 2022, 23, 5778. [Google Scholar] [CrossRef]

- Abbas, R.; Luo, J.; Qi, X.; Naz, A.; Khan, I.A.; Liu, H.; Yu, S.; Wei, J. Silver Nanoparticles: Synthesis, Structure, Properties and Applications. Nanomaterials 2024, 14, 1425. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.P.U.; Dang, N.T.; Doan, L.; Nguyen, T.T.H. Synthesis of Silver Nanoparticles: From Conventional to ‘Modern’ Methods—A Review. Processes 2023, 11, 2617. [Google Scholar] [CrossRef]

- Bruna, T.; Maldonado-Bravo, F.; Jara, P.; Caro, N. Silver Nanoparticles and Their Antibacterial Applications. Int. J. Mol. Sci. 2021, 22, 7202. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Krishnan, S.; Hii, Y.S.; Pan, S.; Chan, Y.S.; Acquah, C.; Danquah, M.K.; Rodrigues, J. Synthesis Approach-Dependent Antiviral Properties of Silver Nanoparticles and Nanocomposites. J. Nanostruct. Chem. 2022, 12, 809–831. [Google Scholar] [CrossRef] [PubMed]

- Duman, H.; Eker, F.; Akdaşçi, E.; Witkowska, A.M.; Bechelany, M.; Karav, S. Silver Nanoparticles: A Comprehensive Review of Synthesis Methods and Chemical and Physical Properties. Nanomaterials 2024, 14, 1527. [Google Scholar] [CrossRef]

- Dhaka, A.; Mali, S.C.; Sharma, S.; Trivedi, R. A Review on Biological Synthesis of Silver Nanoparticles and Their Potential Applications. Results Chem. 2023, 6, 101108. [Google Scholar] [CrossRef]

- Shameli, K.; Ahmad, M.B.; Yunus, W.M.Z.W.; Ibrahim, N.A.; Rahman, R.A.; Jokar, M.; Darroudi, M. Silver/poly (lactic acid) nanocomposites: Preparation, characterization, and antibacterial activity. Int. J. Nanomed. 2010, 5, 573–579. [Google Scholar] [CrossRef]

- Ameh, T.; Sayes, C.M. The potential exposure and hazards of copper nanoparticles: A review. Environ. Toxicol. Pharmacol. 2019, 71, 103220. [Google Scholar] [CrossRef]

- Bruna, J.E.; Muñoz-Shugulí, C.; Espinoza, L.; Herrera, A.; Rodríguez-Mercadoz, F.J.; Ganga, M.A.; Guarda, A.; Galotto, M.J. Poly(lactic acid) and copper-modified montmorillonite nanocomposite films for antimicrobial food packaging. J. Appl. Polym. Sci. 2024, 142, 56406. [Google Scholar] [CrossRef]

- Powar, N.S.; Patel, V.J.; Pagare, P.K.; Pandav, R.S. Cu Nanoparticle: Synthesis, Characterization and Application. Chem. Methodol. 2019, 3, 457–480. [Google Scholar]

- Tan, K.S.; Cheong, K.Y. Advances of Ag, Cu, and Ag–Cu alloy nanoparticles synthesized via chemical reduction route. J. Nanopart. Res. 2013, 15, 1537. [Google Scholar] [CrossRef]

- Luceri, A.; Francese, R.; Lembo, D.; Ferraris, M.; Balagna, C. Silver Nanoparticles: Review of Antiviral Properties, Mechanism of Action and Applications. Microorganisms 2023, 11, 629. [Google Scholar] [CrossRef]

- Gawande, M.B.; Goswami, A.; Felpin, F.-X.; Asefa, T.; Huang, X.; Silva, R.; Zou, X.; Zbořil, R.; Varma, R.S. Cu and Cu-Based Nanoparticles: Synthesis and Applications in Catalysis. Chem. Rev. 2016, 116, 3722–3811. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Del-Ángel, J.E.; Morales-Cepeda, A.B.; Wood-Adams, P.M. Compatibility, Crystallinity and Mechanical Properties of Poly(lactic acid)-Poly(ether-block-amide) Based Copper Nanocomposites. Polym. Int. 2020, 69, 1024–1037. [Google Scholar] [CrossRef]

- Tamayo, L.; Azócar, M.; Kogan, M.; Riveros, A.; Páez, M. Copper-Polymer Nanocomposites: An Excellent and Cost-Effective Biocide for Use on Antibacterial Surfaces. Mater. Sci. Eng. C 2016, 69, 1391–1409. [Google Scholar] [CrossRef] [PubMed]

- Pholharn, D.; Srithep, Y.; Morris, J. Effect of initiators on synthesis of poly(L-lactide) by ring opening polymerization. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 012022. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Deligkiozi, I.; Zoikis-Karathanasis, A.; Nikolaidis, N.; Bikiaris, D.N.; Terzopoulou, Z. Lignin Particle Size Affects the Properties of PLA Composites Prepared by In Situ Ring-Opening Polymerization. Polymers 2024, 16, 3542. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Klonos, P.A.; Kyritsis, A.; Tarani, E.; Chrissafis, K.; Mašek, O.; Tsachouridis, K.; Anastasiou, A.D.; Bikiaris, D.N. Synthesis and Characterization of PLA/Biochar Bio-Composites Containing Different Biochar Types and Content. Polymers 2025, 17, 263. [Google Scholar] [CrossRef]

- Yang, J.-H.; Lin, S.-H.; Lee, Y.-D. Preparation and characterization of poly(L-lactide)–graphene composites using the in situ ring-opening polymerization of PLLA with graphene as the initiator. J. Mater. Chem. 2012, 22, 10805–10815. [Google Scholar] [CrossRef]

- Manju, P.; Krishnan, P.S.G.; Nayak, S.K. In-situ polymerised PLA-SEP bionanocomposites: Effect of silanol groups on the properties of PLA. J. Polym. Res. 2020, 27, 134. [Google Scholar] [CrossRef]

- Ortenzi, M.A.; Basilissi, L.; Farina, H.; Di Silvestro, G.; Piergiovanni, L.; Mascheroni, E. Evaluation of crystallinity and gas barrier properties of films obtained from PLA nanocomposites synthesized via “in situ” polymerization of L-lactide with silane-modified nanosilica and montmorillonite. Eur. Polym. J. 2015, 66, 478–491. [Google Scholar] [CrossRef]

- Klonos, P.A.; Ioannidis, R.O.; Lazaridou, K.; Kyritsis, A.; Bikiaris, D.N. Effects of Small Amounts of Metal Nanoparticles on the Glass Transition, Crystallization, Electrical Conductivity, and Molecular Mobility of Polylactides: Mixing vs. In Situ Polymerization Preparation. Electronics 2025, 14, 3826. [Google Scholar] [CrossRef]

- Gorman, A.M.; Clayton, A.; O’Connell, T.; Johnson, D. A recyclable screen ink with state-of-the-art performance developed using a bottom-up, safety and sustainability-driven approach. MRS Adv. 2023, 8, 311–316. [Google Scholar] [CrossRef]

- Vogel, K.; Carniello, S.; Beni, V.; Sudheshwar, A.; Malinverno, N.; Alesanco, Y.; Torrellas, M.; Harkema, S.; De Kok, M.; Rentrop, C.; et al. Defining and achieving next-generation green electronics: A perspective on best practices through the lens of hybrid printed electronics. IEEE Access 2025, 13, 117135–117161. [Google Scholar] [CrossRef]

- Qian, F.; Jia, R.; Cheng, M.; Chaudhary, A.; Melhi, S.; Mekkey, S.D.; Zhu, N.; Wang, C.; Razak, F.; Xu, X.; et al. An overview of polylactic acid (PLA) nanocomposites for sensors. Adv. Compos. Hybrid Mater. 2024, 7, 75. [Google Scholar] [CrossRef]

- Silva, M.M.; Lopes, P.E.; Li, Y.; Pötschke, P.; Ferreira, F.N.; Paiva, M.C. Polylactic acid/carbon nanoparticle composite filaments for sensing. Appl. Sci. 2021, 11, 2580. [Google Scholar] [CrossRef]

- Bautista-Del-Ángel, J.E.; Morales-Cepeda, A.B.; Lozano-Ramírez, T.; Sánchez, S.; Karami, S.; Lafleur, P. Enhancement of crystallinity and toughness of poly(l-lactic acid) influenced by Ag nanoparticles processed by twin screw extruder. Polym. Compos. 2018, 39, 2368–2376. [Google Scholar] [CrossRef]

- Popescu, V.; Prodan, D.; Cuc, S.; Saroşi, C.; Furtos, G.; Moldovan, A.; Carpa, R.; Bomboş, D. Antimicrobial Poly (Lactic Acid)/Copper Nanocomposites for Food Packaging Materials. Materials 2023, 16, 1415. [Google Scholar] [CrossRef] [PubMed]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Klonos, P.A.; Bikiaris, N.D.; Barmpalexis, P.; Kyritsis, A. Segmental mobility in linear polylactides of various molecular weights. Polymer 2024, 305, 127177. [Google Scholar] [CrossRef]

- Klonos, P.; Terzopoulou, Z.; Stefanos Koutsoumpis, S.; Zidropoulos, S.; Sotiria Kripotou, S.; Papageorgiou, G.Z.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Rigid amorphous fraction and segmental dynamics in nanocomposites based on poly(L–lactic acid) and nano-inclusions of 1–3D geometry studied by thermal and dielectric techniques. Eur. Polym. J. 2016, 82, 16–34. [Google Scholar] [CrossRef]

- Črešnar, K.P.; Zemljič, L.F.; Papadopoulos, L.; Terzopoulou, Z.; Zamboulis, A.; Klonos, P.A.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Effects of Ag, ZnO and TiO2 nanoparticles at low contents on the crystallization, semicrystalline morphology, interfacial phenomena and segmental dynamics of PLA. Mater. Today Commun. 2021, 27, 102192. [Google Scholar] [CrossRef]

- Köroğlu, M.; Ebin, B.; Stopić, S.; Gürmen, S.; Friedrich, B. One Step Production of Silver-Copper (AgCu) Nanoparticles. Metals 2021, 11, 1466. [Google Scholar] [CrossRef]

- Refaa, Z.; Boutaous, M.; Siginer, D.A. PLA crystallization kinetics and morphology development. Int. Polym. Process. 2018, 3, 336–344. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Criado, J.M.; Pérez-Maqueda, L.A.; Popescu, C.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim. Acta 2011, 520, 1–19. [Google Scholar] [CrossRef]

- Müller, A.J.; Michell, R.M.; Lorenzo, A.T. Isothermal Crystallization Kinetics of Polymers. In Polymer Morphology: Principles, Characterization, and Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Lorenzo, A.T.; Arnal, M.L.; Albuerne, J.; Müller, A.J. DSC isothermal polymer crystallization kinetics measurements and the use of the Avrami equation to fit the data: Guidelines to void common problems. Polym. Test. 2007, 26, 222–231. [Google Scholar] [CrossRef]

- Ioannidis, R.O.; Xanthopoulou, E.; Terzopoulou, Z.; Zamboulis, A.; Bikiaris, D.N.; George, Z.; Papageorgiou, G.Z. Synthesis and thermal investigation of poly(propylene terephthalate-co-2,5-furan dicarboxylate) copolyesters. J. Ind. Eng. Chem. 2024, 131, 531–544. [Google Scholar] [CrossRef]

- Klonos, P.A.; Papadopoulos, L.; Papageorgiou, G.Z.; Kyritsis, A.; Pissis, P.; Bikiaris, D.N. Interfacial Interactions, Crystallization, and Molecular Dynamics of Renewable Poly(Propylene Furanoate) In Situ Filled with Initial and Surface Functionalized Carbon Nanotubes and Graphene Oxide. J. Phys. Chem. C 2020, 124, 10220–10234. [Google Scholar] [CrossRef]

- Wu, S.; Li, H.; Huang, G.; Wu, J. Nucleating effect of multi-walled carbon nanotubes and graphene on the crystallization kinetics and melting behavior of olefin block copolymers. RSC Adv. 2014, 4, 19024. [Google Scholar] [CrossRef]

- Salas-Papayanopolos, H.; Morales-Cepeda, A.B.; Wood-Adams, P.; Sanchez, S.; Lafleur, P.G.; Vazquez, H.P. Crystallization effect of poly(L-lactic acid)/silver nanocomposites blends, on barrier and mechanical properties using glyceryl triacetate as plasticizer. Polym. Bull. 2023, 80, 5273–5290. [Google Scholar] [CrossRef]

- Yasuniwa, M.; Iura, K.; Dan, Y. Melting behavior of poly(l-lactic acid): Effects of crystallization temperature and time. Polymer 2007, 48, 5398–5407. [Google Scholar] [CrossRef]

- Zhu, A.J.; Sternstein, S.S. Nonlinear viscoelasticity of nanofilled polymers: Interfaces, chain statistics and properties recovery kinetics. Compos. Sci. Technol. 2003, 63, 1113–1126. [Google Scholar] [CrossRef]

- Chen, Q.; Gong, S.; Moll, J.; Zhao, D.; Kumar, S.K.; Colby, R.H. Mechanical reinforcement of polymer nanocomposites from percolation of a nanoparticle network. ACS Macro Lett. 2015, 4, 398–402. [Google Scholar] [CrossRef] [PubMed]

- Klonos, P.A.; Bikiaris, R.D.; Terzopoulou, Z.; Mouchlianiti, K.; Tsachouridis, K.; Anastasiou, A.D.; Kyritsis, A.; Kyzas, G.Z. Structure-properties relationships in new polymer nanocomposites based on the renewable poly(butylene succinate) filled with low amounts of nanoparticles of 1-3D geometries. Polymer 2024, 296, 126841. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Terzopoulou, Z.; Vlachopoulos, A.; Klonos, P.A.; Kyritsis, A.; Tzetzis, D.; Papageorgiou, G.Z.; Bikiaris, D.N. Synthesis and characterization of novel polymer/clay nanocomposites based on poly (butylene 2,5-furan dicarboxylate). Appl. Clay Sci. 2020, 190, 105588. [Google Scholar] [CrossRef]

- Nabgui, A.; Follain, N.; Vidović, E.; El Haskouri, J.; Marais, S.; El Meziane, A.; Lahcini, M.; Thebault, P. Preparation and study of the thermal, barrier and antibacterial properties of Polylactic acid-Fluorphlogopite-Silver nanoparticles nanocomposite films. Prog. Org. Coat. 2022, 171, 107041. [Google Scholar] [CrossRef]

- Kanon, K.; Sharif, S.S.; Irfan, A.; Sharif, A. Inorganic film materials for flexible electronics: A brief overview, properties, and applications. Eng. Rep. 2024, 6, e13006. [Google Scholar] [CrossRef]

- Bonnassieux, Y.; Brabec, C.J.; Cao, Y.; Carmichael, T.B.; Chabinyc, M.L.; Cheng, K.T.; Cho, G.; Chung, A.; Cobb, C.L.; Distler, A.; et al. The 2021 flexible and printed electronics roadmap. Flex. Print. Electron. 2021, 6, 023001. [Google Scholar] [CrossRef]

- Hui, Z.; Zhang, L.; Ren, G.; Sun, G.; Yu, H.-D.; Huang, W. Green Flexible Electronics: Natural Materials, Fabrication, and Applications. Adv. Mater. 2023, 35, 2211202. [Google Scholar] [CrossRef]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A New Frontier of Printed Electronics: Flexible Hybrid Electronics. Adv. Mater. 2020, 32, 1905279. [Google Scholar] [CrossRef]

- Tümer, E.H.; Yılmaz, S.; Mert, B.; Öztürk, S.; Çolak, M.; Yılmaz, M.; Öztürk, B. Wetting of Superhydrophobic Polylactic Acid Micropillared Patterns. Langmuir 2022, 38, 10052–10064. [Google Scholar] [CrossRef]

| Abbreviation | Content wt% | |

|---|---|---|

| PLA_in situ | 100 | - |

| PLA_melt mixing | 100 | - |

| PLA/0.5%Cu_melt mixing | 99.5 | 0.5 |

| PLA/1.0%Cu_melt mixing | 99.0 | 1.0 |

| PLA/0.5%Ag_melt mixing | 99.5 | 0.5 |

| PLA/1.0%Ag_melt mixing | 99.0 | 1.0 |

| PLA/0.5%Ag_in situ | 99.5 | 0.5 |

| PLA/1.0%Ag_in situ | 99.0 | 1.0 |

| Sample | As Received | Quenched | Cooling | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tm (°C) | ΔHm (J/g) | Tg (°C) | ΔCp [J/(g × °C)] | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | Tc (°C) | ΔHc (J/g) | CFc (%) | |

| PLA_in situ | 170.7 | 32.3 | 54.5 | 0.511 | 102.6 | 36.3 | 169.8 | 39.0 | 102.9 | 34.8 | 37.5 |

| PLA_melt mixing | 172.0 | 42.6 | 59.7 | 0.480 | 105.4 | 32.2 | 172.6 | 36.3 | 99.7 | 5.2 | 5.5 |

| PLA/0.5%Cu_melt mixing | 171.8 | 34.0 | 60.2 | 0.343 | 106.0 | 34.6 | 171.8 | 35.9 | 99.9 | 10.1 | 8.1 |

| PLA/1.0%Cu_melt mixing | 172.5 | 38.7 | 60.0 | 0.609 | 106.0 | 35.6 | 172.2 | 39.1 | 99.3 | 7.7 | 8.4 |

| PLA/0.5%Ag_melt mixing | 173.2 | 40.6 | 59.3 | 0.551 | 108.8 | 35.5 | 172.9 | 37.0 | 99.0 | 2.7 | 8.1 |

| PLA/1.0%Ag_melt mixing | 171.8 | 44.7 | 60.4 | 0.551 | 107.4 | 33.8 | 172.8 | 36.7 | 98.3 | 11.4 | 9.2 |

| PLA/0.5%Ag_in situ | 160.6 | 7.1 | 35.2 | 0.356 | 105.6 | 21.6 | 160.9 | 5.2 | 96.2 | 8.7 | 14.6 |

| PLA/1.0%Ag_in situ | 149.1 | 2.2 | 34.9 | 0.252 | 97.4 | 30.3 | 164.3 | 15.1 | 102.3 | 8.8 | 15.4 |

| Sample | Tensile Stress at Break (MPa) | Tensile Stress at Yield (MPa) | Elongation (%) | Young’s Modulus (MPa) |

|---|---|---|---|---|

| PLA_in situ | 35.5 ± 4.9 | 30.7 ± 2.2 | 1.3 ± 0.1 | 3660.7 ± 78.9 |

| PLA_melt mixing | 53.7 ± 2.1 | 52.1 ± 3.7 | 2.2 ± 0.3 | 3788.1 ± 94.7 |

| PLA/0.5%Cu_melt mixing | 29.0 ± 5.0 | 30.2 ± 4.7 | 1.8 ± 0.5 | 3149.9 ± 680.8 |

| PLA/1.0%Cu_melt mixing | 42.5 ± 4.7 | 43.7 ± 4.8 | 1.9 ± 0.6 | 4003.7 ± 523.7 |

| PLA/0.5%Ag_melt mixing | 47.9 ± 3.4 | 50.4 ± 1.7 | 2.4 ± 0.9 | 3727.9 ± 172.7 |

| PLA/1.0%Ag_melt mixing | 45.1 ± 2.1 | 48.0 ± 2.6 | 2.3 ± 0.4 | 3687.7 ± 87.1 |

| PLA/0.5%Ag_in situ | 15.5 ± 1.5 | 17.7 ± 6.9 | 22.2 ± 0.5 | 1772.3 ± 378.6 |

| PLA/1.0%Ag_in situ | 7.1 ± 1.4 | 10.9 ± 5.0 | 136.9 ± 17.2 | 1484.7 ± 360.8 |

| Samples | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|

| PLA_in situ | 18.8 ± 4.6 | 1126.9 ± 230.2 |

| PLA_melt mixing | 40.1 ± 9.6 | 1658.3 ± 162.9 |

| PLA/0.5%Cu_melt mixing | 35.1 ± 7.9 | 1223.3 ± 213.4 |

| PLA/1.0%Cu_melt mixing | 49.2 ± 12.1 | 1726.0 ± 198.7 |

| PLA/0.5%Ag_melt mixing | 41.1 ± 2.4 | 1817.1 ± 285.3 |

| PLA/1.0%Ag_melt mixing | 43.0 ± 11.5 | 1986.5 ± 325.6 |

| PLA/0.5%Ag_in situ | 0.9 ± 0.4 | 856.9 ± 180.6 |

| PLA/1.0%Ag_in situ | 20.2 ± 2.9 | 268.6 ± 153.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazaridou, K.; Ioannidis, R.O.; Bikiaris, D.N. In Situ Polymerization as an Effective Method, Compared to Melt Mixing, for Synthesis of Flexible Poly(lactic acid) Nanocomposites Based on Metal Nanoparticles. J. Compos. Sci. 2025, 9, 610. https://doi.org/10.3390/jcs9110610

Lazaridou K, Ioannidis RO, Bikiaris DN. In Situ Polymerization as an Effective Method, Compared to Melt Mixing, for Synthesis of Flexible Poly(lactic acid) Nanocomposites Based on Metal Nanoparticles. Journal of Composites Science. 2025; 9(11):610. https://doi.org/10.3390/jcs9110610

Chicago/Turabian StyleLazaridou, Kyriaki, Rafail O. Ioannidis, and Dimitrios N. Bikiaris. 2025. "In Situ Polymerization as an Effective Method, Compared to Melt Mixing, for Synthesis of Flexible Poly(lactic acid) Nanocomposites Based on Metal Nanoparticles" Journal of Composites Science 9, no. 11: 610. https://doi.org/10.3390/jcs9110610

APA StyleLazaridou, K., Ioannidis, R. O., & Bikiaris, D. N. (2025). In Situ Polymerization as an Effective Method, Compared to Melt Mixing, for Synthesis of Flexible Poly(lactic acid) Nanocomposites Based on Metal Nanoparticles. Journal of Composites Science, 9(11), 610. https://doi.org/10.3390/jcs9110610