A Quantitative Framework for Process Control in the Structural Bonding of Aerospace Composites with MGS L418 Epoxy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Experiments

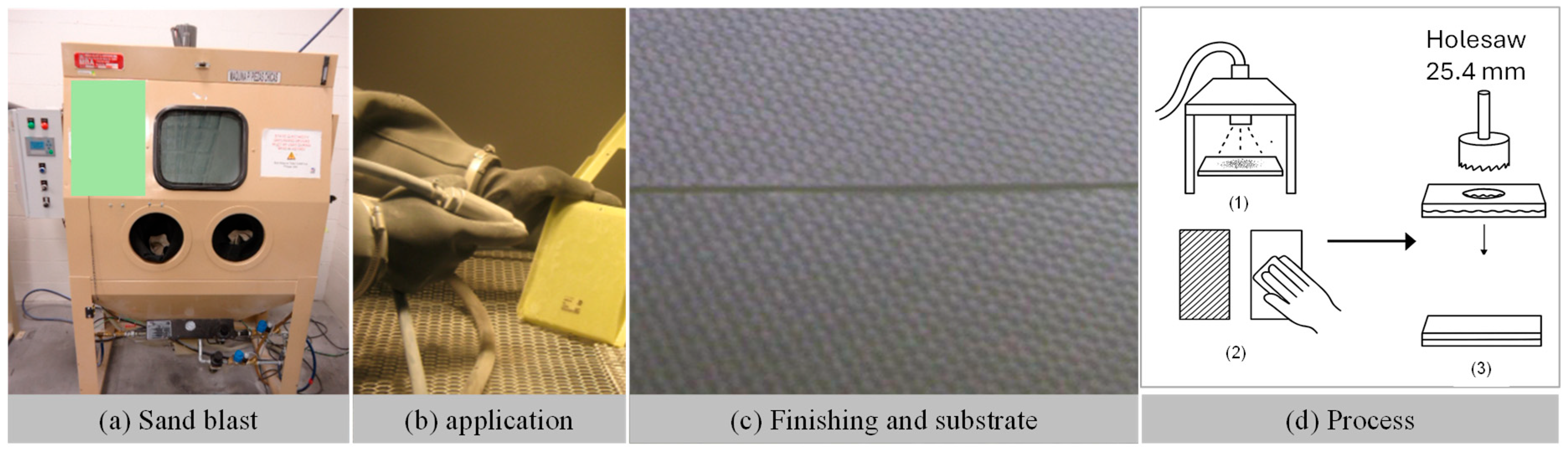

- Surface Preparation: Compared a low-level (solvent wipe-only) with a high-level (mechanical abrasion via sandblasting) method.

- Induction Time: The hold time post-mixing. A 15 min (low) versus an 85 min (high) period was evaluated.

- Humidity: Ambient relative humidity (RH) during application and cure (Low: 40% RH vs. High: 90% RH).

- Stirring: Manual stirring (low) vs. mechanical planetary mixing (high).

- Temperature: Ambient temperature during application (Low: 18 °C vs. High: 25 °C).

- Mix Ratio: Deviations from the nominal 100:40 ratio (Low: 98:40 vs. High: 102:40).

2.3. Sample Preparation and Bonding

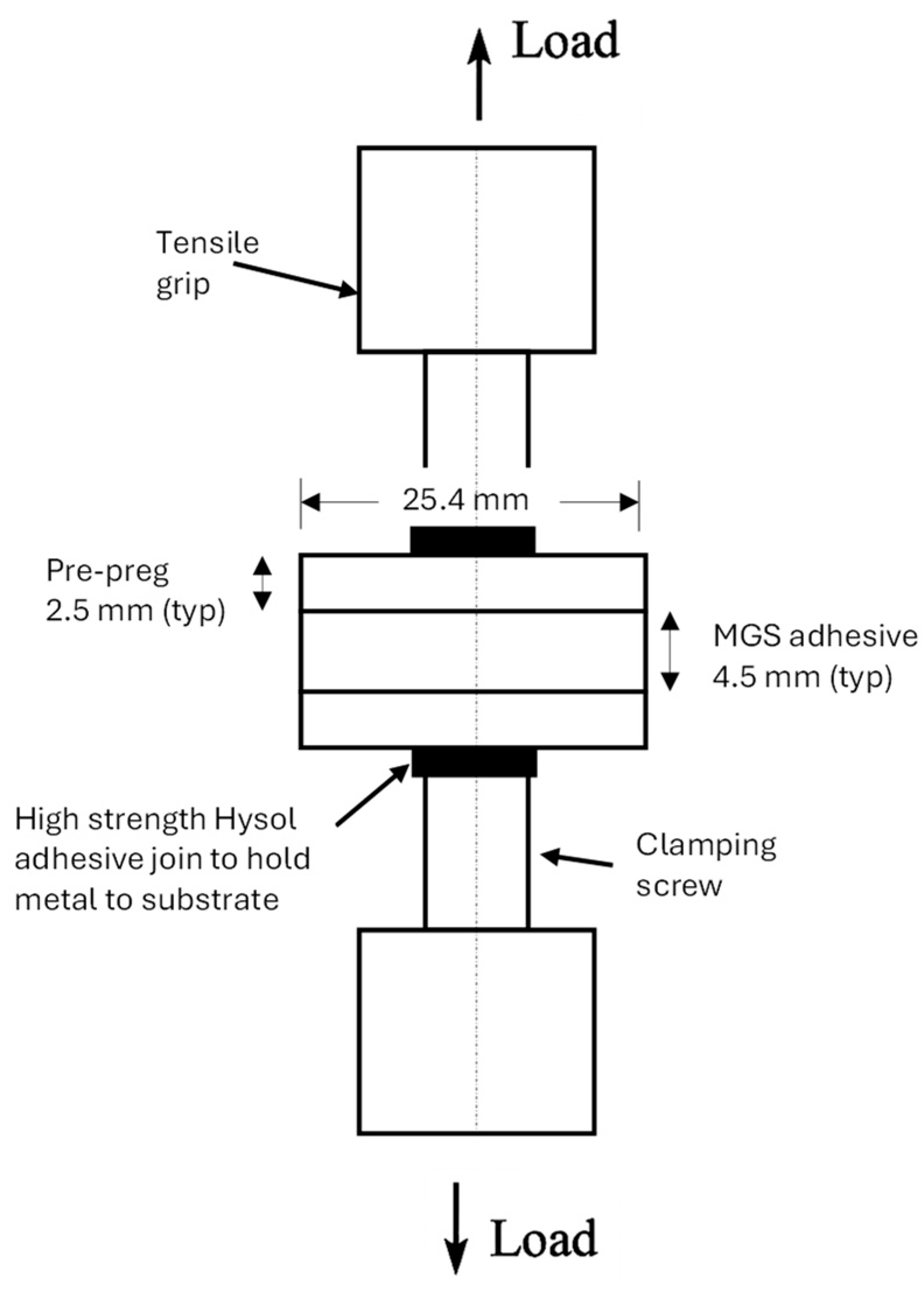

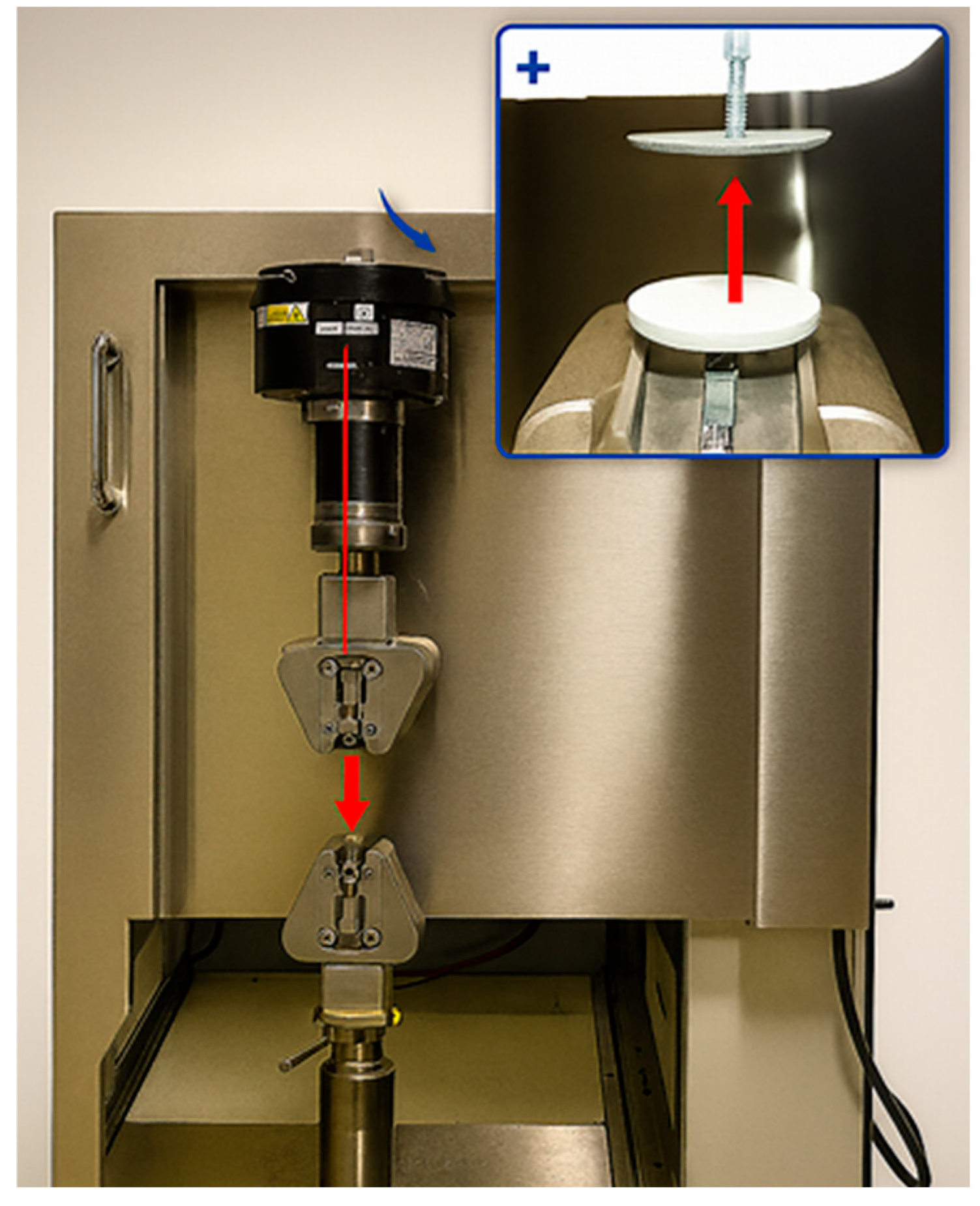

2.4. Mechanical Testing

2.5. Statistical Analysis

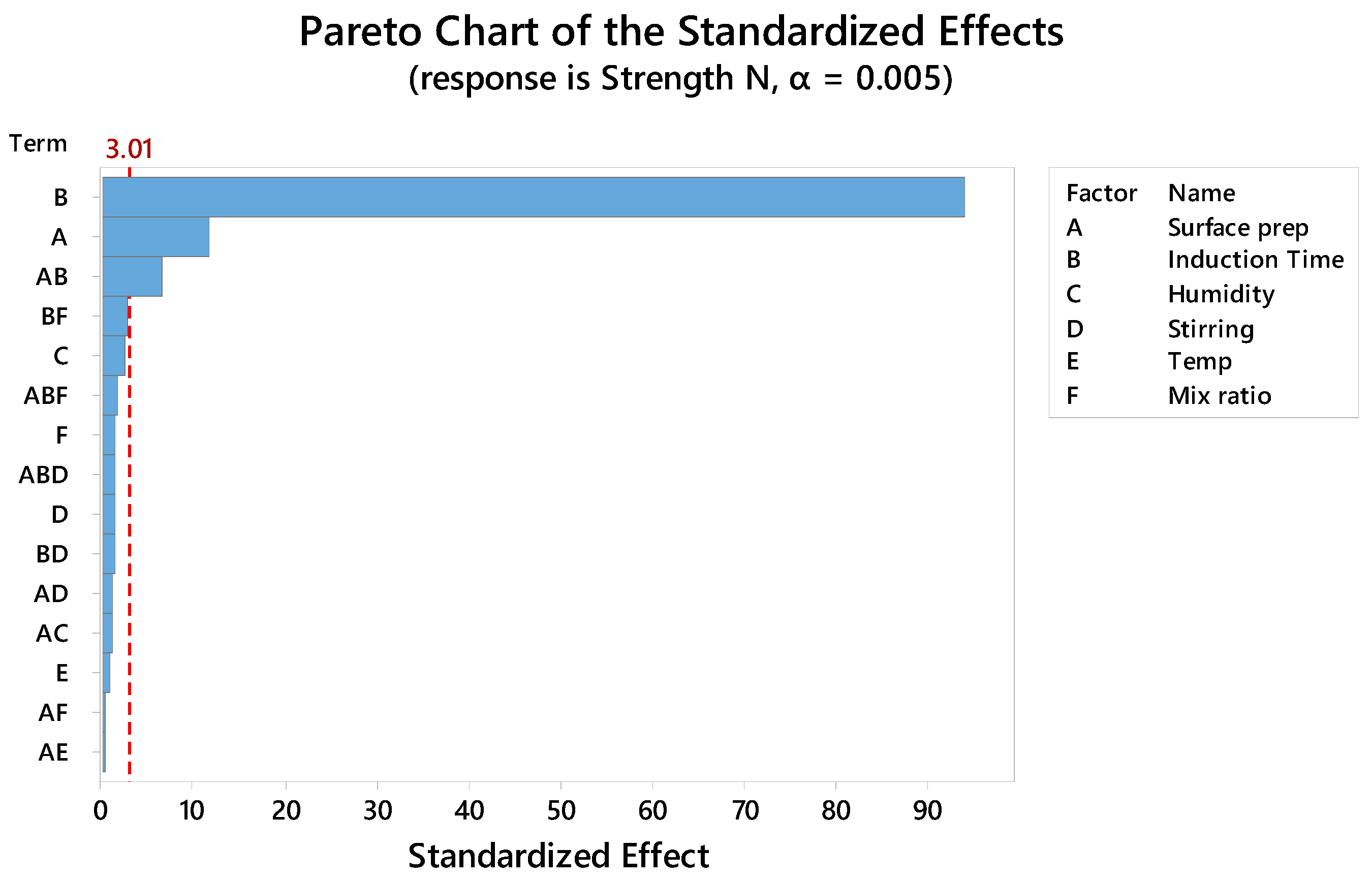

3. Results

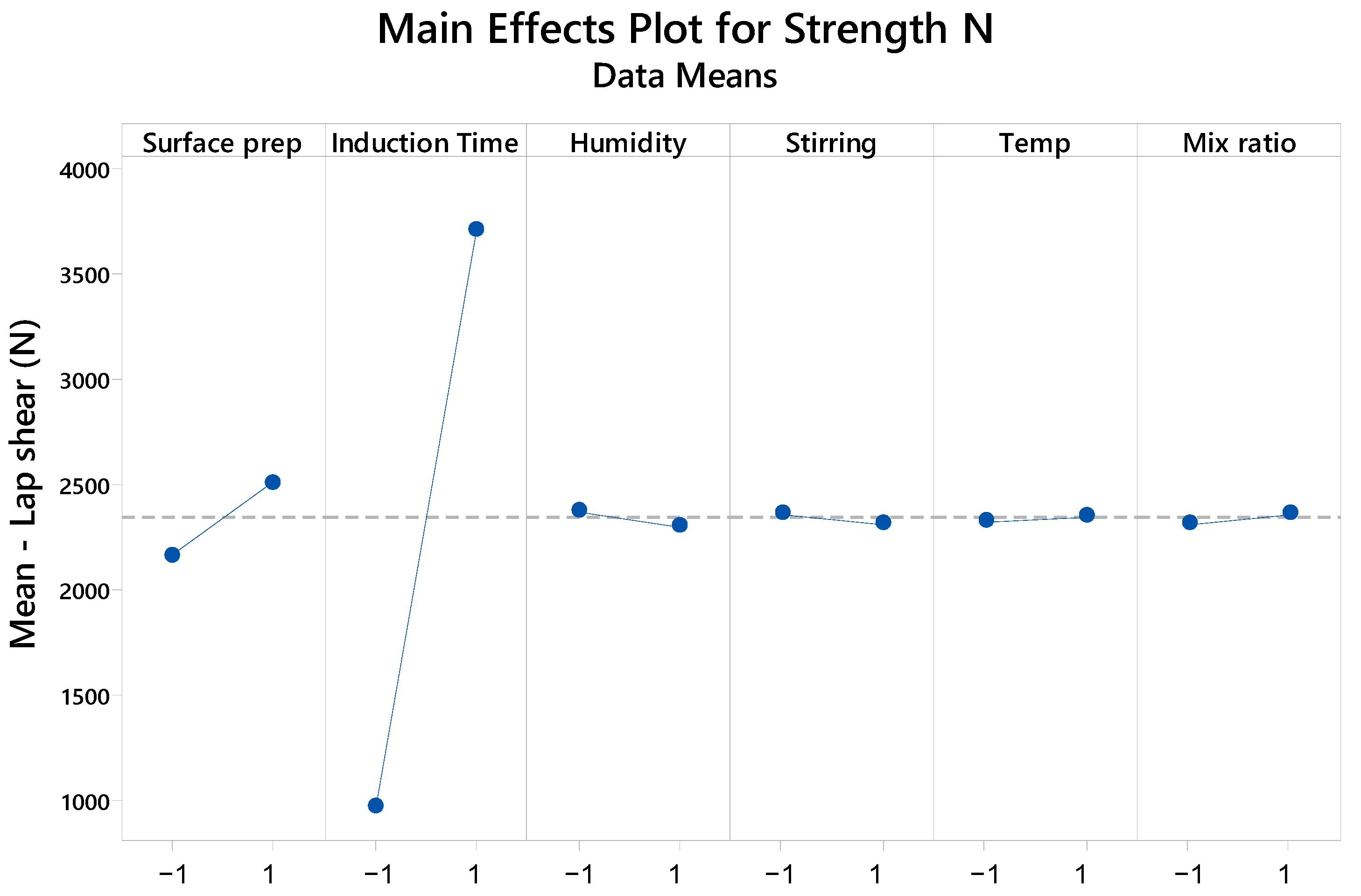

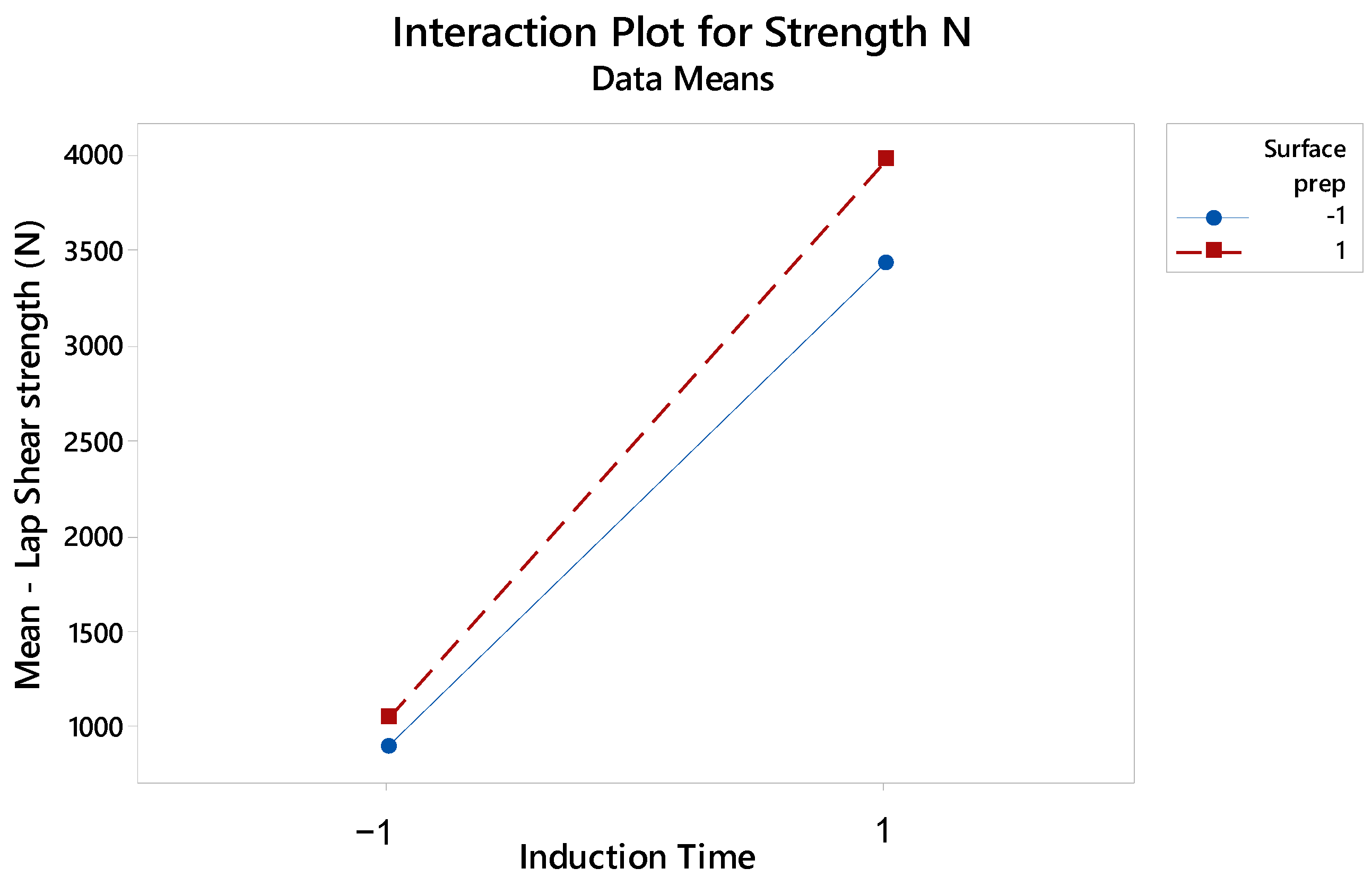

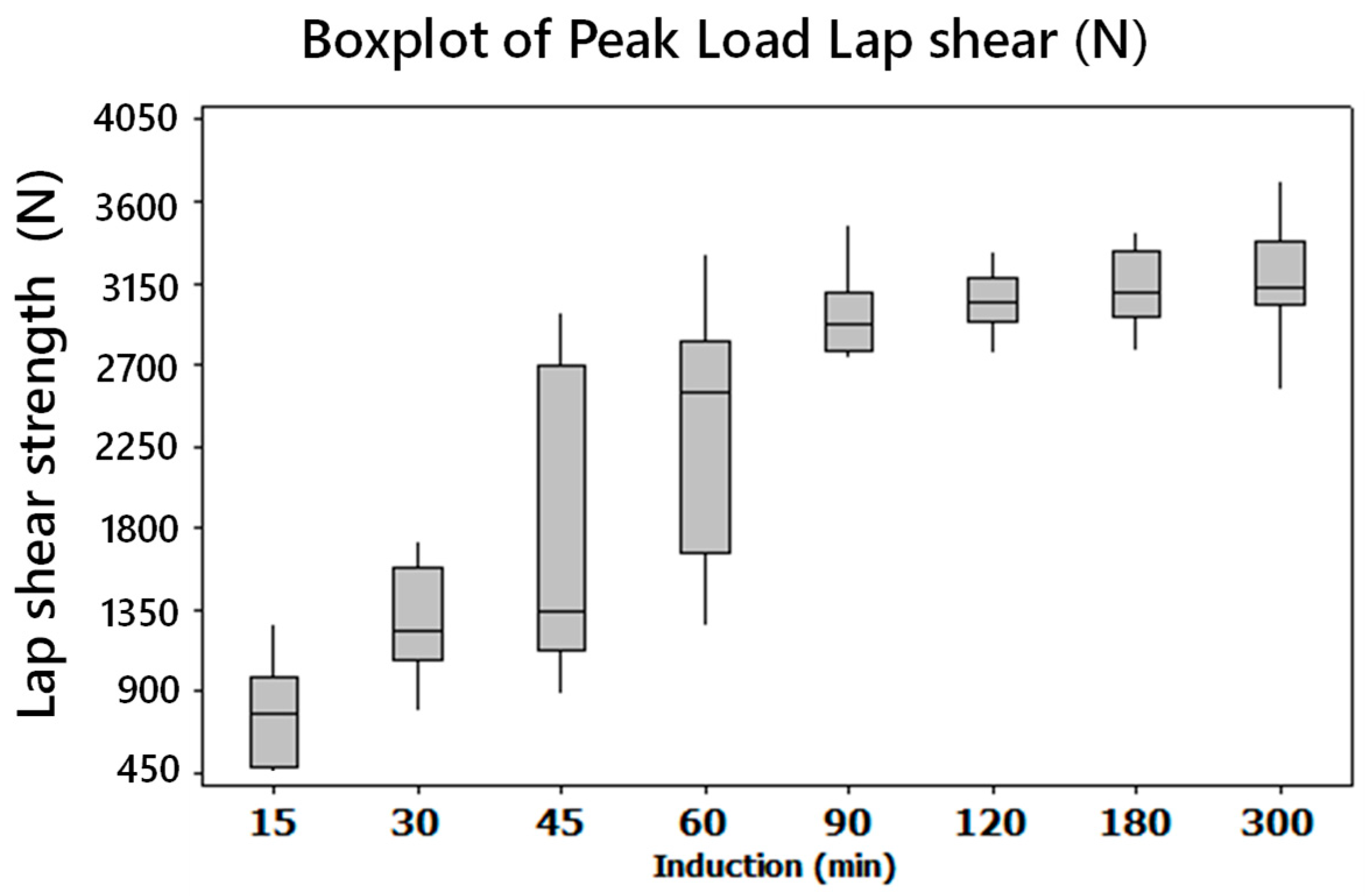

- Factor B (Induction Time) exhibited the largest effect, with an F-value of 8808.87 (p < 0.000).

- Factor A (Surface Preparation) was the second most significant effect, with an F-value of 139.96 (p = 0.000).

- Factor C (Humidity) was marginally significant, with an F-value of 6.9 (p = 0.013).

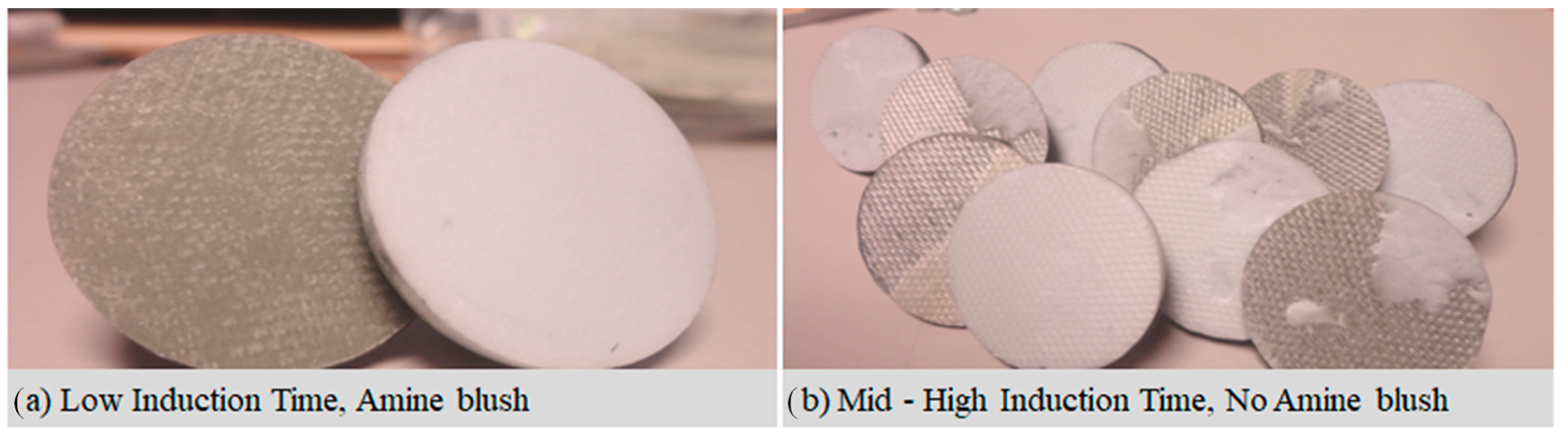

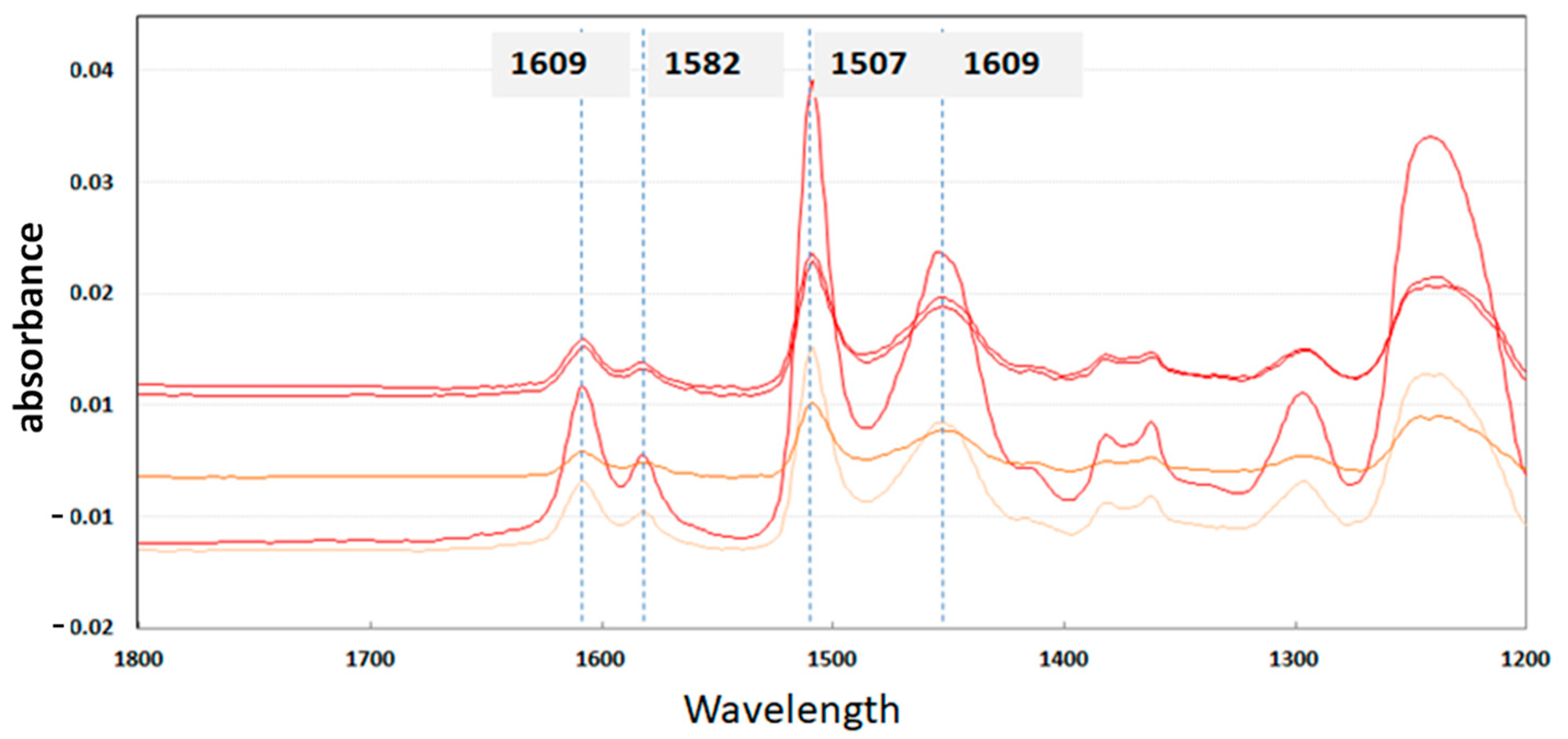

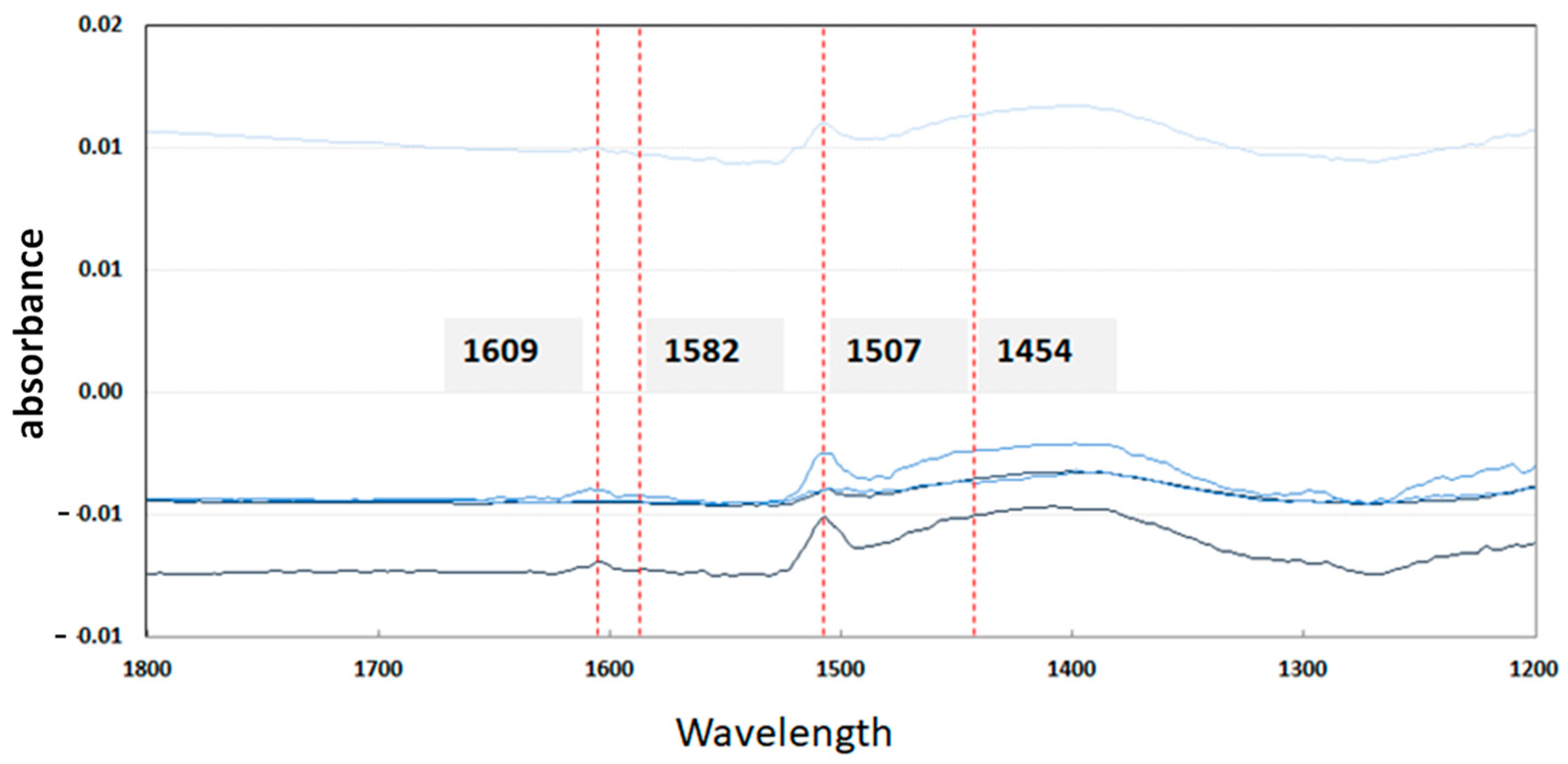

Qualitative Failure Analysis

4. Discussion

4.1. Dominant Effect of Induction Time on Rheology

4.2. Critical Role of Surface Energetics and Mechanics

4.3. Humidity as a Latent Defect Source

4.4. Implications for Process Control

5. Conclusions

- Primary Control: Induction Time must be rigorously controlled. The optimal window (≥85 min, as shown in Figure 10) allows for proper rheological development to prevent joint starvation and ensure high cohesive strength.

- Secondary Control: Surface Preparation Mechanical abrasion is essential to activate the substrate and enable mechanical interlocking, providing a significant and consistent strength benefit.

- Tertiary Control: Ambient Humidity should be maintained below critical levels (<70% RH) to prevent the formation of amine blush and ensure consistent interfacial quality.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of Variance |

| DOE | Design of Experiments |

| FTIR | Fourier-Transform Infrared Spectroscopy |

| lbf | Pound-force (unit of load) |

| MPa | Megapascal (unit of stress) |

| RH | Relative Humidity |

References

- Pocius, A.V. Adhesion and Adhesives Technology: An Introduction, 3rd ed.; Hanser Publications: Cincinnati, OH, USA, 2012; ISBN 9781569905111. [Google Scholar]

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing: Cambridge, UK, 2012. [Google Scholar]

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. (Eds.) Handbook of Adhesion Technology; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-01169-6. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Petrie, E.M. Epoxy Adhesive Formulations; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Adams, R.D. Adhesive Bonding: Science, Technology and Applications; Woodhead Publishing: Cambridge, UK, 2005. [Google Scholar]

- Hernández, M.; Sixou, M.; Budtova, T.; Eceiza, A.; Gabilondo, N. Influence of humidity on the curing process and properties of an amine-cured epoxy system. Polym. Degrad. Stab. 2017, 144, 195–203. [Google Scholar]

- Golewski, P.; Sadowski, T. The Influence of Single Lap Geometry in Adhesive and Hybrid Joints on Their Load Carrying Capacity. Materials 2019, 12, 1884. [Google Scholar] [CrossRef] [PubMed]

- Monajati, L.; Vadean, A.; Boukhili, R. Mechanical Behavior of Adhesively Bonded Joints Under Tensile Loading: A Synthetic Review of Configurations, Modeling, and Design Considerations. Materials 2025, 18, 3557. [Google Scholar] [CrossRef] [PubMed]

- Moya-Sanz, E.M.; Ivañez, I.; Garcia-Castillo, S.K. Effect of the geometry in the strength of single-lap adhesive joints of composite laminates under uniaxial tensile load. Int. J. Adhes. Adhes. 2017, 72, 23–29. [Google Scholar] [CrossRef]

- Packham, D.E. Handbook of Adhesion, 2nd ed.; John Wiley & Sons: Chichester, UK, 2005. [Google Scholar]

- Raos, G.; Zappone, B. Polymer Adhesion: Seeking New Solutions for an Old Problem. Macromolecules 2021, 54, 10617–10644. [Google Scholar] [CrossRef]

- Critchlow, G.W.; Brewis, D.M. Review of surface pretreatments for structural adhesion. Int. J. Adhes. Adhes. 1996, 16, 255–275. [Google Scholar] [CrossRef]

- Wegman, R.F.; Van Twisk, J. Surface Preparation Techniques for Adhesive Bonding, 2nd ed.; William Andrew: Norwich, NY, USA, 2013. [Google Scholar]

- Williams, G.P.; Pocius, A.V. The effects of surface roughness on adhesion. In Adhesion Science and Engineering, Volume 1; Dillard, D.A., Pocius, A.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; pp. 415–455. [Google Scholar]

- Costa, M.; Viana, J.C. The effect of grit blasting on the surface properties and adhesion of composite laminates. Compos. Part B Eng. 2016, 91, 14–22. [Google Scholar]

- Pascault, J.P.; Sautereau, H.; Verdu, J.; Williams, R.J. Thermosetting Polymers; Marcel Dekker: New York, NY, USA, 2002. [Google Scholar]

- García, J.M.; Eon, L.; Cado, A.; Bar-Cohen, Y.; Calvo, F.; Goyanes, S. New insights into the curing of epoxy resins. Prog. Polym. Sci. 2014, 39, 623–652. [Google Scholar]

- Schuft, C. Amine Blush: What it is and how to avoid it. Epoxyworks 1998, 12, 1–3. [Google Scholar]

- De la Fuente, J.L.; Madaleno, E. The effect of amine blushing on the physical and mechanical properties of a DGEBA/polyetheramine system. J. Appl. Polym. Sci. 2006, 102, 4163–4172. [Google Scholar]

- Smith, L.V.; Davis, C.R. Characterization and effects of amine blush on epoxy adhesive bonds. J. Mater. Sci. 2001, 36, 935–942. [Google Scholar]

- Halley, P.J.; Mackay, M.E. The effect of B-stage curing on the rheology of an epoxy resin. Polym. Eng. Sci. 1996, 36, 593–609. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- ASTM D1002-10; Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM International: West Conshohocken, PA, USA, 2019.

| X: Input | Y: Output | ||||||

|---|---|---|---|---|---|---|---|

| Run Order | Surface prep | Induction Time | Humidity | Stirring | Temp | Mix ratio | Peak lap shear Strength (N) |

| 1 | −1 | −1 | −1 | −1 | −1 | −1 | 1053 |

| 2 | 1 | −1 | −1 | −1 | 1 | −1 | 1091 |

| 3 | −1 | 1 | −1 | −1 | 1 | 1 | 3524 |

| 4 | 1 | 1 | −1 | −1 | −1 | 1 | 4028 |

| 5 | −1 | −1 | 1 | −1 | 1 | 1 | 874 |

| 6 | 1 | −1 | 1 | −1 | −1 | 1 | 1071 |

| 7 | −1 | 1 | 1 | −1 | −1 | −1 | 3297 |

| 8 | 1 | 1 | 1 | −1 | 1 | −1 | 3743 |

| 9 | −1 | −1 | −1 | 1 | −1 | 1 | 794 |

| 10 | 1 | −1 | −1 | 1 | 1 | 1 | 1002 |

| 11 | −1 | 1 | −1 | 1 | 1 | −1 | 3553 |

| 12 | 1 | 1 | −1 | 1 | −1 | −1 | 3872 |

| 13 | −1 | −1 | 1 | 1 | 1 | −1 | 698 |

| 14 | 1 | −1 | 1 | 1 | −1 | −1 | 940 |

| 15 | −1 | 1 | 1 | 1 | −1 | 1 | 3450 |

| 16 | 1 | 1 | 1 | 1 | 1 | 1 | 3886 |

| 17 | −1 | −1 | −1 | −1 | −1 | −1 | 988 |

| 18 | 1 | −1 | −1 | −1 | 1 | −1 | 1224 |

| 19 | −1 | 1 | −1 | −1 | 1 | 1 | 3664 |

| 20 | 1 | 1 | −1 | −1 | −1 | 1 | 4199 |

| 21 | −1 | −1 | 1 | −1 | 1 | 1 | 871 |

| 22 | 1 | −1 | 1 | −1 | −1 | 1 | 1101 |

| 23 | −1 | 1 | 1 | −1 | −1 | −1 | 3069 |

| 24 | 1 | 1 | 1 | −1 | 1 | −1 | 4045 |

| 25 | −1 | −1 | −1 | 1 | −1 | 1 | 883 |

| 26 | 1 | −1 | −1 | 1 | 1 | 1 | 1050 |

| 27 | −1 | 1 | −1 | 1 | 1 | −1 | 3388 |

| 28 | 1 | 1 | −1 | 1 | −1 | −1 | 3949 |

| 29 | −1 | −1 | 1 | 1 | 1 | −1 | 879 |

| 30 | 1 | −1 | 1 | 1 | −1 | −1 | 1059 |

| 31 | −1 | 1 | 1 | 1 | −1 | 1 | 3399 |

| 32 | 1 | 1 | 1 | 1 | 1 | 1 | 4071 |

| 33 | −1 | −1 | −1 | −1 | −1 | −1 | 1014 |

| 34 | 1 | −1 | −1 | −1 | 1 | −1 | 1011 |

| 35 | −1 | 1 | −1 | −1 | 1 | 1 | 3527 |

| 36 | 1 | 1 | −1 | −1 | −1 | 1 | 3977 |

| 37 | −1 | −1 | 1 | −1 | 1 | 1 | 843 |

| 38 | 1 | −1 | 1 | −1 | −1 | 1 | 988 |

| 39 | −1 | 1 | 1 | −1 | −1 | −1 | 3325 |

| 40 | 1 | 1 | 1 | −1 | 1 | −1 | 4136 |

| 41 | −1 | −1 | −1 | 1 | −1 | 1 | 845 |

| 42 | 1 | −1 | −1 | 1 | 1 | 1 | 1056 |

| 43 | −1 | 1 | −1 | 1 | 1 | −1 | 3416 |

| 44 | 1 | 1 | −1 | 1 | −1 | −1 | 3937 |

| 45 | −1 | −1 | 1 | 1 | 1 | −1 | 968 |

| 46 | 1 | −1 | 1 | 1 | −1 | −1 | 925 |

| 47 | −1 | 1 | 1 | 1 | −1 | 1 | 3656 |

| 48 | 1 | 1 | 1 | 1 | 1 | 1 | 3908 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 15 | 92,391,076 | 6,159,405 | 601.66 | 0 |

| Linear | 6 | 91,739,180 | 15,289,863 | 1493.55 | 0 |

| Surface prep | 1 | 1,432,830 | 1,432,830 | 139.96 | 0 |

| Induction Time | 1 | 90,178,901 | 90,178,901 | 8808.87 | 0 |

| Humidity | 1 | 70,681 | 70,681 | 6.9 | 0.013 |

| Stirring | 1 | 24,314 | 24,314 | 2.38 | 0.133 |

| Temp | 1 | 7734 | 7734 | 0.76 | 0.391 |

| Mix ratio | 1 | 24,719 | 24,719 | 2.41 | 0.13 |

| 2-Way Interactions | 7 | 592,451 | 84,636 | 8.27 | 0 |

| Surface prep * Induction Time | 1 | 455,739 | 455,739 | 44.52 | 0 |

| Surface prep * Humidity | 1 | 13,333 | 13,333 | 1.3 | 0.262 |

| Surface prep * Stirring | 1 | 14,599 | 14,599 | 1.43 | 0.241 |

| Surface prep * Temp | 1 | 1338 | 1338 | 0.13 | 0.72 |

| Surface prep * Mix ratio | 1 | 1607 | 1607 | 0.16 | 0.695 |

| Induction Time * Stirring | 1 | 19,976 | 19,976 | 1.95 | 0.172 |

| Induction Time * Mix ratio | 1 | 85,859 | 85,859 | 8.39 | 0.007 |

| 3-Way Interactions | 2 | 59,445 | 29,723 | 2.9 | 0.069 |

| Surface prep * Induction Time * Stir | 1 | 24,488 | 24,488 | 2.39 | 0.132 |

| Surface prep * Induction Time * Mix ratio | 1 | 34,957 | 34,957 | 3.41 | 0.074 |

| Error | 32 | 327,593 | 10,237 | ||

| Total | 47 | 92,718,669 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Favela, R. A Quantitative Framework for Process Control in the Structural Bonding of Aerospace Composites with MGS L418 Epoxy. J. Compos. Sci. 2025, 9, 603. https://doi.org/10.3390/jcs9110603

Favela R. A Quantitative Framework for Process Control in the Structural Bonding of Aerospace Composites with MGS L418 Epoxy. Journal of Composites Science. 2025; 9(11):603. https://doi.org/10.3390/jcs9110603

Chicago/Turabian StyleFavela, Ruben. 2025. "A Quantitative Framework for Process Control in the Structural Bonding of Aerospace Composites with MGS L418 Epoxy" Journal of Composites Science 9, no. 11: 603. https://doi.org/10.3390/jcs9110603

APA StyleFavela, R. (2025). A Quantitative Framework for Process Control in the Structural Bonding of Aerospace Composites with MGS L418 Epoxy. Journal of Composites Science, 9(11), 603. https://doi.org/10.3390/jcs9110603