Design Methodology for Tensile Load Capacity of Rivet Nut Connections in Aluminium Alloy Profiles

Abstract

1. Introduction

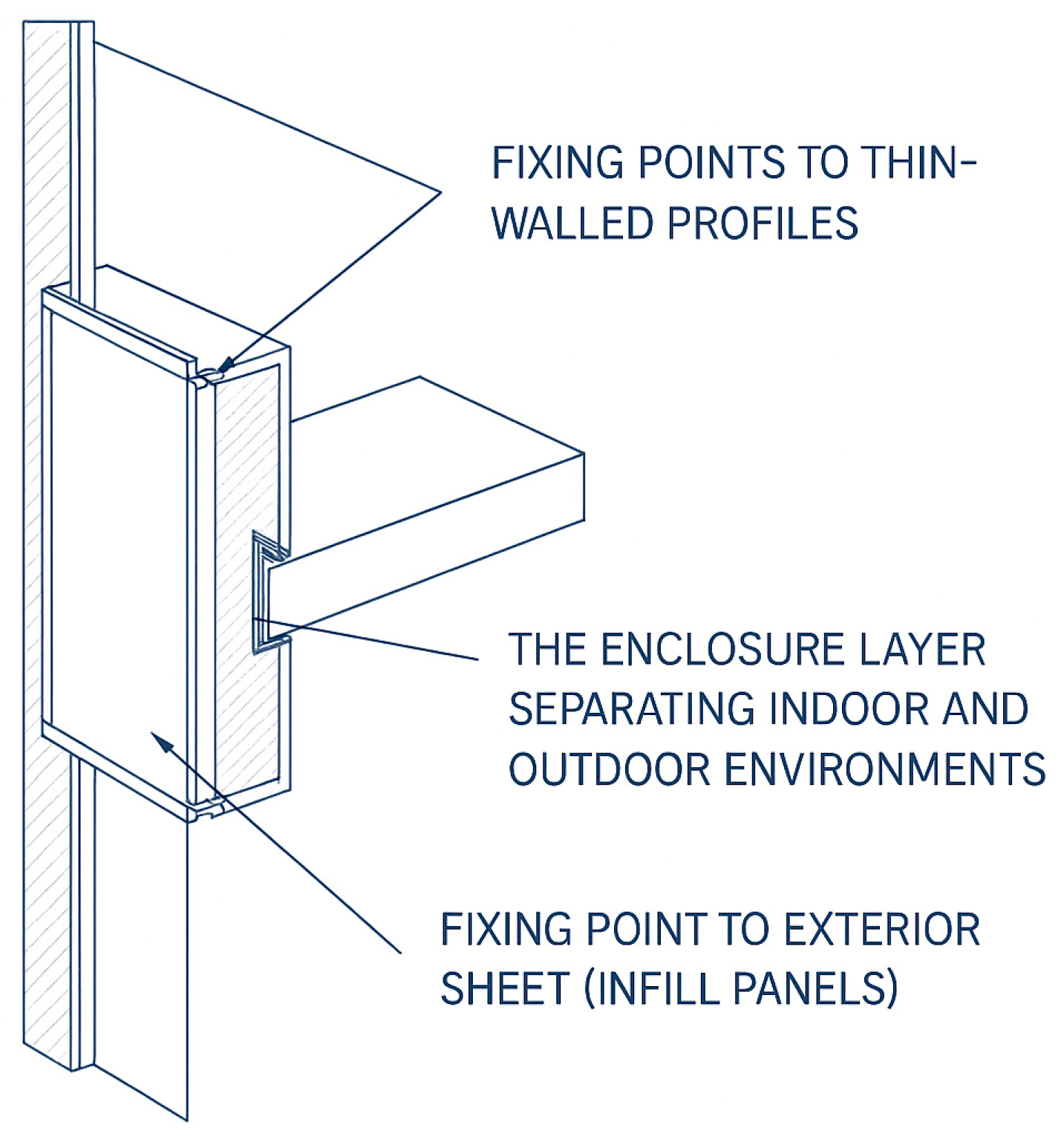

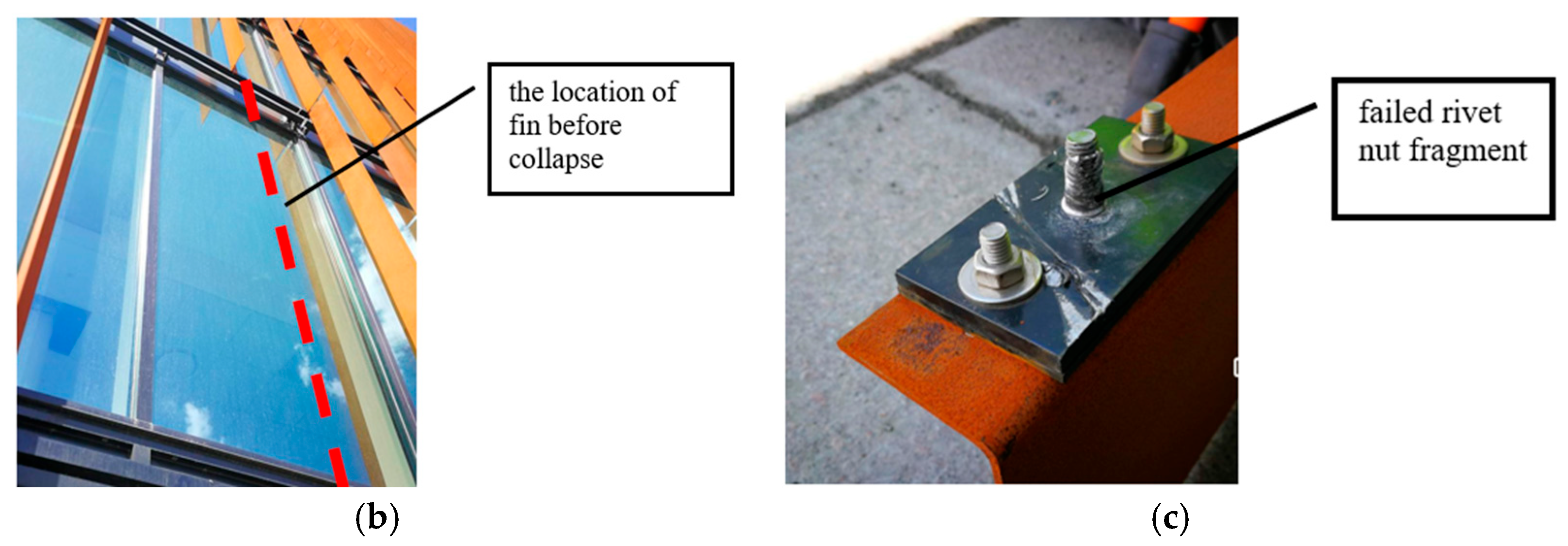

1.1. Significance of the Rivet Nut Joints in Suspended Facades

1.2. Evaluation and Modelling of Rivet Nut Connection Behaviour and Load Capacity: Current State and Research Gaps

2. Materials and Methods

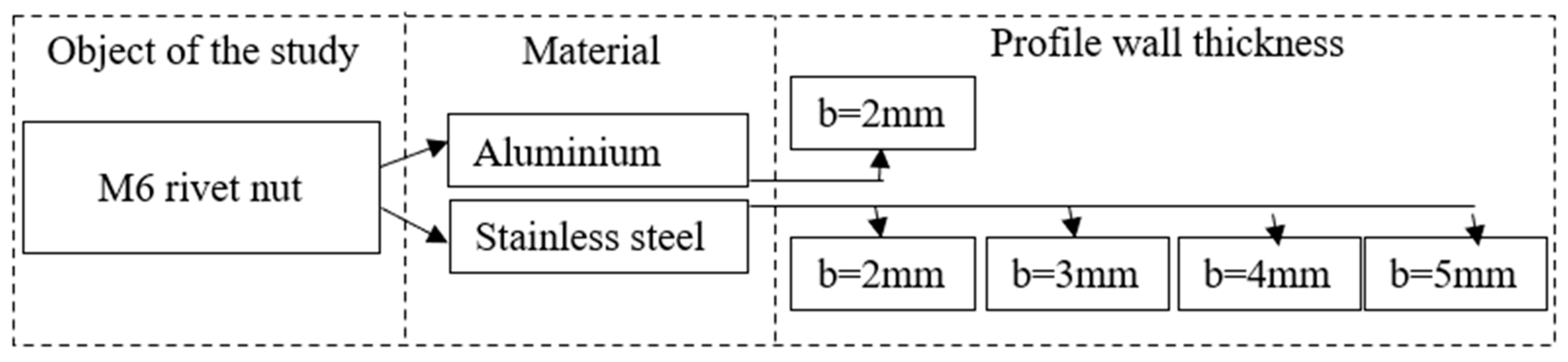

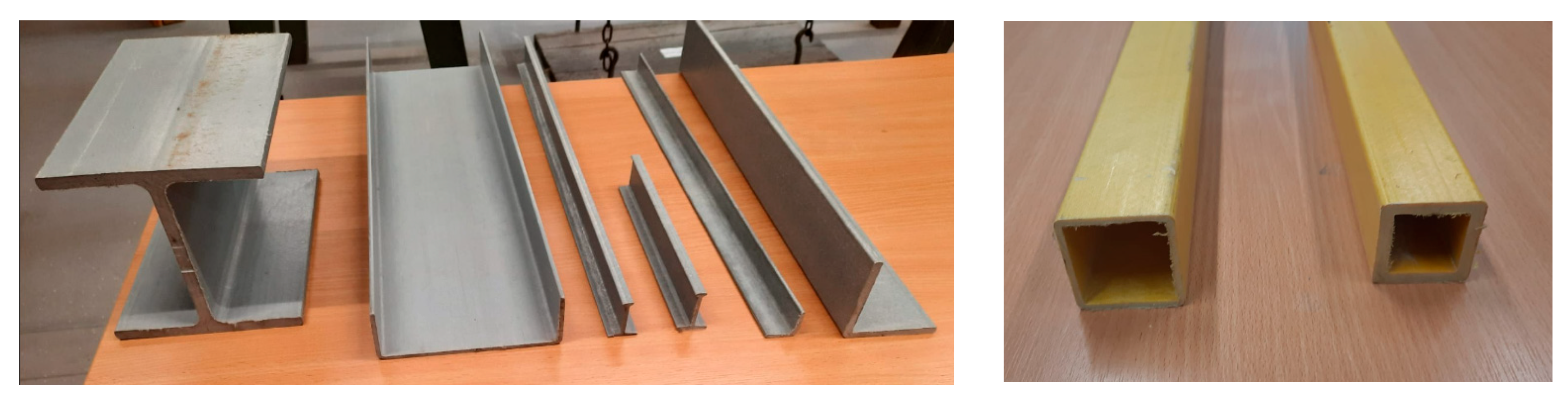

2.1. Description of Object of Investigation

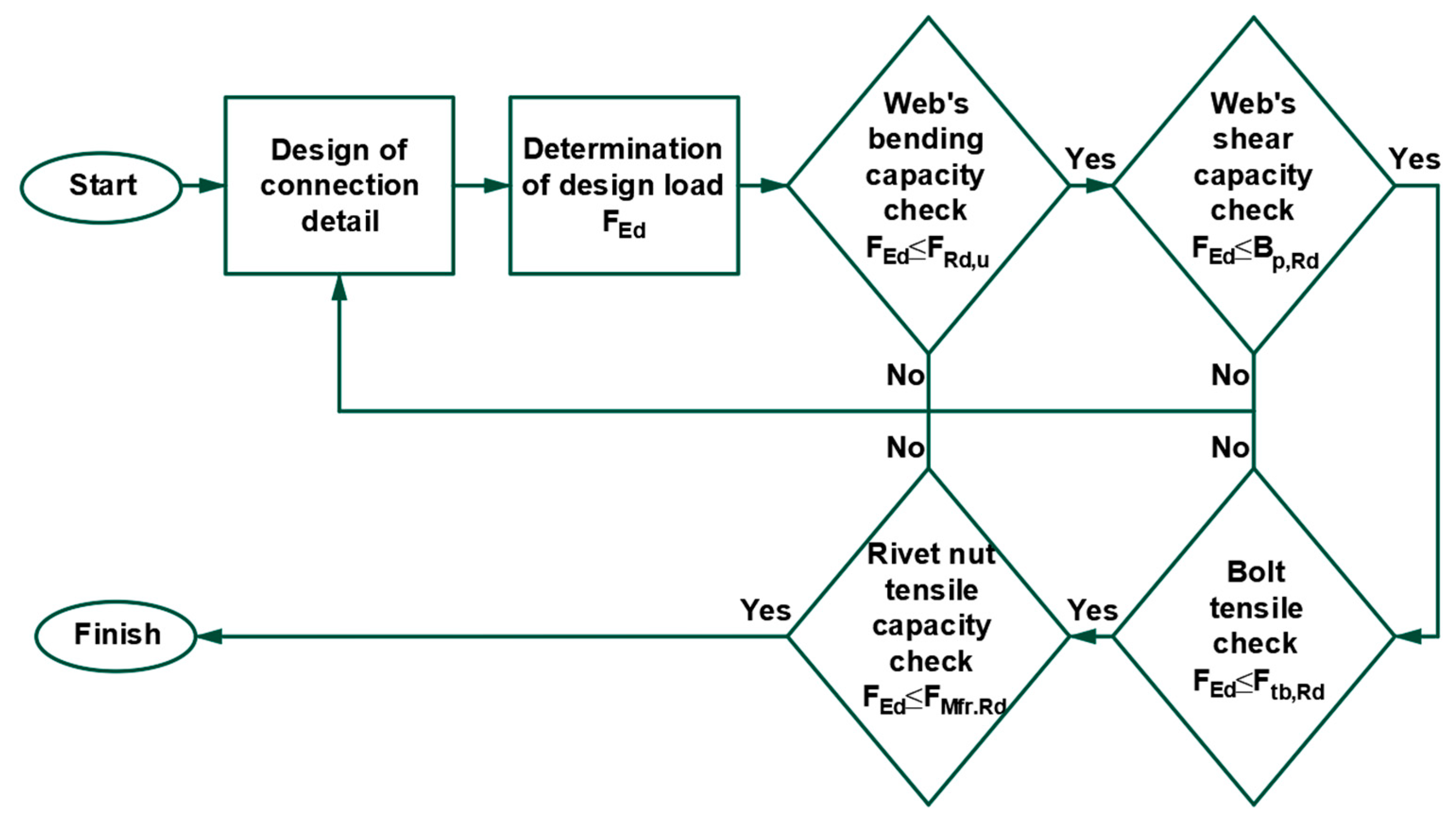

2.2. Development of a Methodology for Assessing the Tensile Load-Bearing Capacity of Rivet Nut Connections in Aluminium Alloy Profiles

- Check the web’s stability of the profile.

- Check the aluminium alloy profile web’s strength in shear.

- Check of the rivet’s nut.

- Check of the rivet’s strength in tension.

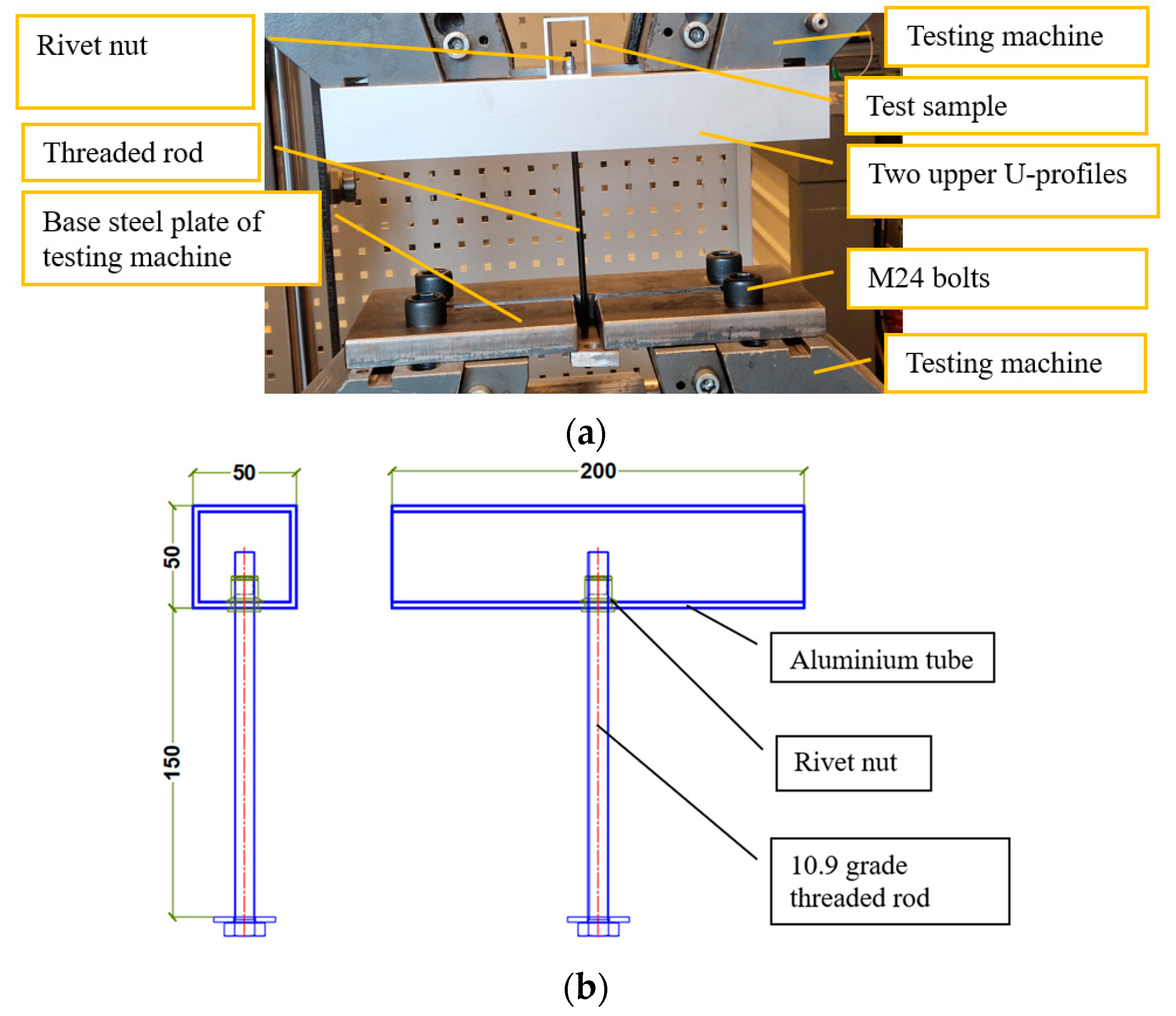

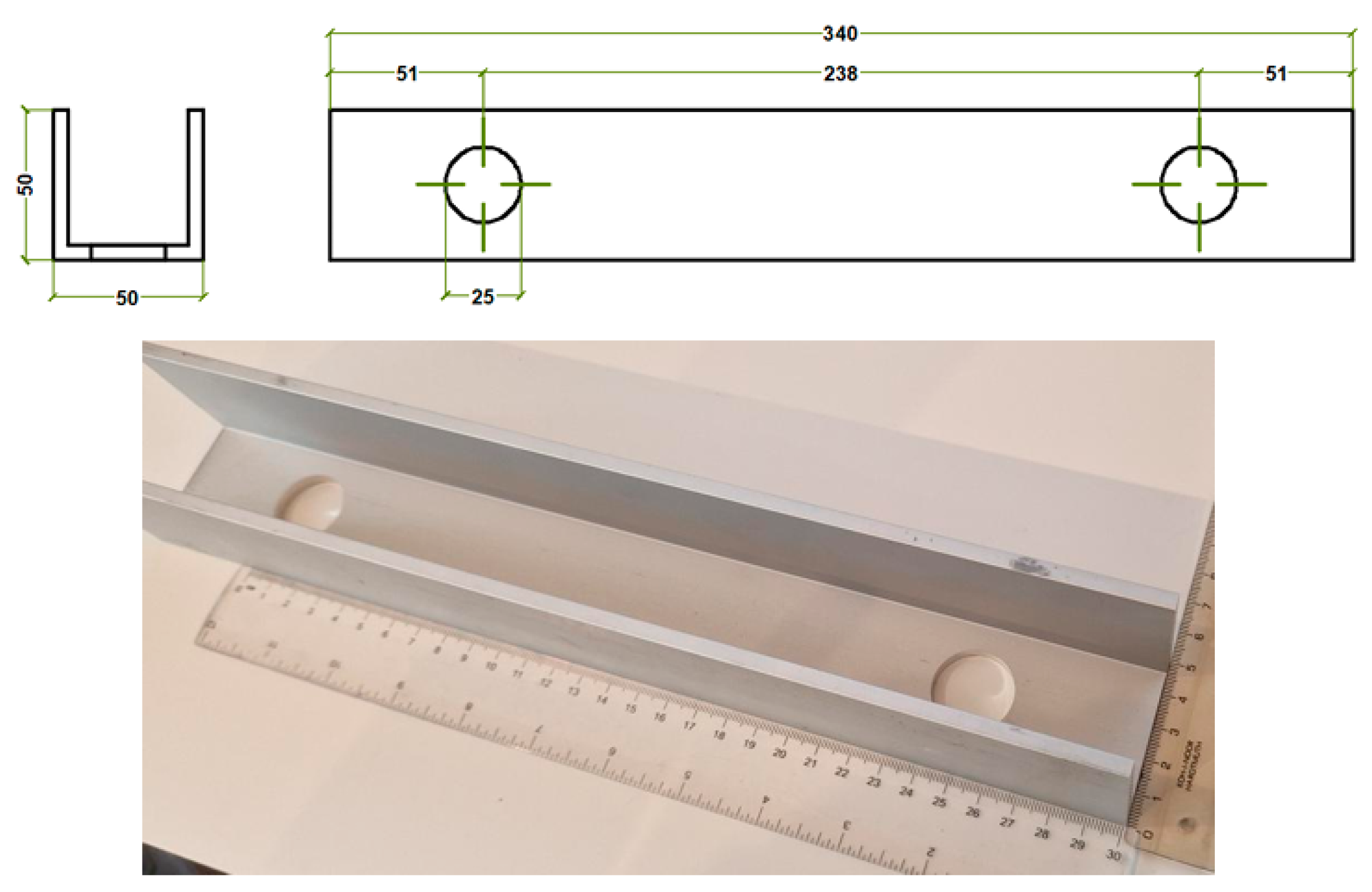

2.3. Experimental Trials

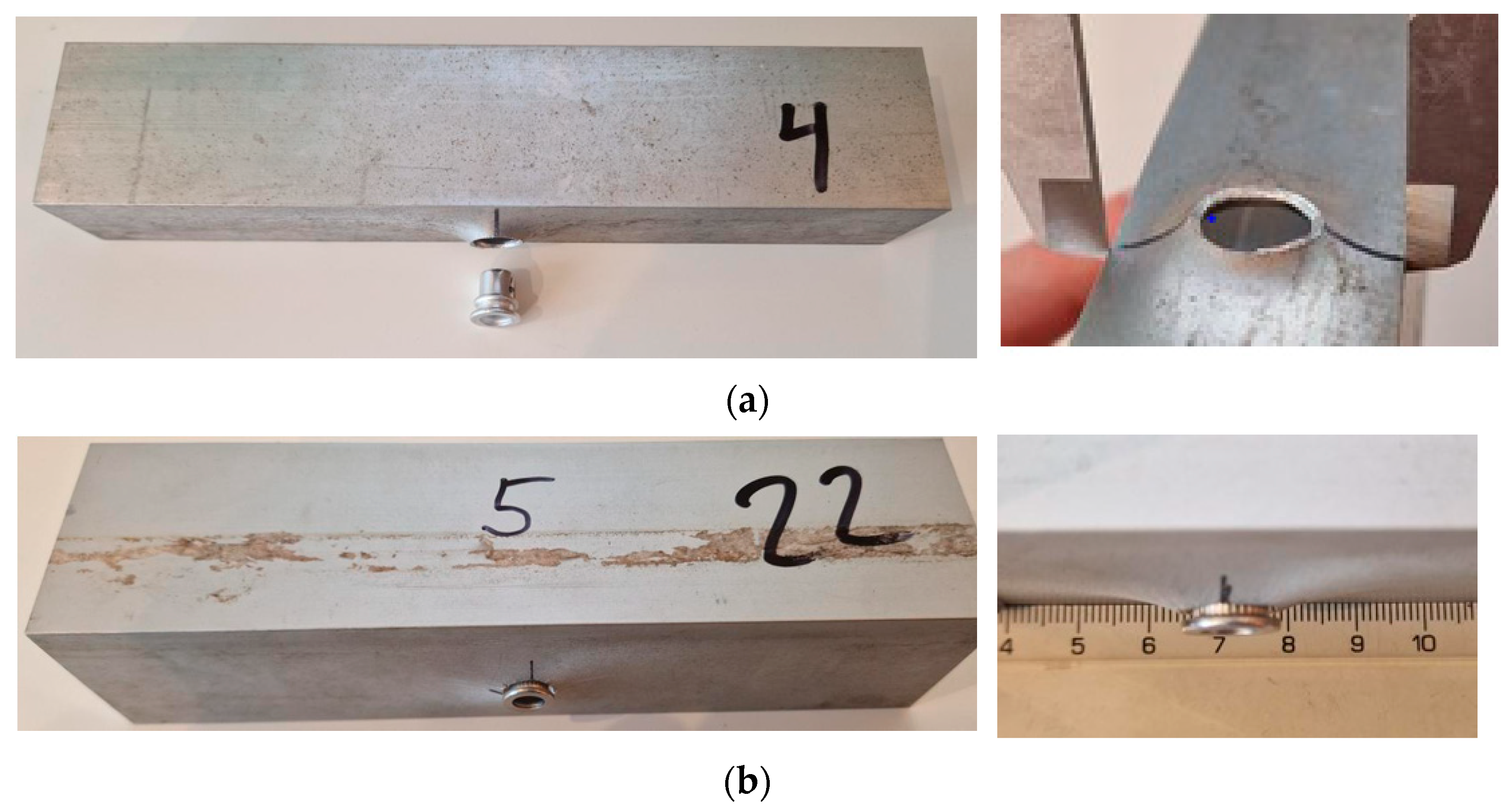

2.4. Experimental Trials

3. Results and Discussions

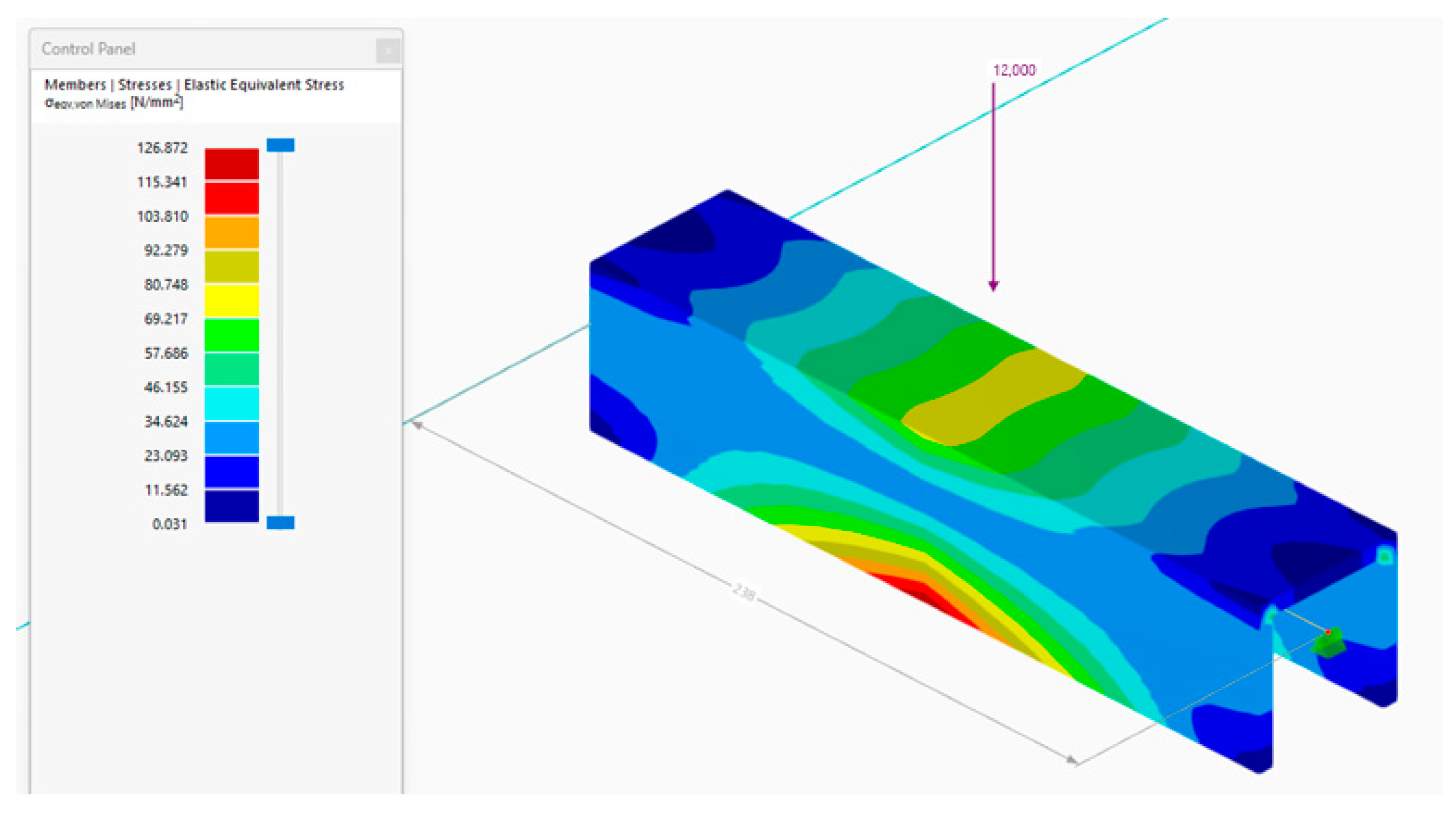

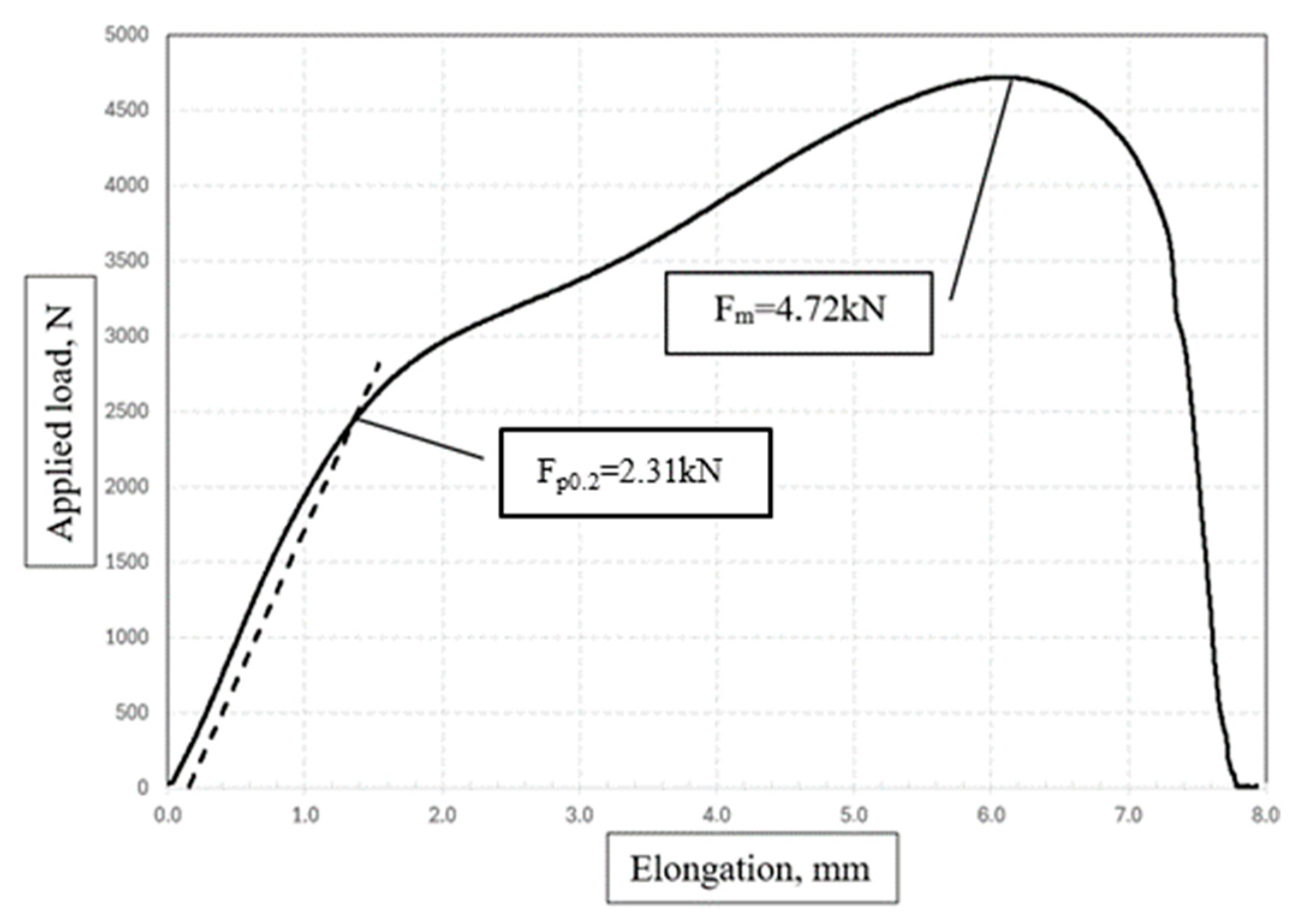

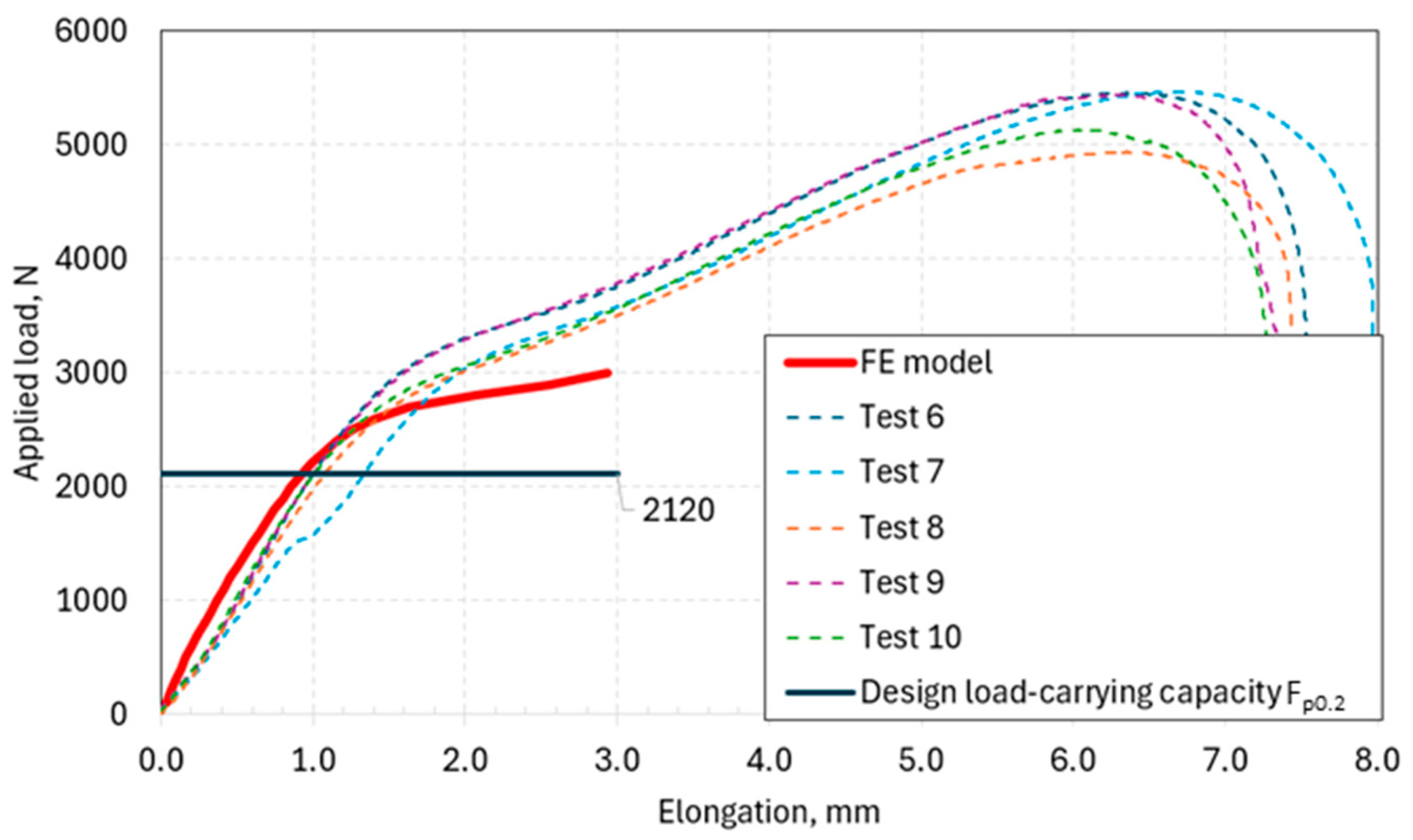

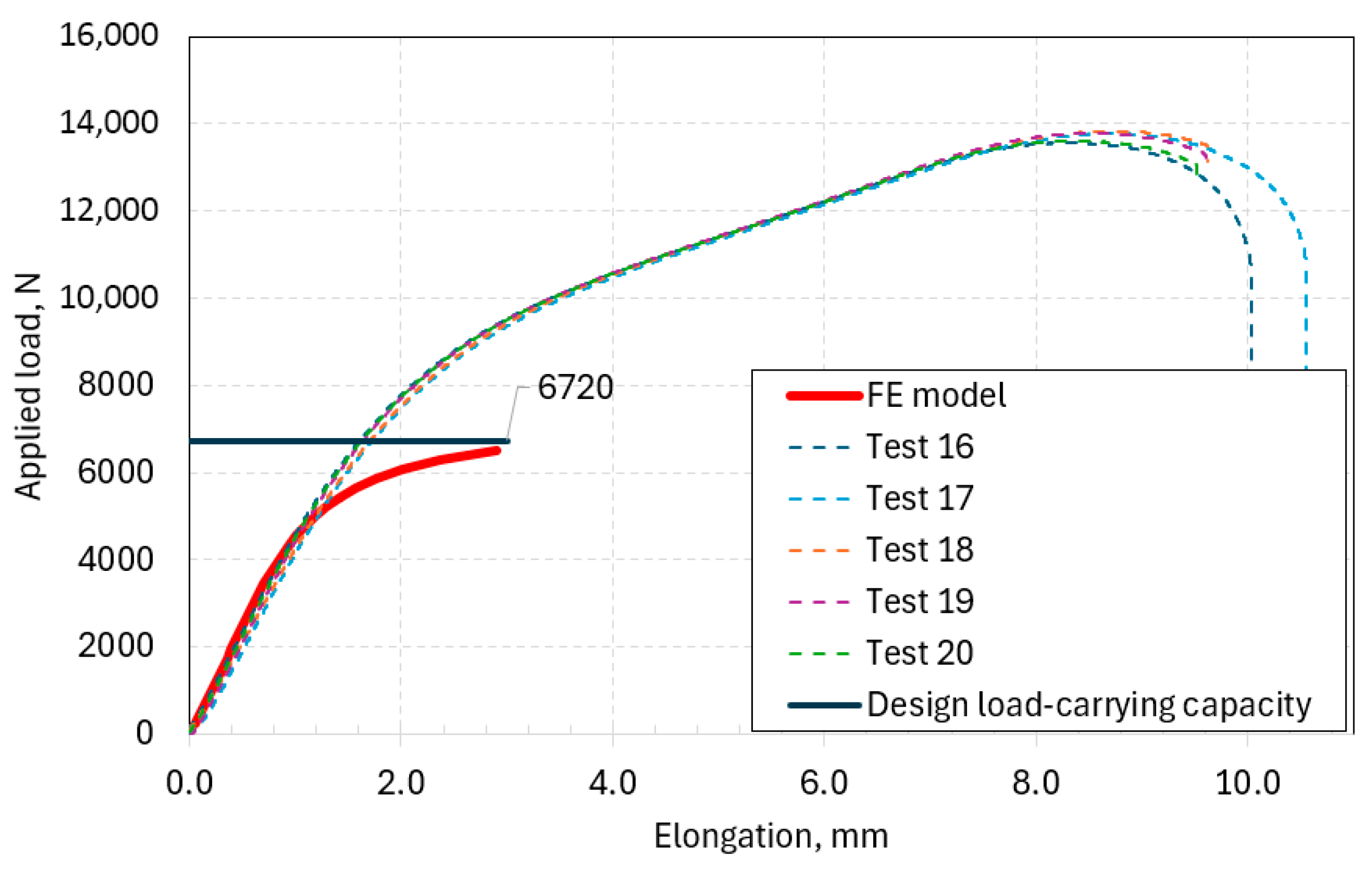

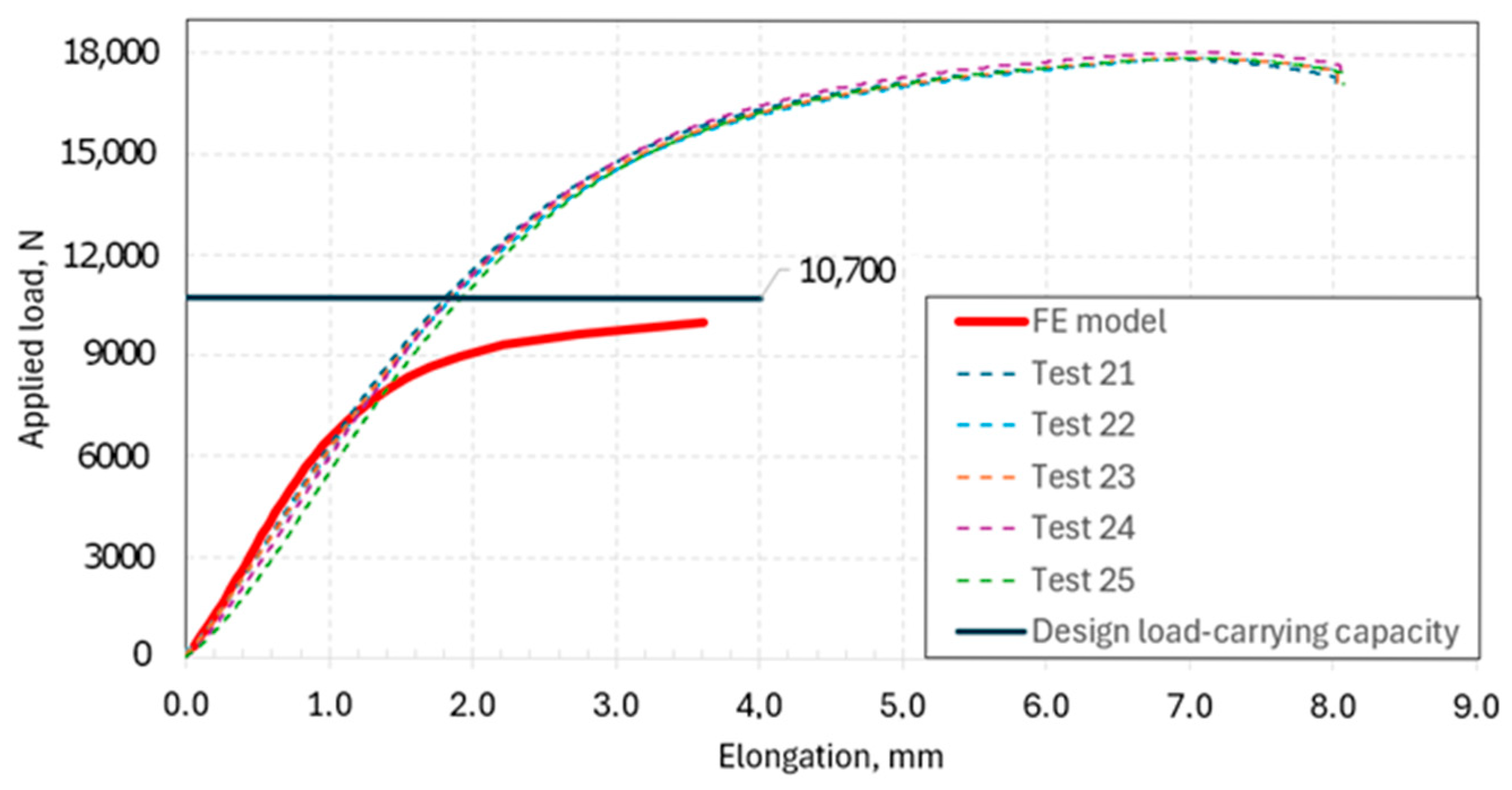

3.1. Results of the Laboratory and Numerical Experiments

3.2. Potential Extension of the Method for Evaluating Rivet Nut Load Capacity in Composite and Hybrid Profiles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yazdi Bahri, S.; Alier Forment, M.; Sanchez Riera, A.; Bagheri Moghaddam, F.; Casañ Guerrero, M.J.; Llorens Garcia, A.M. A Literature Review on Thermal Comfort Performance of Parametric Façades. Energy Rep. 2022, 8, 120–128. [Google Scholar] [CrossRef]

- Galyamichev, A.; Gerasimova, E.; Egorov, D.; Serdjuks, D.; Grossman, A.; Lysenko, D. Bearing Capacity of Riveted Connections of Mineral Wool Sandwich Panels. Mag. Civ. Eng. 2022, 112, 11202. [Google Scholar] [CrossRef]

- Buka-Vaivade, K.; Serdjuks, D.; Pakrastins, L. Cost Factor Analysis for Timber–Concrete Composite with a Lightweight Plywood Rib Floor. Buildings 2022, 12, 761. [Google Scholar] [CrossRef]

- Ziverts, A. Design Methodology for Tensile Load-Bearing Capacity Determination of a Rivet Nut Connection with an Aluminium Alloy Profile. Master’s Thesis, Riga Technical University, Riga, Latvia, 2025. [Google Scholar]

- Setiawan, R.I.; Ramadhani, S. Pengaplikasian Material Aluminium Composite Panel Pada Perancangan Apartemen Dan Soho Di Kota Surabaya. J. Lingkung. Karya Arsit. 2023, 2, 80–86. [Google Scholar] [CrossRef]

- Borowiecki, C.; Iluk, A.; Krysiński, P.; Rusiński, E.; Sawicki, M. Numerical and Experimental Investigation of Bolted Connections with Blind Rivet Nuts. In Proceedings of the 14th International Scientific Conference: Computer Aided Engineering, Wrocław, Poland, 20–23 June 2018; Rusiński, E., Pietrusiak, D., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 88–95. [Google Scholar]

- Satheesh Kumar, K.V.; Selvakumar, P.; Jagadeeswari, R.; Dharmaraj, M.; Uvanshankar, K.R.; Yogeswaran, B. Stress Analysis of Riveted and Bolted Joints Using Analytical and Experimental Approach. Mater. Today Proc. 2021, 42, 1091–1099. [Google Scholar] [CrossRef]

- de Velde, A.V.; Ivens, J.; Maeyens, J.; Coppieters, S. The Effect of the Setting Force on the Fatigue Resistance of a Blind Rivet Nut Set in CFRP. Key Eng. Mater. 2022, 926, 1498–1504. [Google Scholar] [CrossRef]

- Van de Velde, A.; Debruyne, D.; Maeyens, J.; Wevers, M.; Coppieters, S. Towards Best Practice in Numerical Simulation of Blind Rivet Nut Installation. Int. J. Mater. Form. 2021, 14, 1139–1155. [Google Scholar] [CrossRef]

- Cosgun, S.I. Experimental Study on the Pull-Out Capacity of Blind Rivet Nuts (BRNs) Mounted on Cold-Formed Square Hollow Section Members with Different Wall Thickness. Sinop. Uni. J. Nat. Sci. 2023, 8, 202–215. [Google Scholar] [CrossRef]

- Reproducing the Experimental Torque-to-Turn Resistance of Blind Rivet Nuts Using FEA, AIP Conference Proceedings, AIP Publishing. Available online: https://pubs.aip.org/aip/acp/article-abstract/1896/1/110005/998803/Reproducing-the-experimental-torque-to-turn?redirectedFrom=fulltext (accessed on 25 August 2025).

- GÓRKAL 70 Product Description. Www.gorka.com.pl. 2020. Available online: https://www.gorka.com.pl/pdf/en/g70_katalog_en.pdf (accessed on 25 August 2025).

- Van de Velde, A.; Maeyens, J.; Ivens, J.; Coppieters, S. The Effect of the Setting Force on the Static Strength of a Blind Rivet Nut Set in CFRP. Compos. Struct. 2023, 307, 116640. [Google Scholar] [CrossRef]

- Li, P.; Yang, C.; Xu, F.; Li, J.; Jin, D. Reinforcement of Insufficient Transverse Connectivity in Prestressed Concrete Box Girder Bridges Using Concrete-Filled Steel Tube Trusses and Diaphragms: A Comparative Study. Buildings 2024, 14, 2466. [Google Scholar] [CrossRef]

- EN 1993-1-8; Eurocode 3: Design of Steel Structures—Part 1–8: Design of Joints. CEN: Brussels, Belgium, 2005.

- Dose, G.F.; Schwarz, W. Nachweis Der Abstreifsicherheit Axial Beanspruchter Einschraubverbindungen. 2000. Available online: https://www.hexagon.de/dose/dose2.pdf (accessed on 10 September 2025).

- Joints in Steel Construction: Simple Joints to Eurocode 3; Steel Construction Institute: Bracknell, UK; British Constructional Steelwork Association Ltd.: Ascot, London, 2011; ISBN 978-1-85942-201-4.

- Witek, L. Numerical Simulation of Riveting Process Using Blind Rivet. Aviation 2006, 10, 7–12. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Fini, S.; Mele, M.; Olmi, G.; Scapecchi, C.; Tariq, M.H.B. Failure of Threaded Connections: A Literature Review. Machines 2023, 11, 212. [Google Scholar] [CrossRef]

- Egorov, D.; Galyamichev, A.; Gerasimova, E.; Serdjuks, D. Stress-Strain State of Fiber Cement Cladding within Curtain Wall System. Mag. Civ. Eng. 2020, 97, 9709. [Google Scholar] [CrossRef]

- Barkanov, E.; Akishin, P.; Namsone, E.; Auzins, J.; Morozovs, A. Optimization of Pultrusion Processes for an Industrial Application. Mech. Compos. Mater. 2021, 56, 697–712. [Google Scholar] [CrossRef]

- Galyamichev, A.; Kirikova, V.; Gerasimova, E.; Sprince, A. Bearing Capacity of Facade Systems Fixing to Sandwich Panels. Mag. Civ. Eng. 2018, 78, 30–46. [Google Scholar] [CrossRef]

- Studziński, R.; Ciesielczyk, K. Use of Blind Rivets in Sandwich Panels—Experimental Investigation of Static and Quasi-Cyclic Loading. Buildings 2020, 10, 155. [Google Scholar] [CrossRef]

- Nguyen, Q.; Ngo, T.; Mendis, P.; Tran, P. Composite Materials for Next Generation Building Façade Systems. Civ. Eng. Archit. 2013, 1, 88–95. [Google Scholar] [CrossRef]

- Yang, Y.; Bao, Y.; Liu, X.; Wang, J.; Du, F. Progressive Failure Analysis of Composite/Aluminum Riveted Joints Subjected to Pull-Through Loading. Chin. J. Mech. Eng. 2023, 36, 10. [Google Scholar] [CrossRef]

- LVS EN 1993-1-8:2025; 3.Eirokodekss. Tērauda Konstrukciju Projektēšana. 1-8.Daļa: Savienojumu Projektēšana. Latvijas Standards: Rīga, Latvia, 2025.

- LVS EN 1999-1-1:2023; 9.Eirokodekss. Alumīnija konstrukciju Projektēšana. 1-1.Daļa: Vispārīgie Noteikumi. Latvijas Standards: Rīga, Latvia, 2025.

- LVS EN 1999-1-4:2023; 9.Eirokodekss. Alumīnija konstrukciju Projektēšana. 1-4.Daļa: Konstrukcijas no Auksti Velmētām Loksnēm. Latvijas Standards: Rīga, Latvia, 2025.

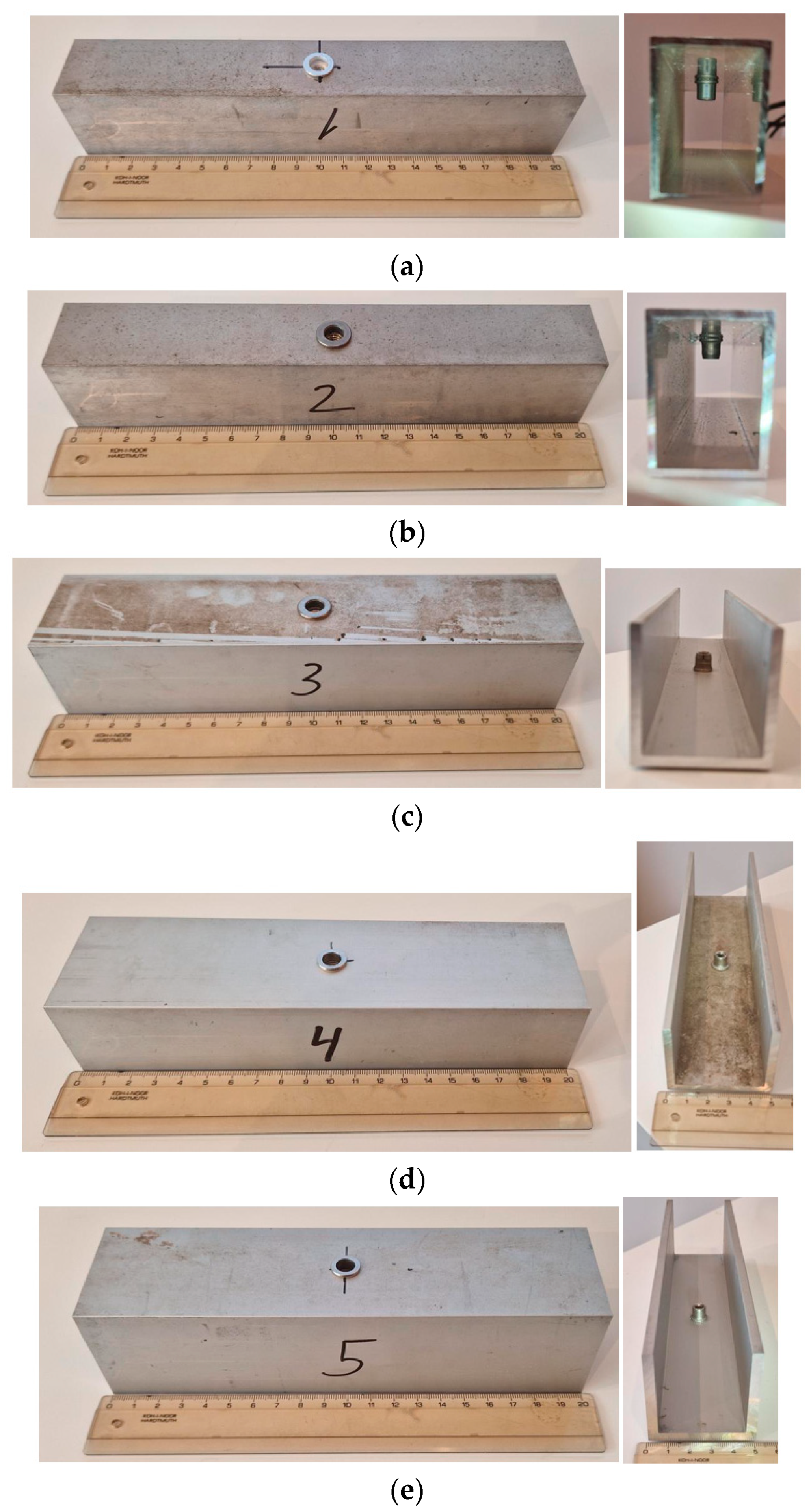

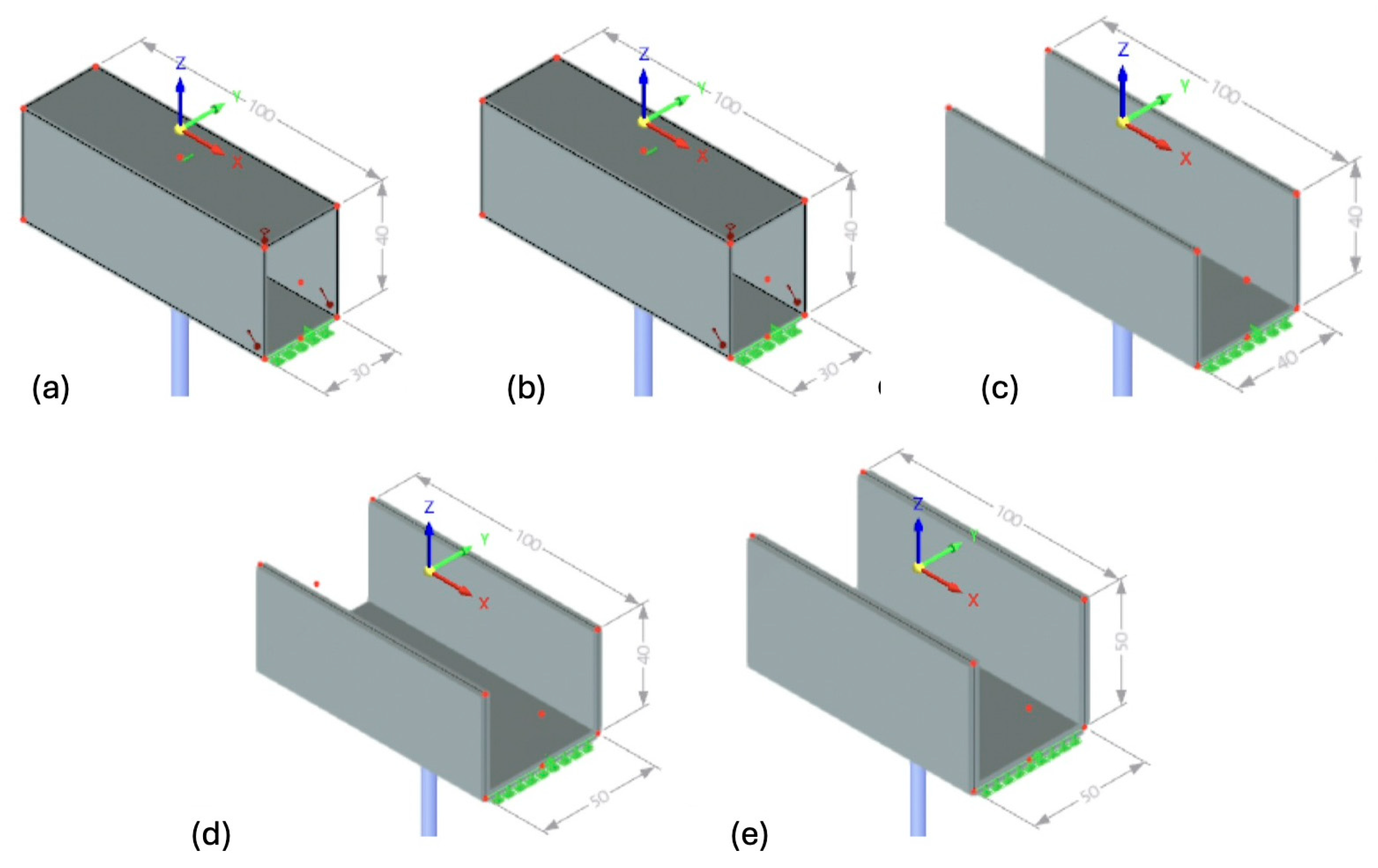

| Number of Specimen Groups | Aluminium Alloy Profile | Rivet Nut |

|---|---|---|

| 1 | aluminium alloy AW 6060 T66, tube, 30 × 40 mm, b = 2 mm | M6, aluminium alloy AW 5052 H32 |

| 2 | aluminium alloy AW 6060 T66, tube, 30 × 40 mm, b = 2 mm | M6, stainless steel AISI 303 1.4305 |

| 3 | aluminium alloy AW 6060 T66, channel(U-profile), 40 × 40 mm, b = 3 mm | M6, stainless steel AISI 303 1.4305 |

| 4 | aluminium alloy AW 6060 T66, channel(U-profile), 40 × 40 mm, b = 4 mm | M6, stainless steel AISI 303 1.4305 |

| 5 | aluminium alloy AW 6060 T66, channel(U-profile), 40 × 40 mm, b = 5 mm | M6, stainless steel AISI 303 1.4305 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziverts, A.; Serdjuks, D.; Sliseris, J.; Briuka, E.; Podkoritovs, A.; Lapkovskis, V. Design Methodology for Tensile Load Capacity of Rivet Nut Connections in Aluminium Alloy Profiles. J. Compos. Sci. 2025, 9, 533. https://doi.org/10.3390/jcs9100533

Ziverts A, Serdjuks D, Sliseris J, Briuka E, Podkoritovs A, Lapkovskis V. Design Methodology for Tensile Load Capacity of Rivet Nut Connections in Aluminium Alloy Profiles. Journal of Composites Science. 2025; 9(10):533. https://doi.org/10.3390/jcs9100533

Chicago/Turabian StyleZiverts, Arturs, Dmitrijs Serdjuks, Janis Sliseris, Elza Briuka, Andrejs Podkoritovs, and Vjaceslavs Lapkovskis. 2025. "Design Methodology for Tensile Load Capacity of Rivet Nut Connections in Aluminium Alloy Profiles" Journal of Composites Science 9, no. 10: 533. https://doi.org/10.3390/jcs9100533

APA StyleZiverts, A., Serdjuks, D., Sliseris, J., Briuka, E., Podkoritovs, A., & Lapkovskis, V. (2025). Design Methodology for Tensile Load Capacity of Rivet Nut Connections in Aluminium Alloy Profiles. Journal of Composites Science, 9(10), 533. https://doi.org/10.3390/jcs9100533