Abstract

As a sustainable construction material, mudbrick can be used widely in areas where common modern construction materials are not easily accessible but high clay content soil is available. The inclusion of locally available natural fibres in mudbrick could improve its mechanical and erosion resistance performance. This study examines the performance of fibre-reinforced mudbrick from spinifex and laterite soil which are abundant in Australia. The main objective of this study is to evaluate the mechanical and durability performance of spinifex fibre-reinforced mudbricks made with Australian laterite soil, focusing on the influence of fibre content, fibre length, and cement stabilisation. Spinifex fibre length (30 mm, 40 mm, 50 mm), spinifex fibre percentage (0.3%, 0.6%, 0.9%), and cement percentage (5% and 10%) are considered as the experiment variables. Results show that compressive strength generally decreases with fibre size. In this regard, specimens with 0.3% spinifex fibre, 40 mm fibre length, and 10% cement, with an average compressive strength value of 4.1 MPa, were found to have the highest strength among all design mixes. The elastic Young’s modulus was highest for the specimens with 0.3% spinifex fibre, 30 mm fibre length, and 10% cement with a 36.1 MPa. A low amount of longer fibres was found to be more effective in reducing water absorption in samples with higher cement content. Water absorption and compressive strength results suggest that, on average, 0.3–0.5% spinifex content of size 30 mm improves both low and high cement content mudbricks properties.

1. Introduction

The use of adobe in the construction sector appears to be an interesting solution for long-term sustainability in remote housing. It is vital to provide affordable housing for remote communities. The high cost of obtaining and shipping resources such as cement and steel remains a barrier to constructing small to medium houses. As a result, low-cost, long-lasting local materials are in high demand. A large body of research has been conducted to produce environmentally friendly and sustainable building components. One of the sustainable building systems for low-cost housing is earthen construction [1,2,3].

Remote populations confront defective and poorly maintained structures, poor nutrition and hygiene, and unemployment [4,5,6,7,8]. After years of public strategy, state and federal government organisations have thoroughly examined these concerns, but a resolution has yet to be identified. The literature found that community engagement reduces barriers in remote communities [9]. Residents’ basic reading skills can be improved, and they will also be encouraged to participate in more outside activities when they are engaged in projects [10,11,12].

Local manufacturers producing ecologically safe, affordable, and readily available local building materials such as mudbricks and utilising these resources in rural dwellings benefit remote communities [11,13]. Local manufacturing and construction can boost community involvement in infrastructure initiatives [12], improve multicultural understanding and community resilience, and provide a range of training possibilities to help residents economically [14]. Remote communities are more likely to accept locally accessible house materials since these materials have a long history of being linked to the Indigenous people’s ideas and rituals [15]. From early Indigenous civilisation, soil and plants have been the most extensively employed resources in constructing fundamental structures [16]. Hence, some communities could consider mudbrick made from local dirt and local spinifex plants a potential construction material [17]. Furthermore, when it comes to Indigenous beliefs and practices, cultural recognition is critical for developing remote housing programmes [18], and using local materials could develop a better sense of belonging and ownership for the residents.

The most natural and cost-effective construction resource for manufacturing mudbricks is soil, which is abundant and readily available [19]. Earth brick was the first material to construct dwellings and structures in many European and emerging countries [20,21]. Mudbricks are valued for affordability, availability, flexibility, durability, and workability [22]. Due to financial restrictions, most underprivileged nations still use mudbrick as their primary construction material [22,23]. When compared to hugely energy-intensive traditional construction materials with large carbon footprints, earthen adobes emit fewer waste products into the environment [24,25]. Because of their relatively high thermal capacity and low thermal conductivity [26], mudbricks are good for maintaining a steady mercury level and managing interior temperature [27,28]. The water permeability of mudbricks is high, allowing water molecules to soak in quickly [29], which helps save energy and promote moist air circulation [30]. Increased thermal mass in a structure minimises temperature variance and slows the rate of wall heating, providing appropriate thermal comfort [31,32].

Fibres to reinforce mudbrick can be natural (from plants or animals) or synthesised [33,34,35]. Fibres are subsequently added to laterite bricks to increase their compressive, flexural, and tensile properties. Adobe is a composite of dirt, cement, silica, and fibres [36]. Fibres in mudbricks form a strong bond inside the soil, eventually increasing the mudbricks’ tensile strength and ductility. It also aids in the consistency of the mud mortar [37,38]. According to the literature, the compressive strengths of filament-reinforced adobes are much higher than those of traditional fibreless earthen materials [39].

Natural plant fibres such as spinifex (Triodia spp.) reinforce earthen matrices by combining mechanisms like mechanical interlocking and interfacial adhesion. The rough, fibrous surface and elongated form of the fibres promote mechanical anchorage within the clay, bridging micro-cracks and enabling effective stress transfer across the fibre–soil interface [40]. This fibre-bridging phenomenon improves the composite’s tensile strength and ductility, delaying crack propagation and enhancing compressive performance relative to unfibred soil [37,40]. Chemical and physical adhesion also play a role: the hydrophilic cellulose in untreated plant fibres can form hydrogen bonds or other polar interactions with clay particles (often via absorbed water), while any natural resins or surface gums on the fibre can contribute additional bonding in the matrix. According to the literature, removing waxy or lignin coatings from fibres (e.g., via alkaline treatment) increases surface roughness and exposes polar –OH groups, which consequently strengthens fibre–clay adhesion and improves load transfer at the interface [40]. These microstructural bonding mechanisms collectively lead to greater strength and durability in fibre-reinforced mud bricks, provided the fibre–matrix bond is sufficiently strong to mobilise fibre tensile resistance [37].

The fibre of a plant known as “the genus Triodia” or “hummock” grass, also named spinifex, could be used to make mudbricks. Spinifex grasses cover over a third of Australia’s area, particularly in arid regions such as central Queensland, Northern Territory, and Western Australia [17,41,42,43]. Spinifex produces a sticky adhesive of volatile and non-volatile bio-organic compounds. Indigenous Australians use spinifex to make gums or adhesives, food, fibre, fixatives, and other wood crafts [15,16,17]. Spinifex is classified into “hard” and “soft” species based on the grade of resin produced [44]. The “hard” species’ leaves are densely packed, complex, and inflexible, with a short and spiky orientation, whereas the “soft” species’ leaves are loosely packed, soft, and delicate, with more smooth and controlled handling [45]. Spinifex is still used to make “bower houses,” which are constructed by sandwiching two layers of hummock grass as a wall and roof covering [17]. Natural fibres can substitute synthetic fibres in composite materials [15]. The material’s accessibility, low cost, biodegradability, low density, rigidity, and workability help to reduce many of the building framework’s inconveniences [44]. Making mudbrick is simple and inexpensive. Stabilised mudbricks may be made without the need for expert labour or costly commercial machinery. Mudbricks that have been air-dried help to minimise shrinkage and cracks that improve compressive strength [24,46,47,48].

Adobes’ long-term durability has been an essential worry, prompting extensive research into how nature impacts mudbricks [49,50,51]. The amount of clay in the dirt used to manufacture adobe bricks should be high enough to ensure that the bricks are both humidity resistant and long-lasting. If too much clay is in a brick, it shrinks as it dries. Physical cracks, shrinkage, and termite infestations are hardly resisted, and durability is limited [52]. The circumstances that caused the construction components to degrade are climate, humidity, hydration, chemical corrosion, and wind-driven water degradation [53]. Mud buildings suffer serious durability problems caused by hydraulic conductivity and evaporation [54]. The cycle of shrinking and swelling in the soil causes a volume change, which affects the structural components of a building [55]. The kinetic energy of rainfall and the erratic movement of minor water sources promote erosion on adobes, and a comprehensive approach must be adopted to overcome these issues [56,57]. Natural waterproofing components, including resin (latex), animal blood, bitumen, and oil, have been employed in earthen materials for a long time [52]. Mudbricks are also strengthened and protected against water and moisture by a mixture of sodium silicate and silicone [54]. Earth plasters and zinc stearate are also found to be used as waterproofing materials [52,58].

The length of the fibres also affects the mechanical strength of earth bricks. The literature compares how the length of fibres affects the durability of earth mortars [59]. Several researchers have employed both long and short fibres in their investigations. According to the reported results, regardless of the type of fibre used, using longer fibres generally improves earth mortars’ compressive and flexural strength [60,61,62,63]. This finding, however, is countered by Préneron et al., who found that long straw fibres may diminish the flexural strength of mortar because the distribution of fibres would not be uniform [64]. The shear strength of mud mortar was also found to be influenced by the length of the fibre. Intermediate-length fibres may enhance soil-reinforcing effects via fibre interaction; nevertheless, overlong fibres induce local aggregation and wrapping inside the soil [65,66]. The enhanced cohesion of the soil–fibre matrix is due to an increase in applied stress caused by fibre tension. The water content in the fibre helps build an absorbed water layer on the clay particles, generating some prestressing in the soil [67]. Table 1 summarises some studies that used different types of fibres and percentages in clay bricks.

Table 1.

Summary table of clay brick with different fibre.

With these in mind, this study analyses the link between fibre length, fibre percentage, and cement percentage to mudbrick strength, as well as analysing mudbrick mechanical properties by investigating compressive strength and erosion. The primary aim of this study is to evaluate the effects of spinifex fibre content, fibre length, and cement stabilisation on the compressive strength, erosion resistance, and water absorption of mudbricks made from Australian laterite soil in order to establish optimum mix ratios for sustainable housing applications in Northern Australia.

2. Experimental Programme

2.1. Materials

2.1.1. Soil

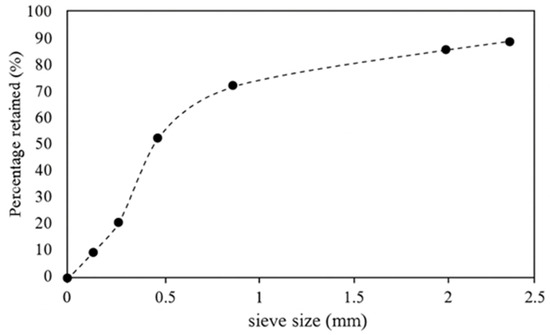

The soil was taken from the Muirhead development in Darwin, NT, at depths ranging from 1500 mm to 2000 mm below the ground surface. The excavated soil was reddish-brown in colour, oily, and hard when dry and sticky when wet, indicating that it was laterite [78,79]. Red-earth laterite soils are commonly found in Australia’s tropical and subtropical regions, such as Northern Territory and Western Australia [80]. Laterite soils generally offer good properties as an earthen construction material and are especially well suited to lime stabilisation due to cementitious interaction with the lime [81]. Because laterite soil has a smaller silica-sesquioxide fraction than typical soils, mudbricks have more flexibility and better interaction with cement [82]. Sieve analysis on the soil was performed according to The Australian Earth Building Handbook [81]. The results of the sieve analysis are presented in Table 2. To adjust the soil properties, particles above 0.85 mm were discarded. Figure 1 demonstrates the particle distribution of soil in graphical form.

Table 2.

Sieve analysis of collected soil.

Figure 1.

Soil sieve test result.

2.1.2. Cement

Soil properties were enhanced by adding cement and the effect of cement inclusion was studied. Five and ten percent cement was considered in this research. Table 3 shows the chemical composition of the general purpose (GP) Portland cement used in this study.

Table 3.

Composition of Portland cement.

2.1.3. Spinifex

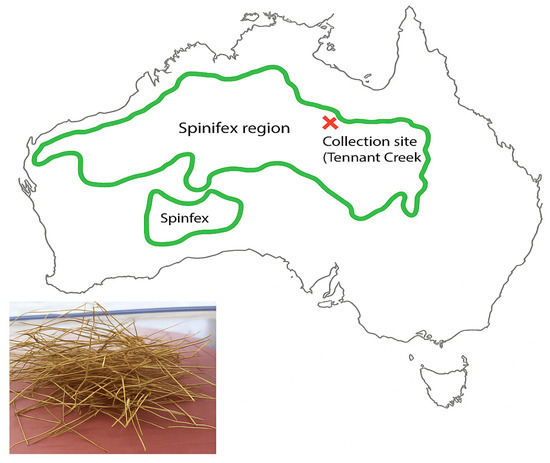

Spinifex, or locally called Baru by Yindjibarndi and Ngarluma people [83], is a common plant throughout Australia, except Tasmania. In recent years, performance of spinifex fibre has been studied for making composites with reasonable mechanical properties [15,84,85]. Figure 2 shows the appearance and location of collecting the spinifex used in this study.

Figure 2.

Spinifex in plant and fibre. (Top): Vegetation map of spinifex in Australia. Source: Website of Australian National Herbarium. (Bottom left): Spinifex used in this study, collected from Tennant Creek, NT, Australia. Source: Australian Government, National Land & Water Audit (2001), published under Creative Commons Attribution 3.0 Australia licence (CC BY 3.0). Link: https://www.anbg.gov.au/photo/vegetation/hummock-grasslands.html, 1 September 2025.

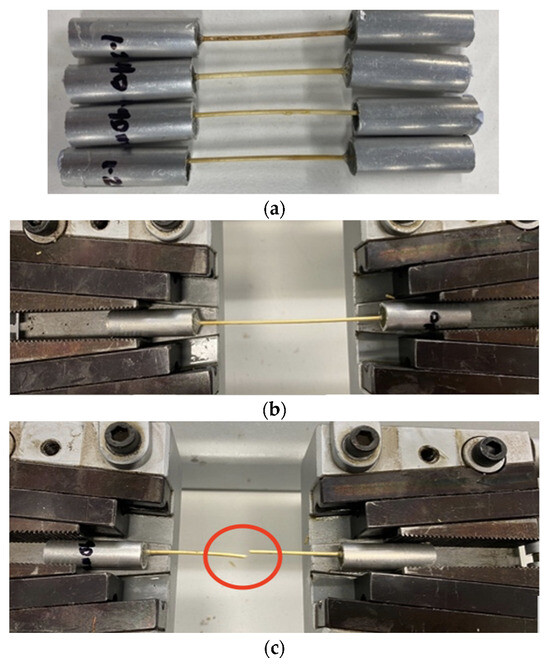

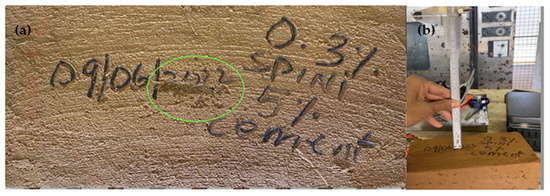

Spinifex was collected from Elliot, Northern Territory. Fibres were cut in 30 mm, 40 mm, and 50 mm. An extensometer was used to find the average tensile strength of the spinifex fibres. Five samples were tested and the average tensile strength recorded for the spinifex was 17.8 MPa. Figure 3 shows the spinifex tensile testing method.

Figure 3.

Tensile test of spinifex: (a) samples of spinifex; (b) spinifex under loading; (c) failure mode, with an average tensile strength of 17.8 MPa obtained from five samples.

2.2. Brick Specimens

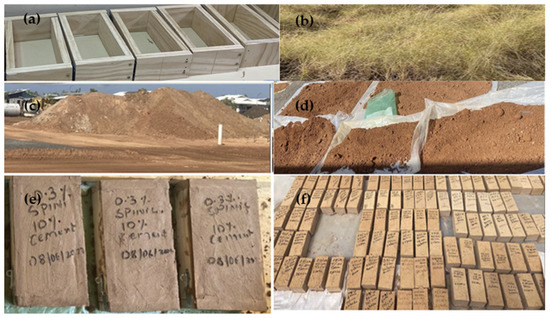

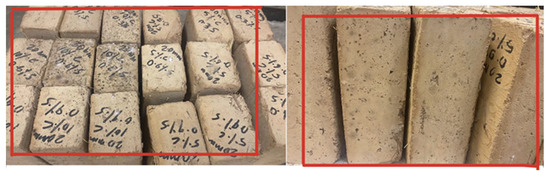

A total of 81 bricks with nominal dimensions of 230 mm × 110 mm × 76 mm were prepared in accordance with The Australian Earth Building Handbook [81]. Six variations of mudbricks were produced for each fibre length (30 mm, 40 mm, and 50 mm), with fibre contents of 0.3%, 0.6%, and 0.9% and cement contents of 5% and 10%. For each composition, 18 specimens were cast to allow testing of compressive strength, erosion resistance, and water absorption, resulting in 81 specimens across all variations. The soil and cement were first dry mixed, after which the required amount of fibres was added. Water was gradually introduced until a workable consistency was achieved, and the mixture was thoroughly hand-mixed before being placed into steel moulds (230 mm × 110 mm × 76 mm) in three layers. Each layer was compacted manually with a wooden tamper to minimise voids. After demoulding, the bricks were air-dried under direct sunlight at an average ambient temperature of ~32 °C and relative humidity of ~60% for four weeks. The overall testing plan, including specimen characteristics and labelling system, is presented in Table 4, while Figure 4 illustrates soil extraction, fibre collection, and sample preparation.

Table 4.

Test plan and sample convention.

Figure 4.

Brick production episodes: (a) moulds; (b) spinifex; (c) soil site; (d) drying soil; (e) sample preparation; (f) bricks drying under sunlight.

2.3. Compression Test Method

Compression tests were conducted in accordance with HB 195 Earth Building [81]. A total of 66 specimens, three from each mix design, were tested using a 300 kN Instron 8802 servo-hydraulic universal testing machine at a displacement rate of 2 mm/min. The maximum load at failure was recorded, and the compressive strength was calculated by dividing this load by the cross-sectional area of the specimen. Failure modes, including cracking and fibre pull-out, were also observed and documented.

2.4. Water Spray (Erosion) Test

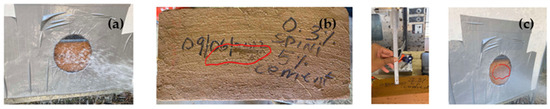

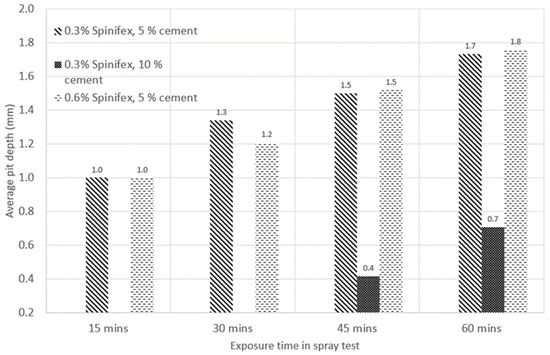

Erosion tests were carried out in accordance with The Australian Earth Building Handbook [81]. Full-sized specimens (230 mm × 110 mm × 76 mm) were continuously sprayed with water at a pressure of 50 kPa for up to 60 min or until the water fully penetrated the specimen thickness. The nozzle was positioned 200 mm from the specimen surface, and three replicates were tested for each mix. Pit depth was measured every 15 min using a digital vernier calliper with an accuracy of ±0.01 mm. The degradation rate was expressed as the penetration depth per hour (mm/h) or, where applicable, by the time required for complete penetration. The test setup is shown in Figure 5, and examples of pit depth measurements are presented in Figure 6.

Figure 5.

Some instances of spray test: (a) bricks under spray test; (b) deterioration of brick; (c) pit depth.

Figure 6.

Average values of pit depth in spray test for some samples.

2.5. Water Absorption Test Method

Along with erosion resistance, water absorption is a critical property of masonry units, as it influences not only the quality of the brick but also the bond strength between brick and mortar, potentially reducing the overall structural performance [86,87]. A 24 h water absorption test was carried out in accordance with HB 195 [81] to determine the percentage of water absorbed under saturation conditions. Results were compared with the optimised ranges recommended for mudbricks in wet environments [81]. The dry weights of the specimens were recorded prior to immersion in water at ambient temperature. After 24 h, the specimens were removed, surface water was wiped off, and the wet weights were recorded. Three specimens were tested for each mix, and weights were measured using a balance with an accuracy of 0.01 g. The water absorption percentage was calculated as the ratio of weight gain to the dry weight of the specimen, expressed as a percentage.

2.6. Data Analysis

For each test, results are reported as the mean of three replicates. Variability was quantified using the coefficient of variation (COV). Data analysis was conducted in Microsoft Excel to calculate means and standard deviations.

3. Results

3.1. Water Spray Test Results

The minimum pitting rate requirement in an erosion resistance test in NT tropical remote areas is 15 mm/h [81]. The depth of the pit caused by the water spray and the erosion rate was measured for bricks with 30 mm fibre length. The average measured pitting rate was recorded at around 1 mm/h and satisfied the minimum requirements well. It suggested that the mudbricks would withstand the spray/erosion test quite easily, which encouraged the authors to perform the water absorption test to check the spray test results. Table 5 summarises the results of the water spray test for bricks with 30 mm fibre length. For each set of samples, the coefficient of variation (COV) was calculated to quantify the relative variability of the measured values. With the COV, expressed as a percentage, the consistency across different fibre–cement mix ratios can be compared.

Table 5.

Spray/erosion test results of 30 mm fibre length.

3.2. Water Absorption Test Results

After 24 h of immersion in tap water (30 °C), the blocks were tested in accordance with the procedure outlined in [81]. The results are compared to the American standard, ASTM C62-17 [88]. According to the code, average water absorption should not exceed 20% of the weight of the bricks [89]. Further, based on the definition in [90,91], bricks might be classified into three groups and water absorption should not be more than 15%, 20%, and 25% for first-, second-, and third-class bricks, respectively. The weight ratio before and after soaking was not recorded in this study and will be considered in future work to better quantify water absorption.

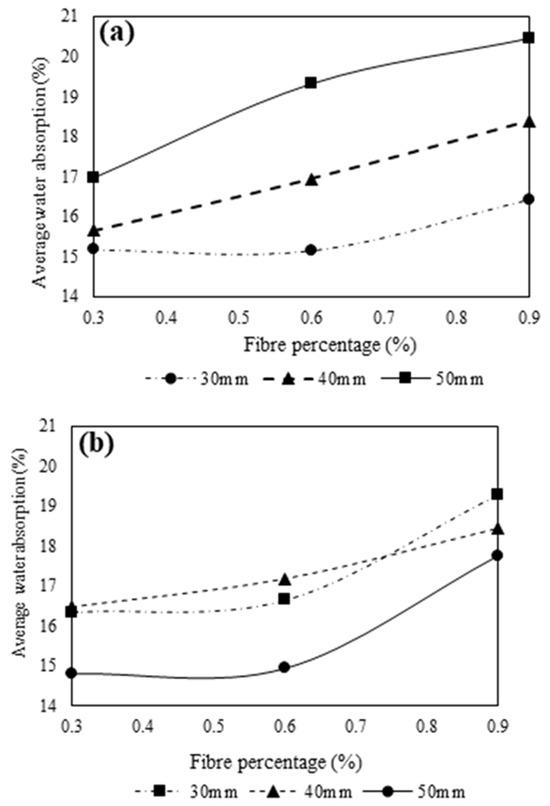

Figure 7 shows the clay bricks in the 24 h water-submerged test and Figure 8 illustrates the visual appearance of the bricks right after being taken out of the water. As expected, water diffusion had increased the weight of each brick matrix, soil particles started to loosen from the clay bricks, and the exposure of fibre to the surroundings and brick shapes became more asymmetrical. Figure 9 shows water absorption test results.

Figure 7.

Water absorption test; bricks submerged under cold water for 24 h.

Figure 8.

Typical bricks after the water absorption test.

Figure 9.

Average values of water absorption test: (a) 5% cement content and (b) 10% cement content.

3.3. Compression Test Results

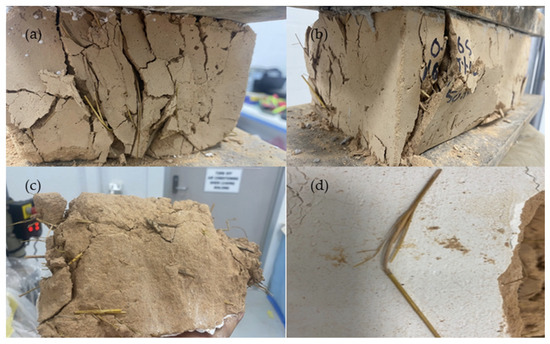

Figure 10 shows the typical unconfined universal compression test of the bricks. For each design combination, three samples were tested according to ASTM C1314-18 [92]. The bricks’ surfaces were cleaned, levelled using a thin layer of grout, and measured before the test. A constant compression load with a 2.0 mm/min rate was applied until failure happened. During the compression test, the bricks initiated small fractures before exhibiting ultimate failure.

Figure 10.

Compression testing conditions: (a) brick under test; (b) crack formation; (c) exposure of fibre; (d) failure of brick.

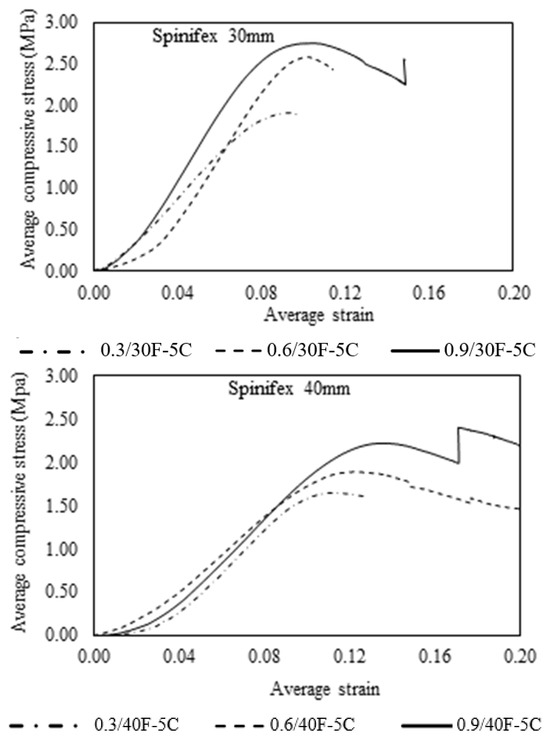

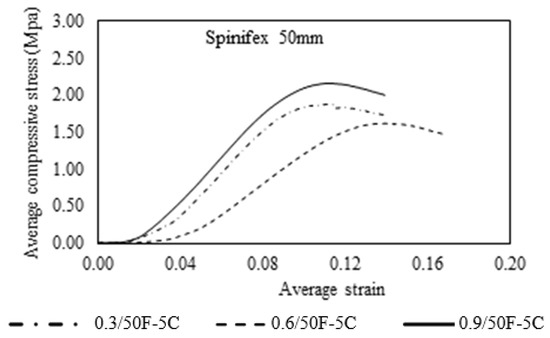

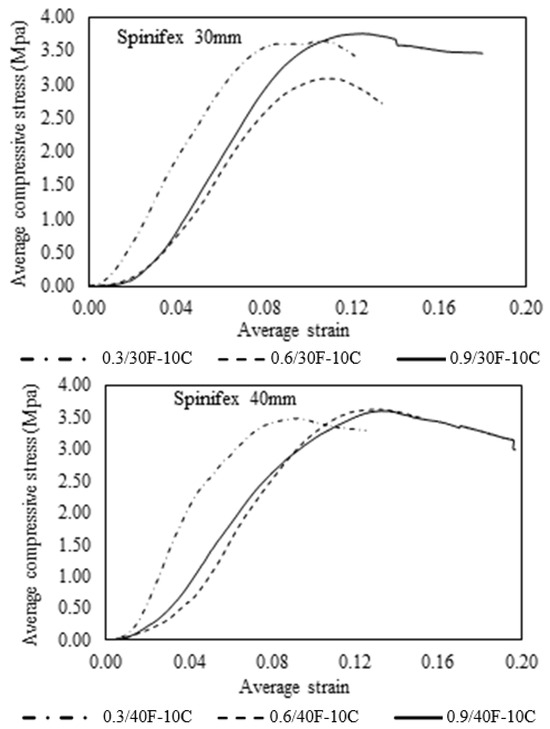

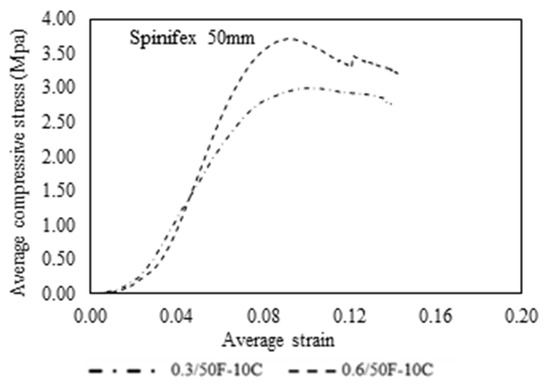

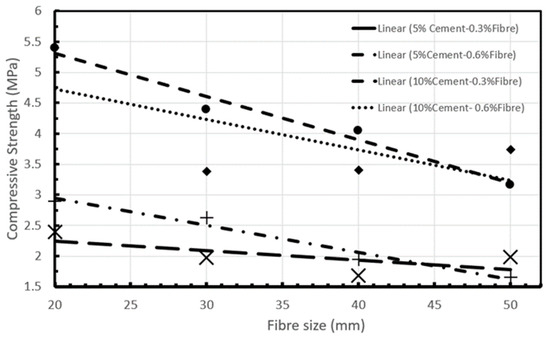

As the applied load increased, the bricks started to depict signs of failure, and spinifex fibres became more visible. In the compression test, the load and deflection of the bricks were measured. The (negative) extension to the initial height ratio of the samples was used to derive strain values. Figure 11 and Figure 12 depict the average strain–stress graphs for samples with 5% and 10% cement contents, respectively. The fibre length and fibre content had a significant effect on the strength of the mudbricks. Figure 13 demonstrates the influence of length and fibre percentage on the average compressive stress. Mixes with fibres over 40 mm were found to be difficult to work with in the production phase.

Figure 11.

Stress versus strain graphs of bricks with 5% cement.

Figure 12.

Stress versus strain graphs of bricks with 10% cement.

Figure 13.

Compressive strength of bricks with different amounts and sizes of spinifex fibre.

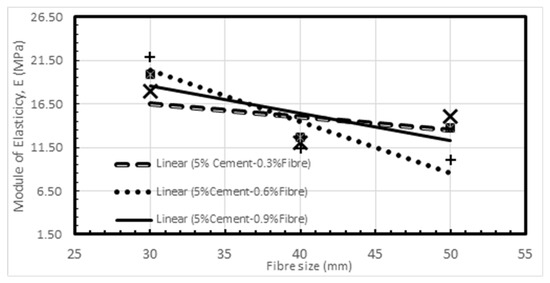

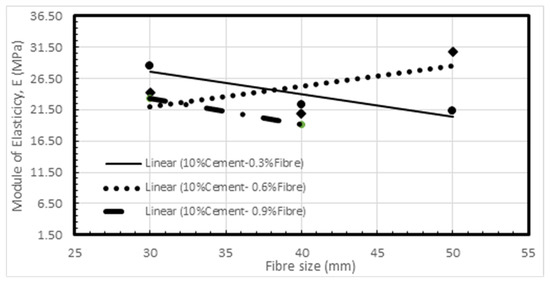

Additionally, the Young’s modulus of the bricks was improved with the addition of fibre and cement content. Figure 14 demonstrates the average peak values of Young’s modulus with respect to the fibre length and content.

Figure 14.

Values of fibre content (%) versus Young’s modulus.

4. Discussion

4.1. Water Spray Test

The results demonstrate that the water spray test had very modest effects on the bricks’ soil erosion, and it had no significant influence on the outer or internal composition of the mudbricks. The pit depth for 0.3/30F-5C samples tends to increase slowly from 1.57 mm to 2.60 mm, with about 0.40 mm increments every 15 min. The 0.3/30F-10C mixture was even more water-jet spray resistant, with the pit depth maintained constant for the first 15 min. The pit depth was 0.20 mm after 30 min, with an average rate of rise of 0.43 mm at the end of 60 min. The 0.6/30F-5C samples behaved similarly to the 0.3/30F-5C samples at nearly a similar pitting rate of 0.45 mm/min. An increase in fibre content from 0.3 to 0.6 shows a negative effect in controlling erosion possibly due to the formation of air voids in the matrix of the design mix. No additional samples were examined for the water spray test because the test results demonstrated only subtle damage to the mudbricks. Figure 15 shows the pit depth measurement for a 0.3/30F-5C sample. The results of the test meet the standard minimum values well.

Figure 15.

Spray test for 0.3/30F-5C sample: (a) pit formation and (b) measurement of pit depth.

4.2. Water Absorption Test

Water absorption is a key factor in determining the quality of a clay brick [89]. As is seen in Figure 9, water absorption increases gradually as the fibre length increases. The bricks containing 0.3% and 0.6% fibre content meet the absorption range of 14–20% according to ASTM C62 [93,94]. In samples with 5% cement, 40 mm and 50 mm fibre lengths enhanced water absorption by 15% to 20% compared to the corresponding samples with 30 mm fibres. In 10% cement content samples, those with 30 mm and 40 mm fibres showed similar a water absorption trend but less water was absorbed when fibres were 50 mm.

Water absorption increased evidently as fibre length and volume increased in samples with 5% cement. The higher water absorption capacity of fibre-reinforced mudbrick can be related to the amount of water absorbed by the cellulose fibres, which is influenced by air voids and the amount of cellulose substance present, both of which affect the density. The matrix’s capacity to pack the fibres and maintain their form declines as the fibre concentration rises, resulting in increasing void volume, density loss, and water absorption [95]. This result correlates with the theory of density that samples with higher densities are less likely to absorb water and vice versa. Soil fibres expand as they absorb water during mixing and drying. On a microscopic scale, the expansion of the fibres pulls the soil away. After drying, the fibres return to their original size, leaving some space around them [96,97].

Figure 9 suggests that in samples with 10% cement and the same amount of fibre, water absorption may increase by using longer fibres. With the same amount of fibre, samples that have shorter fibres host more water absorption sites but are shorter than those with larger fibres. The use of cement in the mix makes the matrix less permeable. Therefore, fibres closer to the sample surfaces are expected to contribute toward water absorption mainly. Given that the amount of fibre is constant, by increasing the length of fibres their number has to decrease. This results in fewer absorption sites in the surfaces of the samples, thus less water absorption in samples with longer fibres. Further, given that permeability is less in samples with a higher amount of cement, absorption declines rapidly along a fibre when it distances from the surfaces. Samples with shorter fibres open more absorption sites on the surface of the bricks and better lead the water in the sample. The matrix is more permeable in samples with less cement (5% samples) than samples with 10% cement. Therefore, the fibres inside the matrix are expected to contribute relatively more to water absorption, which could transmit water through a capillary mechanism into the samples [98].

Figure 16 shows that each sample, regardless of the fibre length, displays a physical indication of deformation; bricks become softer, more fragile, and sometimes begin to lose soil particles. Furthermore, Figure 16 shows that after one week, the wet bricks exhibited inadequate resistance to excess moisture from the wet brick’s absorption test, and extreme adverse weather conditions (35 °C and 70% humidity) created a favourable habitat for the growth of bacteria, mould, and fungi in clay bricks.

Figure 16.

Mould formation on wet bricks.

4.3. Compression Test

The literature shows that earth blocks’ compressive strength can range from 0.3 MPa to 5.5 MPa (see Table 1), depending on whether fibres are included and the percentage of cement used. The current study also shows that the compressive strength of the tested mudbricks depends on the amount of cement used and the length of fibres.

Figure 13 suggests that the compressive strength of mudbricks decreases by fibre length. Similarly, Figure 14 shows that the elastic modulus has generally decreased by fibre size. This could be explained by the fact that spinifex fibres in mudbrick generate weak areas similar to cracks. From a fracture mechanics point of view, stress at the tip of a crack changes by the second root of the crack length. The inclusion of 5% more cement significantly improved the strength of the samples, as Figure 13 shows. In samples with 10% cement and 0.6% of fibre, a slightly different trend in changes in the elastic modulus by the fibre size was observed. See Figure 14.

In samples with 5% cement, the compressive strength in samples with fibre lengths of 30 mm and 40 mm was enhanced with further fibre addition up to 0.6%, while the strength of fibres with lengths of 50 mm was somewhat decreased (0.33 MPa) after further fibre addition. The addition of 10% cement to the design mix had a significant influence on brick strength. The experiment demonstrates that the strength values of all the bricks increased by nearly 50% by adding 5% more cement (totally 10%), meeting the minimum value of 2 MPa needed by HB-195 earth building [81]. The 0.3/30F-10C and 0.3/40F-10C showed maximum strength values of 3.93 MPa and 4.05 MPa, respectively. However, 0.3/50F-10C showed a strength value of 3.16 MPa. When 10% cement was used, there was a strength loss in samples with 0.6% and 0.9% fibre for all spinifex lengths when compared with 0.3% fibre samples. This could be attributed to the voids created by using more fibres. A similar result was discovered in the literature [64]. Figure 17 shows the bricks with 40 mm and 50 mm fibre lengths experiencing fibre bucking due to the applied load. This could explain why the compressive strength decreases by fibre length. Shorter fibres have less chance of bucking, resulting in better load bearing by the fibres. The average tensile strength of spinifex was measured at 17.8 MPa. In samples with 5% cement, the compressive strength increases by the amount of fibre. However, in samples with 10% cement, compressive strength decreases by the amount of fibres. This suggests that the spinifex bond to the matrix is not strong enough to offer more strength to 10% cement samples. The glassy surface of spinifex fibre suggests that as well.

Figure 17.

Internal fibre matrix of brick after compression test: (a) failure of brick; (b) exposure of fibre; (c) internal matrix of fibre; (d) turned spinifex.

Placing these results in context with recent studies, Araya-Letelier et al. (2018) showed that ~0.5% short fibres optimally improved adobe without reducing compressive strength, consistent with our optimum range of 0.3–0.6% [99]. Kasie and Mogne (2025) also reported maximum strength at ~0.9% sisal fibre, while Laborel-Préneron et al. (2021) demonstrated that straw and hemp enhanced erosion resistance in earth blocks [100,101]. These findings confirm that moderate fibre contents (~0.5–1%) generally maximise performance across different earthen composites, supporting the validity of our results.

5. Conclusions and Future Works

Based on the experimental results observed in this study, the following conclusions are drawn:

- The water spray test revealed that the mudbricks withstood the erosion test with minimal damage to their integrity and performed well in a standardised pressure of a 50 kPa water jet that satisfies the Australian guideline requirement. Bricks with 10% cement exhibit superior erosion resistance.

- The experiment suggested that for limiting water absorption, the fibre content should be kept below 0.6% when 10% cement is used and below 0.4% when 5% cement is used. That keeps the water absorption below 18%.

- The lowest water absorption was achieved by using 0.3% fibre content, 10% cement, and 50 mm fibre length. Such bricks are the best-performing sample in terms of the water absorption rate that can be used to build structures in aggressive environments, such as Australia’s Northern Territory.

- The absorption rate rises with the increase in fibre content. Further, wet bricks are more prone to unhygienic bacteria, moulds, and fungi growth. This issue should be addressed in the residential applications of mudbrick with natural fibres in tropical areas.

- The best compressive strength was achieved with 0.3% spinifex fibre at 40 mm length and 10% cement, reaching an average value of 4.1 MPa. Increasing the length of fibres to 50 mm reduced the strength, with the likely chance of fibre buckling during failure.

- To improve the compressive strength, fibre content should be reduced by increasing the cement content. Increasing the fibre content from 0.3% to 0.6% showed a positive impact on low cement content samples but did the opposite on high cement content samples.

In future, this research could be extended to include natural surface treatments of spinifex fibres to enhance bonding with the mudbrick matrix, as well as studies on mudbrick walls and structures incorporating waterproof coatings to evaluate their durability. While the present study demonstrated improved performance of optimised fibre–cement mudbricks under laboratory conditions, their practical application in real construction environments remains untested. Future work should therefore involve pilot projects to validate long-term durability, weathering resistance, and structural stability under actual field conditions, enabling the effective translation of laboratory findings into sustainable housing solutions. In addition, examining the effects of firing spinifex fibre-reinforced bricks at controlled temperatures would provide valuable insights into their mechanical properties and allow direct comparison with conventional fired clay bricks.

Finally, these findings are broadly consistent with recent studies on natural fibre-reinforced earthen materials, which have also identified optimum fibre contents below 1% as the most effective range for improving strength and erosion resistance [99,100,101].

Author Contributions

Methodology, A.R. and M.B.; Validation, D.V.; Formal Analysis, S.T.; Investigation, J.S.; Writing—Review and Editing, N.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bock-Hyeng, C.; Ofori-Boadu, A.N.; Yamb-Bell, E.; Shofoluwe, M.A. Mechanical properties of sustainable adobe bricks stabilized with recycled sugarcane fiber waste. Int. J. Eng. Res. Appl. 2016, 6, 50–59. [Google Scholar]

- Bailie, R.S.; Wayte, K.J. Housing and health in Indigenous communities: Key issues for housing and health improvement in remote Aboriginal and Torres Strait Islander communities. Aust. J. Rural. Health 2006, 14, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Joglekar, S.N.; Kharkar, R.A.; Mandavgane, S.A.; Kulkarni, B.D. Sustainability assessment of brick work for low-cost housing: A comparison between waste based bricks and burnt clay bricks. Sustain. Cities Soc. 2018, 37, 396–406. [Google Scholar] [CrossRef]

- Andrea Jardine-Orr, N.M.; Spring, F.; Anda, M. Indigenous Housing and Governance: Case Studies from Remote Communities in WA and NT. In Proceedings of the Third National Housing Conference, Adelaide, Australia, 27 November 2003; Volume 48. [Google Scholar]

- Hall, J.; Berry, M. What are the Real Costs of Housing Provision in Indigenous Communities in Australia? In Proceedings of the Building for Ddiversity National Housing Conference, Perth, Australia, 26–28 October 2005; pp. 287–304. [Google Scholar]

- John Fien, E.C.; Lee, G.; Morris, D.; Baker, D.; Grice, T. Flexible Guidelines for the Design of Remote Indigenous Community Housing; Australian Housing and Urban Research Institute: Victoria, Australia, 2007; p. 68. [Google Scholar]

- Pholeros, P.; Phibbs, P. Constructing and Maintaining Houses; Closing the Gap Clearinghouse; Australian Institute of Health and Welfare: Canberra, Australia, 2012.

- Zufferey, C.; Chung, D. ‘Red dust homelessness’: Housing, home and homelessness in remote Australia. J. Rural. Stud. 2015, 41, 13–22. [Google Scholar] [CrossRef]

- Grealy, L. Governing disassembly in Indigenous housing. Hous. Stud. 2023, 38, 327–346. [Google Scholar] [CrossRef]

- Fien, J.; Charlesworth, E. ‘Why isn’t it solved?’: Factors affecting improvements in housing outcomes in remote Indigenous communities in Australia. Habitat Int. 2012, 36, 20–25. [Google Scholar] [CrossRef]

- Newman, P.; Director, S.P.U. Sustainability and Housing: More Than a Roof Over Head; Institute for Sustainability and Technology Policy, Murdoch University: Murdoch, Australia, 2002. [Google Scholar]

- Rusch, R.; Best, R. Sustainability: Its adaptation and relevance in remote area housing. Australas. J. Constr. Econ. Build. 2014, 14, 88–104. [Google Scholar] [CrossRef]

- UN-Habitat. Sustainable Housing for Sustainable Cities. 2012. Available online: https://unhabitat.org/sites/default/files/download-manager-files/Sustainable%20Housing%20for%20Sustainable%20Cities.pdf (accessed on 10 September 2025).

- Morris, R. Community Engagement in Rural-Remote and Indigenous Local Government in Australia. 2012. Available online: https://opus.lib.uts.edu.au/bitstream/10453/42104/3/RRI-Community-Engagement.pdf (accessed on 10 September 2025).

- Mondal, S.; Memmott, P.; Martin, D. Preparation and characterization of green bio-composites based on modified spinifex resin and spinifex grass fibres. J. Compos. Mater. 2014, 48, 1375–1382. [Google Scholar] [CrossRef]

- Hayes, E.; Fullagar, R.; Mulvaney, K.; Connell, K. Food or fibercraft? Grinding stones and Aboriginal use of Triodia grass (spinifex). Quat. Int. 2018, 468, 271–283. [Google Scholar] [CrossRef]

- Powell, O.; Fensham, R.J.; Memmott, P. Indigenous use of spinifex resin for hafting in north-eastern Australia. Econ. Bot. 2013, 67, 210–224. [Google Scholar] [CrossRef]

- Foster, T.; Hall, N.L. Housing conditions and health in Indigenous Australian communities: Current status and recent trends. Int. J. Environ. Health Res. 2021, 31, 325–343. [Google Scholar] [CrossRef]

- Chan, C.-M. Effect of natural fibres inclusion in clay bricks: Physico-mechanical properties. Int. J. Civ. Environ. Eng. 2011, 3, 51–57. [Google Scholar]

- Abdelmegeed, M.M. Modified mud bricks for strengthening historic earthen structures: Towards sustainable and green restoration. Shedet 2020, 7, 263–276. [Google Scholar] [CrossRef]

- Friesem, D.E.; Karkanas, P.; Tsartsidou, G.; Shahack-Gross, R. Sedimentary processes involved in mud brick degradation in temperate environments: A micromorphological approach in an ethnoarchaeological context in northern Greece. J. Archaeol. Sci. 2014, 41, 556–567. [Google Scholar] [CrossRef]

- Sheweka, S. Using mud bricks as a temporary solution for Gaza reconstruction. Energy Procedia 2011, 6, 236–240. [Google Scholar] [CrossRef]

- Oskouei, A.V.; Afzali, M.; Madadipour, M. Experimental investigation on mud bricks reinforced with natural additives under compressive and tensile tests. Constr. Build. Mater. 2017, 142, 137–147. [Google Scholar] [CrossRef]

- Dabaieh, M.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J. Clean. Prod. 2020, 275, 122998. [Google Scholar] [CrossRef]

- Murmu, A.L.; Patel, A. Towards sustainable bricks production: An overview. Constr. Build. Mater. 2018, 165, 112–125. [Google Scholar] [CrossRef]

- Baeissa, A.A. Mud-brick high-rise buildings architectural linkages for thermal comfort in Hadhramaut Valley, Yemen. Int. Trans. J. Eng. Manag. Appl. Sci. Technol. 2014, 5, 167–182. [Google Scholar]

- Laborel-Préneron, A.; Giroudon, M.; Aubert, J.; Magniont, C.; Faria, P. Experimental assessment of bio-based earth bricks durability. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Zhang, L.; Sang, G.; Han, W. Effect of hygrothermal behaviour of earth brick on indoor environment in a desert climate. Sustain. Cities Soc. 2020, 55, 102070. [Google Scholar] [CrossRef]

- Zhou, C. Production of eco-friendly permeable brick from debris. Constr. Build. Mater. 2018, 188, 850–859. [Google Scholar] [CrossRef]

- Cagnon, H.; Aubert, J.-E.; Coutand, M.; Magniont, C. Hygrothermal properties of earth bricks. Energy Build. 2014, 80, 208–217. [Google Scholar] [CrossRef]

- Nadarajan, M.; Kirubakaran, V. Simulation studies on small rural residential houses using sustainable building materials for thermal comfort–case comparison. Adv. Build. Energy Res. 2017, 11, 193–207. [Google Scholar] [CrossRef]

- Samuel, D.L.; Dharmasastha, K.; Nagendra, S.S.; Maiya, M.P. Thermal comfort in traditional buildings composed of local and modern construction materials. Int. J. Sustain. Built Environ. 2017, 6, 463–475. [Google Scholar] [CrossRef]

- Babatunde, S.A. Review of strengthening techniques for masonry using fiber reinforced polymers. Compos. Struct. 2017, 161, 246–255. [Google Scholar] [CrossRef]

- Codispoti, R.; Oliveira, D.V.; Olivito, R.S.; Lourenço, P.B.; Fangueiro, R. Mechanical performance of natural fiber-reinforced composites for the strengthening of masonry. Compos. Part B Eng. 2015, 77, 74–83. [Google Scholar] [CrossRef]

- Mahir, F.I.; Keya, K.N.; Sarker, B.; Nahiun, K.M.; Khan, R.A. A brief review on natural fiber used as a replacement of synthetic fiber in polymer composites. Mater. Eng. Res. 2019, 1, 86–97. [Google Scholar] [CrossRef]

- Love, S. Field methods for the analysis of mud brick architecture. J. Field Archaeol. 2017, 42, 351–363. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Shah, T. Investigation of fibre reinforced mud brick as a building material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Prakash, V.; Raj, A.; Aravind, S.; Mathew, B.; Sumith, V. Studies on stabilized mud block as a construction material. Int. J. Innov. Res. Adv. Eng. 2016, 3, 19–24. [Google Scholar]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Mechanical Properties of Fibre-Reinforced Mud Bricks; CCE: Khartoum, Sudan, 2018; pp. 91–96. [Google Scholar]

- Vincenzini, A.; Augarde, C.E.; Gioffrè, M. Experimental characterization of natural fibre–soil interaction: Lessons for earthen construction. Mater. Struct. 2021, 54, 110. [Google Scholar] [CrossRef]

- Allan, G.E.; Southgate, R.I. Fire Regimes in The Spinifex Landscapes of Australia. In Flammable Australia; Cambridge University Press: Cambridge, UK, 2002; pp. 145–176. [Google Scholar]

- Amiralian, N.; Annamalai, P.K.; Memmott, P.; Taran, E.; Schmidt, S.; Martin, D.J. Easily deconstructed, high aspect ratio cellulose nanofibres from Triodia pungens; an abundant grass of Australia’s arid zone. RSC Adv. 2015, 5, 32124–32132. [Google Scholar] [CrossRef]

- Burrows, N.; Ward, B.; Robinson, A. Fire behaviour in spinifex fuels on the Gibson Desert nature reserve, Western Australia. J. Arid. Environ. 1991, 20, 189–204. [Google Scholar] [CrossRef]

- Pitman, H.T.; Wallis, L.A. The Point of Spinifex: Aboriginal Uses of Spinifex Grasses in Australia. 2012. Available online: https://scholarspace.manoa.hawaii.edu/server/api/core/bitstreams/6fcfd632-8186-4f4e-8dd6-f847583d391a/content (accessed on 10 September 2025).

- Horton, H. Of Spinifex and Grasswrens, with Particular Reference to’Amytornis Ballarae’, the Kalkadoon Grasswren. Qld. Nat. 2011, 49, 3–17. [Google Scholar]

- Downton, P. Mud Brick. 2003. Available online: https://www.yourhome.gov.au/materials/mud-brick (accessed on 10 September 2025).

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Smith, E.W.; Puebio, S. Adobe brick production in New Mexico. New Mex. Bur. Mines Miner. Resour. 1981, 3, 17–24. [Google Scholar] [CrossRef]

- Beckett, C.; Ciancio, D.; Huebner, C.; Cardell-Oliver, R. Sustainable and affordable rammed earth houses in Kalgoorlie, Western Australia: Development of thermal monitoring techniques. In Structural Engineering in Australasia–World Standard; Institution of Engineers (Australia): Barton, Australia, 2014; pp. 1–9. [Google Scholar]

- Bui, Q.-B.; Morel, J.-C.; Reddy, B.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Earth construction: Lessons from the past for future eco-efficient construction. Constr. Build. Mater. 2012, 29, 512–519. [Google Scholar] [CrossRef]

- Lanzón, M.; Martínez, E.; Mestre, M.; Madrid, J.A. Use of zinc stearate to produce highly-hydrophobic adobe materials with extended durability to water and acid-rain. Constr. Build. Mater. 2017, 139, 114–122. [Google Scholar] [CrossRef]

- Obonyo, E.; Exelbirt, J.; Baskaran, M. Durability of compressed earth bricks: Assessing erosion resistance using the modified spray testing. Sustainability 2010, 2, 3639–3649. [Google Scholar] [CrossRef]

- Ren, K.B.; Kagi, D.A. Upgrading the durability of mud bricks by impregnation. Build. Environ. 1995, 30, 433–440. [Google Scholar] [CrossRef]

- Bhavsar, S.N.; Patel, A.J. Analysis of swelling & shrinkage properties of expansive soil using brick dust as a stabilizer. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 303–308. [Google Scholar]

- Brooks, K.N.; Ffolliott, P.F.; Magner, J.A. Hydrology and the Management of Watersheds; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Sathiparan, N.; Subramaniam, D.N.; Malsara, K.; Akmal, M. Thermal comfort analysis of fired-clay brick, cement-sand block and cement stabilized earth block masonry house models. Innov. Infrastruct. Solut. 2022, 7, 147. [Google Scholar] [CrossRef]

- Stazi, F.; Nacci, A.; Tittarelli, F.; Pasqualini, E.; Munafò, P. An experimental study on earth plasters for earthen building protection: The effects of different admixtures and surface treatments. J. Cult. Herit. 2016, 17, 27–41. [Google Scholar] [CrossRef]

- Pedergnana, M.; Elias-Ozkan, S.T. Impact of various sands and fibres on the physical and mechanical properties of earth mortars for plasters and renders. Constr. Build. Mater. 2021, 308, 125013. [Google Scholar] [CrossRef]

- Andres, D.M.; Manea, D.L.; Fechete, R.; Jumate, E. Green plastering mortars based on clay and wheat straw. Procedia Technol. 2016, 22, 327–334. [Google Scholar] [CrossRef]

- Caballero-Caballero, M.; Chinas-Castillo, F.; Montes Bernabé, J.L.; Alavéz-Ramirez, R.; Silva Rivera, M.E. Effect on compressive and flexural strength of agave fiber reinforced adobes. J. Nat. Fibers 2018, 15, 575–585. [Google Scholar] [CrossRef]

- Danso, H.; Martinson, D.B.; Ali, M.; Williams, J. Effect of fibre aspect ratio on mechanical properties of soil building blocks. Constr. Build. Mater. 2015, 83, 314–319. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.-C.; Aubert, J.-E.; Ghavami, K. Experimental analysis of Pressed Adobe Blocks reinforced with Hibiscus cannabinus fibers. Constr. Build. Mater. 2014, 52, 71–78. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.-E.; Magniont, C.; Maillard, P.; Poirier, C. Effect of plant aggregates on mechanical properties of earth bricks. J. Mater. Civ. Eng. 2017, 29, 04017244. [Google Scholar] [CrossRef]

- Segetin, M.; Jayaraman, K.; Xu, X. Harakeke reinforcement of soil–cement building materials: Manufacturability and properties. Build. Environ. 2007, 42, 3066–3079. [Google Scholar] [CrossRef]

- Yixian, W.; Panpan, G.; Shengbiao, S.; Haiping, Y.; Binxiang, Y. Study on strength influence mechanism of fiber-reinforced expansive soil using jute. Geotech. Geol. Eng. 2016, 34, 1079–1088. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing compressive strength of soil using natural fibers. Constr. Build. Mater. 2015, 93, 943–949. [Google Scholar] [CrossRef]

- Jové-Sandoval, F.; Barbero-Barrera, M.M.; Medina, N.F. Assessment of the mechanical performance of three varieties of pine needles as natural reinforcement of adobe. Constr. Build. Mater. 2018, 187, 205–213. [Google Scholar] [CrossRef]

- Damanik, N.H.C.; Susanto, D.; Suganda, E. The compressive strength of unfired clay brick with sugarcane bagasse fiber (SBF) and bio-enzyme reinforcements. Int. J. Technol. 2020, 11, 1422–1429. [Google Scholar] [CrossRef]

- Dawood, A.O.; Mussa, F.I.; Al Khazraji, H.; Abd Ulsada, H.A.; Yasser, M.M. Investigation of compressive strength of straw reinforced unfired clay bricks for sustainable building construction. Civ. Environ. Eng. 2021, 17, 150–163. [Google Scholar] [CrossRef]

- Ouedraogo, M.; Bamogo, H.; Sanou, I.; Dao, K.; Ouedraogo, K.A.J.; Aubert, J.-E.; Millogo, Y. Microstructure, physical and mechanical properties of adobes stabilized with rice husks. Int. J. Archit. Herit. 2023, 17, 1348–1363. [Google Scholar] [CrossRef]

- Tripura, D.D.; Gupta, S.; Debbarma, B.; Deep, R.S.S. Flexural strength and failure trend of bamboo and coir reinforced cement stabilized rammed earth wallettes. Constr. Build. Mater. 2020, 242, 117986. [Google Scholar] [CrossRef]

- Eslami, A.; Mohammadi, H.; Banadaki, H.M. Palm fiber as a natural reinforcement for improving the properties of traditional adobe bricks. Constr. Build. Mater. 2022, 325, 126808. [Google Scholar] [CrossRef]

- Sumanasena, V.; Rajabipour, A.; Bazli, M.; Kutay, C.; Guo, D. Strength and erosion resistance of mudbrick as an alternative local material for Australia’s Northern Territory remote housing. Case Stud. Constr. Mater. 2022, 16, e01023. [Google Scholar] [CrossRef]

- Martins, A.; Silva, F.; Toledo Filho, R.D. Mechanical behavior of self-compacting soil-cement-sisal fiber composites. Key Eng. Mater. 2015, 634, 421–432. [Google Scholar] [CrossRef]

- Thanushan, K.; Yogananth, Y.; Sangeeth, P.; Coonghe, J.G.; Sathiparan, N. Strength and durability characteristics of coconut fibre reinforced earth cement blocks. J. Nat. Fibers 2021, 18, 773–788. [Google Scholar] [CrossRef]

- Alausa, S.; Adekoya, B.; Aderibigbe, J.; Nwaokocha, C. Thermal characteristics of laterite-mud and concrete-block for walls in building construction in Nigeria. Int. J. Eng. Appl. Sci 2013, 4, 8269. [Google Scholar]

- Saing, Z.; Samang, L.; Harianto, T.; Patanduk, J. Mechanical characteristic of ferro laterite soil with cement stabilization as a subgrade material. Int. J. Civ. Eng. Technol. 2017, 8, 609–616. [Google Scholar]

- Nott, J.F. The urban geology of Darwin, Australia. Quat. Int. 2003, 103, 83–90. [Google Scholar] [CrossRef]

- Walker, P. The Australian earth building handbook. In The Australian Earth Building Handbook; SAI Global Limited: Sydney, Australia, 2002. [Google Scholar]

- Sadeeq, J.; Ochepo, J.; Salahudeen, A.; Tijjani, S. Effect of bagasse ash on lime stabilized lateritic soil. Jordan J. Civ. Eng. 2015, 9, 203–213. [Google Scholar]

- Corporation, J.A. Wanggalili: Yindjibarndi and Ngarluma Plants; Juluwarlu Aboriginal Corporation: Roebourne, Australia, 2003. [Google Scholar]

- Kępa, K.; Chaléat, C.M.; Amiralian, N.; Batchelor, W.; Grøndahl, L.; Martin, D.J. Evaluation of properties and specific energy consumption of spinifex-derived lignocellulose fibers produced using different mechanical processes. Cellulose 2019, 26, 6555–6569. [Google Scholar] [CrossRef]

- Milan, S.; Christopher, T.; Manivannan, A.; Mayandi, K.; Jappes, J.W. Mechanical and thermal properties of a novel Spinifex Littoreus fiber reinforced polymer composites as an alternate for synthetic glass fiber composites. Mater. Res. Express 2021, 8, 035301. [Google Scholar] [CrossRef]

- Sutcu, M. Influence of expanded vermiculite on physical properties and thermal conductivity of clay bricks. Ceram. Int. 2015, 41, 2819–2827. [Google Scholar] [CrossRef]

- Bakar, B.A.; Saari, S.; Surip, N. Water absorption characteristic of interlocking compressed earth brick units. In Proceedings of the International Conference of Global Network for Innovative Technology and Awam International Conference in Civil Engineering (IGNITE-AICCE’17), Telangana, India, 5–6 December 2018; AIP Publishing LLC: Melville, NY, USA, 2017. [Google Scholar]

- ASTM C62-17; Standard Specification for Building Brick (Solid Masonry Units Made From Clay or Shale). ASTM International: West Conshohocken, PA, USA, 2017.

- Ali, Z.A. Properties of Malaysia Fired Clay Bricks and Their Evaluation with International Masonry Specification—A Case Study; Universiti Teknologi Malaysia: Johor, Malaysia, 2005. [Google Scholar]

- Ali, M.; Room, S.; Khan, M.I.; Masood, F.; Memon, R.A.; Khan, R.; Memon, A.M. Assessment of local earthen bricks in perspective of physical and mechanical properties using Geographical Information System in Peshawar, Pakistan. Structures 2020, 28, 2549–2561. [Google Scholar] [CrossRef]

- Khitab, A. Materials of Construction; Allied Books Lahore: Lahore, Pakistan, 2012. [Google Scholar]

- ASTM C1314-18; Standard Test Method for Compressive Strength of Masonry Prisms. ASTM International: West Conshohocken, PA, USA, 2018.

- Ebadi Jamkhaneh, M.; Ahmadi, M.; Shokri Amiri, M. Sustainable reuse of inorganic materials in eco-friendly clay bricks: Special focus on mechanical and durability assessment. J. Mater. Civ. Eng. 2021, 33, 04021111. [Google Scholar] [CrossRef]

- Fernando, P.R.; Kannangara, G.L.; Buddhika, G.P.; Urushiya, A. Synthesis and characterization of sustainable man-made low cost clay bricks with bamboo leaf ash. Eng. Phys. 2018, 2, 15–22. [Google Scholar] [CrossRef]

- Coutts, R.; Ni, Y. Autoclaved bamboo pulp fibre reinforced cement. Cem. Concr. Compos. 1995, 17, 99–106. [Google Scholar] [CrossRef]

- Ghavami, K.; Toledo Filho, R.D.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Ugwuishiwu, B.; Mama, B.; Okoye, N.M. Effects of natural fiber reinforcement on water absorption of compressed stabilized earth blocks. IJSR Int. J. Sci. Res. 2013, 2, 165–167. [Google Scholar]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Mechanical and physicochemical performances of reinforced unfired clay bricks with recycled Typha-fibers waste as a construction material additive. Clean. Eng. Technol. 2021, 2, 100037. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Concha-Riedel, J.; Antico, F.C.; Valdés, C.; Cáceres, G. Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Constr. Build. Mater. 2018, 174, 645–655. [Google Scholar] [CrossRef]

- Kasie, Y.M.; Mogne, A.Y. Improvement of mechanical properties of adobe brick reinforced with sisal fiber. Discov. Mater. 2025, 5, 69. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Faria, P.; Aubert, J.-E.; Magniont, C. Assessment of Durability of Bio-based Earth Composites. Recent Prog. Mater. 2021, 3, 16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).