Epoxy and Bio-Based Epoxy Glass Fiber Composites: Taguchi Design of Experiments and Future Applications

Abstract

1. Introduction

2. Materials and Methods

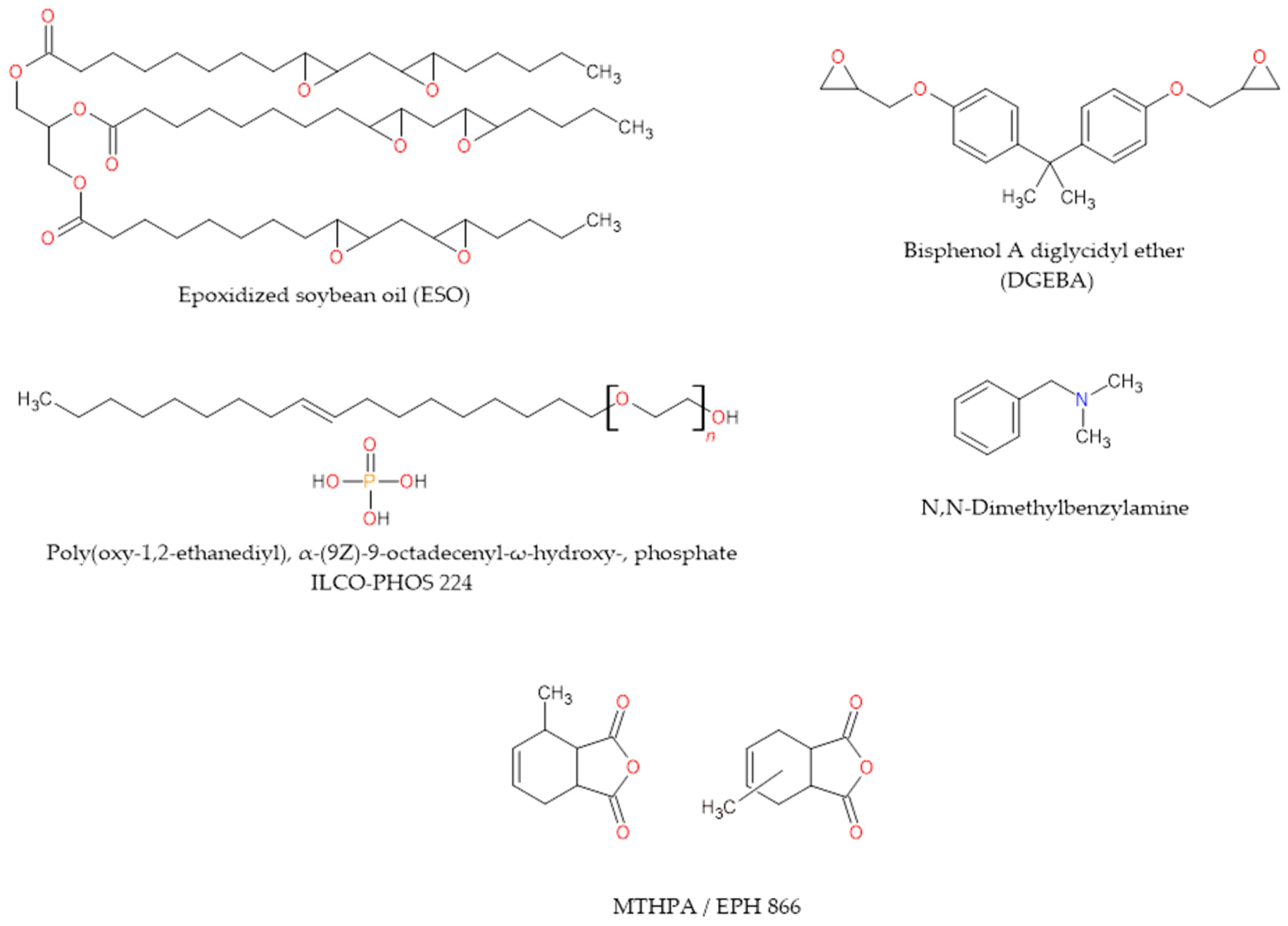

2.1. Materials

2.2. Preparation of Plates for Samples

2.2.1. Preparation of Plates from Pure Resin System

2.2.2. Preparation of Composite Plates

2.3. Methods for Mechanical/Thermal Tests of Samples from Plates

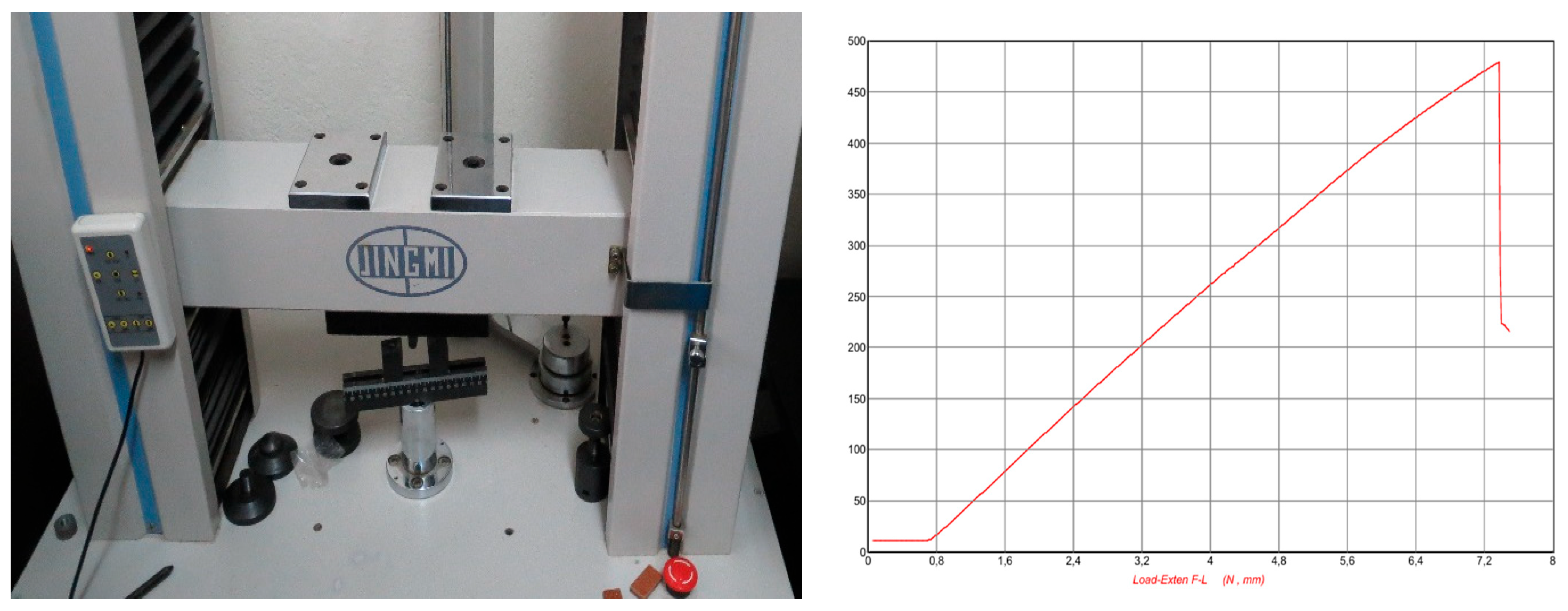

2.3.1. Bending Tests of Samples from Plates

- —applied load to the specimen (N);

- —width of the specimen (mm);

- —thickness of the specimen (mm);

- —length of the span between the supports (mm).

- —slope of the load () versus deflection () curve, which represents the rate of change of load with respect to deflection (N/mm);

- —maximum deflection of the specimen at the center (mm).

2.3.2. Thermal Analysis (DSC) of Samples from Plates

2.4. Taguchi Method

2.5. Manufacture and Tests of Pultruded Rods Samples

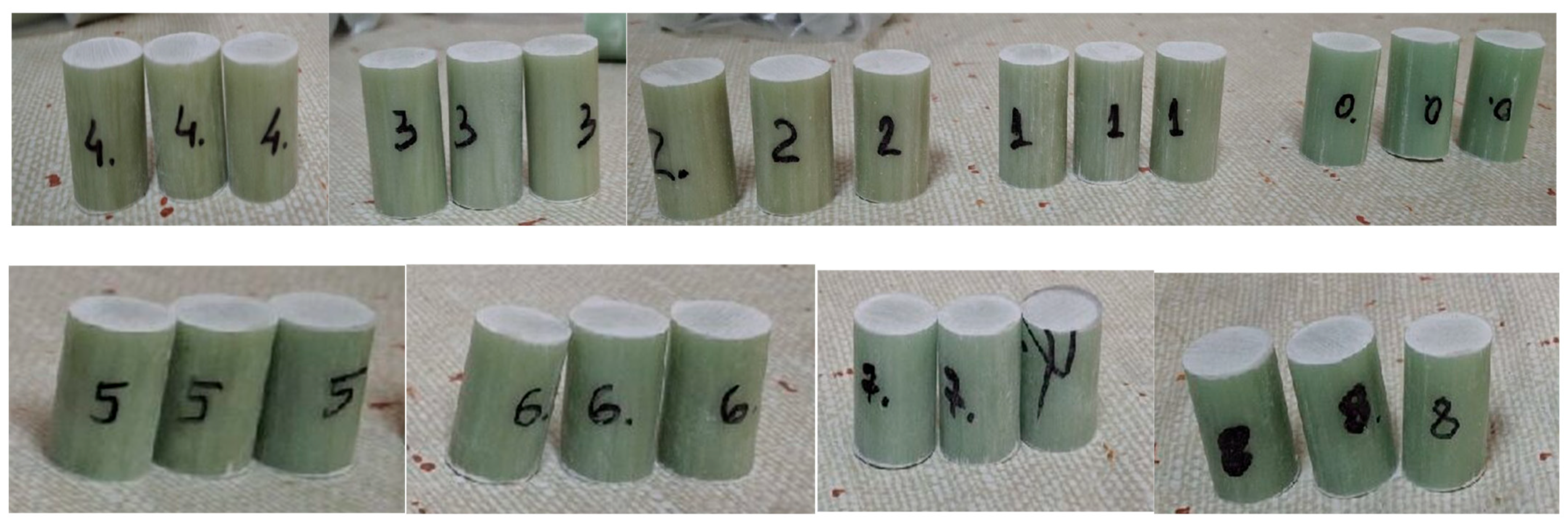

2.5.1. Manufacturing Fiberglass Composites Rods by Pultrusion

2.5.2. Method Tests of Pultruded Rods Samples

Shear and Compression Strength

- S = apparent shear strength (N/mm2 or MPa);

- F = breaking load (N);

- d = specimen width (mm).

Thermal Analysis (DSC/TGA) of Pultruded Rods Samples

3. Results and Discussion

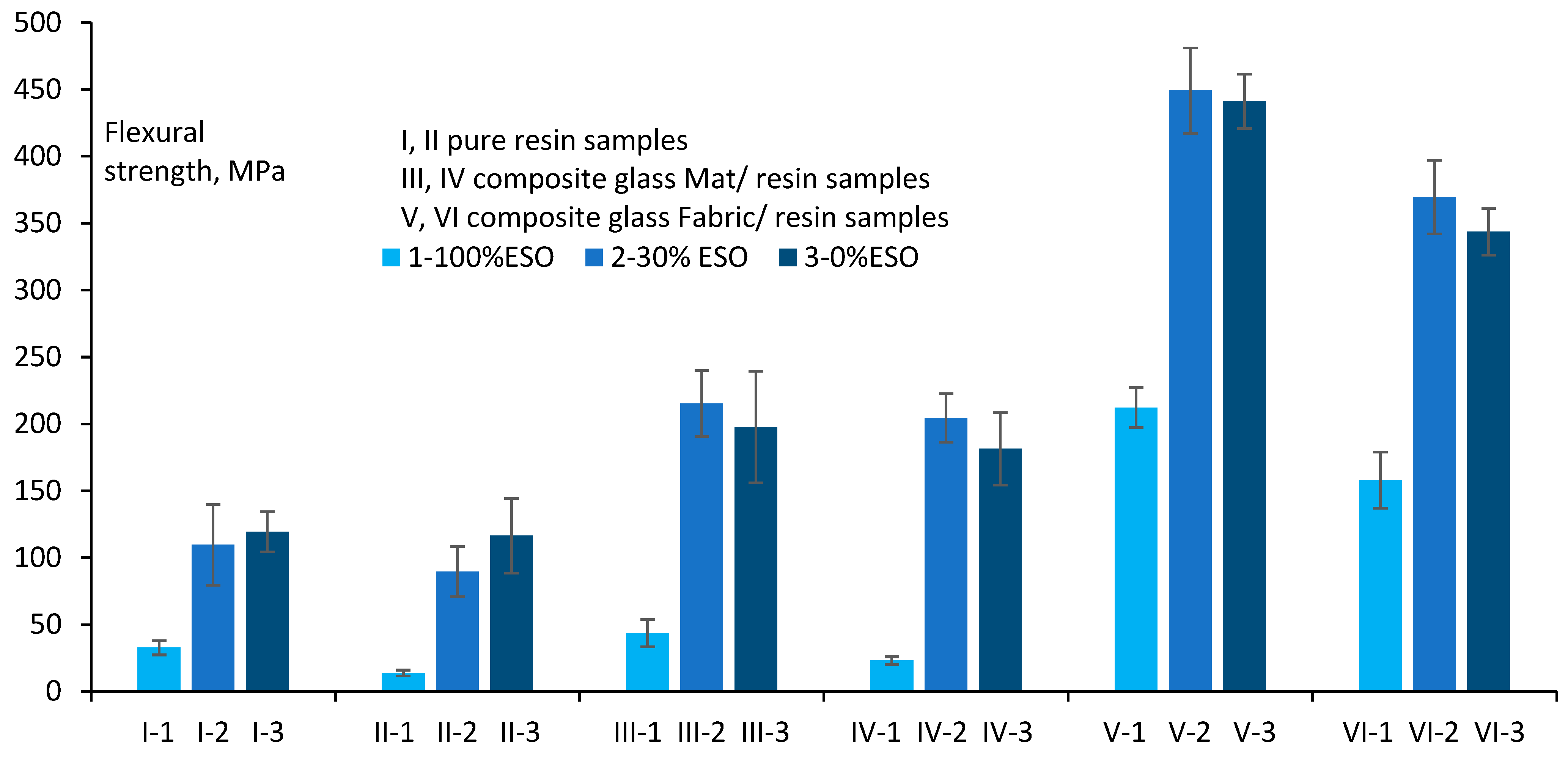

3.1. Tests of Samples from Palates

3.1.1. Bending Test of Samples from Palates

3.1.2. DSC Analysis of Samples from Palates

3.2. Results from Taguchi Method

3.3. Test of Samples from Pultruded Rods

3.3.1. Mechanical Properties of Pultruded Rods

3.3.2. Thermal Properties (DSC/TGA) of Pultruded Rods

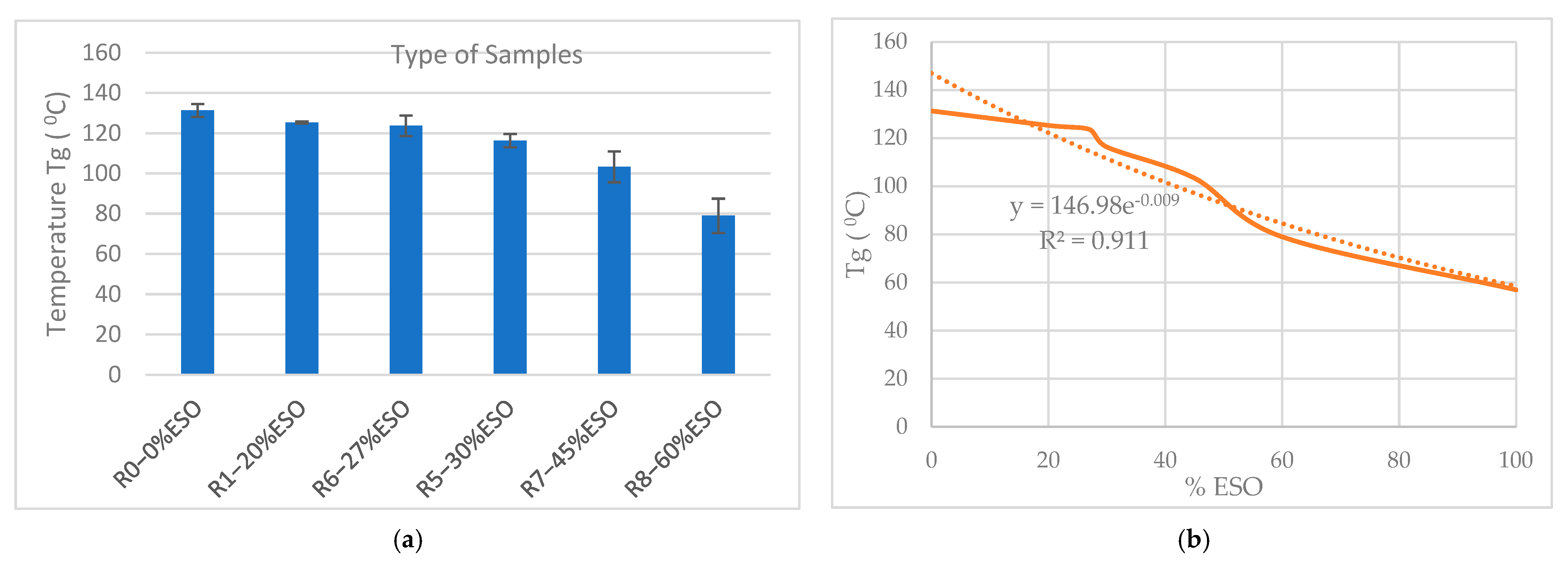

DSC Analysis for Determining Tg of Samples R0–R8

TGA Analysis of Samples R0–R8

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ESO | Epoxidized soybean oil |

| DGEBA | Diglycidyl ether of bisphenol A |

| MTHPA | Methyl tetrahydro phthalic anhydride |

| BDMA | Benzyl dimethyl amine from Huntsman |

| DSC | Differential scanning calorimetry |

| TGA | Thermogravimetric analysis |

| Tg | Glass-transition temperature |

References

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, B.R.; Hinrichsen, G. Natural fibers, biopolymers, and biocomposites: An Introduction. In Natural Fibers, Biopolymers, and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; Taylor & Francis Group: Boca Raton, FL, USA, 2005; pp. 1–36. [Google Scholar]

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and bio composites: A review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Fombuena, V.; Bernardi, L.; Fenollar, O.; Boronat, T.; Balart, R. Characterization of green composites from biobased epoxy matrices and bio-fillers derived from seashell wastes. Mater. Des. 2014, 57, 168–174. [Google Scholar] [CrossRef]

- Chen, Y.; Liting, Y.; Wu, J.; Ma, L.; Finlow, D.E.; Lin, S.; Song, K. Thermal and mechanical properties of epoxy resin toughened with epoxidized soybean oil. J. Therm. Anal. Calorim. 2013, 113, 939–945. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Ungtrakul, T.; Chandrasekar, M.; Kumar, T.S.M.; Rajini, N.; Siengchin, S.; Pulikkalparambil, H.; Parameswaran pillai, J.; Ayrilmis, N. Performance of Sisal/Hemp Bio-based Epoxy Composites Under Accelerated Weathering. J. Polym. Environ. 2021, 29, 624–636. [Google Scholar] [CrossRef]

- Altuna, F.; Esposito, L.; Ruseckaite, R.; Stefani, P. Thermal and Mechanical Properties of Anhydride-Cured Epoxy Resins with Different Contents of Biobased Epoxidized Soybean Oil. J. Appl. Polym. Sci. 2011, 120, 789–798. [Google Scholar] [CrossRef]

- Samper, M.; Fombuena, V.; Boronat, T.; Garcia-Sanoguera, D.; Balart, R. Thermal and Mechanical Characterization of Epoxy Resins (ELO and ESO) Cured with Anhydrides. J. Am. Oil Chem. Soc. 2012, 89, 1521–1528. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, N.; He, J.; Du, R.; Liu, Y.; Zhao, G. Mechanical and anticorrosion properties of furan/epoxy-based basalt f iber-reinforced composites. J. Appl. Polym. Sci. 2017, 134, 44799. [Google Scholar] [CrossRef]

- Wu, M.S.; Jin, B.C.; Li, X.; Nutt, S. A recyclable epoxy for composite wind turbine blades. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 114–127. [Google Scholar] [CrossRef]

- Liu, G.; Jin, C.; Huo, S.; Kong, Z.; Chu, F. Preparation and properties of novel bio-based epoxy resin thermosets from lignin oligomers and cardanol. Int. J. Biol. Macromol. 2021, 193, 1400–1408. [Google Scholar] [CrossRef]

- Mattar, N.; de Anda, A.R.; Vahabi, H.; Renard, E.; Langlois, V. Resorcinol-Based Epoxy Resins Hardened with Limonene and Eugenol Derivatives: From the Synthesis of Renewable Diamines to the Mechanical Properties of Biobased Thermosets. ACS Sustain. Chem. Eng. 2020, 8, 13064–13075. [Google Scholar] [CrossRef]

- Capretti, M.; Giammaria, V.; Santulli, C.; Boria, S.; Del Bianco, G. Use of Bio-Epoxies and Their Effect on the Performance of Polymer Composites: A Critical Review. Polymers 2023, 15, 4733. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, F.A.M.M.; Santos, M.; Cernadas, T.; Ferreira, P.; Alves, P. Advances in the development of biobased epoxy resins: Insight into more sustainable materials and future applications. Int. Mater. Rev. 2021, 67, 119–149. [Google Scholar] [CrossRef]

- Ramon, E.; Sguazzo, C.; Moreira, P.M.G.P. A Review of Recent Research on Bio-Based Epoxy Systems for Engineering Applications and Potentialities in the Aviation Sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Park, S.; Jin, F.; Lee, J. Effect of Biodegradable Epoxidized Castor Oil on Physicochemical and Mechanical Properties of Epoxy Resins, Macromol. Chem. Phys. 2004, 205, 2048–2054. [Google Scholar]

- Niedermann, P.; Szebényi, G.; Toldy, A. Effect of Epoxidized Soybean Oil on Curing, Rheological, Mechanical and Thermal Properties of Aromatic and Aliphatic Epoxy Resins. J. Polym. Environ. 2014, 22, 525–536. [Google Scholar] [CrossRef]

- Lim, S.J.; Kim, D.S. Effect of functionality and content of epoxidized soybean oil on the physical properties of a modified diglycidyl ether of bisphenol A resin system. J. Appl. Polym. Sci. 2021, 138, app50441. [Google Scholar] [CrossRef]

- Salam, H.; Dong, Y.; Davies, I.J.; Pramanik, A. Optimization of material formulation and processing parameters in relation to mechanical properties of bioepoxy/clay nanocomposites using Taguchi design of experiments. J. Appl. Polym. Sci. 2018, 135, 45769. [Google Scholar]

- Chebotar, A.; Domnich, B.; Panchenko, Y.; Donchak, V.; Stetsyshyn, Y.; Voronov, A. Thermal behavior of polymers and copolymers based on plant oils with differing saturated and monounsaturated content. Polym. Int. 2025, 74, 179–285. [Google Scholar]

- Zhang, T.; Chao, X.; Liang, J.; Wang, B.; Sun, M. Enhanced Mechanical Properties of Epoxy Composites Reinforced with Silane- Modified Al2O3 Nanoparticles: An Experimental Study. J. Compos. Sci. 2025, 9, 252. [Google Scholar] [CrossRef]

- ASTM E1868-10; Standard Test Method for Total Carbon and Organic Carbon in Water by High Temperature Combustion. ASTM International: West Conshohocken, PA, USA, 2012.

- Risteska, S.; Stefanovska, M.; Samakoski, B. Factorial Design of Experiment vs. Taguchi Approach in Filament Wound Composites. In Proceedings of the 6th International Symposium on Industrial Engineering, Belgrade, Serbia, 24–25 September 2015. [Google Scholar]

- Jin, F.-L.; Park, S.-J. Impact-strength improvement of epoxy resins reinforced with a biodegradable polymer. Mater. Sci. Eng. A 2008, 478, 402–405. [Google Scholar] [CrossRef]

- Bagheri, S.; Nejad, M. Fully biobased composite made with epoxidized lignin, reinforced with bamboo fibers. Polym. Compos. 2023, 44, 3926–3938. [Google Scholar] [CrossRef]

- Jin, F.; Park, S. Thermomechanical behavior of epoxy resins modified with epoxidized vegetable oils. Polym. Int. 2008, 57, 577–583. [Google Scholar] [CrossRef]

- Di Mauro, C.; Malburet, S.; Genua, A.; Graillot, A.; Mija, A. Sustainable Series of New Epoxidized Vegetable Oil-Based Thermosets with Chemical Recycling Properties. Biomacromolecules 2020, 21, 3923–3935. [Google Scholar] [CrossRef] [PubMed]

- España, J.M.; Sánchez-Nacher, L.; Boronat, T.; Fombuena, V.; Balart, R. Properties of Biobased Epoxy Resins from Epoxidized Soybean Oil (ESBO) Cured with Maleic Anhydride (MA). J. Am. Oil Chem. Soc. 2012, 89, 2067–2075. [Google Scholar] [CrossRef]

- Li, J.; Du, Z.; Li, H.; Zhang, C. Porous epoxy monolith prepared via chemically induced phase separation. Polymer 2009, 50, 1526–1532. [Google Scholar] [CrossRef]

- Liu, Z.; Erhan, S.; Calvert, P. Solid freeform fabrication of epoxidized soybean oil/epoxy composite with bis or polyalkyleneamine curing agents. Compos. Part A 2007, 38, 87–93. [Google Scholar] [CrossRef]

- Bhosale, S.H.; Singh, V.V.; Rangasai, M.C.; Bandyopadhyay-Ghosh, S.; Ghosh, S.B. Integration of biobased functionalized feedstock and plastisol in epoxy resin matrix toward developing structural jute biocomposites with enhanced impact strength and moisture resistance properties. Polym. Composites. 2016, 37, 391–397. [Google Scholar] [CrossRef]

- Chen, Y.; Xi, Z.; Zhao, L. Curing kinetics of bio-based epoxy resin based on epoxidized soybean oil and green curing agent. AIChE J. 2017, 63, 147–153. [Google Scholar] [CrossRef]

- Toldy, A. Development of Environmentally Friendly Epoxy Resin Composites. Doctoral Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2017. [Google Scholar]

- Kumar, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Epoxidized soybean oil-based epoxy blend cured with Anhydride based crosslinker: Thermal and Mechanical Characterization. Ind. Eng. Chem. Res. 2017, 56, 687–698. [Google Scholar] [CrossRef]

- Boursier Niutta, C.; Ciardiello, R.; Tridello, A.; Paolino, D.S. Epoxy and Bio-Based Epoxy Carbon Fiber Twill Composites: Comparison of the Quasi-Static Properties. Materials 2023, 16, 1601. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- EN ISO 14125; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 1998.

- ISO 11357-1; Plastics—Differential Scanning Calorimetry (DSC) Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2023.

- Ganesh Gupta, K.B.N.V.S.; Hiremath, M.M.; Prusty, R.K.; Ray, B.C. Development of advanced fiber-reinforced polymer composites by polymer hybridization technique: Emphasis on cure kinetics, mechanical, and thermomechanical performance. J. Appl. Polym. Sci. 2020, 137, 49318. [Google Scholar] [CrossRef]

- Hazer, B.; Kalaycı, Ö.A. High fluorescence emission silver nano particles coated with poly (styrene-g-soybean oil) graft copolymers: Antibacterial activity and polymerization kinetics. Mater. Sci. Eng. C 2017, 74, 259–269. [Google Scholar] [CrossRef] [PubMed]

- Veloso-Fernández, A.; Ruiz-Rubio, L.; Yugueros, I.; Moreno-Benítez, M.I.; Laza, J.M.; Vilas-Vilela, J.L. Improving the Recyclability of an Epoxy Resin through the Addition of New Biobased Vitrimer. Polymers 2023, 15, 3737. [Google Scholar] [CrossRef] [PubMed]

- Sanivada, U.K.; Brito, F.P.; Moreira, I.P.; Fangueiro, R. Optimization of Processing Parameters of Compression Molding Process by Application of Taguchi and Minitab. Mater. Proc. 2022, 8, 31. [Google Scholar]

- Mohsin, I.; He, K.; Li, Z.; Zhang, F.; Du, R. Optimization of the Polishing Efficiency and Torque by Using Taguchi Method and ANOVA in Robotic Polishing. Appl. Sci. 2020, 10, 824. [Google Scholar] [CrossRef]

- Yusuf, S.S.; Islam, M.N.; Ali, M.H.; Akram, M.W.; Siddique, M.A. Towards the optimization of process parameters for impact strength of natural fiber reinforced composites: Taguchi method. Adv. Mater. Sci. 2020, 20, 54–70. [Google Scholar] [CrossRef]

- Owaid, A.A.; Kaygusuz, H.; Mohammed, F.M. Effect of reinforcing materials on mechanical properties of composite material using Taguchi method. J. Phys. Conf. Ser. 2021, 1973, 012246. [Google Scholar] [CrossRef]

- Bagci, M.; Imrek, H. Application of Taguchi method on optimization of testing parameters for erosion of glass fiber reinforced epoxy composite materials. Mater. Des. 2013, 46, 706–712. [Google Scholar] [CrossRef]

- Beylergil, B.; Al-Nadhari, A.; Yildiz, M. Optimization of Charpy-impact strength of 3D-printed carbon fiber/polyamide composites by Taguchi method. Polym. Compos. 2023, 44, 2846–2859. [Google Scholar] [CrossRef]

- Pawar, J.; Malagi, R.R.; Jadhav, M.; Pawar, G. Enhanced biodegradability and mechanical properties in green composites: A Taguchi approach. Discov. Appl. Sci. 2025, 7, 47. [Google Scholar] [CrossRef]

- Zhu, J.; Chandrashekhara, K.; Flanigan, V.; Kapila, S. Manufacturing and mechanical properties of soy-based composites using pultrusion. Compos. Part A 2004, 35, 95–101. [Google Scholar] [CrossRef]

- Wang, R. Manufacturing of Vegetable Oils-Based Epoxy and Composites for Structural Applications. Doctoral Dissertation, Missouri University of Science and Technology, Rolla, MO, USA, 2014. [Google Scholar]

- Mustata, F.; Tudorachi, N.; Rosu, D. Curing and thermal behavior of resin matrix for composites based on epoxidized soybean oil/diglycidyl ether of bisphenol A. Compos. Part B 2011, 42, 1803–1812. [Google Scholar] [CrossRef]

- ASTM D4475-96; Standard Test Method for Apparent Horizontal Shear Strength of Pultruded Reinforced Plastic Rods By The Short-Beam Metho. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- Zhu, J.; Chandrashekhara, K.; Flanigan, V.; Kapila, S. Curing and mechanical characterization of a soy-based epoxy resin system. J. Appl. Polym. Sci. 2004, 91, 3513–3518. [Google Scholar] [CrossRef]

- Sudha, G.S.; Kalita, H.; Mohanty, S.; Nayak, S. Biobased Epoxy Blends from Epoxidized Castor Oil: Effect on Mechanical, Thermal, and Morphological Properties. Macromol. Res. 2017, 25, 420–430. [Google Scholar] [CrossRef]

| Epoxy Resin | Curing Agent 1 | Curing Agent 2 | Catalyst | Release Mold | Filler | Epoxidized Soybean Oil | Reinforcement Nonwoven/Fiber | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | KER 828 | MTHPA | EPH 866 | BDMA | ILCHO 224 | CaCO3 | ESO | E Glass—Mat | E Glass Roving | E Glass Fabric |

| Density at 20 °C g/cm3 | 1.16 | 1.19–1.21 | 1.19–1.23 | 0.892–0.898 | 1.03 | 2.7 | 0.988–0.998 | 2.51–2.63 | 2.5–2.6 | 2.51–2.6 |

| Viscosity at 25 °C mPas | 12,000–14,000 | 50–70 | 55–75 | 90 | 2300 | Particles <2 µm | 325 | / | / | / |

| EEW/AEW g/eq. | 184–190 | 163 | 166 | / | / | / | 220–246 | / | / | / |

| Epoxy value % | / | / | / | / | / | / | >6.5 | / | / | / |

| Iodine value % | / | / | / | / | / | / | <5 | / | / | / |

| Acid value mg KOH/g | / | / | / | / | / | / | <0.5 | / | / | / |

| weigh g/m2/tex | / | / | / | / | / | / | / | 350 | 4800 | 200 |

| Marking /Code | Plate I-1 | Plate I-2 | Plate I-3 | Plate II-1 | Plate II-2 | Plate II-3 |

|---|---|---|---|---|---|---|

| ESO% | 100 | 30 | 0 | 100 | 30 | 0 |

| DGEBA% | 0 | 70 | 100 | 0 | 70 | 100 |

| Type Curing Agent 85% | MTHPA | MTHPA | MTHPA | EPH 866 | EPH 866 | EPH 866 |

| Catalyst 2–3% | BDMA | |||||

| Marking /Code | Plate III-1 | Plate III-2 | Plate III-3 | Plate IV-1 | Plate IV-2 | Plate IV-3 |

| Reinforcements | 8 layers of MAT continue glass fiber | |||||

| Resin system | Modified epoxy system | |||||

| ESO% | 100 | 30 | 0 | 100 | 30 | 0 |

| DGEBA% | 0 | 70 | 100 | 0 | 70 | 100 |

| Type Curing Agent | MTHPA | MTHPA | MTHPA | EPH 866 | EPH 866 | EPH 866 |

| Catalyst | BDMA | |||||

| Marking /Code | Plate V-1 | Plate V-2 | Plate V-3 | Plate VI-1 | Plate VI-2 | Plate VI-3 |

| Reinforcements% | 8 layers of glass fabric (woven plain) | |||||

| Resin system% | Modified epoxy system | |||||

| ESO% | 100 | 30 | 0 | 100 | 30 | 0 |

| DGEBA% | 0 | 70 | 100 | 0 | 70 | 100 |

| Type Curing Agent | MTHPA | MTHPA | MTHPA | EPH 866 | EPH 866 | EPH 866 |

| Catalyst | BDMA | |||||

| Run | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 1 | 2 | 2 | 2 |

| 3 | 1 | 2 | 2 | 1 | 1 | 2 |

| 4 | 1 | 2 | 2 | 2 | 2 | 1 |

| 5 | 2 | 1 | 2 | 1 | 2 | 1 |

| 6 | 2 | 1 | 2 | 2 | 1 | 2 |

| 7 | 2 | 2 | 1 | 1 | 2 | 2 |

| 8 | 2 | 2 | 1 | 2 | 1 | 1 |

| Trial Number No. | ESO Content (wt%) A | Curing Agent Type B | Mechanical Mixing Time (Min) C | Fiber Content (wt%) D | CaCO3 Content (wt%) E | Mixing Temperature (°C) F |

|---|---|---|---|---|---|---|

| 1 | 0 | EPH 866 | 2 | 0 | 0 | 25 |

| 2 | 0 | EPH 866 | 2 | 60 | 10 | 80 |

| 3 | 0 | MTHPA | 10 | 0 | 0 | 80 |

| 4 | 0 | MTHPA | 10 | 60 | 10 | 25 |

| 5 | 30 | EPH 866 | 10 | 0 | 10 | 25 |

| 6 | 30 | EPH 866 | 10 | 60 | 0 | 80 |

| 7 | 30 | MTHPA | 2 | 0 | 10 | 80 |

| 8 | 30 | MTHPA | 2 | 60 | 0 | 25 |

| Trial No. | DGEBA (wt%) | ESO (wt%) | CaCO3 (wt%) | Hardener 1 MTHPA/ 2 EPH 866 (wt%) | Catalyst BDMA (wt%) | Lubricant Mold ILCHO 224 (wt%) |

|---|---|---|---|---|---|---|

| R0 | 100 | 0 | 10 | 85 1 | 2–3 | 1 |

| R1 | 80 | 20 | 10 | 85 1 | 2–3 | 1 |

| R2 | 80 | 20 | 0 | 85 1 | 2–3 | 1 |

| R3 | 80 | 20 | 0 | 85 2 | 2–3 | 1 |

| R4 | 75 | 25 | 10 | 85 1 | 2–3 | 1 |

| R5 | 73 | 27 | 10 | 85 1 | 2–3 | 1 |

| R6 | 70 | 30 | 10 | 85 1 | 2–3 | 1 |

| R7 | 55 | 45 | 10 | 85 1 | 2–3 | 1 |

| R8 | 40 | 60 | 10 | 85 1 | 2–3 | 1 |

| No. Exp. | Flexural Strength (MPa) | y (med) | S/N | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||

| 1 | 76.68 | 78.93 | 71.48 | 89.62 | 102.52 | 83.85 | 38.26 |

| 2 | 162.22 | 224.55 | 171.22 | 190.78 | 158.78 | 181.51 | 44.97 |

| 3 | 100.19 | 58.12 | 97.03 | 87.84 | 105.34 | 89.70 | 38.41 |

| 4 | 269.51 | 163.43 | 188.25 | 176.28 | 191.23 | 197.74 | 45.56 |

| 5 | 26.33 | 36.4 | 56.67 | 52.73 | 47.38 | 43.90 | 31.79 |

| 6 | 217.72 | 185.31 | 217.8 | 217.88 | 183.97 | 204.54 | 46.13 |

| 7 | 115.48 | 122.26 | 127.16 | 56.26 | 127.42 | 109.72 | 39.35 |

| 8 | 196.65 | 189.97 | 206.97 | 245.05 | 237.59 | 215.25 | 46.53 |

| Level | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 1 | 41.80 | 40.29 | 42.28 | 36.95 | 42.33 | 40.53 |

| 2 | 40.95 | 42.46 | 40.47 | 45.80 | 40.42 | 42.21 |

| Δ | 0.85 | 2.17 | 1.81 | 8.85 | 1.91 | 1.68 |

| Rank | 6 | 2 | 4 | 1 | 3 | 5 |

| Trial | DGEBA | ESO | Tg °C | |||

|---|---|---|---|---|---|---|

| No. | (wt%) | (wt%) | Tg1 | Tg2 | Tg3 | Tg_avg |

| R0 | 100 | 0 | 135 | 130 | 129 | 131.3 |

| R1 | 80 | 20 | 126 | 125.4 | 125 | 125.5 |

| R2 | 80 | 20 | 127.3 | 128 | 124 | 126.4 |

| R3 | 80 | 20 | 125.1 | 127 | 126 | 126.0 |

| R4 | 75 | 25 | 123.5 | 125 | 121 | 123.2 |

| R6 | 73 | 27 | 128 | 125 | 118 | 123.7 |

| R5 | 70 | 30 | 120 | 115 | 114 | 116.3 |

| R7 | 55 | 45 | 110 | 105 | 95 | 103.3 |

| R8 | 40 | 60 | 87 | 80 | 70 | 79.0 |

| Trial | ESO | Teperature °C | |||||||

|---|---|---|---|---|---|---|---|---|---|

| No. | (wt%) | Tonset | T5 | T10 | T50 | Tp1 | Tp2 | Tendest | R (%) |

| R0 | 0 | 280 | 340 | 368 | 400 | 404 | 532 | 595 | 21.5 |

| R1 | 20 | 270 | 320 | 345 | 395 | 400 | 530 | 591 | 22 |

| R2 | 20 | 268 | 322 | 343 | 400 | 400 | 530 | 590 | 22.2 |

| R3 | 20 | 270 | 320 | 345 | 401 | 400 | 530 | 591 | 21.8 |

| R4 | 25 | 267 | 300 | 335 | 390 | 400 | 530 | 590 | 22.5 |

| R6 | 27 | 265 | 295 | 330 | 385 | 385 | 530 | 591 | 22 |

| R5 | 30 | 260 | 290 | 325 | 380 | 365 | 530 | 589 | 22.3 |

| R7 | 45 | 250 | 240 | 300 | 360 | 360 | 525 | 587 | 21.8 |

| R8 | 60 | 240 | 230 | 290 | 370 | 356 | 525 | 580 | 22.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Risteska, S.; Vasileski, I.; Gjorgjieska Angelovska, E.; Pižov, A. Epoxy and Bio-Based Epoxy Glass Fiber Composites: Taguchi Design of Experiments and Future Applications. J. Compos. Sci. 2025, 9, 513. https://doi.org/10.3390/jcs9100513

Risteska S, Vasileski I, Gjorgjieska Angelovska E, Pižov A. Epoxy and Bio-Based Epoxy Glass Fiber Composites: Taguchi Design of Experiments and Future Applications. Journal of Composites Science. 2025; 9(10):513. https://doi.org/10.3390/jcs9100513

Chicago/Turabian StyleRisteska, Svetlana, Ivan Vasileski, Evgenija Gjorgjieska Angelovska, and Aleksandar Pižov. 2025. "Epoxy and Bio-Based Epoxy Glass Fiber Composites: Taguchi Design of Experiments and Future Applications" Journal of Composites Science 9, no. 10: 513. https://doi.org/10.3390/jcs9100513

APA StyleRisteska, S., Vasileski, I., Gjorgjieska Angelovska, E., & Pižov, A. (2025). Epoxy and Bio-Based Epoxy Glass Fiber Composites: Taguchi Design of Experiments and Future Applications. Journal of Composites Science, 9(10), 513. https://doi.org/10.3390/jcs9100513