A Comparative Study of Airbag Covers for Automotive Safety Using Coconut Shell Fiber/PP Composite Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Primary Materials

2.2. Instruments and Equipment

2.3. Sample Preparation

2.3.1. Alkali Treatment of Coconut Shell Fiber

2.3.2. Coupling Agent Treatment of Coconut Shell Fibers

2.3.3. Preparation of Coconut Shell Fiber/PP Composite Material Specimens

- Cross-arranged stacked hot-pressed coconut shell fiber/PP composite-material specimens with lengths of 120–140 mm were processed using a hot press-molding machine to form 1 mm thick sheets of polypropylene granules. The pretreated 120–140 mm coconut shell fibers were then vertically interwoven. These fibers were stacked in layers on polypropylene resin sheets in a layering ratio of 2:3 and mass ratios of 5:95, 10:90, and 15:85. The stacked layers were placed in a 4 mm mold. Hot pressing was carried out using a flat vulcanizing machine at a temperature of 200 °C, a molding pressure of 6 MPa, and a holding time of 20 min. The specimens were then allowed to cool gradually after molding.

- Samples of 3–5 mm mixed injection-molded coconut shell fiber/PP composite material were prepared by uniformly mixing pretreated 3–5 mm coconut shell fibers and PP in mass ratios of 5:95, 10:90, and 15:85. The mixture was then injected into a plastic injection-molding machine, with a temperature of 200 °C, a filling time of 5 s, a cycle time of 15.0 s, a sol time of 4.47 s, a cooling time of 16.1 s, and a shot end point at 2.1 mm. After sample preparation, the specimens were allowed to cool gradually after molding.

- Pure PP material specimens were prepared using the same method as that used for the 3–5 mm mixed injection-molded coconut shell fiber/PP composite material specimens.

2.4. Mechanical Properties Test

Tensile Test

3. Results and Discussion

3.1. The Influence of Processing and Arrangement on the Tensile and Bending Properties of Composite Materials

3.1.1. Analysis of the Tensile Properties of Composite Materials

- Tensile strength

- 2.

- Tensile Modulus

- 3.

- Sample curves from tensile testing

3.1.2. Analysis of the Bending Performance of Composite Materials

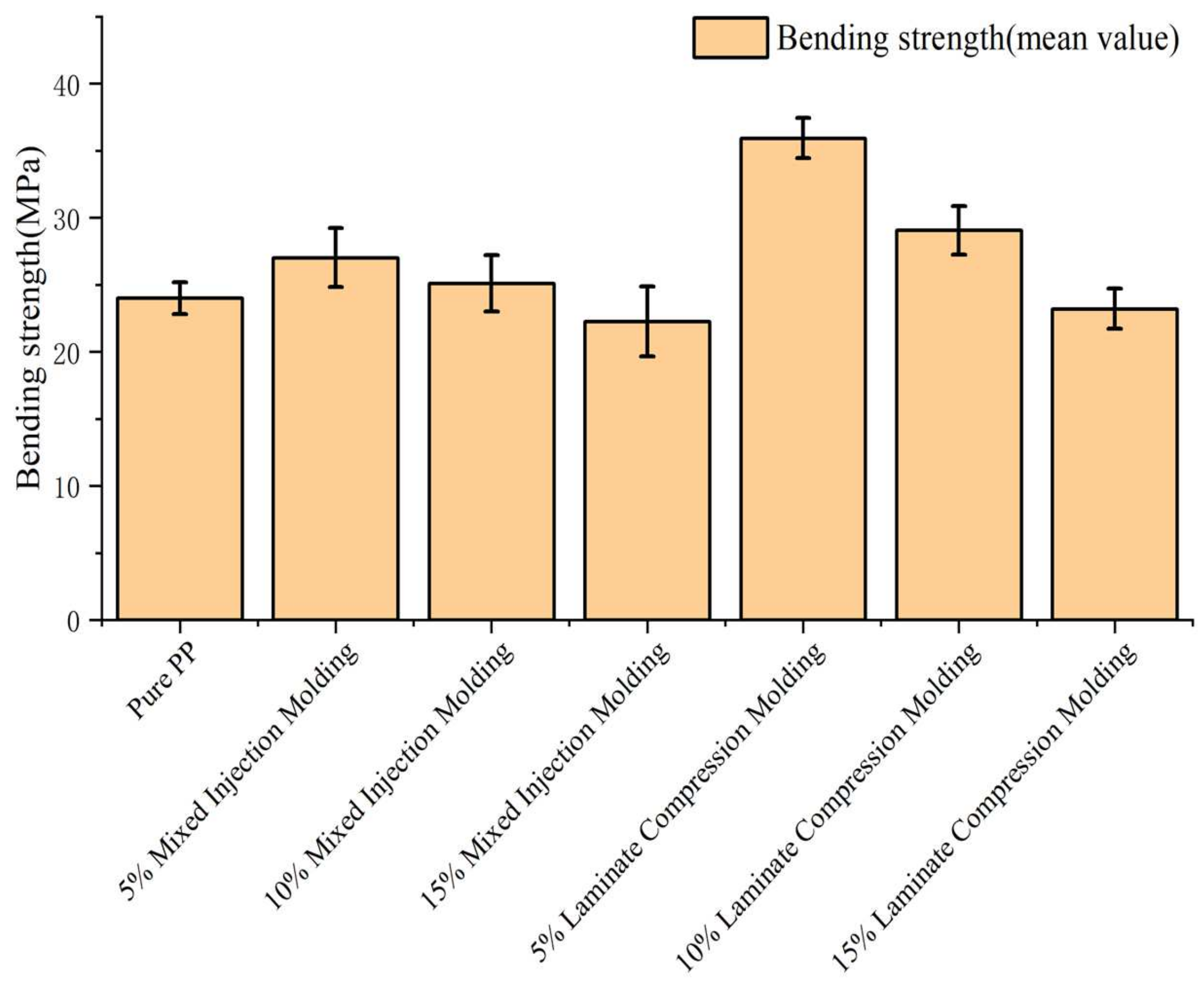

- Bending strength

- 2.

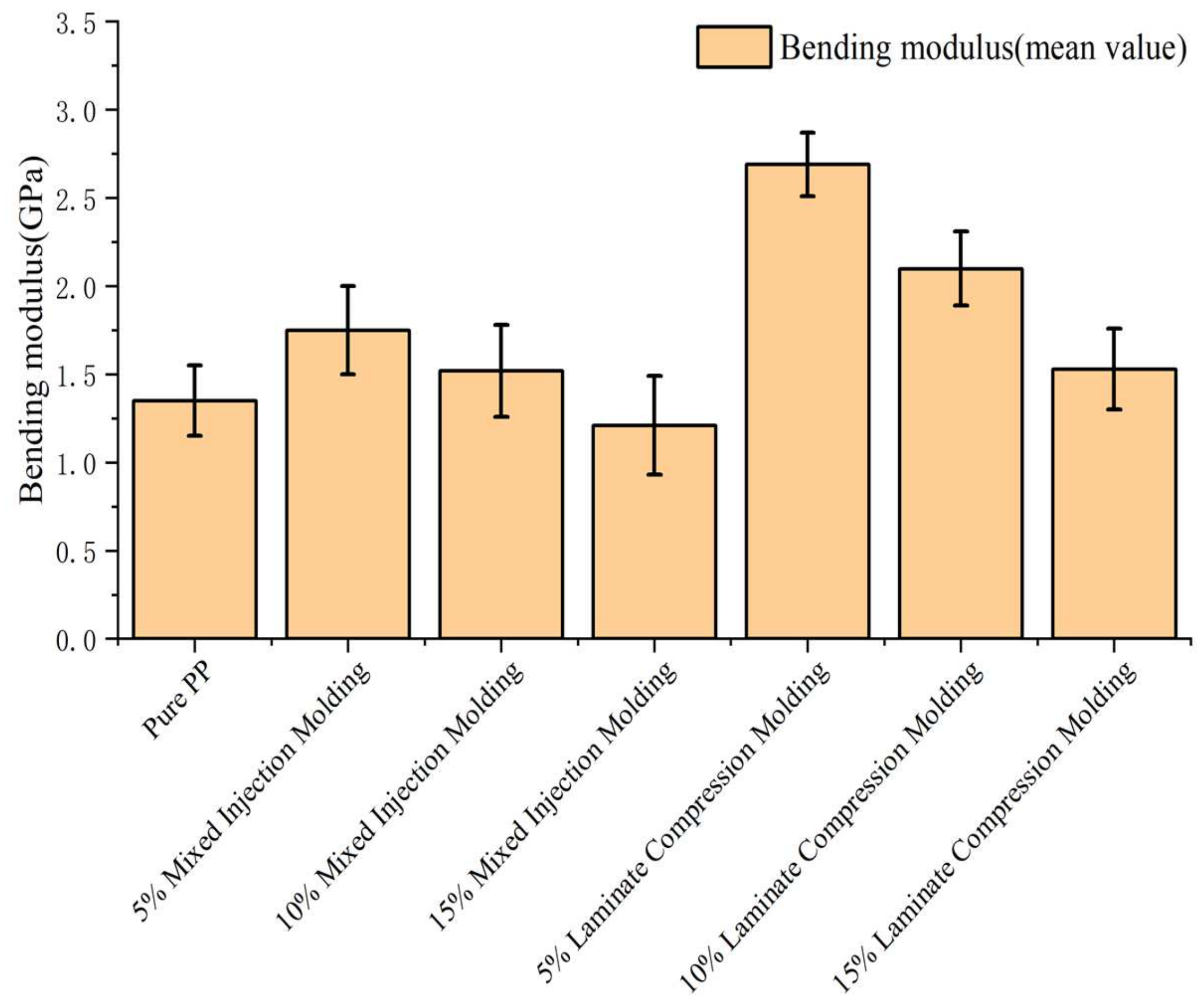

- Bending modulus

- 3.

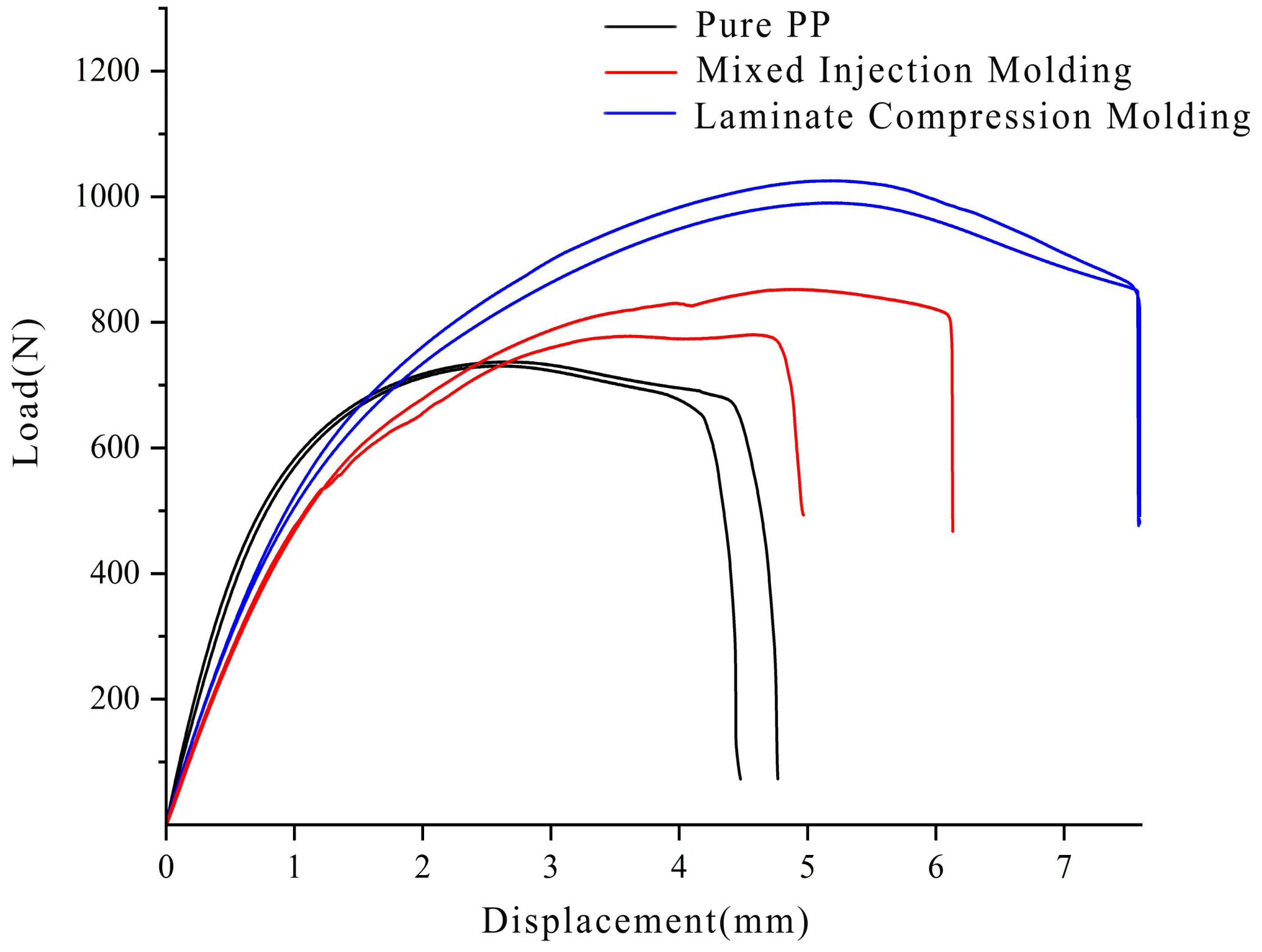

- Bending test curves of specimens

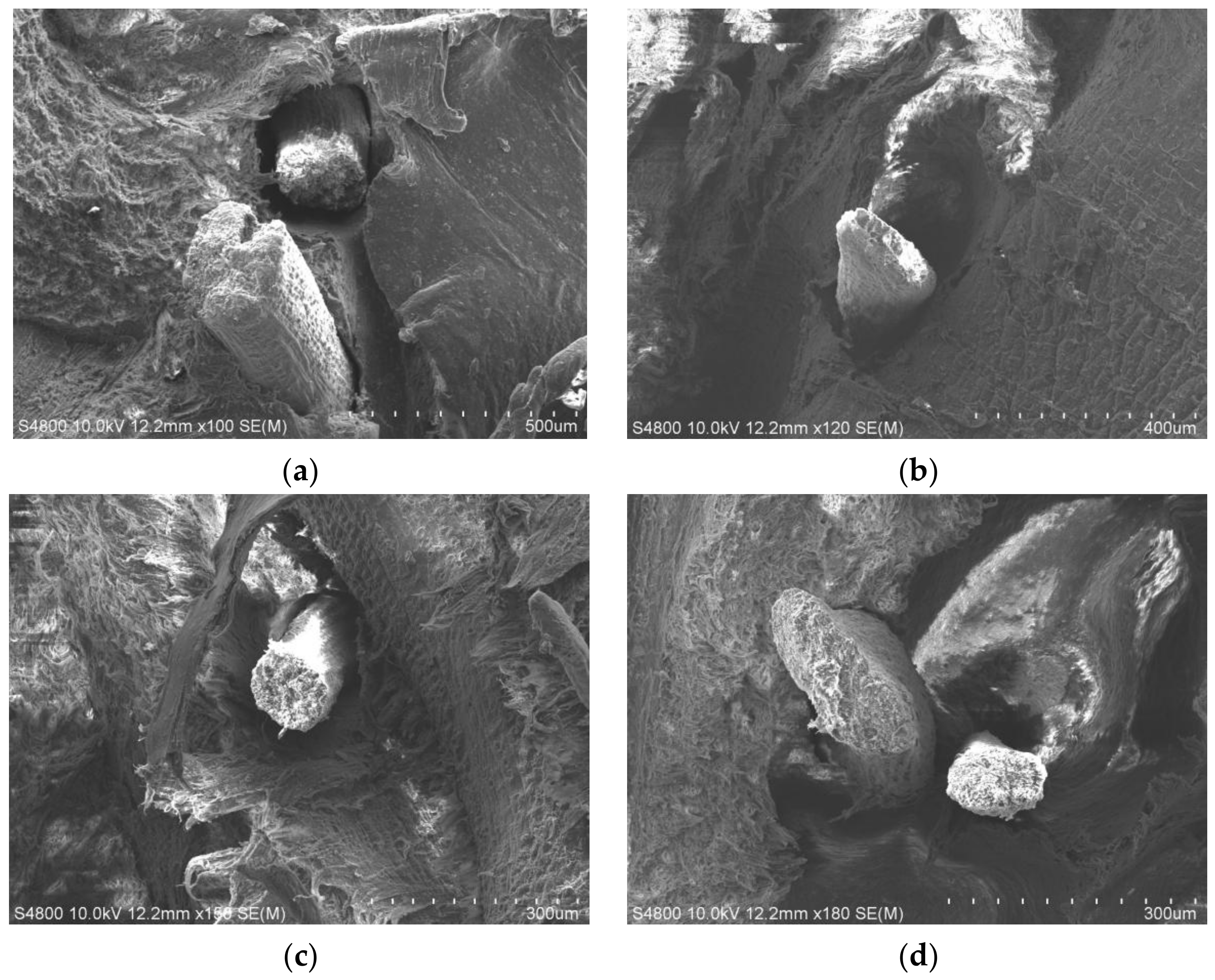

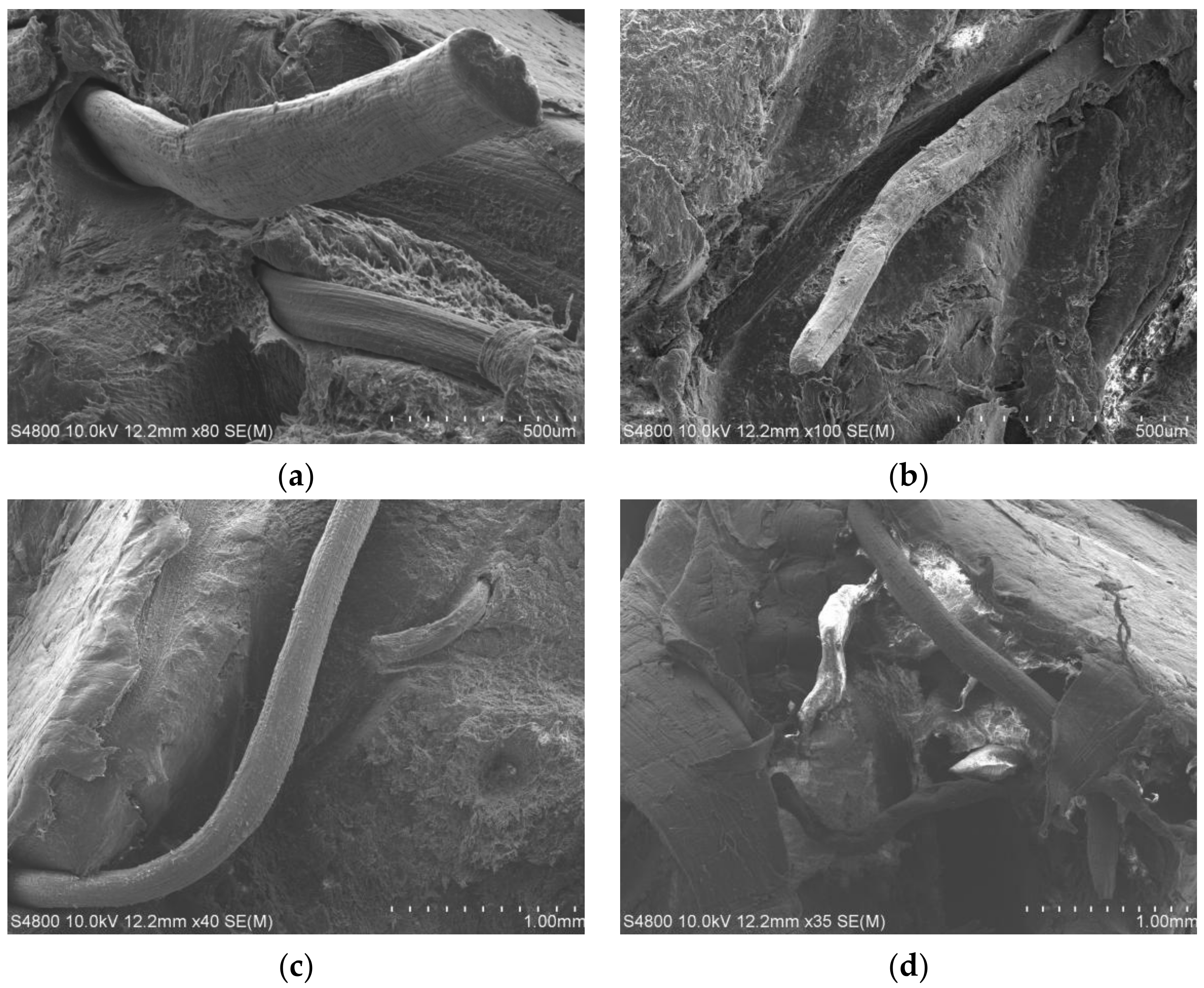

3.2. Scanning Electron Microscopy (SEM) Cross-Section Characterization Analysis

3.2.1. SEM Characterization Analysis of the Tensile Fracture Surface of Laminated Compression-Molded Composite Materials with 5% Coconut Fiber Content

3.2.2. SEM Characterization Analysis of the Tensile Fracture Surface of Injection-Molded Composite Materials with 5% Coconut Fiber Content

4. Finite-Element Analysis

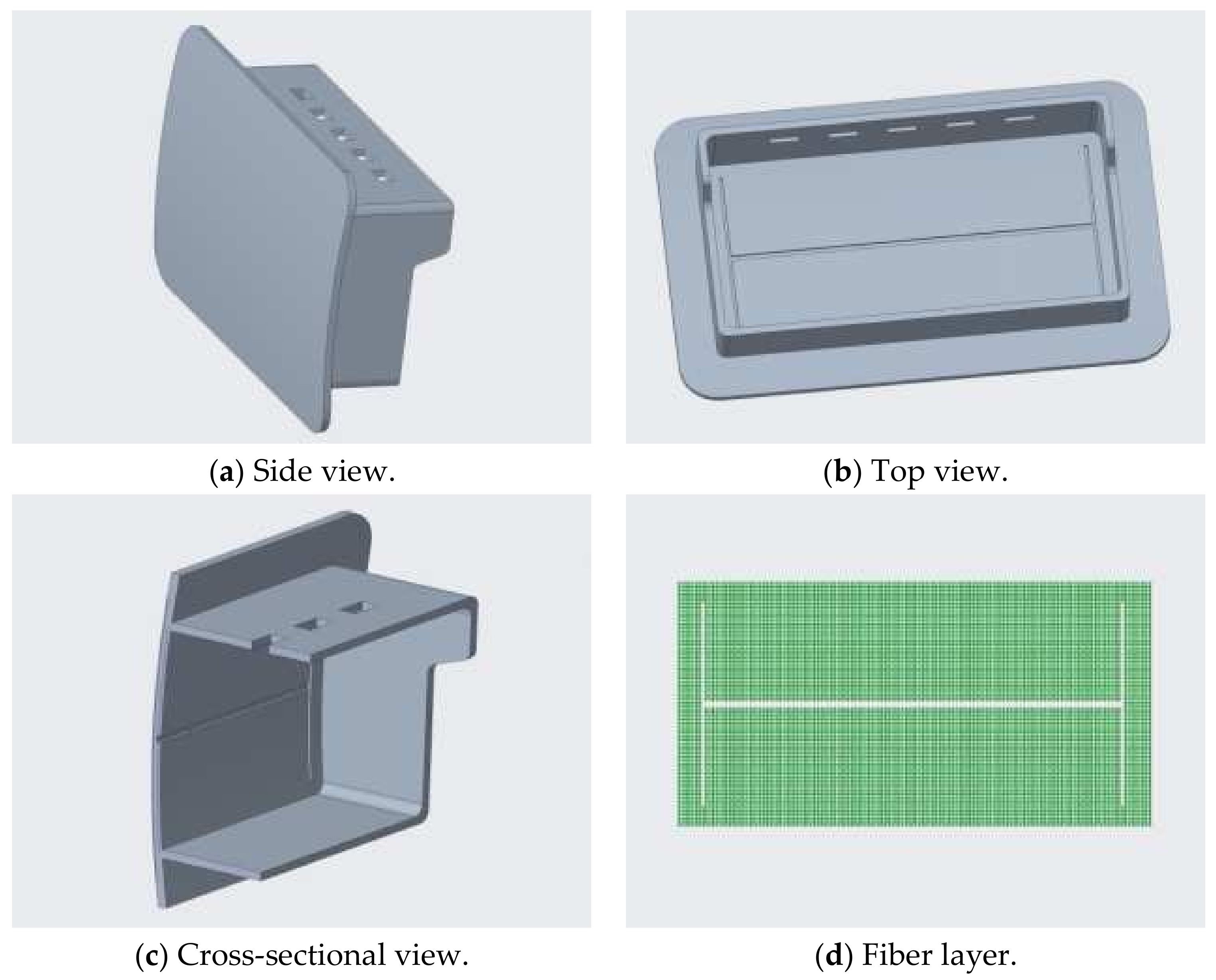

4.1. Airbag Cover Panel Modeling

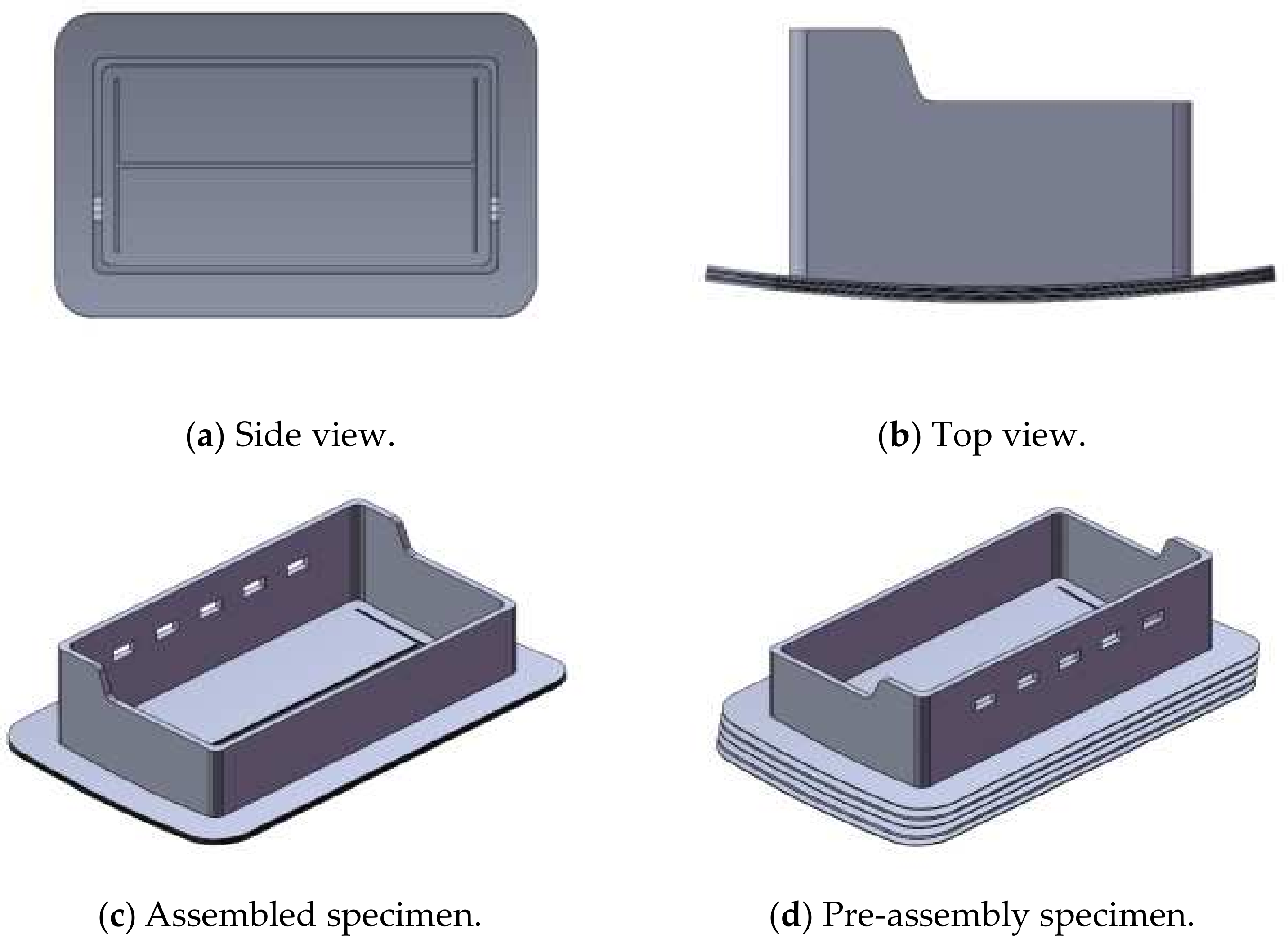

4.2. Simplified Airbag Cover Model

4.3. The Selection of Material Models and Element Types

4.4. Mesh Partitioning

4.5. Setting Up Contact, Constraints, and Applying Loads

4.6. Resolution and Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Czerwinski, F. Current trends in automotive lightweighting strategies and materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Maiti, S.; Islam, R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable fiber-reinforced composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Mohammadi, H.; Ahmad, Z.; Mazlan, S.A.; Johari, M.A.F.; Siebert, G.; Petrů, M.; Koloor, S.S.R. Lightweight glass fiber-reinforced polymer composite for automotive bumper applications: A review. Polymers 2022, 15, 193. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.V.; Pinheiro, I.F.; de Souza, S.F.; Mei, L.H.I.; Lona, L.M.F. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J. Thermoplast. Compos. Mater. 2024. online first. [Google Scholar] [CrossRef]

- Olhan, S.; Khatkar, V.; Behera, B.K. Textile-based natural fibre-reinforced polymeric composites in automotive lightweighting. J. Mater. Sci. 2021, 56, 18867–18910. [Google Scholar] [CrossRef]

- Kumar, S.; Saha, A. Utilization of coconut shell biomass residue to develop sustainable biocomposites and characterize the physical, mechanical, thermal, and water absorption properties. Biomass Convers. Biorefinery 2022, 14, 12815–12831. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Basri, M.S.M.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A review on natural fiber reinforced polymer composites (NFRPC) for sustainable industrial applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Oladele, I.O.; Adelani, S.O.; Makinde-Isola, B.A.; Omotosho, T.F. Coconut/coir fibers, their composites and applications. In Plant Fibers, Their Composites, and Applications; Woodhead Publishing: Cambridge, UK, 2022; pp. 181–208. [Google Scholar]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review. J. Thermoplast. Compos. Mater. 2020, 33, 978–1013. [Google Scholar] [CrossRef]

- Karthik, K.; Rajamanikkam, R.K.; Venkatesan, E.P.; Bishwakarma, S.; Krishnaiah, R.; Saleel, C.A.; Soudagar, M.E.M.; Kalam, M.; Ali, M.M.; Bashir, M.N. State of the Art: Natural Fibre-Reinforced Composites in Advanced Development and their Physical/Chemical/Mechanical Properties. Chin. J. Anal. Chem. 2024, 52, 100415. [Google Scholar] [CrossRef]

- Dev, B.; Rahman, A.; Alam, R.; Repon, R.; Nawab, Y. Mapping the progress in natural fiber reinforced composites: Preparation, mechanical properties, and applications. Polym. Compos. 2023, 44, 3748–3788. [Google Scholar] [CrossRef]

- Bhat, A.R.; Kumar, R.; Mural, P.K.S. Natural fiber reinforced polymer composites: A comprehensive review of tribo-mechanical properties. Tribol. Int. 2023, 189, 108978. [Google Scholar] [CrossRef]

- Dua, S.; Khatri, H.; Naveen, J.; Jawaid, M.; Jayakrishna, K.; Norrrahim, M.; Rashedi, A. Potential of natural fiber based polymeric composites for cleaner automotive component production—A comprehensive review. J. Mater. Res. Technol. 2023, 25, 1086–1104. [Google Scholar] [CrossRef]

- Söylemez, M.A.; Özer, K.; Ozer, D. Biofibers and Their Composites for Industrial Applications. In Handbook of Bioplastics and Biocomposites Engineering Applications; Wiley-Scrivener Publishing LLC: Beverly, MA, USA, 2023; pp. 513–538. [Google Scholar]

- Martinelli, F.R.B.; Ribeiro, F.R.C.; Marvila, M.T.; Monteiro, S.N.; Filho, F.d.C.G.; de Azevedo, A.R.G. A review of the use of coconut fiber in cement composites. Polymers 2023, 15, 1309. [Google Scholar] [CrossRef]

- Inegbedion, F.; Inegbedion, F.; Osasona, I.E. Coconut Fibre (Coir) Composites: A Review. J. Mater. Eng. Struct. Comput. 2024, 3, 15–30. [Google Scholar]

- Stelte, W.; Reddy, N.; Barsberg, S.; Sanadi, A.R. Coir from Coconut Processing Waste as a Raw Material for Applications Beyond Traditional Uses. BioResources 2023, 18, 49. [Google Scholar] [CrossRef]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, mechanical, and thermal properties of natural fiber-reinforced epoxy composites for construction and automotive applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Mou, Y.; Li, J.; Li, J.; Hong, S.; Ji, C. Feasibility study on the application of coconut shell fiber/PP composite material based on Abaqus in automotive airbag cover plates. Plast. Technol. 2020, 48, 94–97. [Google Scholar]

- Mosi, G.; Ikua, B.; Kabini, S.; Mwangi, J. Characterization and Modeling of Mechanical Properties of Additively Manufactured Coconut Fiber-Reinforced Polypropylene Composites. Adv. Mater. Phys. Chem. 2024, 14, 95–112. [Google Scholar] [CrossRef]

- Simamora, P.; Simanjuntak, J.; Sinulingga, K.; Laksono, A.D. Mechanical Properties of Polypropylene Composites with Different Reinforced Natural Fibers—A Comparative Study. J. Ecol. Eng. 2023, 24, 311–317. [Google Scholar] [CrossRef] [PubMed]

- do Nascimento, E.P.; Luna, C.B.B.; Ferreira, E.D.S.B.; dos Santos Filho, E.A.; Siqueira, D.D.; Wellen, R.M.R.; Araújo, E.M. Extraction of natural fibers of Catole coconut (Syagrus Cearensis, application as reinforcing filler in polypropylene-based composites. Polym. Compos. 2023, 44, 5891–5909. [Google Scholar] [CrossRef]

- Yusuf, Y.; Mustafa, N.; Mastura, M.T.; Latip, M.A.M.; Hadi, S.D. Development of 3D Printing Filament Material Using Recycled Polypropylene (rPP) Reinforced with Coconut Fiber. In Additive Manufacturing for Biocomposites and Synthetic Composites; CRC Press: Boca Raton, FL, USA, 2023; pp. 59–75. [Google Scholar]

- Maurya, A.K.; Manik, G. Advances towards development of industrially relevant short natural fiber reinforced and hybridized polypropylene composites for various industrial applications: A review. J. Polym. Res. 2023, 30, 47. [Google Scholar] [CrossRef]

- James, R.M.S.; Gisip, J.; Mohd Yusof, N. Effect of chemical treatment on physical and mechanical properties of coir fibre-polypropylene composites. Sci. Res. J. 2023, 20, 145–157. [Google Scholar]

- Balogun, O.A.; Daramola, O.O.; Adediran, A.A.; Akinwande, A.A.; Bello, O.S. reinforced polypropylene composites for automobile application: Mechanical, wear and flow properties. Alex. Eng. J. 2023, 65, 327–341. [Google Scholar] [CrossRef]

- Kaliappan, S.; Natrayan, L. Polypropylene Composite Materials with Natural Fiber Reinforcement: An Acoustic and Mechanical Analysis for Automotive Implementations; SAE Technical Paper No. 2023-01-5130; SAE International: Warrendale, PA, USA, 2024. [Google Scholar]

- GB/T 1040.1-2018; Determination of Tensile Properties of Plastics Part 1: General Principles. China National Standardization Administration: Beijing, China, 2008.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohohoken, PA, USA, 1995; pp. 99–109.

- Yang, Y.; Zhang, H.; Liu, X.; Deng, Y.; Sun, M.; Wang, J.; Cui, Y.; Pan, L.; Chen, Z. Hierarchical interface design of jute fibers/polypropylene composites for enhanced interfacial and mechanical properties. J. Clean. Prod. 2024, 450, 141966. [Google Scholar] [CrossRef]

- Müller, V.; Brylka, B.; Dillenberger, F.; Glöckner, R.; Kolling, S.; Böhlke, T. Homogenization of elastic properties of short-fiber reinforced composites based on measured microstructure data. J. Compos. Mater. 2016, 50, 297–312. [Google Scholar] [CrossRef]

- Tenek, L.T.; Argyris, J. Finite Element Analysis for Composite Structures; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Hao, W.; Liu, C.; Shen, H. Application Examples of ANSYS in Civil Engineering; China Water & Power Press: Beijing, China, 2005; pp. 14–23. [Google Scholar]

- Maurya, A. Study of Mechanical Properties of Coconut Coir Fiber Reinforced Epoxy Biocomposite. Master’s Thesis, Integral University, Lucknow, India, 2021. [Google Scholar]

- Cheng, Y.; Li, Y.; Yang, C. The design of an airbag automatic inflator and the simulation analysis of airbag in the unfolding process. In Proceedings of the 2020 5th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Harbin, China, 25–27 December 2020; IEEE: Toulouse, France, 2020; pp. 961–965. [Google Scholar]

| The Length of the Cover Panel | The Width of the Cover Panel | The Length of the Airbag Compartment | The Width of the Airbag Compartment | The Height of the Highest Point of the Airbag Compartment | The Height of the Lowest Point of the Airbag Compartment | The Thickness of the Airbag Cover Panel |

|---|---|---|---|---|---|---|

| 250.02 mm | 158.46 mm | 210.02 mm | 112.08 mm | 65.39 mm | 45.93 mm | 4 mm |

| Tensile Strength/MPa | Tensile Modulus/GPa | Bending Strength/MPa | Bending Modulus/GPa | |

|---|---|---|---|---|

| Pure PP material | 18.25 | 1.32 | 24 | 1.35 |

| 5% Stacked Compression Molding | 25.12 | 1.17 | 35.94 | 2.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhou, Y.; Chen, J.; Hu, H.; Sun, M. A Comparative Study of Airbag Covers for Automotive Safety Using Coconut Shell Fiber/PP Composite Materials. J. Compos. Sci. 2024, 8, 328. https://doi.org/10.3390/jcs8080328

Li J, Zhou Y, Chen J, Hu H, Sun M. A Comparative Study of Airbag Covers for Automotive Safety Using Coconut Shell Fiber/PP Composite Materials. Journal of Composites Science. 2024; 8(8):328. https://doi.org/10.3390/jcs8080328

Chicago/Turabian StyleLi, Jinsong, You Zhou, Jiatao Chen, Hongtao Hu, and Mingze Sun. 2024. "A Comparative Study of Airbag Covers for Automotive Safety Using Coconut Shell Fiber/PP Composite Materials" Journal of Composites Science 8, no. 8: 328. https://doi.org/10.3390/jcs8080328

APA StyleLi, J., Zhou, Y., Chen, J., Hu, H., & Sun, M. (2024). A Comparative Study of Airbag Covers for Automotive Safety Using Coconut Shell Fiber/PP Composite Materials. Journal of Composites Science, 8(8), 328. https://doi.org/10.3390/jcs8080328