The Development of Sustainable Polyoxymethylene (POM)-Based Composites by the Introduction of Natural Fillers and Melt Blending with Poly(lactic acid)-PLA

Abstract

1. Introduction

- -

- A lack of effective methods for separating composted polymers from traditional materials;

- -

- Requirements for the conditions of an effective composting process;

- -

- The use of prooxidative additives with traditional thermoplastics (PE/PP) instead of compostable polymers;

- -

- Difficulties in the recycling procedure due to a lack of compatibility/miscibility with traditional polymers;

- -

- A lack of sufficient functional properties to replace petroleum-based materials.

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

3. Results

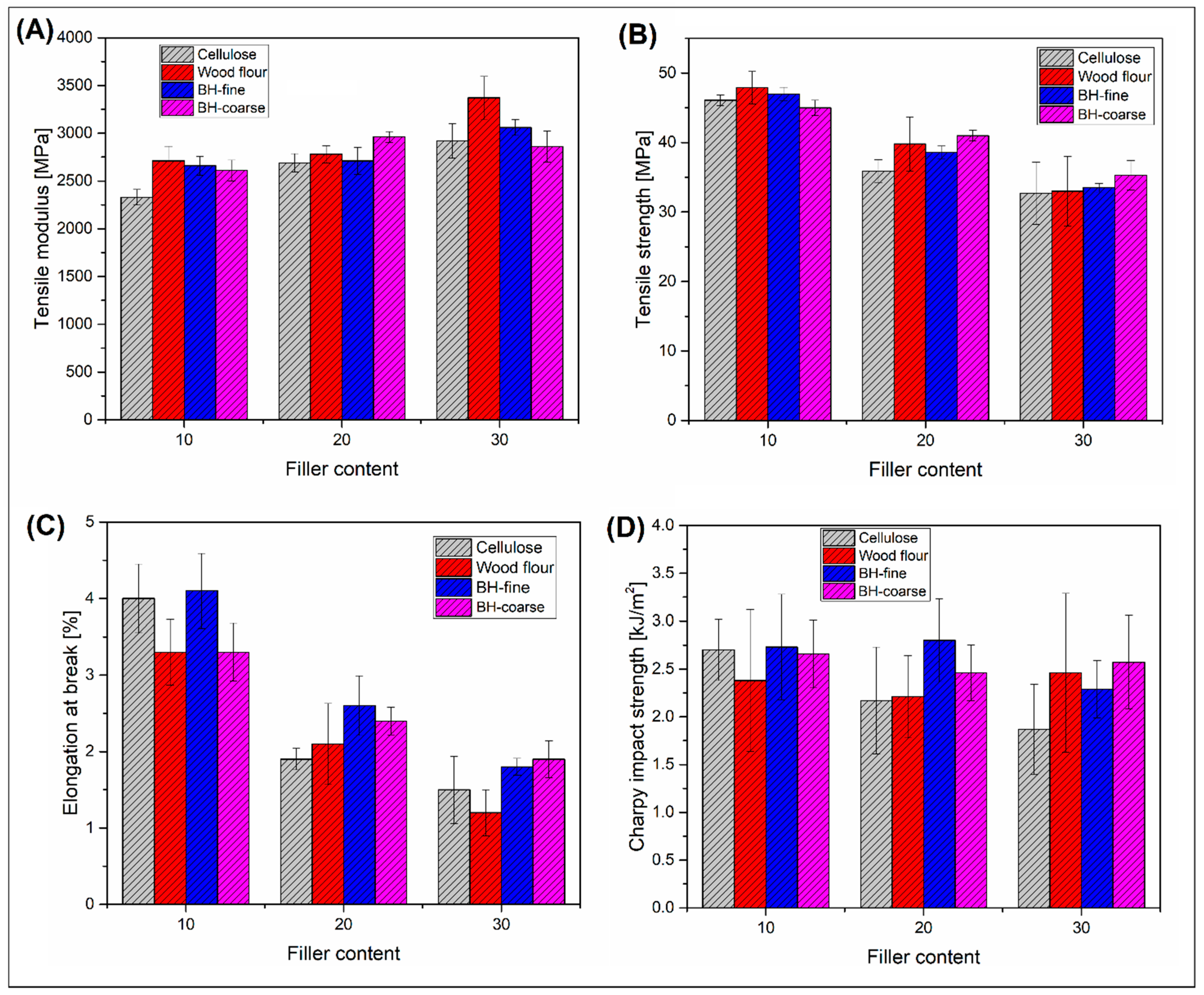

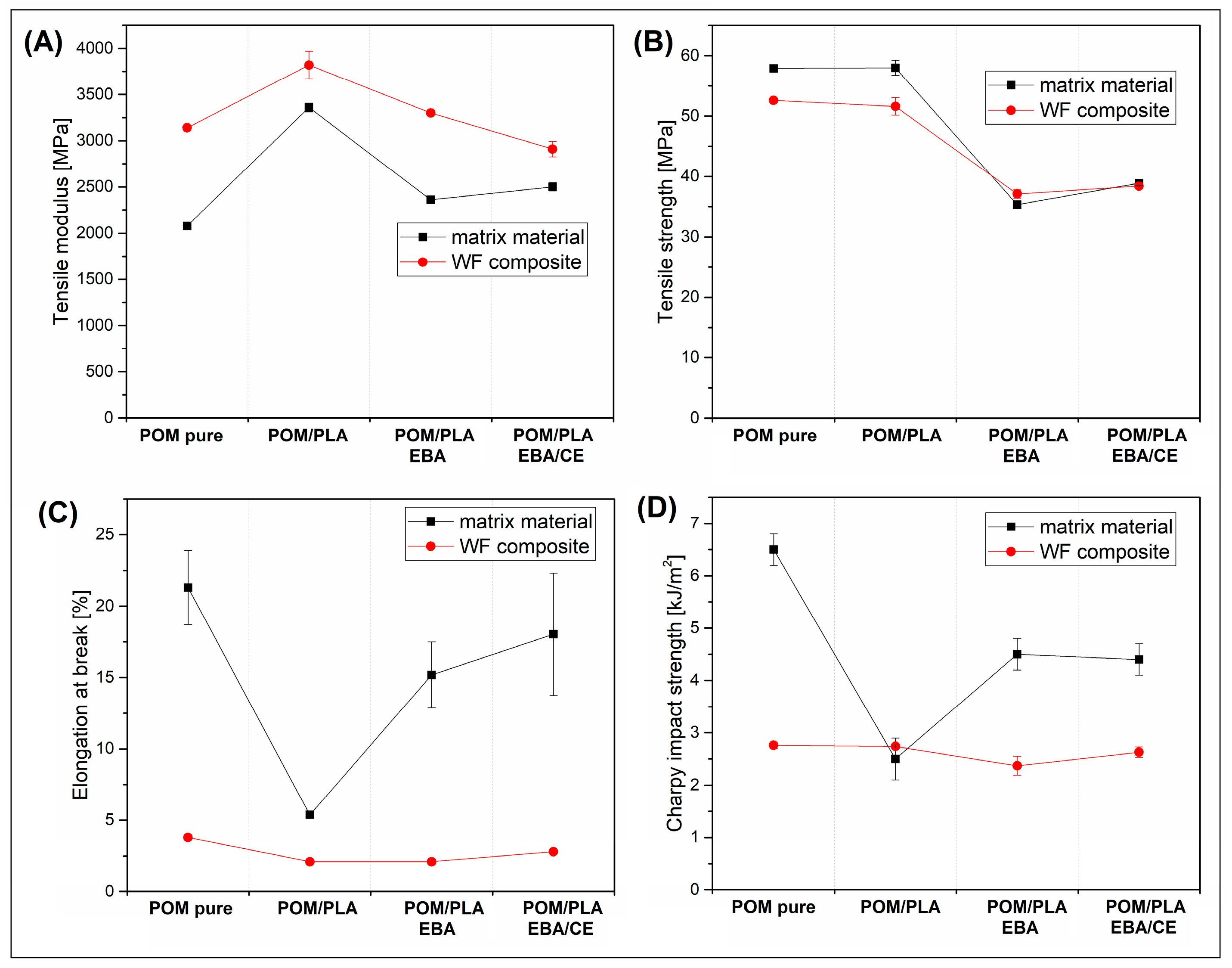

3.1. Mechanical Performance Evaluation—Static Tensile Tests, Charpy Impact Resistance

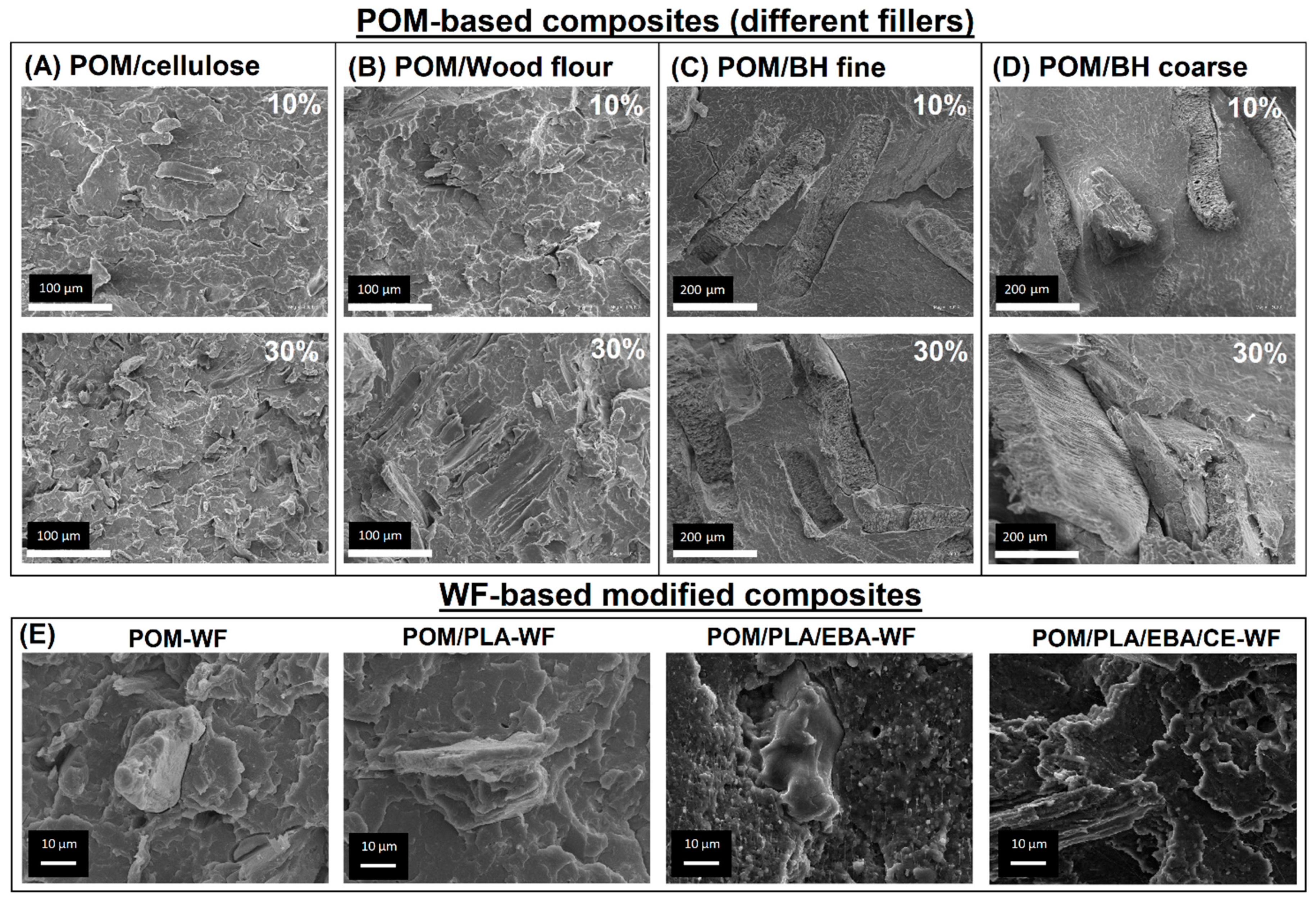

3.2. Structure Evaluation—Scanning Electron Microscopy Observations

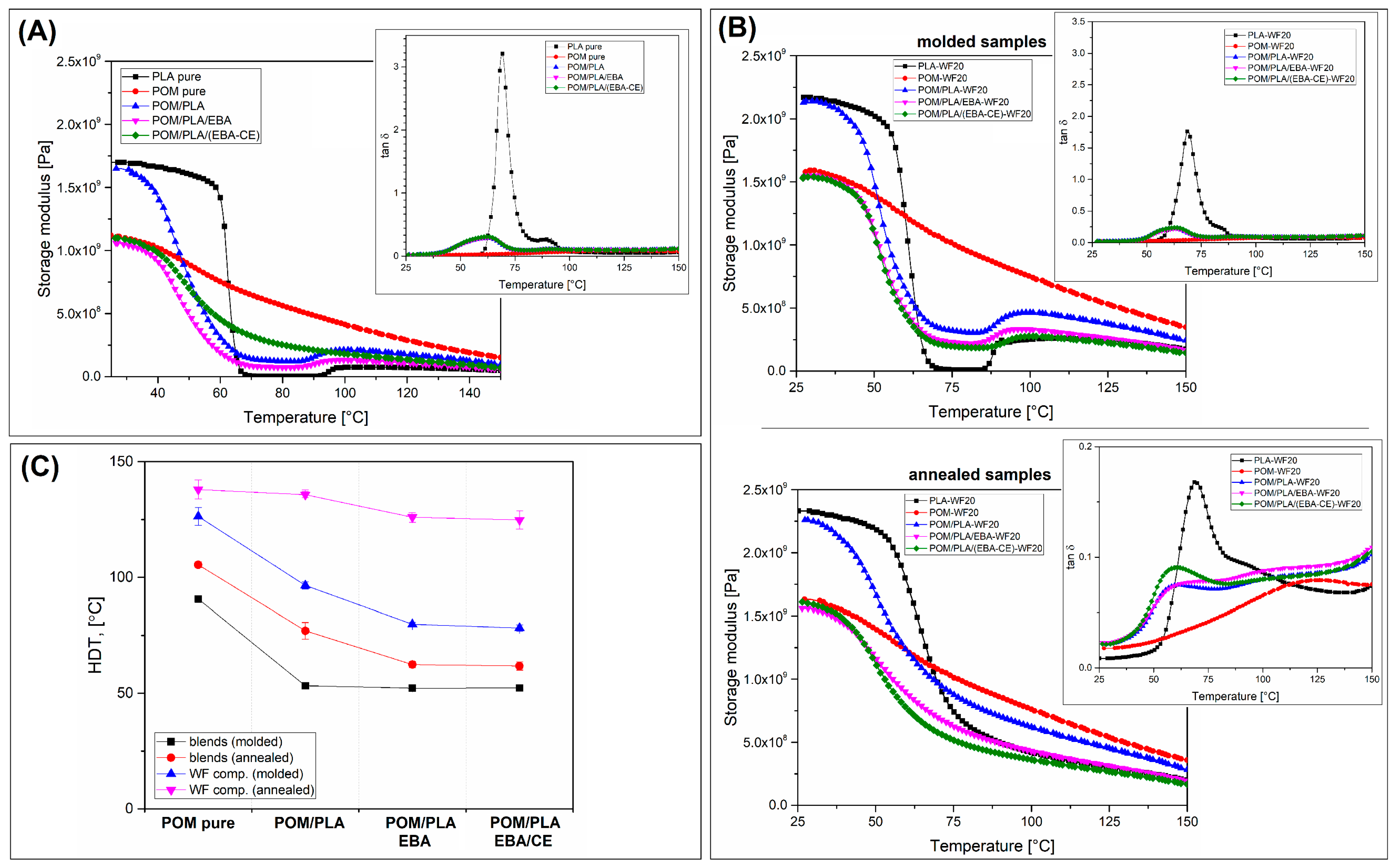

3.3. Thermomechanical Properties—Dynamic Mechanical Thermal Analysis (DMTA), Heat Deflection Temperature (HDT)

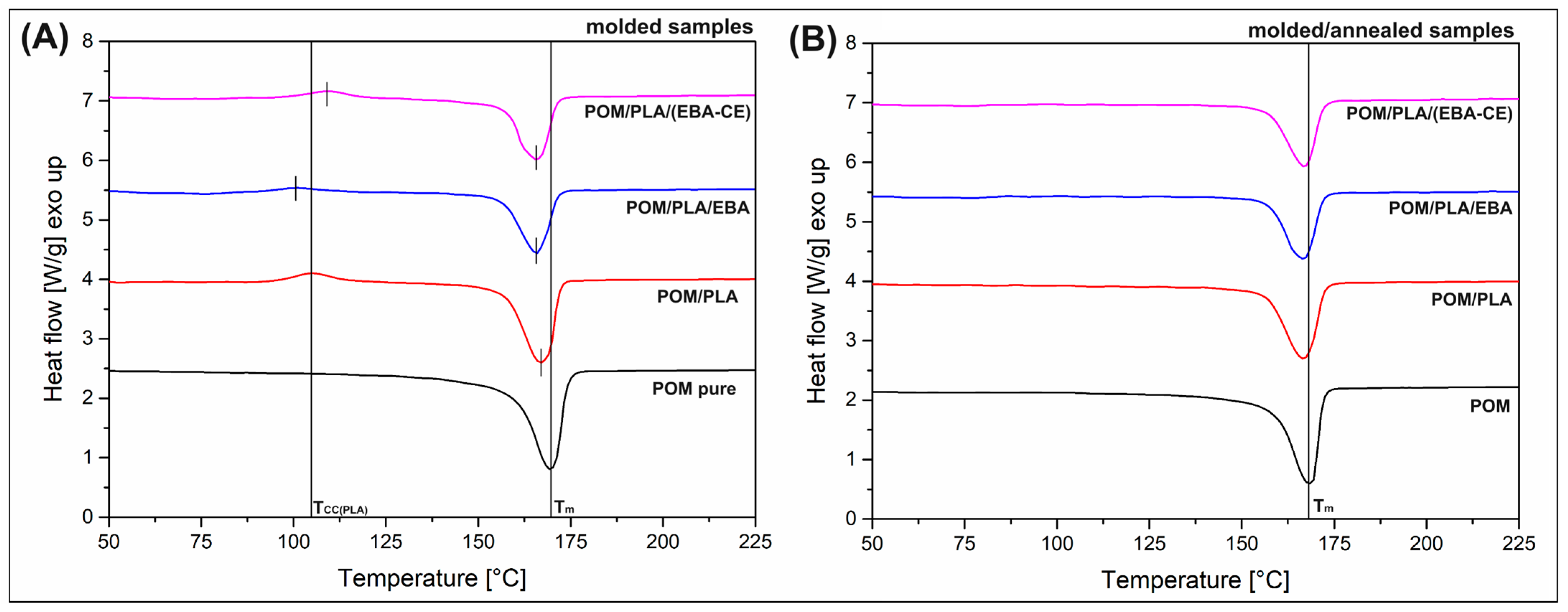

3.4. Thermal Behavior and Phase Transition Changes for POM/PLA Blends—Differential Scanning Calorimetry Analysis (DSC)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Díaz, S.; Ortega, Z.; McCourt, M.; Kearns, M.P.; Benítez, A.N. Recycling of Polymeric Fraction of Cable Waste by Rotational Moulding. Waste Manag. 2018, 76, 199–206. [Google Scholar] [CrossRef] [PubMed]

- Grigorescu, R.M.; Ghioca, P.; Iancu, L.; David, M.E.; Andrei, E.R.; Filipescu, M.I.; Ion, R.-M.; Vuluga, Z.; Anghel, I.; Sofran, I.-E.; et al. Development of Thermoplastic Composites Based on Recycled Polypropylene and Waste Printed Circuit Boards. Waste Manag. 2020, 118, 391–401. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in the EU: Recovery Rates, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, V.; Biswal, M.; Mohanty, S.; Nayak, S.K. Recycling of Engineering Plastics from Waste Electrical and Electronic Equipments: Influence of Virgin Polycarbonate and Impact Modifier on the Final Performance of Blends. Waste Manag. Res. 2014, 32, 379–388. [Google Scholar] [CrossRef] [PubMed]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2015, 31, 378–392. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K. Sustainability Design of Plastic Packaging for the Circular Economy. Polimery 2020, 65, 8–17. [Google Scholar] [CrossRef]

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods 2021, 10, 2702. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef]

- Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Polyethylene Terephthalate Based Multilayer Food Packaging: Deterioration Effects during Mechanical Recycling. Food Packag. Shelf Life 2022, 33, 100890. [Google Scholar] [CrossRef]

- Evans, D.M.; Parsons, R.; Jackson, P.; Greenwood, S.; Ryan, A. Understanding Plastic Packaging: The Co-Evolution of Materials and Society. Glob. Environ. Chang. 2020, 65, 102166. [Google Scholar] [CrossRef]

- Evens, T.; Bex, G.J.; Yigit, M.; De Keyzer, J.; Desplentere, F.; Van Bael, A. The Influence of Mechanical Recycling on Properties in Injection Molding of Fiber-Reinforced Polypropylene. Int. Polym. Process. 2019, 34, 398–407. [Google Scholar] [CrossRef]

- Jubinville, D.; Chang, B.P.; Pin, J.M.; Mohanty, A.K.; Misra, M. Synergistic Thermo-Oxidative Maleation of PA11 as Compatibilization Strategy for PA6 and PBT Blend. Polymers 2019, 179, 121594. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Sustainable Biocomposites from Biobased Polyamide 6,10 and Biocarbon from Pyrolyzed Miscanthus Fibers. J. Appl. Polym. Sci. 2017, 134, 5633. [Google Scholar] [CrossRef]

- Watt, E.; Abdelwahab, M.A.; Mohanty, A.K.; Misra, M. Biocomposites from Biobased Polyamide 4,10 and Waste Corn Cob Based Biocarbon. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106340. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(Ethylene Terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef] [PubMed]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA Composites: From Production to Properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Gironi, F.; Piemonte, V. Bioplastics and Petroleum-Based Plastics: Strengths and Weaknesses. Energy Sources Part A Recovery Util. Environ. Eff. 2011, 33, 1949–1959. [Google Scholar] [CrossRef]

- Aging, T.; Panowicz, R.; Konarzewski, M.; Durejko, T.; Szala, M.; Łazi, M. Properties of Polyethylene Terephthalate (PET) after Thermo-Oxidative Aging. Materials 2021, 14, 3833. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future Trends of Plastic Bottle Recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of Glass Fibre Reinforced Polymer (GFRP) Composite Wastes in Concrete: A Critical Review and Cost Benefit Analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Kennerley, J.R.; Kelly, R.M.; Fenwick, N.J.; Pickering, S.J.; Rudd, C.D. The Characterisation and Reuse of Glass Fibres Recycled from Scrap Composites by the Action of a Fluidised Bed Process. Compos. Part A Appl. Sci. Manuf. 1998, 29, 839–845. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent Progress in Recycling Carbon Fibre Reinforced Composites and Dry Carbon Fibre Wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Chen, R.; Misra, M.; Mohanty, A.K. Injection-Moulded Biocomposites from Polylactic Acid (PLA) and Recycled Carbon Fibre: Evaluation of Mechanical and Thermal Properties. J. Thermoplast. Compos. Mater. 2014, 27, 1286–1300. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Girones, J.; Vo, L.T.T.; Di Giuseppe, E.; Navard, P. Natural Filler-Reinforced Composites: Comparison of Reinforcing Potential among Technical Fibers, Stem Fragments and Industrial by-Products. Cellul. Chem. Technol. 2017, 51, 839–855. [Google Scholar]

- Thakur, V.K.; Thakur, M.K. Processing and Characterization of Natural Cellulose Fibers/Thermoset Polymer Composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Vadori, R.; Misra, M.; Mohanty, A.K. Sustainable Biobased Blends from the Reactive Extrusion of Polylactide and Acrylonitrile Butadiene Styrene. J. Appl. Polym. Sci. 2016, 133, 43771. [Google Scholar] [CrossRef]

- Vadori, R.; Misra, M.; Mohanty, A.K. Statistical Optimization of Compatibilized Blends of Poly(Lactic Acid) and Acrylonitrile Butadiene Styrene. J. Appl. Polym. Sci. 2017, 134, 44516. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel Biocomposites from Biobased PC/PLA Blend Matrix System for Durable Applications. Compos. B Eng. 2017, 130, 158–166. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel Super-Toughened Bio-Based Blend from Polycarbonate and Poly(Lactic Acid) for Durable Applications. RSC Adv. 2016, 6, 105094–105104. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Hydrolytic Stability of Polycarbonate/Poly(Lactic Acid) Blends and Its Evaluation via Poly(Lactic) Acid Median Melting Point Depression. Polym. Degrad. Stab. 2016, 134, 227–236. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Tuning the Compatibility to Achieve Toughened Biobased Poly(Lactic Acid)/Poly(Butylene Terephthalate) Blends. RSC Adv. 2018, 8, 27709–27724. [Google Scholar] [CrossRef] [PubMed]

- Padee, S.; Thumsorn, S.; On, J.W.; Surin, P.; Apawet, C.; Chaichalermwong, T.; Kaabbuathong, N.; O-Charoen, N.; Srisawat, N. Preparation of Poly(Lactic Acid) and Poly(Trimethylene Terephthalate) Blend Fibers for Textile Application. Energy Procedia 2013, 34, 534–541. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Skórczewska, K.; Klozinski, A. Improving the Toughness and Thermal Resistance of Polyoxymethylene/Poly(Lactic Acid) Blends: Evaluation of Structure-Properties Correlation for Reactive Processing. Polymers 2020, 12, 307. [Google Scholar] [CrossRef] [PubMed]

- Andrzejewski, J.; Tutak, N.; Szostak, M. Polypropylene Composites Obtained from Self-Reinforced Hybrid Fiber System. J. Appl. Polym. Sci. 2016, 133, 43283. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection Molding of Highly Filled Polypropylene-Based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization. Polymers 2019, 11, 1881. [Google Scholar] [CrossRef]

- Zemnukhova, L.A.; Shkorina, E.D.; Fedorishcheva, G.A. Composition of Inorganic Components of Buckwheat Husk and Straw. Russ. J. Appl. Chem. 2005, 78, 324–328. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Krawczak, A.; Wesoły, K.; Szostak, M. Rotational Molding of Biocomposites with Addition of Buckwheat Husk Filler. Structure-Property Correlation Assessment for Materials Based on Polyethylene (PE) and Poly(Lactic Acid) PLA. Compos. B Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- ISO 527-1; Plastics—Determination of Tensile Properties. ISO-Committee: Geneva, Switzerland, 2012.

- ISO 180; Plastics—Determination of Izod Impact Strength. ISO-Committee: Geneva, Switzerland, 2019.

- ISO 75; Plastics—Determination of Temperature of Deflection under Load. ISO-Committee: Geneva, Switzerland, 2013.

- Kuciel, S.; Bazan, P.; Liber-Kneć, A.; Gadek-Moszczak, A. Physico-Mechanical Properties of the Poly(Oxymethylene) Composites Reinforced with Glass Fibers under Dynamical Loading. Polymers 2019, 11, 2064. [Google Scholar] [CrossRef] [PubMed]

- Kufel, A.; Para, S.; Kuciel, S. Basalt/Glass Fiber Polypropylene Hybrid Composites: Mechanical Properties at Different Temperatures and under Cyclic Loading and Micromechanical Modelling. Materials 2021, 14, 5574. [Google Scholar] [CrossRef]

- Kneissl, L.M.; Gonçalves, G.; Joffe, R.; Kalin, M.; Emami, N. Mechanical Properties and Tribological Performance of Polyoxymethylene/Short Cellulose Fiber Composites. Polym. Test. 2023, 128, 108234. [Google Scholar] [CrossRef]

- Liu, G.R. A Step-by-Step Method of Rule-of-Mixture of Fiber- and Particle-Reinforced Composite Materials. Compos. Struct. 1997, 40, 313–322. [Google Scholar] [CrossRef]

- Gozdecki, C. Application of the Modified Hybrid Rule of Mixture (ROHM) and Halpin-Tsai Equation for Predicting Mechanical Properties of Wood/Hemp/Polymer Composites. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2019, 106, 4–8. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, W.; Wang, Q.; Wang, H. Application of Mechanical Models to Flax Fiber /Wood/ Plastic Composites. Bioresources 2013, 8, 3276–3288. [Google Scholar] [CrossRef]

- Xu, H.; Yang, Y.; Li, L.; Liu, B.; Fu, X.; Yang, X.; Cao, Y. Mechanical Properties Variation in Wood—Plastic Composites with a Mixed Wood Fiber Size. Materials 2023, 16, 5801. [Google Scholar] [CrossRef] [PubMed]

- Król-Morkisz, K.; Karaś, E.; Majka, T.M.; Pielichowski, K.; Pielichowska, K. Thermal Stabilization of Polyoxymethylene by PEG-Functionalized Hydroxyapatite: Examining the Effects of Reduced Formaldehyde Release and Enhanced Bioactivity. Adv. Polym. Technol. 2019, 2019, 8637. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Gapiński, B.; Islam, A.; Szostak, M. The Influence of the Hybridization Process on the Mechanical and Thermal Properties of Polyoxymethylene (POM) Composites with the Use of a Novel Sustainable Reinforcing System Based on Biocarbon and Basalt Fiber (BC/BF). Materials 2020, 13, 3496. [Google Scholar] [CrossRef] [PubMed]

- Slezák, E.; Ronkay, F.; Bocz, K. Development of an Engineering Material with Increased Impact Strength and Heat Resistance from Recycled PET. J. Polym. Environ. 2023, 31, 5296–5308. [Google Scholar] [CrossRef]

- Chen, Q.; Shan, P.; Tong, C.; Yan, D.; Zhang, Y.; Liu, H.; Hao, C. Influence of Reactive Blending Temperature on Impact Toughness and Phase Morphologies of PLA Ternary Blend System Containing Magnesium Ionomer. J. Appl. Polym. Sci. 2019, 136, 47682. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. A New Approach to Supertough Poly(Lactic Acid): A High Temperature Reactive Blending. Macromol. Mater. Eng. 2016, 301, 1443–1453. [Google Scholar] [CrossRef]

- Poletto, M. Natural Oils as Coupling Agents in Recycled Polypropylene Wood Flour Composites: Mechanical, Thermal and Morphological Properties. Polym. Polym. Compos. 2020, 28, 443–450. [Google Scholar] [CrossRef]

- Sohn, J.S.; Cha, S.W. Effect of Chemical Modification on Mechanical Properties of Wood-Plastic Composite Injection-Molded Parts. Polymers 2018, 10, 1391. [Google Scholar] [CrossRef] [PubMed]

- Seo, Y.R.; Bae, S.U.; Gwon, J.; Wu, Q.; Kim, B.J. Effects of Methylenediphenyl 4,4′-Diisocyanate and Maleic Anhydride as Coupling Agents on the Properties of Polylactic Acid/Polybutylene Succinate/Wood Flour Biocomposites by Reactive Extrusion. Materials 2020, 13, 1660. [Google Scholar] [CrossRef] [PubMed]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent Progresses in Wood-Plastic Composites: Pre-Processing Treatments, Manufacturing Techniques, Recyclability and Eco-Friendly Assessment. Clean Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Zong, G.; Hao, X.; Hao, J.; Tang, W.; Fang, Y.; Ou, R.; Wang, Q. High-Strength, Lightweight, Co-Extruded Wood Flour-Polyvinyl Chloride/Lumber Composites: Effects of Wood Content in Shell Layer on Mechanical Properties, Creep Resistance, and Dimensional Stability. J. Clean Prod. 2020, 244, 118860. [Google Scholar] [CrossRef]

- Kfoury, G.; Raquez, J.-M.; Hassouna, F.; Odent, J.; Toniazzo, V.; Ruch, D.; Dubois, P. Recent Advances in High Performance Poly(Lactide): From “Green” Plasticization to Super-Tough Materials via (Reactive) Compounding. Front. Chem. 2013, 1, 32. [Google Scholar] [CrossRef]

- Pluta, M.; Piorkowska, E. Tough and Transparent Blends of Polylactide with Block Copolymers of Ethylene Glycol and Propylene Glycol. Polym. Test. 2015, 41, 209–218. [Google Scholar] [CrossRef]

- Zhang, K.; Nagarajan, V.; Misra, M.; Mohanty, A.K. Supertoughened Renewable PLA Reactive Multiphase Blends System: Phase Morphology and Performance. ACS Appl. Mater. Interfaces 2014, 6, 12436–12448. [Google Scholar] [CrossRef]

- Qiu, J.; Xing, C.; Cao, X.; Wang, H.; Wang, L.; Zhao, L.; Li, Y. Miscibility and Double Glass Transition Temperature Depression of Poly(L-Lactic Acid) (PLLA)/Poly(Oxymethylene) (POM) Blends. Macromolecules 2013, 46, 5806–5814. [Google Scholar] [CrossRef]

- Ye, L.; Qiu, J.; Wu, T.; Shi, X.; Li, Y. Banded Spherulite Templated Three-Dimensional Interpenetrated Nanoporous Materials. RSC Adv. 2014, 4, 43351–43356. [Google Scholar] [CrossRef]

- Mathurosemontri, S.; Thumsorn, S.; Hiroyuki, H. Tensile Properties Modification of Ductile Polyoxymethylene/Poly (Lactic Acid) Blend by Annealing Technique. In Proceedings of the ANTEC 2016, Indianapolis, IN, USA, 23–25 May 2016; pp. 1222–1227. [Google Scholar]

- Andrzejewski, J.; Grad, K.; Wiśniewski, W.; Szulc, J. The Use of Agricultural Waste in the Modification of Poly(Lactic Acid)-Based Composites Intended for 3d Printing Applications. the Use of Toughened Blend Systems to Improve Mechanical Properties. J. Compos. Sci. 2021, 5, 253. [Google Scholar] [CrossRef]

- Rodriguez-Uribe, A.; Snowdon, M.R.; Abdelwahab, M.A.; Codou, A.; Misra, M.; Mohanty, A.K. Impact of Renewable Carbon on the Properties of Composites Made by Using Three Types of Polymers Having Different Polarity. J. Appl. Polym. Sci. 2021, 138, 49948. [Google Scholar] [CrossRef]

- Takayama, T.; Todo, M.; Tsuji, H. Effect of Annealing on the Mechanical Properties of PLA/PCL and PLA/PCL/LTI Polymer Blends. J. Mech. Behav. Biomed. Mater. 2011, 4, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Deng, C.; Lin, G.-P.; Wang, Y.-Z. Super Toughened and High Heat-Resistant Poly(Lactic Acid) (PLA)-Based Blends by Enhancing Interfacial Bonding and PLA Phase Crystallization. Ind. Eng. Chem. Res. 2015, 54, 5643–5655. [Google Scholar] [CrossRef]

- Marchese, P.; Celli, A.; Fiorini, M.; Gabaldi, M. Effects of Annealing on Crystallinity and Phase Behaviour of PET/PC Block Copolymers. Eur. Polym. J. 2003, 39, 1081–1089. [Google Scholar] [CrossRef]

- Yasumlee, N.; Wacharawichanant, S. Morphology and Properties of Polyoxymethylene/Polypropylene/ Microcrystalline Cellulose Composites. Key Eng. Mater. 2017, 751, 264–269. [Google Scholar] [CrossRef]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-i-Palmer, P.; Mutjé, P. Mechanical and Micromechanical Tensile Strength of Eucalyptus Bleached Fibers Reinforced Polyoxymethylene Composites. Compos. B Eng. 2017, 116, 333–339. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Feldmann, M. Polyoxymethylene Composites with Natural and Cellulose Fibres: Toughness and Heat Deflection Temperature. Compos. Sci. Technol. 2012, 72, 1870–1874. [Google Scholar] [CrossRef]

- Mathurosemontri, S.; Uawongsuwan, P.; Nagai, S.; Hamada, H. The Effect of Processing Parameter on Mechanical Properties of Short Glass Fiber Reinforced Polyoxymethylene Composite by Direct Fiber Feeding Injection Molding Process. Energy Procedia 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Qian, Z.; Wang, Y.; Li, J.; Wang, X.; Wu, D. Development of Sustainable Polyoxymethylene-Based Composites with Recycled Carbon Fibre: Mechanical Enhancement, Morphology, and Crystallization Kinetics. J. Reinf. Plast. Compos. 2014, 33, 294–309. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, S.; Liu, Y.; Yang, B.; Wang, X. The Mechanical and Tribological Properties of Nitric Acid-Treated Carbon Fiber-Reinforced Polyoxymethylene Composites. J. Appl. Polym. Sci. 2015, 132, 41812. [Google Scholar] [CrossRef]

- Heil, J.P. Study and Analysis of Carbon Fiber Recycling. Master Thesis, North Carolina State University, Raleigh, NC, USA, 2011. [Google Scholar]

- Codou, A.; Anstey, A.; Misra, M.; Mohanty, A.K. Novel Compatibilized Nylon-Based Ternary Blends with Polypropylene and Poly(Lactic Acid): Morphology Evolution and Rheological Behaviour. RSC Adv. 2018, 8, 15709–15724. [Google Scholar] [CrossRef]

- Anstey, A.; Codou, A.; Misra, M.; Mohanty, A.K. Novel Compatibilized Nylon-Based Ternary Blends with Polypropylene and Poly(Lactic Acid): Fractionated Crystallization Phenomena and Mechanical Performance. ACS Omega 2018, 3, 2845–2854. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Ogunsona, E.O.; Anstey, A.; Torres Galvez, S.E.; Codou, A.; Jubinville, D.F. Biocarbon and Nylon Based Hybrid Carbonaceous Biocomposites and Methods of Making Those and Using Thereof. US 2018/0022921A1, 25 January 2018. [Google Scholar]

- Mamun, A.A.; Heim, H.-P.; Beg, D.H.; Kim, T.S.; Ahmad, S.H. PLA and PP Composites with Enzyme Modified Oil Palm Fibre: A Comparative Study. Compos. Part A Appl. Sci. Manuf. 2013, 53, 160–167. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of Injection Moulded, Natural Fibre-Reinforced Composites with PP and PLA as Matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Franciszczak, P.; Meljon, A. High Performance Hybrid PP and PLA Biocomposites Reinforced with Short Man-Made Cellulose Fibres and Softwood Flour. Compos. Part A Appl. Sci. Manuf. 2015, 74, 132–139. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood Based PLA and PP Composites: Effect of Fibre Type and Matrix Polymer on Fibre Morphology, Dispersion and Composite Properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Zhou, J.; Jiang, Z.; Wang, Z.; Zhang, J.; Li, J.; Li, Y.; Zhang, J.; Chen, P.; Gu, Q. Synthesis and Characterization of Triblock Copolymer PLA-b-PBT-b-PLA and Its Effect on the Crystallization of PLA. RSC Adv. 2013, 3, 18464. [Google Scholar] [CrossRef]

| Sample | POM | PLA | E/BA/GMA | Cellulose Four (CF) | Wood Flour (WF) | Buckwheat Husk (BH Fine) | Buckwheat Husk (BH Coarse) |

|---|---|---|---|---|---|---|---|

| POM | 100 | - | - | - | - | - | - |

| POM/CF10 | 90 | - | - | 10 | - | - | - |

| POM/CF20 | 80 | - | - | 20 | - | - | - |

| POM/CF30 | 70 | - | - | 30 | - | - | - |

| POM/WF10 | 90 | - | - | - | 10 | - | - |

| POM/WF20 | 80 | - | - | - | 20 | - | - |

| POM/WF30 | 70 | - | - | - | 30 | - | - |

| POM/10BH(fine) | 90 | - | - | - | - | 10 | - |

| POM/20BH(fine) | 80 | - | - | - | - | 20 | - |

| POM/30BH(fine) | 70 | - | - | - | - | 30 | - |

| POM/10BH(coarse) | 90 | - | - | - | - | - | 10 |

| POM/20BH(coarse) | 80 | - | - | - | - | - | 20 |

| POM/30BH(coarse) | 70 | - | - | - | - | - | 30 |

| POM/PLA | 50 | 50 | - | - | - | - | - |

| POM/PLA/EBA | 40 | 40 | 20 | - | - | - | - |

| POM/PLA/EBA/CE * | 40 | 40 | 20 | - | - | - | - |

| POM/PLA-20WF | 40 | 40 | - | - | 20 | - | - |

| POM/PLA/EBA-20WF | 32 | 32 | 16 | - | 20 | - | - |

| POM/PLA/EBA/CE-20WF * | 32 | 32 | 16 | - | 20 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soćko, A.; Andrzejewski, J. The Development of Sustainable Polyoxymethylene (POM)-Based Composites by the Introduction of Natural Fillers and Melt Blending with Poly(lactic acid)-PLA. J. Compos. Sci. 2024, 8, 315. https://doi.org/10.3390/jcs8080315

Soćko A, Andrzejewski J. The Development of Sustainable Polyoxymethylene (POM)-Based Composites by the Introduction of Natural Fillers and Melt Blending with Poly(lactic acid)-PLA. Journal of Composites Science. 2024; 8(8):315. https://doi.org/10.3390/jcs8080315

Chicago/Turabian StyleSoćko, Anna, and Jacek Andrzejewski. 2024. "The Development of Sustainable Polyoxymethylene (POM)-Based Composites by the Introduction of Natural Fillers and Melt Blending with Poly(lactic acid)-PLA" Journal of Composites Science 8, no. 8: 315. https://doi.org/10.3390/jcs8080315

APA StyleSoćko, A., & Andrzejewski, J. (2024). The Development of Sustainable Polyoxymethylene (POM)-Based Composites by the Introduction of Natural Fillers and Melt Blending with Poly(lactic acid)-PLA. Journal of Composites Science, 8(8), 315. https://doi.org/10.3390/jcs8080315