A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications

Abstract

1. Introduction

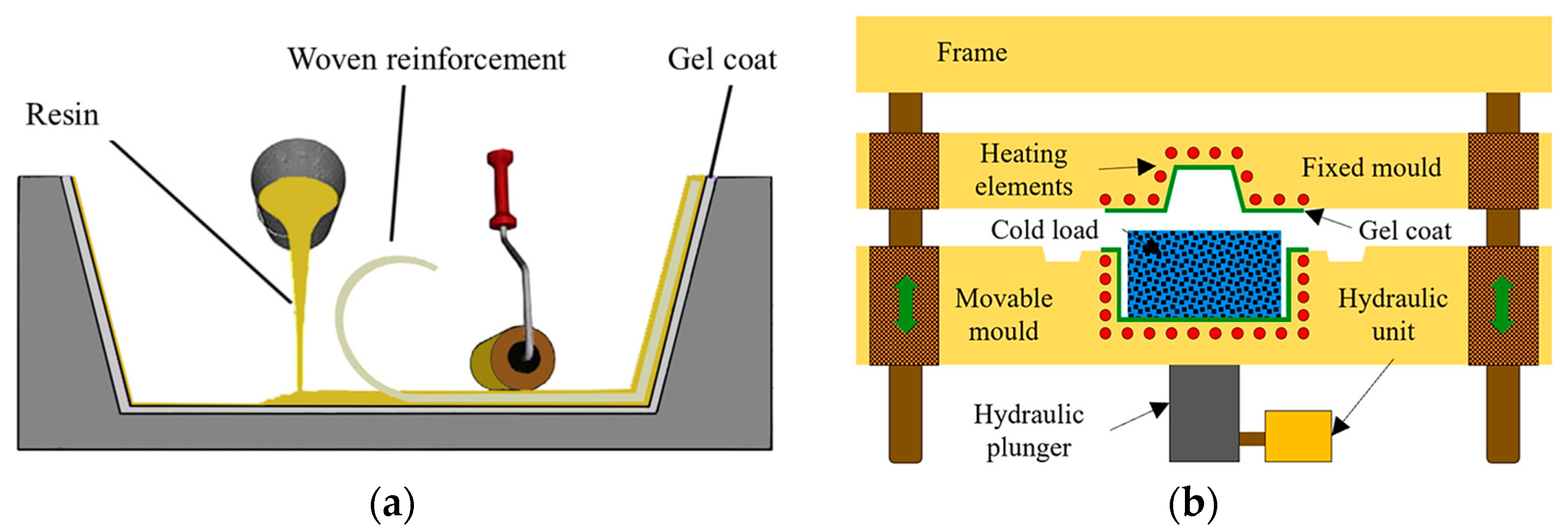

2. Fabrication Methods of Fibrous Composites

3. Fabrication of Commonly Used Structural Composites

3.1. Aramid Fiber and Its Hybrid Composites

3.2. Carbon Fiber and Its Hybrid Composites

3.3. Glass Fiber and Its Hybrid Composites

3.4. Natural Fiber and its Hybrid Composites

4. Mechanical Characterization of Fibrous Composites

4.1. Synthetic Fiber-Reinforced Polymer Composites

4.2. Natural Fiber-Reinforced Polymer Composites

5. Conclusions

- FRPCs were successfully fabricated using both conventional and additive manufacturing techniques. Conventional techniques, such as HL, CM, RTM, VARTM, IM, VI, VARI, FM, and autoclave forming, and AM techniques, such as FDM, MJF, SLS, and SLA, were used to fabricate FRPCs.

- AFs were reinforced with many polymers, such as epoxy, vinyl ester, UHMWPE, polyetherimide, polyamide, and polypropylene, during composite fabrication.

- Polymers, such as epoxy, phenolic resin, polypropylene, polycarbonate, polyamide, and nylon, were used to fabricate CFRP composites.

- Reinforcements were used in the form of short fibers, continuous fibers, woven fabrics, and powders for composite fabrication.

- AF, CF, GF, and natural fiber content varied in the ranges of 5–54 wt.%, 10–64 wt.%, 30–80 wt.%, and 20–80 vol%, respectively, for composite fabrication.

- The highest fiber loadings of 64 wt.% in CFRP composites, 80 wt.% in GFRP composites, and 80 vol% in NFRP composites were achieved by employing the autoclave forming process, SLA, and hybrid AM technique (FDM in combination with shape deposition modeling), respectively.

- HL and FDM were extensively used conventional and AM techniques, respectively, for fabricating AFRP composites.

- AM techniques, such as FFF, FDM, and SLS, were used for CFRP fabrication; however, reports regarding the utilization of other AM techniques were not found during the study.

- Glass fibers were also employed to fabricate hybrid composites by reinforcing them with various natural fibers and polymer resins, such as epoxy, polyester, VE, and phenol formaldehyde resin.

- NFRP composites were fabricated by reinforcing sisal, banana, jute, flax, bamboo, cotton, coir, pineapple leaf, etc., with epoxy, polyester, VE, PLA, and PP resins. Natural fibers were sometimes used in combination with synthetic fibers to fabricate hybrid composites for structural applications.

- Fabricated composites were subject to various tests to evaluate mechanical characteristics, hygro-thermal degradation, tribological characteristics, electrical characteristics, and ballistic impact performance. The mechanical properties of fibrous composites can be tailored by controlling various factors, such as the fiber orientation, fiber volume fraction, and the matrix type.

- Despite the advantages of fibrous composites, there are still challenges associated with their use, such as manufacturing costs, limited design guidelines, and difficulty in predicting their mechanical behavior.

- One future direction is to develop sustainable and eco-friendly manufacturing processes for fibrous composites. The use of renewable resources and recyclable materials in the production of composites could reduce their environmental impact and enhance their sustainability.

- Another challenge is to establish standard design guidelines for fibrous composites. The lack of design guidelines hinders their widespread use in industry, as it becomes difficult to determine the optimal fiber-matrix combination, orientation, and thickness for a given application.

- In addition, the development of multi-functional fibrous composites that can provide additional functionalities, such as thermal, electrical, or magnetic properties, would expand their range of applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AFs | Aramid Fibers | MWCNTs | Multi-Wall CNTs |

| AM | Additive Manufacturing | NFRP | Natural Fiber-Reinforced Polymer |

| BMCs | Bulk Molding Compounds | PA | Polyamide |

| CFRP | Carbon Fiber-Reinforced Polymer | PLA | Polylactic Acid |

| CFs | Carbon Fibers | PP | Polypropylene |

| CM | Compression Molding | PTFE | Polytetrafluoroethylene |

| CNTs | Carbon Nanotubes | RTM | Resin Transfer Molding |

| FDM | Fused Deposition Modeling | SCFs | Short Carbon Fibers |

| FFF | Fused Filament Fabrication | SGFs | Short Glass Fibers |

| FRPCs | Fiber-Reinforced Polymer Composites | SLA | Stereolithography |

| FW | Filament Winding | SLS | Selective Laser Sintering |

| GFs | Glass Fibers | SMCs | Sheet Molding Compounds |

| GFRP | Glass Fiber-Reinforced Polymer | UHMWPE | Ultra-High-Molecular-Weight Polyethylene |

| HL | Hand Lay-Up | VARI | Vacuum-Assisted Resin Injection |

| IM | Injection Molding | VARTM | Vacuum-Assisted Resin Transfer Molding |

| LDM | Liquid Deposition Modeling | VE | Vinyl Ester |

| MJF | Multi-Jet Fusion | VI | Vacuum Infusion |

References

- Lunetto, V.; Galati, M.; Settineri, L.; Iuliano, L. Sustainability in the manufacturing of composite materials: A literature review and directions for future research. J. Manuf. Process. 2023, 85, 858–874. [Google Scholar] [CrossRef]

- Xu, J. A review on tool wear issues in drilling CFRP laminates. Front. Mater. 2022, 9, 990773. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA fiber on the abrasion and cracking resistance, pore structure and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Divya, H.V.; Jeevan, T.P.; Ashrith, H.S.; Rudresh, B.M. Effect of wood filler on the mechanical and thermal behavior of polypropylene/short glass/short carbon fiber-reinforced hybrid composites. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 265. [Google Scholar] [CrossRef]

- Xu, J.; Yin, Y.; Davim, J.P.; Li, L.; Ji, M.; Geier, N.; Chen, M. A critical review addressing drilling-induced damage of CFRP composites. Compos. Struct. 2022, 294, 115594. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Dang, J.; El Mansori, M.; Ren, F. A study on drilling high-strength CFRP laminates: Frictional heat and cutting temperature. Materials 2018, 11, 2366. [Google Scholar] [CrossRef]

- Khan, H.A.; Nigar, M.; Chaudhry, I.A. Tensile behavior of unidirectional carbon reinforced composites for aerospace structures under varying strain rates. Appl. Mech. Mater. 2015, 798, 357–361. [Google Scholar]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2018, 232, 28–38. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, H.-G.; Kim, H.-S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Compos. Struct. 2015, 131, 742–752. [Google Scholar] [CrossRef]

- Stepanova, M.; Korzhikova-Vlakh, E. Modification of cellulose micro-and nanomaterials to improve properties of aliphatic polyesters/cellulose composites: A review. Polymers 2022, 14, 1477. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Nguong, C.; Lee, S.; Sujan, D. A review on natural fibre reinforced polymer composites. Int. J. Mater. Metall. Eng. 2013, 7, 52–59. [Google Scholar]

- Vishkaei, M.S.; Salleh, M.A.M.; Yunus, R.; Biak, D.R.A.; Danafar, F.; Mirjalili, F. Effect of short carbon fiber surface treatment on composite properties. J. Compos. Mater. 2011, 45, 1885–1891. [Google Scholar] [CrossRef]

- Botelho, E.; Rezende, M.; Lauke, B. Mechanical behavior of carbon fiber reinforced polyamide composites. Compos. Sci. Technol. 2003, 63, 1843–1855. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of UV and water spraying on the mechanical properties of flax fabric reinforced polymer composites used for civil engineering applications. Mater. Des. 2015, 71, 17–25. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Investigating ballistic impact properties of woven kenaf-aramid hybrid composites. Fibers Polym. 2016, 17, 275. [Google Scholar] [CrossRef]

- Biron, M. Thermosets and Composites: Material Selection, Applications, Manufacturing and Cost Analysis; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Raji, M.; Abdellaoui, H.; Essabir, H.; Kakou, C.-A.; Bouhfid, R.; Qaiss, A.E.K. Prediction of the cyclic durability of woven-hybrid composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 27–62. [Google Scholar]

- Liu, S.-J. Injection molding in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Elsevier: Amsterdam, The Netherlands, 2012; pp. 15–46. [Google Scholar]

- Kariminejad, M.; Tormey, D.; Huq, S.; Morrison, J.; McAfee, M. Ultrasound sensors for process monitoring in injection moulding. Sensors 2021, 21, 5193. [Google Scholar] [CrossRef]

- Wang, P.; Molimard, J.; Drapier, S.; Vautrin, A.; Minni, J.-C. Monitoring the resin infusion manufacturing process under industrial environment using distributed sensors. J. Compos. Mater. 2012, 46, 691–706. [Google Scholar] [CrossRef]

- Witik, R.A.; Gaille, F.; Teuscher, R.; Ringwald, H.; Michaud, V.; Månson, J.-A.E. Economic and environmental assessment of alternative production methods for composite aircraft components. J. Clean. Prod. 2012, 29, 91–102. [Google Scholar] [CrossRef]

- Yalcinkaya, M.A.; Sozer, E.M.; Altan, M.C. Fabrication of high quality composite laminates by pressurized and heated-VARTM. Compos. Part A Appl. Sci. Manuf. 2017, 102, 336–346. [Google Scholar] [CrossRef]

- Carlone, P.; Baran, I.; Hattel, J.H.; Palazzo, G. Computational approaches for modeling the multiphysics in pultrusion process. Adv. Mech. Eng. 2013, 5, 301875. [Google Scholar] [CrossRef]

- Dai, D.; Fan, M. Wood fibres as reinforcements in natural fibre composites: Structure, properties, processing and applications. In Natural Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–65. [Google Scholar]

- Sentis, D.F.; Cochereau, T.; Orgéas, L.; Dumont, P.J.; Roscoat, S.R.D.; Laurencin, T.; Terrien, M.; Sager, M. Tensile behaviour of uncured sheet moulding compounds: Rheology and flow-induced microstructures. Compos. Part A Appl. Sci. Manuf. 2017, 101, 459–470. [Google Scholar] [CrossRef]

- Nicolais, L.; Kenny, J.M.; Maffezzoli, A.; Torre, L.; Trivisano, A. Science and Technology of Polymer Composites. In The Interfacial Interactions in Polymeric Composites; Akovali, G., Ed.; Springer: Dordrecht, The Netherlands, 1993; pp. 321–357. [Google Scholar]

- Lee, S.M. Handbook of Composite Reinforcements; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Li, N.; Li, Y.; Jelonnek, J.; Link, G.; Gao, J. A new process control method for microwave curing of carbon fibre reinforced composites in aerospace applications. Compos. Part B Eng. 2017, 122, 61–70. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O. Design, manufacturing processes and their effects on bio-composite properties. In Sustainable Composites for Lightweight Applications; Dhakal, H.N., Ismail, S.O., Eds.; Woodhead Publishing: Cambridge, UK, 2021; pp. 121–177. [Google Scholar]

- Alagirusamy, R. Hybrid yarns for thermoplastic composites. In Technical Textile Yarns; Alagirusamy, R., Das, A., Eds.; Woodhead Publishing: Cambridge, UK, 2010; pp. 387–428. [Google Scholar]

- Gupta, M.; Jain, A.; Kamineni, J.N.; Burela, R.G. Advances and applications of biofiber-based polymer composites. In Advances in Bio-Based Fiber; Rangappa, S.M., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 575–602. [Google Scholar]

- Gopanna, A.; Rajan, K.P.; Thomas, S.P.; Chavali, M. Polyethylene and polypropylene matrix composites for biomedical applications. In Materials for Biomedical Engineering; Grumezescu, V., Grumezescu, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 6; pp. 175–216. [Google Scholar]

- Schäfer, J.; Gries, T. Braiding pultrusion of thermoplastic composites. In Advances in Braiding Technology; Kyosev, Y., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 405–428. [Google Scholar]

- Ratna, D. Thermoset composites. In Recent Advances and Applications of Thermoset Resins, 2nd ed.; Ratna, D., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; Chapter 4; pp. 317–418. [Google Scholar]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on additive manufacturing technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Galati, M.; Calignano, F.; Viccica, M.; Iuliano, L. Additive manufacturing redesigning of metallic parts for high precision machines. Crystals 2020, 10, 161. [Google Scholar] [CrossRef]

- Konta, A.A.; García-Piña, M.; Serrano, D.R. Personalised 3D printed medicines: Which techniques and polymers are more successful? Bioengineering 2017, 4, 79. [Google Scholar] [CrossRef]

- Kumar, S.; Kruth, J.-P. Composites by rapid prototyping technology. Mater. Des. 2010, 31, 850–856. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent progress in additive manufacturing of fiber reinforced polymer composite. Adv. Mater. Technol. 2019, 4, 1800271. [Google Scholar] [CrossRef]

- Tsouknidas, A. Friction induced wear of rapid prototyping generated materials: A review. Adv. Tribol. 2011, 2011, 746270. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Dharmavarapu, P.; Sreekara Reddy, M.B.S. Aramid fibre as potential reinforcement for polymer matrix composites: A review. Emergent Mater. 2022, 5, 1561–1578. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R.; Banaie, K.A. The evaluation of the thermal and mechanical properties of aramid/semi-carbon fibers hybrid composites. Fibers Polym. 2017, 18, 296–302. [Google Scholar] [CrossRef]

- Haque, M.M.; Munshi, M.R.; Alam, S.S.; Haque, M.R.; Hasan, M.; Gafur, M.A.; Ullah, Z.; Sifat, R.S.; Khan, A. Effect of Different Fibers Loading on Palm and Aramid Fiber Reinforced Hybrid Epoxy Composite. Adv. Mater. Process. Technol. 2022, 8, 1889–1900. [Google Scholar] [CrossRef]

- Anidha, S.; Latha, N.; Muthukkumar, M. Reinforcement of Aramid fiber with bagasse epoxy bio-degradable composite: Investigations on mechanical properties and surface morphology. J. Mater. Res. Technol. 2019, 8, 3198–3212. [Google Scholar] [CrossRef]

- Udaya Kumar, P.; Suresha, B.; Rajini, N.; Satyanarayana, K. Effect of treated coir fiber/coconut shell powder and aramid fiber on mechanical properties of vinyl ester. Polym. Compos. 2018, 39, 4542–4550. [Google Scholar] [CrossRef]

- Gürgen, S.; Çelik, O.N.; Kuşhan, M.C. Tribological behavior of UHMWPE matrix composites reinforced with PTFE particles and aramid fibers. Compos. Part B Eng. 2019, 173, 106949. [Google Scholar] [CrossRef]

- Valarmathi, T.; Sangeetha, M.; Venkata, G.G.; Muppala, D.; Siva, R. Hygro-thermal degradation studies on E-glass woven rovings and aramid fiber composites. Mater. Today Proc. 2021, 44, 3823–3828. [Google Scholar]

- Batra, N.; Dikshit, I. Evaluation of mechanical properties of polytherimide reinforced carbon/glass/aramid hybrid composites. Mater. Today Proc. 2020, 33, 1472–1476. [Google Scholar] [CrossRef]

- Arroyo, M.; Bell, M. Morphology/behavior relationship and recyclability of composites based on PP/EPDM blends and short aramid fibers. J. Appl. Polym. Sci. 2002, 83, 2474–2484. [Google Scholar] [CrossRef]

- Müller, K.; Reußmann, T.; Lützkendorf, R.; Schmitt, M. Aramid pulp for the reinforcement of thermoplastic elastomers. Int. Polym. Sci. Technol. 2011, 38, 162–164. [Google Scholar] [CrossRef]

- Louis, B.M.; Maldonado, J.; Klunker, F.; Ermanni, P. Measurement of nanoparticle distribution in composite laminates produced by resin transfer molding. In Proceedings of the 16th European Conference on Composite Materials (ECCM), Seville, Spain, 22–26 June 2014. [Google Scholar]

- Song, Y.S. Multiscale fiber-reinforced composites prepared by vacuum-assisted resin transfer molding. Polym. Compos. 2007, 28, 458–461. [Google Scholar] [CrossRef]

- Da Silva, L.F.; Lavoratti, A.; Pereira, I.M.; Dias, R.R.; Amico, S.C.; Zattera, A.J. Development of multilaminar composites for vehicular ballistic protection using ultra-high molecular weight polyethylene laminates and aramid fabrics. J. Compos. Mater. 2019, 53, 1907–1916. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, Z.; Kong, H.; Qiao, M.; Hu, Z.; Zhang, L.; Yu, M. Influences of graphene oxide addition on mechanical properties of aramid fiber reinforced composites. Mater. Express 2019, 9, 578–586. [Google Scholar] [CrossRef]

- Nagendra, J.; Prasad, M.G. FDM process parameter optimization by Taguchi technique for augmenting the mechanical properties of nylon–aramid composite used as filament material. J. Inst. Eng. Ser. C 2020, 101, 313–322. [Google Scholar] [CrossRef]

- Chen, J.; Tan, P.; Liu, X.; Tey, W.S.; Ong, A.; Zhao, L.; Zhou, K. High-strength light-weight aramid fibre/polyamide 12 composites printed by Multi Jet Fusion. Virtual Phys. Prototyp. 2022, 17, 295–307. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Mansori, M.E.; Liu, G.; Chen, M. Study on the Frictional Heat at Tool-Work Interface when Drilling CFRP Composites. Procedia Manuf. 2018, 26, 415–423. [Google Scholar] [CrossRef]

- Geier, N.; Xu, J.; Pereszlai, C.; Poór, D.I.; Davim, J.P. Drilling of carbon fibre reinforced polymer (CFRP) composites: Difficulties, challenges and expectations. Procedia Manuf. 2021, 54, 284–289. [Google Scholar] [CrossRef]

- Altin Karataş, M.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, P.; Ning, F. Joining of carbon fiber reinforced polymer/titanium stacks using directed energy deposition additive manufacturing. Compos. Struct. 2023, 310, 116775. [Google Scholar] [CrossRef]

- Ji, M.; Xu, J.; Chen, M.; Mansori, M.E.I. Effects of Different Cooling Methods on the Specific Energy Consumption when Drilling CFRP/Ti6Al4V Stacks. Procedia Manuf. 2020, 43, 95–102. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Chen, M.; El Mansori, M. Experimental investigation on drilling machinability and hole quality of CFRP/Ti6Al4V stacks under different cooling conditions. Int. J. Adv. Manuf. Technol. 2020, 109, 1527–1539. [Google Scholar] [CrossRef]

- Badakhsh, A.; An, K.-H.; Kim, B.-J. Enhanced surface energetics of CNT-grafted carbon fibers for superior electrical and mechanical properties in CFRPs. Polymers 2020, 12, 1432. [Google Scholar] [CrossRef] [PubMed]

- Srikanth, I.; Kumar, S.; Kumar, A.; Ghosal, P.; Subrahmanyam, C. Effect of amino functionalized MWCNT on the crosslink density, fracture toughness of epoxy and mechanical properties of carbon–epoxy composites. Compos. Part A: Appl. Sci. Manuf. 2012, 43, 2083–2086. [Google Scholar] [CrossRef]

- Eslami, Z.; Yazdani, F.; Mirzapour, M.A. Thermal and mechanical properties of phenolic-based composites reinforced by carbon fibres and multiwall carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2015, 72, 22–31. [Google Scholar] [CrossRef]

- Tariq, F.; Shifa, M.; Baloch, R.A. Mechanical and thermal properties of multi-scale carbon nanotubes–carbon fiber–epoxy composite. Arab. J. Sci. Eng. 2018, 43, 5937–5948. [Google Scholar] [CrossRef]

- Poodts, E.; Minak, G.; Mazzocchetti, L.; Giorgini, L. Fabrication, process simulation and testing of a thick CFRP component using the RTM process. Compos. Part B: Eng. 2014, 56, 673–680. [Google Scholar] [CrossRef]

- Jagannatha, T.; Harish, G. Mechanical properties of carbon/glass fiber reinforced epoxy hybrid polymer composites. Int. J. Mech. Eng. Robot. Res. 2015, 4, 131–137. [Google Scholar]

- Fu, S.-Y.; Lauke, B.; Mäder, E.; Yue, C.-Y.; Hu, X.; Mai, Y.-W. Hybrid effects on tensile properties of hybrid short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. J. Mater. Sci. 2001, 36, 1243–1251. [Google Scholar] [CrossRef]

- Junaedi, H.; Albahkali, E.; Baig, M.; Dawood, A.; Almajid, A. Ductile to brittle transition of short carbon fiber-reinforced polypropylene composites. Adv. Polym. Technol. 2020, 2020, 6714097. [Google Scholar] [CrossRef]

- Gupta, A.; Fidan, I.; Hasanov, S.; Nasirov, A. Processing, mechanical characterization, and micrography of 3D-printed short carbon fiber reinforced polycarbonate polymer matrix composite material. Int. J. Adv. Manuf. Technol. 2020, 107, 3185–3205. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Xu, L.; Shi, Y. Preparation, characterisation and processing of carbon fibre/polyamide-12 composites for selective laser sintering. Compos. Sci. Technol. 2011, 71, 1834–1841. [Google Scholar] [CrossRef]

- Wang, L.; Kiziltas, A.; Mielewski, D.F.; Lee, E.C.; Gardner, D.J. Closed-loop recycling of polyamide12 powder from selective laser sintering into sustainable composites. J. Clean. Prod. 2018, 195, 765–772. [Google Scholar] [CrossRef]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing technologies of carbon/glass fiber-reinforced polymer composites and their properties: A review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- Tsao, V. Experimental study of drilling composite materials with step-core drill. Mater. Des. 2008, 29, 1740–1744. [Google Scholar] [CrossRef]

- Palanikumar, K. Experimental investigation and optimisation in drilling of GFRP composites. Measurement 2011, 44, 2138–2148. [Google Scholar] [CrossRef]

- Choudhary, M.; Sharma, A.; Dwivedi, M.; Patnaik, A. A comparative study of the physical, mechanical and thermo-mechanical behavior of GFRP composite based on fabrication techniques. Fibers Polym. 2019, 20, 823–831. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Shim, C.S.; Sturtevant, C.; Kim, D.; Song, H.C. Mechanical properties and production quality of hand-layup and vacuum infusion processed hybrid composite materials for GFRP marine structures. Int. J. Nav. Archit. Ocean. Eng. 2014, 6, 723–736. [Google Scholar] [CrossRef]

- Faudree, M.C.; Nishi, Y.; Salvia, M. Increasing impact strength of a short glass fiber compression molded BMC by shortening fibers without change in equipment. Materials 2022, 15, 1145. [Google Scholar] [CrossRef] [PubMed]

- Khalid, M.Y.; Arif, Z.U.; Sheikh, M.F.; Nasir, M.A. Mechanical characterization of glass and jute fiber-based hybrid composites fabricated through compression molding technique. Int. J. Mater. Form. 2021, 14, 1085–1095. [Google Scholar] [CrossRef]

- Rafiee, R. Experimental and theoretical investigations on the failure of filament wound GRP pipes. Compos. Part B: Eng. 2013, 45, 257–267. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 207, 330–335. [Google Scholar] [CrossRef]

- Huang, G.; Sun, H. Effect of water absorption on the mechanical properties of glass/polyester composites. Mater. Des. 2007, 28, 1647–1650. [Google Scholar] [CrossRef]

- Lee, G.-W.; Lee, N.-J.; Jang, J.; Lee, K.-J.; Nam, J.-D. Effects of surface modification on the resin-transfer moulding (RTM) of glass-fibre/unsaturated-polyester composites. Compos. Sci. Technol. 2002, 62, 9–16. [Google Scholar] [CrossRef]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Yang, L.; Chen, P.; Yan, C.; Cai, C.; Li, H.; Li, L.; Shi, Y. Glass fiber-reinforced phenol formaldehyde resin-based electrical insulating composites fabricated by selective laser sintering. Polymers 2019, 11, 135. [Google Scholar] [CrossRef]

- Benal, M.G.M.; GS, P.K.; Tambrallimath, V.; HR, G.; Khan, T.Y.; Rajhi, A.A.; Baig, M.A.A. Influence of Short Glass Fibre Reinforcement on Mechanical Properties of 3D Printed ABS-Based Polymer Composites. Polymers 2022, 14, 1182. [Google Scholar]

- Sai Shravan Kumar, P.; Viswanath Allamraju, K. A Review Of Natural Fiber Composites [Jute, Sisal, Kenaf]. Mater. Today Proc. 2019, 18, 2556–2562. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Wilson, A. Vehicle weight is the key driver for automotive composites. Reinf. Plast. 2017, 61, 100–102. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Ray, D.; Mohanty, A.K.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Pickering, K.L., Ed.; Woodhead Publishing: Cambridge, UK, 2008; pp. 221–268. [Google Scholar]

- Saravana Kumar, A.; Selvi, P.M.; Rajeshkumar, L. Delamination in drilling of sisal/banana reinforced composites produced by hand lay-up process. Appl. Mech. Mater. 2017, 867, 29–33. [Google Scholar]

- Meenakshi, C.; Krishnamoorthy, A. Preparation and mechanical characterization of flax and glass fiber reinforced polyester hybrid composite laminate by hand lay-up method. Mater. Today Proc. 2018, 5, 26934–26940. [Google Scholar] [CrossRef]

- Seetha Girish, A.V.; Vijaya, B.; Arjun, S.; Raghavendra, S. Manufacturing and mechanical characterization of coir fibre composites based on vinyl ester. Adv. Mater. Process. Technol. 2022, 8, 1997–2006. [Google Scholar]

- Prasad, V.; Hunize, C.M.; Abhiraj, R.; Jospeh, M.; Sekar, K.; Ali, M. Mechanical properties of flax fiber reinforced composites manufactured using hand layup and compression molding—A comparison. In Advances in Industrial and Production Engineering: Select Proceedings of FLAME 2018; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Zhang, J.; Khatibi, A.A.; Castanet, E.; Baum, T.; Komeily-Nia, Z.; Vroman, P.; Wang, X. Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-composites compression moulded by nonwoven mats. Compos. Commun. 2019, 13, 12–17. [Google Scholar] [CrossRef]

- Oksman, K. High quality flax fibre composites manufactured by the resin transfer moulding process. J. Reinf. Plast. Compos. 2001, 20, 621–627. [Google Scholar] [CrossRef]

- Gorrepotu, S.R.; Debnath, K.; Mahapatra, R.N. Multi-response Optimization of the Chemical Treatment Process Parameters Influencing the Tensile, Flexural, Compression, and Shear Properties of the Injection Moulded Green Composites. J. Polym. Environ. 2023, 31, 112–130. [Google Scholar] [CrossRef]

- Long, H.; Wu, Z.; Dong, Q.; Shen, Y.; Zhou, W.; Luo, Y.; Zhang, C.; Dong, X. Mechanical and thermal properties of bamboo fiber reinforced polypropylene/polylactic acid composites for 3D printing. Polym. Eng. Sci. 2019, 59, E247–E260. [Google Scholar] [CrossRef]

- Anandkumar, R.; Babu, S.R.; Sathyamurthy, R. Investigations on the mechanical properties of natural fiber granulated composite using hybrid additive manufacturing: A novel approach. Adv. Mater. Sci. Eng. 2021, 2021, 5536171. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, Y.; Jiang, K.; Zhang, H. Preparation and selective laser sintering of bamboo flour/copolyester composite and post-processing. J. Thermoplast. Compos. Mater. 2017, 30, 1045–1055. [Google Scholar] [CrossRef]

- Jaiswal, G.; Singha, M.K.; Das, D. Mechanical behavior of aramid-polypropylene fiberweb composites. Compos. Struct. 2021, 268, 113938. [Google Scholar] [CrossRef]

- Kandekar, S.; Talikoti, R. Study of torsional behavior of reinforced concrete beams strengthened with aramid fiber strips. Int. J. Adv. Struct. Eng. 2018, 10, 465–474. [Google Scholar] [CrossRef]

- Liu, X.; Tey, W.S.; Tan, P.; Leong, K.K.; Chen, J.; Tian, Y.; Ong, A.; Zhao, L.; Zhou, K. Effect of the fibre length on the mechanical anisotropy of glass fibre–reinforced polymer composites printed by Multi Jet Fusion. Virtual Phys. Prototyp. 2022, 17, 734–748. [Google Scholar] [CrossRef]

- Thomason, J. Dependence of interfacial strength on the anisotropic fiber properties of jute reinforced composites. Polym. Compos. 2010, 31, 1525–1534. [Google Scholar] [CrossRef]

- Ouali, A.-A.; Rinberg, R.; Nendel, W.; Kroll, L.; Siegel, C.; Buchelt, B.; Wagenführ, A.; Trommler, K.; Schreiter, K.; John, R. Natural unidirectional sheet processes for fibre reinforced bioplastics. AIP Conf. Proc. 2017, 1914, 060005. [Google Scholar]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

| Manufacturing Technique | Type of Matrix | Type of Reinforcement | Investigations Performed | Ref. |

|---|---|---|---|---|

| Autoclave molding technique | Epoxy | AFs | Mechanical properties | [57] |

| UHMWPE | AFs | Dynamic mechanical properties | [56] | |

| CM | Epoxy | GFs and AFs | Hygro-thermal degradation and mechanical properties | [50] |

| Epoxy | MWCNTs and CF | Thermal and mechanical properties | [71] | |

| Epoxy | GFs and Jute Fibers | Flexural and impact properties | [85] | |

| Phenolic resin | MWCNTs and CFs | Thermal and mechanical properties | [70] | |

| Polyester | SGFs and Calcium Carbonate | Impact characteristics | [84] | |

| Polylactic acid | Bamboo, Cotton, and Flax Fibers | Mechanical, thermal, damping, and acoustic characteristics | [101] | |

| Polyetherimide | CFs, GFs, and AFs | Mechanical characteristics | [51] | |

| UHMWPE | PTFE and AFs | Wear performance | [49] | |

| FDM | ABS | SGFs | Mechanical properties | [92] |

| Nylon | AFs | Tensile, flexural, compression, and impact properties | [58] | |

| Nylon | CFs, GFs, and Kevlar Fibers | Tension and flexure performances | [77] | |

| PP/PLA | Bamboo Fibers | Mechanical and thermal characteristics | [104] | |

| FDM and shape deposition modeling | Epoxy | Sugarcane, Jute, Ramie, Banana, Pineapple Fibers, and Seashell Powder | Mechanical properties | [105] |

| Fused filament fabrication | Polycarbonate | SCFs | Tensile, flexural, compression, and micro-hardness properties | [76] |

| FW | Epoxy | MWCNTs and CFs | Mechanical properties | [69] |

| Polyester | GFs | Tensile characteristics | [86] | |

| HL | Epoxy | AFs and Kenaf Fibers | Ballistic impact performance | [17] |

| Epoxy | AFs and CFs | Thermal and mechanical characteristics | [45] | |

| Epoxy | AFs and Palm Fibers | Tensile, flexural, impact, hardness, and water absorption tests | [46] | |

| Epoxy | AFs and Bagasse Fibers | Tensile, flexural, and impact strength | [47] | |

| Epoxy | CFs | Electrical and mechanical properties | [68] | |

| Epoxy | Sisal and Banana Fibers | Delamination characteristics | [97] | |

| Hybrid VE | Coir Fibers, AFs, and Coconut Shell Powder | Hardness, tensile, and flexural characteristics | [48] | |

| Polyester | GFs and Jute Fibers | Tensile, flexural, and interlaminar shear characteristics | [87] | |

| Polyester | Flax Fibers and GFs | Mechanical and water absorption characteristics | [98] | |

| VE | Coir Fibers | Tensile and flexural characteristics | [99] | |

| HL and vacuum infusion | Epoxy VE and plain VE | GFs | Tensile, compression, and in-plane shear characteristics | [83] |

| Hand layup and compression molding | Epoxy | Flax Fibers | Mechanical and thermal characterization | [100] |

| HL and VARTM | Epoxy | GFs | Mechanical and thermo-mechanical properties | [82] |

| IM | PLA | Bamboo Fibers | Tensile, flexural, compression, and shear properties | [103] |

| PA | AFs | Tensile, flexural, impact, and tribological characteristics | [53] | |

| PP | SGFs and CFs | Mechanical characteristics | [74] | |

| PP | SCFs | Tensile strength and modulus | [75] | |

| PP and ethylene- propylene-diene | Short AFs | Mechanical characteristics | [52] | |

| MJF | PA12 | AFs | Mechanical properties | [59] |

| RTM | Epoxy | AFs and Alumina Nanoparticle | Nanoparticle distribution | [54] |

| Epoxy | CNTs and AFs | Flexural characteristics | [55] | |

| Epoxy | CFs | Porosity and mechanical characteristics | [72] | |

| Epoxy | Flax Fibers | Mechanical properties | [102] | |

| Polyester | GFs | Void contents and flexural characteristics | [89] | |

| SLA | Epoxy | Glass Powder, Chopped Glass Strand Mat, and Fiberglass Fabric | Tensile characteristics | [90] |

| SLS | Polyester | Bamboo flour | Tensile, flexural, and impact strength | [106] |

| PA12 | Milled CFs | Mechanical and thermal properties | [78] | |

| Phenol formaldehyde | GFs | Mechanical and electrical properties | [91] | |

| Vacuum-assisted resin injection | Polyester | GFs | Water immersion on the mechanical performance | [88] |

| Vacuum bagging | Epoxy | CFs and GFs | Hardness, tensile strength, and modulus | [73] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashrith, H.S.; Jeevan, T.P.; Xu, J. A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications. J. Compos. Sci. 2023, 7, 252. https://doi.org/10.3390/jcs7060252

Ashrith HS, Jeevan TP, Xu J. A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications. Journal of Composites Science. 2023; 7(6):252. https://doi.org/10.3390/jcs7060252

Chicago/Turabian StyleAshrith, H. S., T. P. Jeevan, and Jinyang Xu. 2023. "A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications" Journal of Composites Science 7, no. 6: 252. https://doi.org/10.3390/jcs7060252

APA StyleAshrith, H. S., Jeevan, T. P., & Xu, J. (2023). A Review on the Fabrication and Mechanical Characterization of Fibrous Composites for Engineering Applications. Journal of Composites Science, 7(6), 252. https://doi.org/10.3390/jcs7060252