The Influence of the Carbide-Forming Metallic Additives (W, Mo, Cr, Ti) on the Microstructure and Thermal Conductivity of Copper–Diamond Composites

Abstract

1. Introduction

2. Materials and Methods

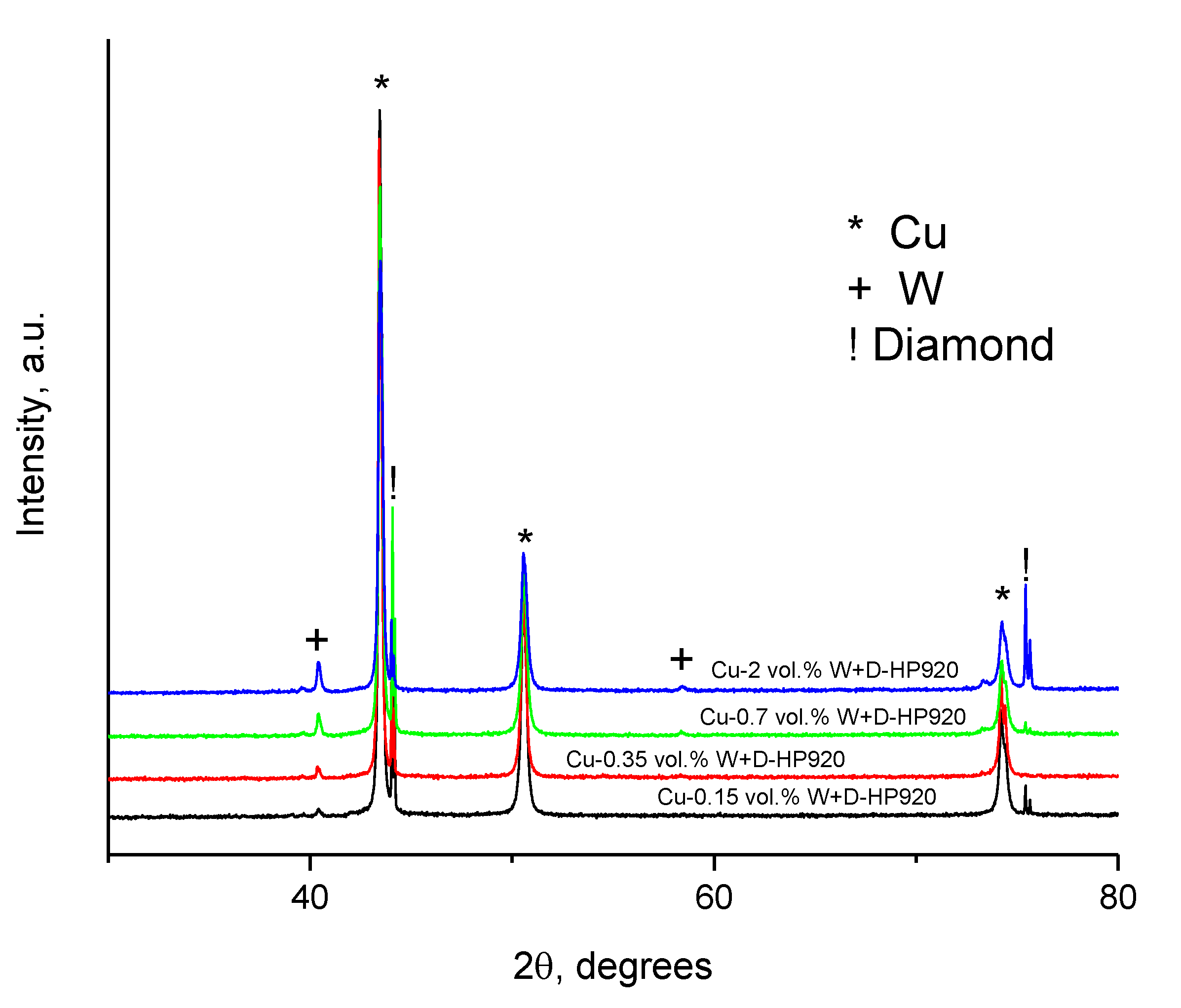

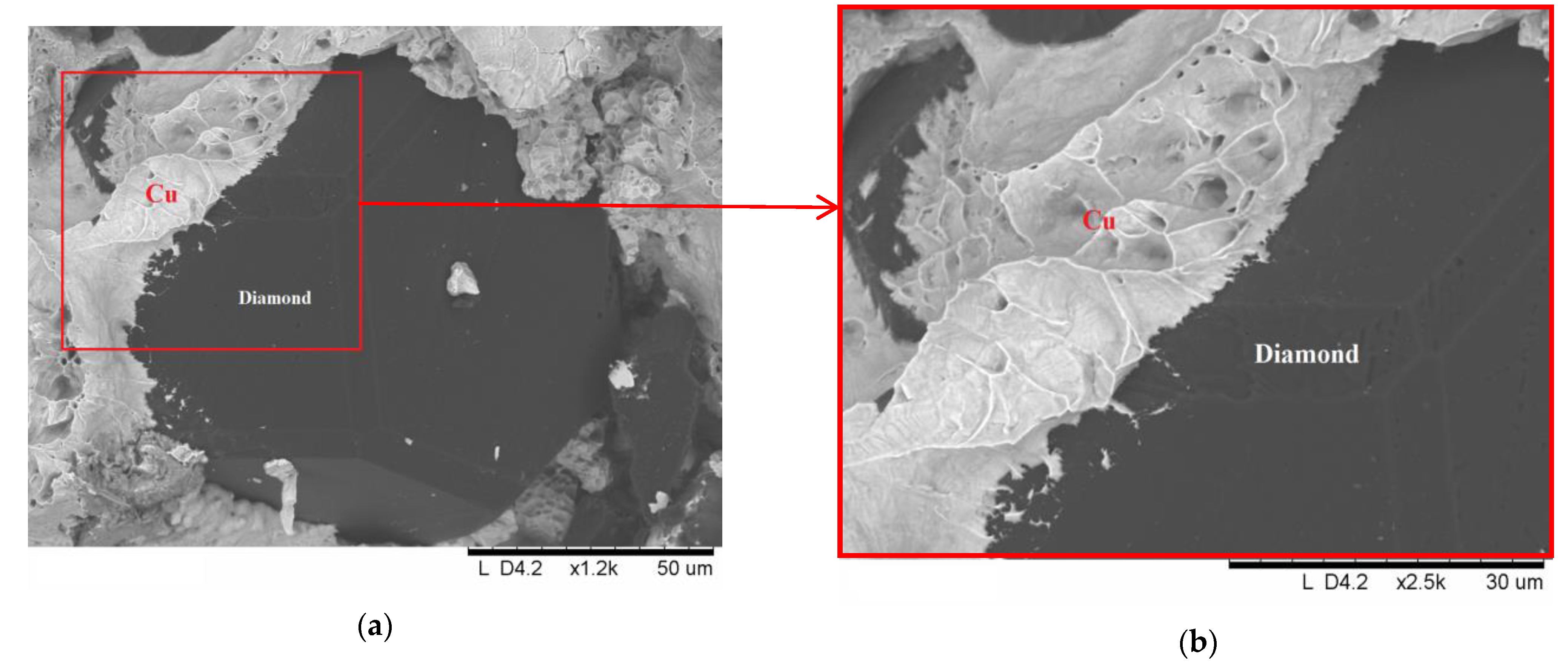

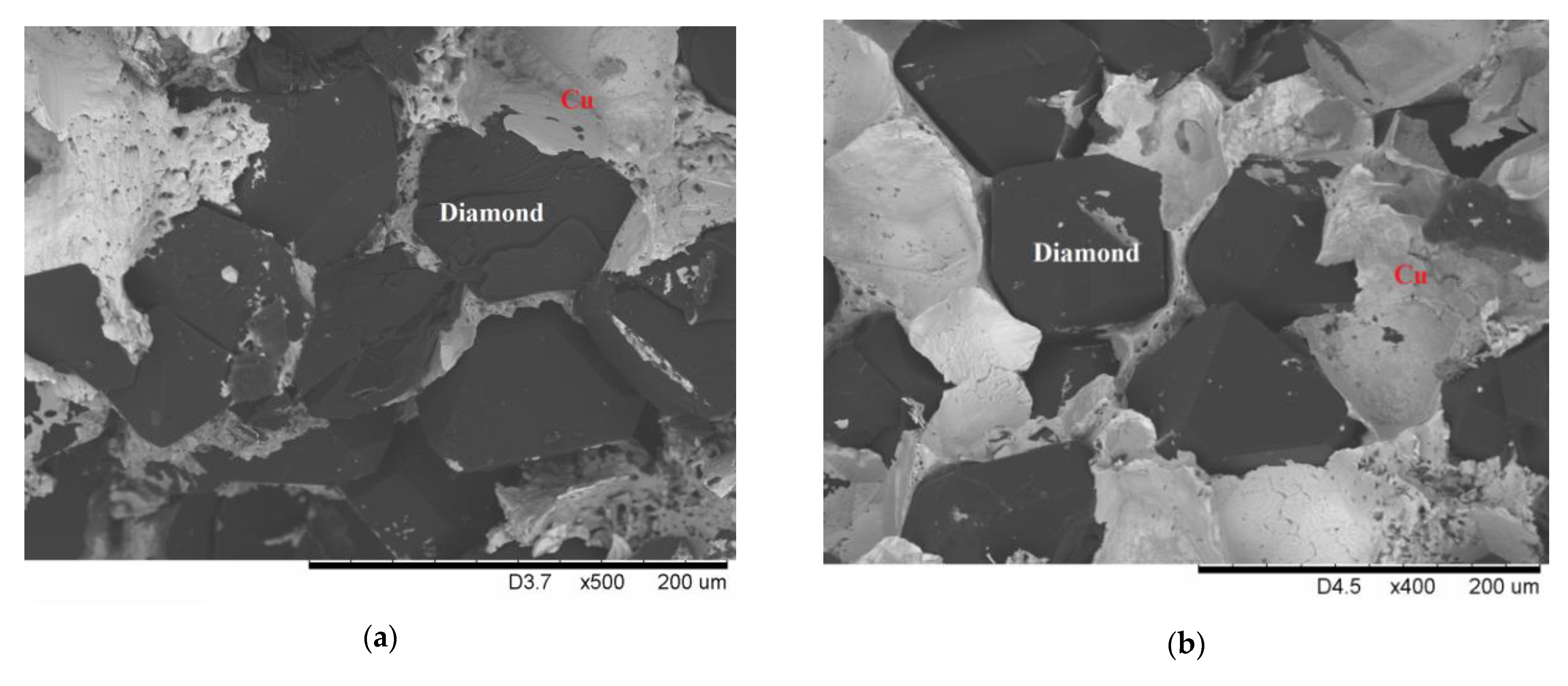

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Imai, T.; Tanabe, K.; Tsuno, T.; Kumazawa, Y.; Fujimori, N. The measurement of thermal properties of diamond. Diam. Relat. Mater. 1997, 6, 1057–1061. [Google Scholar] [CrossRef]

- Dai Sh Li, J.; Lu, N. Research progress of diamond/copper composites with high thermal conductivity. Diam. Relat. Mater. 2020, 108, 107993. [Google Scholar]

- Zhou, H.; Ran, M.; Li, Y.; Yin, Z.; Tang, Y.; Zhang, W.; Zheng, W.; Liu, J. Improvement of thermal conductivity of diamond/Al composites by optimization of liquid-solid separation process. J. Mater. Process. Technol. 2021, 297, 117267. [Google Scholar] [CrossRef]

- JunCho, H.; Yan, D.; Tam, J.; Erb, U. Effects of diamond particle size on the formation of copper matrix and the thermal transport properties in electrodeposited copper-diamond composite materials. J. Alloy. Compd. 2019, 791, 1128–1137. [Google Scholar]

- Abyzov, A.; Kidalov, S.; Shakhov, F. High thermal conductivity composite of diamond particles with tungsten coating in a copper matrix for heat sink application. Appl. Therm. Eng. 2012, 48, 72–80. [Google Scholar] [CrossRef]

- Ciupiński, Ł.; Kruszewski, M.; Grzonka, J.; Chmielewski, M.; Zielińsk, R.; Moszczyńska, D.; Michalski, A. Design of interfacial Cr3C2 carbide layer via optimization of sintering parameters used to fabricate copper/diamond composites for thermal management applications. Mater. Des. 2017, 120, 170–185. [Google Scholar] [CrossRef]

- Rape, A.; Liu, X.; Kulkarni, A.; Singh, J. Alloy development for highly conductive thermal management materials using copper-diamond composites fabricated by field assisted sintering technology. J. Mater. Sci. 2013, 48, 1262–1267. [Google Scholar] [CrossRef]

- Chu, K.; Liu Zh Jia Ch Chen, H.; Liang, X.; Gao, W.; Tian, W.; Guo, H. Thermal conductivity of SPS consolidated Cu/diamond composites with Cr-coated diamond particles. J. Alloy. Compd. 2010, 490, 453–458. [Google Scholar] [CrossRef]

- Kang, Q.P.; He, X.B.; Ren, S.B.; Liu, T.T.; Liu, Q.; Wu, M.; Qu, X.H. Microstructure and thermal properties of copper-diamond composites with tungsten carbide coating on diamond particles. Mater. Charact. 2015, 105, 18–23. [Google Scholar] [CrossRef]

- Huang, S.H.; Guo, H.; Zhang, Z.; Zhang, X.M.; Xie, H.F.; Xie, Z.N.; Peng, L.J.; Mi, X.J. Comparative study on the properties and microscopic mechanism of Ti coating and W coating diamond-copper composites. Mater. Res. Express 2020, 7, 76517. [Google Scholar] [CrossRef]

- Lei, L.; Bolzoni, L.; Yang, F. High thermal conductivity and strong interface bonding of a hot-forged Cu/Ti-coated-diamond composite. Carbon 2020, 168, 553–563. [Google Scholar] [CrossRef]

- Wang, L.; Li, J.; Catalano, M.; Bai, G.; Li, N.; Dai, J.; Wang, X.; Zhang, H.; Wang, J.; Kim, M.J. Enhanced thermal conductivity in Cu/diamond composites by tailoring the thickness of interfacial TiC layer. Compos. A Appl. Sci. Manuf. 2018, 113, 76–82. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Lang, R. Fabrication and use of Cu-Cr-diamond composites for the application in deep feed grinding of tungsten carbide. Diam. Relat. Mater. 2021, 120, 108668. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Inoue, K.; Agari, Y.; Sugioka, M.; Tanaka, M.; Takeuchi, T.; Tani, T.; Kawahara, M.; Makino, Y.; Ito, M. Effect of chromium addition on the thermal conductivity of Cu/diamond composites fabricated by SPS. J. Jpn. Soc. Powder Powder Metall. 2015, 62, 357–364. [Google Scholar] [CrossRef]

- Mańkowski, P.; Dominiak, A.; Domański, R.; Kruszewski, M.J.; Ciupiński, Ł. Thermal conductivity enhancement of copper–diamond composites by sintering with chromium additive. J. Therm. Anal. Calorim. 2014, 116, 881–885. [Google Scholar] [CrossRef]

- Li, J.; Wang, X.; Qiao, Y.; Zhang, Y.; He, Z.; Zhang, H. High thermal conductivity through interfacial layer optimization in diamond particles dispersed Zr-alloyed Cu matrix composites. Scr. Mater. 2015, 109, 72–75. [Google Scholar] [CrossRef]

- Shen, W.; Shao, W.; Wang, Q.; Ma, M. Thermal conductivity and thermal expansion coefficient of diamond/5 wt% Si–Cu composite by vacuum hot pressing. Fusion Eng. Des. 2010, 85, 2237–2240. [Google Scholar] [CrossRef]

- Tan, Z.; Li, Z.; Fan, G.; Kai, X.; Ji, G.; Zhang, L.; Zhang, D. Fabrication of diamond/aluminum composites by vacuum Hot Pressing: Process optimization and thermal properties. Composites. Pt. B Eng. 2013, 47, 173–180. [Google Scholar] [CrossRef]

- Chen, H.; Jia, C.; Li, S.; Jia, X.; Yang, X. Selective interfacial bonding and thermal conductivity of diamond/Cu-alloy composites prepared by HPHT technique. Int. J. Miner. Metall. Mater. 2012, 19, 364–371. [Google Scholar] [CrossRef]

- Schubert, T.; Trindade, B.; Weißgärber, T.; Kieback, B. Interfacial design of Cubased composites prepared by powder metallurgy for heat sink applications. Mater. Sci. Eng. A 2008, 475, 39–44. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C.; Guo, H.; Li, W. On the thermal conductivity of Cu–Zr/diamond composites. Mater. Des. 2013, 45, 36–42. [Google Scholar] [CrossRef]

- Chung, C.-Y.; Lee, M.-T.; Tsai, M.-Y.; Chu, C.-H.; Lin, S.-J. High thermal conductive diamond/Cu–Ti composites fabricated by pressureless sintering technique. Appl. Therm. Eng. 2014, 69, 208–213. [Google Scholar] [CrossRef]

- Rosinski, M.; Ciupinski, L.; Grzonka, J.; Michalski, A.; Kurzydlowski, K.J. Synthesis and characterization of the diamond/copper composites produced by the pulse plasma sintering (PPS) method. Diam. Relat. Mater. 2012, 27–28, 29–35. [Google Scholar] [CrossRef]

- Mizuuchi, K.; Agari, Y.; Yamada, S.; Inoue, K.; Tanaka, M.; Sugioka, M.; Takeuchi, T.; Tani, J.-I.; Kawahara, M.; Lee, J.-H.; et al. Thermal Properties of Diamond-Particle-Dispersed Cu-Matrix Composites Fabricated by Spark Plasma Sintering (SPS). Mater. Sci. Forum 2010, 638–642, 2115–2120. [Google Scholar] [CrossRef]

- Ukhina, A.; Dudina, D.; Esikov, M.; Samoshkin, D.; Stankus, S.; Skovorodin, I.; Galashov, E.; Bokhonov, B. The influence of morphology and composition of metal–carbide coatings deposited on the diamond surface on the properties of copper–diamond composites. Surf. Coat. Technol. 2020, 401, 126272. [Google Scholar] [CrossRef]

- Tan, Z.; Ji, G.; Addad, A.; Li, Z.; Silvain, J.-F.; Zhang, D. Tailoring interfacial bonding states of highly thermal performance diamond/Al composites: Spark plasma sintering vs. vacuum hot pressing. Composites. Pt. A Appl. Sci. Manuf. 2016, 91, 9–19. [Google Scholar] [CrossRef]

- Ukhina, A.; Dudina, D.; Samoshkin, D.; Galashov, E.; Skovorodin, I.; Bokhonov, B. Effect of the surface modification of synthetic diamond with nickel or tungsten on the properties of copper–diamond composites. Inorg. Mater. 2018, 54, 426–433. [Google Scholar] [CrossRef]

- Ukhina, A.; Dudina, D.; Bokhonov, B. Selective Deposition of Mo2C-Containing Coatings on {100} Facets of Synthetic Diamond Crystals. Int. J. Mol. Sci. 2022, 23, 8511. [Google Scholar] [CrossRef]

- Vidyuk, T.; Dudina, D.; Korchagin, M.; Gavrilov, A.; Skripkina, T.; Ukhina, A.; Anisimov, A.; Bokhonov, B. Melting at the inter-particle contacts during Spark Plasma Sintering: Direct microstructural evidence and relation to particle morphology. Vacuum 2020, 181, 109566. [Google Scholar] [CrossRef]

- Vidyuk, T.; Dudina, D.; Korchagin, M.; Gavrilov, A.; Bokhonov, B.; Ukhina, A.; Esikov, M.; Shikalov, V.; Kosarev, V. Spark plasma sintering treatment of cold sprayed materials for synthesis and structural modification: A case study using TiC-Cu composites. Mater. Lett. X 2022, 14, 100140. [Google Scholar] [CrossRef]

- Dudina, D.; Vidyuk, T.; Korchagin, M.; Gavrilov, A.; Bulina, N.; Esikov, M.; Datekyu, M.; Kato, H. Interaction of a Ti–Cu alloy with carbon: Synthesis of composites and model experiments. Materials 2019, 12, 1482. [Google Scholar] [CrossRef] [PubMed]

- Abedi, M.; Asadi, A.; Sovizi, S.; Moskovskikh, D.; Vorotilo, S.; Mukasyan, A. Influence of pulsed direct current on the growth rate of intermetallic phases in the Ni–Al system during reactive spark plasma sintering. Scr. Mater. 2022, 216, 114759. [Google Scholar] [CrossRef]

| Sample Number | Sintering Method | Additive | Concentrations of the Additive, Cu and Diamond, Vol.% | Sintering Time, min | Relative Density, % | Thermal Conductivity, W m−1 K−1 | ||

|---|---|---|---|---|---|---|---|---|

| Additive | Cu | Diamond | ||||||

| 1 | HP | W | 0.15 | 49.85 | 50 | 15 | 90 ± 1 | 188 ± 9 |

| 2 | HP | W | 0.35 | 49.65 | 50 | 15 | 91 ± 1 | 192 ± 10 |

| 3 | HP | W | 0.7 | 49.3 | 50 | 15 | 88 ± 1 | 203 ± 10 |

| 4 | HP | W | 2 | 48 | 50 | 15 | 90 ± 1 | 172 ± 9 |

| 5 | SPS | W | 0.7 | 49.3 | 50 | 3 | 80 ± 1 | 170 ± 9 |

| 6 | SPS | W | 0.7 | 49.3 | 50 | 10 | 86 ± 1 | 190 ± 10 |

| 7 | SPS | Mo | 0.7 | 49.3 | 50 | 10 | 91 ± 1 | 194 ± 10 |

| 8 | SPS | Cr | 0.7 | 49.3 | 50 | 10 | 89 ± 1 | 385 ± 19 |

| 9 | SPS | Ti | 0.7 | 49.3 | 50 | 10 | 86 ± 1 | 420 ± 21 |

| 10 | HP | Ti | 0.7 | 49.3 | 50 | 15 | 89 ± 1 | 178 ± 9 |

| 11 | SPS | Ti | 0.35 | 49.65 | 50 | 10 | 82 ± 1 | 362 ± 18 |

| 12 | SPS | Ti | 2 | 48 | 50 | 10 | 82 ± 1 | 67 ± 3 |

| 13 | HP | Ti | 0.35 | 49.65 | 50 | 15 | 90 ± 1 | 265 ± 13 |

| 14 | HP | Ti | 2 | 48 | 50 | 15 | 77 ± 1 | 63 ± 3 |

| Sample Number | Concentrations of the Ti, Vol.% | Sintering Method | Cu Lattice Parameter, Å |

|---|---|---|---|

| 1 | 0.35 | HP | 3.6172 ± 0.0014 |

| 2 | 0.35 | SPS | 3.6169 ± 0.0018 |

| 3 | 0.7 | HP | 3.6176 ± 0.0016 |

| 4 | 0.7 | SPS | 3.6181 ± 0.0012 |

| 5 | 2 | HP | 3.623 ± 0.002 |

| 6 | 2 | SPS | 3.6221 ± 0.0016 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ukhina, A.V.; Dudina, D.V.; Esikov, M.A.; Samoshkin, D.A.; Stankus, S.V. The Influence of the Carbide-Forming Metallic Additives (W, Mo, Cr, Ti) on the Microstructure and Thermal Conductivity of Copper–Diamond Composites. J. Compos. Sci. 2023, 7, 219. https://doi.org/10.3390/jcs7060219

Ukhina AV, Dudina DV, Esikov MA, Samoshkin DA, Stankus SV. The Influence of the Carbide-Forming Metallic Additives (W, Mo, Cr, Ti) on the Microstructure and Thermal Conductivity of Copper–Diamond Composites. Journal of Composites Science. 2023; 7(6):219. https://doi.org/10.3390/jcs7060219

Chicago/Turabian StyleUkhina, Arina V., Dina V. Dudina, Maksim A. Esikov, Dmitrii A. Samoshkin, and Sergei V. Stankus. 2023. "The Influence of the Carbide-Forming Metallic Additives (W, Mo, Cr, Ti) on the Microstructure and Thermal Conductivity of Copper–Diamond Composites" Journal of Composites Science 7, no. 6: 219. https://doi.org/10.3390/jcs7060219

APA StyleUkhina, A. V., Dudina, D. V., Esikov, M. A., Samoshkin, D. A., & Stankus, S. V. (2023). The Influence of the Carbide-Forming Metallic Additives (W, Mo, Cr, Ti) on the Microstructure and Thermal Conductivity of Copper–Diamond Composites. Journal of Composites Science, 7(6), 219. https://doi.org/10.3390/jcs7060219