Experimental Investigation of Mechanical Property and Wear Behaviour of T6 Treated A356 Alloy with Minor Addition of Copper and Zinc

Abstract

1. Introduction

2. Methodology

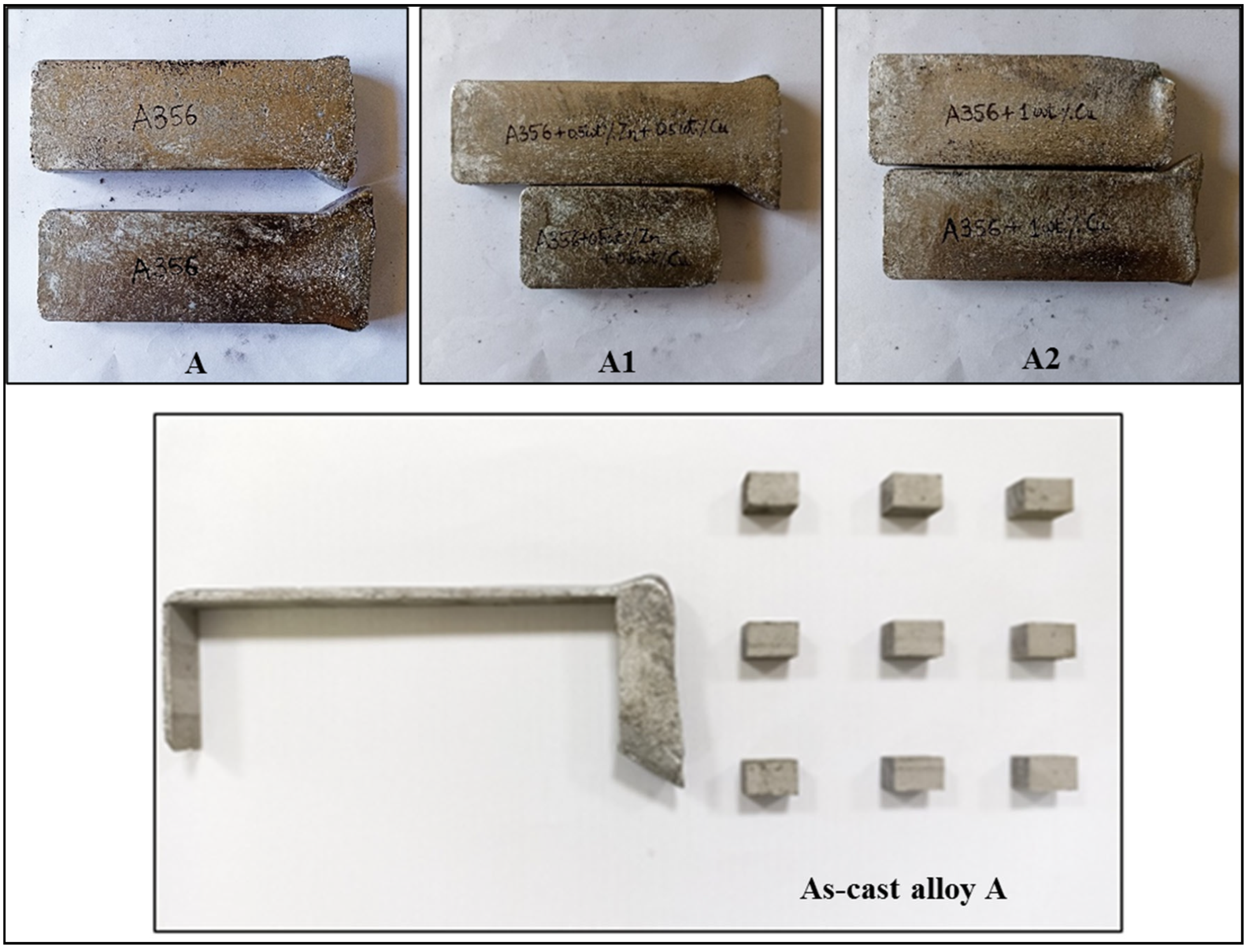

2.1. Preparation of Alloys

2.2. Age Hardening Treatment of A, A1, and A2 Alloys

2.3. Characterization of A, A1, and A2 Alloys

2.4. Wear Test of A, A1, and A2 Alloys

3. Results and Discussion

3.1. Microstructure Studies of As-Cast Alloys

3.2. Hardness of As-Cast A, A1, and A2 Alloys

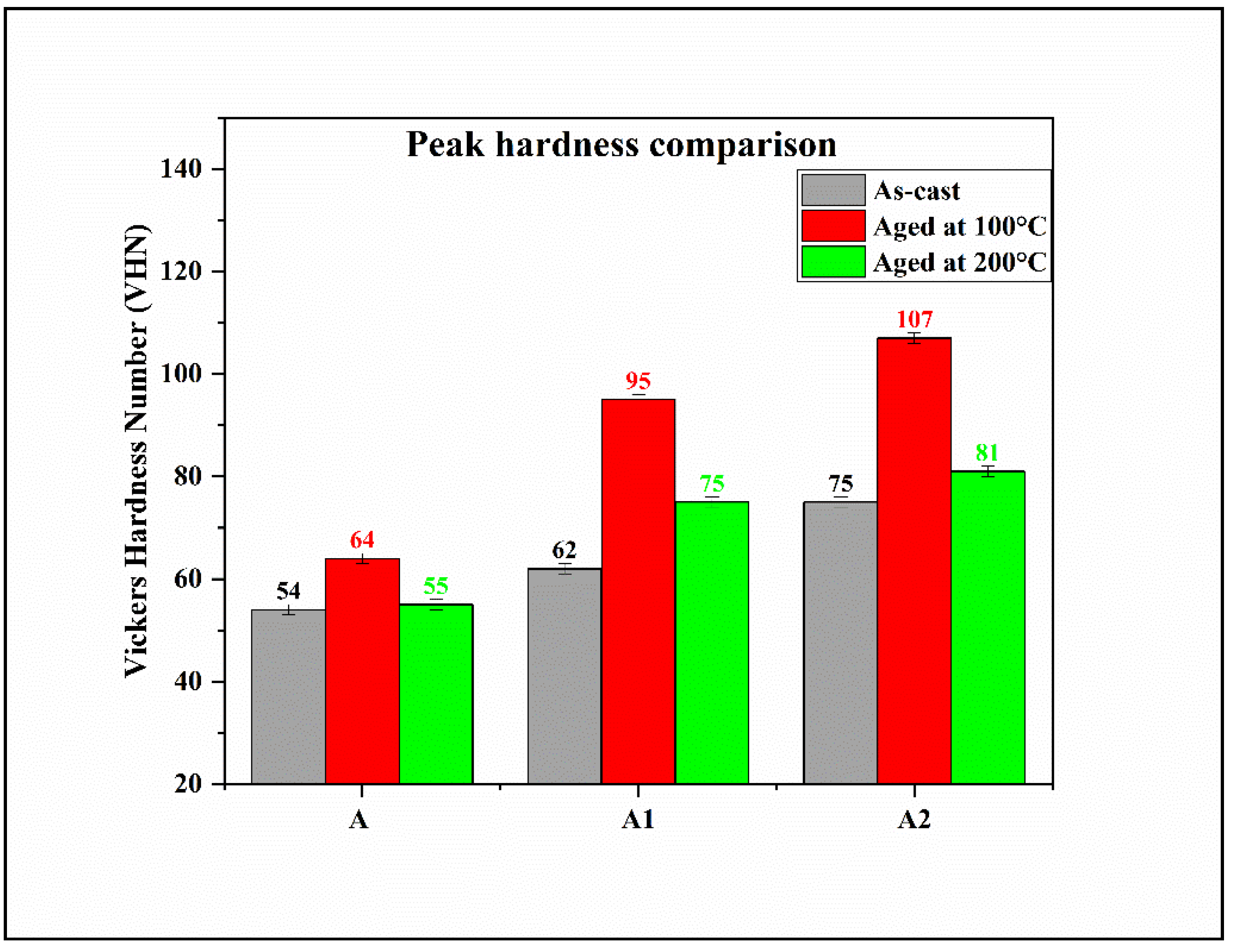

3.3. Aging Hardening Treatment of A, A1, and A2 Alloys

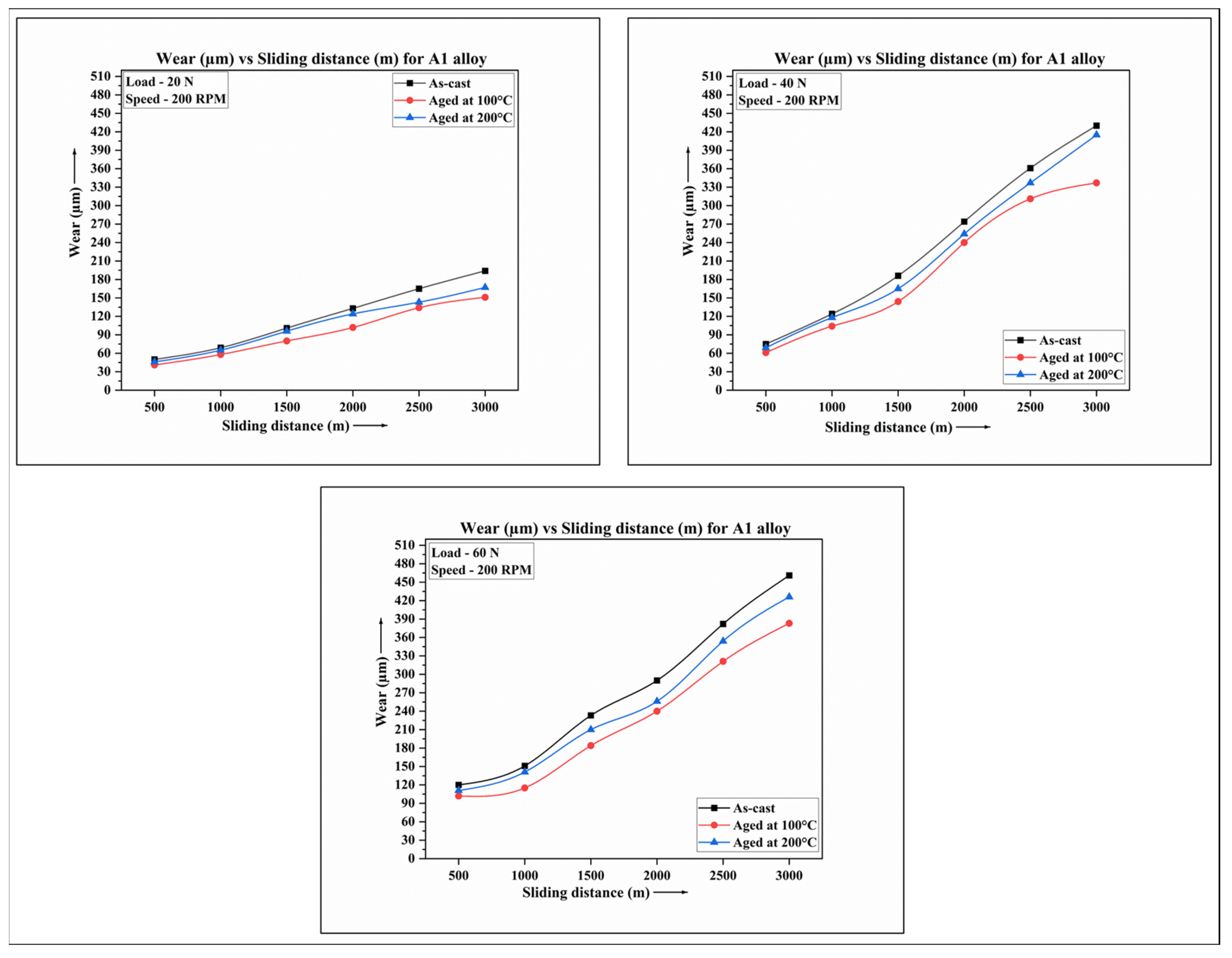

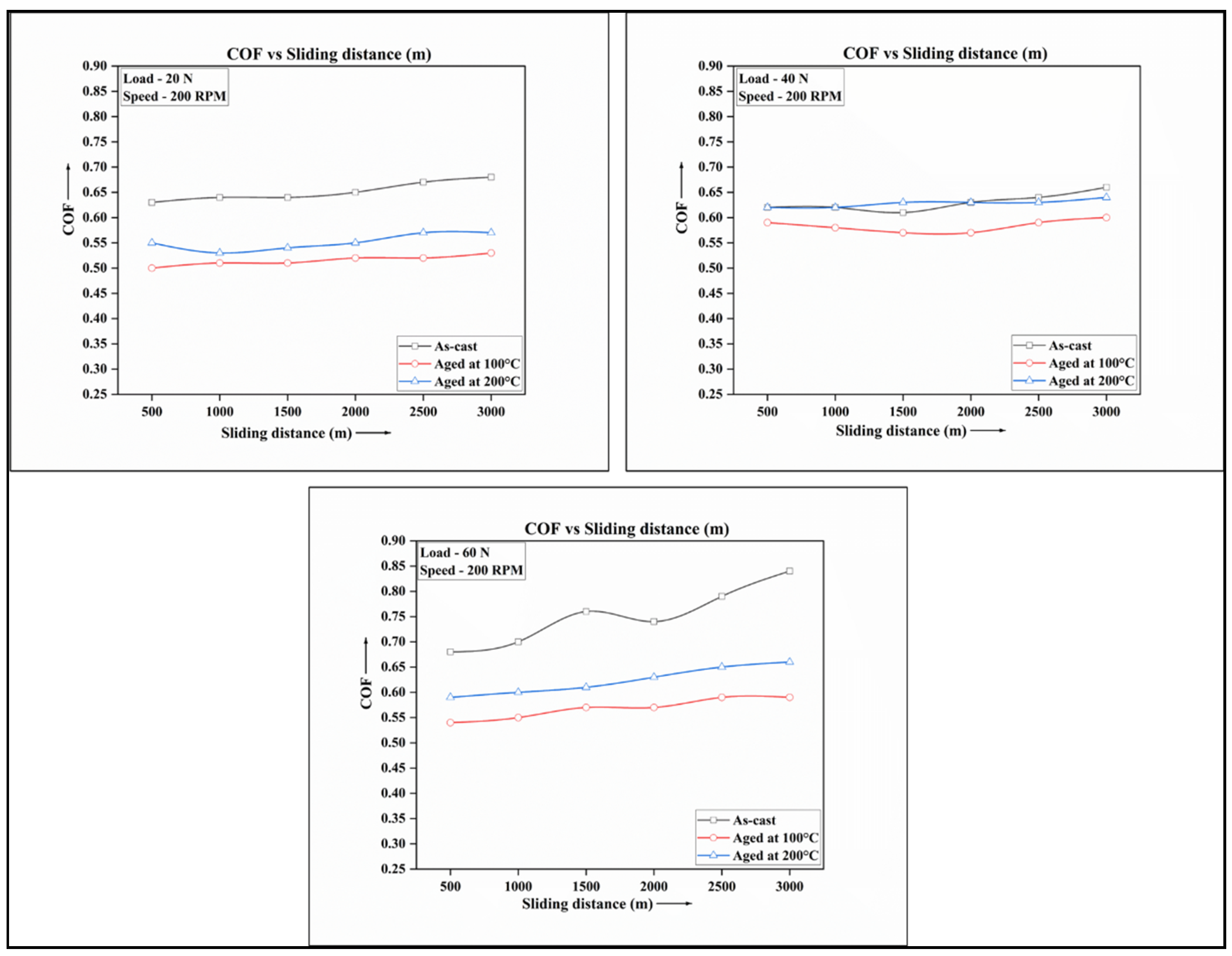

3.4. Wear Studies of As-Cast and Age Hardened A, A1, and A2 Alloys

4. Conclusions

- The microstructure analysis revealed that under as-cast conditions the addition of zinc to the A356 alloy has no role in controlling grain size during the solidification process. On the other hand, the inclusion of 1% copper as an alloying element to A356 resulted in the formation of a greater amount of pro-eutectic α-Al, leading to finer eutectic colonies of Al-Si. Furthermore, the microstructure study found that adding only 0.5% copper to the A356 alloy may not be sufficient to produce a substantial amount of Al2Cu intermetallic phase. This information supports the conclusion that the presence of copper as an alloying element has an impact on the solidification process and the resulting grain structure, but a higher concentration of copper is necessary for the formation of a notable quantity of Al2Cu intermetallic phase.

- The highest hardness value of 75 VHN in as-cast alloy specimens was obtained with the addition of 1% copper (A2 alloy), and this was attributed to the precipitation of the Mg2Si and Al2Cu intermetallic phases. The addition of copper to the A356 alloy was found to enhance the age hardening properties when quenched and subjected to aging conditions through both solid solutions strengthening and the formation of various intermetallic phases. Aging of alloys at 100 °C displayed a 95% improvement in hardness at the peak aging stage, although the process took longer than aging at 200 °C.

- The 100 °C peak aging and 1 wt.% Cu as an alloying element to A356 alloy resulted in maximum wear resistance property. Improvement in wear resistance property in A1 (0.5 wt.% Zn + 0.5 wt.% Cu) and A2 (1 wt.% Cu) alloy compared to base alloy A356 can be summarized as follows:

- Precipitation hardening treatment and the addition of a minor quantity of zinc and copper as an alloying element to A356 alloy has resulted in the overall improvement in wear resistance with a lesser coefficient of friction.

- At lower load conditions (20 N), A1 (0.5 wt.% Zn + 0.5 wt.% Cu) alloy showed 15–22% increase in wear resistance aged at 200 °C and 29–35% increase in wear resistance aged at 100 °C, whereas A2 (1 wt.% Cu) alloy showed 36–40% increase in wear resistance aged at 200 °C and 58–75% improvement in wear resistance property aged at 100 °C.

- At higher load conditions (40–60 N), A1 (0.5 wt.% Zn + 0.5 wt.% Cu) alloy showed 6–14% increase in wear resistance aged at 200 °C and 30–40% increase in wear resistance aged at 100 °C, whereas A2 alloy showed 29–35% increase in wear resistance aged at 200 °C and 150–182% improvement in wear resistance property aged at 100 °C.

- Worn surface analysis of A356 + 1 wt.% Cu (A2) alloy confirmed the presence of an oxidation layer between the mating surfaces, which resulted in a reduction in wear rate and coefficient of friction both at lower and higher load conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Elmadagli, M.; Perry, T.; Alpas, A.T. A parametric study of the relationship between microstructure and wear resistance of Al-Si alloys. Wear 2006, 262, 79–92. [Google Scholar] [CrossRef]

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Torabi Parizi, M. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Nwobi-okoye, C.C.; Ochieze, B.Q. Age hardening process modeling and optimization of aluminum alloy A356/Cow horn particulate composite for brake drum application using RSM, ANN and simulated annealing. Def. Technol. 2018, 14, 336–345. [Google Scholar] [CrossRef]

- Deepak Kumar, S.; Dewangan, S.; Jha, S.K.; Mandal, A. Tribo-performance of thixoformed A356-5TiB2 in-situ composites. IOP Conf. Ser. Mater. Sci. Eng. 2019, 653, 012045. [Google Scholar] [CrossRef]

- Khomamizadeh, F.; Ghasemi, A. Evaluation of quality index of A356 aluminum alloy by microstructural analysis. Sci. Iran. 2004, 11, 386–391. [Google Scholar]

- Avner, S.H. Introduction to Physical Metallurgy; McGraw Hill: New York, NY, USA, 1984; Volume 1. [Google Scholar]

- Rajan, T.V.; Sharma, C.P.; Ashok, S. Heat Treatment—Principles and Techniques; PHI Learning Pvt. Ltd.: Delhi, India, 2011; Volume 2. [Google Scholar]

- Sarkar, A.D.; Clarke, J. Friction and wear of aluminium-silicon alloys. Wear 1980, 61, 157–167. [Google Scholar] [CrossRef]

- Clarke, J.; Sarkar, A.D. Wear characteristics of as-cast binary aluminium-silicon alloys. Wear 1979, 54, 7–16. [Google Scholar] [CrossRef]

- Sarkar, A.D. Wear of aluminium-silicon alloys. Wear 1975, 31, 331–343. [Google Scholar] [CrossRef]

- Chandrashekharaiah, T.M.; Kori, S.A. Effect of grain refinement and modification on the dry sliding wear behaviour of eutectic Al-Si alloys. Tribol. Int. 2009, 42, 59–65. [Google Scholar] [CrossRef]

- Kori, S.A.; Prabhudev, M.S.; Chandrashekharaiah, T.M. Studies on the microstructure and mechanical properties of A356 alloy with minor additions of copper and magnesium. Trans. Indian Inst. Met. 2009, 62, 353–356. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 9, 4924–4939. [Google Scholar] [CrossRef]

- Ding, X.P.; Cui, H.; Zhang, J.X.; Li, H.X.; Guo, M.X.; Lin, Z.; Zhuang, L.Z.; Zhang, J.S. The effect of Zn on the age hardening response in an Al-Mg-Si alloy. Mater. Des. 2015, 65, 1229–1235. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; Mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Srinivas, D.; Gowrishankar, M.C.; Hiremath, P.; Sharma, S.; Shettar, M.; Jayashree, P.K. Influence of various trace metallic additions and reinforcements on A319 and A356 alloys—A review. Cogent Eng. 2022, 9, 2007746. [Google Scholar] [CrossRef]

- Baradarani, B.; Raiszadeh, R. Precipitation hardening of cast Zr-containing A356 aluminium alloy. Mater. Des. 2011, 32, 935–940. [Google Scholar] [CrossRef]

- Sağlam, I.; Özyürek, D.; Çetinkaya, K. Effect of ageing treatment on wear properties and electrical conductivity of Cu-Cr-Zr alloy. Bull. Mater. Sci. 2011, 34, 1465–1470. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Moemeni, H. Effect of copper and solidification conditions on the microstructure and mechanical properties of Al-Si-Mg alloys. J. Mater. Process. Technol. 2004, 153–154, 193–198. [Google Scholar] [CrossRef]

- Su, J.H.; Dong, Q.M.; Liu, P.; Li, H.J.; Kang, B.X. Research on aging precipitation in a Cu-Cr-Zr-Mg alloy. Mater. Sci. Eng. A 2005, 392, 422–426. [Google Scholar] [CrossRef]

- Tang, J.G.; Chen, H.; Zhang, X.M.; Liu, S.D.; Liu, W.J.; Ouyang, H.; Li, H.P. Influence of quench-induced precipitation on aging behavior of Al-Zn-Mg-Cu alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1255–1263. [Google Scholar] [CrossRef]

- Colak, M.; Findik, F.; Yetgin, S.H. Investigation of the effect of adding cu on al alloys for wear and friction proper-ties. Int. J. Res. Engg. Technol. 2016, 1, 448–453. [Google Scholar]

- Hassan, A.M.; Alrashdan, A.; Hayajneh, M.T.; Mayyas, A.T. Wear behavior of Al-Mg-Cu-based composites containing SiC particles. Tribol. Int. 2009, 42, 1230–1238. [Google Scholar] [CrossRef]

- Alias, T.Y.; Haque, M.M. Wear properties of aluminum—silicon eutectic alloy. Int. Conf. Mech. Eng. 2003, 2003, 26–28. [Google Scholar]

- Sudarshan; Surappa, M.K. Dry sliding wear of fly ash particle reinforced A356 Al composites. Wear 2008, 265, 349–360. [Google Scholar] [CrossRef]

- Prabhudev, M.S.; Auradi, V.; Venkateswarlu, K.; Siddalingswamy, N.H.; Kori, S.A. Influence of Cu addition on dry sliding wear behaviour of A356 alloy. Procedia Eng. 2014, 97, 1361–1367. [Google Scholar] [CrossRef]

- Kori, S.A.; Prabhudev, M.S. Sliding wear characteristics of Al-7Si-0.3Mg alloy with minor additions of copper at elevated temperature. Wear 2011, 271, 680–688. [Google Scholar] [CrossRef]

- Bannaravuri, P.K.; Birru, A.K. Strengthening of mechanical and tribological properties of Al-4.5%Cu matrix alloy with the addition of bamboo leaf ash. Results Phys. 2018, 10, 360–373. [Google Scholar] [CrossRef]

- Şimşek, İ.; Özyürek, D. Investigation of the effects of Mg amount on microstructure and wear behavior of Al-Si-Mg alloys. Eng. Sci. Technol. Int. J. 2019, 22, 370–375. [Google Scholar] [CrossRef]

- Kral, M.V.; McIntyre, H.R.; Smillie, M.J. Identification of intermetallic phases in a eutectic Al-Si casting alloy using electron backscatter diffraction pattern analysis. Scr. Mater. 2004, 51, 215–219. [Google Scholar] [CrossRef]

- Tuncay, T.; Bayoglu, S. The effect of iron content on microstructure and mechanical properties of A356 Cast Alloy. Miner. Met. Mater. Soc. 2017, 48, 794–804. [Google Scholar] [CrossRef]

- Seifeddine, S.; Sjolander, E. Optimization of solution treatment of cast Al-7Si-0.3Mg and Al-8Si-3Cu-0.5Mg Alloys. Miner. Met. Mater. Soc. 2013, 45, 1916–1927. [Google Scholar] [CrossRef]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Cai, Z.; Zhang, C.; Wang, R.; Peng, C.; Wu, X. Effect of copper content on microstructure and mechanical properties of Al/Sip composites consolidated by liquid phase hot pressing. Mater. Des. 2016, 110, 10–17. [Google Scholar] [CrossRef]

- Doddapaneni, S.; Kumar, S.; Shettar, M.; Rao, S.; Sharma, S.; Gowrishankar, M.C. Experimental investigation to confirm the presence of TiB2 reinforcements in the matrix and effect of artificial ag-ing on hardness and tensile properties of stir-cast LM4-TiB2 composite. Crystals 2022, 12, 1114. [Google Scholar] [CrossRef]

- Abdelaziz, M.H.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Effect of morphological changes of eutectic Si particles on the ambient and high temperature tensile properties of Zr containing Al–Si alloys. J. Mater. Res. Technol. 2020, 9, 5962–5981. [Google Scholar] [CrossRef]

- Long, H.C.; Chen, J.H.; Liu, C.H.; Li, D.Z.; Li, Y.Y. The negative effect of solution treatment on the age hardening of A356 alloy. Mater. Sci. Eng. A 2013, 566, 112–118. [Google Scholar] [CrossRef]

- Radhika, N.; Sasikumar, J.; Sylesh, J.L.; Kishore, R. Dry reciprocating wear and frictional behaviour of B4C reinforced functionally graded and homogenous aluminium matrix composites. J. Mater. Res. Technol. 2020, 9, 1578–1592. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Guo, R.Q.; Huang, P.; Ray, S. Friction and abrasion resistance of cast aluminum alloy-fly ash composites. Metall. Mater.Sci. 1997, 28, 245–250. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Arif, S.; Aziz, T.; Waseem, A.; Shaikh, M.A.N.; Ali, M. Microstructural, mechanical and tribological behaviour of powder metallurgy processed SiC and RHA reinforced Al-based composites. Surf. Interfaces 2019, 15, 166–179. [Google Scholar] [CrossRef]

- Shanmughasundaram, P.; Subramanian, R.; Prabhu, G. Some studies on aluminium—Fly ash composites fabricated by two step stir casting method. Eur. J. Sci. Res. 2011, 63, 204–218. [Google Scholar]

- Vinod, B.; Ramanathan, S.; Anandajothi, M. Effect of organic and inorganic reinforcement on tribological behaviour of aluminium A356 matrix hybrid compo-site. J. Bio-Tribo-Corrosion 2018, 4, 45. [Google Scholar] [CrossRef]

- Ram, S.C.; Chattopadhyay, K.; Chakrabarty, I. Effect of magnesium content on the microstructure and dry sliding wear behavior of centrifugally cast functionally graded A356-Mg2Si in situ composites. Mater. Res. Express 2018, 5, 046535. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Khan, A.R.A.; Ravikumar, N.; Savanprabhu, P. Prediction of wear coefficient of Al6061-TiO2 composites. Wear 2005, 259, 602–608. [Google Scholar] [CrossRef]

- Li, H.; Jiao, L.; Xu, R.; Li, F.; Lu, S.B.; Qiao, Y.P.; Li, C.Y.; Zhang, P. Surface wear behavior and friction and wear mechanism studies of A356/3 wt.% Al3Zr composites. J. Mater. Eng. Perform. 2021, 30, 3892–3902. [Google Scholar] [CrossRef]

- Shivaprasad, C.G.; Aithal, K.; Narendranath, S.; Desai, V.; Mukunda, P.G. Effect of combined grain refinement and modification on microstructure and mechanical properties of hypoeutectic, eutectic and hypereutectic Al-Si alloys. Int. J. Microstruct. Mater. Prop. 2015, 10, 274–284. [Google Scholar] [CrossRef]

- Ravikiran, A.; Surappa, M.K. Effect of sliding speed on wear behaviour of A356 Al-30 wt.% SiCp MMC. Wear 1997, 206, 33–38. [Google Scholar] [CrossRef]

- Prasad, D.S.; Krishna, A.R. Tribological properties of A356.2/RHA composites. J. Mater. Sci. Technol. 2012, 28, 367–372. [Google Scholar] [CrossRef]

- Wu, Y.C. Tailoring microstructure and its effect on wear behavior of an Al—7Si alloy reinforced with in situ formed Al 3 Ti particulates. J. Mat. Res. Tech. 2020, 9, 7136–7148. [Google Scholar] [CrossRef]

| Casting | Designation |

|---|---|

| A356 + 1 wt.% Mg | A |

| A356 + 1 wt.% Mg + 0.5 wt.%Zn + 0.5 wt.% Cu | A1 |

| A356 + 1 wt.% Mg + 1 wt.% Cu | A2 |

| Designation | Si | Mg | Cu | Zn | Fe | Others | Al |

|---|---|---|---|---|---|---|---|

| A356 | 6.5 | 0.2 | 0.2 | 0.1 | 0.2 | 0.1 | Bal. |

| A | 6.5 | 1.2 | 0.2 | 0.1 | 0.2 | 0.1 | Bal. |

| A1 | 6.5 | 1.2 | 0.7 | 0.6 | 0.2 | 0.1 | Bal. |

| A2 | 6.5 | 1.2 | 1.2 | 0.1 | 0.2 | 0.1 | Bal. |

| Model | TR 20 Neo |

|---|---|

| Disc size | ɸ100 × 6 mm thickness |

| Material | Hardened ground steel (EN-31), 65 HRC |

| Rotational Speed | 80 rpm (min.) and 800 rpm (max.) |

| Motor | AC motor, 230 V, 0.37 kW |

| Wear track diameter | 20 mm (min.) and 80 mm (max.) |

| Normal load | Upto 200 N max |

| Designation | Vickers Hardness Number (VHN) | Average Vickers Hardness Number (VHN) | ||||

|---|---|---|---|---|---|---|

| Trail 1 | Trail 2 | Trail 3 | Trail 4 | Trail 5 | ||

| A | 54.2 | 53.7 | 52.1 | 53.0 | 53.4 | 54 |

| A1 | 61.7 | 62.3 | 61.1 | 62.5 | 61.9 | 62 |

| A2 | 75.5 | 76.1 | 74.0 | 73.8 | 72.5 | 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashimat, N.; Sharma, S.; Nayak, R.; Manjunathaiah, K.B.; Shettar, M.; Chennegowda, G.M. Experimental Investigation of Mechanical Property and Wear Behaviour of T6 Treated A356 Alloy with Minor Addition of Copper and Zinc. J. Compos. Sci. 2023, 7, 149. https://doi.org/10.3390/jcs7040149

Kashimat N, Sharma S, Nayak R, Manjunathaiah KB, Shettar M, Chennegowda GM. Experimental Investigation of Mechanical Property and Wear Behaviour of T6 Treated A356 Alloy with Minor Addition of Copper and Zinc. Journal of Composites Science. 2023; 7(4):149. https://doi.org/10.3390/jcs7040149

Chicago/Turabian StyleKashimat, Nithesh, Sathyashankara Sharma, Rajesh Nayak, Karthik Birur Manjunathaiah, Manjunath Shettar, and Gowrishankar Mandya Chennegowda. 2023. "Experimental Investigation of Mechanical Property and Wear Behaviour of T6 Treated A356 Alloy with Minor Addition of Copper and Zinc" Journal of Composites Science 7, no. 4: 149. https://doi.org/10.3390/jcs7040149

APA StyleKashimat, N., Sharma, S., Nayak, R., Manjunathaiah, K. B., Shettar, M., & Chennegowda, G. M. (2023). Experimental Investigation of Mechanical Property and Wear Behaviour of T6 Treated A356 Alloy with Minor Addition of Copper and Zinc. Journal of Composites Science, 7(4), 149. https://doi.org/10.3390/jcs7040149