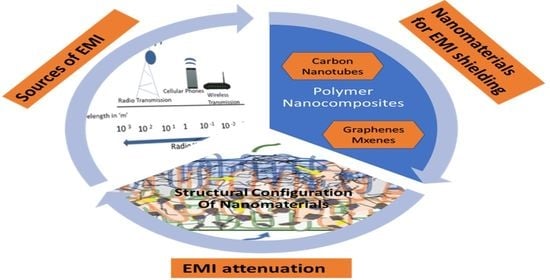

Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding

Abstract

1. Introduction

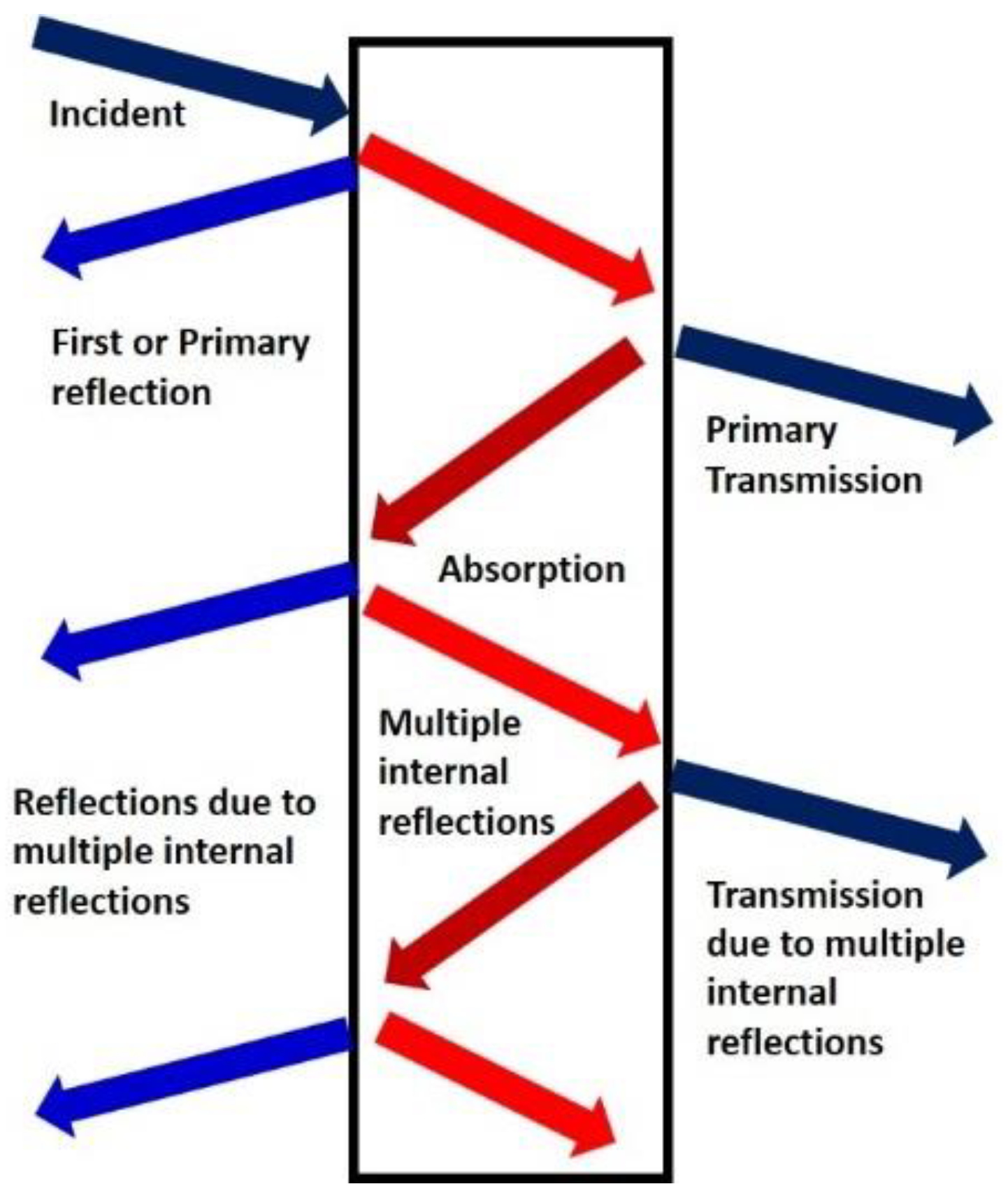

2. EMI Shielding Measurements

3. EMI Shielding Materials

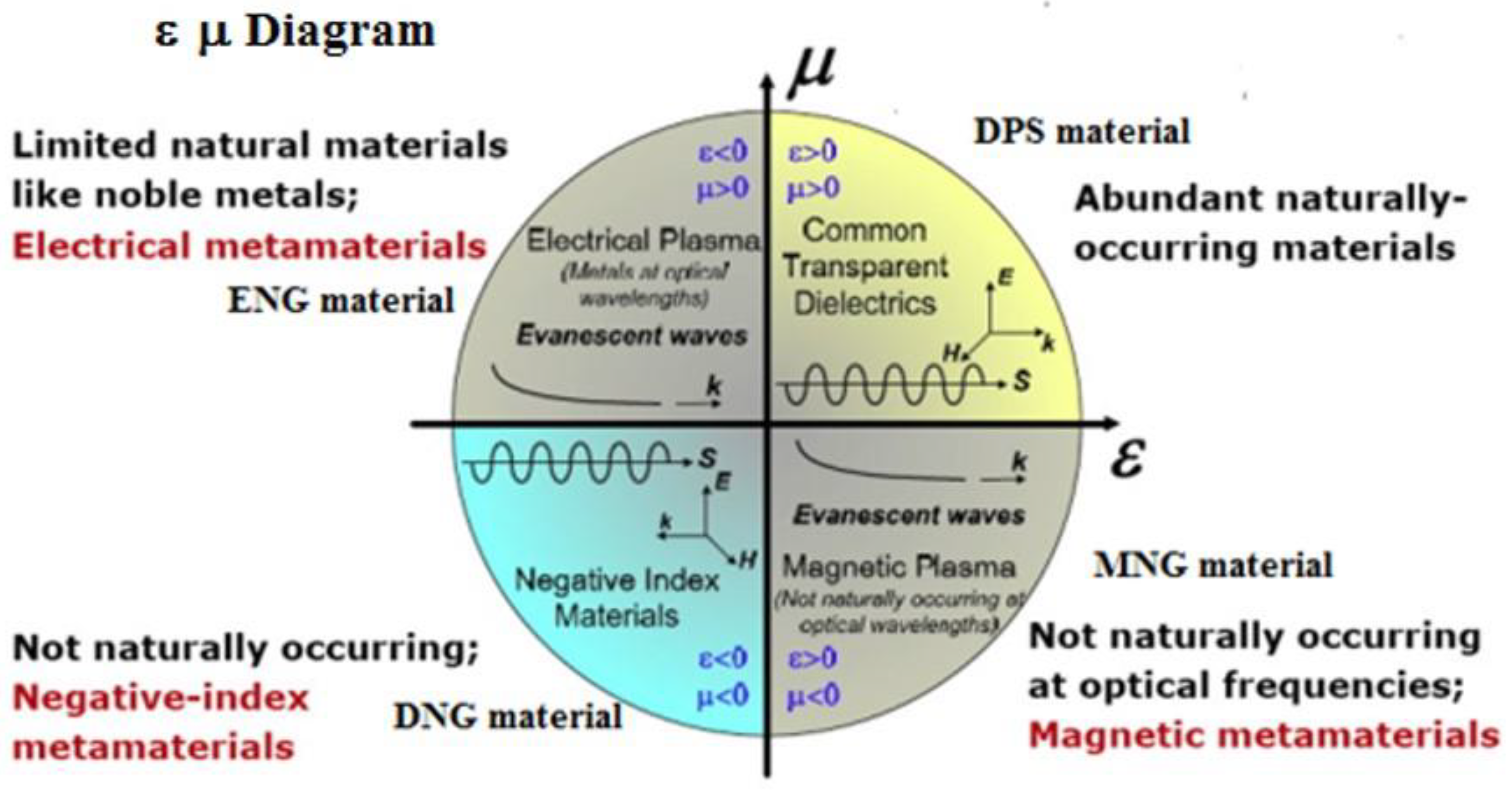

4. Metamaterials

- DPS (double positive material/medium)

- ENG (epsilon negative material/medium)

- DNG (double negative material/medium)

- MNG (mu negative material/medium)

5. Carbon Nanotubes

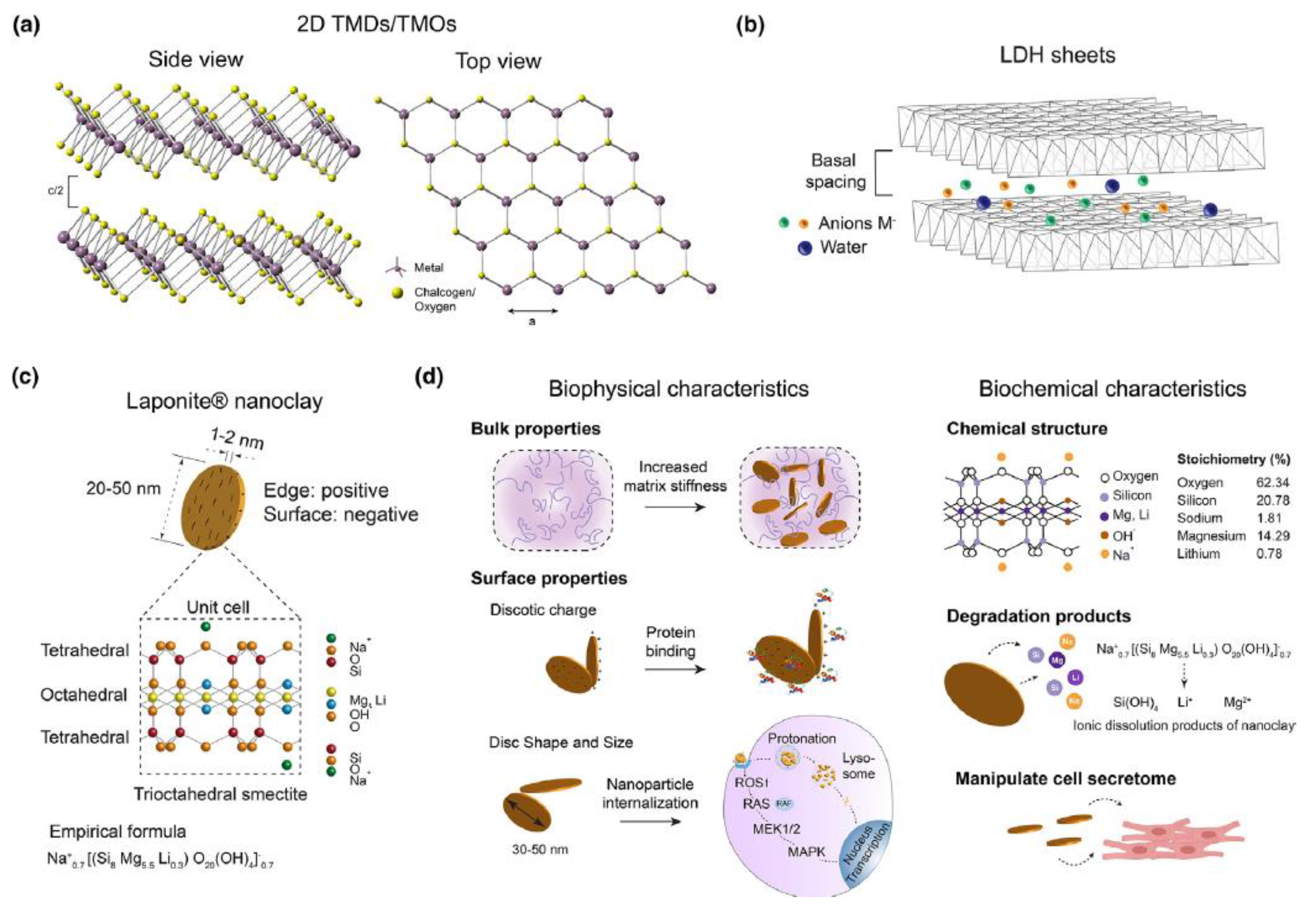

6. 2D Nanomaterials

7. MXenes

8. Polymer Nanocomposites

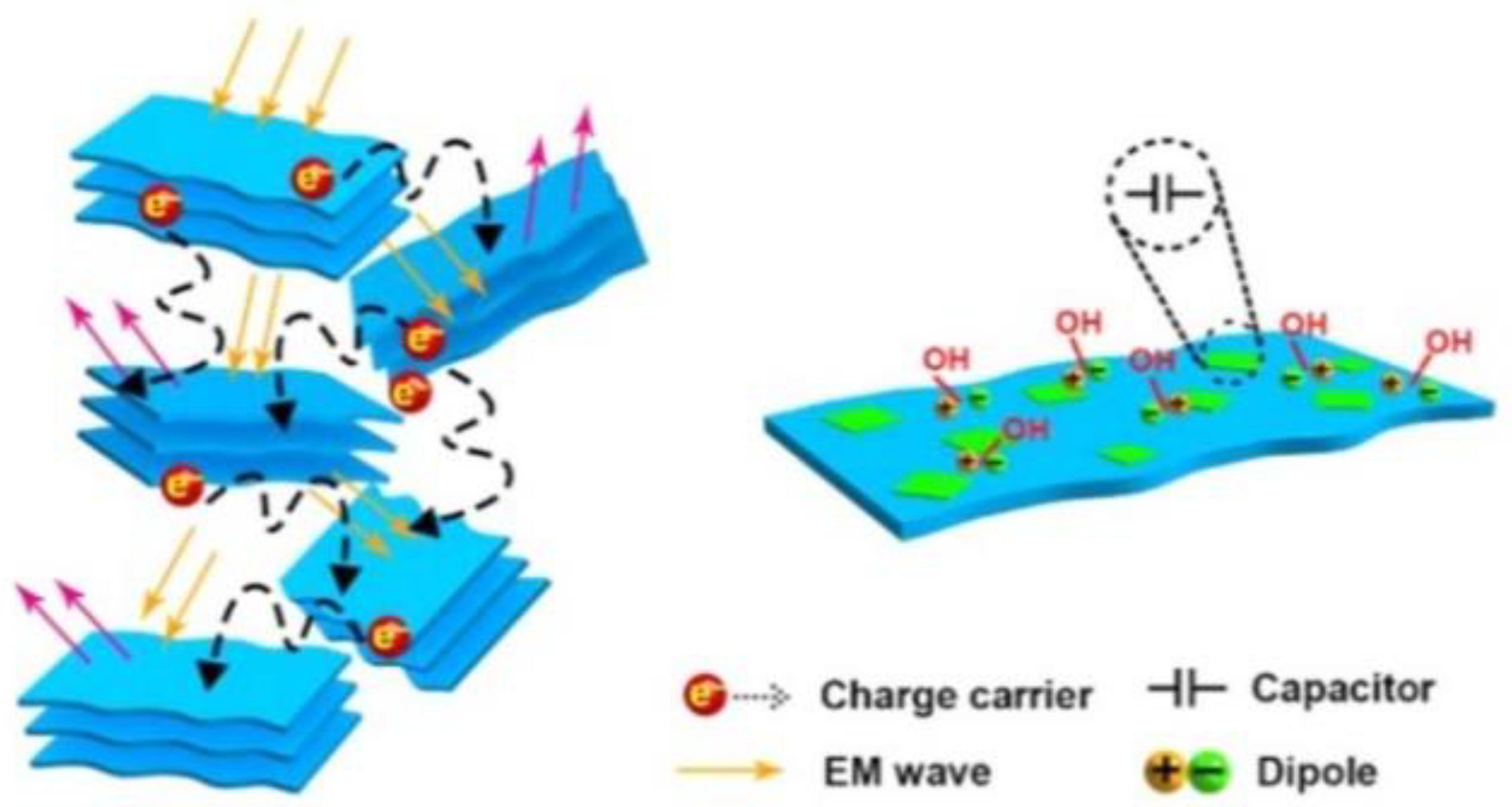

9. 2D Nanomaterials-Based Polymer Nanocomposites

10. Conclusions and Future Perspectives

- (a)

- Enhancing the internal path length with the presence of scatterers. The morphology of the scatterers plays a crucial role in the number of scatterers for effective shielding.

- (b)

- Alignment of conducting nano-rods enhances reflection-based shielding while retaining a low number of fillers.

- (c)

- For absorption dominant shielding, the presence of magnetic nanoparticles is desirable. Additionally, surface modification enhances the scattering at the surface thereby reducing the amount of radiation entering the shield.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Violette, J.L.N.; White, D.R.J.; Violette, M.F. An Introduction to Electromagnetic Compatibility. In Electromagnetic Compatibility Handbook; Springer: Dordrecht, The Netherlands, 1987; pp. 1–12. [Google Scholar]

- Jang, J.O.; Park, J.W. Coating Materials for Shielding Electromagnetic Waves. U.S. Patent 6355707 B1, 12 March 2002. Available online: https://patents.google.com/patent/US6355707B1/en,2002 (accessed on 1 December 2022).

- Schulz, R.; Plantz, V.; Brush, D. Shielding theory and practice. IEEE Trans. Electromagn. Compat. 1988, 30, 187–201. [Google Scholar] [CrossRef]

- Yang, Y.; Gupta, M.C.; Dudley, K.L.; Lawrence, R.W. Conductive Carbon Nanofiber-Polymer Foam Structures. Adv. Mater. 2005, 17, 1999–2003. [Google Scholar] [CrossRef]

- Uiseok, H.; Junyoung, K.; Mina, S.; Bumhee, L.; In-Kyung, P.; Jonghwan, S.; Jae-Do, N. Quantitative Interpretation of Electromagnetic Interference Shielding Efficiency: Is It Really a Wave Absorber or a Reflector? ACS Omega 2022, 7, 4135–4139. [Google Scholar]

- Seung, H.R.; You, K.H.; Suk, J.K.; Taehoon, K.; Byung, M.J.; Sang-Bok, L.; Byeongjin, P. Absorption-dominant, low re-flection EMI shielding materials with integrated metal mesh/TPU/CIP composite. Chem. Eng. J. 2022, 428, 131167. [Google Scholar]

- Kumar, G.S.; Patro, T.U.; Raagulan, K.; Braveenth, R.; Jang, H.J.; Seon Lee, Y.; Yang, C.M.; Mi Kim, B.; Moon, J.J.; Chai, K.Y. Electromagnetic Shielding by MXene-Graphene-PVDF Composite with Hydrophobic, Lightweight and Flexible Graphene Coated Fabric. Materials 2018, 11, 1803. [Google Scholar]

- Xie, P.; Liu, Y.; Feng, M.; Niu, M.; Liu, C.; Wu, N.; Sui, K.; Patil, R.R.; Pan, D.; Guo, Z.; et al. Hierarchically porous Co/C nano-composites for ultralight high-performance microwave absorption. Adv. Compos. Hybrid Mater. 2021, 4, 173–185. [Google Scholar] [CrossRef]

- Wei, S.; Chen, T.; Wang, Q.; Shi, Z.; Li, W.; Chen, S. Metal-organic framework derived hollow CoFe@C composites by the tun-able chemical composition for efficient microwave absorption. J. Coll. Inter. Sci. 2021, 593, 370–379. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, M.; Ibrahim, M.M.; Haikun, W.; Yan, W.; Yang, L.; Mersal, G.A.M.; Azab, I.H.E.; El-Bahy, S.M.; Huang, M.; et al. Flexible polystyrene/graphene composites with epsilon-near-zero prop-erties. Adv. Compos. Hybrid Mater. 2022, 5, 1054–1066. [Google Scholar] [CrossRef]

- Xie, P.; Shi, Z.; Feng, M.; Sun, K.; Liu, Y.; Yan, K.; Liu, C.; Moussa, T.A.A.; Huang, M.; Meng, S.; et al. Recent advances in radio-frequency negative dielectric metamaterials by designing heterogeneous composites. Adv. Compos. Hybrid Mater. 2022, 5, 679–695. [Google Scholar] [CrossRef]

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Fan, X.; Guan, J.; Wang, W.; Tong, G. Morphology evolution, magnetic and microwave absorption properties of nano/submicrometre iron particles obtained at different reduced temperatures. J. Phys. D Appl. Phys. 2009, 42, 075006. [Google Scholar] [CrossRef]

- Cao, M.; Song, W.; Hou, Z.; Wen, B.; Yuan, J. The effects of temperature and frequency on the dielectric properties, electro-magnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon 2010, 48, 788–796. [Google Scholar] [CrossRef]

- Xie, P.; Li, H.; He, B.; Dang, F.; Lin, J.; Fan, R.; Hou, C.; Liu, H.; Zhang, J.; Ma, Y.; et al. Bio-gel derived nickel/carbon nanocom-posites with enhanced microwave absorption. J. Mater. Chem. C 2018, 6, 8812–8822. [Google Scholar] [CrossRef]

- Omana, L.; Chandran, A.; John, R.E.; Wilson, R.; George, K.C.; Unnikrishnan, N.V.; Varghese, S.S.; George, G.; Simon, S.M.; Paul, I. Recent Advances in Polymer Nanocomposites for Electromagnetic Interference Shielding: A Review. ACS Omega 2022, 7, 25921–25947. [Google Scholar] [CrossRef]

- Pai, A.R.; Azeez, N.P.; Thankan, B.; Gopakumar, N.; Jaroszewski, M.; Paoloni, C.; Kalarikkal, N.; Thomas, S. Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review. Energies 2022, 15, 3901. [Google Scholar] [CrossRef]

- Dar, M.A.; Kotnala, R.K.; Verma, V.; Shah, J.; Siddiqui, W.A.; Alam, M. High Magneto-Crystalline Anisotropic Core–Shell Structured Mn0.5Zn0.5Fe2O4/Polyaniline Nanocomposites Prepared by in Situ Emulsion Polymerization. J. Phys. Chem. 2012, 116, 5277–5287. [Google Scholar] [CrossRef]

- Saini, P.; Choudhary, V.; Singh, B.P.; Mathur, R.B.; Dhawan, S.K. Enhanced microwave absorption behaviour of polyan-iline-CNT/polystyrene blend in 12.4–18.0 GHz Range. Synth. Met. 2011, 161, 1522–1526. [Google Scholar] [CrossRef]

- Choudhary, V.; Dhawan, S.K.; Saini, P. Polymer Based Nanocomposites for Electromagnetic Interference (EMI) Shielding EM Shielding—Theory and Development of New Materials; Jaroszewski, M., Ziaja, J., Eds.; Research Signpost: Thiruvananthapuram, India, 2012; pp. 1–29. ISBN 978-81-308-0499-6. [Google Scholar]

- Khan, R.; Khan, Z.M.; Bin Aqeel, H.; Javed, S.; Shafqat, A.; Qazi, I.; Basit, M.A.; Jan, R. 2D nanosheets and composites for EMI shielding analysis. Sci. Rep. 2020, 10, 21550. [Google Scholar] [CrossRef]

- Chung, D.D.L. Materials for electromagnetic interference shielding. Mater. Chem. Phys. 2020, 255, 123587. [Google Scholar] [CrossRef]

- Cui, T.J.; Smith, D.R.; Liu, R. Metamaterials: Theory, Design, and Applications; Springer: Berlin/Heidelberg, Germany, 2010; ISBN 9781441905727. [Google Scholar]

- Engheta, N.; Ziolkowski, R.W. Metamaterials: Physics and Engineering Explorations; Wiley IEEE Press: New York, NY, USA, 2006; pp. 3–30, 37, 143–150, 215–234, 240–256. [Google Scholar]

- Saïd, Z.; Ari Sihvola, A.; Vinogradov, A.P. Metamaterials and Plasmonics: Fundamentals, Modelling, Applications; Springer: New York, NY, USA, 2008; Volume 106, pp. 3–10. [Google Scholar]

- Smith, D.R.; Pendry, J.B. Homogenization of metamaterials by field averaging. J. Opt. Soc. Am. B 2006, 23, 321. [Google Scholar] [CrossRef]

- Davi, B.B. Metamaterial Inspired Improved Antenna and Circuits; Electromagnetism; Télécom ParisTech: Paris, France, 2010; pp. 19–27, English. ffpastel-00749642f, UFRN. [Google Scholar]

- Engheta, N.; Ziolkowski, R.W. Antennas Propagation, Special Issue on Metamaterials. IEEE Trans. 2003, 51, 2546–2750. [Google Scholar]

- Engheta, N.; Ziolkowski, R. A positive future for double-negative metamaterials. IEEE Trans. Microw. Theory Technol. 2005, 53, 1535–1556. [Google Scholar] [CrossRef]

- Buriak, I.; Zhurba, V.O.; Vorobjov, G.S.; Kulizhko, V.R.; Kononov, O.; Rybalko, O. Metamaterials: Theory, Classification and Application Strategies (Review). J. Nano-Electron. Phys. 2016, 8, 04088. [Google Scholar] [CrossRef]

- Depine, R.A.; Lakhtakia, A. A new condition to identify isotropic dielectric-magnetic materials displaying negative phase velocity. Microw. Opt. Technol. Lett. 2004, 41, 315–316. [Google Scholar] [CrossRef]

- Voznesenskaya, A.; Kabanova, D. Analysis of Ray Tracing through Optical Systems with Metamaterial Elements. Sci. Technol. J. Inf. 2012, 81, 5–10. [Google Scholar]

- Yasser, Z.; Kyong, Y.R. A simple methodology to predict the tunnelling conductivity of polymer/CNT nanocomposites by the roles of tunneling distance, interphase and CNT waviness. RSC Adv. 2017, 7, 34912. [Google Scholar]

- Razavi, R.; Zare, Y.; Rhee, K.Y. A two-step model for the tunneling conductivity of polymer carbon nanotube nanocomposites assuming the conduction of interphase regions. RSC Adv. 2017, 7, 50225–50233. [Google Scholar] [CrossRef]

- Kovacs, J.Z.; Velagala, B.S.; Schulte, K.; Bauhofer, W. Two percolation thresholds in carbon nanotube epoxy composites. Compos. Sci. Technol. 2007, 67, 922–928. [Google Scholar] [CrossRef]

- Kumar, G.S.; Patro, T.U. Efficient electromagnetic interference shielding and radar absorbing properties of ultrathin and flexible polymer-carbon nanotube composite films. Mater. Res. Express 2018, 5, 115304. [Google Scholar] [CrossRef]

- Hoang, A.S. Electrical conductivity and electromagnetic interference shielding characteristics of multiwalled carbon nanotube filled polyurethane composite films. Adv. Nat. Sci. Nanosci. Nanotechnol. 2011, 2, 025007. [Google Scholar] [CrossRef]

- Hoang, A.S.; Nguyen, H.N.; Bui, H.T.; Tuan, A.T.; Anh, D.V.; Nguyen, B.; Van, B.N. Carbon nanotubes materials and their application to guarantee safety from exposure to electromagnetic fields. Adv. Nat. Sci. Nanosci. Nanotechnol. 2013, 4, 025012. [Google Scholar] [CrossRef]

- Verma, R.; Rathod, M.J.; Goyal, R.K. High electromagnetic interference shielding of poly(ether-sulfone)/multi-walled carbon nanotube nanocomposites fabricated by an eco-friendly route. Nanotechnology 2020, 31, 385702. [Google Scholar] [CrossRef] [PubMed]

- Bertolini, M.C.; Ramoa, S.D.A.S.; Merlini, C.; Barra, G.M.O.; Soares, B.G.; Pegoretti, A. Hybrid Composites Based on Thermo-plastic Polyurethane with a Mixture of Carbon Nanotubes and Carbon Black Modified with Polypyrrole for Electromagnetic Shielding. Front. Mater. 2020, 7, 174. [Google Scholar] [CrossRef]

- Ramírez-Herrera, C.A.; Gonzalez, H.; de la Torre, F.; Benitez, L.; Cabañas-Moreno, J.G.; Lozano, K. Electrical Properties and Electromagnetic Interference Shielding Effectiveness of Interlayered Systems Composed by Carbon Nanotube Filled Carbon Nanofiber Mats and Polymer Composites. Nanomaterials 2019, 9, 238. [Google Scholar] [CrossRef]

- Yanju, L.; Di, S.; Chunxia, W.; Jinsong, L. EMI shielding performance of nanocomposites with MWCNTs, nanosized Fe3O4 and Fe. Compos. B Eng. 2014, 63, 34–40. [Google Scholar]

- Li, J.; Lu, W.; Suhr, J.; Chen, H.; Xiao, J.Q.; Chou, T.-W. Superb electromagnetic wave-absorbing composites based on large-scale graphene and carbon nanotube films. Sci. Rep. 2017, 7, 2349. [Google Scholar] [CrossRef]

- Zhengkang, X.; Aili, J.; Xulin, Y.; Yang, X.; Feng, W.; Wang, P.; Li, K.; Lei, W.; He, H.; Tian, Y.; et al. Controllable modification of helical carbon nanotubes for high-performance microwave absorption. Nanotechnol. Rev. 2021, 10, 671–679. [Google Scholar]

- Zuomin, L.; Dingkun, T.; Xuebin, L.; Jianhong, W.; Krishnamoorthy, R.; Tao, Z.; Yougen, H.; Pengli, Z.; Rong, S.; Ching-Ping, W. Electrically conductive gradient structure design of thermoplastic polyurethane composite foams for efficient electro-magnetic interference shielding and ultra-low microwave reflectivity. Chem. Eng. J. 2021, 424, 130365. [Google Scholar]

- Jianming, Y.; Xia, L.; Gui, W.; Wang, J.; Jia, C.; Wanyu, T.; Tengfei, W.; Guangxian, L. Fabrication of lightweight and flexible silicon rubber foams with ultra-efficient electromagnetic interference shielding and adjustable low reflectivity. J. Mater. Chem. C 2020, 8, 147–157. [Google Scholar]

- Shu, Z.; Qingya, Z.; Mengya, W.; Jackson, D.; Zhe, Q.; Yuchi, F.; Meifang, Z.; Changhuai, Y. Modulating electromagnetic interference shielding performance of ultra-lightweight composite foams through shape memory function. Compos. B Eng. 2021, 204, 108497. [Google Scholar]

- Dongwei, L.; Zichao, M.; Binghao, L.; Leilei, Y.; Zhongfu, H.; Hai, Z.; Zikang, T.; Xuchun, G. Flexible, lightweight carbon nano-tube sponges and composites for high-performance electromagnetic interference shielding. Carbon 2018, 133, 457–463. [Google Scholar]

- Wang, Y.Y.; Zhou, Z.H.; Zhou, C.G.; Sun, W.J.; Gao, J.F.; Dai, K.; Yan, D.X.; Li, Z.M. Lightweight and Robust Carbon Nano-tube/Polyimide Foam for Efficient and Heat-Resistant Electromagnetic Interference Shielding and Microwave Absorption. ACS Appl. Mater. Interfaces 2020, 12, 8704–8712. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Mei, X.; Liang, L.; Xin, P.; Guibin, W.; Shuling, Z. Structure-function integrated poly (aryl ether ketone)-grafted MWCNTs/poly (ether ether ketone) composites with low percolation threshold of both conductivity and electromagnetic shielding. Compos. Sci. Technol. 2022, 217, 109032. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yang, S.; Sun, W.-J.; Dai, K.; Yan, D.X.; Li, Z.M. Highly enhanced microwave absorption for carbon nano-tube/barium ferrite composite with ultra-low carbon nanotube loading. J. Mater. Sci. Technol. 2022, 102, 115–122. [Google Scholar] [CrossRef]

- Anjaneyalu, A.M.; Zeraati, A.S.; Sundararaj, U. Enhanced electromagnetic interference shielding effectiveness of hybrid fillers by segregated structure. AIP Conf. Proc. 2019, 2065, 040009. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; Dong, C.; Chen, G.; Guan, H. Preparation and electromagnetic shielding effectiveness of cobalt ferrite nanoparticles/carbon nanotubes composites. Nanomater. Nanotechnol. 2019, 9, 1–7. [Google Scholar] [CrossRef]

- Li, G.; Sheng, L.; Liming, Y.L.; An, K.; Ren, W.; Zhao, X. Electromagnetic and microwave absorption properties of sin-gle-walled carbon nanotubes and CoFe2O4 nanocomposites. Mater. Sci. Eng. B 2015, 193, 153–159. [Google Scholar] [CrossRef]

- Phan, C.H.; Mariatti, M.; Koh, Y.H. Electromagnetic interference shielding performance of epoxy composites filled with mul-tiwalled carbon nanotubes/manganese zinc ferrite hybrid fillers. J. Magn. Magn. Mater. 2016, 401, 472–478. [Google Scholar] [CrossRef]

- Rosdi, N.; Azis, R.S.; Ismail, I.; Mokhtar, N.; Zulkimi, M.M.M.; Mustaffa, M.I. Structural, microstructural, magnetic and elec-tromagnetic absorption properties of spiraled multiwalled carbon nanotubes/barium hexaferrite (MWCNTs/BaFe12O19) hy-brid. Sci. Rep. 2021, 11, 15982. [Google Scholar] [CrossRef]

- Yu, L.; Zhu, Y.; Qian, C.; Fu, Q.; Zhao, Y.; Fu, Y. Nanostructured Barium Titanate/Carbon Nanotubes Incorporated Polyaniline as Synergistic Electromagnetic Wave Absorbers. J. Nanomater. 2016, 2016, 6032307. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Saadeh, W.H.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Kuang, T.; Chang, L.; Chen, F.; Sheng, Y.; Fu, D.; Peng, X. Facile preparation oflightweight high-strength biodegradable poly-mer/multi-walled carbon nanotubes nanocomposite foams for electromagnetic interference shielding. Carbon 2016, 4, 052. [Google Scholar]

- Sainia, P.; Choudhary, V.; Singh, B.P.; Mathur, R.B.; Dhawan, S.K. Polyaniline–MWCNT nanocomposites for microwave absorp-tion and EMI shielding. Mat. Chem. Phy. 2009, 113, 919–926. [Google Scholar] [CrossRef]

- Tan, C.; Cao, X.; Wu, X.-J.; He, Q.; Yang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.-H.; et al. Recent Advances in Ultrathin Two-Dimensional Nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef]

- Low, J.; Cao, S.; Yu, J.; Wageh, S. Two-dimensional layered composite photocatalysts. Chem. Commun. 2014, 50, 10768–10777. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Fiori, G.; Bonaccorso, F.; Iannaccone, G.; Palacios, T.; Neumaier, D.; Seabaugh, A.; Banerjee, S.K.; Colombo, L. Electronics based on two-dimensional materials. Nat. Nanotechnol. 2014, 9, 768–779, Erratum in Nat. Nanotechnol. 2014, 9, 1063. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, S.; Xie, Y. Atomically-thick two-dimensional crystals: Electronic structure regulation and energy device con-struction. Chem. Soc. Rev. 2014, 43, 530–546. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Y.; Wang, X. Two-dimensional covalent carbon nitride nanosheets: Synthesis, functionalization, and applications. Energy Environ. Sci. 2015, 8, 3092–3108. [Google Scholar] [CrossRef]

- Naguib, M.; Mochalin, V.N.; Barsoum, M.W.; Gogotsi, Y. 25th Anniversary Article: MXenes: A New Family of Two-Dimensional Materials. Adv. Mater. 2015, 26, 992–1005. [Google Scholar] [CrossRef]

- Aparna, M.; Giriraj, L.; Kaivalya, A.; Brokesh, A.; Gaharwar, A.K. Emerging 2D nanomaterials for biomedical applications. Mat. Today 2021, 50, 276–302. [Google Scholar]

- Jain, A.; Ong, S.P.; Hautier, G.; Chen, W.; Richards, W.D.; Dacek, S.; Cholia, S.; Gunter, D.; Skinner, D.; Ceder, G.; et al. The Materials Project: A materials genome approach to accelerating materials innovation. APL Mater. 2013, 1, 011002. [Google Scholar] [CrossRef]

- Jurgen, S.; Stefan, K.E. Perspectives on the Theory of Defects. Front. Mater. 2018, 5, 70. [Google Scholar] [CrossRef]

- Huang, W.; Hu, L.; Tang, Y.; Xie, Z.; Zhang, H. Recent Advances in Functional 2D MXene-Based Nanostructures for Next-Generation Devices. Adv. Funct. Mater. 2020, 30, 2005223. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Mukherjee, M.; Datta, A.; Chakravorty, D. Electrical resistivity of nanocrystalline PbS grown in a polymer matrix. Appl. Phys. Lett. 1994, 64, 1159–1161. [Google Scholar] [CrossRef]

- Chen, T.K.; Tien, Y.I.; Wei, K.H. Synthesis and characterization of novel segmented polyurethane/clay nanocomposites. Polymer 2000, 41, 1345–1353. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, X.; Song, Y.; Han, B.; Hu, X.; Wang, X.; Lin, Y.; Deng, X. Magnetic biodegradable Fe3O4/CS/PVA nanofibrous membranes for bone regeneration. Biomed. Mater. 2011, 6, 055008. [Google Scholar] [CrossRef]

- Kharazmi, A.; Saion, E.; Faraji, N.; Soltani, N.; Dehzangi, A. Optical Properties of CdS/PVA Nanocomposite Films Synthesized using the Gamma-Irradiation-Induced Method. Chin. Phys. Lett. 2013, 30, 057803. [Google Scholar] [CrossRef]

- Chen, J.; Beake, B.D.; Bell, Y.; Yalan, T.; Fengge, G. Effects in nylon 6-clay nanocomposites and Probing polymer chain con-straint and synergistic effects in nylon 6- clay nanocomposites and nylon 6-silica flake sub-micro composites with nano me-chanics. Nanocomposites 2016, 1, 185–194. [Google Scholar] [CrossRef]

- Abulyazied, D.E.; Mokhtar, S.M.; Motawie, A.M. Nanoindentation Behaviorand Physical Properties of Polyvinyl Chloride/Styrene co-maleic anhydride blend reinforced by Nano-Bentonite. IOSR-JAC 2014, 7, 32–44. [Google Scholar]

- El-kader, F.H.A.; Hakeem, N.A.; Elashmawi, I.S.; Ismail, A.M. Structural, Optical and Thermal Characterization of ZnO Nanoparticles Doped in PEO / PVA Blend Films. Aust. J. Basic Appl. Sci. 2013, 7, 608–619. [Google Scholar]

- Okada, A.; Usuki, A. Twenty years of polymer-clay nanocomposites. Macromol. Mater. Eng. 2006, 291, 449–1476. [Google Scholar] [CrossRef]

- Winey, K.I.; Vaia, R.A. Polymer nanocomposites. Mater. Res. Bull. 2007, 32, 314–322. [Google Scholar] [CrossRef]

- Krishnamoorti, R.; Vaia, R.A. Polymer nanocomposites. J. Polym. Sci. B Polym. Phys. 2007, 45, 3252–3256. [Google Scholar] [CrossRef]

- Balazs, A.C.; Emrick, T.; Russell, T.P. Nanoparticle Polymer Composites: Where Two Small Worlds Meet. Science 2006, 314, 1107–1110. [Google Scholar] [CrossRef]

- Schaefer, D.W.; Justice, R.S. How nano are nanocomposite? Macromolecules 2007, 40, 8501–8517. [Google Scholar] [CrossRef]

- Julia, B.; Popall, M. Applications of hybrid organic—Inorganic nanocomposites. J. Mater. Chem. 2005, 15, 3559–3592. [Google Scholar]

- Qin, M.; Zhang, L.; Wu, H. Dielectric Loss Mechanism in Electromagnetic Wave Absorbing Materials. Adv. Sci. 2022, 9, e2105553. [Google Scholar] [CrossRef] [PubMed]

- Lecocq, H.; Garois, N.; Lhost, O.; Girard, P.-F.; Cassagnau, P.; Serghei, A. Polypropylene/carbon nanotubes composite materials with enhanced electromagnetic interference shielding performance: Properties and modelling. Comp. Part B Eng. 2020, 189, 107866. [Google Scholar] [CrossRef]

- Han, M.; Yin, X.; Wu, H.; Hou, Z.; Song, C.; Li, X.; Zhang, L.; Cheng, L. Ti3C2 MXenes with Modified Surface for High-Performance Electromagnetic Absorption and Shielding in the X-Band. ACS Appl. Mater. Interfaces 2016, 8, 21011–21019. [Google Scholar] [CrossRef] [PubMed]

- Filipa, M.; Rui Gusmão, O. Recent Advances in the Electromagnetic Interference Shielding of 2D Materials beyond Graphene. ACS Appl. Elect. Mat. 2020, 2, 3048–3071. [Google Scholar]

- Jan, R.; Habib, A.; Aftab Akram, M.; Ahmad, I.; Shah, A.; Sadiq, M.; Hussain, A. Flexible, thin films of graphene-polymer composites for EMI shielding. Mat. Res. Exp. 2017, 4, 035605. [Google Scholar] [CrossRef]

- Zhenyu, W.; Wenzhen, Y.; Rui, L.; Zhang, X.; Nie, H.; Liu, Y. Highly stretchable graphene/polydimethylsiloxane composite lattices with tailored structure for strain-tolerant EMI shielding performance. Compos. Sci. Technol. 2021, 206, 108652. [Google Scholar]

- Al-Saleh, M.H. Electrical and electromagnetic interference shielding characteristics of GNP/UHMWPE composites. J. Phys. D Appl. Phys. 2016, 49, 195302. [Google Scholar] [CrossRef]

- Zeranska-Chudek, K.; Wróblewska, A.; Kowalczyk, S.; Plichta, A.; Zdrojek, M. Graphene Infused Ecological Polymer Composites for Electromagnetic Interference Shielding and Heat Management Applications. Materials 2021, 14, 2856. [Google Scholar] [CrossRef] [PubMed]

- Madinehei, M.; Kuester, S.; Kaydanova, T.; Moghimian, N.; David, É. Influence of Graphene Nanoplatelet Lateral Size on the Electrical Conductivity and Electromagnetic Interference Shielding Performance of Polyester Nanocomposites. Polymers 2021, 13, 2567. [Google Scholar] [CrossRef] [PubMed]

- Santhosi, B.; Ramji, K.; Rao, N.M. Design and development of polymeric nanocomposite reinforced with graphene for effective EMI shielding in X-band. Phys. B Condens. Matter 2020, 586, 412144. [Google Scholar] [CrossRef]

- Lin, J.-H.; Lin, Z.-I.; Pan, Y.-J.; Chen, C.H.; Lin, C.; Chen-Hung, H.; Lou, C.W. Improvement in Mechanical Properties and Electromagnetic Interference Shielding Effectiveness of PVA-Based Composites: Synergistic Effect Between Graphene Nano-Sheets and Multi-Walled Carbon Nanotubes. Macromol. Mater. Eng. 2016, 301, 199–211. [Google Scholar] [CrossRef]

- Khan, M.; Khan, A.N.; Saboor, A.; Gul, I.H. Investigating mechanical, dielectric, and electromagnetic interference shielding properties of polymer blends and three component hybrid composites based on polyvinyl alcohol, polyaniline, and few layer graphene. Polym. Compos. 2017, 39, 3686–3695. [Google Scholar] [CrossRef]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten Years of Progress in the Synthesis and Development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef]

- Weng, C.; Xing, T.; Jin, H.; Wang, G.; Dai, Z.; Pei, Y.; Liu, L.; Zhang, Z. Mechanically robust ANF/MXene composite films with tunable electromagnetic interference shielding performance. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105927. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Zhang, X.; Tian, D.; Zhan, Z.; Lu, C. Ultrathin MXene/Calcium Alginate Aerogel Film for High-Performance Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2019, 6, 1802040. [Google Scholar] [CrossRef]

- Ying, S.; Youxin, J.; Jingwen, D.; Gui, Y.; Zhang, X.; Su, F.; Feng, Y.; Liu, C. Sandwiched cellulose nanofiber /boron nitride nanosheet /Ti3C2Tx MXene composite film with high electromagnetic shielding and thermal conductivity yet insulation per-formance. Compos. Sci. Technol. 2021, 214, 108974. [Google Scholar]

- Aakyiir, M.; Kingu, M.-A.S.; Araby, S. Stretchable, mechanically resilient, and high electromagnetic shielding polymer/MXene nanocomposites. J. Appl. Polym. Sci. 2021, 138, e50509. [Google Scholar] [CrossRef]

- Shengchi, B.; Xingzhong, G.; Xuyang, Z.; Parchment, D.; Anasori, B.; Koo, C.M.; Friedman, G.; Gogotsi, Y. Ti3C2Tx MXene-AgNW composite flexible transparent conductive films for EMI shielding. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106545. [Google Scholar]

- Raagulan, K.; Braveenth, R.; Kim, B.M.; Lim, K.J.; Lee, S.B.; Kim, M.; Chai, K.Y. An effective utilization of MXene and its effect on electromagnetic interference shielding: Flexible, free-standing and thermally conductive composite from MXene–PAT–poly(p-aminophenol)–polyaniline co-polymer. RSC Adv. 2020, 10, 1613–1633. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, H.-B.; Xie, X.; Yang, R.; Liu, Z.; Liu, Y.; Yu, Z.-Z. Multifunctional, Superelastic, and Lightweight MXene/Polyimide Aerogels. Small 2018, 14, e1802479. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.K.; Liu, J.; Zhang, H.B.; Zhang, Y.; Wu, X.; Deng, Z.; Yu, Z.Z. Electrically Conductive Ti3C2Tx MXene/Polypropylene Nanocomposites with an Ultralow Percolation Threshold for Efficient Electromagnetic Interference Shielding. Ind. Eng. Chem. Res. 2021, 60, 4342–4350. [Google Scholar] [CrossRef]

- Vu, M.C.; Mani, D.; Kim, J.B.; Jeong, T.H.; Park, S.; Murali, G.; In, I.; Won, J.C.; Losic, D.; Lim, C.S.; et al. Hybrid shell of MXene and reduced graphene oxide assembled on PMMA bead core towards tunable thermoconductive and EMI shielding nanocomposites. Compos. Part A Appl. Sci. 2021, 149, 106574. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, L.; Du, Z.; Wang, Y.; Liu, C.; Shen, C. Biodegradable PLA/CNTs/Ti3C2Tx MXene nanocomposites for efficient electromagnetic interference shielding. J. Mater. Sci. Mater. Electron. 2021, 32, 25952–25962. [Google Scholar] [CrossRef]

- Pandey, M.; Deshmukh, K.; Pasha, S.K. Mxene-based materials for lithium–sulfur and multivalent rechargeable batteries. In Mxenes and Their Composites; Elsevier: Amsterdam, The Netherlands, 2022; Chapter 10; pp. 343–369. [Google Scholar]

- Kumar, Y.R.; Deshmukh, K.; Ali, M.N.; Rajabathar, J.R.; Theerthagiri, J.; Pandey, M.; Khadheer Pasha, S.K. Structure defects and elec-tronic properties of MXenes. In Mxenes and their Composites; Elsevier: Amsterdam, The Netherlands, 2022; Chapter 3; pp. 91–129. [Google Scholar]

- Shakir, M.F.; Khan, A.N.; Khan, R.; Javed, S.; Tariq, A.; Azeem, M.; Riaz, A.; Shafqat, A.; Cheema, H.M.; Akram, M.A.; et al. EMI shielding properties of polymer blends with inclusion of graphene nano platelets. Results Phys. 2019, 14, 102365. [Google Scholar] [CrossRef]

- Hamidinejad, M.; Zhao, B.; Zandieh, A.; Moghimian, N.; Filleter, T.; Park, C.B. Enhanced Electrical and Electromagnetic Inter-ference Shielding Properties of Polymer–Graphene Nanoplatelet Composites Fabricated via Supercritical-Fluid Treatment and Physical Foaming. Appl. Mater. Inter. 2018, 10, 30752–30761. [Google Scholar] [CrossRef]

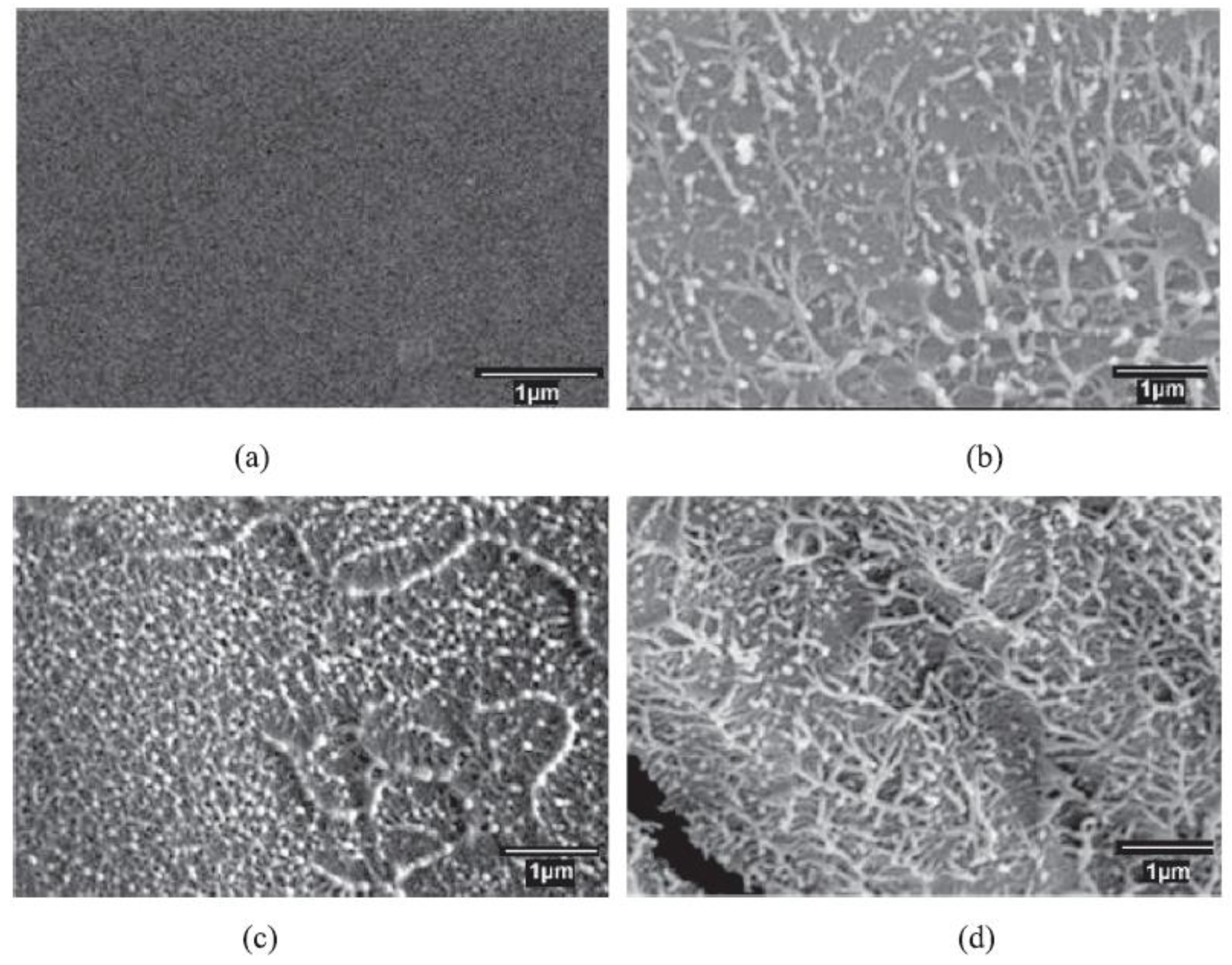

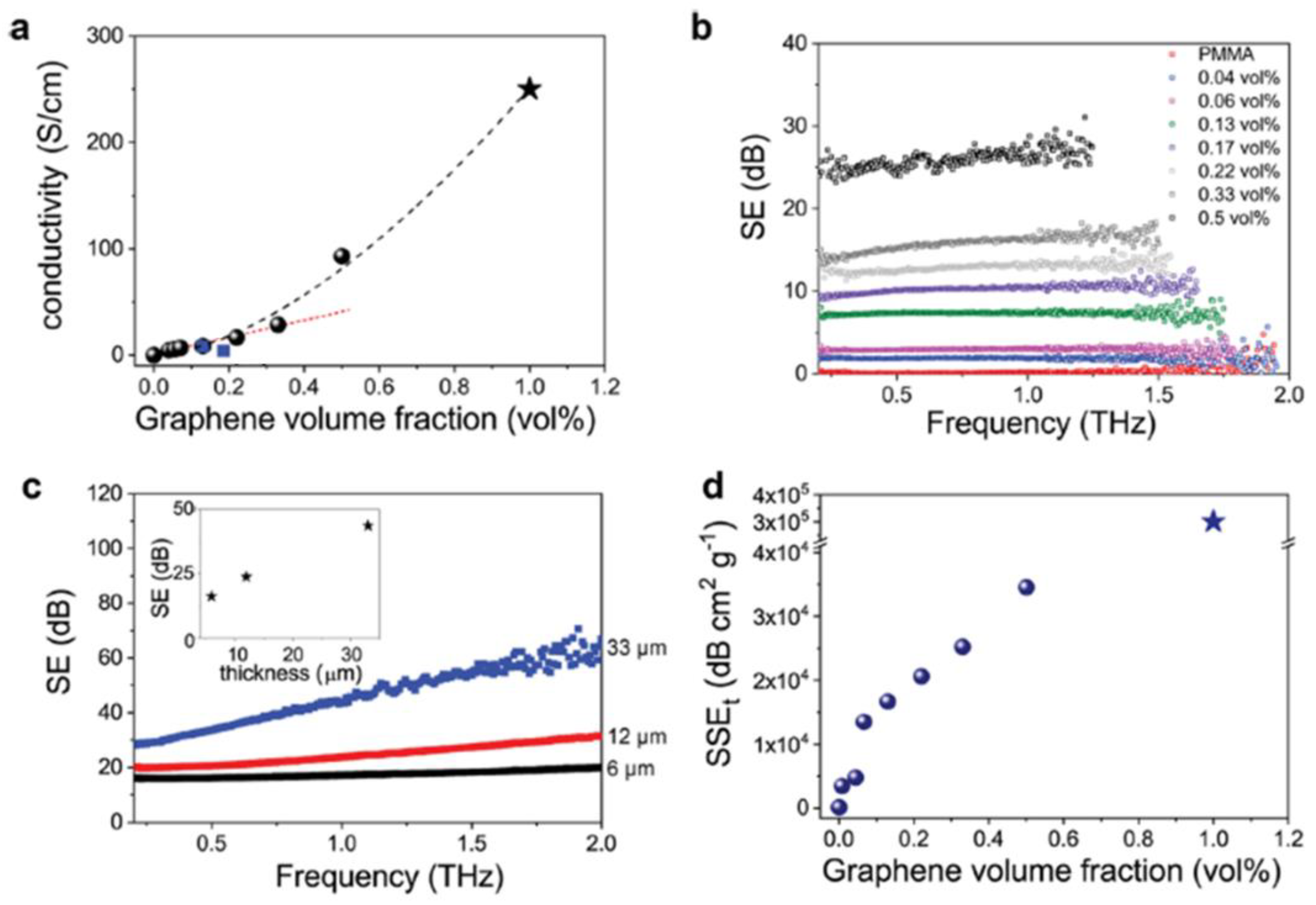

- Pavlou, C.; Carbone, M.G.P.; Manikas, A.C.; Trakakis, G.; Koral, C.; Papari, G.; Andreone, A.; Galiotis, C. Effective EMI shielding behaviour of thin graphene/PMMA nanolaminates in the THz range. Nat. Commun. 2021, 12, 4655. [Google Scholar] [CrossRef] [PubMed]

- Marka, S.K.; Srikanth, V.V.S.S.; Sindam, B.; Hazra, B.K.; Raju, K.C.J.; Srinath, S. Graphene-Wrapped MgO/Poly(vinyl alcohol) Composite Sheets: Dielectric and Electromagnetic Interference Shielding Properties at Elevated Temperatures. ACS Appl. Mater. Inter. 2019, 11, 23714–23730. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Hamidinejad, M.; Zhao, B.; Liang, C.; Park, C.B. Layered Foam/Film Polymer Nanocomposites with Highly Efficient EMI Shielding Properties and Ultralow Reflection. Nano-Micro Lett. 2021, 14, 19. [Google Scholar] [CrossRef]

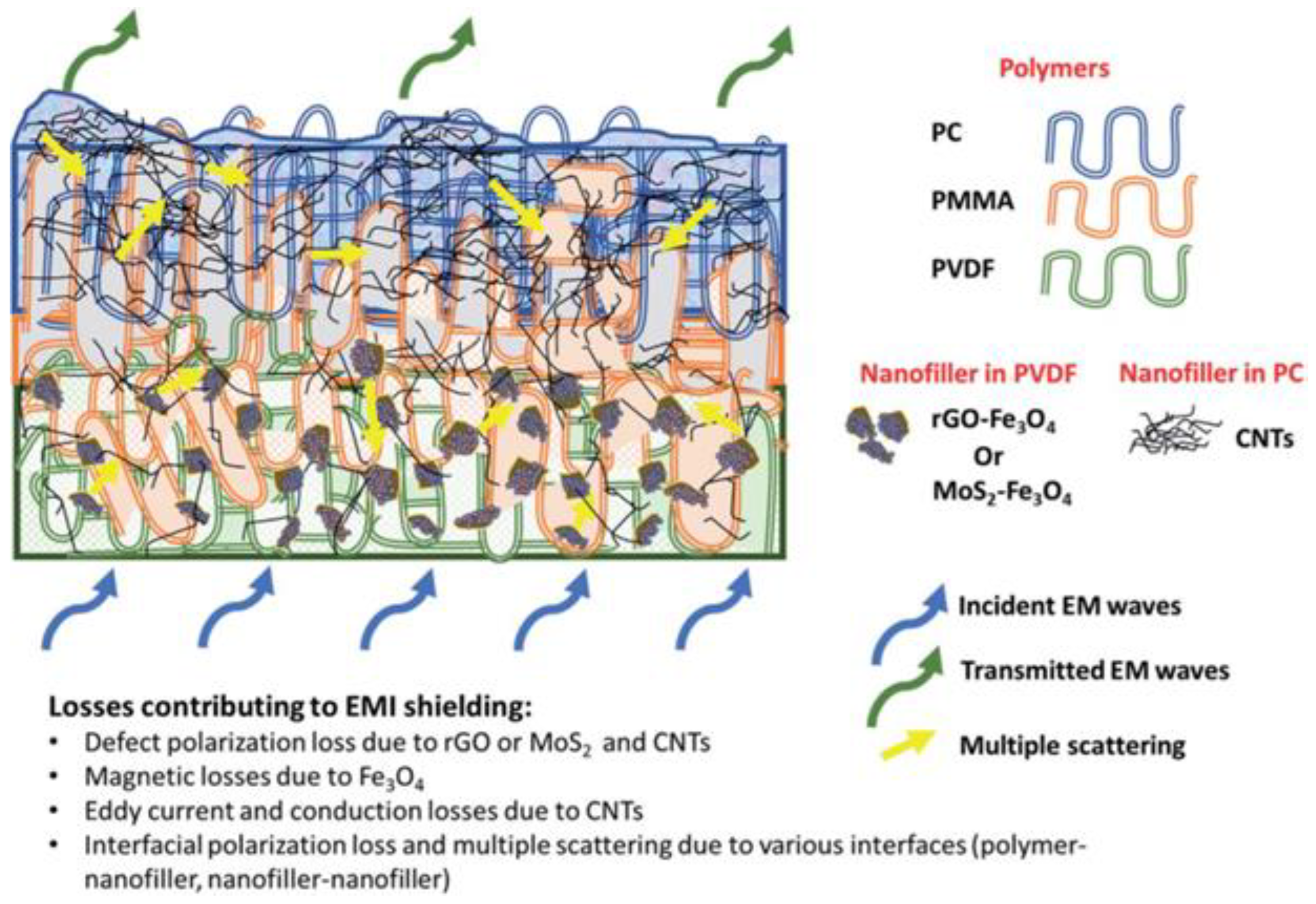

- Sushmita, K.; Formanek, P.; Fischer, D.; Potschke, P.; Madras, G.; Bose, S. Ultrathin structures derived from interfacially modified polymeric nanocomposites to curb electromagnetic pollution. Nanoscale Adv. 2021, 3, 2632. [Google Scholar] [CrossRef] [PubMed]

- Vineeta, S. Review of electromagnetic interference of shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640. [Google Scholar]

- Liang, Z.; Julong, H.; Xingang, W.; Hongbo, W.; Zhenjun, W.; Zhuo, L.; Hongqian, Z.; Wenyu, M. Dielectric properties and electromagnetic interference shielding effectiveness of Al2O3-based composites filled with FeSiAl and flaky graphite. J. Alloys Comp. 2020, 829, 154556. [Google Scholar]

- Khossossi, N.; Singh, D.; Ainane, A.; Ahuja, R. Recent progress of defect chemistry on 2D materials for advanced battery anodes. Chem. Asian J. 2020, 15, 3390–3404. [Google Scholar] [CrossRef]

- Chang, M.; Jia, Z.; He, S.; Zhou, J.; Zhang, S.; Tian, M.; Wang, B.; Wu, G. Two-dimensional interface engineering of NiS/MoS2/Ti3C2Tx heterostructures for promoting electromagnetic wave absorption capability. Compos. Part B Eng. 2021, 225, 109306. [Google Scholar] [CrossRef]

- Zhao, B.; Zhao, C.; Hamidinejad, M.; Wang, C.; Li, R.; Wang, S.; Yasamin, K.; Park, C.B. Incorporating a microcellular structure into PVDF/graphene–nanoplatelet composites to tune their electrical conductivity and electromagnetic interference shielding properties. J. Mater. Chem. C 2018, 6, 10292–10300. [Google Scholar] [CrossRef]

- Fan, D.; Li, N.; Li, M.; Wang, S.; Li, S.; Tang, T. Polyurethane/polydopamine/graphene auxetic composite foam with high-efficient and tunable electromagnetic interference shielding performance. Chem. Eng. J. 2021, 427, 131635. [Google Scholar] [CrossRef]

- Zhan, Y.; Lago, E.; Santillo, C.; Castillo, A.E.E.D.R.; Hao, S.; Buonocore, G.G.; Chen, Z.; Xia, H.; Lavorgna, M.; Bonaccorso, F. An anisotropic layer-by-layer carbon nanotube/boron nitride/rubber composite and its application in electromagnetic shielding. Nanoscale 2020, 12, 7782–7791. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Kong, Q.-Q.; Jia, H.; Xie, L.-J.; Chen, J.; Tao, Z.; Wang, Z.; Jiang, D.; Chen, C.-M. Dual-functional 3D multi-wall carbon nanotubes/graphene/silicone rubber elastomer: Thermal management and electromagnetic interference shielding. Carbon 2021, 183, 216–224. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Yang, M.; Yang, S.; Wu, H.; Guo, S.; Wang, Y. Ordered multilayer film of (graphene oxide/polymer and boron nitride/polymer) nanocomposites: An ideal EMI shielding material with excellent electrical insulation and high thermal conductivity. Compos. Sci. Technol. 2016, 136, 104–110. [Google Scholar] [CrossRef]

- Saboor, A.; Mahmood Khalid, S.; Jan, R.; Khan, A.N.; Zia, T.; Umer Farooq, M.; Afridi, S.; Sadiq, M.; Arif, M. PS/PANI/MoS2 Hybrid Polymer Composites with High Dielectric Behavior and Electrical Conductivity for EMI Shielding Ef-fectiveness. Materials 2019, 12, 2690. [Google Scholar] [CrossRef]

- Nguyen, V.-T.; Min, B.K.; Yi, Y.; Kim, S.J.; Choi, C.-G. MXene (Ti3C2TX)/graphene/PDMS composites for multifunctional broad-band electromagnetic interference shielding skins. Chem. Eng. J. 2020, 393, 124608. [Google Scholar] [CrossRef]

- Yadav, R.S.; Anju; Jamatia, T.; Kuřitka, I.; Vilčáková, J.; Škoda, D.; Urbánek, P.; Machovský, M.; Masař, M.; Urbánek, M.; et al. Excellent, Lightweight and Flexible Electromagnetic Interference Shielding Nanocomposites Based on Polypropylene with MnFe2O4 Spinel Ferrite Nanoparticles and Reduced Graphene Oxide. Nanomaterials 2020, 10, 2481. [Google Scholar] [CrossRef]

- Zubair, K.; Ashraf, A.; Gulzar, H.; Shakir, H.M.F.; Nawab, Y.; Rehan, Z.A.; Rashid, I.A. Study of mechanical, electrical and EMI shielding properties of polymer-based nanocomposites incorporating polyaniline coated graphene nanoparticles. Nano Express 2021, 2, 010038. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, J.; Zhang, S.; Lan, D.; Zhao, Z.; Kou, K. Strategies for electromagnetic wave absorbers derived from zeolite imidazole framework (ZIF-67) with ferrocene containing polymers. Polymer 2020, 202, 122679. [Google Scholar] [CrossRef]

- Liang, C.; Qiu, H.; Han, Y.; Gu, H.; Song, P.; Wang, L.; Kong, J.; Cao, D.; Gu, J. Superior electromagnetic interference shielding 3D graphene nanoplatelets/reduced graphene oxide foam/epoxy nanocomposites with high thermal conductivity. J. Mater. Chem. C 2019, 7, 2725–2733. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.-K. Highly Aligned Graphene/Polymer Nanocomposites with Excellent Dielectric Properties for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Tao, M.; Ling, J.; Zheng, W. Lightweight, Multifunctional Polyetherimide/Graphene@Fe3O4 Composite Foams for Shielding of Electromagnetic Pollution. ACS Appl. Mater. Inter. 2013, 5, 11383–11391. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.B.; Yan, Q.; Zheng, W.G.; He, Z.; Yu, Z.Z. Tough Graphene-Polymer Microcellular Foams for Electromagnetic Inter-ference Shielding. ACS Appl. Mater. Inter. 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Yao, B.; Hong, W.; Chen, T.; Han, Z.; Xu, X.; Hu, R.; Hao, J.; Li, H.; Perini, S.E.; Lanagan, M.T.; et al. Highly Stretchable Polymer Composite with Strain-Enhanced Electromagnetic Interference Shielding Effectiveness. Adv. Mater. 2020, 5, 1907499. [Google Scholar] [CrossRef]

- Wu, X.; Han, B.; Zhang, H.B.; Xie, X.; Tu, T.; Zhang, Y.; Dai, Y.; Yang, R.; Yu, Z.Z. Compressible, durable and conductive polydi-methylsiloxane-coated MXene foams for high-performance electromagnetic interference shielding. Chem. Eng. J. 2020, 381, 122622. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, X.; Qin, Y.; Fang, Y.; Liu, G.; Wang, Z.; Matz, J.; Dong, P.; Shen, J.; Ye, M. Hierarchically porous polyimide/Ti3C2Tx film with stable electromagnetic interference shielding after resisting harsh conditions. Sci. Adv. 2021, 7, eabj1663. [Google Scholar] [CrossRef] [PubMed]

- Sun, R.; Zhang, H.B.; Liu, J.; Xie, X.; Yang, R.; Li, Y.; Hong, S.; Yu, Z.Z. Highly Conductive Transition Metal Car-bide/Carbonitride(MXene)@polystyrene Nanocomposites Fabricated by Assembly for Highly Efficient Electromagnetic Inter-ference Shielding. Adv. Funct. Mater. 2017, 27, 1702807. [Google Scholar] [CrossRef]

- Shi, Y.-D.; Li, J.; Tan, Y.-J.; Chen, Y.-F.; Wang, M. Percolation Behavior of Electromagnetic Interference Shielding in Poly-mer/Multi- Walled Carbon Nanotube Nanocomposites. Compos. Sci. Technol. 2019, 170, 70–76. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of Size and Aggregation/Agglomeration of Nanoparticles on the Interfa-cial/Interphase Properties and Tensile Strength of Polymer Nanocomposites. Nanoscale. Res. Lett. 2018, 13, 214. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Fan, S.; Li, Y.; Qiang, Y.; Li, Y.; Ruan, K.; Zhang, S.; Zhang, J.; Kong, J.; Gu, J. Synchronously improved electromagnetic interference shielding and thermal conductivity for epoxy nanocompo-sites by constructing 3D copper nanowires/thermally annealed graphene aerogel framework. Compos. Appl. Sci. Manuf. 2020, 128, 105670. [Google Scholar] [CrossRef]

| Materials | CNT Content | Thickness, t (mm) | EMI SE (dB) | Frequency (GHz) | Ref. |

|---|---|---|---|---|---|

| PVDF | 4 wt% | 0.1 | 32 | 10.3 | [36] |

| PU | 22 wt% | 0.1 | 20 | 8–12 (X band) | [37] |

| PMMA/Epoxy | 25 wt% | 0.1 | 20 | 8–12 (X band) | [38] |

| PES | 6.67 wt% | 0.9 | 30 | 8–12 (X band) | [39] |

| TPU/CB-PPy | 5–8 wt% | 0.5 | 20 | 10 | [40] |

| Ppy/CNF/CF | 15 wt% | 0.65 | 11.9–52 (multilayered) | S band | [41] |

| Epoxy/Nano-Fe3O4/nano FE | 5–10 wt% | 3 | 40–100 | 13–40 | [42] |

| Fe3O4/Graphene/CNT | CNT film | 0.25 | (−44 to −10) | 18 | [43] |

| F-CNTS | 1:9 wt % | 0.0002 | (−45) | 17.5 | [44] |

| AgFD/TPU/ | 0.103 vol% | 3.4 | 80 | X band | [45] |

| Silicon rubber/Fe3O4 | 2.08 vol% Fe3O4@MWCNTs and 0.81 vol% Ag | - | 90 | 8.2–12.4 | [46] |

| SWNT/GA-chitosan | Up to 40 wt% | 10–40 | 56 | X band | [47] |

| PDMS | 1 | 2.0 | 46.3 | X band | [48] |

| CNT/PI/PVP | 100 w/v % | 3.2 | 41.1 | X band | [49] |

| PAEK-g-MWCNTs/PEEK | 0.372 vol% and 0.496 vol% | - | 56 | 36 | [50] |

| CNT/BaFe12O19 | 2.0 wt% | 1.5 | (−43.9) | 3.9 | [51] |

| CNT/NiNW or CNT/ZnONW in PS | 2.0 vol% | 1.1 | (16.6 to −24.0) | X band | [52] |

| CoFe2O4/CNTs | 0.34 w/v% | 2 | 22–25 | Ku Band | [53] |

| SWCNT/CoFe2O4 | 10 wt % | 2 | (−37 to−10) | 12.9–7.2 | [54] |

| MWCNTs/ MnZn ferrite/Epoxy | 4.0 vol % | 2 | 44 | 10 | [55] |

| MWCNTs/ BaFe12O19 | 10 wt% | 2 | (−3.58 to −43.99) | 2.56 | [56] |

| CNTs/BaTiO3/PANI | 2:3 mass ratio | 4 | (−30.9 to −10) | 7.5 to 10.2 | [57] |

| ABS/MWCNT/CNF/CB | 2–15 wt% | 1.1 | 39.9 to 40.7 | X band | [58] |

| PLLA/MWCNT | 0.5–10 wt% | 2.54 | 19 to 23 | X band | [59] |

| PANI/MWCNT | 5–25 wt% | 2 | −27.5 to −39.2 | Ku band | [60] |

| Materials | Content (wt%) | Thickness, (mm) | EMI SE (dB) | Frequency (GHz) | Ref. |

|---|---|---|---|---|---|

| PVDF/GnPs | 10 | 1.5–3 | 12.4–32.2 | 26.4–40 | [121] |

| PU/PD/graphene auxetic composite foam | 10.8–36.9 | 0.8–5 | upto 57.5 | K-band | [122] |

| CNT/h-BN/rubber composite | 10.7 | 1.4 | 22.1 | 10.3 | [123] |

| MWCNT/graphene/silicone rubber elastomer | 3.79 | - | 42 | K-band | [124] |

| GO/styrene-ethylene/butylene-styrene/ BN/PHDDT) | ~40 | 0.02–4 | 37.92 | 8–12 | [125] |

| PS/PANI/MoS2 | 0.1–1 | 0.1 | 92 | 100 Hz | [126] |

| PDMS/Fe3O4 intercalated MXene and graphene | 11.35 | 1 | 77–80 | X and K band | [127] |

| PE/GnP/Graphene black | 5–25 | 3 | 23–27 | 8–13 | [94] |

| PP/rGO/MnFe2O4 | 10 | 0.5 | 71.3 | 8.2–12.4 | [128] |

| PANI/rGO | 40 | 0.25–0.27 | 104 | 0.1 to 10 | [129] |

| FCPs/Zeolite imidazole framework (ZIF 67) | 2.5–3.7 | (−53 to −38.4) | 4.4 to 6.6 | [130] | |

| 3DGNPs/rGO/Epoxy | 0–20.4 | 3 | 51 | X band | [131] |

| rGO/Epoxy | 0.5–2.0 | - | 38 | 0.5 to 5 | [132] |

| PEI/G@Fe3O4 | 1–10 | 2.5 | 3–18 | X band | [133] |

| PMMA/Graphene | 0.2–1.8 | 4 | 13–19 | X band | [134] |

| LM/GNs/CNTs/Ti3C2Tx | 1.65–69.59 | 1.2–3 | 5–80 | X band | [135] |

| SA/PDMS/Ti3C2Tx | 62–100 | 2 | 9.1–53 | X band | [136] |

| PI/Ti3C2Tx | 0.2–2 | 0.09–0.21 | 19–77.4 | X band | [137] |

| PS/Ti3C2Tx | 0.4–2.0 | 1–2 | 4–62 | X band | [138] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kallambadi Sadashivappa, P.; Venkatachalam, R.; Pothu, R.; Boddula, R.; Banerjee, P.; Naik, R.; Radwan, A.B.; Al-Qahtani, N. Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding. J. Compos. Sci. 2023, 7, 77. https://doi.org/10.3390/jcs7020077

Kallambadi Sadashivappa P, Venkatachalam R, Pothu R, Boddula R, Banerjee P, Naik R, Radwan AB, Al-Qahtani N. Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding. Journal of Composites Science. 2023; 7(2):77. https://doi.org/10.3390/jcs7020077

Chicago/Turabian StyleKallambadi Sadashivappa, Prashanth, Revathi Venkatachalam, Ramyakrishna Pothu, Rajender Boddula, Prasun Banerjee, Ramachandra Naik, Ahmed Bahgat Radwan, and Noora Al-Qahtani. 2023. "Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding" Journal of Composites Science 7, no. 2: 77. https://doi.org/10.3390/jcs7020077

APA StyleKallambadi Sadashivappa, P., Venkatachalam, R., Pothu, R., Boddula, R., Banerjee, P., Naik, R., Radwan, A. B., & Al-Qahtani, N. (2023). Progressive Review of Functional Nanomaterials-Based Polymer Nanocomposites for Efficient EMI Shielding. Journal of Composites Science, 7(2), 77. https://doi.org/10.3390/jcs7020077