Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy

Abstract

:1. Introduction

2. Background Theory

3. Materials and Method

3.1. Bio-Based Epoxy

3.2. Carbon Nanotubes

3.3. Wear Test Specimen Preparation

4. Results and Discussion

4.1. Characterization of Carbon Nanotubes

4.2. Functionalization and Surface Properties

4.3. Implications for Composite Materials

5. Wear Test

5.1. Experimental Design and Methodology

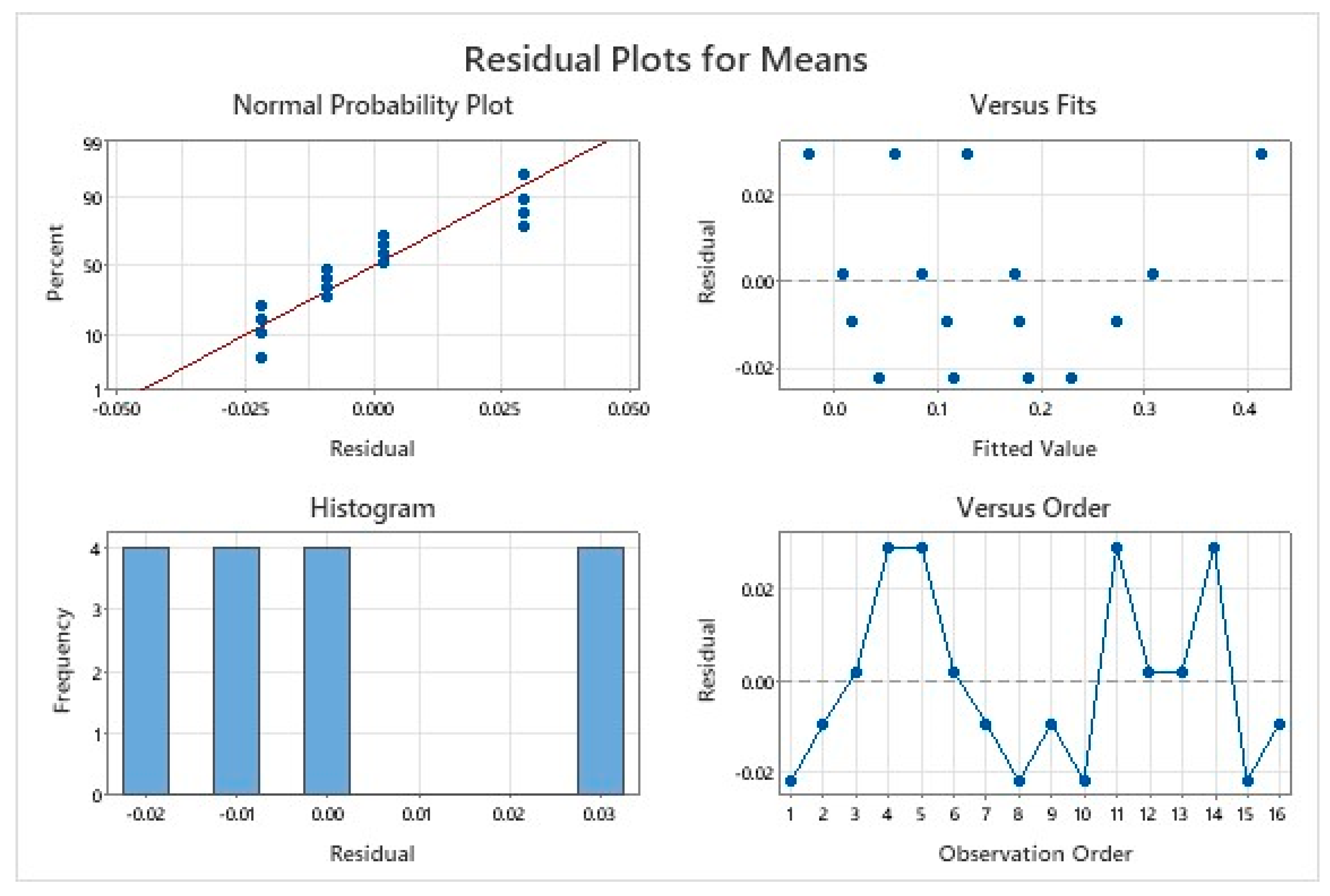

5.2. Statistical Analysis

5.2.1. Linear Model Analysis

5.2.2. Analysis of Variance (ANOVA)

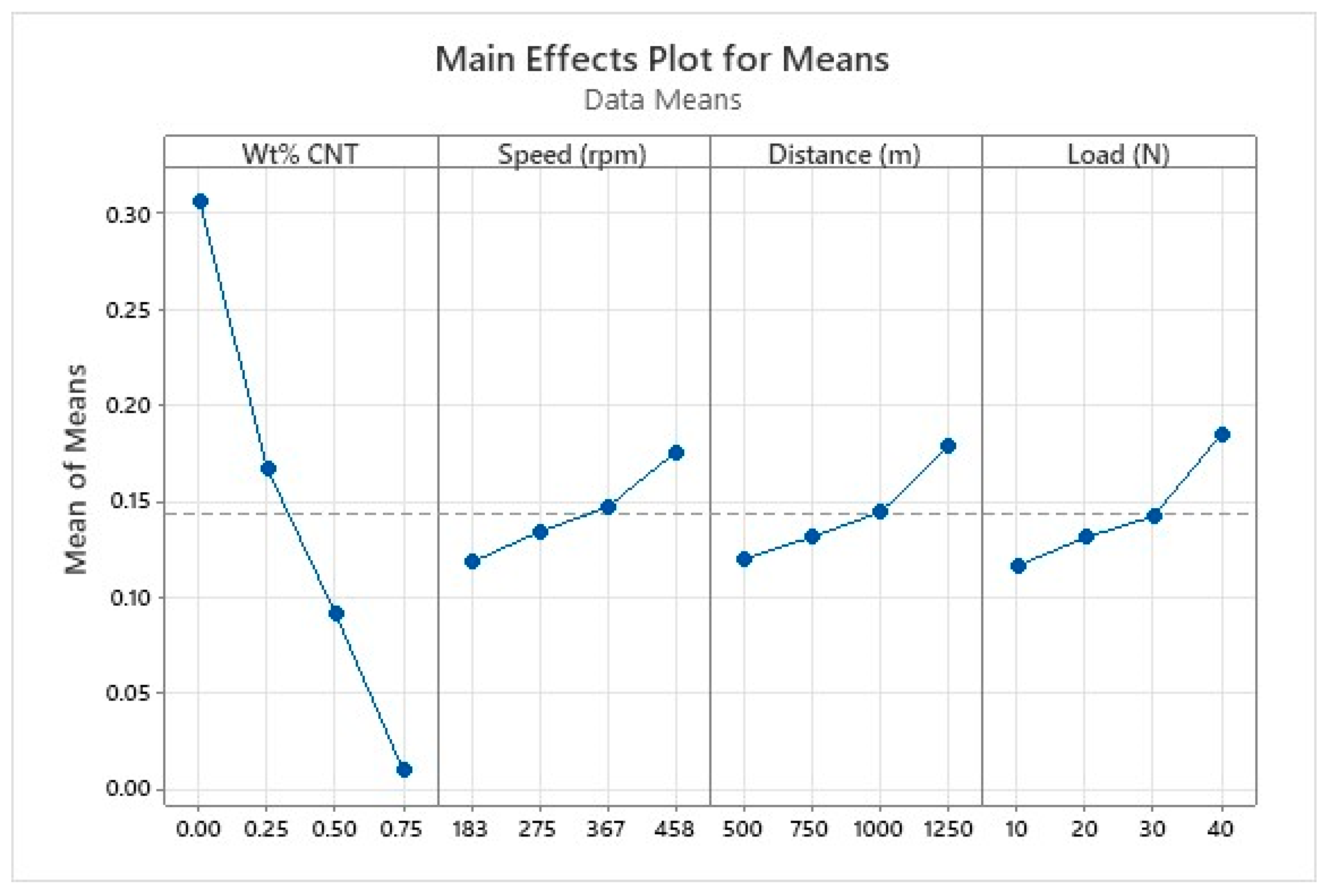

5.3. Interpretation of Results

Main Effect and Residual Plots

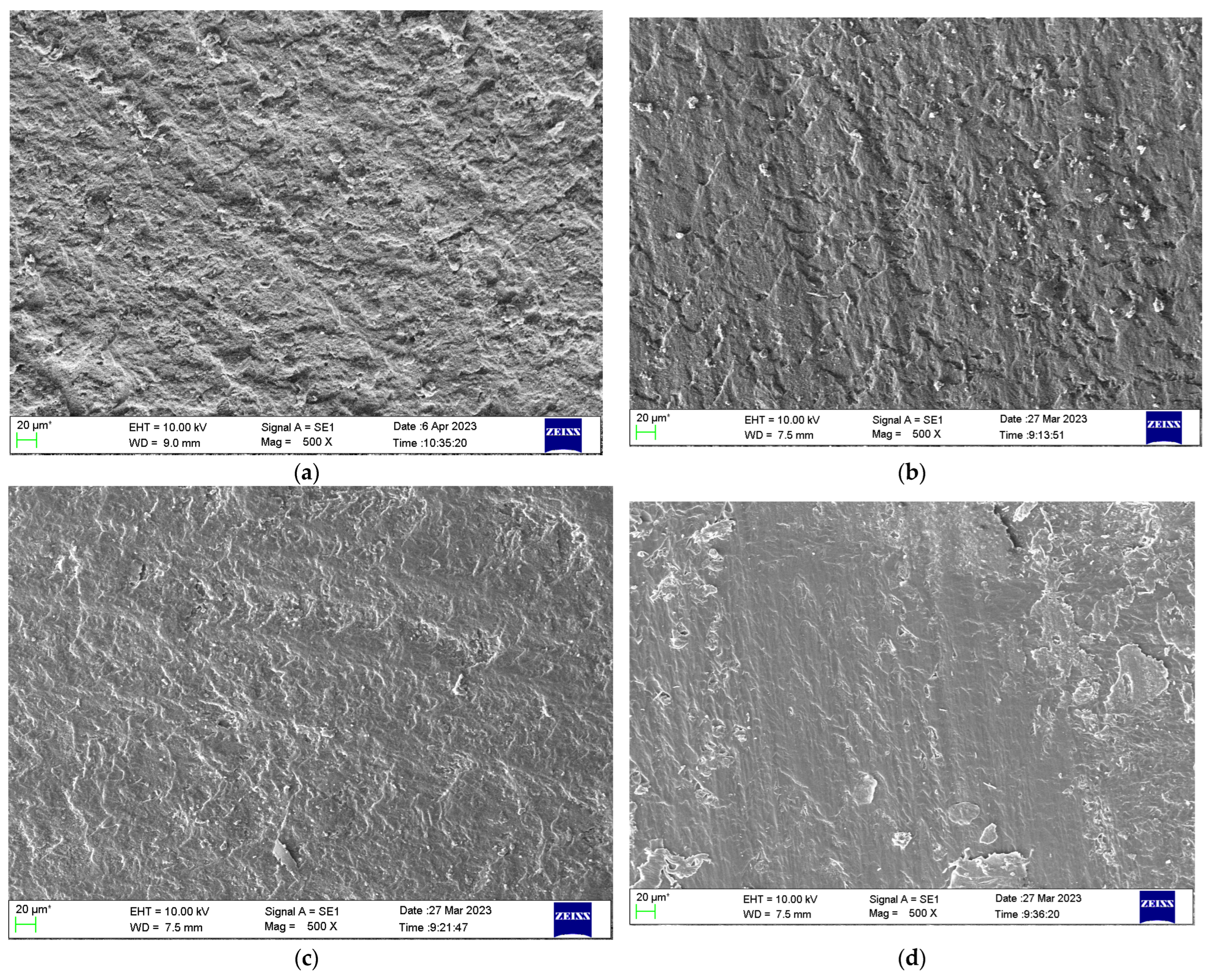

5.4. Wear Surface Analysis Using Scanning Electron Microscope

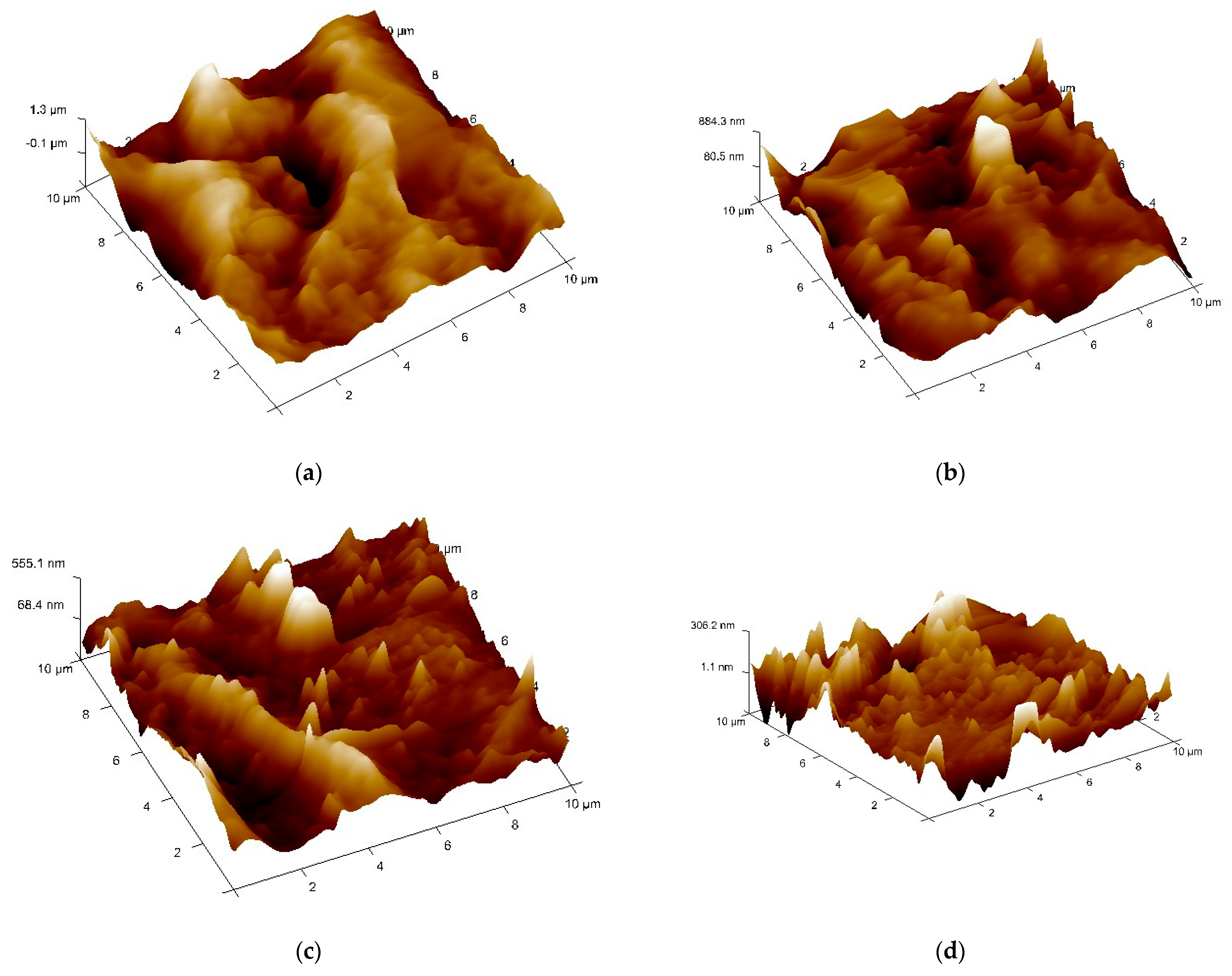

5.5. Surface Roughness Analysis

5.5.1. For 0 Wt.% CNTs

5.5.2. For 0.025 Wt.% CNTs

5.5.3. For 0.05 Wt.% CNTs

5.5.4. For 0.075 Wt.% CNTs

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duongthipthewa, A.; Su, Y.; Zhou, L. Electrical conductivity and mechanical property improvement by low-temperature carbon nanotube growth on carbon fiber fabric with nanofiller incorporation. Compos. Part B Eng. 2020, 182, 107581. [Google Scholar] [CrossRef]

- Ponnusamy, M.; Natrayan, L.; Kaliappan, S.; Velmurugan, G.; Thanappan, S. Effectiveness of Nanosilica on Enhancing the Mechanical and Microstructure Properties of Kenaf/Carbon Fiber-Reinforced Epoxy-Based Nanocomposites. Adsorpt. Sci. Technol. 2022, 2022, 4268314. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Overview of wear performance of aluminium matrix composites reinforced with ceramic materials under the influence of controllable variables. Ceram. Int. 2016, 42, 56–81. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Zhang, Y.-Y.; Sun, Z.; Huang, P.; Li, Y.-Q.; Chen, Q.; Fu, S.-Y. Experimental and numerical investigations of wear behaviors of short-carbon-fiber reinforced polyetherimide composite. Compos. Struct. 2021, 270, 114057. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive Review of the Properties and Modifications of Carbon Fiber-Reinforced Thermoplastic Composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhu, Y.; Yan, L.; Sun, L.; Zhu, Y. Epoxy composite reinforced with three-dimensional polyimide fiber felt: Fabrication and tribological properties investigation. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Quirino, R.L.; Monroe, K.; Fleischer, C.H.; Biswas, E.; Kessler, M.R. Thermosetting polymers from renewable sources. Polym. Int. 2021, 70, 167–180. [Google Scholar] [CrossRef]

- Wong, M.K.; Lock, S.S.M.; Chan, Y.H.; Yeoh, S.J.; Tan, I.S. Towards sustainable production of bio-based ethylene glycol: Progress, perspective and challenges in catalytic conversion and purification. Chem. Eng. J. 2023, 468, 143699. [Google Scholar] [CrossRef]

- Schäfer, J.-L.; Schölch, S.; Prucker, O.; Brandstetter, T.; Rühe, J.; Stockert, A.R.V.; Meckel, T.; Biesalski, M. Accessibility of fiber surface sites for polymeric additives determines dry and wet tensile strength of paper sheets. Cellulose 2021, 28, 5775–5791. [Google Scholar] [CrossRef]

- Novikov, I.V.; Krasnikov, D.V.; Vorobei, A.M.; Zuev, Y.I.; Butt, H.A.; Fedorov, F.S.; Gusev, S.A.; Safonov, A.A.; Shulga, E.V.; Konev, S.D.; et al. Multifunctional Elastic Nanocomposites with Extremely Low Concentrations of Single-Walled Carbon Nanotubes. ACS Appl. Mater. Interfaces 2022, 14, 18866–18876. [Google Scholar] [CrossRef] [PubMed]

- Zhu, R.; Pan, E.; Roy, A.K. Molecular dynamics study of the stress–strain behavior of carbon-nanotube reinforced Epon 862 composites. Mater. Sci. Eng. A 2007, 447, 51–57. [Google Scholar] [CrossRef]

- Wernik, J.M.; Cornwell-Mott, B.J.; Meguid, S.A. Determination of the interfacial properties of carbon nanotube reinforced polymer composites using atomistic-based continuum model. Int. J. Solids Struct. 2012, 49, 1852–1863. [Google Scholar] [CrossRef]

- Mokashi, V.V.; Qian, D.; Liu, Y. A study on the tensile response and fracture in carbon nanotube-based composites using molecular mechanics. Compos. Sci. Technol. 2007, 67, 530–540. [Google Scholar] [CrossRef]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef]

- Fan, L.; Wang, C.; Chen, M.; Zhu, B. Recent development of ceria-based (nano)composite materials for low temperature ceramic fuel cells and electrolyte-free fuel cells. J. Power Sources 2013, 234, 154–174. [Google Scholar] [CrossRef]

- Yamamoto, G.; Hashida, T.; Adachi, K.; Takagi, T. Tribological properties of single-walled carbon nanotube solids. J. Nanosci. Nanotechnol. 2008, 8, 2665–2670. [Google Scholar] [CrossRef]

- Bansal, S.A.; Khanna, V.; Singh, A.P.; Kumar, S. Small percentage reinforcement of carbon nanotubes (CNTs) in epoxy (bisphenol-A) for enhanced mechanical performance. Mater. Today Proc. 2022, 61, 275–279. [Google Scholar] [CrossRef]

- Kasemsiri, P.; Lorwanishpaisarn, N.; Pongsa, U.; Ando, S. Reconfigurable shape memory and self-welding properties of epoxy phenolic novolac/cashew nut shell liquid composites reinforced with carbon nanotubes. Polymers 2018, 10, 482. [Google Scholar] [CrossRef]

- Chen, X.; Peng, F.; Wang, C.; Zhou, H.; Lin, X.; Liu, W.; Zhang, A. Improving the flame retardancy and mechanical properties of epoxy composites significantly with a low-loading CNT-based hierarchical hybrid decorated with reactive hyperbranched polyphosphoramide. Appl. Surf. Sci. 2022, 576, 151765. [Google Scholar] [CrossRef]

- Tripathi, K.M.; Vincent, F.; Castro, M.; Feller, J.-F. Flax fibers–epoxy with embedded nanocomposite sensors to design lightweight smart bio-composites. Nanocomposites 2016, 2, 125–134. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, X.; Yu, X.; Zhao, J.; Li, S.; Liu, F.; Gao, P.; Zhang, Y.; Zhao, T.; Li, Q. Bio-inspired aggregation control of carbon nanotubes for ultra-strong composites. Sci. Rep. 2015, 5, 11533. [Google Scholar] [CrossRef]

- Lachman, N.; Wagner, H.D. Correlation between interfacial molecular structure and mechanics in CNT/epoxy nano-composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1093–1098. [Google Scholar] [CrossRef]

- Varghai, D.; Maiorana, A.; Meng, Q.; Gross, R.A.; Manas-Zloczower, I. Sustainable, electrically-conductive bioepoxy nanocomposites. Polymer 2016, 107, 292–301. [Google Scholar] [CrossRef]

- Huang, X.; Li, R.; Zeng, L.; Li, X.; Xi, Z.; Wang, K.; Li, Y. A multifunctional carbon nanotube reinforced nanocomposite modified via soy protein isolate: A study on dispersion, electrical and mechanical properties. Carbon 2020, 161, 350–358. [Google Scholar] [CrossRef]

- Zeng, L.; Tao, W.; Zhao, J.; Li, Y.; Li, R. Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement. Nanotechnol. Rev. 2022, 11, 625–636. [Google Scholar] [CrossRef]

- Vinay, S.S.; Sanjay, M.R.; Siengchin, S.; Venkatesh, C.V. Basalt fiber reinforced polymer composites filled with nano fillers: A short review. Mater. Today Proc. 2022, 52, 2460–2466. [Google Scholar] [CrossRef]

- Lorwanishpaisarn, N.; Srikhao, N.; Jetsrisuparb, K.; Knijnenburg, J.T.N.; Theerakulpisut, S.; Okhawilai, M.; Kasemsiri, P. Self-healing ability of epoxy vitrimer nanocomposites containing bio-based curing agents and carbon nanotubes for corrosion protection. J. Polym. Environ. 2022, 30, 472–482. [Google Scholar] [CrossRef]

- Dinesh, T.; Kadirvel, A.; Hariharan, P. Thermo-mechanical and wear behaviour of surface-treated pineapple woven fibre and nano-silica dispersed mahua oil toughened epoxy composite. Silicon 2020, 12, 2911–2920. [Google Scholar] [CrossRef]

- Shettar, M.; Kowshik, S.; Hiremath, P.; Sharma, S. Water sorption-desorption-resorption effects on mechanical properties of epoxy-nanoclay nanocomposites. Int. J. Automot. Mech. Eng. 2022, 19, 9478–9486. [Google Scholar] [CrossRef]

- Wu, K.; Niu, Y.; Zhang, Y.; Yong, Z.; Li, Q. Continuous growth of carbon nanotube films: From controllable synthesis to real applications. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106359. [Google Scholar] [CrossRef]

- Hiremath, P.; Kini U, A.; Shettar, M.; Sharma, S.; PK, J. Investigation on tensile properties and analysis of wear property of glass fiber-epoxy-nanoclay ternary nanocomposite using response surface methodology. Cogent Eng. 2021, 8, 1877869. [Google Scholar] [CrossRef]

- Lubi, M.C.; Thachil, E.T. Cashew nut shell liquid (CNSL)—A versatile monomer for polymer synthesis. Des. Monomers Polym. 2000, 3, 123–153. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Deléglise, M.; Lacrampe, M.-F.; Krawczak, P. Thermosetting (bio)materials derived from renewable resources: A critical review. Prog. Polym. Sci. 2010, 35, 487–509. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent Progress in Hybrid Biocomposites: Mechanical Properties, Water Absorption, and Flame Retardancy. Materials 2020, 13, 5145. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- Kaczmarek, K.; Konieczny, B.; Siarkiewicz, P.; Leniart, A.; Lukomska-Szymanska, M.; Skrzypek, S.; Lapinska, B. Surface Characterization of Current Dental Ceramics Using Scanning Electron Microscopic and Atomic Force Microscopic Techniques. Coatings 2022, 12, 1122. [Google Scholar] [CrossRef]

- Birch, M.E.; Ruda-Eberenz, T.A.; Chai, M.; Andrews, R.; Hatfield, R.L. Properties that influence the specific surface areas of carbon nanotubes and nanofibers. Ann. Occup. Hyg. 2013, 57, 1148–1166. [Google Scholar]

- Sitko, R.; Zawisza, B.; Malicka, E. Modification of carbon nanotubes for preconcentration, separation and determination of trace-metal ions. TrAC Trends Anal. Chem. 2012, 37, 22–31. [Google Scholar] [CrossRef]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- Bongale, A.M.; Kumar, S.; Sachit, T.S.; Jadhav, P. Wear rate optimization of Al/SiCnp/e-glass fibre hybrid metal matrix composites using Taguchi method and genetic algorithm and development of wear model using artificial neural networks. Mater. Res. Express 2018, 5, 035005. [Google Scholar] [CrossRef]

- Kurapati, V.B.; Kommineni, R.; Sundarrajan, S. Statistical analysis and mathematical modeling of dry sliding wear parameters of 2024 aluminium hybrid composites reinforced with fly ash and SiC particles. Trans. Indian Inst. Met. 2018, 71, 1809–1825. [Google Scholar] [CrossRef]

- Aliyu, I.K.; Azam, M.U.; Lawal, D.U.; Samad, M.A. Optimization of SiC concentration and process parameters for a wear-resistant UHMWPE nancocomposite. Arab. J. Sci. Eng. 2020, 45, 849–860. [Google Scholar] [CrossRef]

- Jarvis, D.I.; Brown, A.H.D.; Cuong, P.H.; Collado-Panduro, L.; Latournerie-Moreno, L.; Gyawali, S.; Tanto, T.; Sawadogo, M.; Mar, I.; Sadiki, M.; et al. A global perspective of the richness and evenness of traditional crop-variety diversity maintained by farming communities. Proc. Natl. Acad. Sci. USA 2008, 105, 5326–5331. [Google Scholar] [CrossRef] [PubMed]

| Parameter | FormuLITE |

|---|---|

| Calculated bio-content | 36.6 |

| Mix ratio by weight | 100:30 |

| Mix ratio by volume | 100:36 |

| Mix viscosity at 25 °C (cPs) | 700 |

| Mix viscosity at 40 °C (cPs) | 242 |

| Pot life at 25 °C (min) | 105 |

| Pot life at 40 °C (min) | 57 |

| Tg (°C) | 92 |

| Tensile strength (MPa) | 62 |

| Tensile modulus (MPa) | 2615 |

| Elongation at Fmax (%)/Elongation at break (%) | 4.8/6.4 |

| Flexural strength (MPa) | 92 |

| Flexural modulus (MPa) | 2262 |

| Parameter | Values |

|---|---|

| Typical diameter | ≈120 nm |

| Typical length | Up to 1 mm |

| Aspect ratio | 4000 |

| Elastic modulus | 900 GPa |

| Tensile strength | 45 GPa |

| Thermal conductivity at 300 K | 2500 W/(m·K) |

| The smallest effective dose for an anti-static additive | 0.5% |

| Sl. No. | Wt.% CNTs | Speed (rpm) | Distance (m) | Load (N) | Weight Loss (mg) |

|---|---|---|---|---|---|

| 1 | 0.00 | 183 | 500 | 10 | 0.208 |

| 2 | 0.00 | 275 | 750 | 20 | 0.263 |

| 3 | 0.00 | 367 | 1000 | 30 | 0.311 |

| 4 | 0.00 | 458 | 1250 | 40 | 0.444 |

| 5 | 0.25 | 183 | 750 | 30 | 0.157 |

| 6 | 0.25 | 275 | 500 | 40 | 0.177 |

| 7 | 0.25 | 367 | 1250 | 10 | 0.169 |

| 8 | 0.25 | 458 | 1000 | 20 | 0.165 |

| 9 | 0.50 | 183 | 1000 | 40 | 0.099 |

| 10 | 0.50 | 275 | 1250 | 30 | 0.094 |

| 11 | 0.50 | 367 | 500 | 20 | 0.088 |

| 12 | 0.50 | 458 | 750 | 10 | 0.086 |

| 13 | 0.75 | 183 | 1250 | 20 | 0.009 |

| 14 | 0.75 | 275 | 1000 | 10 | 0.003 |

| 15 | 0.75 | 367 | 750 | 40 | 0.020 |

| 16 | 0.75 | 458 | 500 | 30 | 0.007 |

| Term | Coef. | SE Coef. | T | p |

|---|---|---|---|---|

| Constant | 0.14375 | 0.01091 | 13.172 | 0.001 |

| Wt.% CNTs 0.00 | 0.16275 | 0.0189 | 8.61 | 0.003 |

| Wt.% CNTs 0.25 | 0.02325 | 0.0189 | 1.23 | 0.306 |

| Wt.% CNTs 0.50 | −0.052 | 0.0189 | −2.751 | 0.071 |

| Speed (r 183) | −0.0255 | 0.0189 | −1.349 | 0.27 |

| Speed (r 275) | −0.0095 | 0.0189 | −0.503 | 0.65 |

| Speed (r 367) | 0.00325 | 0.0189 | 0.172 | 0.874 |

| Distance 500 | −0.02375 | 0.0189 | −1.256 | 0.298 |

| Distance 750 | −0.01225 | 0.0189 | −0.648 | 0.563 |

| Distance 1000 | 0.00075 | 0.0189 | 0.04 | 0.971 |

| Load (N) 10 | −0.02725 | 0.0189 | −1.442 | 0.245 |

| Load (N) 20 | −0.0125 | 0.0189 | −0.661 | 0.556 |

| Load (N) 30 | −0.0015 | 0.0189 | −0.079 | 0.942 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | p |

|---|---|---|---|---|---|---|

| Wt.% CNTs | 3 | 0.190753 | 0.190753 | 0.063584 | 33.37 | 0.008 |

| Speed (rpm) | 3 | 0.007037 | 0.007037 | 0.002345 | 1.23 | 0.434 |

| Distance (m) | 3 | 0.007829 | 0.007829 | 0.00261 | 1.37 | 0.401 |

| Load (N) | 3 | 0.01041 | 0.01041 | 0.00347 | 1.82 | 0.317 |

| Residual Error | 3 | 0.005717 | 0.005717 | 0.001906 | ||

| Total | 15 | 0.221745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiremath, P.; Ranjan, R.; DeSouza, V.; Bhat, R.; Patil, S.; Maddodi, B.; Shivamurthy, B.; Perez, T.C.; Naik, N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. J. Compos. Sci. 2023, 7, 478. https://doi.org/10.3390/jcs7110478

Hiremath P, Ranjan R, DeSouza V, Bhat R, Patil S, Maddodi B, Shivamurthy B, Perez TC, Naik N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. Journal of Composites Science. 2023; 7(11):478. https://doi.org/10.3390/jcs7110478

Chicago/Turabian StyleHiremath, Pavan, Rakesh Ranjan, Vir DeSouza, Ritesh Bhat, Santosh Patil, Balakrishna Maddodi, B. Shivamurthy, Teresa Castillo Perez, and Nithesh Naik. 2023. "Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy" Journal of Composites Science 7, no. 11: 478. https://doi.org/10.3390/jcs7110478

APA StyleHiremath, P., Ranjan, R., DeSouza, V., Bhat, R., Patil, S., Maddodi, B., Shivamurthy, B., Perez, T. C., & Naik, N. (2023). Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. Journal of Composites Science, 7(11), 478. https://doi.org/10.3390/jcs7110478