Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements

Abstract

1. Introduction

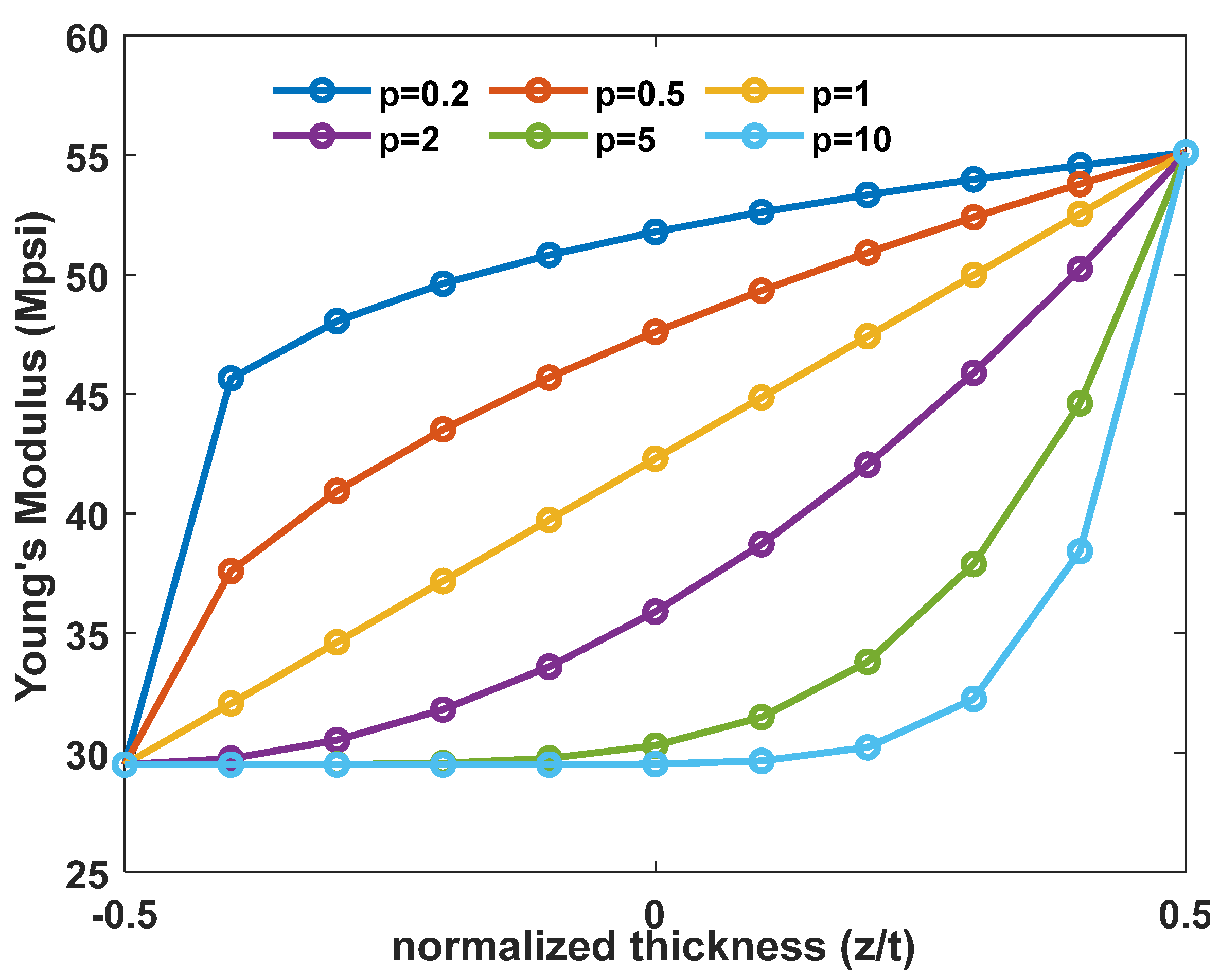

2. Materials and Methods

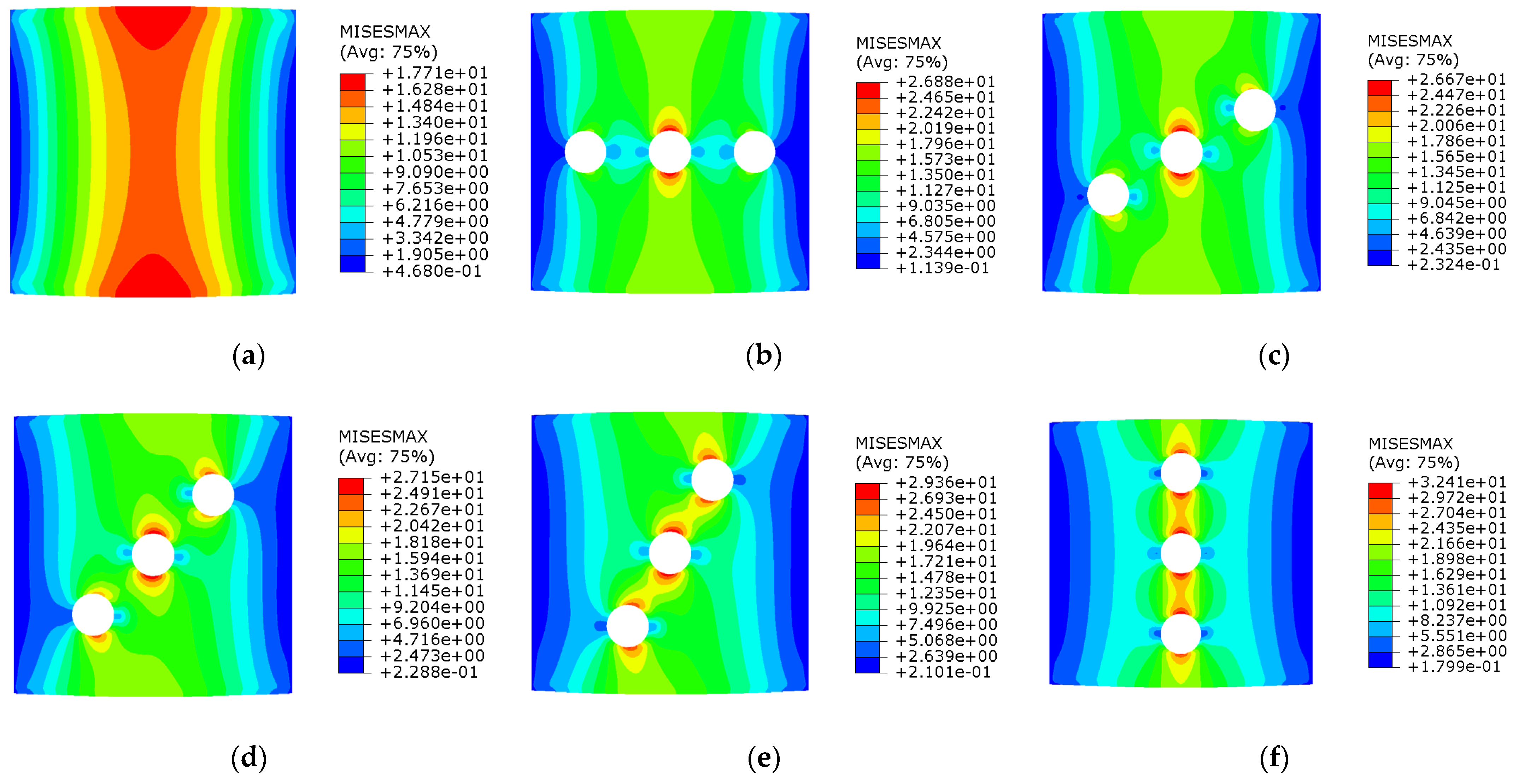

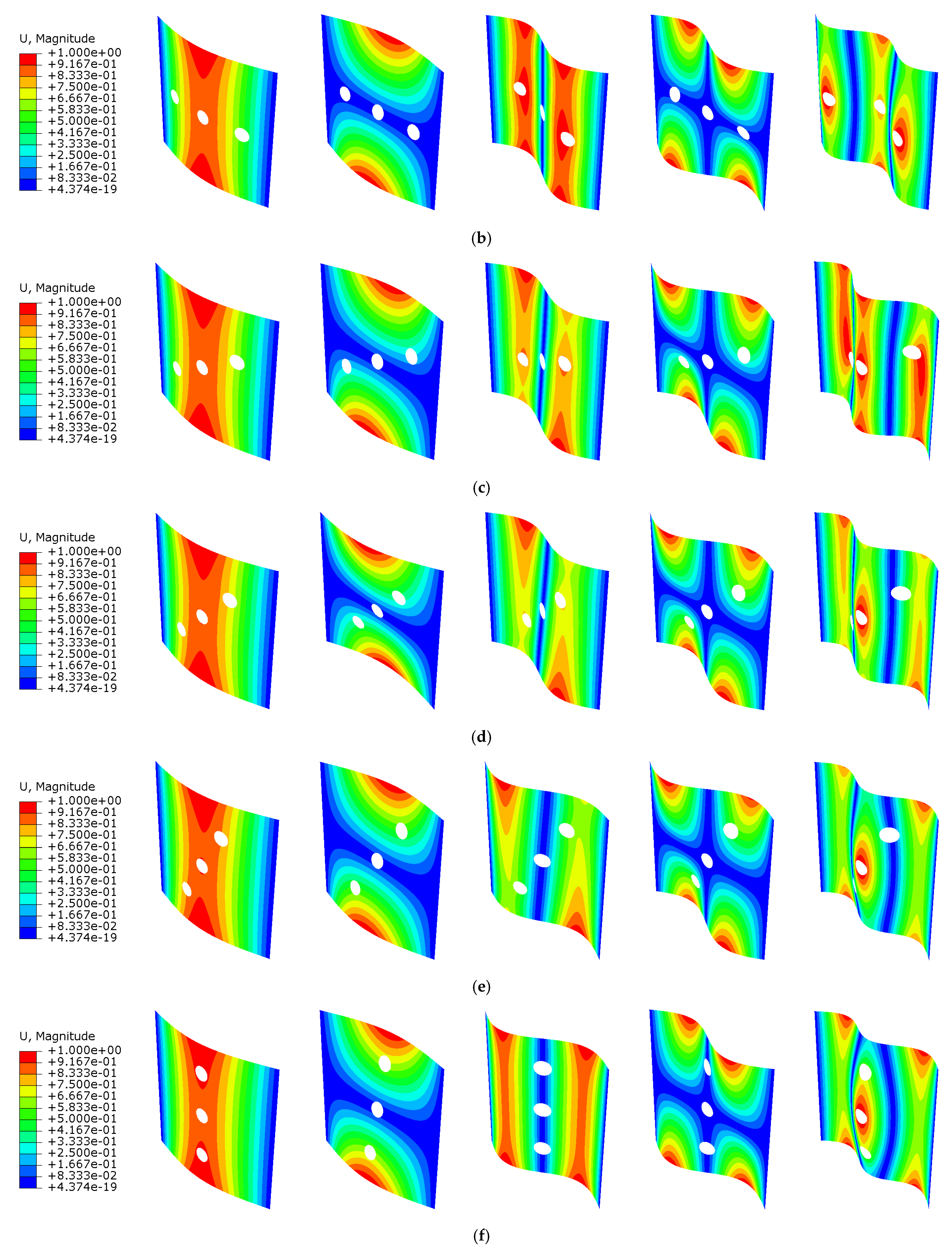

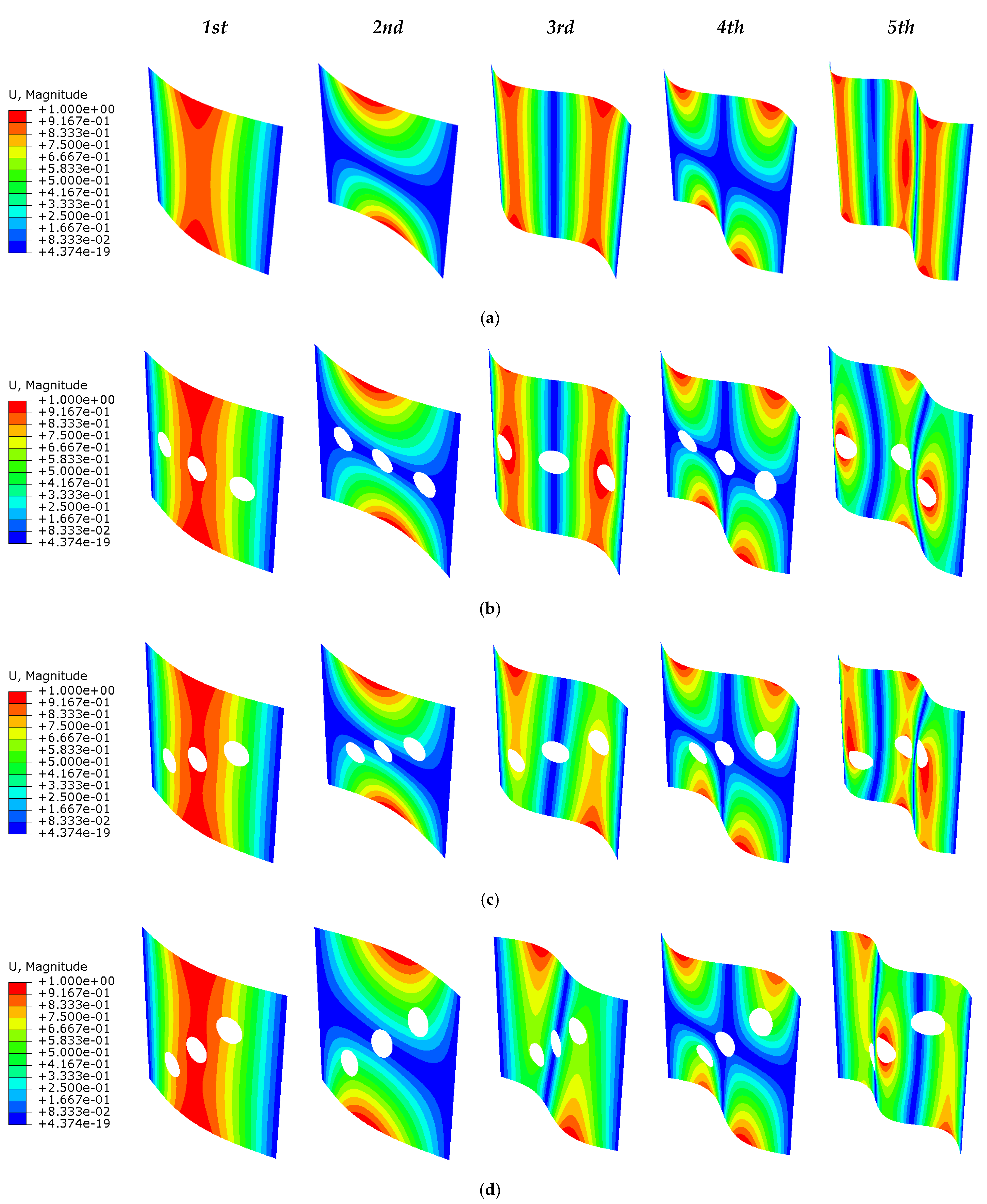

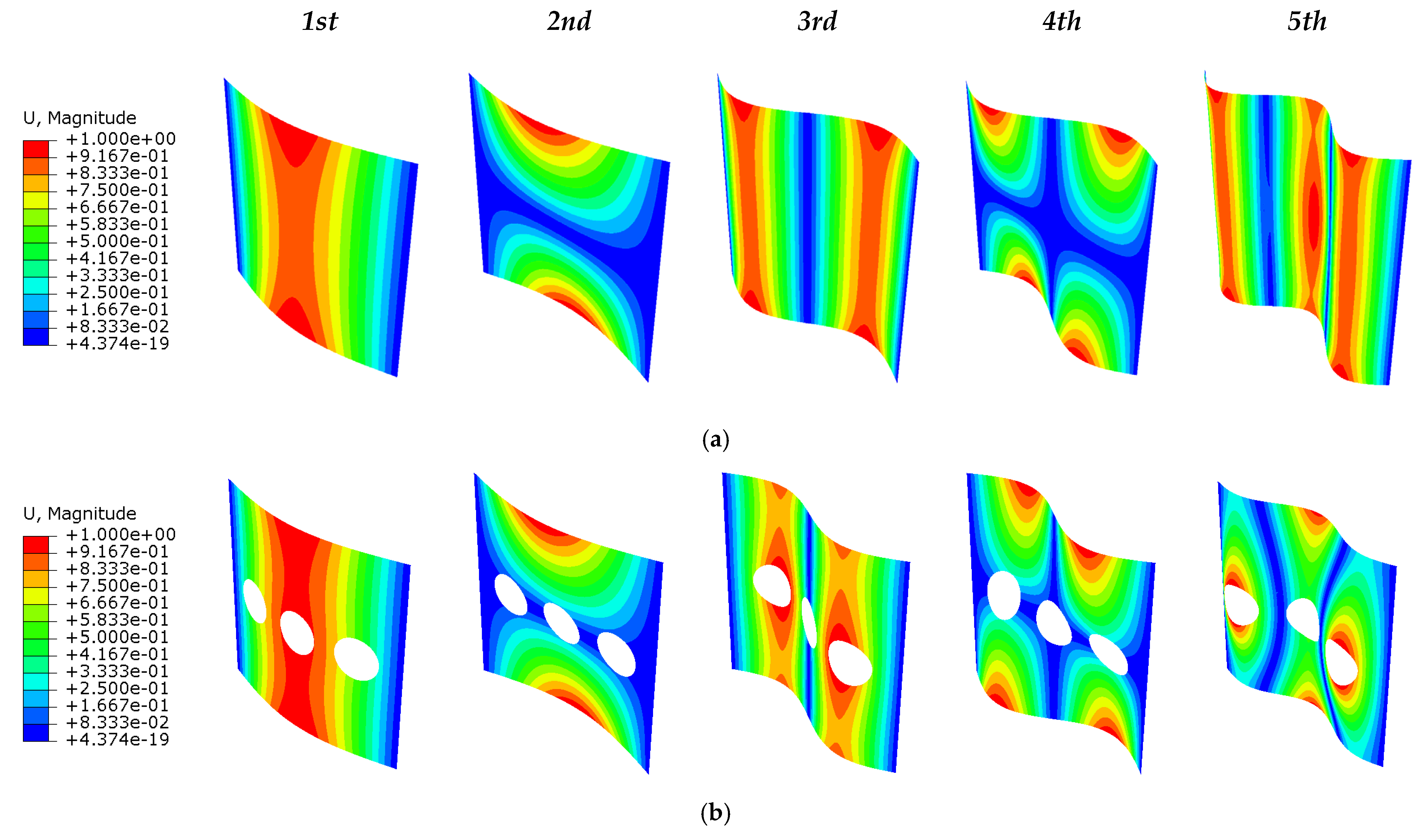

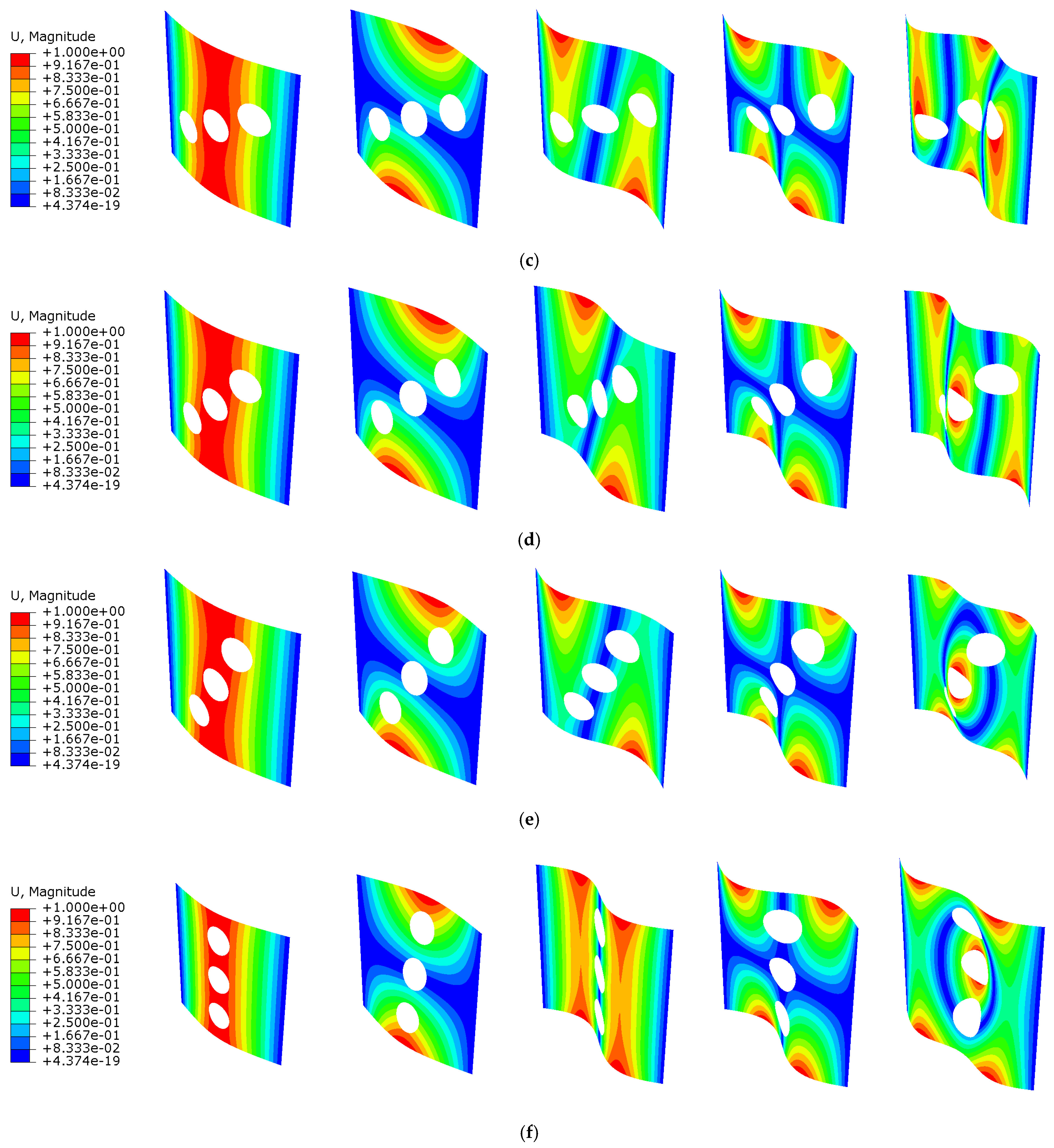

3. Results

4. Discussion

5. Conclusions

- The increase in the plate thickness and decrease in the circular cutout diameter increases the critical buckling load of the FGM thin plate.

- Horizontal arrangements exhibit the highest critical buckling load and best buckling performance. As the arrangement shifts to a vertical one, the critical buckling value decreases.

- The normalized buckling load decreases as the plate thickness and cutout size increase. The change in the normalized buckling load is more apparent as the cutout arrangements approach a vertical position.

- Generally, FGM plates with a horizontal circular cutout arrangement, a smaller cutout diameter, and a larger thickness provide the highest critical buckling load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, H.; Cheng, Y.; Lv, H.; Ji, G.; Du, Y. A novel hierarchically porous magnetic carbon derived from biomass for strong lightweight microwave absorption. Carbon 2018, 142, 245–253. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Lei, J.; Zhang, Z.; Sun, Q.; Chen, W.; Xiao, L.; Sun, J. Microstructural dependence of strength and ductility in a novel high strength β titanium alloy with Bi-modal structure. Mater. Sci. Eng. A 2019, 762, 138086. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; You, Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review. Compos. Part B Eng. 2020, 201, 108340. [Google Scholar] [CrossRef]

- Ali, A.; Andriyana, A. Properties of multifunctional composite materials based on nanomaterials: A review. RSC Adv. 2020, 10, 16390–16403. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Liu, F.; Wang, L. Enhancing indentation and impact resistance in auxetic composite materials. Compos. Part B Eng. 2020, 198, 108229. [Google Scholar] [CrossRef]

- Alashkar, A.; Alami, A.H. Energy Harvesting Materials: Overview of Thermoelectrical Material. Ref. Modul. Mater. Sci. 2021, 4, 319–325. [Google Scholar]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-Hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- El-Galy, I.M.; Saleh, B.I.; Ahmed, M.H. Functionally graded materials classifications and development trends from industrial point of view. SN Appl. Sci. 2019, 1, 1378. [Google Scholar] [CrossRef]

- Zhang, N.; Khan, T.; Guo, H.; Shi, S.; Zhong, W.; Zhang, W. Functionally Graded Materials: An Overview of Stability, Buckling, and Free Vibration Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 1354150. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Hosseini, S.M.H.; Arvin, H. Thermo-rotational buckling and post-buckling analyses of rotating functionally graded microbeams. Int. J. Mech. Mater. Des. 2020, 17, 55–72. [Google Scholar] [CrossRef]

- Zhang, P.; Qing, H. Buckling analysis of curved sandwich microbeams made of functionally graded materials via the stress-driven nonlocal integral model. Mech. Adv. Mater. Struct. 2020, 29, 1211–1228. [Google Scholar] [CrossRef]

- Ziou, H.; Guenfoud, H.; Guenfoud, M. Buckling analysis behavior of functionally graded beams. Jordan J. Civ. Eng. 2020, 14, 347–358. [Google Scholar]

- Daikh, A.A.; Guerroudj, M.; El Adjrami, M.; Megueni, A. Thermal Buckling of Functionally Graded Sandwich Beams. Adv. Mater. Res. 2019, 1156, 43–59. [Google Scholar] [CrossRef]

- Wu, W.-Q.; Xu, Y.-F.; Rao, H.-S.; Su, C.-Y.; Kuang, D.-B. Trilayered Photoanode of TiO2 Nanoparticles on a 1D–3D Nanostructured TiO2-Grown Flexible Ti Substrate for High-Efficiency (9.1%) Dye-Sensitized Solar Cells with Unprecedentedly High Photocurrent Density. J. Phys. Chem. C 2014, 118, 16426–16432. [Google Scholar] [CrossRef]

- Belkhodja, Y.; Ouinas, D.; Zaoui, F.Z.; Fekirini, H. An exponential-trigonometric higher order shear deformation theory (HSDT) for bending, free vibration, and buckling analysis of functionally graded materials (FGMs) plates. Adv. Compos. Lett. 2020, 29, 1–19. [Google Scholar] [CrossRef]

- Zenkour, A.M.; Aljadani, M.H. Buckling analysis of actuated functionally graded piezoelectric plates via a quasi-3D refined theory. Mech. Mater. 2020, 151, 103632. [Google Scholar] [CrossRef]

- Njim, E.K.; Al-Waily, M.; Bakhy, S.H. A Critical Review of Recent Research of Free Vibration and Stability of Functionally Graded Materials of Sandwich Plate. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012081. [Google Scholar] [CrossRef]

- Fiorini, A.; Ruta, G. Buckling of circular plates with functional grading in two directions. Meccanica 2021, 56, 245–252. [Google Scholar] [CrossRef]

- Van Vinh, P.; Van Chinh, N.; Tounsi, A. Static bending and buckling analysis of bi-directional functionally graded porous plates using an improved first-order shear deformation theory and FEM. Eur. J. Mech. A/Solids 2022, 96, 104743. [Google Scholar] [CrossRef]

- Ali, E.Y.; Bayleyegn, Y.S. Analytical and numerical buckling analysis of rectangular functionally-graded plates under uniaxial compression. In Proceedings of the Annual Stability Conference Structural Stability Research Council, St. Louis, MO, USA, 2–5 April 2019; Volume 2, pp. 534–547. [Google Scholar]

- Cuong-Le, T.; Nguyen, K.D.; Nguyen-Trong, N.; Khatir, S.; Nguyen-Xuan, H.; Abdel-Wahab, M. A three-dimensional solution for free vibration and buckling of annular plate, conical, cylinder and cylindrical shell of FG porous-cellular materials using IGA. Compos. Struct. 2020, 259, 113216. [Google Scholar] [CrossRef]

- Khatir, S.; Tiachacht, S.; Le Thanh, C.; Ghandourah, E.; Mirjalili, S.; Wahab, M.A. An improved Artificial Neural Network using Arithmetic Optimization Algorithm for damage assessment in FGM composite plates. Compos. Struct. 2021, 273, 114287. [Google Scholar] [CrossRef]

- Le Thanh, C.; Nguyen, T.N.; Vu, T.H.; Khatir, S.; Wahab, M.A. A geometrically nonlinear size-dependent hypothesis for porous functionally graded micro-plate. Eng. Comput. 2020, 38, 449–460. [Google Scholar] [CrossRef]

- Li, D.M.; Featherston, C.A.; Wu, Z. An element-free study of variable stiffness composite plates with cutouts for enhanced buckling and post-buckling performance. Comput. Methods Appl. Mech. Eng. 2020, 371, 113314. [Google Scholar] [CrossRef]

- Evran, S.; Yildir, S.Z. Eigenvalue Buckling Analysis of Beams with Different Width and Square Cutout. Aksaray Univ. J. Sci. Eng. 2022, 6, 71–78. [Google Scholar] [CrossRef]

- Bash, A.M.; Mnawe, S.E.; Salah, S.A. Numerical buckling analysis of carbon fibre-epoxy composite plates with different cutouts number by finite element method. AIMS Mater. Sci. 2020, 7, 46–59. [Google Scholar] [CrossRef]

- Akbar, R.M.; Suryoatmono, B. Numerical study of inelastic buckling behavior of rectangular steel plates with circular openings under shear forces. MATEC Web Conf. 2019, 258, 05026. [Google Scholar] [CrossRef]

- Yanli, G.; Xiaoqing, S.; Xiao, L.; Xingyou, Y.; Zhifan, X.; Bin, X.; Jianyi, S. Elastic buckling of thin plate with circular holes in bending. E3S Web Conf. 2019, 136, 04043. [Google Scholar] [CrossRef]

- Wang, G.; Sun, H.; Peng, H.; Uemori, R. Buckling and ultimate strength of plates with openings. Ships Offshore Struct. 2009, 4, 43–53. [Google Scholar] [CrossRef]

- Kumar, R.; Lal, A.; Sutaria, B. Comparative buckling analysis of laminated composite plates with various shapes of hole. Mater. Today Proc. 2020, 44, 4009–4012. [Google Scholar] [CrossRef]

- Ansari, R.; Hassani, R.; Torabi, J. Mixed-type formulation of higher-order shear deformation theory for vibration and buckling analysis of FG-GPLRC plates using VDQFEM. Compos. Struct. 2019, 235, 111738. [Google Scholar] [CrossRef]

- Erdem, S.; Kaman, M.O.; Gur, M. Post-buckling behavior of carbon fiber epoxy composite plates. J. Mech. Sci. Technol. 2019, 33, 1723–1730. [Google Scholar] [CrossRef]

- Vivek, K.; Babu, T.S.; Ram, K.S. Buckling analysis of functionally graded thin square plates with triangular cut-out subjected to uni-axial loads. Mater. Today: Proc. 2020, 24, 662–672. [Google Scholar] [CrossRef]

- Elkafrawy, M.; Alashkar, A.; Hawileh, R.; AlHamaydeh, M. FEA Investigation of Elastic Buckling for Functionally Graded Material (FGM) Thin Plates with Different Hole Shapes under Uniaxial Loading. Buildings 2022, 12, 802. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, T.; Bui, T.Q. Composite FG plates with different internal cutouts: Adaptive IGA buckling analysis without trimmed surfaces. Compos. Struct. 2020, 259, 113392. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Plate Width | 2000 | mm | |

| Plate Height | 2000 | mm | |

| Plate Thickness | 25, 50, 75 | mm | |

| Cutout Diameter | 200, 300, 400 | mm | |

| Cutout Distance | 600 | mm | |

| Arrangement Angle | 0, 30, 45, 60, 90 | ||

| Position of Material | 0 | - | |

| Power Index | 1 | - | |

| Volume Fraction | 0.5 | - | |

| Young Modulus of Ceramic | 380 | ||

| Young Modulus of Metal | 203 | ||

| Young Modulus of FGM | 292 | ||

| Poisson’s Ratio | 0.3 | - | |

| Element Type | - | Shell S4R | - |

| Mesh Size | - | 20 | mm2 |

| Thickness (mm) | Diameter (mm) | Buckling Load (kN) | |

|---|---|---|---|

| 25 | - | - | 1972 |

| 0 | 1868 | ||

| 30 | 1852 | ||

| 45 | 1833 | ||

| 60 | 1810 | ||

| 90 | 1783 | ||

| 0 | 1762 | ||

| 30 | 1727 | ||

| 45 | 1683 | ||

| 60 | 1627 | ||

| 90 | 1561 | ||

| 400 | 0 | 1642 | |

| 30 | 1578 | ||

| 45 | 1494 | ||

| 60 | 1390 | ||

| 90 | 1265 | ||

| 50 | - | - | 15,737 |

| 0 | 14,894 | ||

| 30 | 14,768 | ||

| 200 | 45 | 14,612 | |

| 60 | 14,423 | ||

| 90 | 14,198 | ||

| 0 | 14,045 | ||

| 30 | 13,765 | ||

| 300 | 45 | 13,401 | |

| 60 | 12,950 | ||

| 90 | 12,408 | ||

| 0 | 13,093 | ||

| 30 | 12,568 | ||

| 400 | 45 | 11,885 | |

| 60 | 11,037 | ||

| 90 | 10,030 | ||

| 75 | - | - | 52,950 |

| 0 | 50,074 | ||

| 30 | 49,638 | ||

| 200 | 45 | 49,104 | |

| 60 | 48,450 | ||

| 90 | 47,668 | ||

| 0 | 47,208 | ||

| 30 | 46,244 | ||

| 300 | 45 | 44,996 | |

| 60 | 43,450 | ||

| 90 | 41,592 | ||

| 0 | 44,012 | ||

| 30 | 42,190 | ||

| 400 | 45 | 39,846 | |

| 60 | 36,962 | ||

| 90 | 33,556 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alashkar, A.; Elkafrawy, M.; Hawileh, R.; AlHamaydeh, M. Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements. J. Compos. Sci. 2022, 6, 277. https://doi.org/10.3390/jcs6090277

Alashkar A, Elkafrawy M, Hawileh R, AlHamaydeh M. Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements. Journal of Composites Science. 2022; 6(9):277. https://doi.org/10.3390/jcs6090277

Chicago/Turabian StyleAlashkar, Adnan, Mohamed Elkafrawy, Rami Hawileh, and Mohammad AlHamaydeh. 2022. "Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements" Journal of Composites Science 6, no. 9: 277. https://doi.org/10.3390/jcs6090277

APA StyleAlashkar, A., Elkafrawy, M., Hawileh, R., & AlHamaydeh, M. (2022). Buckling Analysis of Functionally Graded Materials (FGM) Thin Plates with Various Circular Cutout Arrangements. Journal of Composites Science, 6(9), 277. https://doi.org/10.3390/jcs6090277