Abstract

Lignocellulosic fillers have attracted considerable attention over the years as a promising alternative to conventional petroleum-based fillers (carbon black) in rubber composites due to their renewability, biodegradability, availability, high mechanical properties, low density and low cost. Based on the literature available, a comprehensive review is presented here of rubber biocomposites reinforced with plant-based fillers. The study is divided into different sections depending on the matrix (natural or synthetic rubber) and the type of lignocellulosic fillers (natural fiber, microcrystalline cellulose, lignin and nanocellulose). This review focuses on the curing characteristics, mechanical properties and dynamic mechanical properties of the resulting rubber biocomposites. In addition, the effect of hybrid filler systems, lignocellulosic filler surface modification and modification of the rubber matrix on the properties of these rubber biocomposites are presented and compared. A conclusion is finally presented with some openings for future works.

1. Introduction

Rubbers are elastomeric materials containing unsaturated bonds in their backbone that can be strengthened by the vulcanization process (crosslinking reaction). Vulcanized rubbers have exceptional properties, such as high elasticity, excellent abrasion resistance, low compression set, high elongation, and high tensile and tear strength. Therefore, they can be used for various products, such as tires, hoses, belts, gloves, footwear, gaskets, etc. [1,2]. Additionally, rubber composites can be used in biomedical applications as well as electrical and thermal devices such as sensors [3]. However, unfilled rubber is remains inappropriate for industrial applications and must be reinforced with fillers to generate composite structures [1].

Fillers are classified into three categories: (i) reinforcing, (ii) semi-reinforcing and (iii) non-reinforcing. Reinforcing fillers are used to improve the properties (mechanical, thermal, electrical and chemical) of the composites. However, non-reinforcing fillers are used to decrease the costs, but they may also decrease the mechanical properties [4]. Today, carbon black (CB) is still the most widely used reinforcing filler for rubber composites; it can effectively improve the mechanical and dynamic mechanical properties since strong interfacial interactions are formed between the CB particles and rubber chains. However, CB is a non-renewable and non-biodegradable petroleum-based material. In addition, a large amount of energy is consumed during its production, leading to environmental issues [5,6,7]. For example, the CO2 emission and energy consumption factors are 3.3 tons CO2/ton of CB and 44 GJ/ton of CB, respectively [8]. Therefore, replacing CB with more sustainable and green fillers has garnered increased attention, generating several studies on the subject.

Lignocellulosic fillers are attracting considerable attention as alternative reinforcements in rubber composites due to their renewability, biodegradability, availability, high mechanical properties, low density and low cost [9,10]. For example, the annual production of mill wood residues in Canada for 2004 was estimated at 21.2 million bone-dry tons (BDt), of which 87% was used in applications such as pulp and paper, wood fuels, animal bedding, pellets, etc. However, the other 13% (2.7 million BDt) was discarded [11]. This represents a substantial source of low-cost fillers to be used in composite applications. However, lignocellulosic materials are generally classified as non-reinforcing fillers for rubber composites due to the poor compatibility between hydrophobic rubber molecules and hydrophilic fillers. Therefore, the properties of rubber composites filled with pristine lignocellulosic fillers are expected to be lower than those filled with CB. Consequently, some modifications must be applied to the lignocellulosic fillers to improve their compatibility with the rubber matrix [12]. Nevertheless, these modifications require additional costs and could also decrease the biodegradability of natural fillers. Moreover, additional steps are necessary for the fillers’ purification and their mixing with a rubber matrix, especially for nanoscale fillers.

In this review, lignocellulosic fillers are classified into natural fibers, microcrystalline cellulose (MCC), lignin and nanocellulose to determine their effect on the curing characteristics and mechanical and dynamic mechanical properties of rubber biocomposites. Furthermore, lignocellulosic fillers’ surface modifications are presented and compared. The review is divided in two main sections: natural rubber (NR) and synthetic rubbers. Since NR is also bio-based, most studies have focused on NR biocomposites. Nevertheless, some applications of lignocellulosic filler addition into synthetic rubbers are also reported to complete the review.

2. Natural Rubber (NR)

2.1. Natural Fiber/NR Composite

Raw natural fibers (NF) are generally categorized as non-reinforcing fillers, but the specific features of these materials, such as renewability, biodegradability, availability, and high mechanical properties, make them promising candidates for NR composite applications. Moreover, NF/NR composites have low cost and low density. NF are classified into plant-based, mineral-based and animal-based fibers. Plant-based fibers are the most abundant natural fibers and are extracted from different sources and parts of plants. Therefore, the main components of plant fibers are similar (cellulose, hemicellulose and lignin), but their compositions are different [13]. The chemical compositions of typical natural fibers are reported in Table 1.

Table 1.

Chemical composition of typical natural fibers [13].

2.1.1. Effect of Natural Fiber Physical Properties

Filler size is a critical factor affecting the mechanical properties of composites. A smaller filler size has a higher surface area and has a greater possibility to bind to the rubber. On the other hand, it is also more difficult to disperse into polymer matrices. Therefore, composites filled with smaller fillers have better mechanical properties than those containing larger particles, providing good dispersion. Sareena et al. [14] compared two different particle sizes of coconut shell powder (0–45 μm and 45–90 μm) and reported that the filler surface area can control the mechanical properties of NR composites. The tensile strength of composites containing 10 parts/100 rubber (phr) of coconut shell powders with a size of 0–45 μm was 26% higher than the one with a size of 45–90 μm. Ismail et al. [15,16] also reported similar results for the effect of oil palm wood flour size on the mechanical properties of NR composites.

Natural fibers can have a wide range of length-to-diameter ratio (aspect ratio). The fiber aspect ratio plays an essential role in the mechanical properties of composites. It must be above a critical value to be effective for interfacial stress transfer. The critical fiber aspect ratio is defined as the minimum value to maximize the interfacial stress transfer between the fiber and the matrix. Below this value, the fibers are simply acting as fillers. On the other hand, if the aspect ratio is too high, the fibers may entangle during mixing, leading to poor dispersion [17]. Joseph et al. [18] indicated that in addition to the fiber aspect ratio, fiber orientation has a strong effect on mechanical properties. They showed that the tensile strength of NR composites filled with 20 phr of oil palm fibers in the longitudinal direction was 15% higher than that in the transversal direction.

2.1.2. Biodegradability

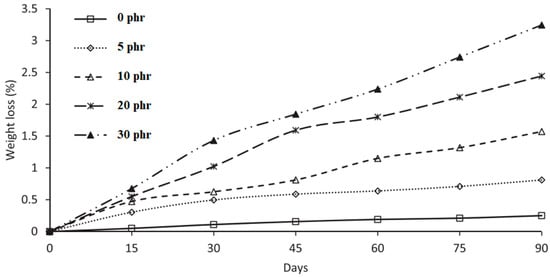

Biodegradability is one of the most important features of natural fibers, making them interesting for polymer composites. Abdel-Hakim et al. [19] studied the biodegradation of sisal fiber/NR composites of different filler contents using simulated soil containing equal parts soil, sand and animal manure. The samples were buried under a layer of soil (1 cm) with a pH of 7.5. The biodegradation period was 90 days, and the weight loss was measured every 2 weeks. Figure 1 shows the weight loss of sisal fiber/NR composites as a function of filler content. The weight loss of neat NR was 0.25% after 90 days, while this value for the composites containing 5, 10, 20 and 30 phr of sisal fiber was 0.81%, 1.57%, 2.44% and 3.25%, respectively. It was found that the degree of biodegradability increased with increasing the amount of sisal fiber in NR composites. The authors also reported that, although coating the sisal fibers with a hydrophobic polymer (styrene butyl acrylate) improved the mechanical properties of NR composites, this treatment resulted in lower weight loss during biodegradation. Similar results were obtained by Jacob et al. [20]. They confirmed that the biocomposite weight loss in soil increased with natural fiber (sisal and oil palm) addition to NR, but performing chemical treatments (mercerization and silanization) on the fibers reduced the biodegradability.

Figure 1.

Weight loss of sisal fiber/NR composites with different filler contents (adapted with permission from [19]).

2.1.3. Curing Characteristics

Curing characteristics are critical parameters because they control the degree of crosslinking with respect to the curing time and temperature and thus help understand the processability of rubber compounds. The scorch time (t’10), optimum curing time (t’90), minimum torque (ML) and maximum torque (MH) are generally obtained from the curing curve, where t’x represents the time to reach x% of torque increase:

t’x = minutes to ML + x (MH − ML) · 100 torque

Scorch time, also known as induction time, is the time before vulcanization. The optimum cure time represents the degree of crosslinking or curing time required to prepare the vulcanized NR. Minimum torque is related to processability, while maximum torque is associated with the stiffness and crosslink density of the rubber compound.

Since NF are stiffer than NR, their addition leads to a restriction in the deformation and mobility of rubber chains, increasing the compound viscosity. The minimum torque and maximum torque are increased with their addition, and more energy is required to process the rubber compounds. As a result, more heat is generated due to additional friction (viscous dissipation), leading to shorter scorch time and optimum cure time [14,21,22,23,24,25]. For example, the curing characteristics of NR composites filled with coconut shell powders are reported in Table 2.

Table 2.

Curing characteristics of NR composites filled with coconut shell powders [14].

2.1.4. Mechanical Properties

Various natural fibers have been used as fillers in NR composites. Although the main components of most natural fibers of plant origin are the same (cellulose, hemicellulose and lignin), their chemical compositions are different (Table 1). This leads to differences in the mechanical properties of NR composites filled with different NF. Some examples are listed in Table 3.

Table 3.

Mechanical properties of NR composites filled with different types of natural fibers.

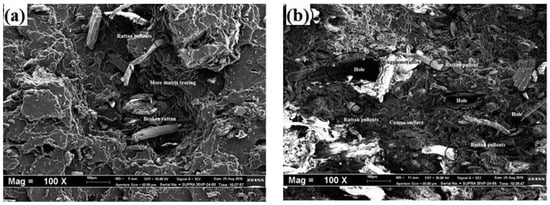

The results in Table 3 show that the tensile strength of NR composites decreased with increasing natural fiber content because of poor filler dispersion, limited interfacial adhesion, and restricted strain-induced crystallization of NR. The poor compatibility between NF and NR is clearly visible through SEM analysis (Figure 2). SEM images show that rattan fibers can be easily pulled out from the rubber matrix, leaving holes due to weak interfacial adhesion. Moreover, agglomerations are formed when 30 phr of fillers are added. Filler–rubber incompatibility can also be observed by studying the swelling properties of NR composites in a good solvent (toluene). Since the solvent dissolves unvulcanized (uncrosslinked) NR and swells crosslinked NR, it can be used as a molecular probe in vulcanized rubbers to study the internal structure of composites. Several studies confirmed the incompatibility between untreated natural fibers and NR using this technique [23,25,30,31]. In addition, the high content of natural fibers may lead to a discontinuous phase of the NR matrix and thereby decrease the possibility of strain-induced crystallization. In other words, the addition of a high amount of filler limited the mobility of NR chains and their orientation during stretching, causing the onset of stress-induced crystallization to be shifted to smaller strains compared to unfilled NR. Consequently, the tensile strength and elongation at break decreased sharply at higher filler loadings [32,33]. In contrast, the tensile modulus and hardness continuously increased with natural fiber content because these fillers were much stiffer than NR. Similar trends were observed in NR composites filled with rattan powder [25], bamboo fiber [26], cotton [27], jute [28], aspen wood flour [29], sisal [30], grass [31], maple [34], flax [35], hemp [36], oil palm [37], wheat straw [38], pineapple leaf [39], coir [22], isora [40], silk [41], coconut shell powder [14] and peanut shell powder [24].

Figure 2.

SEM micrographs of the tensile fracture surface of NR composites filled with (a) 5 phr and (b) 30 phr rattan powder (reproduced with permission from [25]).

2.1.5. Dynamic Mechanical Properties

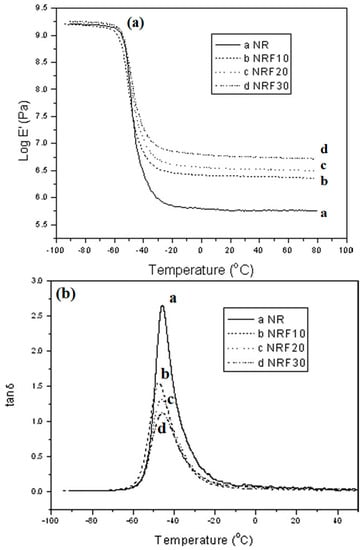

Dynamic mechanical properties are very important for rubber applications, such as tires, since they can simulate the performance of a compound under real-life conditions. Several studies have been carried out on the dynamic behavior of NF/NR composites. Most of them reported improvement in storage modulus (E’) and reduction in loss factor (tan δ = E”/E’) after adding natural fibers to NR [28,42,43,44,45,46,47,48,49,50].

Figure 3 presents typical values of E’ and tan δ as a function of temperature for NR composites filled with different contents of untreated oil palm fibers. The storage modulus curve gives useful information on stiffness, filler/matrix interfacial interaction and degree of crosslinking. In all cases, E’ decreases with increasing temperature, and a significant reduction is observed between −60 and −40 °C. In the glassy region, the composite is in a frozen state and is immobile. Therefore, the storage modulus difference between all the samples is very small. As the temperature increased, the composites became more mobile and the modulus decreased. At higher temperatures (−20 to 80 °C), E’ became a function of filler content, and the highest modulus was observed for the composite having the highest filler loading (30 phr), as natural fibers can increase the stiffness of rubber composites. This improvement in storage modulus led to a decrease of the loss factor; i.e., tan δ decreased with increasing filler content [49].

Figure 3.

(a) Storage modulus and (b) loss factor (tan δ) as a function of temperature for NR composites filled with different contents of untreated oil palm fiber. NRFx denotes oil palm/NR composites, where x is the filler content in phr (adapted with permission from [49]).

2.1.6. Natural Fiber Modification

Because of the poor compatibility between the hydrophilic NF and the hydrophobic NR, it is necessary to apply surface treatments on the natural fibers. The most common chemical modifications for NF are alkali treatment, functionalization with hydrophobic functional groups and the use of a coupling agent, as described in the following section.

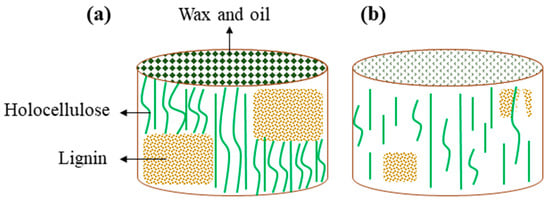

Alkali Treatment

Alkali treatment is one of the simplest treatments for NF, and Figure 4 presents the mechanism involved. In this technique, sodium hydroxide (NaOH) is used to remove waxes, natural fats and other impurities from the surface of natural fibers. Therefore, the alkali treatment increases the surface area available for bonding with the matrix, improves surface roughness and decreases the surface tension of the filler. After an alkali treatment, the fiber diameter decreases and the fiber aspect ratio increases [51,52]. Moreover, the alkali treatment partially removes the amorphous regions (hemicellulose and lignin) from the fibers, leading to higher crystallinity [53,54].

Figure 4.

Structure of natural fibers (a) before and (b) after alkaline treatment.

Although the thermal and mechanical properties of the composites are significantly improved by this treatment, excessive delignification can take place if the alkali concentration is higher than the optimum condition, leading to damaged/weaken fibers. For example, Jacob et al. [55] used different NaOH concentrations (0.5%, 1%, 2%, 4% and 10%) for the treatment of sisal/oil palm fibers for 1 h and reported that the best results were obtained when 4% NaOH was used. In another work, Ray et al. [56] treated jute fibers with 5% NaOH for 2, 4, 6 and 8 h. The results showed that the optimal time was 4 h. Other researchers studied the effect of alkali treatment on the mechanical properties of NR composites and showed that the values were all improved [14,18,22,24,39,40,55,57,58,59,60]. For example, Geethamma et al. [22] showed that the tensile strength of NR composites containing 35 phr of coir fiber was improved by 44% after treatment with 5% NaOH for 24 h. However, the tensile strength was still 64% lower than unfilled NR. So other treatments can be applied to improve all properties.

Modification with Hydrophobic Functional Groups

Natural fibers are hydrophilic and rich in hydroxyl groups. This high number of hydroxyl groups generates hydrogen bonds between natural fibers, leading to possible agglomeration in a polymer matrix. Consequently, the replacement of hydroxyl groups by hydrophobic functional groups can prevent agglomeration and improve compatibility with NR. Moreover, this treatment is known to decrease the water absorption of natural fibers [12,61]. Typical treatments are acetylation, benzoylation, peroxide, potassium permanganate and acrylic acid treatment.

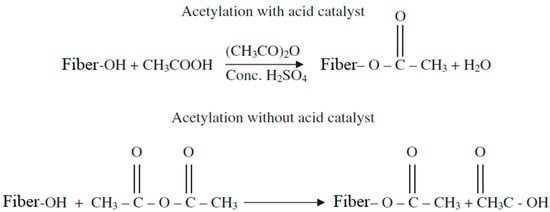

In the acetylation treatment, the hydroxyl groups (OH) are replaced by acetyl groups (CH3CO) using acetic anhydride reactions. To accelerate this reaction, an acid catalyst can be used to graft acetyl groups onto the cellulose structure, as shown in Scheme 1. Acetylation decreases the fibers hydrophilicity and improves the mechanical properties of NR composites due to better compatibility [62,63,64,65,66,67,68]. Varghese et al. [68] reported that the tensile strength of NR composite containing 40 phr of sisal fibers increased by 65% after acetylation, but still was 22% lower than that of unfilled NR. Mathew et al. [67] compared both alkali treatment and acetylation for isora fibers. Their results showed that acetylation was more effective in improving the mechanical properties of NR.

Scheme 1.

Reaction mechanism of fiber acetylation with and without acid catalyst (reproduced with permission from [69]).

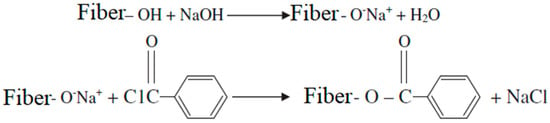

Benzoylation uses benzoyl chloride to decrease the hydrophilic nature of fibers and increase interfacial adhesion, thereby improving the mechanical properties of NR composites. This treatment is generally performed after an alkali pre-treatment by replacing hydroxyl groups with benzoyl groups (C6H5CO-), as shown in Scheme 2 [61]. Lopattananon et al. [39] used a benzoyl peroxide treatment and reported that the tensile strength of NR composite with 20 phr of pineapple leaf fiber was improved by 57%. They also reported that benzoyl peroxide treatment gave better results than alkali treatment.

Scheme 2.

Reaction mechanism of fiber benzoylation [69].

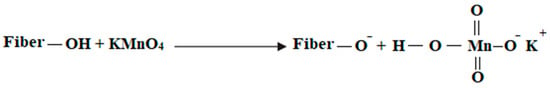

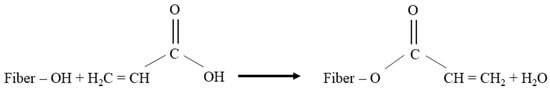

Potassium permanganate (Scheme 3) and acrylic acid (Scheme 4) are two other treatments for natural fibers. Dhanalakshmi et al. [70] compared the effect of untreated, alkali-treated, potassium permanganate–treated, benzoyl chloride–treated and acrylic acid–treated areca fibers on the mechanical properties of NR composites. The results showed that the highest value was obtained when 60% of acrylic acid–treated fibers was used.

Scheme 3.

Reaction mechanism of potassium permanganate fiber treatment [71].

Scheme 4.

Reaction mechanism of acrylic acid fiber treatment [70].

Silane Coupling Agents

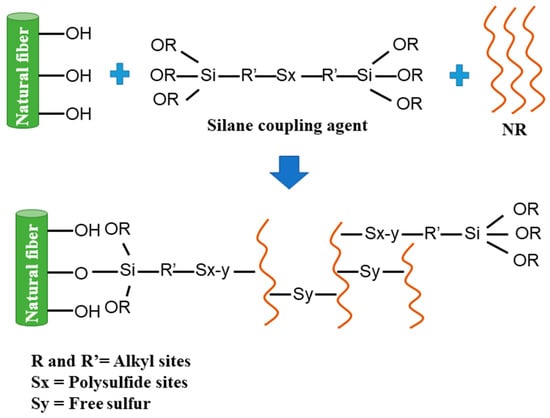

Silane coupling agents are widely used for silica-filled NR composites, as they chemically react with both the filler and the matrix and thus significantly improve the fiber-matrix interfacial adhesion (Figure 5). Bis(3-(triethoxysilyl) propyl) tetrasulfide (TESPT) is the most common silane coupling agent for NR composites [72].

Figure 5.

The mechanism of silane coupling agent treatment in rattan/NR composites.

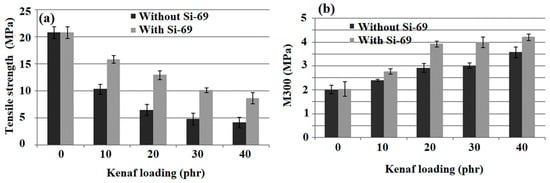

Some publications reported on the mechanical property improvements for NR composites filled with NF after silanization [25,31,60,67,73,74,75,76,77,78,79,80]. All the treatments presented in above were used to improve the filler–matrix physical interactions. However, silane coupling agents can form a covalent bond between NF and NR, producing stronger adhesion. Mathew et al. [67] reported that isora fibers treated with a silane coupling agent showed better results than alkali, acetylation and benzoylation treatment to reinforce NR composites. The mechanical properties of kenaf fiber/NR composites before and after treatment with TESPT as a coupling agent are presented in Figure 6 [75]. The results show a significant improvement (up to 105% increase in tensile strength for 40 phr filler content) compared to untreated fibers, but this treatment is still not sufficient to reinforce NR composites. Moreover, silane coupling agents have several disadvantages, such as alcoholic by-products, challenging processing and high costs [4].

Figure 6.

(a) Tensile strength and (b) modulus at 300% strain of kenaf fiber/NR composites before and after treatment with TESPT as a coupling agent (adapted with permission from [75]).

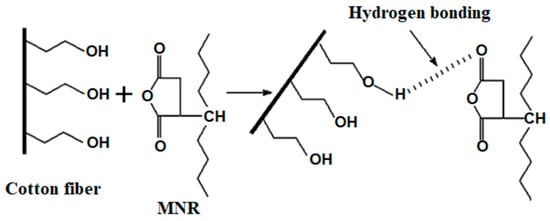

2.1.7. Natural Rubber Modification

Maleated natural rubber (MNR) is obtained via NR chemical modification by blending maleic anhydride with NR. As shown in Figure 7, MNR can form a hydrogen bond with the hydroxyl groups of cellulose, thus improving interfacial adhesion and composite mechanical properties. Some work used MNR as a compatibilizer for NF/NR composites and reported mechanical property improvements using this compatibilizing strategy [30,81,82,83,84]. Zeng et al. [27] observed that the tensile strength of NR composite with 10 phr MNR at 10 phr cotton fiber was 11% higher than that without MNR.

Figure 7.

Schematic representation of the interaction between cotton fiber and MNR through hydrogen bonding (reproduced with permission from [27]).

Epoxidized natural rubber (ENR) is an NR modification prepared with acetic or formic acid and hydrogen peroxide. ENR has better resistance to heat/oxidation degradation and hydrophobic solvents (like oil) than NR because of the oxirane ring. ENR has polar epoxy groups and is hydrophilic; hence, better compatibility with lignocellulosic fillers is created. Wongsorat et al. [30] compared both MNR and ENR as a compatibilizer in sisal fiber/NR composites. It was observed that MNR was more effective than ENR to improve the mechanical properties of NR composites. At 10 phr sisal fiber content, the MNR compatibilized composite showed 43%, 13%, 44% and 53% higher tensile strength, hardness, modulus at 100% strain and modulus at 300% strain compared to the uncompatibilized NR composite, respectively.

2.1.8. NF/NR Composites Reinforced with Hybrid Fillers

CB and silica are the most common reinforcing fillers for NR composites. Although lignocellulosic fillers have a high potential for NR compounds, they cannot be used to fully replace conventional fillers. Although NF addition to NR decreases the tensile strength and elongation at break, it can improve other properties such as hardness, tensile modulus and storage modulus, while decreasing density and costs. Therefore, to obtain the advantages of natural fibers without their drawbacks, the idea was to combine them with more standard fillers (silica and CB) to produce hybrid systems. Hybrid fillers can result in an optimal balance between different properties of NR composites [34,60,85,86,87,88].

Tzounis et al. [89] studied short jute fibers/multiwall carbon nanotube (MWCNT) hybrid fillers to improve the interaction between the hydrophilic fibers and the NR matrix. Firstly, to increase water dispersion and interactions with jute fibers, MWCNT was functionalized under mild acidic conditions (HNO3) to generate carboxylic acid moieties. As a result, hydrogen bonds were formed between the hydroxyl groups of jute fibers and the carboxyl groups of treated MWCNT. The hybrid fillers showed higher hydrophobicity than the jute fibers alone, resulting in better compatibility with NR. The tensile strength of NR composite with 10 phr hybrid fillers was 25% and 76% higher than that with 10 phr jute fiber alone and neat NR, respectively.

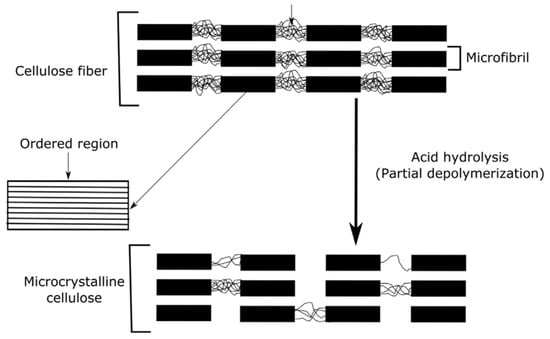

2.2. Microcrystalline Cellulose (MCC)/NR Composite

The main components of NF fibers are cellulose, hemicellulose and lignin (Table 1). Cellulose has a crystalline structure, the highest content of hydroxyl groups (18.5 mmol/g) and is stronger than the other components [90]. Different techniques were proposed for extracting cellulose from natural fibers. Alkali treatment followed by acid hydrolysis is a simple method to produce microcrystalline cellulose (MCC). The alkali solution removes impurities from the natural fibers and facilitates the hydrolysis process, while an acid hydrolysis removes the amorphous phases (lignin and hemicellulose) to obtain the cellulose fibers (Figure 8). MCC has a higher specific surface area (smaller diameter) than natural fibers and therefore has more interaction and bonding possibilities with the polymer matrix [91]. In addition to MCC, some studies also used regenerated cellulose as fillers for rubber matrices [92,93,94,95,96].

Figure 8.

Schematic illustration of the microcrystalline cellulose separation during acid hydrolysis (reproduced with permission from [91]).

Roy et al. [82,97] showed that adding 5 phr of MCC to NR improved the tensile strength by 13–16%. However, other studies showed that the tensile strength decreased when more than 10 phr of MCC was used in NR composites due to poor filler dispersion and poor filler–matrix compatibility [33,98,99]. For example, Chuayjuljit et al. [33] reported that the tensile strength decreased by about 50% when the MCC content increased from 0 to 30 phr. However, cellulose modifications can improve the mechanical properties of NR composites. Deng et al. [100,101] reported that the tensile strength of NR composite containing 5 phr MCC was 9% higher than that of unfilled rubber, which can be increased up to 32% after grafting MCC with ethyl acrylate, butyl acrylate or methyl methacrylate monomers.

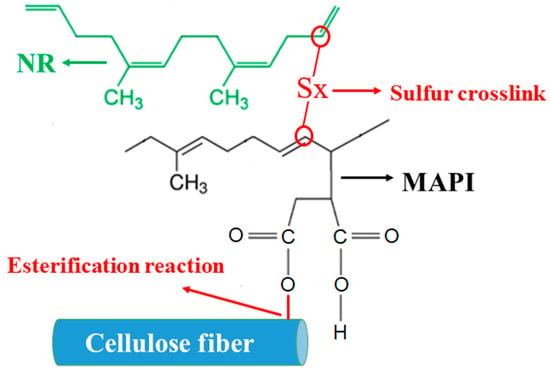

In another study [102], the effect of CB replacement with MCC as well as the effect of cellulose surface treatment via maleic anhydride grafted to polyisoprene (MAPI) in NR composite were investigated. The results showed that replacing CB with cellulose decreased density while increasing curing time due to accelerator absorption by the cellulose hydroxyl groups. In addition, the tensile modulus and dynamic mechanical properties were improved after cellulose addition. However, the tensile strength dropped rapidly with increasing concentration above 10 phr of neat cellulose. On the other hand, 50% replacement of CB with modified cellulose produced even better results than the composite filled with CB alone. The tensile strength was only 7% lower, but the tensile modulus at 100%, elongation at break and storage modulus at 25 °C were respectively 24%, 35% and 22% higher. This was associated with a crosslinking reaction between the modified cellulose and NR chains, as shown in Figure 9.

Figure 9.

Mechanism of possible crosslinking reaction between cellulose modified with maleic anhydride grafted to polyisoprene (MAPI) and NR chains [102].

2.3. Lignin/NR Composite

Lignin is an inexpensive material, since it is commonly available as a by-product of the pulp and paper industries and from emerging cellulosic ethanol production (biorefineries). Even today, about 98% of lignin is usually burned to generate energy or simply disposed of in landfills [7]. Lignin is more hydrophobic than the other plant cell wall components (cellulose and hemicellulose) [103,104]. Therefore, it is more compatible with NR. The amount of hydroxyl groups for lignin is 5.3 mmol/g, which is 3.5 times less than for cellulose (18.5 mmol/g) [90].

2.3.1. Curing Characteristics and Mechanical and Dynamic Mechanical Properties of Lignin/NR Composites

Adding lignin to NR significantly increases the curing time of rubber compounds. Jiang et al. [105] reported that the scorch time and optimal cure time of lignin/NR composites increased by 200% and 70%, respectively, when the lignin concentration increased from 0 to 40 phr. This was associated with a radical scavenging effect of the hindered phenol groups in lignin. However, the authors showed that lignin had less effect on the cure time when a compatibilizer was added to the rubber compounds.

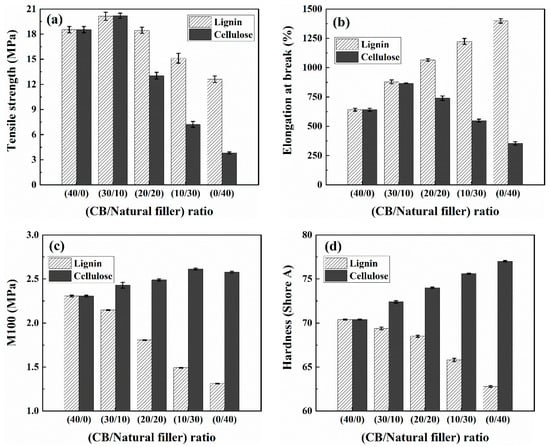

Kazemi et al. [106] compared cellulose and lignin to replace CB in NR composites. The results showed that the lignin/NR composites exhibited longer curing time than the composites filled with cellulose. They compared the mechanical properties of NR composites filled with cellulose and lignin at different concentrations, as shown in Figure 10. Higher tensile strength and elongation at break were observed for the lignin-filled NR composite, since lignin is more hydrophobic than cellulose. On the other hand, cellulose generated higher modulus and hardness in NR composites compared to lignin because cellulose is more crystalline and more rigid compared to amorphous lignin.

Figure 10.

Mechanical properties of NR composites filled with cellulose and lignin at different concentrations: (a) tensile strength, (b) elongation at break, (c) modulus at 100% elongation and (d) hardness (reproduced with permission from [106]).

Lignin-filled rubber composites can be prepared by two methods: conventional milling (dry mixing) or latex co-precipitation (suspension mixing). Dry mixing of lignin with rubber exhibits little or almost no reinforcing effect due to the high content of hydroxyl groups present on the lignin surface, resulting in agglomeration (poor dispersion). Lignin agglomeration is the origin of lower tensile strength in rubber composites compared to a reference sample [107,108,109]. For example, Datta et al. [108] reported that the tensile strength dropped by 48% after the addition of 40 phr lignin to NR. On the other hand, lignin particles were homogeneously dispersed inside the matrix in latex mixing, and a finer particle aggregate of lignin was formed [110,111]. The mechanical properties of lignin/rubber composites prepared with different methods are compared in Table 4. Similarly, the dynamic mechanical properties showed that the loss factor increased with increasing lignin content in the case of dry mixing [112]. On the other hand, latex mixing led to a lower loss factor at higher lignin concentrations [113].

Table 4.

Mechanical properties of NR nanocomposites filled with lignin.

Ikeda et al. [113] showed that adding 5 phr of lignin to NR by dry mixing did not affect the tensile modulus but decreased the tensile strength by 9%. In contrast, at the same filler content, the composite prepared by latex mixing showed 96% higher tensile strength and 157% higher modulus at 300% strain compared to the neat NR. However, significant tensile strength reduction was observed when more than 5 phr lignin was added to NR using latex mixing. For example, the tensile strength dropped by 44% when the lignin content increased from 5 phr to 20 phr. At 20 phr lignin, the compound prepared by dry mixing showed even higher tensile strength (15%) compared to latex mixing. This result confirmed that it is not possible to add high amounts of lignin to NR using latex mixing. Nevertheless, the preparation of lignin-based rubber composites via latex mixing is time consuming and requires the use of water or organic solvents, which are not suitable for industrial production [105].

2.3.2. Lignin/NR Composite Modification

Similar to other lignocellulosic fillers, the most important problem with lignin addition in rubber composites arises from its high amount of hydroxyl groups (5.3 mmol/g) and poor compatibility with the NR matrix [107,114]. Some treatments, such as acetylation [107], silanization [115] or using epoxidized natural rubber as a compatibilizer [105], were developed to improve lignin–NR interfacial adhesion. Jiang et al. [105] developed a method for modifying and mixing lignin/NR composites. First, the lignin was mixed with ENR on a two-roll mill. Then, the compound underwent high-temperature dynamic heat treatment (HTDHT), i.e., sealed in an internal mixer at 60 rpm and 180 °C for 30 min. This treatment led to a ring-opening reaction between lignin and ENR, resulting in a substantial improvement of the mechanical and dynamic mechanical properties of the rubber composites. Compared to a direct mixing of rubber compounds, the tensile strength and modulus at 300% strain of the heat-treated rubber composites filled with 40 phr of lignin were increased by 114% and 400%, respectively.

2.3.3. Lignin/NR Composites Reinforced with Hybrid Fillers

Hybrid systems containing lignin and conventional fillers are attracting considerable attention for rubber composites [106,111]. Yu et al. [111] showed that replacing silica with lignin decreased the Payne effect and improved processability, as well as increased the curing time and elongation at break. However, the tensile strength, tensile modulus and hardness decreased with increasing silica replacement. The results also showed that replacing silica with lignin led to higher loss factor and heat build-up. This indicates that lignin is not a good alternative to completely replace conventional fillers in rubber composites. Nevertheless, it can be used to partially replace them and produce more sustainable composites. In their case, 30 phr of silica and 20 phr of lignin produced the optimal overall mechanical properties.

2.4. Nanocellulose/NR Nanocomposite

Unlike macro-sized lignocellulosic fillers, which are mainly known as non-reinforcing fillers for NR, nanocellulose can be used to greatly improve all mechanical and dynamic mechanical properties of NR compounds. Jong et al. [116] showed that NF can change from non-reinforcing fillers to reinforcing fillers by decreasing the filler size from the macro level to the nano level. One of the greatest advantages of nanocellulose arises from its high dispersion in water. Since NR latex is also an aqueous suspension, a uniform filler distribution is achieved in the rubber matrix when nanocellulose is added to the NR latex. Moreover, during the casting/evaporation step, the nanocellulose particles move closer to each other due to their hydrophilic heads (OH functional groups) through hydrogen bonding attractions forming a strong continuous 3D network in the matrix. This network is the origin of NR nanocomposite reinforcement [3].

Casting/evaporation is the most common method to produce rubber nanocomposites from latex. The nanocomposite is prepared by mixing a suspension of NR latex and nanocellulose in an aqueous solution. The nanocellulose is firstly dispersed in the NR latex for 0.5–12 h. Then, the aqueous suspension is cast in a mold and left to dry. This is the best method to disperse nanoparticles with a high surface area in a rubber matrix [3]. Ismail et al. [117,118] compared mechanical mixing with solution mixing and showed that better mechanical properties were obtained with solution mixing, since better filler dispersion was achieved.

Plant-based nanocellulose can be classified into two categories, depending on the preparation method: cellulose nanocrystals (CNC) and cellulose nanofibrils (CNF). Other common names for CNC are nanocrystalline cellulose (NCC) and cellulose nanowhiskers (CNW). CNC is usually extracted from the plant cell walls by a chemical acid hydrolysis process (usually 60–65 wt.% H2SO4 aqueous solution). In this method, the amorphous materials (hemicellulose and lignin) are removed from the cell wall, and the rod-shaped crystalline cellulose fibers are isolated. On the other hand, CNF is prepared by mechanical treatment (high-pressure homogenization) with or without chemical pre-treatment or enzymatic hydrolysis [119]. Bacterial cellulose whiskers (BCW) are another type of nanocellulose produced by gram-negative non-pathogenic bacterial genera like the genus Komagataeibacter (formerly Acetobacter or commonly acetic acid bacteria) [120].

CNF are long flexible fibers with a diameter at the nanometer level. Therefore, CNF have higher aspect ratios than CNC. Another difference between CNF and CNC comes from their chemical compositions. Except for crystalline cellulose, some amorphous components, like hemicellulose and lignin, are also present in the structure of CNF. Agrebi et al. [121] compared CNW and CNF to study the filler-matrix interface using attenuated total reflectance/Fourier transform infrared spectroscopy (ATR/FTIR). The results showed that the interfacial adhesion in NR nanocomposites filled with CNF was better than for CNW because of the presence of lignin on the CNF surface acting as a compatibilizer.

Nanocelluloses can have a wide range of aspect ratios (from 10 to 100) depending on their source and preparation methods. Neto et al. [122] reported that higher aspect ratio led to a better reinforcing effect on NR nanocomposites by comparing their storage modulus with data taken from the literature. The authors reported that a higher aspect ratio provided a higher surface area, leading to improved interfacial contact surface between the filler and matrix. Similarly, Kumagai et al. [123] showed that decreasing the cellulose nanoparticle diameters resulted in better filler dispersion and better mechanical properties of NR nanocomposites.

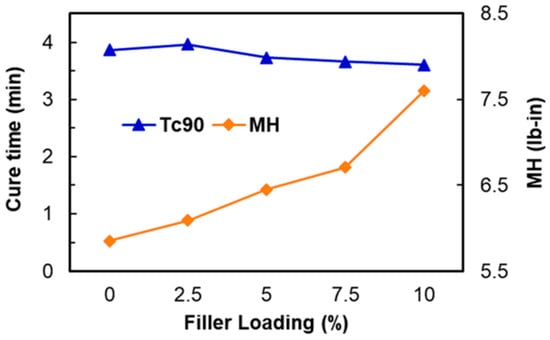

2.4.1. Curing Characteristics

The addition of nanocellulose to NR increases the viscosity of rubber compounds. This is because of the high rigidity of CNC, as well as the filler network formation in the rubber matrix leading to higher torque imposed on the rubber compounds. However, the curing time did not vary after CNC addition to NR. This is due to the CNC concentration in the rubber compound being too low (0–10 wt.%) to affect the curing behavior [124,125]. The curing characteristics of NR nanocomposites reinforced with different CNC concentration are reported in Figure 11.

Figure 11.

Curing characteristics of NR nanocomposites reinforced with CNC at different concentrations (reproduced with permission from [124]).

2.4.2. Mechanical Properties

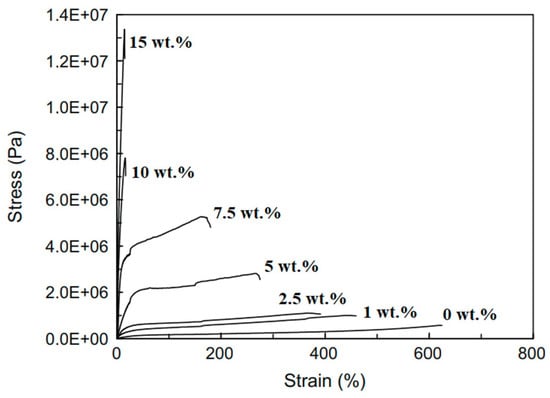

Typical stress-strain curves of nanocellulose/NR nanocomposites are presented in Figure 12. Neat NR exhibits a typical nonlinear elastic behavior like all amorphous polymers. The addition of nanocellulose to NR significantly increased the tensile strength and tensile modulus but decreased the elongation at break. For NR nanocomposites up to 5 wt.%, the mechanical behavior is similar to the neat NR. However, a further increase in nanocellulose concentration (above the percolation threshold) completely changed the mechanical behavior, as the nanocomposites became stiffer and more brittle. This is due to the formation of the filler network after the addition of a high concentration (5–10 wt.%) of nanocellulose to NR [125,126,127,128,129,130,131]. The mechanical properties of nanocellulose/NR nanocomposites are compared in Table 5.

Figure 12.

Typical stress–strain curves of cellulose nanowhiskers/NR nanocomposites at different filler concentrations (adapted with permission from [131]).

Table 5.

Mechanical properties of NR nanocomposites filled with nanocellulose.

Abraham et al. [130,132,133] assumed that the elasticity of nanocellulose/NR nanocomposites is related to the double network (Zn–cellulose complex) formation and the presence of a high number of entanglements. They reported that cellulose can form complexes with zinc (II) to produce a 3D network (cellulose/cellulose network and Zn/cellulose network) in the NR matrix, which was the origin of significant improvements in mechanical properties. However, other studies showed that the tensile strength decreased when more than 10 wt.% of nanocellulose was added [116,134,135]. This was associated with the presence of a high number of hydroxyl groups in the nanocellulose, causing agglomerations in the rubber matrix.

Although most publications reported an inverse relationship between filler concentration and elongation at break for nanocellulose/NR nanocomposites, some studies observed higher elongation at break when the nanocellulose content increased from 5 to 10 wt.%. The authors explained that higher viscosity of the nanocellulose/latex suspension prevented the sedimentation of nanoparticles during casting/evaporation (better stability). As a result, better filler dispersion was achieved, leading to higher stiffness and ductility due to a more homogeneous structure [3].

2.4.3. Dynamic Mechanical Properties

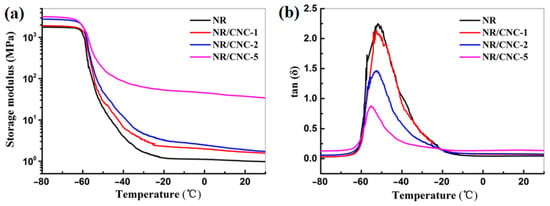

The addition of nanocellulose to NR can substantially increase the storage modulus of nanocomposites (Table 6). As previously discussed, this reinforcing effect is related to the formation of a stiff continuous filler network. In contrast, adding a small amount (less than 10 phr) of cellulose nanoparticles to NR only slightly increases the loss modulus. As a result, nanocellulose addition decreases the loss factor and heat buildup of the NR nanocomposite [122,126,127,128,130,131,136,137,138,139]. Interestingly, some studies showed that increasing the nanocellulose content from 5 to 10 wt.% significantly increased the storage modulus, but a further increase in nanocellulose concentration was less effective. For example, Bendahou et al. [126] showed that increasing the nanocellulose concentration from 5 to 10 wt.% improved the storage modulus by 1556%, while only a 92% improvement was reported when the nanocellulose content increased from 10 to 15 wt.%. This indicates that the percolation threshold for nanocellulose/NR systems is in the range of 5–10 wt.% for the filler network to be formed. Figure 13 presents the dynamic mechanical properties of NR nanocomposites reinforced with different CNC contents. On the other hand, Kulshrestha et al. [140] studied the dynamic mechanical properties as a function of temperature and reported that 2.0 phr CNF produced a good balance between properties such as rolling resistance, traction and heat build-up. In another study [141], additional rheological analyses were performed, such as stress decomposition via Chebyshev harmonics. The results showed that the relative contribution of the viscous nonlinearity gradually decreases with increasing CNC content, while the elastic nonlinearity contribution becomes more important with CNC addition.

Table 6.

Storage modulus (E’) at 25 °C of NR nanocomposites with different nanocellulose contents.

Figure 13.

Effect of nanocellulose content on (a) storage modulus and (b) tan δ as a function of temperature (tests performed at 1 Hz) (reproduced with permission from [138]).

2.4.4. Nanocellulose/NR Nanocomposite Modifications

Even though nanocellulose is known as a reinforcing filler for NR, it is a hydrophilic material and has poor compatibility with the rubber matrix. Therefore, some studies attempted to develop new modifications to improve nanocellulose/NR interactions. Kato et al. [142] modified CNF with unsaturated fatty acids (long hydrophobic molecules) to improve its compatibility with NR. They also proposed that a sulfur crosslinking reaction can be formed between the modified CNF and NR. This modification improved by 1530% the Young’s modulus of NR nanocomposites containing 5 wt.% of CNF compared to the neat NR, and by 530% compared to the nanocomposite without treatment. In another study, Thakore et al. [143] used the acetylation method to produce hydrophobic cellulose acetate nanofiller for NR nanocomposites. The authors claimed that adding this filler (up to 40 phr) to NR linearly increased the tensile strength by 300%. Yasin et al. [144] studied the effect of ionic liquid (1-ethyl-3-methylimidazolium acetate ([EMIM]OAc)) on CNC- and CNF-filled NR compounds and vulcanizates. The results showed that ionic liquid improved the dispersion of cellulosic nanofillers in NR and increased both the crosslinking density and mechanical strength of the NR vulcanizates. The authors also investigated the viscoelastic rheological behavior of nanocellulose-NR compounds compared to vulcanizates. The results showed that the amplitude of the Payne effect decreased in the compounds but increased in the vulcanizates with increasing cellulosic nanofillers and ionic liquid addition.

Some researchers attempted to create a covalent bond between nanocellulose and NR to produce stronger interfacial adhesion. Kanoth et al. [145] modified CNC by grafting thiol functional groups onto cellulose nanoparticles using an esterification reaction with 11-mercaptoundecanoic acid. They showed that in addition to increasing the hydrophobicity, the modified CNC could form crosslinks with NR after UV irradiation, which improved all the properties (tensile strength, strain to failure and toughness) of CNC/NR nanocomposites. Similarly, Li et al. [146] developed a new modification to form a covalent bond between modified CNC (treated with 3-amino-1,2,4-triazole-5-thiol (ATT)) and NR by UV irradiation. This modification was found to significantly improve the mechanical properties of NR nanocomposites. For example, the tensile strength as well as Young’s and storage moduli respectively increased by 160%, 468% and 1041% with the addition of 10 wt.% modified CNC compared to neat NR. The same reaction was used by Zhu et al. [147] to crosslink CNF with NR.

The effect of NR modification was studied by Mariano et al. [148] using KMnO4 to oxidize NR (more hydrophilic) and increase its interaction with the hydroxyl groups of CNC through hydrogen bonding. Different levels of NR oxidation (1 to 5) were used according to the molar ratio of –OH groups borne by NR to the number of CNC particles. The best results were obtained for an intermediate oxidation (level 3), where the hydroxyl molar ratio of NR to CNC was 1.5 × 102. After NR oxidation, the Young’s modulus and tensile strength of NR nanocomposite with 5 wt.% of CNC were improved by 530% and 27%, respectively. Trovatti et al. [149] used both CNC and NR modifications to prepare nanocomposites. In this study, NR was modified with furan, and the CNF was treated with maleic anhydride. The combined effect of both modifications formed a crosslink between the filler and matrix with reversible bonds, which is useful for recycling and reprocessing.

Using ENR as a matrix is also a common modification method for nanocellulose-based rubber nanocomposites. This comes from the strong interaction between the hydroxyl groups of nanocellulose and the epoxy groups of ENR (Figure 14) [150,151]. Cao et al. [150] reported that the addition of 10 wt.% of CNC into ENR improved the tensile strength and modulus at 300% strain by 57% and 683%, respectively. Further reinforcement can also be obtained with the nanocellulose modification and its addition to the ENR. Studies showed that the application of carboxyl functional groups onto the CNC surface after treating with maleic anhydride [152] or 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) [153] can generate a possible ester bond with the epoxy groups of ENR. In addition to excellent mechanical properties, nanocellulose/ENR showed good self-healing ability [154] and water-responsive sensitivity [155] for various biomedical applications.

Figure 14.

Schematic illustration of the CNC/ENR nanocomposite structure (reproduced with permission from [150]).

In other studies, the effect of bonding agents, such as TESPT [156,157], MNR [158] and resorcinol/hexamethylenetetramine [159], to improve nanocellulose/NR interactions, as well as the effect of dispersants, such as cetyltrimethyl ammonium bromide (CTMAB) [160], on the nanocellulose dispersion were also investigated. Although all these modifications generated better filler–matrix interactions, the amount of nanocellulose used in rubber compounds was still limited due to strong filler–filler interactions and the formation of agglomerations.

2.4.5. Nanocellulose/NR Composites Reinforced with Hybrid Fillers

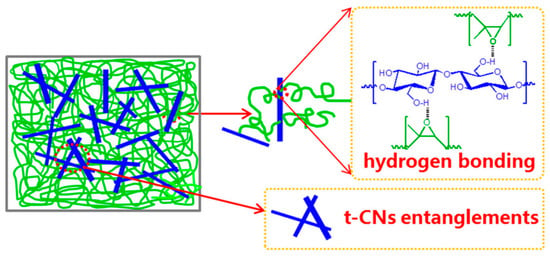

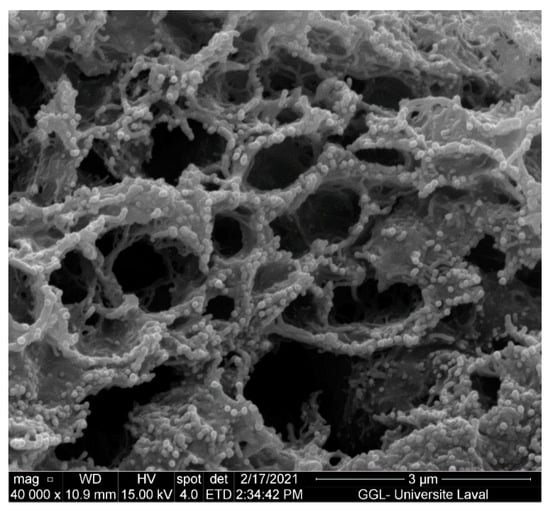

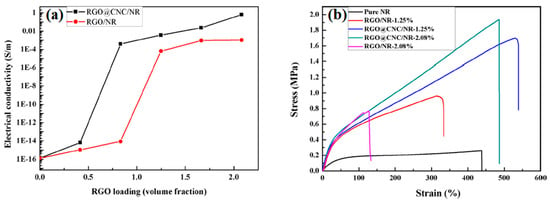

Some work investigated the effect of partial CB replacement by nanocellulose. The results showed that in addition to increased sustainability, nanocellulose/CB hybrid fillers can produce an optimal balance between different properties of NR composites and generate a better reinforcing effect than using CB alone [140,161,162,163]. Hybridization of nanocellulose with conductive fillers, such as carbon nanotube (CNT) [135,164,165], graphene [166,167] and conductive carbon black [168,169], is also interesting for some applications, such as flexible strain sensors and energy storage. These hybrid fillers can produce a 3D conductive network inside a rubber matrix (Figure 15), leading to improved conductivity (thermal and electrical) as well as mechanical and dynamic mechanical properties (Figure 16).

Figure 15.

SEM micrograph of the resulting conductive network skeleton (after toluene extraction) from NCC/CNT/NR nanocomposites (reproduced with permission from [135]).

Figure 16.

Reduced graphene oxide (RGO)/CNC/NR nanocomposite properties: (a) electrical conductivity and (b) tensile properties (reproduced with permission from [167]).

Kazemi et al. [135] showed that the NCC/CNT hybrid filler system produced superior properties (lower swelling weight ratio in toluene, higher tensile strength, higher tensile modulus, higher storage modulus and higher thermal conductivity) compared to each nanoparticle used separately. When 10 phr of hybrid filler (filler ratio of 1) was added to NR, the tensile modulus at 300% elongation, storage modulus at 10% strain, tensile strength and thermal conductivity were increased by 137%, 120%, 57% and 30%, respectively. It was also found that the NR nanocomposite properties can be controlled by tuning the NCC/CNT filler ratio. In fact, the presence of NCC increased the NCC/CNT hybrid filler dispersion by forming a 3D network, while the presence of CNT improved the filler–matrix interaction and thermal conductivity.

3. Synthetic Rubbers

Several synthetic rubbers are available, and typical examples are nitrile butadiene rubber (NBR), styrene butadiene rubber (SBR), butadiene rubber (BR), silicone rubber (SR), ethylene-propylene diene monomer rubber (EPDM) and ethylene-co-vinyl acetate rubber (EVA). Similar to NR, synthetic rubbers can undergo a crosslinking reaction and be toughened, but they also need to be reinforced with fillers. Among all the synthetic rubbers, NBR is the most interesting matrix for biocomposite applications due to the presence of polar nitrile groups (C≡N) in the polymer backbone. The NBR hydrophilicity mainly depends on the acrylonitrile content. The nitrile groups of NBR can form hydrogen bonds with the hydroxyl groups of the lignocellulosic fillers. NBR can also be used as a compatibilizer for other rubber-based biocomposites reinforced with lignocellulosic fillers. Hydrogenated acrylonitrile-butadiene rubber (HNBR) and carboxylated acrylonitrile-butadiene rubber (XNBR) are derivatives of NBR; they have better mechanical properties, better thermal resistance and better oil resistance compared to NBR [3].

SBR, along with NBR, is the most commonly used synthetic matrix for rubber biocomposite applications. SBR is mainly used in the tire industry because of its high abrasion resistance, thermal stability and resistance against crack formation. Carboxylated butadiene-styrene rubber (XSBR) is a derivative of SBR and is more compatible with lignocellulosic fillers due to the presence of hydrophilic groups in its backbone [3]. The studies performed on lignocellulosic filler addition in NBR and SBR are listed in Table 7. Additionally, some examples are described in more detail in Table 8. Other studies also used BR [170,171,172], SR [173,174,175,176,177], EPDM [178,179] and EVA [180], as well as rubber blends such as NR/SBR [181,182,183,184,185,186], NR/NBR [187], NR/SBR/BR [188,189], NR/BR [190], NR/EVA [191] and SBR/NBR [192] as a matrix for lignocellulosic-based rubber composites.

Table 7.

List of publications on NBR and SBR biocomposites reinforced with lignocellulosic fillers.

Table 8.

Examples of NBR and SBR biocomposites reinforced with lignocellulosic fillers.

4. Conclusions

In this review, lignocellulosic fillers were divided into four categories (natural fibers, microcrystalline cellulose, lignin and nanocellulose) as biobased reinforcement for vulcanized rubbers (natural or synthetic). Natural fibers are generally known as non-reinforcing fillers and are mainly used to reduce the costs in rubber applications. The addition of pristine natural fibers is not comparable with conventional fillers like CB and silica, as their addition to rubber matrices decreases the tensile strength of the composites due to poor filler–matrix interactions. Therefore, several modifications (alkali treatment, acetylation, benzoylation, silane coupling agents, maleated coupling agent, etc.) have been developed to improve their compatibility with rubbers. In some cases, MCC show better mechanical properties than natural fibers, but they can also decrease the tensile strength above an optimal concentration (around 10 phr) in the rubber matrix. On the other hand, lignin is more compatible with rubbers than natural fibers and MCC. Therefore, adding lignin to rubbers has a less negative effect on the tensile properties, but it cannot improve the tensile modulus and hardness compared to natural fibers and cellulose. However, lignin can effectively reinforce rubber composites when mixed into the rubber matrix by the latex co-precipitation method.

Nanocellulose is another derivative of lignocellulosic fillers. Unlike macro-fillers (natural fiber, MCC and lignin), nanocellulose is known as a reinforcing filler for rubber composites that can improve all the mechanical and dynamic mechanical properties. In recent years, most studies focused on nanocellulose as a bio-reinforcement for rubber applications. Although nanocellulose itself is a reinforcing filler, some modifications (hydrophobic molecule treatment, grafting with thiol functional groups, coupling agent addition, etc.) were also developed to improve its interaction with the rubber matrix. However, the amount of nanocellulose used in rubber compounds is limited due to strong filler–filler interactions and the formation of agglomerations. Therefore, rubber composites reinforced with low concentrations of nanocellulose are not suitable for industrial applications.

Based on the results available, it is recommended to further develop hybrid filler systems, especially using multi-scale particles such as macro-sized lignocellulosic fillers (as a non-reinforcing filler to reduce the costs) and nanocellulose (as a reinforcing filler) for rubber biocomposites. Due to its availability and different compositions, further studies should be conducted on lignin as a potential reinforcing filler for rubber biocomposites. Increasing the dispersion of lignin in the rubber matrix, as well as developing new treatments to create a stronger interaction between lignin and the matrix, can be useful to develop biobased composites. According to the literature, some lignocellulosic-based rubber biocomposites can not only increase the sustainability but also provide standard requirements for various general rubber applications, such as tires, hoses, belts, gloves, footwear, gaskets, etc. Rubber biocomposites can also be used for some specific biomedical applications. However, since lignocellulosic fillers are generally known as non-conductive materials, some modifications are required to improve their conductivity (thermal and electrical) for high-tech applications, such as sensors, electrical devices and energy storage.

Author Contributions

First draft, H.K.; revision, D.R. and F.M. All authors have read and agreed to the published version of the manuscript.

Funding

Funding was received from the Natural Sciences and Engineering Research Council of Canada (RGPIN-2016-05958).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge CAMSO-BR (Canada) and the Natural Sciences and Engineering Research Council of Canada (NSERC) for their financial support, as well as the Research Center on Advanced Materials (CERMA) for technical support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sisanth, K.S.; Thomas, M.G.; Abraham, J.; Thomas, S. General Introduction to Rubber Compounding. In Progress in Rubber Nanocomposites; Thomas, S., Maria, H.J., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 1–39. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (Gtr)/rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Kazemi, H.; Mighri, F.; Rodrigue, D. Application of Nanocelluloses in Rubbers. In Cellulose Nanoparticles: Synthesis and Manufacturing; Thakur, V.K., Frollini, E., Scott, J., Eds.; Royal Society of Chemistry: London, UK, 2021; pp. 38–65. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A Critical Review on the Utilization of Various Reinforcement Modifiers in Filled Rubber Composites. J. Elastomers Plast. 2020, 52, 167–193. [Google Scholar] [CrossRef]

- Peterson, S.C. Silica-Milled Paulownia Biochar as Partial Replacement of Carbon Black Filler in Natural Rubber. J. Compos. Sci. 2019, 3, 107. [Google Scholar] [CrossRef] [Green Version]

- Peterson, S.C. Coppiced Biochars as Partial Replacement of Carbon Black Filler in Polybutadiene/natural Rubber Composites. J. Compos. Sci. 2020, 4, 147. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Lignin as Alternative Reinforcing Filler in the Rubber Industry: A Review. Front. Mater. 2020, 6, 329. [Google Scholar] [CrossRef] [Green Version]

- Chikri, Y.A.; Wetzels, W. Decarbonisation Options for the Dutch Carbon Black Industry; PBL Netherlands Environmental Assessment Agency: Dutch, The Netherlands, 2020. [Google Scholar]

- Barrera, C.S.; Cornish, K. Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications. J. Compos. Sci. 2019, 3, 102. [Google Scholar] [CrossRef] [Green Version]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Recent Advances of Natural Fibers Based Green Rubber Composites: Properties, Current Status, and Future Perspectives. J. Appl. Polym. Sci. 2021, 138, 50866. [Google Scholar] [CrossRef]

- Natural Resources Canada; Forest Products Association of Canada. Estimated Production, Consumption and Surplus Mill Wood Residues in Canada—2004; Natural Resources Canada: Ottawa, ON, Canada, 2005.

- John, M.J.; Anandjiwala, R.D. Recent Developments in Chemical Modification and Characterization of Natural Fiber-Reinforced Composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Ngo, T.-D. Natural Fibers for Sustainable Bio-Composites. In Natural and Artificial Fiber-Reinforced Composites as Renewable Sources; Günay, E., Ed.; IntechOpen: London, UK, 2018; pp. 107–126. [Google Scholar] [CrossRef] [Green Version]

- Sareena, C.; Ramesan, M.T.M.; Purushothaman, E. Utilization of Coconut Shell Powder as a Novel Filler in Natural Rubber. J. Reinf. Plast. Compos. 2012, 31, 533–547. [Google Scholar] [CrossRef]

- Ismail, H.; Jaffei, R.M.; Jaffri, R.M. Curing Characteristics and Mechanical Properties of Oil Palm Wood Flour Reinforced Epoxidized Natural Rubber Composites. Int. J. Polym. Mater. Polym. Biomater. 1997, 36, 241–254. [Google Scholar] [CrossRef]

- Ismail, H.; Rozman, H.D.; Jaffri, R.M.; Mohd Ishak, Z.A. Oil Palm Wood Flour Reinforced Epoxidized Natural Rubber Composites: The Effect of Filler Content and Size. Eur. Polym. J. 1997, 33, 1627–1632. [Google Scholar] [CrossRef]

- Fan, M.; Fu, F. Advanced High Strength Natural Fibre Composites in Construction; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar] [CrossRef]

- Joseph, S.; Joseph, K.; Thomas, S. Green Composites from Natural Rubber and Oil Palm Fiber: Physical and Mechanical Properties. Int. J. Polym. Mater. Polym. Biomater. 2006, 55, 925–945. [Google Scholar] [CrossRef]

- Abdel-Hakim, A.; El-Wakil, A.E.A.A.; El-Mogy, S.; Halim, S. Effect of Fiber Coating on the Mechanical Performance, Water Absorption and Biodegradability of Sisal Fiber/natural Rubber Composite. Polym. Int. 2021, 70, 1356–1366. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Biodegradability and Aging Studies of Hybrid Biofiber Reinforced Natural Rubber Biocomposites. J. Biobased Mater. Bioenergy 2008, 1, 118–126. [Google Scholar] [CrossRef]

- Kanking, S.; Niltui, P.; Wimolmala, E.; Sombatsompop, N. Use of Bagasse Fiber Ash as Secondary Filler in Silica or Carbon Black Filled Natural Rubber Compound. Mater. Des. 2012, 41, 74–82. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Joseph, R.; Thomas, S. Short Coir Fiber-reinforced Natural Rubber Composites: Effects of Fiber Length, Orientation, and Alkali Treatment. J. Appl. Polym. Sci. 1995, 55, 583–594. [Google Scholar] [CrossRef]

- Ismail, H.; Jaffri, R.M.; Rozman, H.D. The Effects of Filler Loading and Vulcanisation System on Properties of Oil Palm Wood Flour-Natural Rubber Composites. J. Elastomers Plast. 2003, 35, 181–192. [Google Scholar] [CrossRef]

- Sareena, C.; Ramesan, M.T.; Purushothaman, E. Utilization of Peanut Shell Powder as a Novel Filler in Natural Rubber. J. Appl. Polym. Sci. 2012, 125, 2322–2334. [Google Scholar] [CrossRef]

- Ismail, H.; Othman, N.; Komethi, M. Curing Characteristics and Mechanical Properties of Rattan-Powder-Filled Natural Rubber Composites as a Function of Filler Loading and Silane Coupling Agent. J. Appl. Polym. Sci. 2012, 123, 2805–2811. [Google Scholar] [CrossRef]

- Ismail, H.; Edyham, M.R.; Wirjosentono, B. Bamboo Fibre Filled Natural Rubber Composites: The Effects of Filler Loading and Bonding Agent. Polym. Test. 2002, 21, 139–144. [Google Scholar] [CrossRef]

- Zeng, Z.; Ren, W.; Xu, C.; Lu, W.; Zhang, Y.; Zhang, Y. Maleated Natural Rubber Prepared through Mechanochemistry and Its Coupling Effects on Natural Rubber/cotton Fiber Composites. J. Polym. Res. 2010, 17, 213–219. [Google Scholar] [CrossRef]

- Datta, J.; Włoch, M. Preparation, Morphology and Properties of Natural Rubber Composites Filled with Untreated Short Jute Fibres. Polym. Bull. 2017, 74, 763–782. [Google Scholar] [CrossRef]

- Hong, H.; He, H.; Jia, D.; Zhang, H. Effect of Wood Flour on the Curing Behavior, Mechanical Properties, and Water Absorption of Natural Rubber/wood Flour Composites. J. Macromol. Sci. Part B Phys. 2011, 50, 1625–1636. [Google Scholar] [CrossRef]

- Wongsorat, W.; Suppakarn, N.; Jarukumjorn, K. Effects of Compatibilizer Type and Fiber Loading on Mechanical Properties and Cure Characteristics of Sisal Fiber/natural Rubber Composites. J. Compos. Mater. 2014, 48, 2401–2411. [Google Scholar] [CrossRef]

- De, D.; De, D.; Adhikari, B. The Effect of Grass Fiber Filler on Curing Characteristics and Mechanical Properties of Natural Rubber. Polym. Adv. Technol. 2004, 15, 708–715. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Piszczyk, Ł.; Saeb, M.R.; Colom, X. Processing and Structure–property Relationships of Natural Rubber/wheat Bran Biocomposites. Cellulose 2016, 23, 3157–3175. [Google Scholar] [CrossRef]

- Chuayjuljit, S.; Su-Uthai, S.; Tunwattanaseree, C.; Charuchinda, S. Preparation of Microcrystalline Cellulose from Waste-Cotton Fabric for Biodegradability Enhancement of Natural Rubber Sheets. J. Reinf. Plast. Compos. 2009, 28, 1245–1254. [Google Scholar] [CrossRef]

- Kazemi, H.; Mighri, F.; Park, K.; Shahamati Fard, F.; Rodrigue, D. Vulcanization Kinetics and Properties of Natural Rubber Hybrid Composites Based on Maple/silica/carbon Black. Elastomery 2019, 23, 227–240. [Google Scholar]

- Stelescu, M.-D.D.; Manaila, E.; Craciun, G.; Chirila, C. Development and Characterization of Polymer Eco-Composites Based on Natural Rubber Reinforced with Natural Fibers. Materials 2017, 10, 787. [Google Scholar] [CrossRef]

- Osabohien, E.; Egboh, S.H.O. Utilization of Bowstring Hemp Fiber as a Filler in Natural Rubber Compounds. J. Appl. Polym. Sci. 2008, 107, 210–214. [Google Scholar] [CrossRef]

- Ismail, H.; Haw, F.S. Curing Characteristics and Mechanical Properties of Hybrid Palm Ash/silica/natural Rubber Composites. J. Reinf. Plast. Compos. 2010, 29, 105–111. [Google Scholar] [CrossRef]

- Rybiński, P.; Syrek, B.; Masłowski, M.; Miedzianowska, J.; Strzelec, K.; Żukowski, W.; Bradło, D. Influence of Lignocellulose Fillers on Properties Natural Rubber Composites. J. Polym. Environ. 2018, 26, 2489–2501. [Google Scholar] [CrossRef] [Green Version]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of Pineapple Leaf Fiber-Natural Rubber Composites: The Effect of Fiber Surface Treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, R. Mechanical Properties of Short-Isora-Fiber-Reinforced Natural Rubber Composites: Effects of Fiber Length, Orientation, and Loading; Alkali Treatment; and Bonding Agent. J. Appl. Polym. Sci. 2007, 103, 1640–1650. [Google Scholar] [CrossRef]

- Setua, D.K.; De, S.K. Short Silk Fiber Reinforced Natural Rubber Composites. Rubber Chem. Technol. 1983, 56, 808–826. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic Mechanical Behavior of Short Coir Fiber Reinforced Natural Rubber Composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Roy, K.; Chandra Debnath, S.; Das, A.; Heinrich, G.; Potiyaraj, P. Exploring the Synergistic Effect of Short Jute Fiber and Nanoclay on the Mechanical, Dynamic Mechanical and Thermal Properties of Natural Rubber Composites. Polym. Test. 2018, 67, 487–493. [Google Scholar] [CrossRef]

- Surajarusarn, B.; Hajjar-Garreau, S.; Schrodj, G.; Mougin, K.; Amornsakchai, T. Comparative Study of Pineapple Leaf Microfiber and Aramid Fiber Reinforced Natural Rubbers Using Dynamic Mechanical Analysis. Polym. Test. 2020, 82, 106289. [Google Scholar] [CrossRef]

- Correia, C.A.; De Oliveira, L.M.; Valera, T.S. The Influence of Bleached Jute Fiber Filler on the Properties of Vulcanized Natural Rubber. Mater. Res. 2017, 20, 472–478. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural Rubber Composites Filled with Cereals Straw Modified with Acetic and Maleic Anhydride: Preparation and Properties. J. Polym. Environ. 2018, 26, 4141–4157. [Google Scholar] [CrossRef] [Green Version]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Influence of Peroxide Modifications on the Properties of Cereal Straw and Natural Rubber Composites. Cellulose 2018, 25, 4711–4728. [Google Scholar] [CrossRef] [Green Version]

- Jacob, M.; Francis, B.; Thomas, S.; Varughese, K.T. Dynamical Mechanical Analysis of Sisal/oil Palm Hybrid Fiber-Reinforced Natural Rubber Composites. Polym. Compos. 2006, 27, 671–680. [Google Scholar] [CrossRef]

- Joseph, S.; Appukuttan, S.P.; Kenny, J.M.; Puglia, D.; Thomas, S.; Joseph, K. Dynamic Mechanical Properties of Oil Palm Microfibril-Reinforced Natural Rubber Composites. J. Appl. Polym. Sci. 2010, 117, 1298–1308. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of Surface Treatments and Filler Loading on the Properties of Hemp Fiber/natural Rubber Composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Khan, M.A.; Hinrichsen, G. Surface Modification of Jute and Its Influence on Performance of Biodegradable Jute-fabric/Biopol Composites. Compos. Sci. Technol. 2000, 60, 1115–1124. [Google Scholar] [CrossRef]

- Ahmed, K.; Nizami, S.S.; Riza, N.Z. Reinforcement of Natural Rubber Hybrid Composites Based on Marble sludge/Silica and Marble Sludge/rice Husk Derived Silica. J. Adv. Res. 2014, 5, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Wong, S.; Shanks, R. Biocomposites of Natural Fibers and Poly(3-Hydroxybutyrate) and Copolymers: Improved Mechanical Properties through Compatibilization at the Interface. In Biodegradable Polymer Blends and Composites from Renewable Resources; Yu, L., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 303–347. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. The Effect of Chemical Treatment on the Properties of Hemp, Sisal, Jute and Kapok for Composite Reinforcement. Angew. Makromol. Chem. 1999, 272, 108–116. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical Properties of Sisal/oil Palm Hybrid Fiber Reinforced Natural Rubber Composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. Effect of Alkali Treated Jute Fibres on Composite Properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef]

- Xu, Z.H.; Kong, Z.N. Mechanical and Thermal Properties of Short-Coirfiber-Reinforced Natural Rubber/polyethylene Composites. Mech. Compos. Mater. 2014, 50, 353–358. [Google Scholar] [CrossRef]

- Joseph, S.; Thomas, S.; Joseph, K.; Cvelbar, U.; Panja, P.; Ceh, M. Molecular Transport of Aromatic Solvents through Oil Palm Micro Fiber Filled Natural Rubber Composites: Role of Fiber Content and Interface Adhesion on Transport. J. Adhes. Sci. Technol. 2012, 26, 271–288. [Google Scholar] [CrossRef]

- Jain, M.; Pradhan, M.K. Morphology and Mechanical Properties of Sisal Fiber and Nano Cellulose Green Rubber Composite: A Comparative Study. Int. J. Plast. Technol. 2016, 20, 378–400. [Google Scholar] [CrossRef]

- Nwabanne, J.T.; Igbokwe, P.K.; Ezeonyebuchi, E.J.A. Effect of Palmyra Palm Fiber Filler on Properties of Natural Rubber Vulcanizate. World J. Eng. 2014, 11, 565–574. [Google Scholar] [CrossRef]

- Mohit, H.; Arul Mozhi Selvan, V. A Comprehensive Review on Surface Modification, Structure Interface and Bonding Mechanism of Plant Cellulose Fiber Reinforced Polymer Based Composites. Compos. Interfaces 2018, 25, 629–667. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S.; Joseph, K. Effect of Adhesion on the Equilibrium Swelling of Short Sisal Fiber Reinforced Natural Rubber Composites. Rubber Chem. Technol. 1995, 68, 37–49. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Thomas, S. Diffusion of Water and Artificial Seawater through Coir Fiber Reinforced Natural Rubber Composites. Polym. Compos. 2005, 26, 136–143. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, X.; Liang, M.; Lu, C. Mechanochemical Preparation of Surface-Acetylated Cellulose Powder to Enhance Mechanical Properties of Cellulose-Filler-Reinforced NR Vulcanizates. Compos. Sci. Technol. 2008, 68, 2479–2484. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S. Short Sisal Fibre Reinforced Natural Rubber Composites: High-Energy Radiation, Thermal and Ozone Degradation. Polym. Degrad. Stab. 1994, 44, 55–61. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S. Stress Relaxation in Short Sisal-fiber-reinforced Natural Rubber Composites. J. Appl. Polym. Sci. 1994, 53, 1051–1060. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Isora Fibres and Their Composites with Natural Rubber. Prog. Rubber Plast. Recycl. Technol. 2004, 20, 337–349. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S.; Koshy, A.T. Mechanical and Viscoelastic Properties of Short Fiber Reinforced Natural Rubber Composites: Effects of Interfacial Adhesion, Fiber Loading, and Orientation. J. Adhes. Sci. Technol. 1994, 8, 235–248. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Dhanalakshmi, S.; Ramadevi, P.; Basavaraju, B. Effect of Chemical Treatments on Tensile Strength of Areca Fiber Reinforced Natural Rubber Composites. IOSR J. Appl. Chem. Ver. II 2015, 8, 43–52. [Google Scholar] [CrossRef]

- Rajesh, M.; Pitchaimani, J. Mechanical Characterization of Natural Fiber Intra-Ply Fabric Polymer Composites: Influence of Chemical Modifications. J. Reinf. Plast. Compos. 2017, 36, 1651–1664. [Google Scholar] [CrossRef]

- Kaewsakul, W.; Sahakaro, K.; Dierkes, W.K.; Noordermeer, J.W.M. Mechanistic Aspects of Silane Coupling Agents with Different Functionalities on Reinforcement of Silica-Filled Natural Rubber Compounds. Polym. Eng. Sci. 2015, 55, 836–842. [Google Scholar] [CrossRef]

- Ismail, H.; Shuhelmy, S.; Edyham, M.R. The Effects of a Silane Coupling Agent on Curing Characteristics and Mechanical Properties of Bamboo Fibre Filled Natural Rubber Composites. Eur. Polym. J. 2002, 38, 39–47. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Visconte, L.L.Y.; Nunes, R.C.R.; Furtado, C.R.G. The Effect of Coupling Agent and Chemical Treatment on Rice Husk Ash- Filled Natural Rubber Composites. J. Appl. Polym. Sci. 2000, 76, 1019–1027. [Google Scholar] [CrossRef]

- Ismail, H.; Mahir, N.A.; Ahmad, Z. The Effect of Bis-(3-Triethoxysilylpropyl) Tetrasulphide (Si-69) as a Coupling Agent on Properties of Natural Rubber/kenaf Fibre Composites. Polym.-Plast. Technol. Eng. 2011, 50, 893–897. [Google Scholar] [CrossRef]

- Lopattananon, N.; Jitkalong, D.; Seadan, M. Hybridized Reinforcement of Natural Rubber with Silane-Modified Short Cellulose Fibers and Silica. J. Appl. Polym. Sci. 2011, 120, 3242–3254. [Google Scholar] [CrossRef]

- Ismail, H. The Effects of Filler Loading and a Silane Coupling Agent on the Dynamic Properties and Swelling Behaviour of Bamboo Filled Natural Rubber Compounds. J. Elastomers Plast. 2003, 35, 149–159. [Google Scholar] [CrossRef]

- Ismail, H.; Muniandy, K.; Othman, N. Fatigue Life, Morphological Studies, and Thermal Aging of Rattan Powder-Filled Natural Rubber Composites as a Function of Filler Loading and a Silane Coupling Agent. BioResources 2012, 7, 841–858. [Google Scholar] [CrossRef]

- Muniandy, K.; Ismail, H.; Othman, N. Biodegradation, Morpholgical, and Ftir Study of Rattan Powder-Filled Natural Rubber Composites as a Function of Filler Loading and a Silane Coupling Agent. BioResources 2012, 7, 957–971. [Google Scholar] [CrossRef]

- Muniandy, K.; Ismail, H.; Othman, N. Studies on Natural Weathering of Rattan Powder-Filled Natural Rubber Composites. BioResources 2012, 7, 3999–4011. [Google Scholar] [CrossRef]

- Artchomphoo, J.; Rattanapan, S. Maleated Natural Rubber as a Coupling Agent for Sawdust Powder Filled Natural Rubber Composites. Adv. Mater. Res. 2013, 770, 181–184. [Google Scholar] [CrossRef]

- Roy, K.; Potiyaraj, P. Development of High Performance Microcrystalline Cellulose Based Natural Rubber Composites Using Maleated Natural Rubber as Compatibilizer. Cellulose 2018, 25, 1077–1087. [Google Scholar] [CrossRef]

- Ujianto, O.; Noviyanti, R.; Wijaya, R.; Ramadhoni, B. Effect of Maleated Natural Rubber on Tensile Strength and Compatibility of Natural Rubber/coconut Coir Composite. IOP Conf. Ser. Mater. Sci. Eng. 2017, 223, 12014. [Google Scholar] [CrossRef] [Green Version]

- Wongsorat, W.; Suppakarn, N.; Jarukumjorn, K. Sisal Fiber/natural Rubber Composites: Effect of Fiber Content and Interfacial Modification. Adv. Mater. Res. 2012, 410, 63–66. [Google Scholar] [CrossRef]

- Abdel Bary, E.M.; Al-Moghazy, H.; Harmal, A.N. Influence of Nanofibers Prepared from Rice Husk on the Properties of Natural Rubber. Int. J. Environ. Stud. 2019, 76, 412–427. [Google Scholar] [CrossRef]

- Pittayavinai, P.; Thanawan, S.; Amornsakchai, T. Manipulation of Mechanical Properties of Short Pineapple Leaf Fiber Reinforced Natural Rubber Composites through Variations in Cross-Link Density and Carbon Black Loading. Polym. Test. 2016, 54, 84–89. [Google Scholar] [CrossRef]

- Muniandy, K.; Ismail, H.; Othman, N. Effects of Partial Replacement of Rattan Powder by Commercial Fillers on the Properties of Natural Rubber Composites. BioResources 2012, 7, 4640–4657. [Google Scholar] [CrossRef] [Green Version]

- Ismail, H.; Abdul Khalil, H.P.S. The Effects of Partial Replacement of Oil Palm Wood Flour by Silica and Silane Coupling Agent on Properties of Natural Rubber Compounds. Polym. Test. 2000, 20, 33–41. [Google Scholar] [CrossRef]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High Performance Natural Rubber Composites with a Hierarchical Reinforcement Structure of Carbon Nanotube Modified Natural Fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Ben, H.; Chen, X.; Han, G.; Shao, Y.; Jiang, W.; Pu, Y.; Ragauskas, A.J. Characterization of Whole Biomasses in Pyridine Based Ionic Liquid at Low Temperature by 31P NMR: An Approach to Quantitatively Measure Hydroxyl Groups in Biomass as Their Original Structures. Front. Energy Res. 2018, 6, 13. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Hui Chuin, C.T.; Sabar, S.; Fazita, M.R.N.; Taiwo, O.F.A.; Hassan, T.M.; Haafiz, M.K.M. Microcrystalline Cellulose: Isolation, Characterization and Bio-Composites application—A Review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, R.M.B.; Visconte, L.L.Y.; Nunes, R.C.R. Curing Characteristics and Aging Properties of Natural Rubber/epoxidized Natural Rubber and Cellulose II. Int. J. Polym. Mater. Polym. Biomater. 2011, 60, 351–364. [Google Scholar] [CrossRef]

- Martins, A.F.; De Meneses, S.M.; Visconte, L.L.Y.; Nunes, R.C.R. Mechanical and Dynamical Mechanical Properties of Chloroprene Rubber and Cellulose II Composites. J. Appl. Polym. Sci. 2004, 92, 2425–2430. [Google Scholar] [CrossRef]

- Yu, P.; He, H.; Luo, Y.; Jia, D.; Dufresne, A. Reinforcement of Natural Rubber: The Use of in Situ Regenerated Cellulose from Alkaline-Urea-Aqueous System. Macromolecules 2017, 50, 7211–7221. [Google Scholar] [CrossRef]