Mechanical Properties of Polylactide Filled with Micronized Chalcedonite

Abstract

1. Introduction

2. Materials and Methods

2.1. Polylactide (PLA)

2.2. Micronized Chalcedonite

2.3. Research Methodology

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heimowska, A. Threat to the marine environment by drifting polymer materials. Res. Pap. Marit. Univ. Gdyn. 2019, 93, 141–145. [Google Scholar]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Useof Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Vasile, C.; Kulshereshtha, A.K.; Bumbu, G.G. Terminology. In Handbook of Polymer Blends and Composites, Tom 3A; Rapra Technology Limited: Shawbury, UK, 2003. [Google Scholar]

- Meneses, R.A.M.; Cabrera-Papamija, G.; Machuca-Martínez, F.; Rodríguez, L.A.; Diosa, J.E.; Mosquera-Vargas, E. Plastic recycling, and their use as raw material for the synthesis of carbonaceous materials. Heliyon 2022, 8, e09028. [Google Scholar] [CrossRef] [PubMed]

- Wilczyński, K.; Garbarski, J.; Nastaj, A.; Lewandowski, A.; Fabijański, M.; Wilczyński, K.J.; Buziak, K.; Narowski, P.; Zawistowski, H. Processing of Polymer Materials; Publishing House of the Warsaw University of Technology: Warsaw, Poland, 2018. [Google Scholar]

- Rajeshkumar, L. Biodegradable polymer blends and composites from renewable resources. In Woodhead Publishing Series in Composites Science and Engineering, Biodegradable Polymers, Blends and Composites; Woodhead Publishing: Cambridge, UK, 2022; pp. 527–549. [Google Scholar] [CrossRef]

- Krajenta, J.; Pawlak, A.; Galeski, A. All-polymer composites–a new approach with the use of disentangled semi-crystalline polymers. Part II. Preparation of composites from partially disentangled polylactide. Polimery 2020, 65, 261–267. [Google Scholar] [CrossRef]

- Tejada-Oliveros, R.; Fiori, S.; Gomez-Caturla, J.; Lascano, D.; Montanes, N.; Quiles-Carrillo, L.; Garcia-Sanoguera, D. Development and Characterization of Polylactide Blends with Improved Toughness by Reactive Extrusion with Lactic Acid Oligomers. Polymers 2022, 14, 1874. [Google Scholar] [CrossRef]

- Agarwal, S. Biodegradable Polymers: Present Opportunities and Challenges in Providing a Microplastic-Free Environment. Macromol. Chem. Phys. 2020, 221, 2000017. [Google Scholar] [CrossRef]

- Wang, X.; Peng, S.; Chen, H.; Yu, X.; Zhao, X. Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos. B Eng. 2019, 173, 107028. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polim. Nauka. 2018, 135, 45726. [Google Scholar] [CrossRef]

- Fabijański, M. Effect of calcium carbonate addition on mechanical properties of polylactidepolilaktydu. Przem. Chem. 2017, 96, 894–896. [Google Scholar] [CrossRef]

- Müllera, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.; Miesbauera, O.; Bianchin, A.; Hankin, S.; Bölz, U. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomateriały 2017, 7, 74. [Google Scholar] [CrossRef]

- Osman, A.F.; Siah, L.; Alrashdi, A.A.; Ul-Hamid, A.; Ibrahim, I. Improving the Tensile and Tear Properties of Thermoplastic Starch/Dolomite Biocomposite Film through Sonication Process. Polymers 2021, 13, 274. [Google Scholar] [CrossRef] [PubMed]

- Tryznowski, M.; Żołek-Tryznowska, Z. Surface Properties of Poly (Hydroxyurethane)s Based on Five-Membered Bis-Cyclic Carbonate of Diglycidyl Ether of Bisphenol A. Materials 2020, 13, 5184. [Google Scholar] [CrossRef] [PubMed]

- Avolio, R.; Castaldo, R.; Goj, G.; Ambrogi, V.; Fiori, S.; Avella, M.; Cocca, M.; Errico, M.E. Plasticization of poly (lactic acid) through blending with oligomers of lactic acid: Effect of the physical aging on properties. Eur. Polim. J. 2015, 66, 533–542. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. [Google Scholar] [CrossRef]

- Tábi, T.; Ageyeva, T.; Kovács, J.G. Improving the ductility and heat deflection temperature of injection molded Poly (lactic acid) products: Comprehensive review. Polym. Test. 2021, 101, 107282. [Google Scholar] [CrossRef]

- Żochowski, P.; Bajkowski, M.; Grygoruk, R.; Magier, M.; Burian, W.; Pyka, D.; Bocian, M.; Jamroziak, K. Finite element modeling of ballistic inserts containing aramid fabrics under projectile impact conditions–comparison of methods. Compos. Struct. 2022, 294, 115752. [Google Scholar] [CrossRef]

- Foltynowicz, Z.; Jakubiak, P. Polylactid acid—biodegradable polymer obtained from vegetable resources. Polimery 2022, 47, 769–774. [Google Scholar] [CrossRef]

- Fabijański, M. Study on mechanical properties of phosphogypsum-filled polylactide. Przem. Chemi. 2016, 95, 2227–2229. [Google Scholar] [CrossRef]

- Fabijański, M. Effect of multiple processing on the strength properties of polylactide/polystyrene mixture. Przem. Chem. 2022, 101, 65–68. [Google Scholar] [CrossRef]

- Haneef, I.N.H.M.; Buys, Y.F.; Shaffiar, N.M.; Shaharuddin, S.I.S.; Hamid, A.M.A.; Sabri, M.F.M.; Afifi, A.M. Effect of HNT on mechanical and thermal properties of poly (lactic acid)/polypropylene carbonate blends. Polimery 2021, 66, 459–465. [Google Scholar] [CrossRef]

- Gałęski, A.; Piórkowska, E.; Pluta, M.; Kuliński, Z.; Masirek, R. Modification of physical properties of polylactide. Polimery 2022, 50, 562–569. [Google Scholar] [CrossRef]

- He, Y.; Wu, S.; Yuen, A.C.Y.; Huang, F.; Boyer, C.; Wang, C.H.; Zhang, J. Scalable Manufacturing Process and Multifunctional Performance of Cotton Fibre-Reinforced Poly (Lactic Acid) (PLA) Bio-Composites Coated by Graphene Oxide. Polymers 2022, 14, 3946. [Google Scholar] [CrossRef] [PubMed]

- Naziemiec, Z.; Saramak, D. Effective methods of chalcedonite processing. Min. Sci. 2021, 28, 7–18. [Google Scholar] [CrossRef]

- Gawenda, T.; Surowiak, A.; Stempkowska, A.; Krawczykowska, A.; Saramak, D. Effective Removing of Light Impurities from an Aggregate in SEL Separator. Inż. Miner. 2021, 1, 53–60. [Google Scholar] [CrossRef]

- Surowiak, A.; Gawenda, T.; Stempkowska, A.; Niedoba, T.; Nad, A. The Influence of Selected Properties of Particles in the Jigging Process of Aggregates on an Example of Chalcedonite. Minerals 2020, 10, 600. [Google Scholar] [CrossRef]

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Current issues of processing and industrial utilization of chalcedonite. Inż. Miner. 2017, 1, 89–96. [Google Scholar]

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Methods of improvement chalcedonite processing effectiveness with the use of density separation. Miner. Resourc. Manag. 2017, 33, 163–178. [Google Scholar] [CrossRef][Green Version]

- Data Sheet: IngeoBiopolymer 3100HP. Available online: https://www.natureworksllc.com/~/media/Files/NatureWorks/Technical-Documents/Technical-Data-Sheets/TechnicalDataSheet_3100HP_injection-molding_pdf.pdf (accessed on 7 November 2022).

- Data Sheet: CRUSiL M 20. Available online: https://crusil.pl/wp-content/uploads/2017/11/Karta-katalogowa-Chalcedonit_mikronizowany_20_PL_v1.pdf (accessed on 7 November 2022).

- PN-EN ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- PN-EN ISO 179-1:2010; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2010.

- PN-EN ISO 868:2005; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2005.

- PN-EN ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

| Composition, % wt. | |

|---|---|

| SiO2 | >98.5 |

| Al2O3 | <0.02 |

| Fe2O3 | <0.09 |

| CaO | <0.05 |

| MgO | <0.05 |

| K2O | <0.08 |

| Na2O | <0.05 |

| TiO2 | <0.02 |

| Parameters | Value |

|---|---|

| Specific density | 2.60 g/cm3 |

| Bulk density | 0.59 g/cm3 |

| Bulk density | 1.17 g/cm3 |

| Loss on ignition LOI 1 h 950 °C | 0.90% |

| Standard refractoriness PN-EN 993-12sP | 173 (1730 °C) |

| Granulation D97 | 20 µm |

| Granulation D50 | 6.45 µm |

| Optical properties L/a/b | 95.8/0.32/1.2 |

| Lp. | PLA, % wt. | Crusil M20, % wt. |

|---|---|---|

| 0 | 100 | 0 |

| 1 | 95 | 5 |

| 2 | 90 | 10 |

| 3 | 85 | 15 |

| 4 | 80 | 20 |

| 5 | 70 | 30 |

| Injection Parameters | Values | |

|---|---|---|

| injection: | ||

| speed | 30% | |

| pressure | 120 bar | |

| processing temperature | zone 1 | 200 °C |

| zone 2 | 190 °C | |

| zone 3 | 180 °C | |

| zone 4 | 160 °C | |

| zone 5 | 80 °C | |

| pressure: | ||

| time | 8 s | |

| holding pressure | 50 bar | |

| closing force: | ||

| average | 844 N | |

| closing the mold: | ||

| pressure | 170 bar | |

| speed | 40% | |

| time to secure the form | 5 s | |

| cycle time | 120 s | |

| against pressure | 5 bar | |

| mold opening: | ||

| against pressure | 10 bar | |

| cooling time | 30 s | |

| temperature | 80 °C | |

| Filler Content, %wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| The average weight of the paddles, g | 24.48 | 25.07 | 25.61 | 26.20 | 26.83 | 27.87 | 27.80 |

| Average weight of the bars, g | 14.78 | 15.04 | 15.59 | 15.65 | 15.90 | 16.24 | 16.58 |

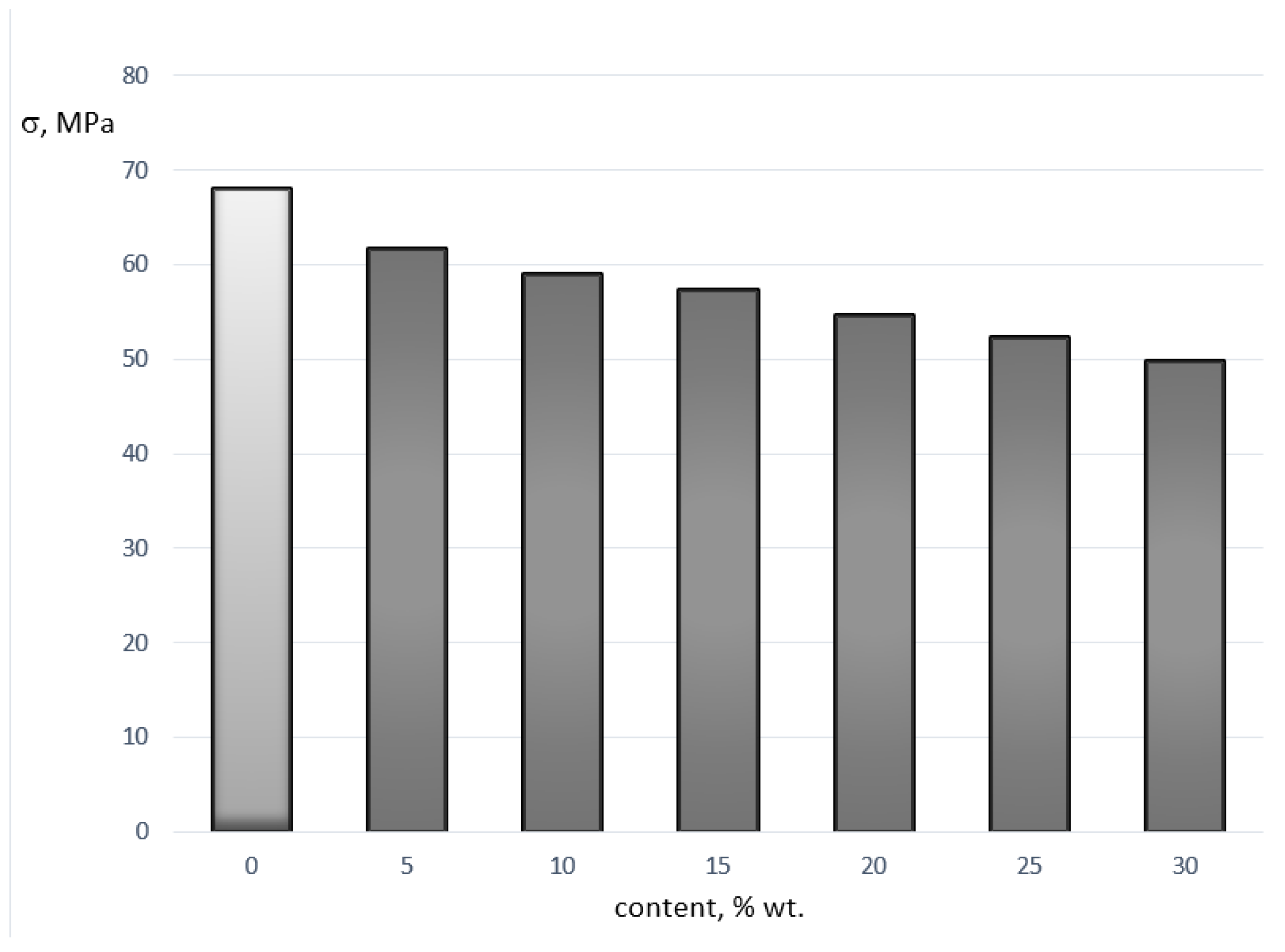

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Tensile strength, σ, MPa | 68.10 | 61.60 | 59.00 | 57.30 | 54.60 | 52.30 | 49.80 |

| Standard deviation | 2.91 | 1.50 | 0.82 | 1.76 | 1.76 | 0.79 | 1.07 |

| Elongation, ε, % | 4.8 | 5.4 | 5.7 | 3.9 | 3.5 | 3.3 | 2.9 |

| Standard deviation | 0.09 | 0.15 | 0.09 | 0.12 | 0.13 | 0.12 | 0.11 |

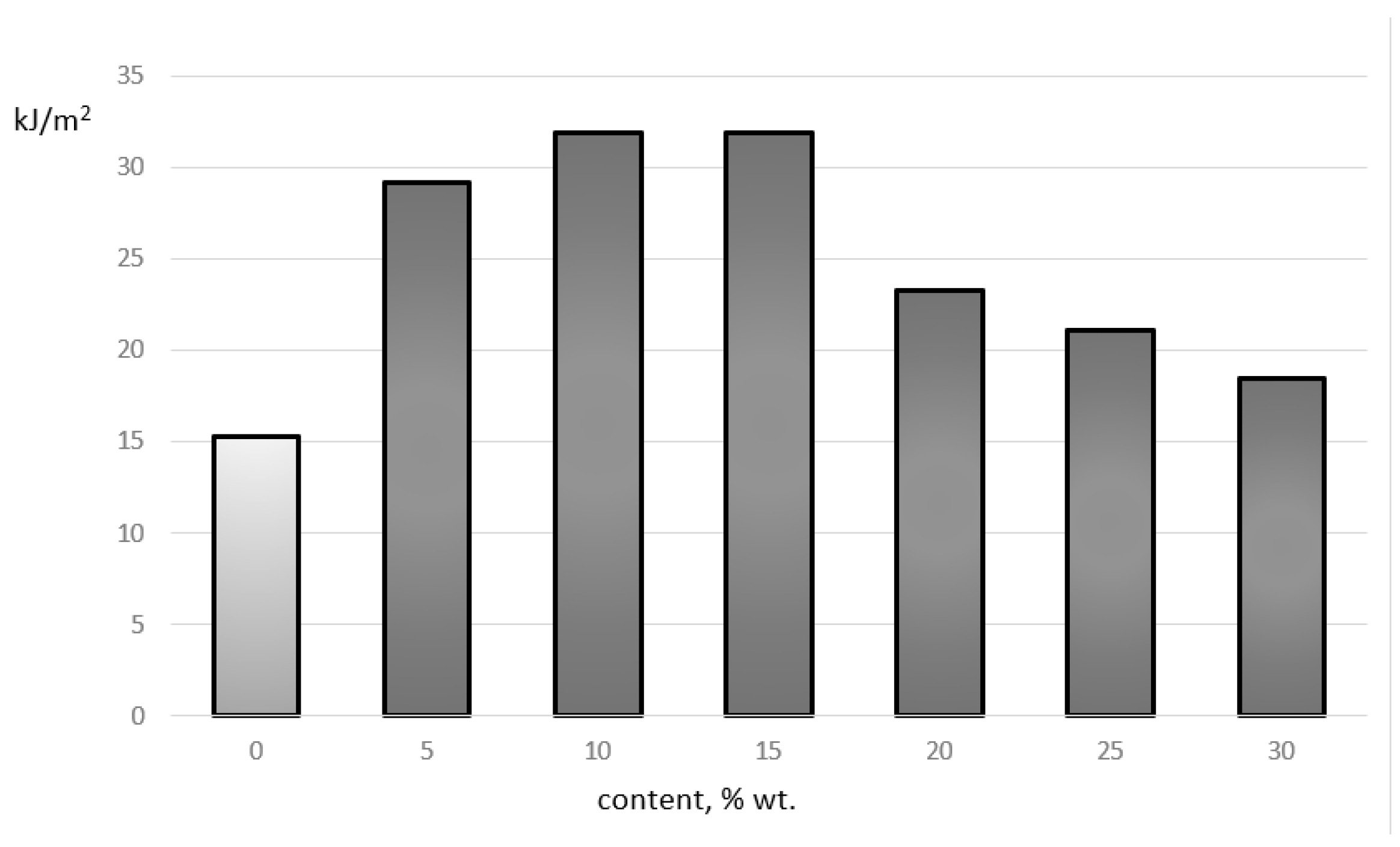

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Impact strength, kJ/m2 | 15.25 | 29.12 | 31.87 | 31.87 | 23.25 | 21.12 | 18.50 |

| Standard deviation | 0.54 | 1.14 | 1.28 | 1.54 | 1.24 | 1.56 | 1.52 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Shore hardness, scale D | 61.0 | 61.6 | 61.4 | 61.5 | 61.5 | 60.9 | 61.0 |

| Standard deviation | 1.38 | 0.67 | 1.71 | 0.75 | 0.83 | 0.84 | 0.85 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Average weight of samples before soaking, g | 10.534 | 10.850 | 11.102 | 11.380 | 11.594 | 12.041 | 12.060 |

| Average weight of samples after soaking for 24 h, g | 10.523 | 10.866 | 11.083 | 11.364 | 11.596 | 12.054 | 12.053 |

| Average weight of samples after soaking for 168 h, g | 10.577 | 10.892 | 11.143 | 11.420 | 11.632 | 12.075 | 12.097 |

| Weight difference after 7 h | 0.021 | 0.017 | 0.018 | 0.015 | 0.016 | 0.015 | 0.016 |

| The difference in weight after 168 h | 0.042 | 0.042 | 0.041 | 0.040 | 0.037 | 0.034 | 0.037 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fabijanski, M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. J. Compos. Sci. 2022, 6, 387. https://doi.org/10.3390/jcs6120387

Fabijanski M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. Journal of Composites Science. 2022; 6(12):387. https://doi.org/10.3390/jcs6120387

Chicago/Turabian StyleFabijanski, Mariusz. 2022. "Mechanical Properties of Polylactide Filled with Micronized Chalcedonite" Journal of Composites Science 6, no. 12: 387. https://doi.org/10.3390/jcs6120387

APA StyleFabijanski, M. (2022). Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. Journal of Composites Science, 6(12), 387. https://doi.org/10.3390/jcs6120387