Implementation on a Preparation and Controlled Compaction Procedure for Waste-Fiber-Reinforced Raw Earth Samples

Abstract

:1. Introduction

2. Materials and Methods

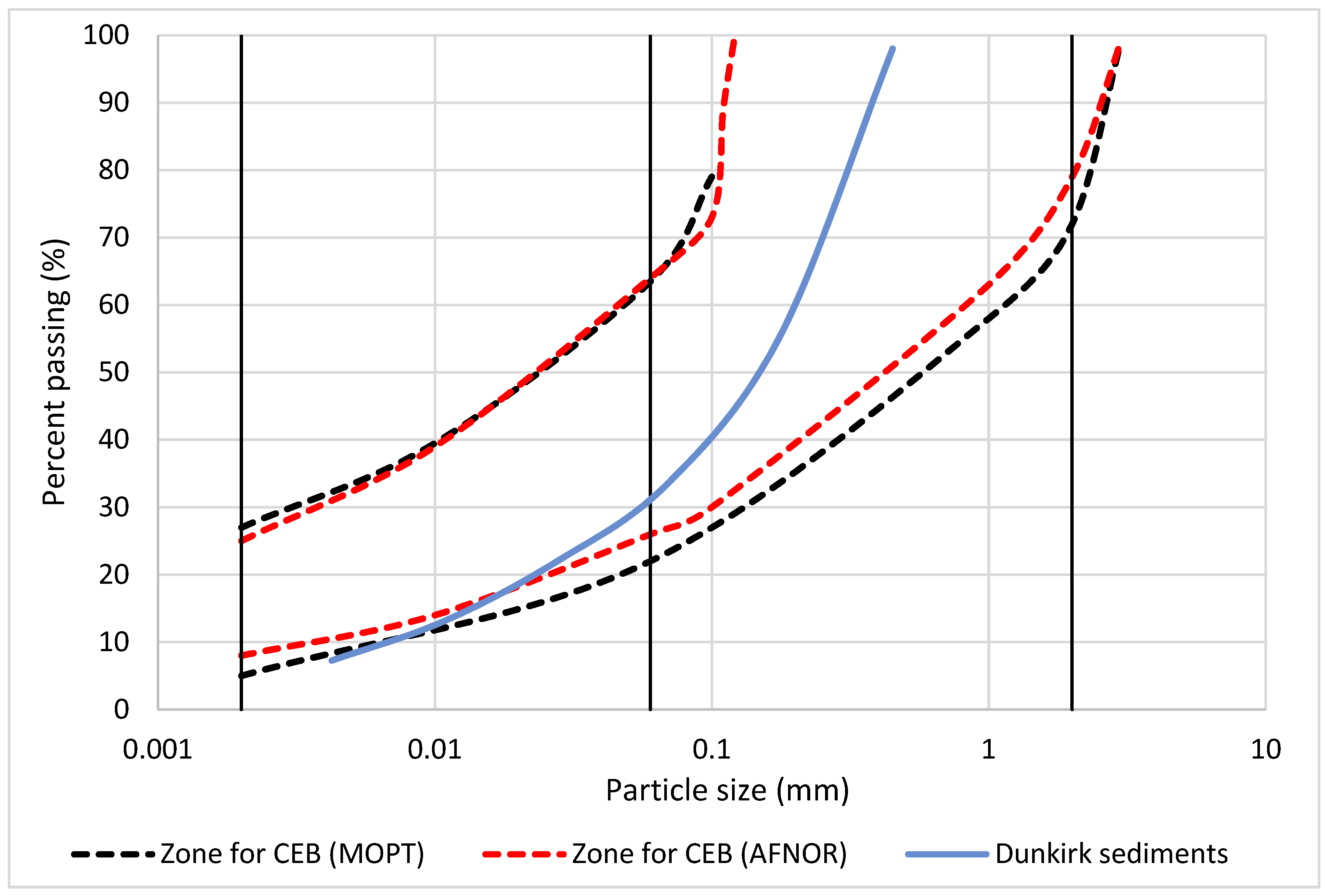

2.1. Dunkirk Sediments

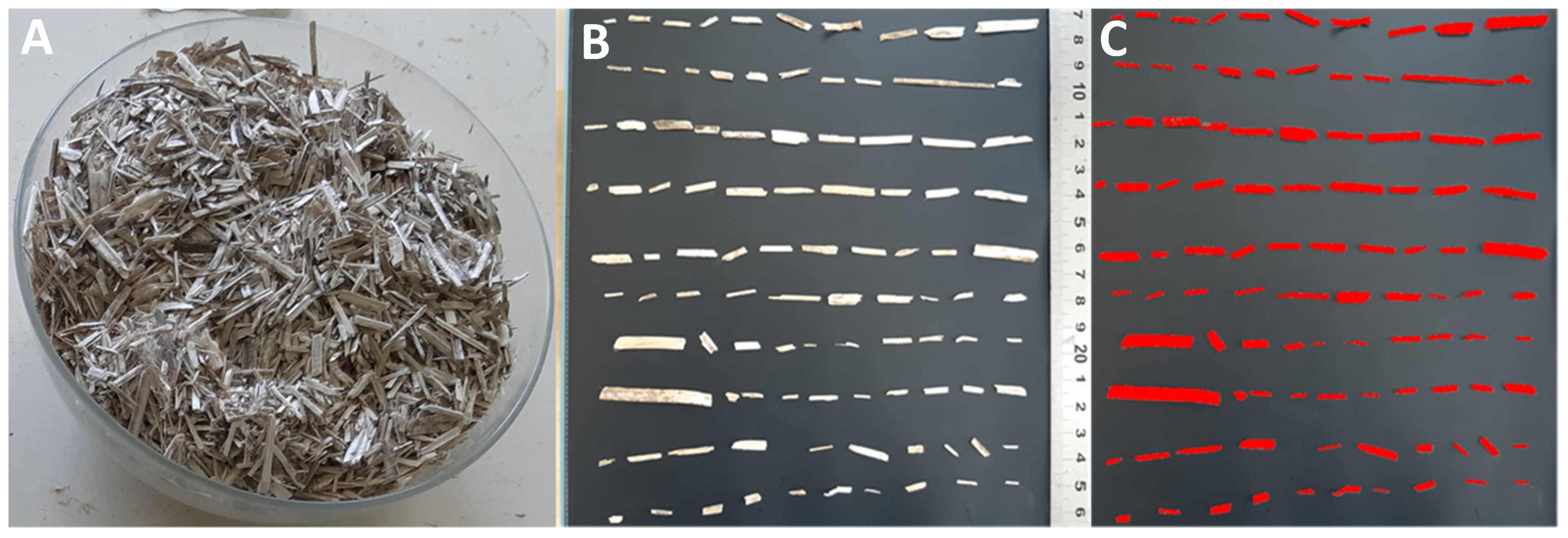

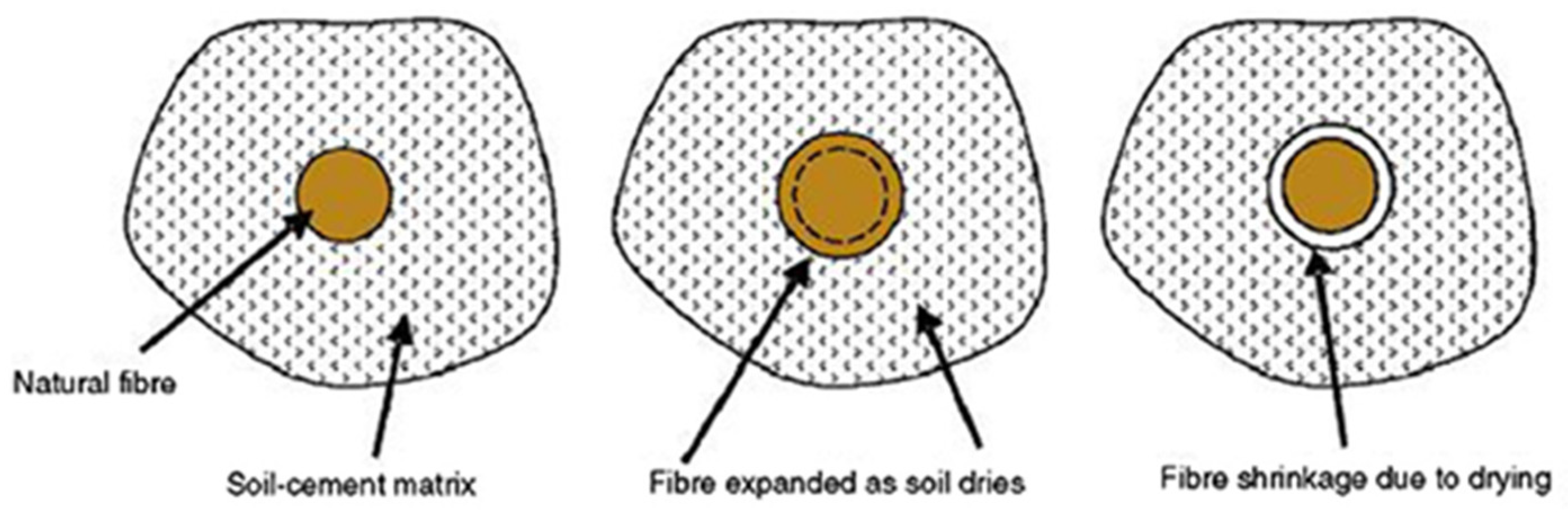

2.2. Hemp Shiv

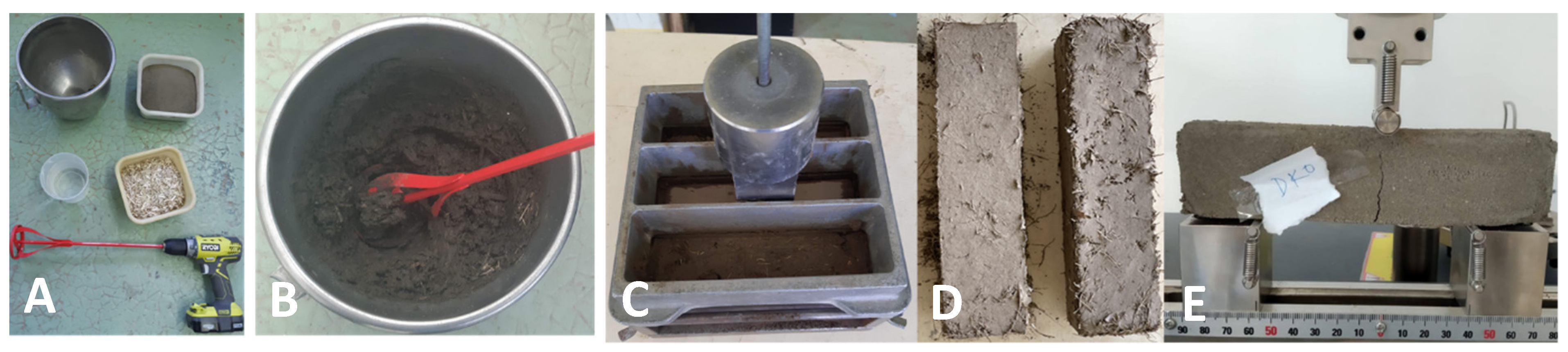

2.3. Manufacturing of Crude Bricks

2.4. Compaction of Crude Bricks

3. Testing of Bricks

3.1. Flexural Strength of Bricks

3.2. Toughness Index (I5) of Crude Bricks

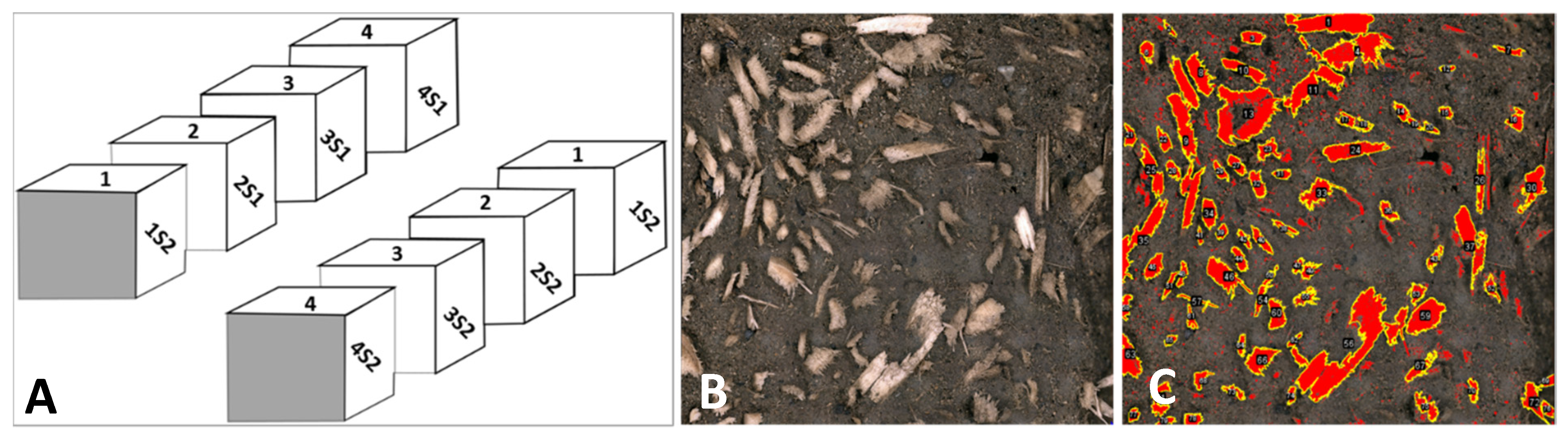

3.3. Fibers Distribution

4. Results and Discussion

4.1. Manufacturing of Bricks

4.2. Dry Density of Bricks

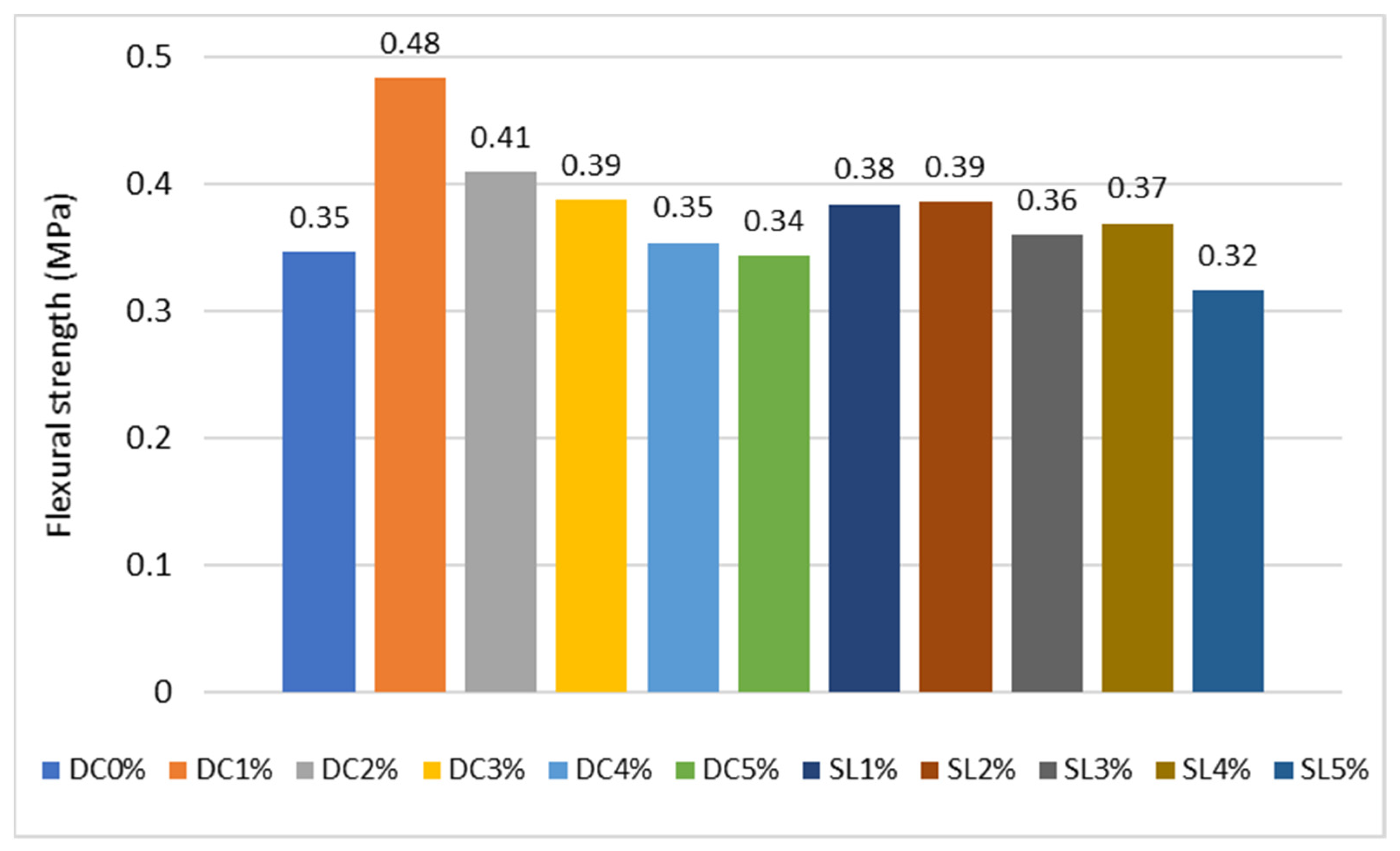

4.3. Flexural Strength of Bricks

4.4. Toughness Index (I5) of Bricks

4.5. Image Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. The sustainability of adobe construction: Past to future. Int. J. Archit. Herit. 2018, 13, 639–674. [Google Scholar] [CrossRef]

- Bock-Hyeng, C.; Ofori-Boadu, A.N.; Yamb-Bell, E.; Shofoluwe, M.A. Mechanical properties of sustainable adobe bricks stabilized with recycled sugarcane fiber waste. J. Eng. Res. Appl. 2016, 6, 50–59. [Google Scholar]

- Ministère de la Transition Ecologique, France. Energie Dans les Bâtiments. 2021. Available online: https://www.ecologie.gouv.fr/energie-dans-batiments (accessed on 27 November 2021).

- Sheehan, C.; Harrington, J.; Murphy, J.D. Dredging and Dredged Material Beneficial Use in Ireland; Terra et Aqua: The Hague, The Netherlands, 2009; pp. 3–14. [Google Scholar]

- Rakshith, S.; Singh, D.N. Utilization of dredged sediments: Contemporary issues. J. Waterw. Port Coast. Ocean. Eng. 2017, 143, 04016025. [Google Scholar] [CrossRef]

- Dubois, V.; Abriak, N.E.; Zentar, R.; Ballivy, G. The use of marine sediments as a pavement base material. Waste Manag. 2009, 29, 774–782. [Google Scholar] [CrossRef]

- AFNOR XP P13-901; Compressed Earth Blocks for Walls and Partitions: Definitions–Specifications–Test Methods–Delivery Acceptance Conditions. AFNOR: Saint-Denis, France, 2001.

- CDI-CRATerre-EAG. CDI-Center for the Development of Industry; Compressed Earth Blocks: Standards-Technology Series; LomCP-EU Convention: Brussels, Belgium, 1998; 144p. [Google Scholar]

- Houben, H.; Guillaud, H. Earth Construction—A Comprehensive Guide; Intermediate Technology Publications Ltd.: London, UK, 1994; ISBN 9781853391934. [Google Scholar]

- Delgado, M.C.J.; Guerrero, I.C. The selection of soils for unstabilised earth building: A normative review. Constr. Build. Mater. 2007, 21, 237–251. [Google Scholar] [CrossRef]

- Fgaier, F.E.; Lafhaj, Z.; Chapiseau, C.; Antczak, E. Effect of sorption capacity on thermo-mechanical properties of unfired clay bricks. J. Build. Eng. 2016, 6, 86–92. [Google Scholar] [CrossRef]

- Yetgin, S.; Cavdar, Ö.; Çavdar, A. The effects of the fiber contents on the mechanic properties of the adobes. Constr. Build. Mater. 2008, 22, 222–227. [Google Scholar] [CrossRef]

- Uguryol, M.; Kulakoglu, F. A preliminary study for the characterization of Kültepe’s adobe soils with the purpose of providing data for conservation and archaeology. J. Cult. Herit. 2013, 14, e117–e124. [Google Scholar] [CrossRef]

- Hakkoum, S.; Kriker, A.; Mekhermeche, A. Thermal characteristics of Model houses Manufactured by date palm fiber reinforced earth bricks in desert regions of Ouargla Algeria. Energy Procedia 2017, 119, 662–669. [Google Scholar] [CrossRef]

- Chaib, H.; Kriker, A.; Mekhermeche, A. Thermal study of earth bricks reinforced by date palm fibers. Energy Procedia 2015, 74, 919–925. [Google Scholar] [CrossRef] [Green Version]

- Calatan, G.; Hegyi, A.; Dico, C.; Mircea, C. Determining the optimum addition of vegetable materials in adobe bricks. Procedia Technol. 2016, 22, 259–265. [Google Scholar] [CrossRef] [Green Version]

- Lertwattanaruk, P.; Choksiriwanna, P. The physical and thermal properties of adobe brick containing bagasse for earth construction. Built 2011, 1, 57–66. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Shah, T. Investigation of fibre reinforced mud brick as a building material. Constr. Build. Mater. 2005, 19, 313–318. [Google Scholar] [CrossRef]

- Azhary, K.E.; Chihab, Y.; Mansour, M.; Laaroussi, N.; Garoum, M. Energy efficiency and thermal properties of the composite material clay-straw. Energy Procedia 2017, 141, 160–164. [Google Scholar] [CrossRef]

- Ismail, S.; Yaacob, Z. Properties of laterite brick reinforced with oil palm empty fruit bunch fibres. Pertanika J. Sci. Technol. 2011, 19, 33–43. [Google Scholar]

- Saleem, M.A.; Abbas, S.; Haider, M. Jute Fiber Reinforced Compressed Earth Bricks (FR-CEB)—A Sustainable Solution. Pak. J. Eng. Appl. Sci. 2016, 19, 83–90. [Google Scholar]

- Ghavami, K.; Filho, R.D.T.; Barbosa, N.P. Behaviour of composite soil reinforced with natural fibres. Cem. Concr. Compos. 1999, 21, 39–48. [Google Scholar] [CrossRef]

- Bruno, A.W.; Gallipoli, D.; Perlot, C.; Mendes, J. Optimization of bricks production by earth hypercompaction prior to firing. J. Clean. Prod. 2018, 214, 475–482. [Google Scholar] [CrossRef]

- Mellaikhafi, A.; Tilioua, A.; Souli, H.; Garoum, M.; Hamdi, M.A. Characterization of different earthen construction materials in oasis of south-eastern Morocco (Errachidia Province). Case Stud. Constr. Mater. 2020, 14, e00496. [Google Scholar] [CrossRef]

- Hall, M.; Djerbib, Y. Rammed earth sample production: Context, recommendations and consistency. Constr. Build. Mater. 2004, 18, 281–286. [Google Scholar] [CrossRef]

- Marandi, S.M.; Bagheripour, M.H.; Rahgozar, R.; Zare, H. Strength and Ductility of Randomly Distributed Palm Fibers Reinforced Silty-Sand Soils. Am. J. Appl. Sci. 2008, 5, 209–220. [Google Scholar] [CrossRef]

- SADC ZW HS 983; Rammed Earth Structures—Code of Practice. African Organisation of Standardisation: Gaborone, Botswana, 2014.

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Mechanical Properties of Fibre-Reinforced Mud Bricks; CCE: Khartoum, Sudan, 2018. [Google Scholar]

- Dormohamadi, M.; Rahimnia, R. Combined effect of compaction and clay content on the mechanical properties of adobe brick. Case Stud. Constr. Mater. 2020, 13, e00402. [Google Scholar] [CrossRef]

- Li Piani, T.; Weerheijm, J.; Peroni, M.; Koene, L.; Krabbenborg, D.; Solomos, G.; Sluys, L.G. Dynamic behaviour of adobe bricks in compression: The role of fibres and water content at various loading rates. Constr. Build. Mater. 2020, 230, 117038. [Google Scholar] [CrossRef]

- Cárdenas-Haro, X.; Todisco, L.; León, J. Database with compression and bending tests on unbaked earth specimens and comparisons with international code provisions. Constr. Build. Mater. 2021, 276, 122232. [Google Scholar] [CrossRef]

- Kafodya, K.; Okonta, F.; Kloukinas, P. Role of fiber inclusion in adobe masonry construction. J. Build. Eng. 2019, 26, 100904. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Effect of banana fibers on the compressive and flexural strength of compressed earth blocks. Buildings 2015, 5, 282–296. [Google Scholar] [CrossRef] [Green Version]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. A review on the assessment and prediction of the orientation and distribution of fibres for concrete. Compos. Part B Eng. 2018, 151, 274–290. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Loganayagan, S.; Kowshika, G.; Ramprakash, C.; Aruneshwaran, M. Adobe blocks reinforced with natural fibres: A review. Mater. Today Proc. 2021, 45, 6493–6499. [Google Scholar] [CrossRef]

- Adam, E.A.; Agib, A.R.A. Compressed Stabilised Earth Block Manufacture in Sudan; United Nations Educational, Scientific and Cultural Organization, UNESCO: Paris, France, 2001. [Google Scholar]

- Brakni, S.; Abriak, N.E.; Hequette, A. Formulation of artificial aggregates from dredged harbour sediments for coastline stabilization. Environ. Technol. 2009, 30, 849–854. [Google Scholar] [CrossRef]

- AFNOR NF X31-107; Qualité du Sol—Détermination de la Distribution Granulométrique Des Particules du Sol-Méthode à la Pipette. AFNRO: Saint-Denis, France, 2003.

- AFNOR NF EN ISO 17892-12; Reconnaissance et Essais Geotechniques-Essais de Laboratoire Sur Les Sols-Partie 12: Détermination Des Limites de Liquidité et de Plasticité. AFNRO: Saint-Denis, France, 2018.

- XP P 94-047; Sols: Reconnaissance et Essais. Détermination de la Teneur Pondérale en Matières Organiques d’un Matériau. AFNR: Saint-Denis, France, 2007.

- NF ISO 10694, AFNOR 1995; Qualité du Sol–Dosage du Carbone Organique et du Carbone Total Apres Combustion Seche (Analyse Elementaire). AFNOR: Saint-Denis, France, 1995.

- MOPT. Bases Para el Diseño y Construccio’n con Tapial. Centro de Publicaciones, Secretarı’a General Te’cnica, Ministerio de Obras Pu’blicas y Transportes; MOPT: Madrid, Spain, 1992. [Google Scholar]

- AFNOR EN 196-1; Méthodes d’essais Des Ciments—Partie 1: Détermination Des Résistances. AFNRO: Saint-Denis, France, 2016.

- AFNOR NF EN 1015-11; Méthodes d’essai Des Mortiers Pour Maçonnerie—Partie 11: Détermination de la Résistance en Flexion et en Compression du Mortier Durci. AFNOR: Saint-Denis, France, 2019.

- Donkor, P.; Obonyo, E. Earthen construction materials: Assessing the feasibility of improving strength and deformability of compressed earth blocks using polypropylene fibers. Mater. Des. 2015, 83, 813–819. [Google Scholar] [CrossRef]

- ASTM D 790–03; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- ASTM C 1018–97; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). American Society for Testing and Materials: West Conshohocken, PA, USA, 1998.

- Bui, T.T.H. Study on Performance Enhancement of Coconut Fibres Reinforced Cementitious Composites. Ph.D. thesis, Caen University, Caen, France, 2021. [Google Scholar]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- NZS 4298; Materials and Workmanship for Earth Buildings. [Building Code Compliance Document E2 (AS2)]. Standards New Zealand: Wellington, New Zealand, 1998.

- NORMA E.080. Diseño y Construcción Con Tierra Reforzada. Ministerio de Vivienda, Construcción y Saneamiento. Anexo-Resolución Ministerial N° 121-2017-Vivienda. Available online: https://procurement-notices.undp.org/view_file.cfm?doc_id=109376 (accessed on 27 November 2021).

- Araya-Letelier, G.; Antico, F.C.; Burbano-Garcia, C.; Concha-Riedel, J.; Norambuena-Contreras, J.; Concha, J.; Flores, E.I.S. Experimental evaluation of adobe mixtures reinforced with jute fibers. Constr. Build. Mater. 2020, 276, 122127. [Google Scholar] [CrossRef]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable adobe bricks with seagrass fibres. Mechanical and thermal properties characterization. Constr. Build. Mater. 2020, 239, 117699. [Google Scholar] [CrossRef]

- Abdulla, K.F.; Cunningham, L.S.; Gillie, M. Cunningham, and Martin Gillie. Experimental Study on the Mechanical Properties of Straw Fiber–Reinforced Adobe Masonry. J. Mater. Civ. Eng. 2020, 32, 04020322. [Google Scholar] [CrossRef]

- Kumar, N.; Barbato, M. Effects of sugarcane bagasse fibers on the properties of compressed and stabilized earth blocks. Constr. Build. Mater. 2022, 315, 125552. [Google Scholar] [CrossRef]

- Khoudja, D.; Taallah, B.; Izemmouren, O.; Aggoun, O.; Herihiri, O.; Guettala, A. Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr. Build. Mater. 2021, 270, 121824. [Google Scholar] [CrossRef]

| Sediments | Clay (%) | Silt (%) | Sand (%) | CaCO3 (%) | Wopt * (%) | OM * (%) | MBV * (g/100 g) | pH | LL (%) | PL (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| DK | 4.3 | 24.8 | 70.9 | 13.3 | 20.5 | 5.29 | 0.6 | 8.4 | 18.9 | 8.2 |

| Average Length (mm) | Average Thickness (mm) | Water Absorption (%) |

|---|---|---|

| 11.7 | 2.24 | 298 |

| Amount of Fibers (%) | 0 | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|

| Dry density SL (kg/m3) | - | 1650.0 | 1547.6 | 1509.1 | 1433.4 | 1350.0 |

| Dry density DC (kg/m3) | 1585.6 | 1549.4 | 1428.9 | 1478.3 | 1282.4 | 1329.1 |

| Fiber | Fiber Content (wt %) | Tensile Strength (MPa) | References |

|---|---|---|---|

| Jute | 0.5–2 | 0.55–0.66 | [52] |

| Seagrass | 0.5–3 | 0.4–0.6 | [53] |

| Straw | 0.5 | 0.71 | [54] |

| Sugarcane bagasse | 0–1 | 0.29–0.89 * | [55] |

| Date palm waste | 0–10 | 0.29–2.26 | [56] |

| Bricks | DC0 | DC1 | DC2 | DC3 | DC4 | DC5 |

| I5 | 1 | 2.42 | 2.78 | 2.74 | 3.34 | 3.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, M.; Levacher, D.; Saouti, L.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A. Implementation on a Preparation and Controlled Compaction Procedure for Waste-Fiber-Reinforced Raw Earth Samples. J. Compos. Sci. 2022, 6, 3. https://doi.org/10.3390/jcs6010003

Hussain M, Levacher D, Saouti L, Leblanc N, Zmamou H, Djeran-Maigre I, Razakamanantsoa A. Implementation on a Preparation and Controlled Compaction Procedure for Waste-Fiber-Reinforced Raw Earth Samples. Journal of Composites Science. 2022; 6(1):3. https://doi.org/10.3390/jcs6010003

Chicago/Turabian StyleHussain, Mazhar, Daniel Levacher, Léo Saouti, Nathalie Leblanc, Hafida Zmamou, Irini Djeran-Maigre, and Andry Razakamanantsoa. 2022. "Implementation on a Preparation and Controlled Compaction Procedure for Waste-Fiber-Reinforced Raw Earth Samples" Journal of Composites Science 6, no. 1: 3. https://doi.org/10.3390/jcs6010003

APA StyleHussain, M., Levacher, D., Saouti, L., Leblanc, N., Zmamou, H., Djeran-Maigre, I., & Razakamanantsoa, A. (2022). Implementation on a Preparation and Controlled Compaction Procedure for Waste-Fiber-Reinforced Raw Earth Samples. Journal of Composites Science, 6(1), 3. https://doi.org/10.3390/jcs6010003