New Perspectives on Zirconia Composites as Biomaterials

Abstract

:1. Introduction

2. Materials and Methods

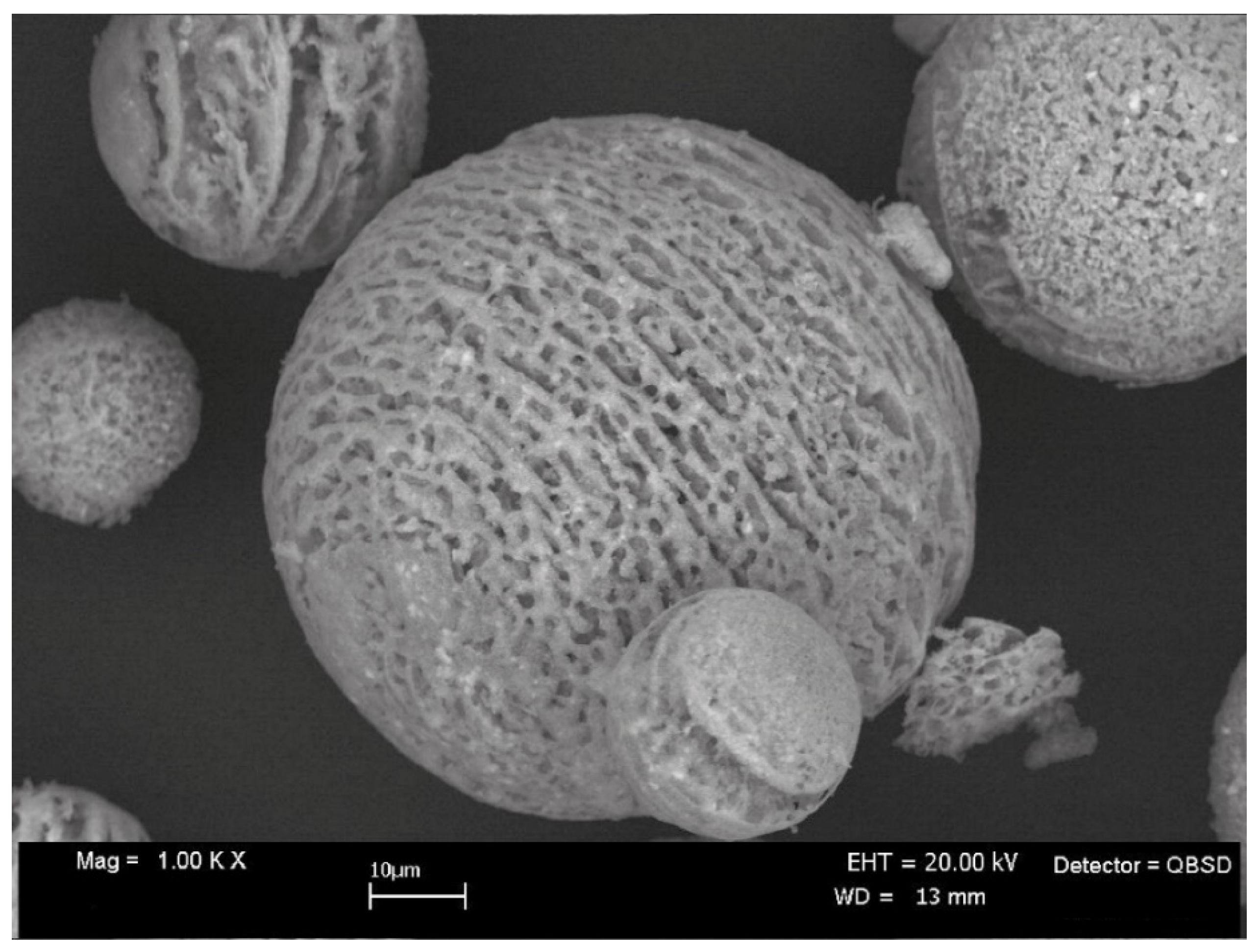

2.1. Ceramic Mixtures and Sample Preparation

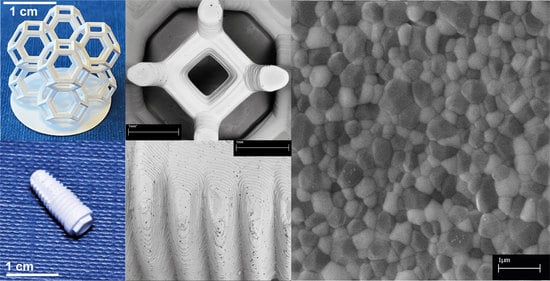

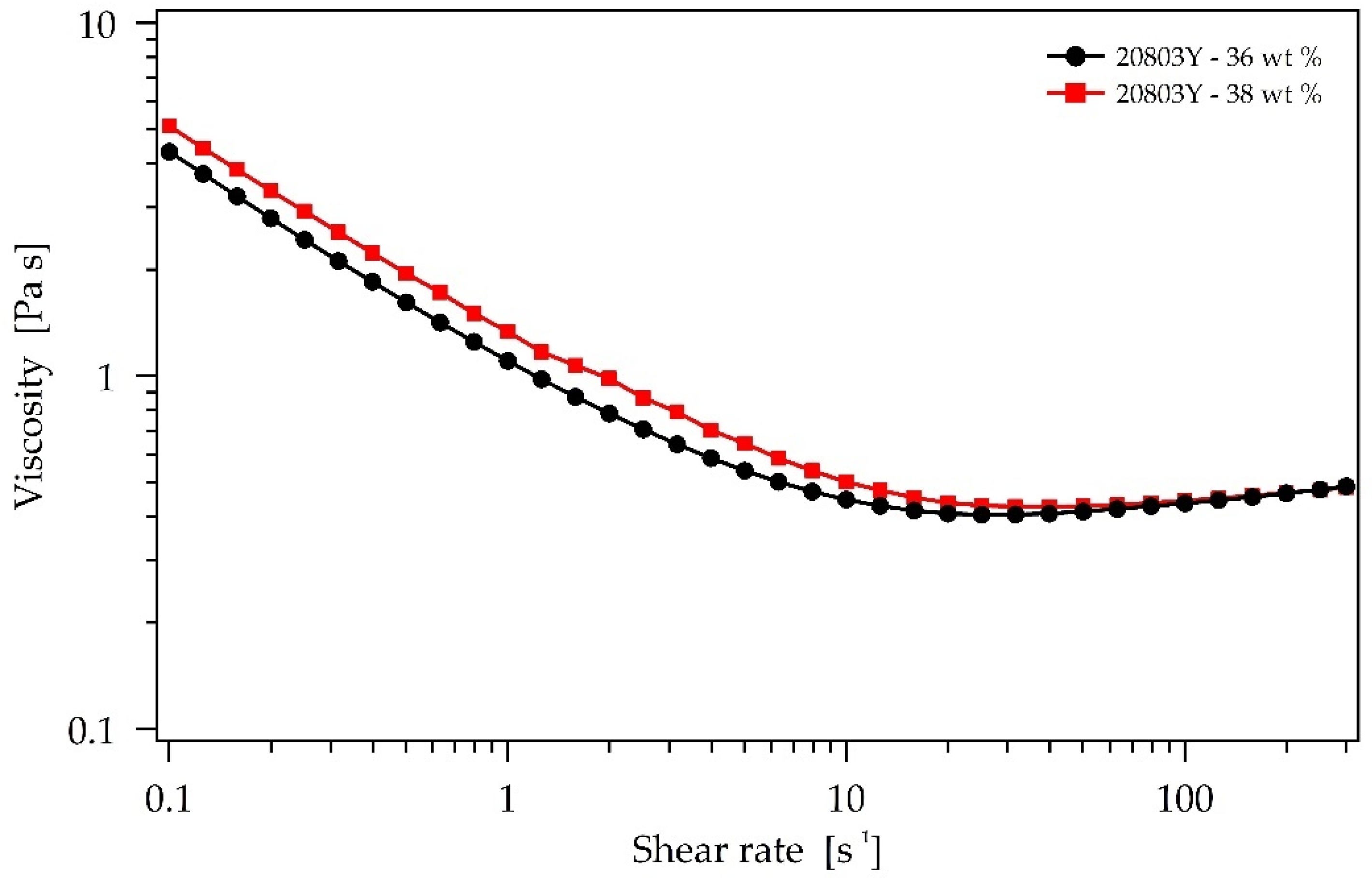

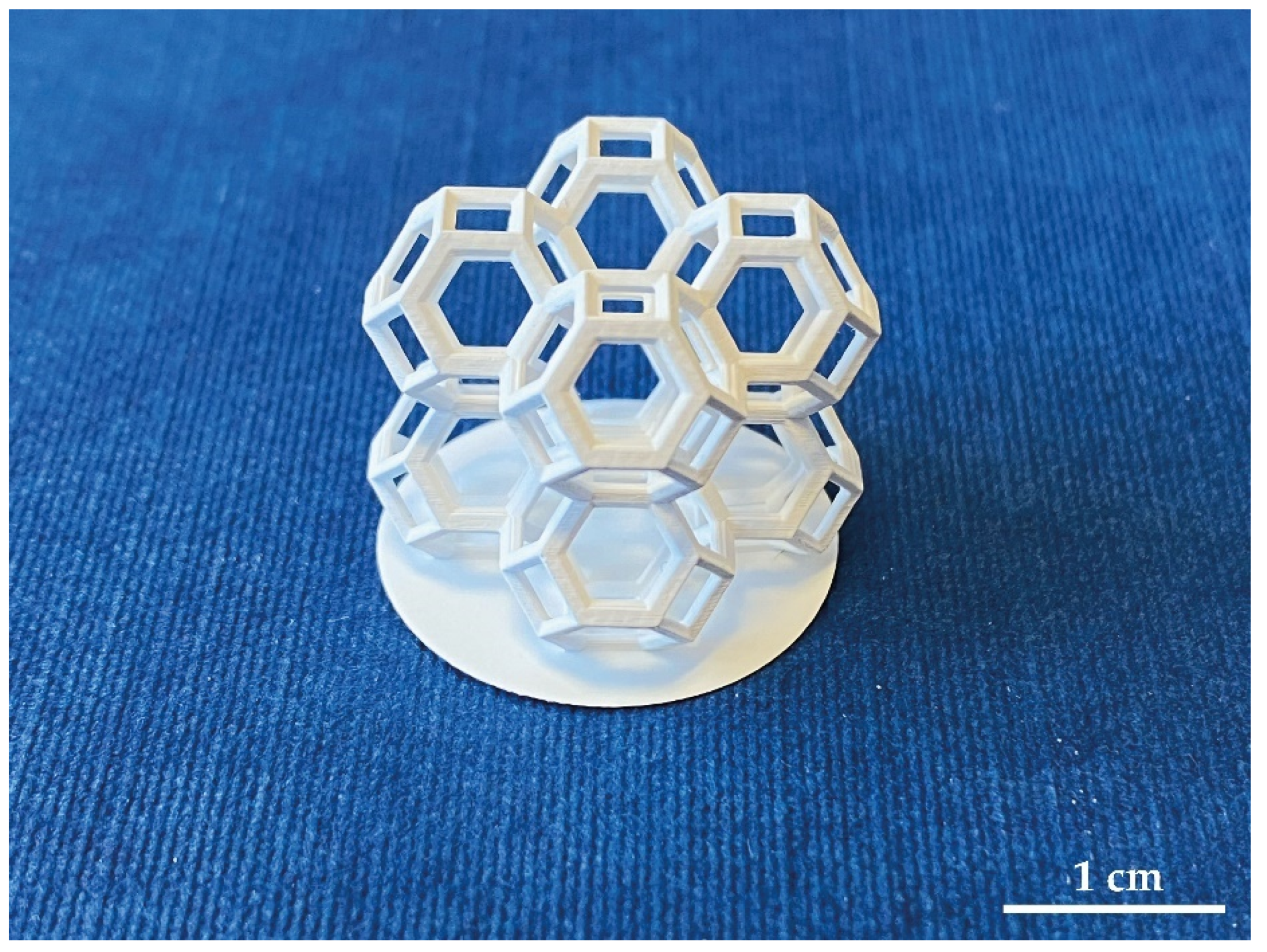

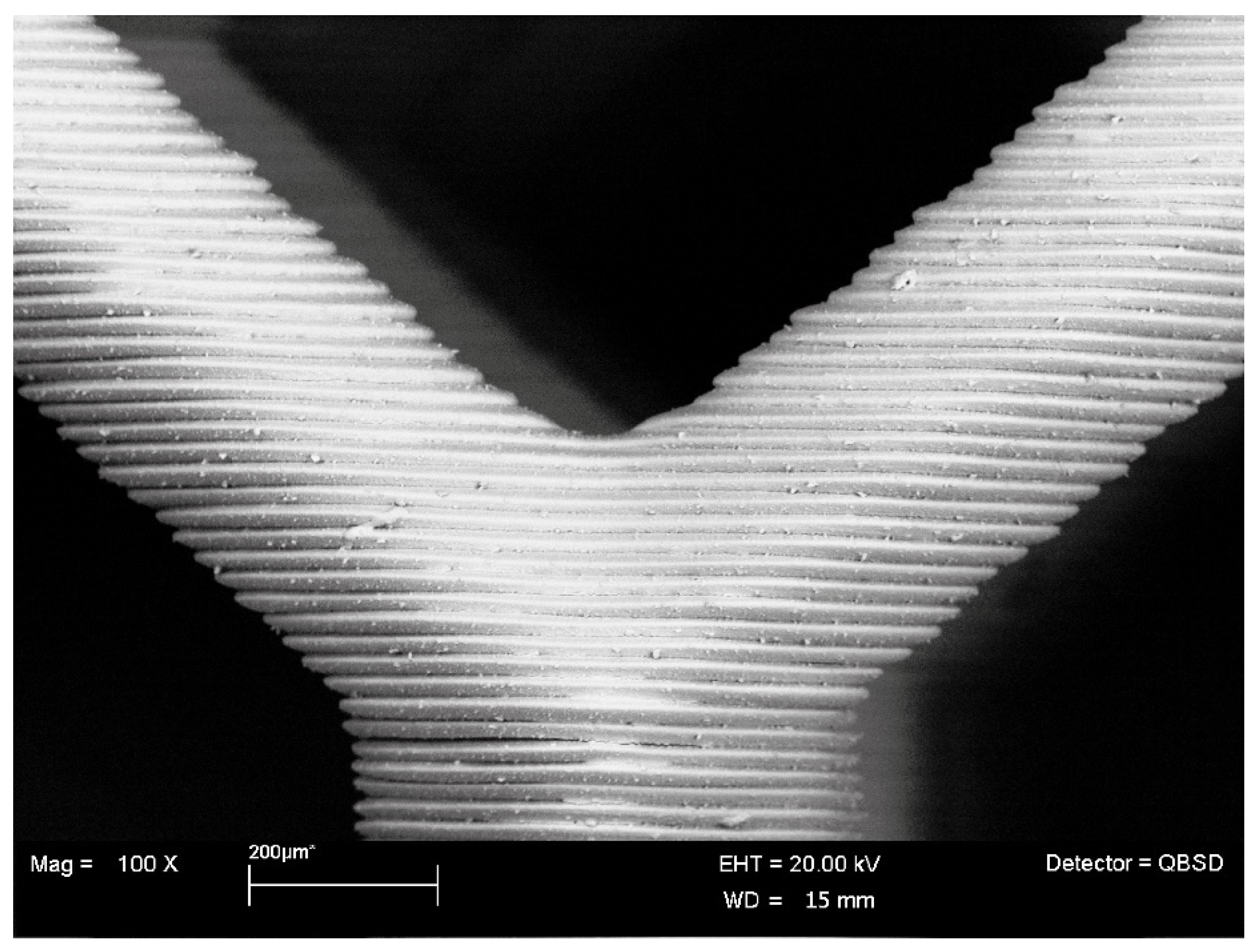

2.2. Ceramic Resin and 3D Printing

2.3. Sintering Process: Thermal Cycles

2.4. Physical, Microstructural and Mechanical Characterization

3. Results and Discussion

3.1. Stabilization of Zirconia: Variables That Influence Transformability

3.1.1. Type of Stabilizer

3.1.2. Stabilizer Content

3.1.3. Critical Grain Size

3.2. Parameters That Influence Mechanical Properties

3.3. New Manufacturing Techniques: 3D Printing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Claussen, N. Fracture Toughness of Al2O3 with an unstabilized ZrO2 dispersed phase. J. Am. Ceram. Soc. 1976, 59, 49–51. [Google Scholar] [CrossRef]

- Wang, J.; Stevens, R. Zirconia-toughened alumina (ZTA) ceramics. J. Mater. Sci. 1989, 24, 3421–3440. [Google Scholar] [CrossRef]

- Maji, A.; Choubey, G. Microstructure and mechanical properties of alumina toughened zirconia (ATZ). Mater. Today Proc. 2018, 5, 7457–7465. [Google Scholar] [CrossRef]

- Wimmer, M.A.; Pacione, C.; Yuh, C.; Chan, Y.-M.; Kunze, J.; Laurent, M.P.; Chubinskaya, S. Articulation of an alumina-zirconia composite ceramic against living cartilage—An in vitro wear test. J. Mech. Behav. Biomed. Mater. 2020, 103, 103531. [Google Scholar] [CrossRef]

- Solarino, G.; Piconi, C.; De Santis, V.; Piazzolla, A.; Moretti, B. Ceramic Total knee arthroplasty: Ready to go? Joints 2017, 05, 224–228. [Google Scholar] [CrossRef] [Green Version]

- Piconi, C.; Sprio, S. Zirconia implants: Is there a future? Curr. Oral Health Rep. 2018, 5, 186–193. [Google Scholar] [CrossRef]

- Tsukuma, K.; Ueda, K.; Shimada, M. Strength and fracture toughness of isostatically hot-pressed composites of Al2O3 and Y2O3-partially-stabilized ZrO2. J. Am. Ceram. Soc. 1985, 68, C4–C5. [Google Scholar] [CrossRef]

- Tuan, W.H.; Chen, R.Z.; Wang, T.C.; Cheng, C.H.; Kuo, P.S. Mechanical properties of Al2O3/ZrO2 composites. J. Eur. Ceram. Soc. 2002, 22, 2827–2833. [Google Scholar] [CrossRef]

- Shin, Y.-S.; Rhee, Y.-W.; Kang, S.-J.L. Experimental evaluation of toughening mechanisms in alumina-zirconia composites. J. Am. Ceram. Soc. 1999, 82, 1229–1232. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Tsukuma, K.; Takahata, T.; Shiomi, M. Strength and fracture toughness of Y-TZP, Ce-TZP, Y-TZP/Al2O3, and Ce-TZP/Al2O3. In Advances in Ceramics: Science and Technology of Zirconia III; Sōmiya, S., Yamamoto, N., Yanagida, H., Eds.; The American Ceramic Society: Columbus, OH, USA, 1988; Volume 24B, pp. 721–728. ISBN 9780916094874. [Google Scholar]

- Lange, F.F. Transformation toughening: Part 1 Size effects associated with the thermodynamics of constrained transformations. J. Mater. Sci. 1982, 17, 225–234. [Google Scholar] [CrossRef]

- Garvie, R.C. The occurrence of metastable tetragonal zirconia as a crystallite size effect. J. Phys. Chem. 1965, 69, 1238–1243. [Google Scholar] [CrossRef]

- Gutknecht, D.; Chevalier, J.; Garnier, V.; Fantozzi, G. Key role of processing to avoid low temperature ageing in alumina zirconia composites for orthopaedic application. J. Eur. Ceram. Soc. 2007, 27, 1547–1552. [Google Scholar] [CrossRef]

- Zadorozhnaya, O.Y.; Khabas, T.A.; Tiunova, O.V.; Malykhin, S.E. Effect of grain size and amount of zirconia on the physical and mechanical properties and the wear resistance of zirconia-toughened alumina. Ceram. Int. 2020, 46, 9263–9270. [Google Scholar] [CrossRef]

- Cotič, J.; Jevnikar, P.; Kocjan, A.; Kosmač, T. Complexity of the relationships between the sintering-temperature-dependent grain size, airborne-particle abrasion, ageing and strength of 3Y-TZP ceramics. Dent. Mater. 2016, 32, 510–518. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Schneider, J.; Begand, S.; Kriegel, R.; Kaps, C.; Glien, W.; Oberbach, T. Low-temperature aging behavior of alumina-toughened zirconia. J. Am. Ceram. Soc. 2008, 91, 3613–3618. [Google Scholar] [CrossRef]

- Chevalier, J.; Grandjean, S.; Kuntz, M.; Pezzotti, G. On the kinetics and impact of tetragonal to monoclinic transformation in an alumina/zirconia composite for arthroplasty applications. Biomaterials 2009, 30, 5279–5282. [Google Scholar] [CrossRef]

- Deville, S.; Chevalier, J.; Fantozzi, G.; Bartolomé, J.F.; Requena, J.; Moya, J.S.; Torrecillas, R.; Díaz, L.A. Low-temperature ageing of zirconia-toughened alumina ceramics and its implication in biomedical implants. J. Eur. Ceram. Soc. 2003, 23, 2975–2982. [Google Scholar] [CrossRef] [Green Version]

- Fabbri, P.; Piconi, C.; Burresi, E.; Magnani, G.; Mazzanti, F.; Mingazzini, C. Lifetime estimation of a zirconia-alumina composite for biomedical applications. Dent. Mater. 2014, 30, 138–142. [Google Scholar] [CrossRef]

- Lughi, V.; Sergo, V. Low temperature degradation -aging- of zirconia: A critical review of the relevant aspects in dentistry. Dent. Mater. 2010, 26, 807–820. [Google Scholar] [CrossRef] [PubMed]

- Deville, S.; Chevalier, J.; Dauvergne, C.; Fantozzi, G.; Bartolomé, J.F.; Moya, J.S.; Torrecillas, R. Microstructural investigation of the aging behavior of (3Y-TZP)–Al2O3 composites. J. Am. Ceram. Soc. 2005, 88, 1273–1280. [Google Scholar] [CrossRef] [Green Version]

- Tsubakino, H.; Nozato, R.; Hamamoto, M. Effect of alumina addition on the tetragonal-to-monoclinic phase transformation in zirconia–3 mol% yttria. J. Am. Ceram. Soc. 1991, 74, 440–443. [Google Scholar] [CrossRef]

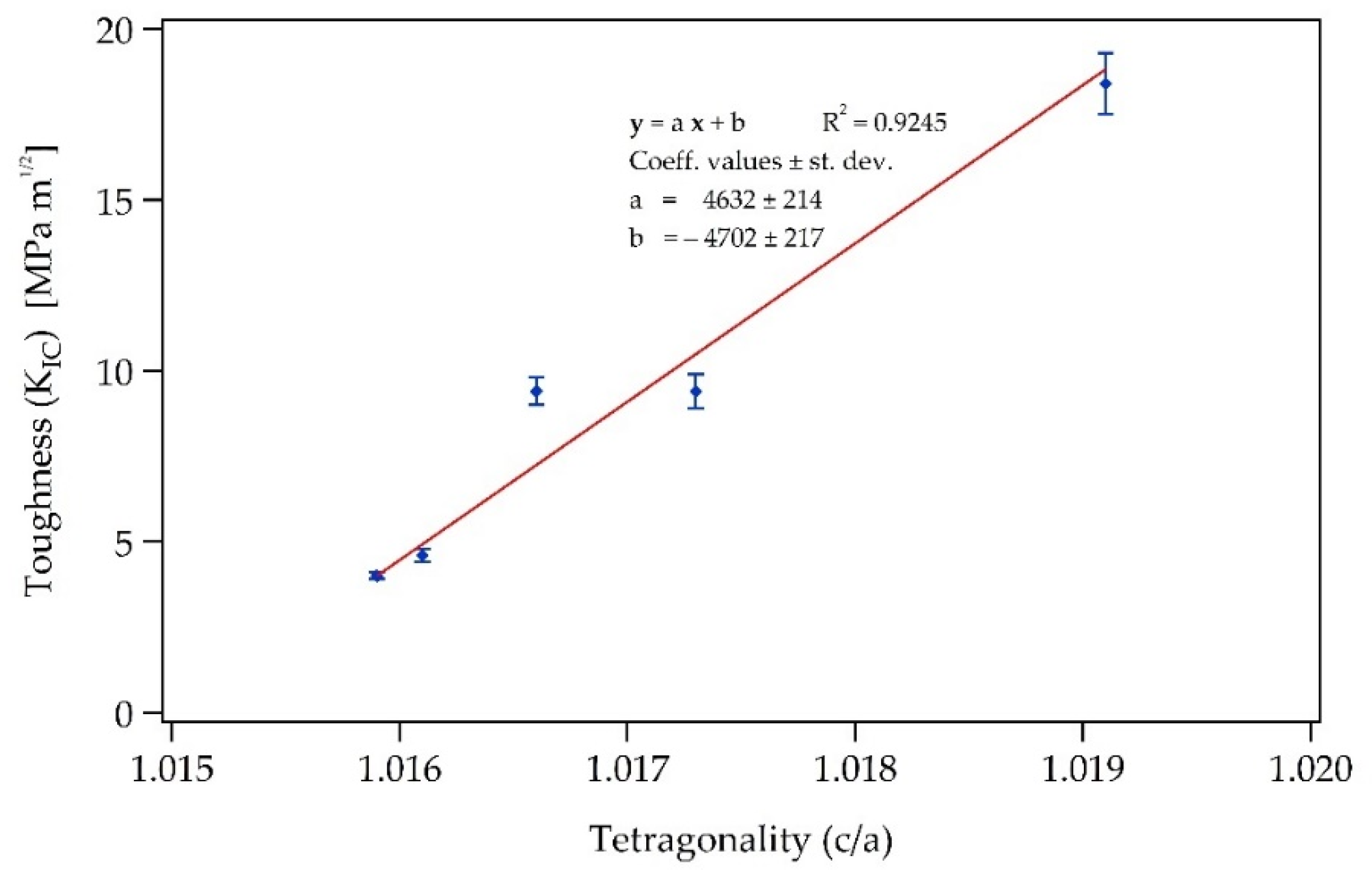

- Tolkachev, O.S.; Dvilis, E.S.; Alishin, T.R.; Khasanov, O.L.; Miheev, D.A.; Chzhan, T. Assessment of the hydrothermal resistance of Y-TZP ceramics by the degree of tetragonality of major phases. Lett. Mater. 2020, 10, 416–421. [Google Scholar] [CrossRef]

- Zhang, F.; Vanmeensel, K.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Van Meerbeek, B.; Naert, I.; Vleugels, J. Critical influence of alumina content on the low temperature degradation of 2–3 mol% yttria-stabilized TZP for dental restorations. J. Eur. Ceram. Soc. 2015, 35, 741–750. [Google Scholar] [CrossRef]

- Kohorst, P.; Borchers, L.; Strempel, J.; Stiesch, M.; Hassel, T.; Bach, F.W.; Hübsch, C. Low-temperature degradation of different zirconia ceramics for dental applications. Acta Biomater. 2012, 8, 1213–1220. [Google Scholar] [CrossRef]

- Nogiwa-Valdez, A.A.; Rainforth, W.M.; Zeng, P.; Ross, I.M. Deceleration of hydrothermal degradation of 3Y-TZP by alumina and lanthana co-doping. Acta Biomater. 2013, 9, 6226–6235. [Google Scholar] [CrossRef]

- Zhang, F.; Vanmeensel, K.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Van Meerbeek, B.; Naert, I.; Vleugels, J. 3Y-TZP ceramics with improved hydrothermal degradation resistance and fracture toughness. J. Eur. Ceram. Soc. 2014, 34, 2453–2463. [Google Scholar] [CrossRef]

- Gremillard, L.; Chevalier, J.; Epicier, T.; Deville, S.; Fantozzi, G. Modeling the aging kinetics of zirconia ceramics. J. Eur. Ceram. Soc. 2004, 24, 3483–3489. [Google Scholar] [CrossRef] [Green Version]

- Hallmann, L.; Mehl, A.; Ulmer, P.; Reusser, E.; Stadler, J.; Ha, C.H.F.; Zenobi, R.; Stawarczyk, B.; Mutlu, O. The influence of grain size on low-temperature degradation of dental zirconia. J. Biomed. Mater. Res. B Appl. Biomater. 2012, 100, 447–456. [Google Scholar] [CrossRef]

- Lange, F.F. Transformation toughening: Part 3 Experimental observations in the ZrO2-Y2O3 system. J. Mater. Sci. 1982, 17, 240–246. [Google Scholar] [CrossRef]

- Becher, P.F.; Swain, M. V Grain-size-dependent transformation behavior in polycrystalline tetragonal zirconia. J. Am. Ceram. Soc. 1992, 75, 493–502. [Google Scholar] [CrossRef]

- Suresh, A.; Mayo, M.J.; Porter, W.D.; Rawn, C.J. Crystallite and grain-size-dependent phase transformations in yttria-doped zirconia. J. Am. Ceram. Soc. 2003, 86, 360–362. [Google Scholar] [CrossRef]

- Bravo-Leon, A.; Morikawa, Y.; Kawahara, M. Fracture toughness of nanocrystalline tetragonal zirconia with low yttria content. Acta Mater. 2002, 50, 4555–4562. [Google Scholar] [CrossRef]

- Eichler, J.; Rödel, J.; Eisele, U.; Hoffman, M. Effect of Grain size on mechanical properties of submicrometer 3Y-TZP: Fracture strength and hydrothermal degradation. J. Am. Ceram. Soc. 2007, 90, 2830–2836. [Google Scholar] [CrossRef]

- SmarTech Markets Publishing. Ceramics Additive Manufacturing Markets 2017–2028. An Opportunity Analysis and Ten-Year Market Forecast; SmarTech Analysis: Crozet, VA, USA, 2018; Available online: https://www.smartechanalysis.com (accessed on 10 September 2020).

- SmarTech Analysis. Ceramics Additive Manufacturing Production Markets: 2019–2030; SmarTech Analysis: Crozet, VA, USA, 2020; Available online: http://www.smartechanalysis.com (accessed on 10 September 2020).

- Sun, Y.; Wang, C.; Zhao, Z. ZTA Ceramic materials for DLP 3D printing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 678, 012020. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; Lin, L.; Li, L.; Li, Y.; Tian, Z.; Zhao, Z.; Ji, X.; Xie, Z.; Wu, S. Preparation of alumina-toughened zirconia via 3D printing and liquid precursor infiltration: Manipulation of the microstructure, the mechanical properties and the low temperature aging behavior. J. Mater. Sci. 2019, 54, 7447–7459. [Google Scholar] [CrossRef]

- Coppola, B.; Lacondemine, T.; Tardivat, C.; Montanaro, L.; Palmero, P. Designing alumina-zirconia composites by DLP-based stereolithography: Microstructural tailoring and mechanical performances. Ceram. Int. 2021, 47, 13457–13468. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: A state-of-the-art review. J. Mater. Res. Technol. 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Zhang, J.; Duan, Y.; Bai, H.; Li, J.; Jiang, D. Dispersion and properties of zirconia suspensions for stereolithography. Int. J. Appl. Ceram. Technol. 2020, 17, 239–247. [Google Scholar] [CrossRef] [Green Version]

- de Camargo, I.L.; Morais, M.M.; Fortulan, C.A.; Branciforti, M.C. A review on the rheological behavior and formulations of ceramic suspensions for vat photopolymerization. Ceram. Int. 2021, 47, 11906–11921. [Google Scholar] [CrossRef]

- Niihara, K. A fracture mechanics analysis of indentation-induced Palmqvist crack in ceramics. J. Mater. Sci. Lett. 1983, 2, 221–223. [Google Scholar] [CrossRef]

- Li, P.; Chen, I.-W.; Penner-Hahn, J.E. Effect of dopants on zirconia stabilization–An X-ray absorption study: II, tetravalent dopants. J. Am. Ceram. Soc. 1994, 77, 1281–1288. [Google Scholar] [CrossRef]

- Nisticò, R. Zirconium oxide and the crystallinity hallows. J. Aust. Ceram. Soc. 2021, 57, 225–236. [Google Scholar] [CrossRef]

- Jang, J.W.; Kim, D.J.; Lee, D.Y. Size effect of trivalent oxides on low temperature phase stability of 2Y-TZP. J. Mater. Sci. 2001, 36, 5391–5395. [Google Scholar] [CrossRef]

- Zhang, F.; Batuk, M.; Hadermann, J.; Manfredi, G.; Mariën, A.; Vanmeensel, K.; Inokoshi, M.; Van Meerbeek, B.; Naert, I.; Vleugels, J. Effect of cation dopant radius on the hydrothermal stability of tetragonal zirconia: Grain boundary segregation and oxygen vacancy annihilation. Acta Mater. 2016, 106, 48–58. [Google Scholar] [CrossRef]

- Tien, T.Y. Toughened Ceramics. U.S. Patent U.S. 4,886,768A, 12 December 1987. [Google Scholar]

- Yoshimura, M. Phase stability of zirconia. Am. Ceram. Soc. Bull. 1988, 67, 1950–1955. [Google Scholar]

- Matsui, K.; Horikoshi, H.; Ohmichi, N.; Ohgai, M.; Yoshida, H.; Ikuhara, Y. Cubic-formation and grain-growth mechanisms in tetragonal zirconia polycrystal. J. Am. Ceram. Soc. 2003, 86, 1401–1408. [Google Scholar] [CrossRef]

- Shimozono, T.; Ikeda, J.; Pezzotti, G. Evaluation of transformation zone around propagating cracks in zirconia biomaterials using raman microprobe spectroscopy. In Proceedings of the Bioceramics 18, Kyoto, Japan, 8–12 December 2005; Nakamura, T., Yamashita, K., Neo, M., Eds.; Trans Tech Publications Ltd.: Bäch, Switzerland, 2006; Volume 309–311, pp. 1207–1210. [Google Scholar] [CrossRef]

- Matsumoto, R.L.K. Aging Behavior of Ceria-Stabilized Tetragonal Zirconia Polycrystals. J. Am. Ceram. Soc. 1988, 71, C128–C129. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L. Ceramics for medical applications: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009, 29, 1245–1255. [Google Scholar] [CrossRef]

- Kim, D.-J. Effect of Ta2O5, Nb2O5, and HfO2 alloying on the transformability of Y2O3-stabilized tetragonal ZrO2. J. Am. Ceram. Soc. 1990, 73, 115–120. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.-J.; Tien, T.-Y. Phase Stability and Physical Properties of Cubic and Tetragonal ZrO2 in the System ZrO2-Y2O3-Ta2O5. J. Am. Ceram. Soc. 1991, 74, 3061–3065. [Google Scholar] [CrossRef]

- Ramesh, S.; Gill, C.; Lawson, S. Effect of copper oxide on sintering, microstructure, mechanical properties and hydrothermal ageing of coated 2.5Y-TZP ceramics. J. Mater. Sci. 1999, 34, 5457–5467. [Google Scholar] [CrossRef]

- Magnani, G.; Brillante, A. Effect of the composition and sintering process on mechanical properties and residual stresses in zirconia-alumina composites. J. Eur. Ceram. Soc. 2005, 25, 3383–3392. [Google Scholar] [CrossRef]

- Yoshimura, M.; Yashima, M.; Noma, T.; Sōmiya, S. Formation of diffusionlessly transformed tetragonal phases by rapid quenching of melts in ZrO2-RO1.5 systems (R = rare earths). J. Mater. Sci. 1990, 25, 2011–2016. [Google Scholar] [CrossRef]

- Rice, R.W. Ceramic tensile strength-grain size relations: Grain sizes, slopes, and branch intersections. J. Mater. Sci. 1997, 32, 1673–1692. [Google Scholar] [CrossRef]

- Trunec, M. Effect of grain size on mechanical properties of 3Y-TZP ceramics. Ceram. Silikaty 2008, 52, 165–171. [Google Scholar]

- Casellas, D.; Alcalá, J.; Llanes, L.; Anglada, M. Fracture variability and R-curve behavior in yttria-stabilized zirconia ceramics. J. Mater. Sci. 2001, 36, 3011–3025. [Google Scholar] [CrossRef]

- Chevalier, J.; Liens, A.; Reveron, H.; Zhang, F.; Reynaud, P.; Douillard, T.; Preiss, L.; Sergo, V.; Lughi, V.; Swain, M.; et al. Forty years after the promise of «ceramic steel?»: Zirconia-based composites with a metal-like mechanical behavior. J. Am. Ceram. Soc. 2020, 103, 1482–1513. [Google Scholar] [CrossRef]

- Sadowski, T.; Łosiewicz, K.; Boniecki, M.; Szutkowska, M. Assessment of mechanical properties by nano- and microindentation of alumina/zirconia composites. Mater. Today Proc. 2021, 45, 4196–4201. [Google Scholar] [CrossRef]

- Krell, A. Load dependence of hardness in sintered submicrometer Al2O3 and ZrO2. J. Am. Ceram. Soc. 1995, 78, 1417–1419. [Google Scholar] [CrossRef]

- Chintapalli, R.; Mestra, A.; García Marro, F.; Yan, H.; Reece, M.; Anglada, M. Stability of nanocrystalline spark plasma sintered 3Y-TZP. Materials 2010, 3, 800–814. [Google Scholar] [CrossRef] [Green Version]

- Yao, W.; Liu, J.; Holland, T.B.; Huang, L.; Xiong, Y.; Schoenung, J.M.; Mukherjee, A.K. Grain size dependence of fracture toughness for fine grained alumina. Scr. Mater. 2011, 65, 143–146. [Google Scholar] [CrossRef]

- Borrell, A.; Salvador, M.D.; Peñaranda-Foix, F.L.; Cátala-Civera, J.M. Microwave sintering of zirconia materials: Mechanical and microstructural properties. Int. J. Appl. Ceram. Technol. 2013, 10, 313–320. [Google Scholar] [CrossRef]

- Chen, I.-W.; Wang, X.-H. Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 2000, 404, 168–171. [Google Scholar] [CrossRef]

- Loong, T.H.; Soosai, A.; Muniandy, S. Effect of temperature and holding time on zirconia toughened alumina (ZTA) prepared by two-stage sintering. Mater. Sci. Forum 2021, 1030, 11–18. [Google Scholar] [CrossRef]

- Sivanesan, S.; Loong, T.H.; Namasivayam, S.; Fouladi, M.H. Two-stage sintering of alumina-Y-TZP (Al2O3/Y-TZP) composites. Key Eng. Mater. 2019, 814, 12–18. [Google Scholar] [CrossRef]

- Xiong, Y.; Hu, J.; Shen, Z. Dynamic pore coalescence in nanoceramic consolidated by two-step sintering procedure. J. Eur. Ceram. Soc. 2013, 33, 2087–2092. [Google Scholar] [CrossRef]

- Bergstrom, L. Colloidal Processing of Ceramics. In Handbook of Applied Surface and Colloid Chemistry; Holmberg, K., Ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2001; Volume 1, pp. 201–218. [Google Scholar]

| Samples | ZrO2-3Y (wt%) | ZrO2-TZ0 (wt%) | Ta2O5 (wt%) | CeO2 (wt%) | CuO (wt%) | Al2O3 (wt%) | Cr2O3 (wt%) |

|---|---|---|---|---|---|---|---|

| Zr3Y | 100 | - | - | - | - | - | - |

| Zr2Y | 67.2 | 32.8 | - | - | - | - | - |

| Zr3YTa | 99.85 | - | 0.15 | - | - | - | - |

| ZrCe | - | 84 | - | 16 | - | - | - |

| Zr3YCu | 99.9 | - | - | - | 0.1 | - | - |

| 20803Y | 80 | - | - | - | - | 20 | - |

| 50502Y | 33.42 | 16.32 | - | - | - | 50 | - |

| 50502.5Y | 41.8 | 8.2 | - | - | - | 50 | - |

| 50503Y | 50 | - | - | - | - | 50 | - |

| 60402Y | 26.8 | 13.08 | - | - | - | 59.52 | 0.60 |

| 60403Y | 39.88 | - | - | - | - | 59.52 | 0.60 |

| Samples | DR (%) | Tetragonal ph. (vol%) | Monoclinic ph. (vol%) | c/a | KIC (MPa m1/2) | HV (GPa) |

|---|---|---|---|---|---|---|

| ZrCe | 98 | 100 | - | 1.0191 | 18.4 ± 0.9 | 8.7 ± 0.2 |

| Zr2Y | 98 | 83 | 17 | 1.0166 | 9.4 ± 0.4 | 12.5 ± 0.5 |

| Zr3Y | 99 | 100 | - | 1.0159 | 4.0 ± 0.1 | 11.0 ± 0.3 |

| Zr3YTa | 99 | 100 | - | 1.0173 | 9.4 ± 0.5 | 12.7 ± 0.4 |

| Zr3YCu | 98 | 100 | - | 1.0161 | 4.6 ± 0.2 | 12.5 ± 0.4 |

| Samples | DR (%) | c/a | Tetragonal ph. (vol%) | Cubic ph. (vol%) | Monoclinic ph. (vol%) | KIC (MPa m1/2) | HV (GPa) | MOR (MPa) |

|---|---|---|---|---|---|---|---|---|

| 60403Y | 99.9 | 1.0168 | 76.3 | 23.7 | 0 | 5.1 ± 0.3 | 17.7 ± 0.3 | 660 ± 23 |

| 60402Y | 98.8 | 1.0169 | 98.0 | 0 | 2 | 6.2 ± 0.2 | 18.0 ± 0.3 | 794 ± 98 |

| 50503Y 1 | 99.3 | 1.0165 | 98.7 | 1.3 | 0 | 6.0 ± 0.1 | 14.9 ± 0.5 | - |

| 50502.5Y 1 | 99.9 | 1.0170 | 94.6 | 5.4 | 0 | 5.6 ± 0.2 | 15.7 ± 0.3 | - |

| 50502Y 1 | 99.2 | 1.0175 | 100 | 0 | 0 | 8.1 ± 0.1 | 15.4 ± 0.2 | - |

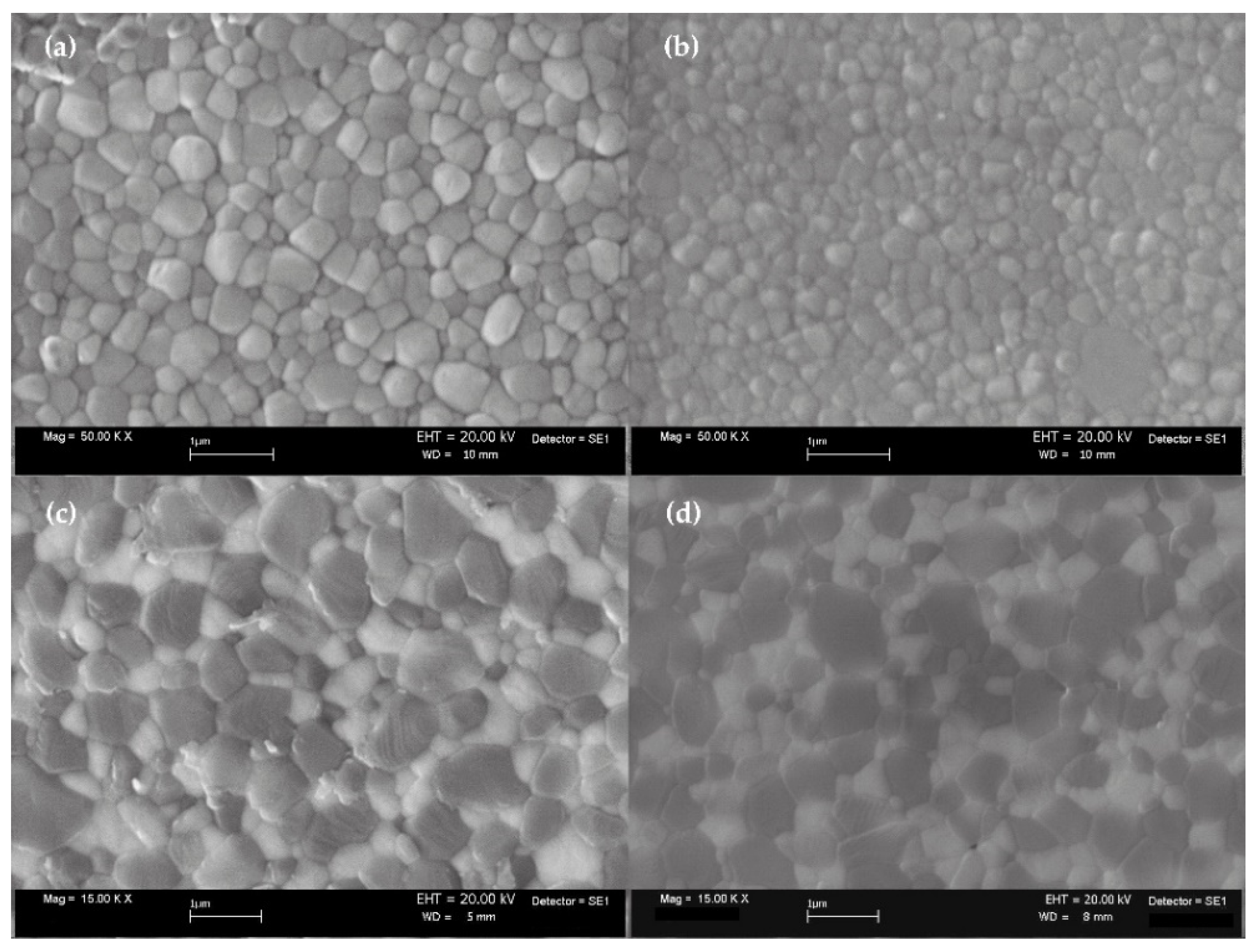

| Thermal Cycle | DR (%) | Dm (µm) | c/a | KIC (MPa m1/2) | HV (GPa) |

|---|---|---|---|---|---|

| 1500 °C—2 h | 98.9 | 0.53 | 1.0159 | 5.0 ± 0.1 | 11.0 ± 0.2 |

| 1550 °C—20 h | 99.9 | 0.78 | 1.0164 | 5.3 ± 0.1 | 12.1 ± 0.2 |

| 1550 °C—30 h | 99.6 | 0.87 | 1.0165 | 5.4 ± 0.1 | 11.5 ± 0.2 |

| 1550 °C—40 h | 99.9 | 0.95 | 1.0165 | 6.6 ± 0.2 | 11.9 ± 0.2 |

| 1550 °C—60 h | 99.6 | 1.19 | 1.0167 | 7.7 ± 0.1 | 11.0 ± 0.2 |

| 1550 °C—80 h | 95.8 | - | 1.0162 | - | - |

| Samples | Thermal Cycle | DR (%) | Dm A/Z (µm) | c/a | KIC (MPa m1/2) | HV (GPa) | MOR (MPa) |

|---|---|---|---|---|---|---|---|

| 3Y-TZP SSS | 1500 °C—1 h | 99.7 | 0.33 | 1.0154 | 5.0 ± 0.1 | 13.3 ± 0.3 | 1095 ± 75 |

| 3Y-TZP TSS | 1400/1350 °C—30 h | 99.8 | 0.18 | 1.0157 | 4.9 ± 0.1 | 13.4 ± 0.2 | 1102 ± 85 |

| 60402Y SSS | 1550 °C—1 h | 98.8 | 0.71/0.44 | 1.0169 | 6.2 ± 0.2 | 18.0 ± 0.3 | 794 ± 98 |

| 60402Y TSS | 1500/1450 °C—30 h | 98.6 | 0.58/0.35 | - | 5.5 ± 0.3 | 16.1 ± 0.4 | 660 ± 89 |

| 60402Y TSS FD | 1500/1450 °C—30 h | 98.7 | 0.59/0.34 | - | - | - | 872 ± 47 |

| 60403Y SSS | 1550 °C—1 h | 99.9 | 0.70/0.43 | 1.0168 | 5.1 ± 0.3 | 17.7 ± 0.3 | 660 ± 23 |

| 60403Y TSS | 1500/1450 °C—30 h | 99.8 | 0.58/0.36 | - | 4.8 ± 0.2 | 16.0 ± 0.2 | 700 ± 57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magnani, G.; Fabbri, P.; Leoni, E.; Salernitano, E.; Mazzanti, F. New Perspectives on Zirconia Composites as Biomaterials. J. Compos. Sci. 2021, 5, 244. https://doi.org/10.3390/jcs5090244

Magnani G, Fabbri P, Leoni E, Salernitano E, Mazzanti F. New Perspectives on Zirconia Composites as Biomaterials. Journal of Composites Science. 2021; 5(9):244. https://doi.org/10.3390/jcs5090244

Chicago/Turabian StyleMagnani, Giuseppe, Paride Fabbri, Enrico Leoni, Elena Salernitano, and Francesca Mazzanti. 2021. "New Perspectives on Zirconia Composites as Biomaterials" Journal of Composites Science 5, no. 9: 244. https://doi.org/10.3390/jcs5090244

APA StyleMagnani, G., Fabbri, P., Leoni, E., Salernitano, E., & Mazzanti, F. (2021). New Perspectives on Zirconia Composites as Biomaterials. Journal of Composites Science, 5(9), 244. https://doi.org/10.3390/jcs5090244