Static Fatigue of SiC/SiC Minicomposites at High Temperatures Up to 1200 °C in Air: Multiscale Approach

Abstract

:1. Introduction

2. Theory: Static Fatigue of Filaments and Tows. The Concept of Critical Filament

2.1. Static Fatigue of Single Filaments under Constant Stress

2.2. Lifetime of Fiber Tows under Constant Force

2.2.1. Equal Load Sharing

2.2.2. Local Load Sharing

3. Experimental Procedure

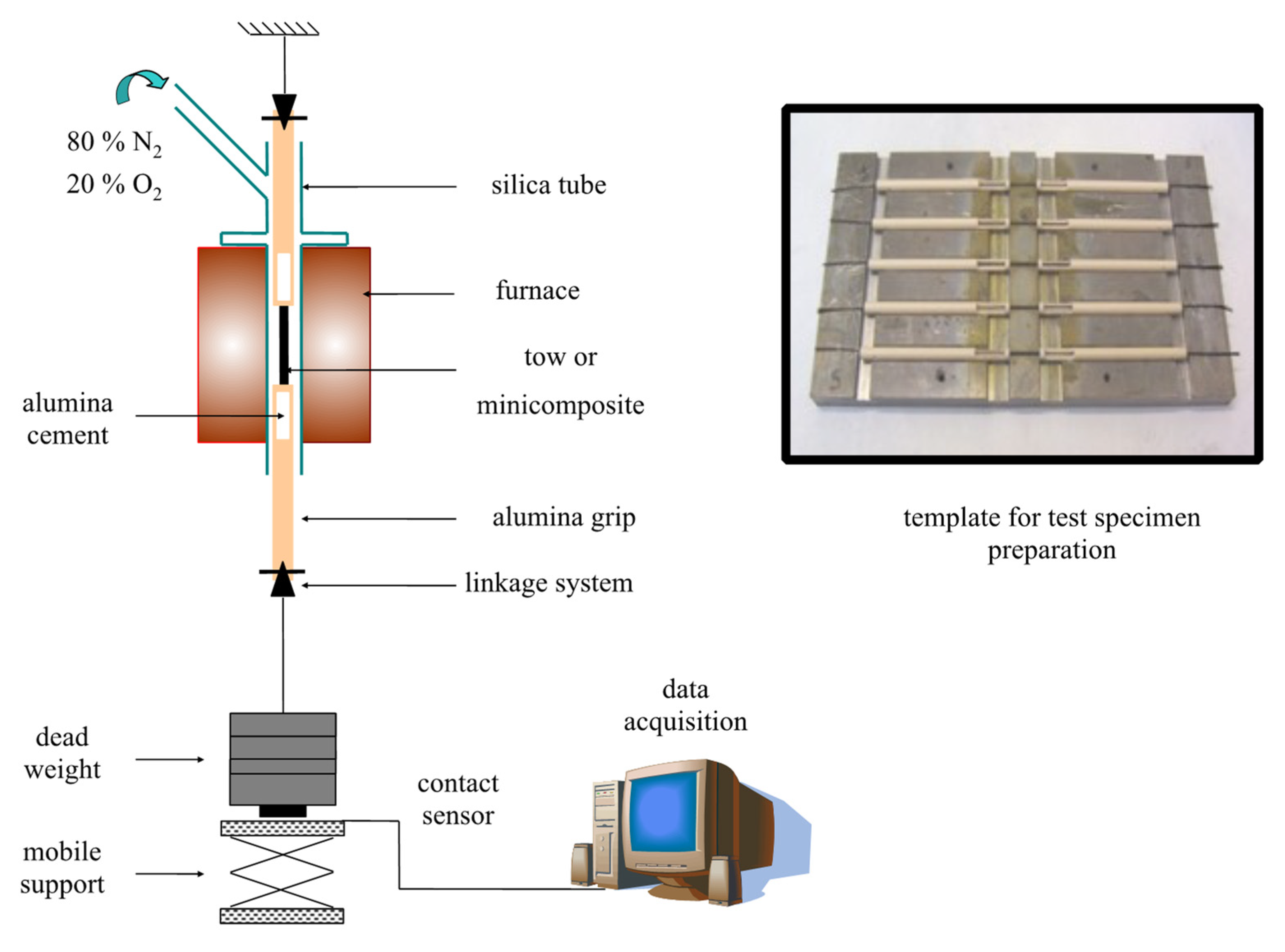

3.1. Static Fatigue Tests on Minicomposites

3.2. Tensile Behavior of Minicomposites at Room Temperature

4. Results

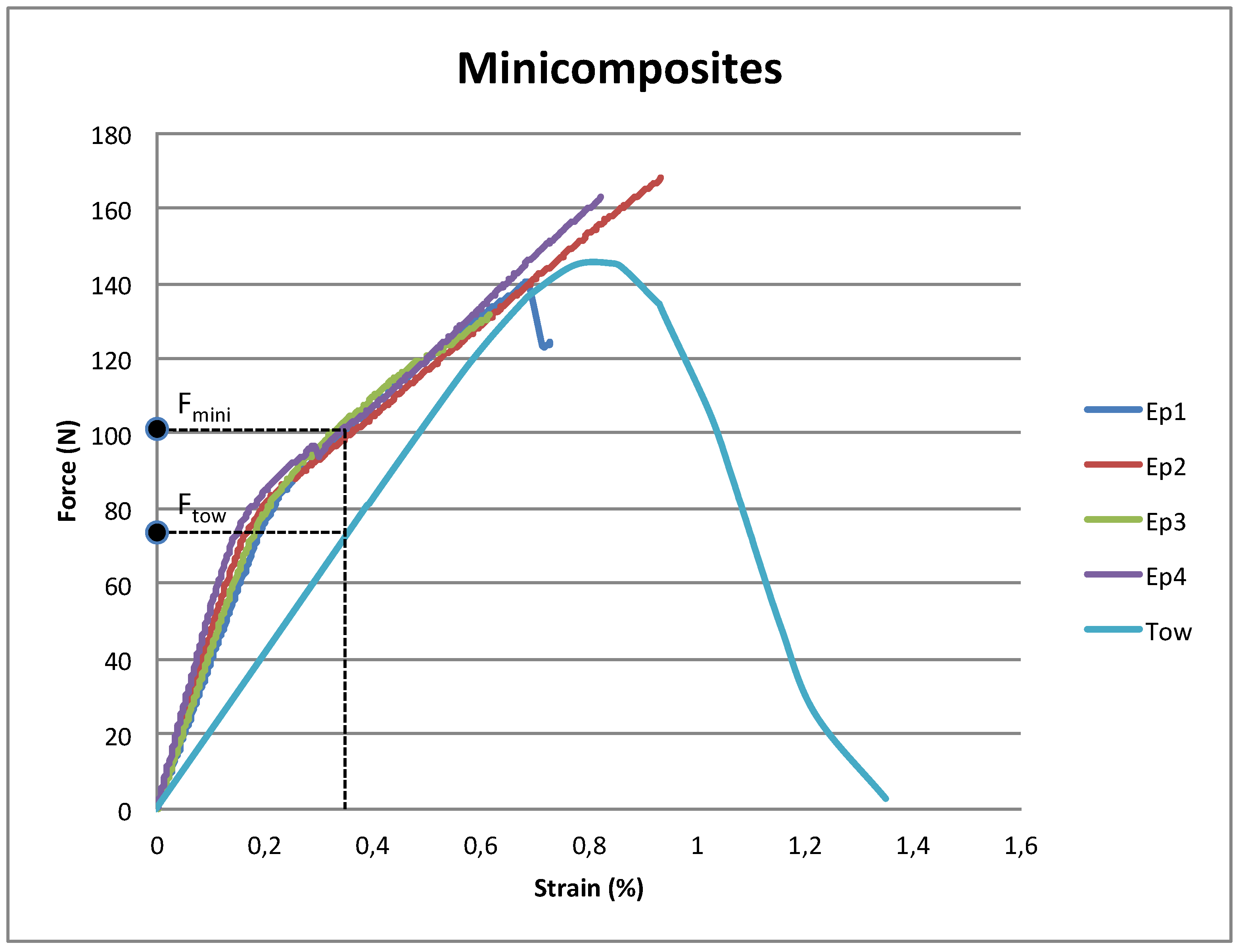

4.1. Tensile Behavior of Tows and Minicomposites

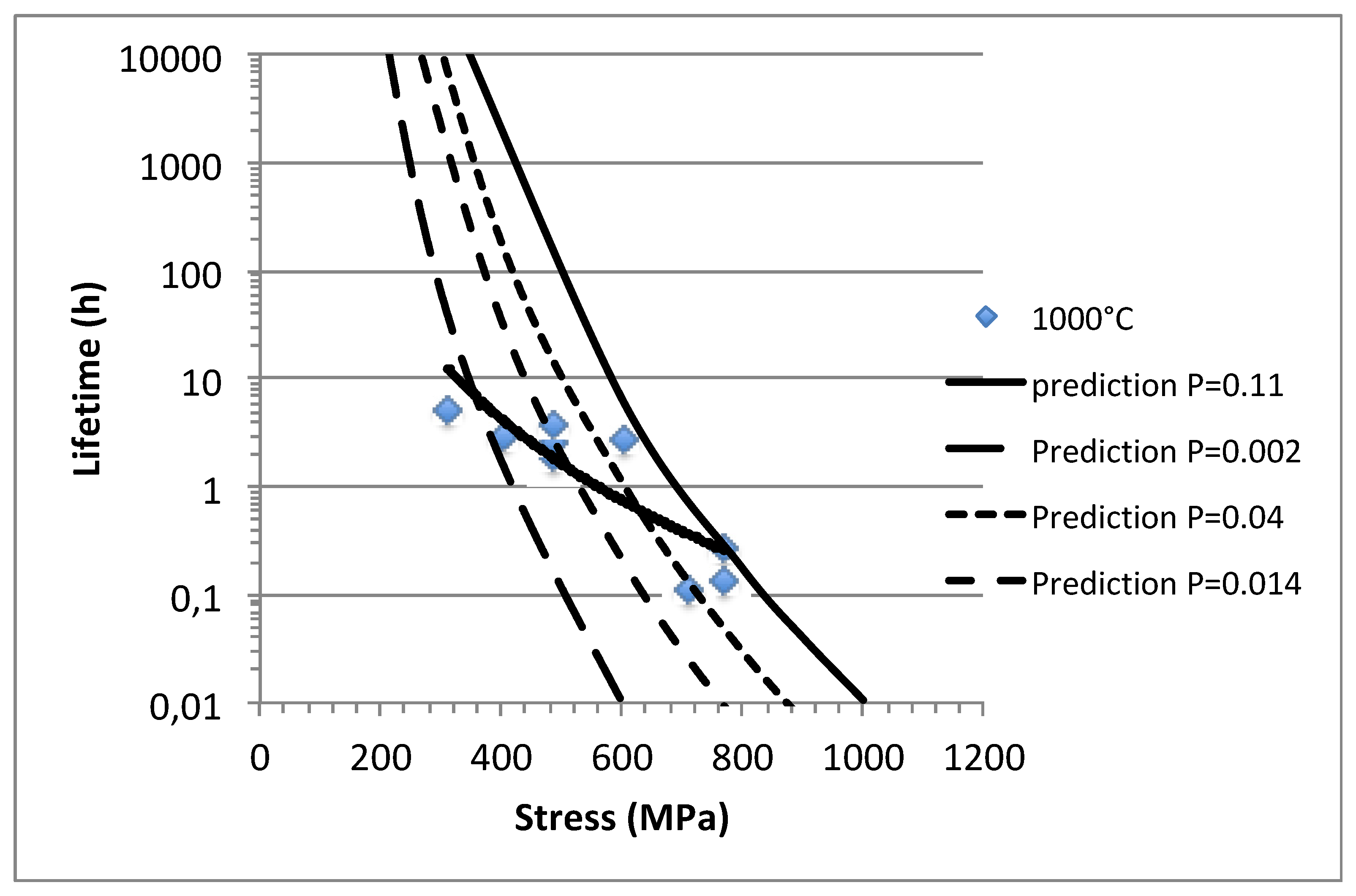

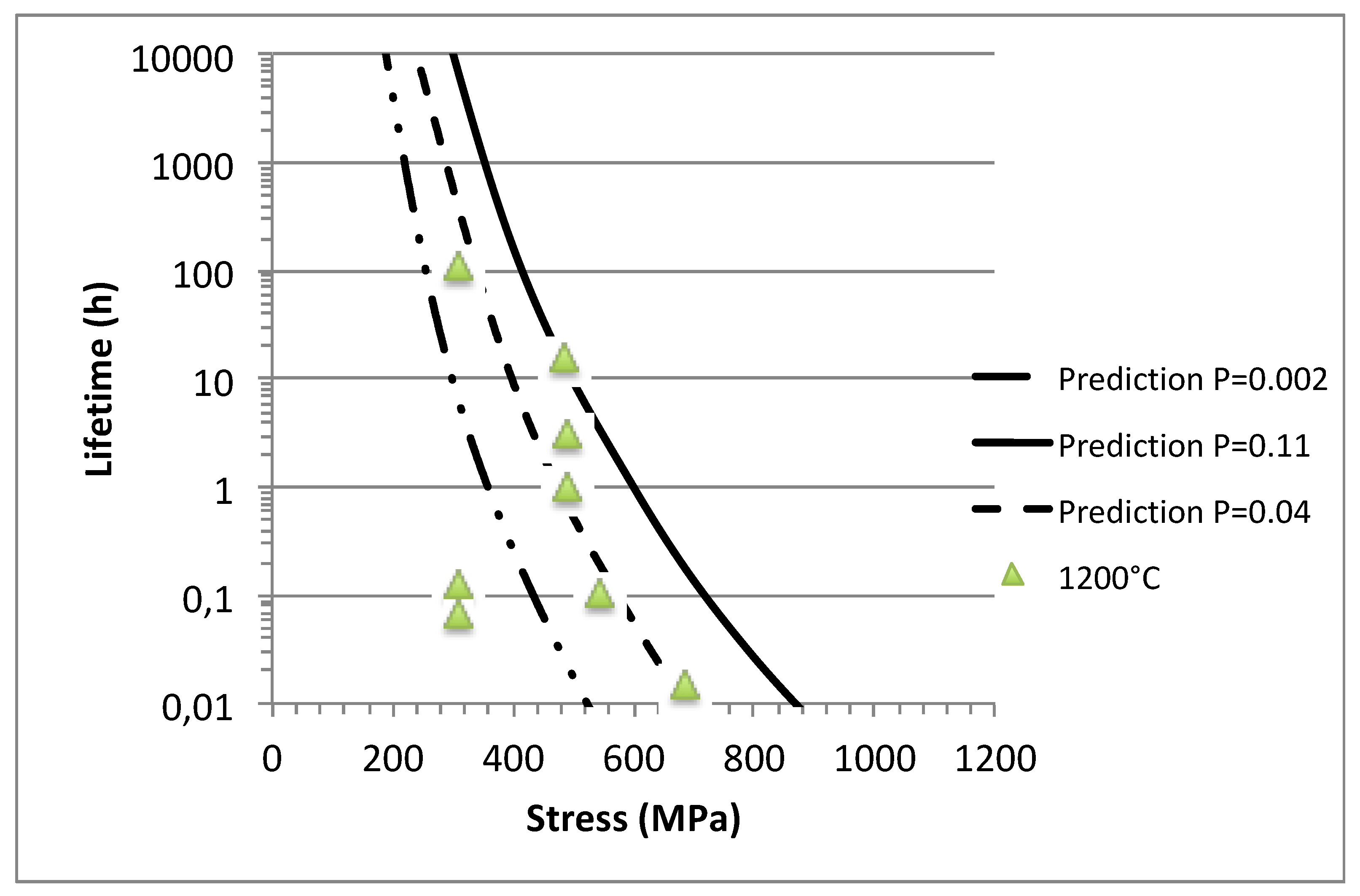

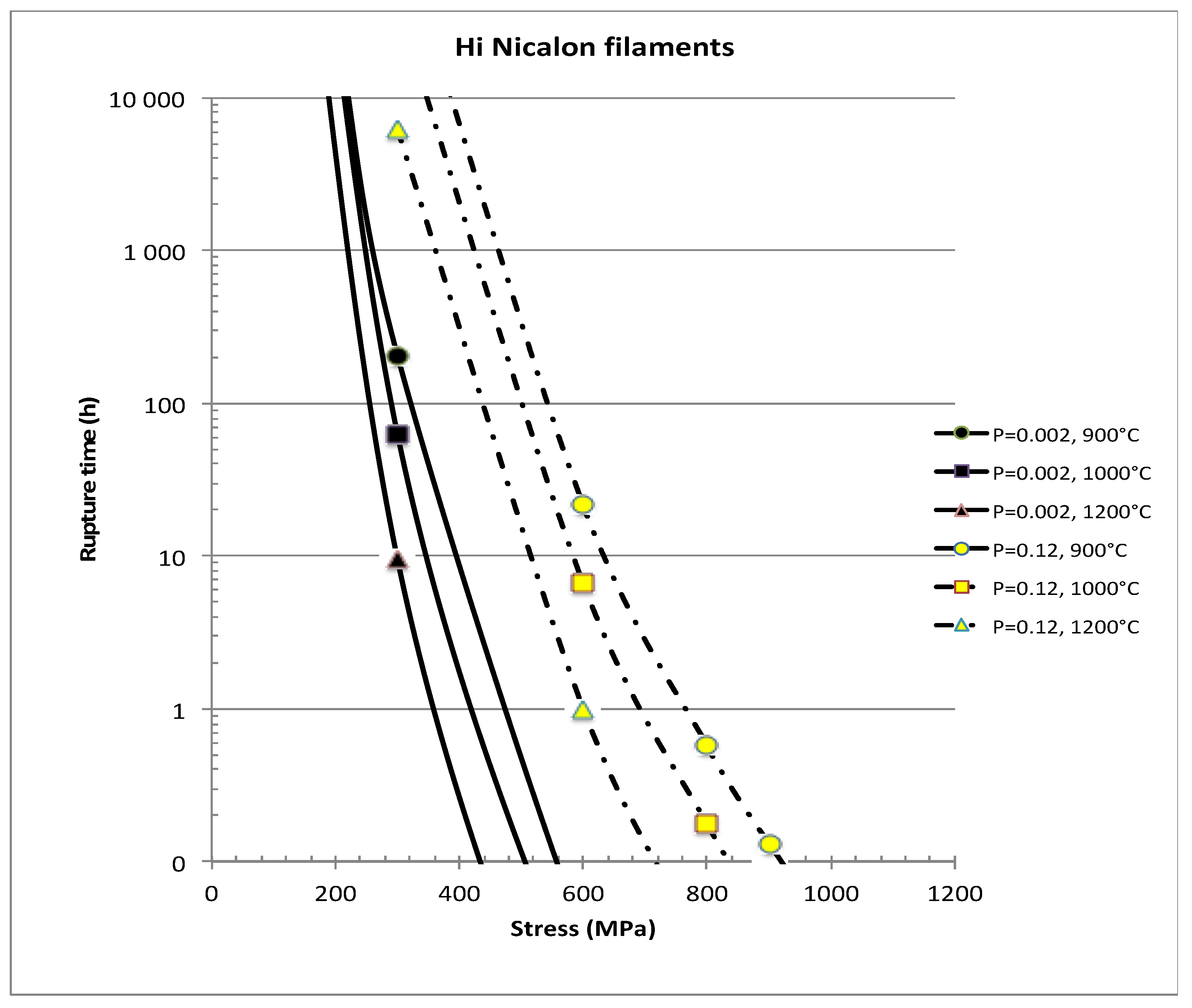

4.2. Stress–Rupture Time Diagrams of Minicomposites

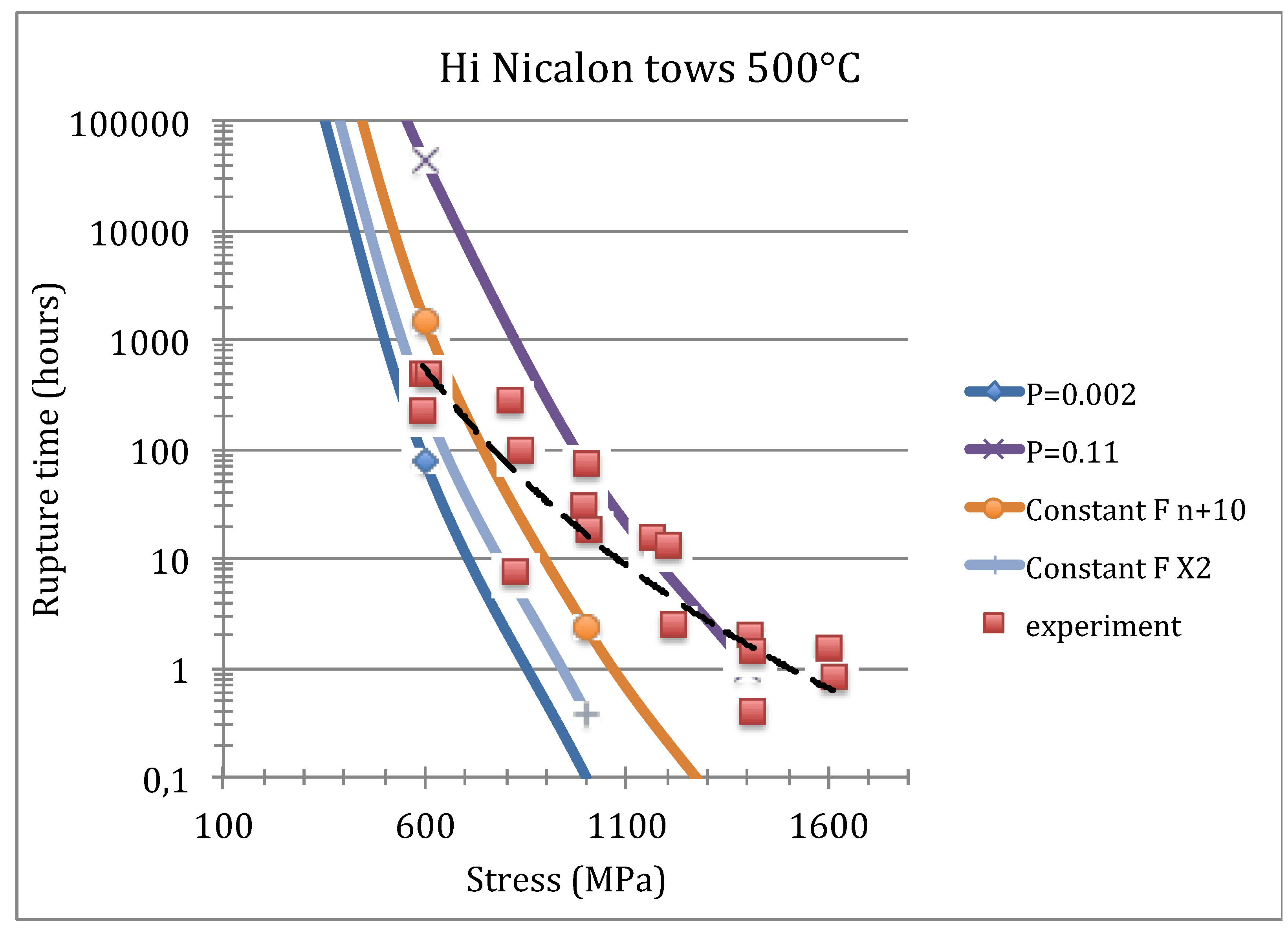

4.3. Comparison with Dry Tows

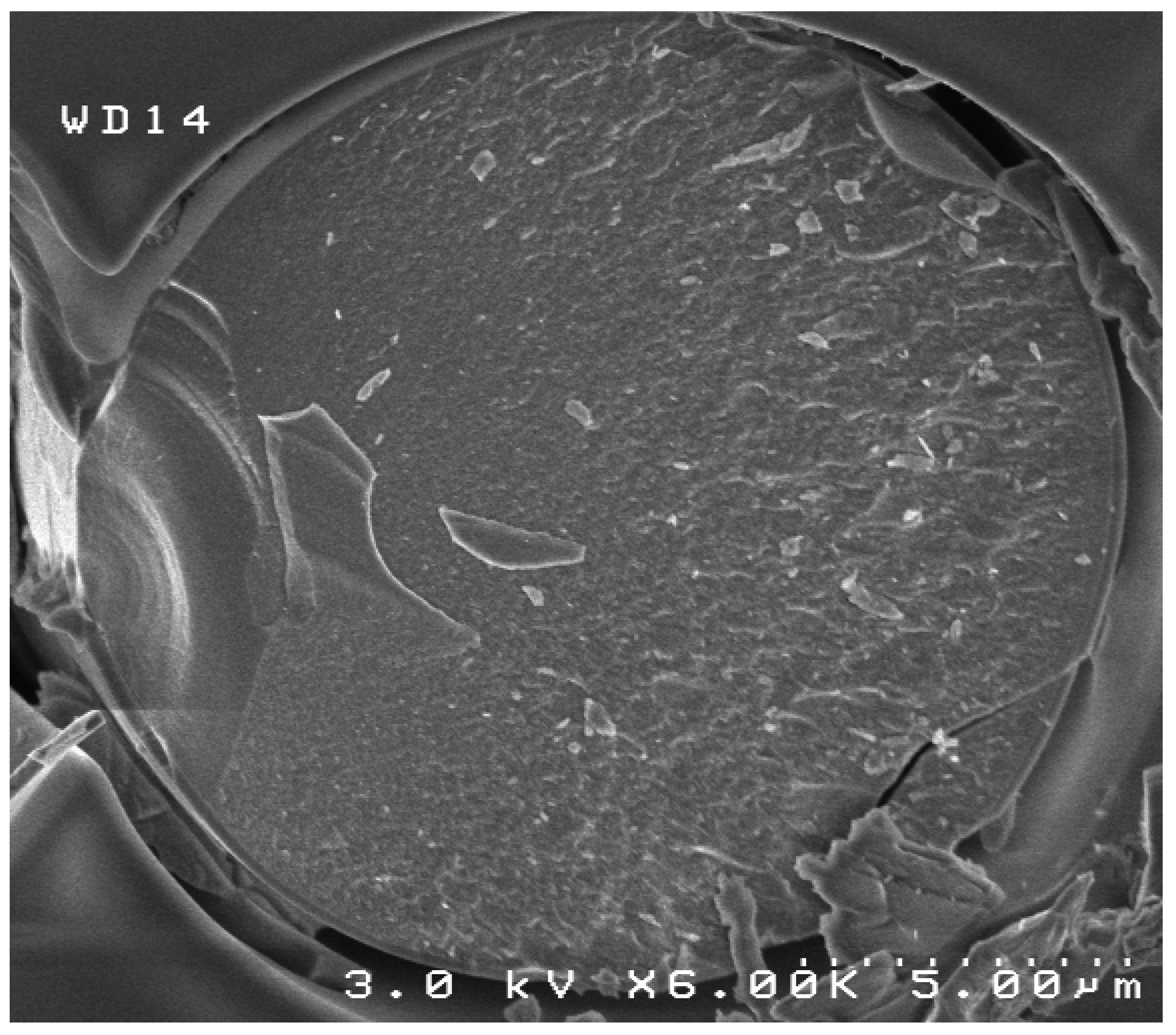

4.4. SEM Inspection of Minicomposites after Failure

- -

- -

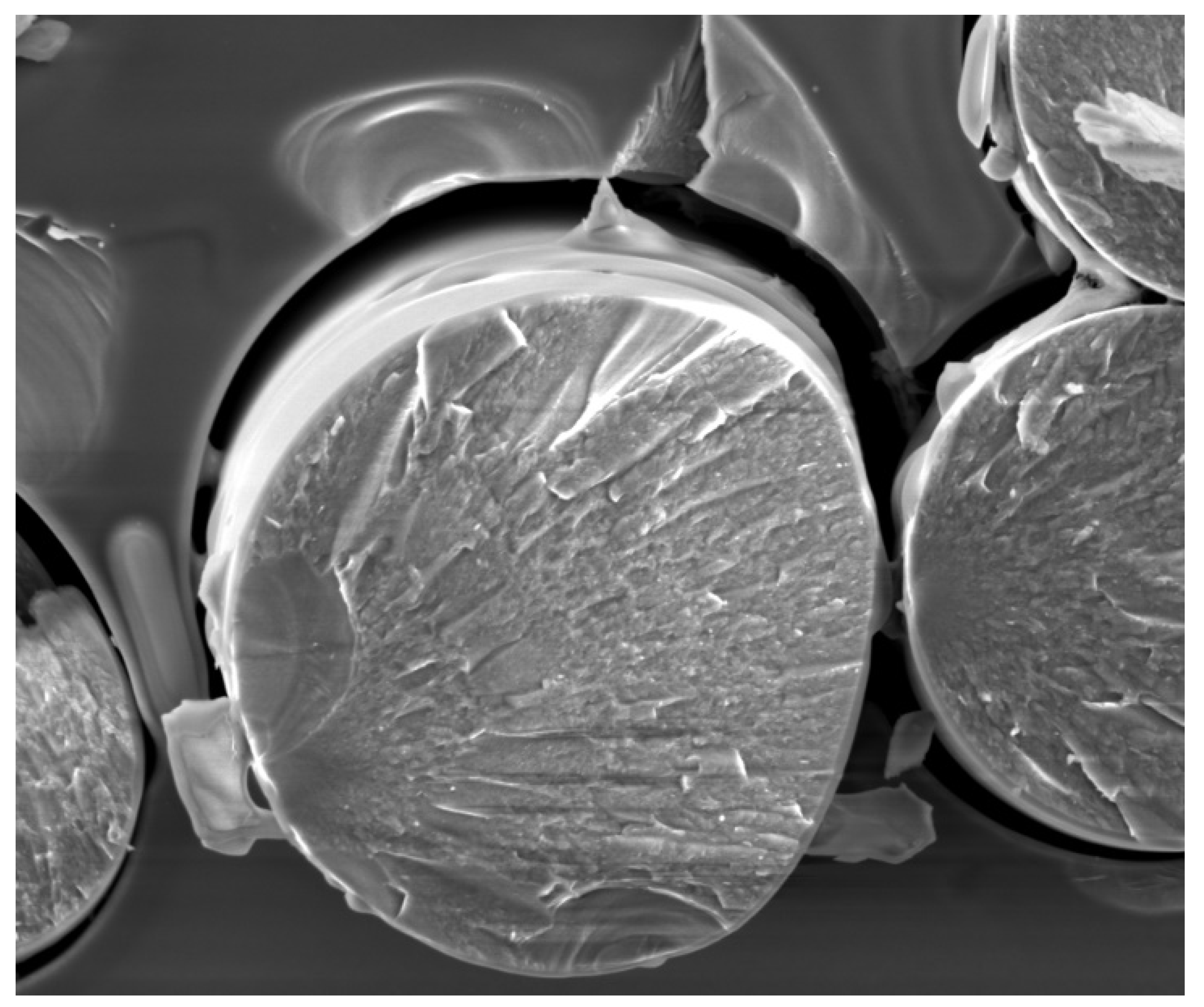

- Mirrors on the fractured surface of some filaments that are indicative of catastrophic fracture from flaws inherent in the filaments. From this it can be inferred that the stress operating on the filaments was sufficiently high, and much higher than the stress applied during the fatigue test (Figure 11).

- -

- Smooth filament fracture surfaces indicative of catastrophic fracture initiated outside the fiber (Figure 12).

- -

- -

- -

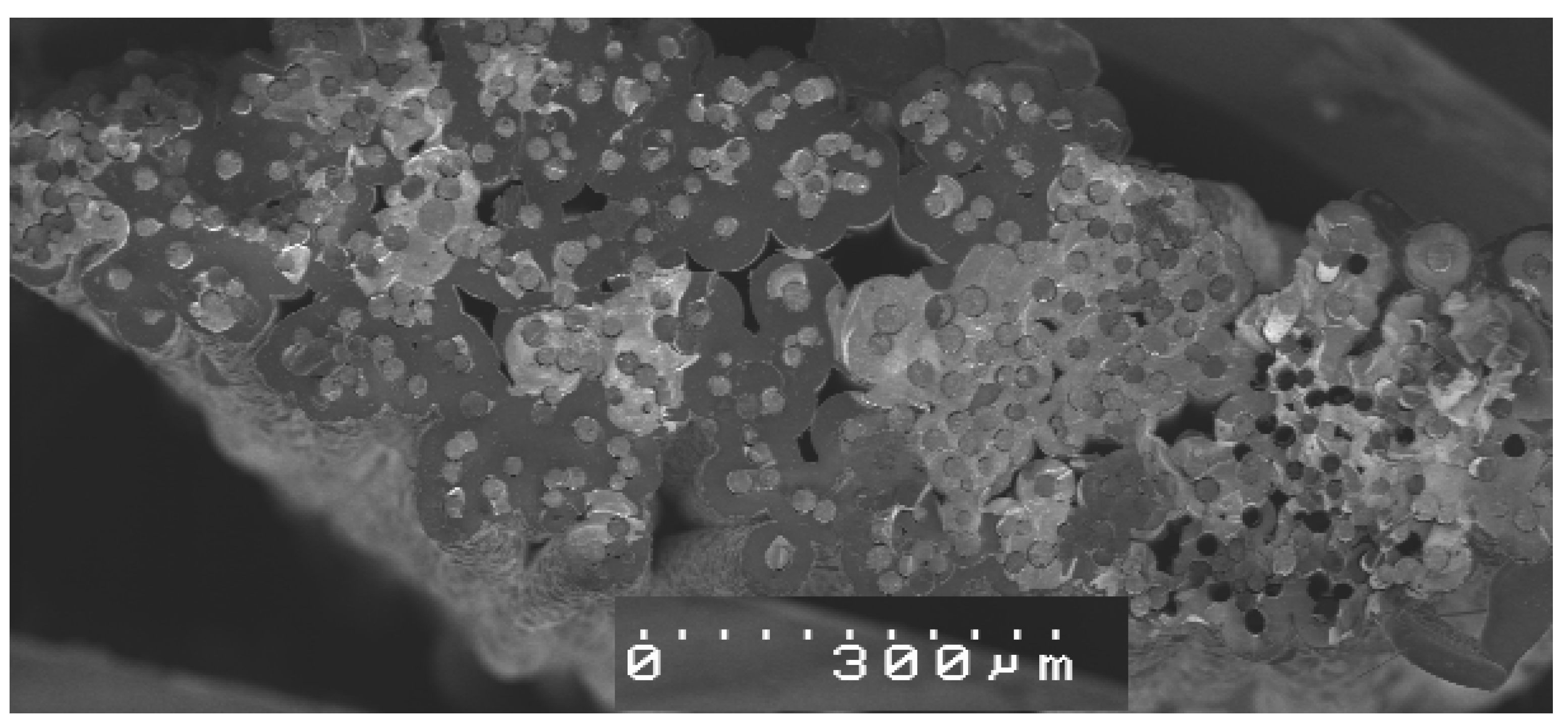

- Oxide filling some fiber–matrix interfaces in place of the initial PyC interphase (Figure 13), or coating the filament and the matrix after tests at 1200 °C (Figure 13). The oxide layers at interface depended on the location of the filament within the minicomposite. The minicomposites tested at 1200 °C contained both debonded fibers, which are visible in Figure 14 as pulled out filaments, and filaments bonded to the matrix by oxide (Figure 13 and Figure 14).

4.5. Fracture Mechanism of Minicomposites

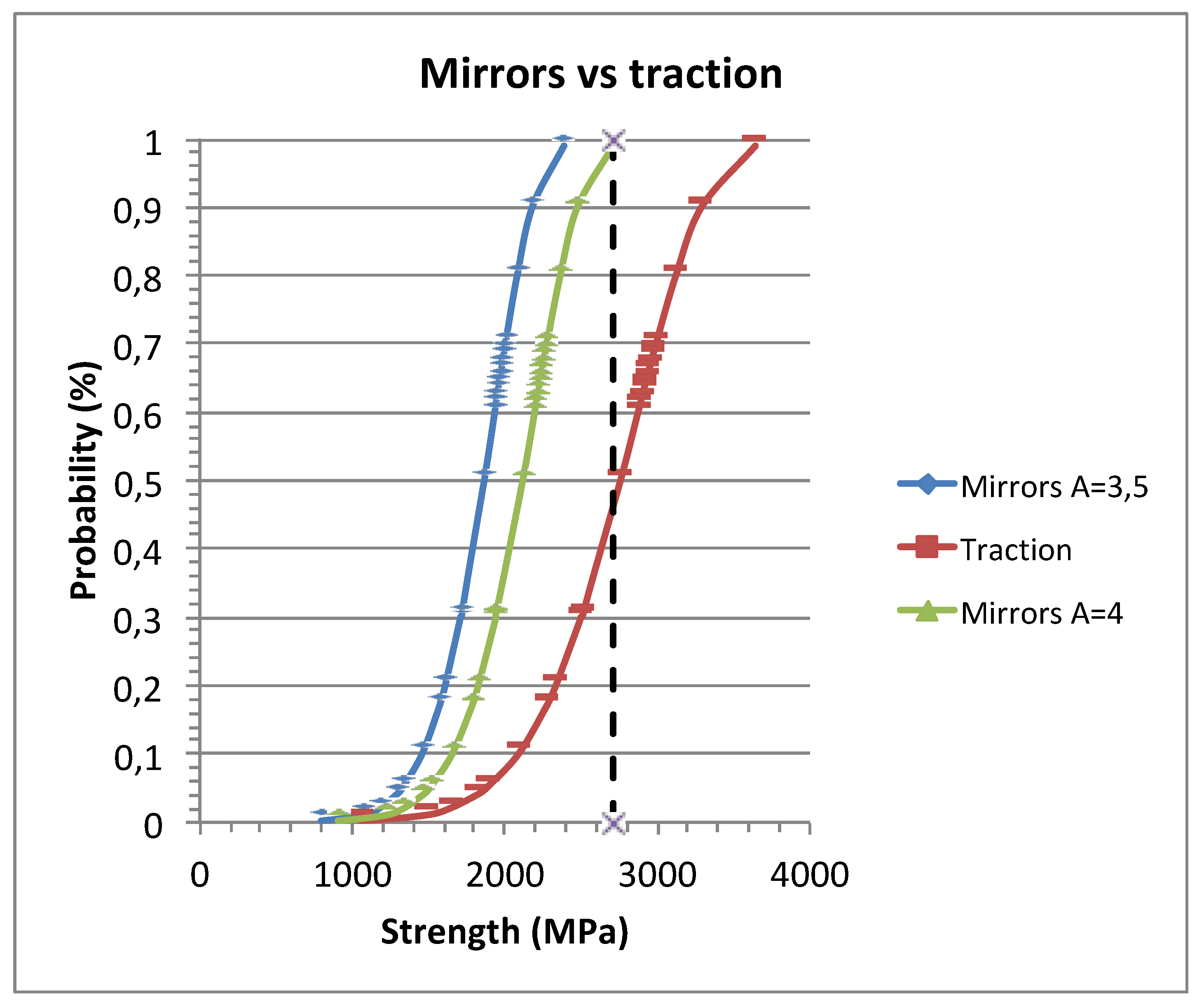

4.5.1. Fracture Mirrors

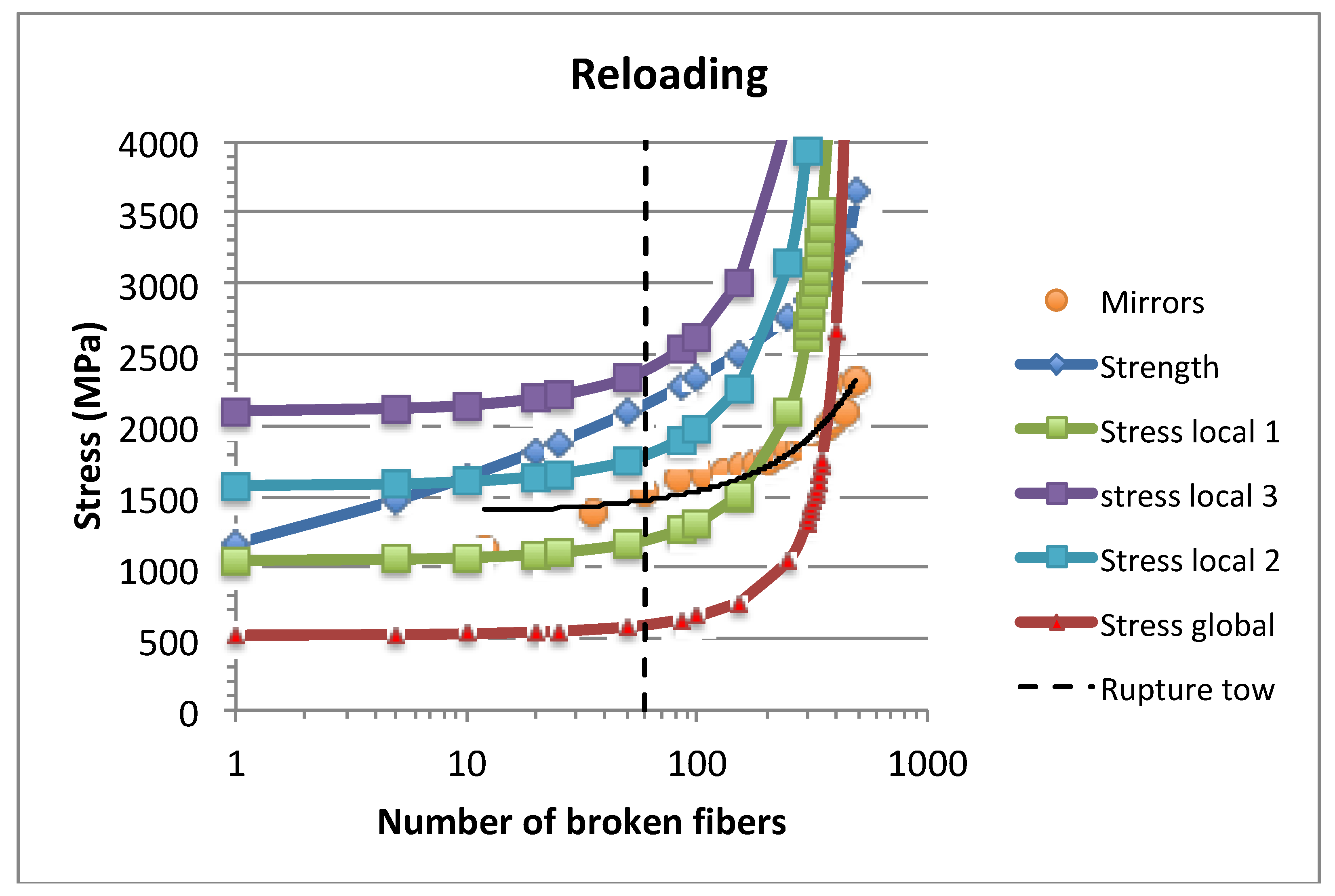

4.5.2. Fiber Overstressing

5. Discussion

5.1. Mechanisms: The Contribution of the Oxide Scale on Filaments

5.2. Stress–Rupture Time Diagram: Comparison of n and p Parameters

5.3. Rupture of Dry Tows and Minicomposites

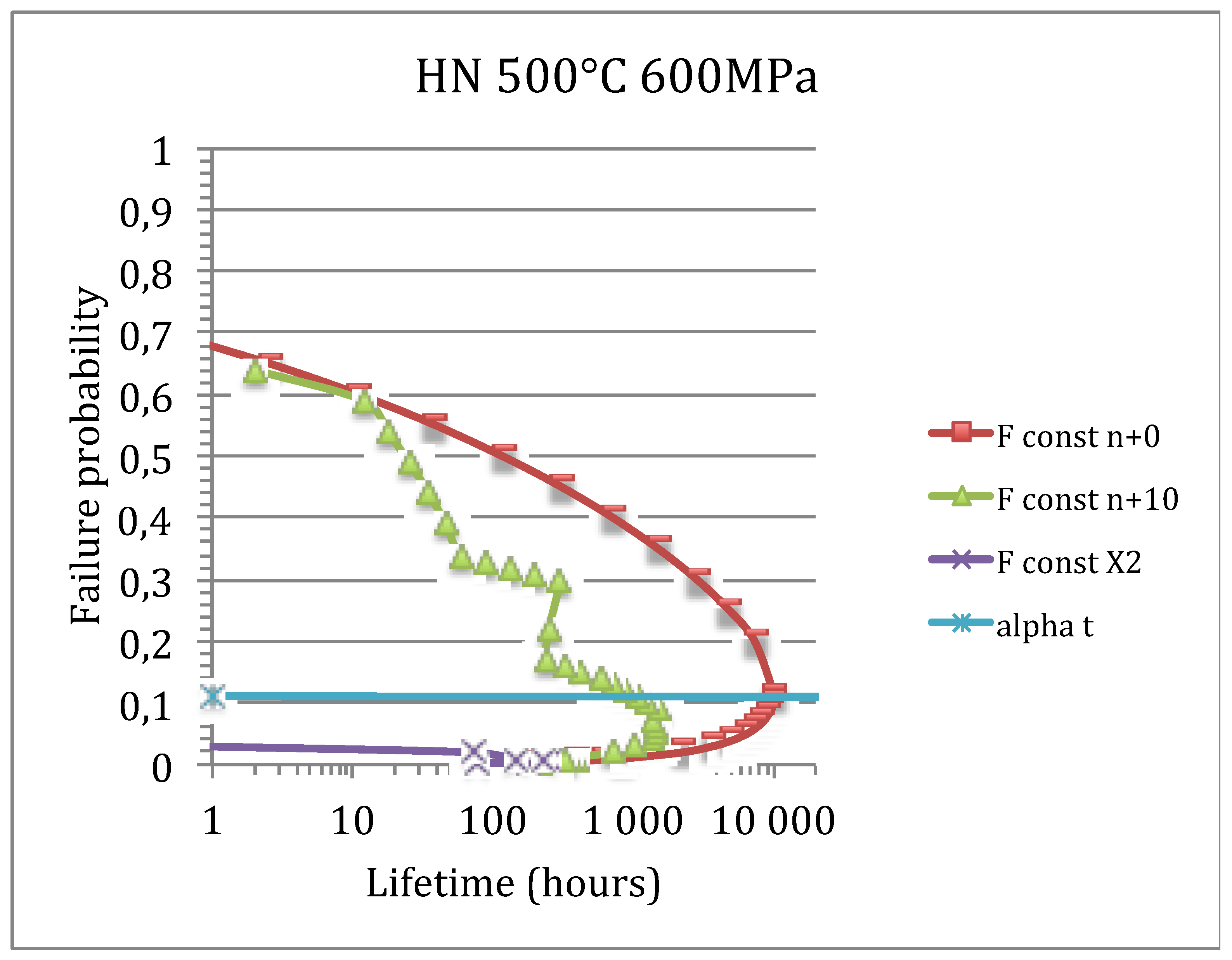

5.4. Variability of Critical Filament

5.5. Consequences: Guidelines to Improve Lifetime of Minicomposites

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Filament Residual Strength

References

- Bansal, N.P.; Lamon, J. (Eds.) Ceramic Matrix Composites: Materials, Modeling and Applications; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2015; ISBN 9781118231166. [Google Scholar]

- Lamon, J. CVI SiC/SiC Composites. In Handbook of Ceramics and Glasses; Bansal, N.P., Ed.; Kluwer Academic Publishers: New York, NY, USA, 2005; pp. 55–76. [Google Scholar]

- Berger, M.; Hochet, N.; Bunsell, A.R. Small diameter SiC-based fibers. In Fine Ceramic Fibers; Bunsell, A.R., Berger, M.H., Eds.; Marcel Dekker: New York, NY, USA, 1999; p. 265. [Google Scholar]

- Yun, H.M.; Di Carlo, J.A. Time/temperature-dependent tensile strength of SiC and Al2O3-based fibers. In Ceramic Transactions, Advances in Ceramic-Matrix Composites II; Bansal, N.P., Singh, J.P., Eds.; American Ceramic Society: Westerville, OH, USA, 1996; Volume 74, pp. 17–26. [Google Scholar]

- Bunsell, A.R.; Piant, A. A review of the development of three generations of small diameter silicon carbide fibers. J. Mater. Sci. 2006, 41, 823–839. [Google Scholar] [CrossRef]

- Shimoo, T.; Okamura, K.; Mutoh, W. Oxidation behavior and mechanical properties of low-oxygen SiC fibers prepared by vacuum heat-treatment of electron-beam-cured poly(carbosilane) precursor. J. Mater. Sci. 2003, 38, 1653–1660. [Google Scholar] [CrossRef]

- Sha, J.J.; Park, J.S.; Hinoki, T.; Kohyama, A. Tensile properties and microstructure characterization of Hi-Nicalon SiC fibers after loading at high temperature. Int. J. Fract. 2006, 142, 1–8. [Google Scholar] [CrossRef]

- DiCarlo, J.A.; Yun, H.M. Non-oxyde silicon carbide fibers. In Handbook of Ceramics and Glasses; Bansall, N., Ed.; Kluwer Academic Publishers: New York, NY, USA, 2005; pp. 33–52. [Google Scholar]

- Lara-Curzio, E. Stress-rupture of Nicalon/SiC continuous fiber ceramic composites in air at 950 °C. J. Am. Ceram. Soc. 1997, 80, 3268–3272. [Google Scholar] [CrossRef]

- Lara-Curzio, E. Analysis of oxidation-assisted stress-rupture of continuous fiber-reinforced ceramic matrix composites at intermediate temperatures. Compos. Part A 1999, 30, 549–554. [Google Scholar] [CrossRef]

- Parthasarathy, T.A.; Przybyla, C.P.; Hay, R.S.; Cinibulk, M.K. Modeling Environmental Degradation of SiC-Based Fibers. J. Am. Ceram. Soc. 2016, 99, 1725–1734. [Google Scholar] [CrossRef]

- DiCarlo, J.A.; Yun, H.M. Creep of ceramic fibers: Mechanisms, fundamentals and applications. In Creep Deformation: Fundamentals and Applications; Mishra, R.S., Earthman, J.C., Raj, S.V., Eds.; The Minerals, Metals and Materials Society: Warrendale, PA, USA, 2002; pp. 195–208. [Google Scholar]

- DiCarlo, J.A.; Yun, H.M. Factors controlling stress-rupture of fiber reinforced ceramic composites. In Proceedings of the ICCM-12, Paris, France, 7–9 July 1999; p. 750. [Google Scholar]

- Morscher, G.N. Tensile Stress Rupture of SiCf/SiCmMinicomposites with Carbon and Boron Nitride Interphases at Elevated Temperatures in Air. J. Am. Ceram. Soc. 1997, 80, 2029–2042. [Google Scholar] [CrossRef]

- Morscher, G.N. Stress-rupture of new Tyranno Si-C-O-Zr fiber reinforced minicomposites. Ceram. Eng. Sci. Proc. 1999, 20, 379–386. [Google Scholar]

- Gauthier, W.; Lamon, J. Delayed failure of Hi-Nicalon and Hi-Nicalon S multifilament tows and single filaments at intermediate temperatures (500–800 °C). J. Am. Ceram. Soc. 2009, 92, 702–709. [Google Scholar] [CrossRef]

- Gauthier, W.; Lamon, J.; Pailler, R. Oxidation of silicon carbide fibers in air at intermediate temperature during static fatigue in air at intermediate temperatures. J. Am. Ceram. Soc. 2009, 92, 2067–2073. [Google Scholar] [CrossRef]

- Loseille, O.; Lamon, J. Prediction of lifetime in static fatigue at high temperatures for ceramic matrix composites. J. Adv. Mater. Res. 2010, 112, 129–140. [Google Scholar] [CrossRef] [Green Version]

- Laforet, A. Lifetime in Fatigue of Ceramic Matrix Composites at Temperatures between 800 °C and 1400 °C (French title: Durée en Fatigue des Composites à Matrice Céramique à des Températures Comprises Entre 800 °C et 1400 °C). Ph.D. Thesis, University of Bordeaux, Bordeaux, France, April 2009. [Google Scholar]

- Lamon, J. Static fatigue of SiC multifilament tows at temperatures up to 1200 °C in air. Ceramics 2019, 2, 33. [Google Scholar] [CrossRef] [Green Version]

- Lamon, J.; R’Mili, M. Damage and failure of SiC fiber tows during environment activated slow crack growth: Residual behavior and Strength-Probability-Time diagrams. Acta Mater. 2017, 131, 197–205. [Google Scholar] [CrossRef]

- Lissart (Godin), N.; Lamon, J. Damage and failure in ceramic matrix minicomposites: Exprimental study and model. Acta Mater. 1997, 45, 1025–1044. [Google Scholar] [CrossRef]

- Davidge, R.W.; McLaren, J.R.; Tappin, G. Strength-probability-time (SPT) relationships in ceramics. J. Mater. Sci. 1973, 8, 1699–1705. [Google Scholar] [CrossRef]

- Charles, R.J.; Hillig, W.B. The kinetics of glass failure by stress corrosion. In Proceedings of the Symposium on Mechanical Strength of Glass and Ways of Improving It, Florence, Italy, 25–29 September 1961; Union Scientifique du Verre: Charleroi, Belgium, 1962. [Google Scholar]

- Wiederhorn, S.M. Subcritical crack growth in ceramics. In Fracture Mechanics of Ceramics; Plenum Press: New York, NY, USA, 1974; Volume 2, pp. 613–646. [Google Scholar]

- Coleman, B.D. Time dependence of mechanical breakdown in bundles of fibers. I. Constant Total Load. J. Appl. Phys. 1957, 28, 1058. [Google Scholar] [CrossRef]

- Daniels, H.E. The statistical theory of the strength of bundles of threads I. Proc. R. Soc. 1945, A183, 405–435. [Google Scholar]

- International Standard ISO/22459. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Reinforcement of Ceramic Composites—Determination of Distribution of Tensile Strength and Tensile Strain to Failure of Filaments within a Multifilament Tow at Ambient Temperature 2020. Available online: https://www.iso.org/standard/73268.html (accessed on 28 February 2021).

- Bertrand, S. Improvement of Lifetime of SiC/SiC Composites with Nanosized Multilayered Interphases. Ph.D. Thesis, University of Bordeaux, Bordeaux, France, September 1998. [Google Scholar]

- Hurst, J.; Yun, H.M.; Gorican, D. A comparison of the mechanical properties of three polymer-derived small diameter SiC fibers. In Advances in Ceramic-Matrix Composites III; Bansal, N.P., Singh, J.P., Eds.; The American Ceramic Society: Columbus, OH, USA, 1996; Volume 74, pp. 3–15. [Google Scholar]

900 °C;

900 °C;  1000 °C;

1000 °C;  1200 °C) and Hi Nicalon/SiC minicomposites at elevated temperatures >900 °C.

1200 °C) and Hi Nicalon/SiC minicomposites at elevated temperatures >900 °C.

900 °C;

900 °C;  1000 °C;

1000 °C;  1200 °C) and Hi Nicalon/SiC minicomposites at elevated temperatures >900 °C.

1200 °C) and Hi Nicalon/SiC minicomposites at elevated temperatures >900 °C.

| Filaments | Hi-Nicalon | Reference |

|---|---|---|

| Young’s modulus: Ef (GPa) | 280 | [19] |

| Filament radius: rf (μm) | 7 | |

| Gauge length: l0 (mm) | 25 | |

| KIC (MPa√m) | 1.7 | [21] |

| Y | 1.12 | |

| n | 12.6 | [24] |

| V0* (m/s) | 40.5 | [24] |

| V* (m/s) 500 °C | 4.98 × 10−9 | [24] |

| V* (m/s) 800 °C | 2.96 × 10−6 | [24] |

| V* (m/s) 900 °C | 1.15 × 10−5 | |

| V* (m/s) 1000 °C | 3.76 × 10−5 | |

| V* (m/s) 1200 °C | 2.48 × 10−4 | |

| Activation energy (kJ/mol) | 146.7 | [24] |

| m | 6.8 | [16] |

| σ0 (MPa) | 61 | [16] |

| Reference volume: v0 (m3) | 1 | |

| Tows | ||

| Number of filaments: N0 | 500 |

| Minicomposites | ||

|---|---|---|

| Cross sectional area | Smini (mm2) | 0.25 |

| Fiber volume fraction | Vf (%) | 29 |

| Rupture force | FR (N) | 130–167 |

| Strain-to-failure | εR(%) | 0.48–0.76 |

| Force at proportional limit | Fe (N) | 58–73 |

| Strain at | εe(%) | 0.052–0.12 |

| Young’s modulus | Emini (GPa) | 362 |

| Force at matrix cracking Saturation | Fsat (N) | 98 |

| Strain at matrix cracking Saturation | εsat(%) | 0.28 |

| Tows | ||

| Number of filaments | 500 | |

| Fiber Young’s modulus | (GPa) | 280 |

| Tow force at proportional limit | Fte (N) | 120 |

| Tow strain at | εte(%) | 0.58 |

| Tow maximum force | Ft (N) | 145 |

| Tow strain at maximum force | εt(%) | 0.8 |

| Temperature | 900 °C | 1000 °C | 1200 °C |

|---|---|---|---|

| p | 5.4 | 4.3 | 3.8 |

| A (sec.MPan) | 6 × 10 18 | 2.5 × 10 15 | 3.5 × 10 13 |

| R2 | 0.8 | 0.7 | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamon, J.; Laforêt, A. Static Fatigue of SiC/SiC Minicomposites at High Temperatures Up to 1200 °C in Air: Multiscale Approach. J. Compos. Sci. 2021, 5, 67. https://doi.org/10.3390/jcs5030067

Lamon J, Laforêt A. Static Fatigue of SiC/SiC Minicomposites at High Temperatures Up to 1200 °C in Air: Multiscale Approach. Journal of Composites Science. 2021; 5(3):67. https://doi.org/10.3390/jcs5030067

Chicago/Turabian StyleLamon, Jacques, and Adrien Laforêt. 2021. "Static Fatigue of SiC/SiC Minicomposites at High Temperatures Up to 1200 °C in Air: Multiscale Approach" Journal of Composites Science 5, no. 3: 67. https://doi.org/10.3390/jcs5030067

APA StyleLamon, J., & Laforêt, A. (2021). Static Fatigue of SiC/SiC Minicomposites at High Temperatures Up to 1200 °C in Air: Multiscale Approach. Journal of Composites Science, 5(3), 67. https://doi.org/10.3390/jcs5030067