Synthetic Polymeric Materials for Bone Replacement

Abstract

:1. Introduction

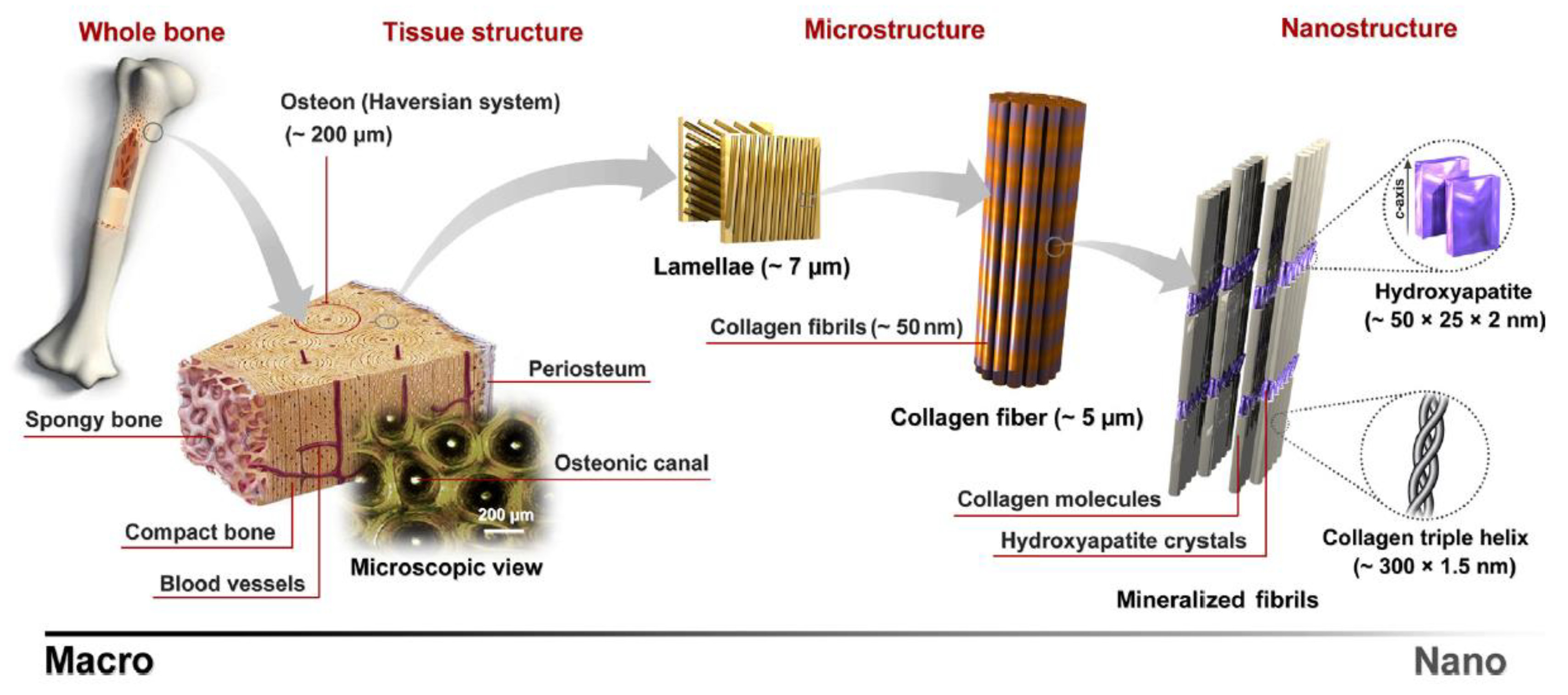

2. Bone Composition

3. Polymers in Orthopedic Applications

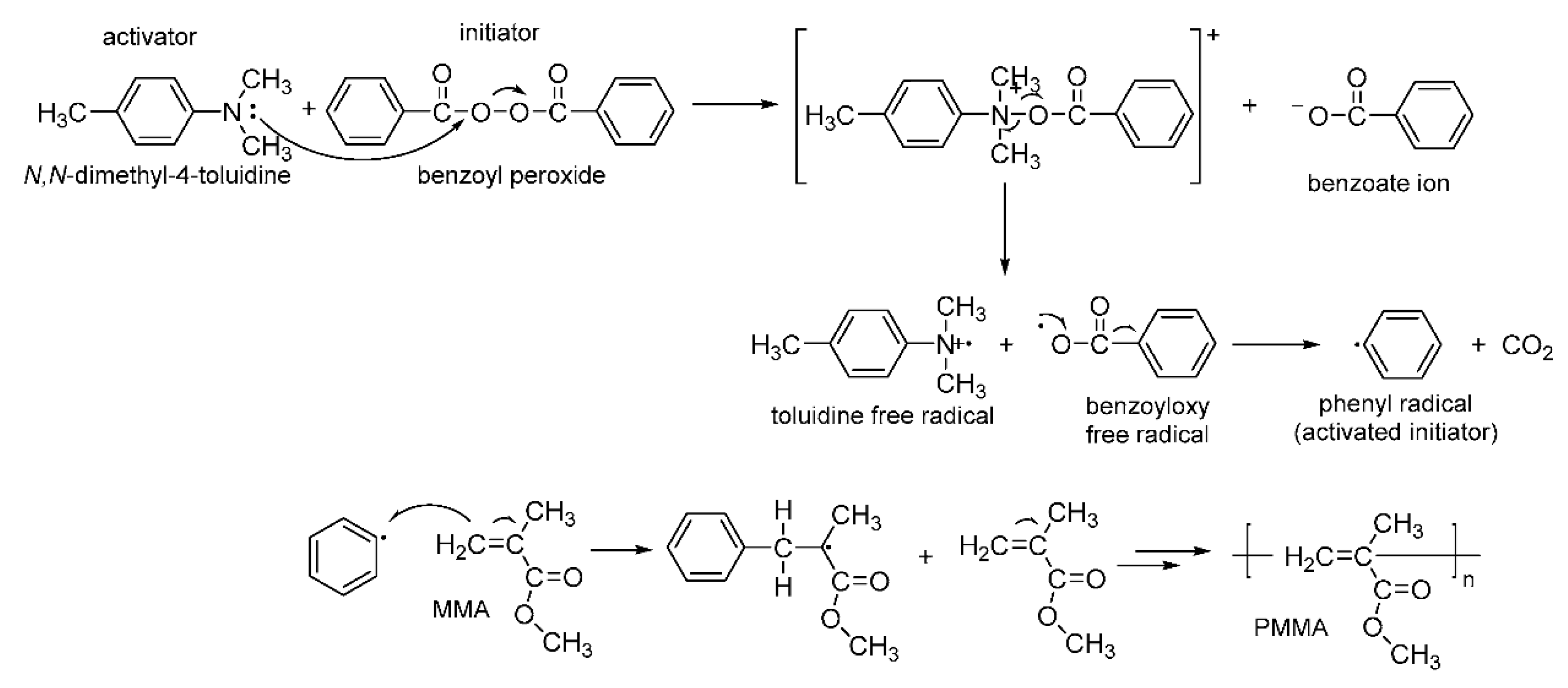

3.1. Poly(Methyl Methacrylate)

3.2. Poly(Ether-Ether-Ketone)

3.3. Ultra-High Molecular Weight Polyethylene in Orthopedic Applications

| Material | Elastic Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|

| Trabecular bone | 0.02–0.05 [24] | 1–5 [59] |

| Cortical bone trabecular | 3–30 [24] | 50–151 [59] |

| UHMWPE | 0.9–2.7 [60] | 33–66 [61] |

| PMMA | 1.88–3.3 [60] | 68 [62] |

| PEEK | 3.5–4.0 [63] | 118 [62] |

| Co-Cr-Mo alloy | 210–232 [60] | 1173 [64] |

| Ti-6Al-4V alloy | 116 [60] | 1018 [65] |

4. UHMWPE/HA Composites for Biomedical Application

4.1. Hydroxyapatite

4.2. UHMWPE/HA Properties

5. Final Considerations

Author Contributions

Funding

Conflicts of Interest

References

- Haach, L.C.A.; Purqueiro, B.M.; Silva Júnior, N.F.; Gaspar, A.M.M.; Fortulan, C.A. Comparison of Two Composites Developed to be Used as Bone Replacement–PMMA/Bioglass 45S5® Microfiber and PMMA/Hydroxyapatite. Bioceram. Dev. Appl. 2014, 4, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Oryan, A.; Alidadi, S.; Moshiri, A.; Maffulli, N. Bone regenerative medicine: Classic options, novel strategies, and future directions. J. Orthop. Surg. Res. 2014, 9, 1–27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bobbert, F.S.L.; Zadpoor, A.A. Effects of bone substitute architecture and surface properties on cell response, angiogenesis, and structure of new bone. J. Mater. Chem. B 2017, 5, 6175–6192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Williams, A.; Szabo, R.M. Bone transplantation. Orthopedics 2004, 27, 488–495. [Google Scholar] [CrossRef] [PubMed]

- Pinto, J.G.S. Enxerto autógeno x biomateriais no tratamento de fraturas e deformidades faciais–uma revisão de conceitos atuais. Rev. Fac. Odontol.-UPF 2010, 12, 79–84. [Google Scholar] [CrossRef]

- Amini, A.R.; Laurencin, C.T.; Nukavarapu, S.P. Bone tissue engineering: Recent advances and challenges. Crit. Rev. Biomed. Eng. 2012, 40, 363–408. [Google Scholar] [CrossRef] [Green Version]

- Delloye, C.; Cornu, O.; Druez, V.; Barbier, O. Bone allografts: What they can offer and what they cannot. J. Bone Jt. Surg. 2007, 89-B, 574–580. [Google Scholar] [CrossRef] [Green Version]

- Bus, M.; Dijkstra, P.; van de Sande, M.A.J.; Taminiau, A.H.M.; Schreuder, H.W.B.; Jutte, P.C.; van der Geest, I.C.M.; Schaap, G.R.; Bramer, J.A.M. Intercalary Allograft Reconstructions Following Resection of Primary Bone Tumors. JBJS 2014, 96, 1–11. [Google Scholar] [CrossRef]

- Sheikh, Z.; Sima, C.; Glogauer, M. Bone replacement materials and techniques used for achieving vertical alveolar bone augmentation. Materials 2015, 8, 2953–2993. [Google Scholar] [CrossRef]

- Bose, S.; Banerjee, D.; Bandyopadhyay, A. Introduction to Biomaterials and Devices for Bone Disorders. In Materials and Devices for Bone Disorders; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 1–27. ISBN 9780128027929. [Google Scholar]

- Pryor, L.S.; Gage, E.; Langevin, C.-J.; Herrera, F.; Breithaupt, A.D.; Gordon, C.R.; Afifi, A.M.; Zins, J.E.; Meltzer, H.; Gosman, A.; et al. Review of bone substitutes. Craniomaxillofac. Trauma Reconstr. 2009, 2, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Saini, M. Implant biomaterials: A comprehensive review. World J. Clin. Cases 2015, 3, 52–57. [Google Scholar] [CrossRef] [PubMed]

- Sattari, M.; Naimi-Jamal, M.R.; Khavandi, A. Interphase evaluation and nano-mechanical responses of UHMWPE/SCF/nano- SiO2 hybrid composites. Polym. Test. 2014, 38, 26–34. [Google Scholar] [CrossRef]

- Mirsalehi, S.A.; Sattari, M.; Khavandi, A.; Mirdamadi, S.; Naimi-Jamal, M.R. Tensile and biocompatibility properties of synthesized nano-hydroxyapatite reinforced ultrahigh molecular weight polyethylene nanocomposite. J. Compos. Mater. 2016, 50, 1725–1737. [Google Scholar] [CrossRef]

- Aparecida, A.H.; Fook, M.V.L.; Guastaldi, A.C. Biomimetic apatite formation on Ultra-High Molecular Weight Polyethylene (UHMWPE) using modified biomimetic solution. J. Mater. Sci. Mater. Med. 2009, 20, 1215–1222. [Google Scholar] [CrossRef] [PubMed]

- Macuvele, D.L.P.; Nones, J.; Matsinhe, J.V.; Lima, M.M.; Soares, C.; Fiori, M.A.; Riella, H.G. Advances in ultra high molecular weight polyethylene/hydroxyapatite composites for biomedical applications: A brief review. Mater. Sci. Eng. C 2017, 76, 1248–1262. [Google Scholar] [CrossRef] [PubMed]

- Porter, J.R.; Ruckh, T.T.; Popat, K.C. Bone tissue engineering: A review in bone biomimetics and drug delivery strategies. Biotechnol. Prog. 2009, 25, 1539–1560. [Google Scholar] [CrossRef]

- Boyle, W.J.; Simonet, W.S.; Lacey, D.L. Osteoclast differentiation and activation and Activation. Nature 2003, 423, 337–342. [Google Scholar] [CrossRef]

- Boskey, A.L. Bone composition: Relationship to bone fragility and antiosteoporotic drug effects. Bonekey Rep. 2013, 2, 447. [Google Scholar] [CrossRef] [Green Version]

- Sommerfeldt, D.; Rubin, C. Biology of bone and how it orchestrates the form and function of the skeleton. Eur. Spine J. 2001, 10, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Jiang, W.; Liu, H. Nanocomposites for bone repair and osteointegration with soft tissues. In Nanocomposites for Musculoskeletal Tissue Regeneration; Liu, H., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 241–257. ISBN 9781782424758. [Google Scholar]

- Seeman, E.M.D.; Delmas, P.D. Bone Quality-The Material and Structural Basis of Bone Strength and Fragility. N. Engl. J. Med. 2006, 354, 2250–2261. [Google Scholar] [CrossRef] [Green Version]

- Rizzo, D.C. Fundamentals of Anatomy and Physiology, 3rd ed.; Delmar Cengage Learning: New York, NY, USA, 2010; ISBN 9781435438712. [Google Scholar]

- Michael, F.M.; Khalid, M.; Walvekar, R.; Ratnam, C.T.; Ramarad, S.; Siddiqui, H.; Hoque, M.E. Effect of nanofillers on the physico-mechanical properties of load bearing bone implants. Mater. Sci. Eng. C 2016, 67, 792–806. [Google Scholar] [CrossRef] [PubMed]

- Sadat-Shojai, M.; Khorasani, M.T.; Dinpanah-Khoshdargi, E.; Jamshidi, A. Synthesis methods for nanosized hydroxyapatite with diverse structures. Acta Biomater. 2013, 9, 7591–7621. [Google Scholar] [CrossRef] [PubMed]

- Salgado, A.J.; Coutinho, O.P.; Reis, R.L. Bone tissue engineering: State of the art and future trends. Macromol. Biosci. 2004, 4, 743–765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bozic, K.J. Sixth Annual AJRR Annual Report on Hip and Knee Arthroplasty Data. Am. Jt. Replace. Regist. 2019. Available online: https://connect.ajrr.net/hubfs/PDFs%20and%20PPTs/AAOS_AJRR_2019_Annual_Report_Update_FINAL_150DPI.pdf?hsCtaTracking=1d80e9fa-66fe-4525-a5cb-15c30ec19a1f%7C8becda93-a51e-41cc-bcfa-ca9130c1add6 (accessed on 1 November 2020).

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. J. Bone Jt. Surg. Am. Vol. 2007, 89A, 780–785. [Google Scholar] [CrossRef]

- Dang, T.T.; Nikkhah, M.; Memic, A.; Khademhosseini, A. Polymeric Biomaterials for Implantable Prostheses; Elsevier Inc.: Amsterdam, The Netherlands, 2014; ISBN 9780123969835. [Google Scholar]

- Gohil, S.V.; Suhail, S.; Rose, J.; Vella, T.; Nair, L.S. Polymers and Composites for Orthopedic Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 978-0-12-802792-9. [Google Scholar]

- Navarro, M.; Michiardi, A.; Castaño, O.; Planell, J.A. Biomaterials in orthopaedics. J. R. Soc. Interface 2008, 5, 1137–1158. [Google Scholar] [CrossRef] [Green Version]

- Arora, M.; Chan, E.K.; Gupta, S.; Diwan, A.D. Polymethylmethacrylate bone cements and additives: A review of the literature. World J. Orthop. 2013, 4, 67–74. [Google Scholar] [CrossRef]

- Chen, L.; Zhai, D.; Huan, Z.; Ma, N.; Zhu, H.; Wu, C.; Chang, J. Silicate bioceramic/PMMA composite bone cement with distinctive physicochemical and bioactive properties. RSC Adv. 2015, 5, 37314–37322. [Google Scholar] [CrossRef]

- Nussbaum, D.A.; Gailloud, P.; Murphy, K. The Chemistry of Acrylic Bone Cements and Implications for Clinical Use in Image-guided Therapy. J. Vasc. Interv. Radiol. 2004, 15, 121–126. [Google Scholar] [CrossRef]

- Sa, Y.; Yang, F.; De Wijn, J.R.; Wang, Y.; Wolke, J.G.C.; Jansen, J.A. Physicochemical properties and mineralization assessment of porous polymethylmethacrylate cement loaded with hydroxyapatite in simulated body fluid. Mater. Sci. Eng. C 2016, 61, 190–198. [Google Scholar] [CrossRef]

- Goñi, I.; Rodríguez, R.; García-Arnáez, I.; Parra, J.; Gurruchaga, M. Preparation and characterization of injectable PMMA-strontium-substituted bioactive glass bone cement composites. J. Biomed. Mater. Res. Part B Appl. Biomater. 2017, 1–13. [Google Scholar] [CrossRef] [PubMed]

- D’Onofrio, A.; Kent, N.W.; Shahdad, S.A.; Hill, R.G. Development of novel strontium containing bioactive glass based calcium phosphate cement. Dent. Mater. 2016, 32, 703–712. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Huang, C.; Zhang, M.; Ruan, C.; Peng, S.; Li, L.; Liu, W.; Wang, T.; Li, B.; Huang, W.; et al. Enhanced osteointegration of poly (methylmethacrylate) bone cements by incorporating strontium-containing borate bioactive glass. J. R. Soc. Interface 2017, 14, 20161057. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M. Synthesis and Processing of PEEK for Surgical Implants; Elsevier Inc.: Amsterdam, The Netherlands, 2012; ISBN 9781437744637. [Google Scholar]

- Kemmish, D.J.; Wilson, B. Aromatic Polyetherketones. U.S. Patent 6,909,015 B2, 21 June 2005. [Google Scholar]

- Lu, T.; Qian, S.; Meng, F.; Ning, C.; Liu, X. Enhanced osteogenic activity of poly ether ether ketone using calcium plasma immersion ion implantation. Colloids Surf. B Biointerfaces 2016, 142, 192–198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johansson, P.; Jimbo, R.; Naito, Y.; Kjellin, P.; Currie, F.; Wennerberg, A. Polyether ether ketone implants achieve increased bone fusion when coated with nano-sized hydroxyapatite: A histomorphometric study in rabbit bone. Int. J. Nanomed. 2016, 11, 1435–1442. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.; Guo, D. Evaluating the bioactivity of a hydroxyapatite-incorporated polyetheretherketone biocomposite. J. Orthop. Surg. Res. 2019, 14, 1–13. [Google Scholar] [CrossRef]

- Monich, P.R.; Berti, F.V.; Porto, L.M.; Henriques, B.; Novaes de Oliveira, A.P.; Fredel, M.C.; Souza, J.C.M. Physicochemical and biological assessment of PEEK composites embedding natural amorphous silica fibers for biomedical applications. Mater. Sci. Eng. C 2017, 79, 354–362. [Google Scholar] [CrossRef]

- Khoury, J.; Selezneva, I.; Pestov, S.; Tarassov, V.; Ermakov, A.; Mikheev, A.; Lazov, M.; Kirkpatrick, S.R.; Shashkov, D.; Smolkov, A. Surface bioactivation of PEEK by neutral atom beam technology. Bioact. Mater. 2019, 4, 132–141. [Google Scholar] [CrossRef]

- Terpiłowski, K.; Wiącek, A.E.; Jurak, M. Influence of nitrogen plasma treatment on the wettability of polyetheretherketone and deposited chitosan layers. Adv. Polym. Technol. 2018, 37, 1557–1569. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wei, W.; Yang, L.; Pan, Y.; Wang, X.; Wang, T.; Tang, S.; Yao, Y.; Hong, H.; Wei, J. Stimulation of cell responses and bone ingrowth into macro-microporous implants of nano-bioglass/polyetheretherketone composite and enhanced antibacterial activity by release of hinokitiol. Colloids Surf. B Biointerfaces 2018, 164, 347–357. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, L.; Xiao, L.; Zhang, Q.; Liu, Y. Enhanced osteogenic activity of phosphorylated polyetheretherketone via surface-initiated grafting polymerization of vinylphosphonic acid. Colloids Surf. B Biointerfaces 2019, 173, 591–598. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Liu, L.; Ma, Y.; Xiao, L.; Liu, Y. Enhanced Osteoblasts Responses to Surface-Sulfonated Polyetheretherketone via a Single-Step Ultraviolet-Initiated Graft Polymerization. Ind. Eng. Chem. Res. 2018, 57, 10403–10410. [Google Scholar] [CrossRef]

- Ma, R.; Tang, T. Current strategies to improve the bioactivity of PEEK. Int. J. Mol. Sci. 2014, 15, 5426–5445. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasemo, B. Biological surface science Bengt. Surf. Sci. 2002, 500, 656–677. [Google Scholar] [CrossRef]

- Almasi, D.; Iqbal, N.; Sadeghi, M.; Sudin, I.; Abdul Kadir, M.R.; Kamarul, T. Preparation Methods for Improving PEEK’s Bioactivity for Orthopedic and Dental Application: A Review. Int. J. Biomater. 2016, 2016. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Poulsson, A.H.C.; Richards, R.G. Surface Modification Techniques of Polyetheretherketone, Including Plasma Surface Treatment; Elsevier Inc.: Amsterdam, The Netherlands, 2012; ISBN 9781437744637. [Google Scholar]

- Wang, H.; Lu, T.; Meng, F.; Zhu, H.; Liu, X. Enhanced osteoblast responses to poly ether ether ketone surface modified by water plasma immersion ion implantation. Colloids Surf. B Biointerfaces 2014, 117, 89–97. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Devine, J.N. PEEK biomaterials in trauma, orthopedic, and spinal implants. Biomaterials 2007, 28, 4845–4869. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.; Tang, S.; Tan, H.; Lin, W.; Wang, Y.; Wei, J.; Zhao, L.; Tang, T. Preparation, characterization, and in vitro osteoblast functions of a nano-hydroxyapatite/polyetheretherketone biocomposite as orthopedic implant material. Int. J. Nanomed. 2014, 9, 3949–3961. [Google Scholar] [CrossRef] [Green Version]

- Kurtz, S.M. UHMWPE Biomaterials Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices; William Andrew: Oxford, UK, 2015; ISBN 9780323354011. [Google Scholar]

- Roeder, R.K.; Converse, G.L.; Kane, R.J.; Yue, W. Hydroxyapatite-reinforced polymer biocomposites for synthetic bone substitutes. J. Miner. Met. Mater. Soc. 2008, 60, 38–45. [Google Scholar] [CrossRef]

- Wagoner Johnson, A.J.; Herschler, B.A. A review of the mechanical behavior of CaP and CaP/polymer composites for applications in bone replacement and repair. Acta Biomater. 2011, 7, 16–30. [Google Scholar] [CrossRef]

- Aherwar, A.; KSingh, A.K.; Patnaik, A. Current and future biocompatibility aspects of biomaterials for hip prosthesis. AIMS Bioeng. 2016, 3, 23–43. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, H.; Zhang, Z.; Celli, J.; Percec, S.; Ren, F. Nanoindentation study of time-dependent mechanical properties of ultra-high-molecular-weight polyethylene (UHMWPE) at different temperatures. Polym. Test. 2020, 91, 106787. [Google Scholar] [CrossRef]

- Muhsin, S.A.; Hatton, P.V.; Johnson, A.; Sereno, N.; Wood, D.J. Determination of Polyetheretherketone (PEEK) mechanical properties as a denture material. Saudi Dent. J. 2019, 31, 382–391. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers, 2nd ed.; ChemTec Publishing: Toronto, ON, USA, 2016; ISBN 9781895198928. [Google Scholar]

- Kajima, Y.; Takaichi, A.; Kittikundecha, N.; Nakamoto, T.; Kimura, T.; Nomura, N.; Kawasaki, A.; Hanawa, T.; Takahashi, H.; Wakabayashi, N. Effect of heat-treatment temperature on microstructures and mechanical properties of Co–Cr–Mo alloys fabricated by selective laser melting. Mater. Sci. Eng. A 2018, 726, 21–31. [Google Scholar] [CrossRef]

- Ao, N.; Liu, D.; Liu, C.; Zhang, X.; Liu, D. Face-centered titanium induced by ultrasonic surface rolling process in Ti-6Al-4V alloy and its tensile behavior. Mater. Charact. 2018, 145, 527–533. [Google Scholar] [CrossRef]

- Massin, P.; Achour, S. Wear products of total hip arthroplasty: The case of polyethylene. Morphologie 2016, 101, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Tateiwa, T.; Takahashi, Y. Vitamin E-stabilized highly crosslinked polyethylenes: The role and effectiveness in total hip arthroplasty. J. Orthop. Sci. 2017, 22, 384–390. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Gawel, H.A.; Patel, J.D. History and systematic review of wear and osteolysis outcomes for first-generation highly crosslinked polyethylene. Clin. Orthop. Relat. Res. 2011, 469, 2262–2277. [Google Scholar] [CrossRef] [Green Version]

- Bracco, P.; Oral, E. Vitamin E-stabilized UHMWPE for total joint implants: A review. Clin. Orthop. Relat. Res. 2011, 469, 2286–2293. [Google Scholar] [CrossRef] [Green Version]

- Yousef, S.; Visco, A.; Galtieri, G.; Nocita, D.; Espro, C. Wear behaviour of UHMWPE reinforced by carbon nanofiller and paraffin oil for joint replacement. Mater. Sci. Eng. C 2017, 73, 234–244. [Google Scholar] [CrossRef]

- Affatato, S.; Freccero, N.; Taddei, P. The biomaterials challenge: A comparison of polyethylene wear using a hip joint simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Ni, Z.; Qian, S.; Zhao, Y. Biotribological behaviour of Vitamin E-blended highly cross-linked UHMWPE in a hip joint simulator. Ind. Lubr. Tribol. 2016, 68, 548–553. [Google Scholar] [CrossRef]

- Bozic, K. Fifth Ajrr Annual Report on Hip and Knee Arthroplasty Data; American Joint Replacement Registry: Rosemont, IL, USA, 2018. [Google Scholar]

- Quan, C.; Tang, Y.; Liu, Z.; Rao, M.; Zhang, W.; Liang, P.; Wu, N.; Zhang, C.; Shen, H.; Jiang, Q. Effect of modification degree of nanohydroxyapatite on biocompatibility and mechanical property of injectable poly(methyl methacrylate)-based bone cement. J. Biomed. Mater. Res.-Part B Appl. Biomater. 2016, 104, 576–584. [Google Scholar] [CrossRef] [PubMed]

- Best, S.M.; Porter, A.E.; Thian, E.S.; Huang, J. Bioceramics: Past, present and for the future. J. Eur. Ceram. Soc. 2008, 28, 1319–1327. [Google Scholar] [CrossRef]

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Fabrication, Properties and Applications of Dense Hydroxyapatite: A Review. J. Funct. Biomater. 2015, 6, 1099–1140. [Google Scholar] [CrossRef] [Green Version]

- Maksimkin, A.V.; Kaloshkin, S.D.; Tcherdyntsev, V.V.; Senatov, F.S.; Danilov, V.D. Structure and properties of ultra-high molecular weight polyethylene filled with disperse hydroxyapatite. Inorg. Mater. Appl. Res. 2012, 3, 288–295. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, Y.; Wang, Q.; Ge, S. Biotribological behavior of ultra high molecular weight polyethylene composites containing bovine bone hydroxyapatite. J. China Univ. Min. Technol. 2008, 18, 606–612. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, J.; Ge, S. Study on Biotribological Behavior of the Combined Joint of CoCrMo and UHMWPE/BHA Composite in a Hip Joint Simulator. J. Bionic Eng. 2009, 6, 378–386. [Google Scholar] [CrossRef]

- Fang, L.; Leng, Y.; Gao, P. Processing of hydroxyapatite reinforced ultrahigh molecular weight polyethylene for biomedical applications. Biomaterials 2005, 26, 3471–3478. [Google Scholar] [CrossRef]

- Mirsalehi, S.A.; Khavandi, A.; Mirdamadi, S.; Naimi-Jamal, M.R.; Kalantari, S.M. Nanomechanical and tribological behavior of hydroxyapatite reinforced ultrahigh molecular weight polyethylene nanocomposites for biomedical applications. J. Appl. Polym. Sci. 2015, 132, 1–11. [Google Scholar] [CrossRef]

- Fang, L.; Leng, Y.; Gao, P. Processing and mechanical properties of HA/UHMWPE nanocomposites. Biomaterials 2006, 27, 3701–3707. [Google Scholar] [CrossRef]

- Fang, L.; Gao, P.; Leng, Y. High strength and bioactive hydroxyapatite nano-particles reinforced ultrahigh molecular weight polyethylene. Compos. Part B Eng. 2007, 38, 345–351. [Google Scholar] [CrossRef]

- Senra, M.R.; Vieira Marques, M.d.F.; de Holanda Saboya Souza, D. Ultra-high molecular weight polyethylene bioactive composites with carbonated hydroxyapatite. J. Mech. Behav. Biomed. Mater. 2020, 110, 103938. [Google Scholar] [CrossRef]

- Liao, S.; Watari, F.; Uo, M.; Ohkawa, S.; Tamura, K.; Wang, W.; Cui, F. The Preparation and Characteristics of a Carbonated Hydroxyapatite/Collagen Composite at Room Temperature. J. Biomed. Mater. Res.-Part B Appl. Biomater. 2005, 74, 817–821. [Google Scholar] [CrossRef]

- Senra, M.R.; Lima, R.B.; Souza, D.d.H.S.; Marques, M.d.F.V.; Monteiro, S.N. Thermal characterization of hydroxyapatite or carbonated hydroxyapatite hybrid composites with distinguished collagens for bone graft. J. Mater. Res. Technol. 2020, 9, 7190–7200. [Google Scholar] [CrossRef]

- Crowley, J.; Chalivendra, V.B. Mechanical characterization of ultra-high molecular weight polyethylene-hydroxyapatite nanocomposites. Biomed. Mater. Eng. 2008, 18, 149–160. [Google Scholar] [CrossRef]

- Panin, S.V.; Kornienko, L.A.; Chaikina, M.V.; Sergeev, V.P.; Ivanova, L.R.; Shilko, S.V. Nano- and Micro-Structured UHMWPE Composites Filled With Hydroxyapatite Irradiated by Nitrogen Ion Beams for Bio-Medical Applications. Russ. Phys. J. 2014, 56, 1137–1143. [Google Scholar] [CrossRef]

- Li, F.; Gao, L.; Gao, H.; Cui, Y. The Mechanical Properties and Modeling of Creep Behavior of UHMWPE/Nano-HA Composites. J. Mater. Eng. Perform. 2017, 26, 4514–4521. [Google Scholar] [CrossRef]

- Hacker, M.C.; Krieghoff, J.; Mikos, A.G. Synthetic polymers. In Principles of Regenerative Medicine; Atala, A., Lanza, R., Mikos, A.G., Nerem, R., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 559–590. ISBN 9780128098806. [Google Scholar]

- Haugen, H.J.; Lyngstadaas, S.P.; Rossi, F.; Perale, G. Bone grafts: Which is the ideal biomaterial? J. Clin. Periodontol. 2019, 46, 92–102. [Google Scholar] [CrossRef]

- Saravanan, I.; Devaraju, A. Wear mechanism of UHMWPE polymer composites for bio medical applications. Mater. Res. Express 2019, 6, 1–11. [Google Scholar] [CrossRef]

- Salari, M.; Mohseni Taromsari, S.; Bagheri, R.; Faghihi Sani, M.A. Improved wear, mechanical, and biological behavior of UHMWPE-HAp-zirconia hybrid nanocomposites with a prospective application in total hip joint replacement. J. Mater. Sci. 2019, 54, 4259–4276. [Google Scholar] [CrossRef]

- Macuvele, D.L.P.; Colla, G.; Cesca, K.; Ribeiro, L.F.B.; da Costa, C.E.; Nones, J.; Breitenbach, E.R.; Porto, L.M.; Soares, C.; Fiori, M.A.; et al. UHMWPE/HA biocomposite compatibilized by organophilic montmorillonite: An evaluation of the mechanical-tribological properties and its hemocompatibility and performance in simulated blood fluid. Mater. Sci. Eng. C 2019, 100, 411–423. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, J.; Gao, H.; Gao, L. Biaxial fatigue crack propagation behavior of ultrahigh molecular weight polyethylene reinforced by carbon nanofibers and hydroxyapatite. J. Biomed. Mater. Res.-Part B Appl. Biomater. 2020, 108, 1603–1615. [Google Scholar] [CrossRef] [PubMed]

- Shi, G.; Yan, X.; Wang, Q.; Cao, Z.; Min, L.; Ji, L. Hydroxyapatite/ultra-high molecular weight polyethylene nanocomposites fabricated by in situ hydrothermal synthesis for wear-resistance and friction reduction. J. Appl. Polym. Sci. 2020, 137, 1–14. [Google Scholar] [CrossRef]

- Taromsari, S.M.; Salari, M.; Bagheri, R.; Sani, M.A.F. Optimizing tribological, tensile & in-vitro biofunctional properties of UHMWPE based nanocomposites with simultaneous incorporation of graphene nanoplatelets (GNP) & hydroxyapatite (HAp) via a facile approach for biomedical applications. Compos. Part B Eng. 2019, 175, 107181. [Google Scholar] [CrossRef]

- Powell, S.K.; Cruz, R.L.J.; Ross, M.T.; Woodruff, M.A. Past, Present, and Future of Soft-Tissue Prosthetics: Advanced Polymers and Advanced Manufacturing. Adv. Mater. 2020, 32, 1–21. [Google Scholar] [CrossRef]

- Ahangar, P.; Cooke, M.E.; Weber, M.H.; Rosenzweig, D.H. Current biomedical applications of 3D printing and additive manufacturing. Appl. Sci. 2019, 9, 1713. [Google Scholar] [CrossRef] [Green Version]

- Winkler, T.; Sass, F.A.; Duda, G.N.; Schmidt-Bleek, K. A review of biomaterials in bone defect healing, remaining shortcomings and future opportunities for bone tissue engineering: The unsolved challenge. Bone Jt. Res. 2018, 7, 232–243. [Google Scholar] [CrossRef]

- Ghilan, A.; Chiriac, A.P.; Nita, L.E.; Rusu, A.G.; Neamtu, I.; Chiriac, V.M. Trends in 3D Printing Processes for Biomedical Field: Opportunities and Challenges. J. Polym. Environ. 2020, 28, 1345–1367. [Google Scholar] [CrossRef]

| Bone Type | Composition (% Mass) | Mechanical Properties | |||

|---|---|---|---|---|---|

| Protein | CaP | Water | Strength (MPa) | Elastic Modulus (GPa) | |

| Cortical | 28 | 60 | 12 | 70–200 | 3–30 |

| Trabecular | 26 | 54 | 20 | 0.1–30 | 0.02–0.5 |

| Cell Type | Function |

|---|---|

| Osteoblasts | Synthesis and regulation of the deposition and mineralization of the extracellular bone matrix; Response to mechanical stimuli. |

| Osteocyte | Calcification of the osteoid matrix; Bone maintenance; Mechanosensory cell of the bone. |

| Osteoclast | Bone resorption. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senra, M.R.; Marques, M.d.F.V. Synthetic Polymeric Materials for Bone Replacement. J. Compos. Sci. 2020, 4, 191. https://doi.org/10.3390/jcs4040191

Senra MR, Marques MdFV. Synthetic Polymeric Materials for Bone Replacement. Journal of Composites Science. 2020; 4(4):191. https://doi.org/10.3390/jcs4040191

Chicago/Turabian StyleSenra, Mônica Rufino, and Maria de Fátima Vieira Marques. 2020. "Synthetic Polymeric Materials for Bone Replacement" Journal of Composites Science 4, no. 4: 191. https://doi.org/10.3390/jcs4040191

APA StyleSenra, M. R., & Marques, M. d. F. V. (2020). Synthetic Polymeric Materials for Bone Replacement. Journal of Composites Science, 4(4), 191. https://doi.org/10.3390/jcs4040191