Nitrogen-Doped Carbon Nanotube/Polypropylene Composites with Negative Seebeck Coefficient

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Thermoelectric Properties

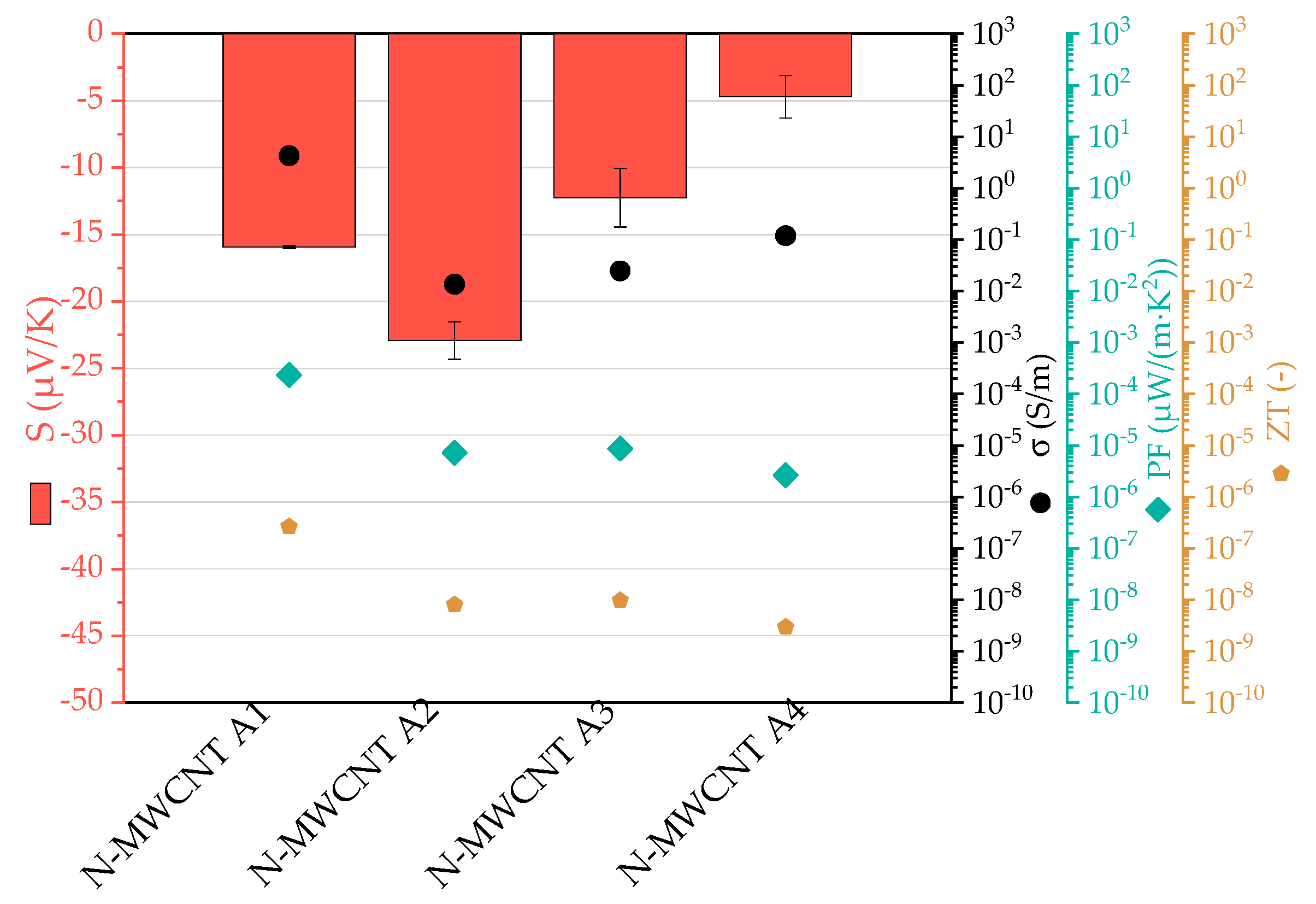

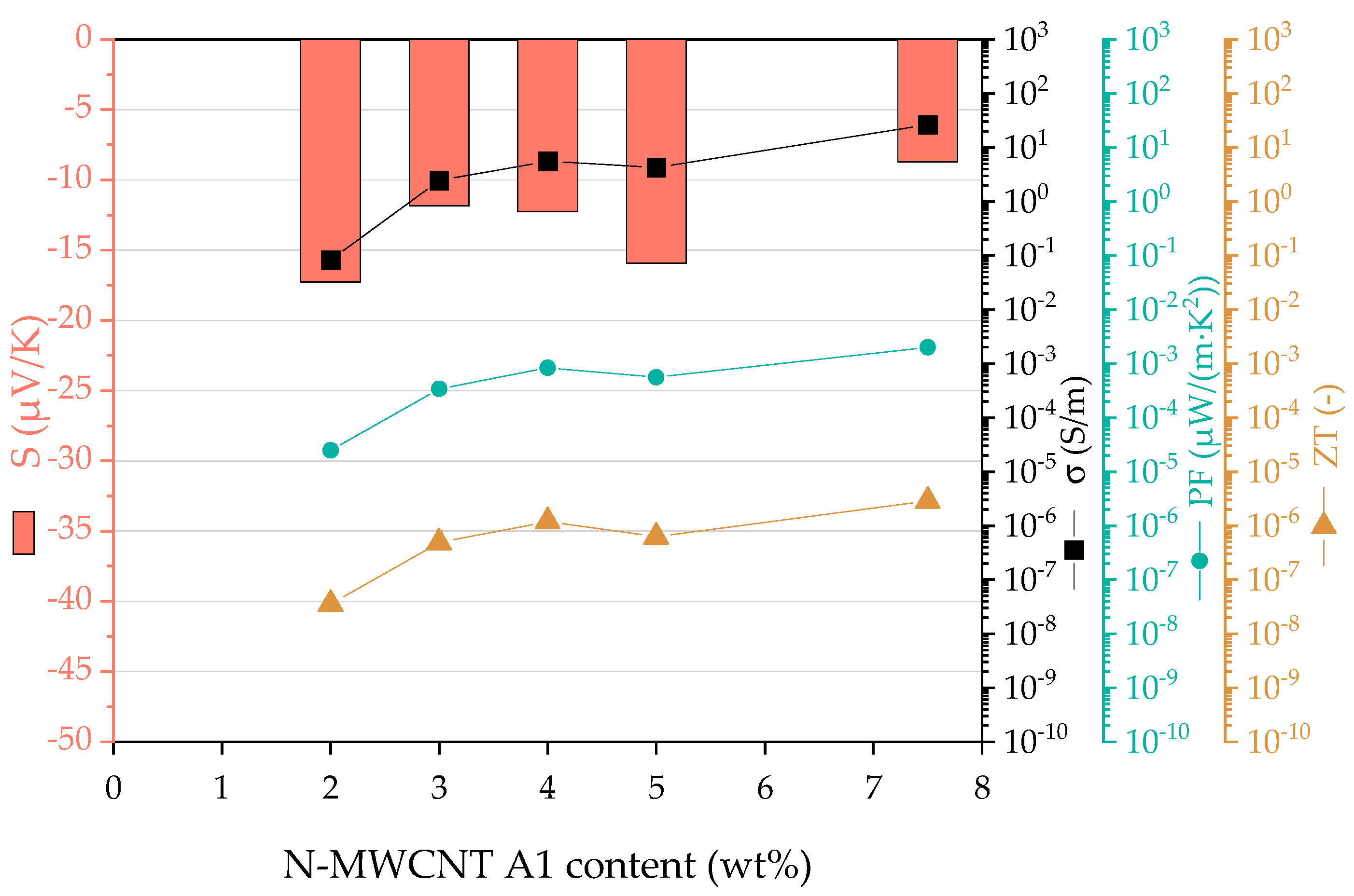

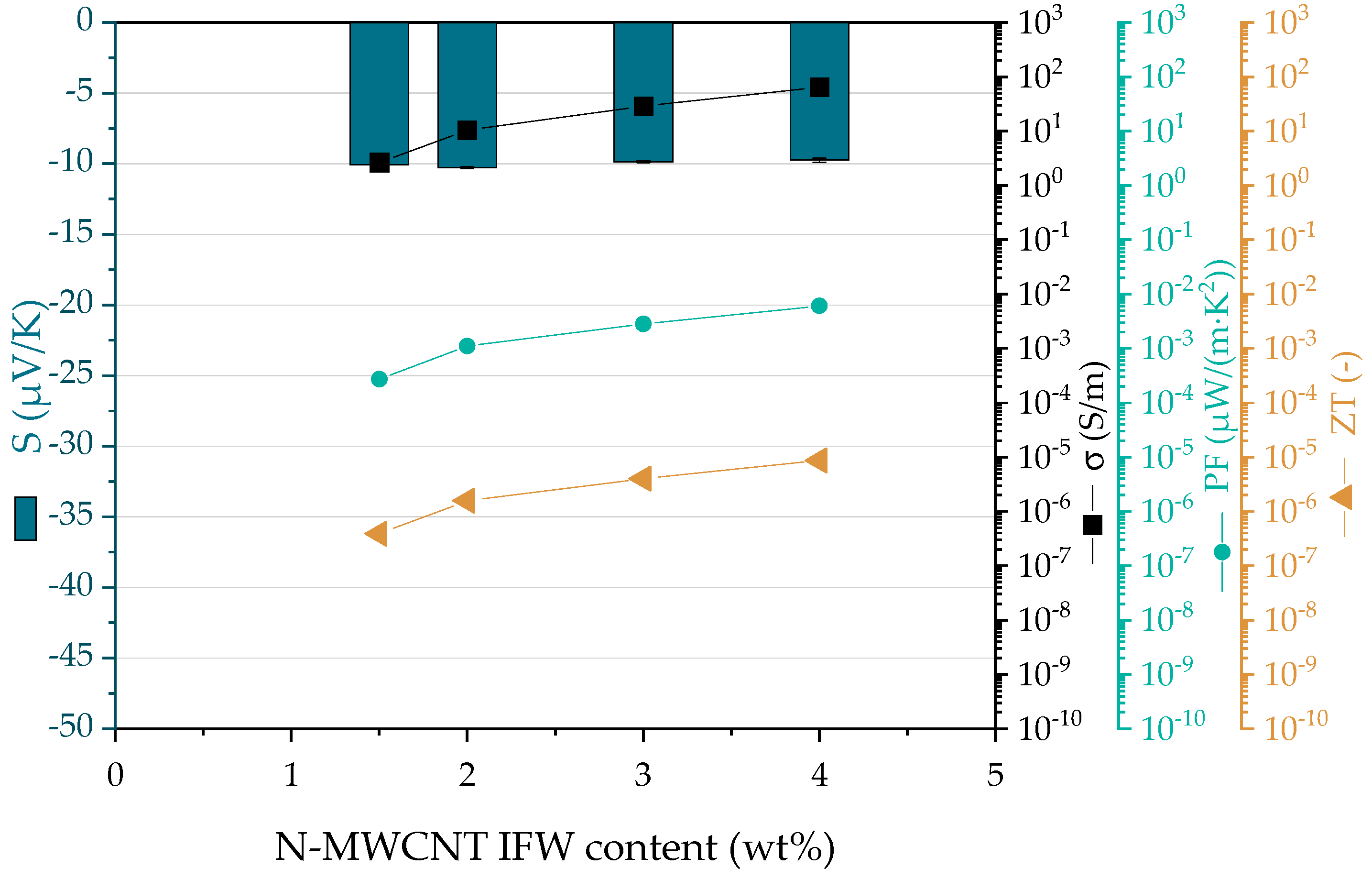

3.1.1. Measurements at 40 °C

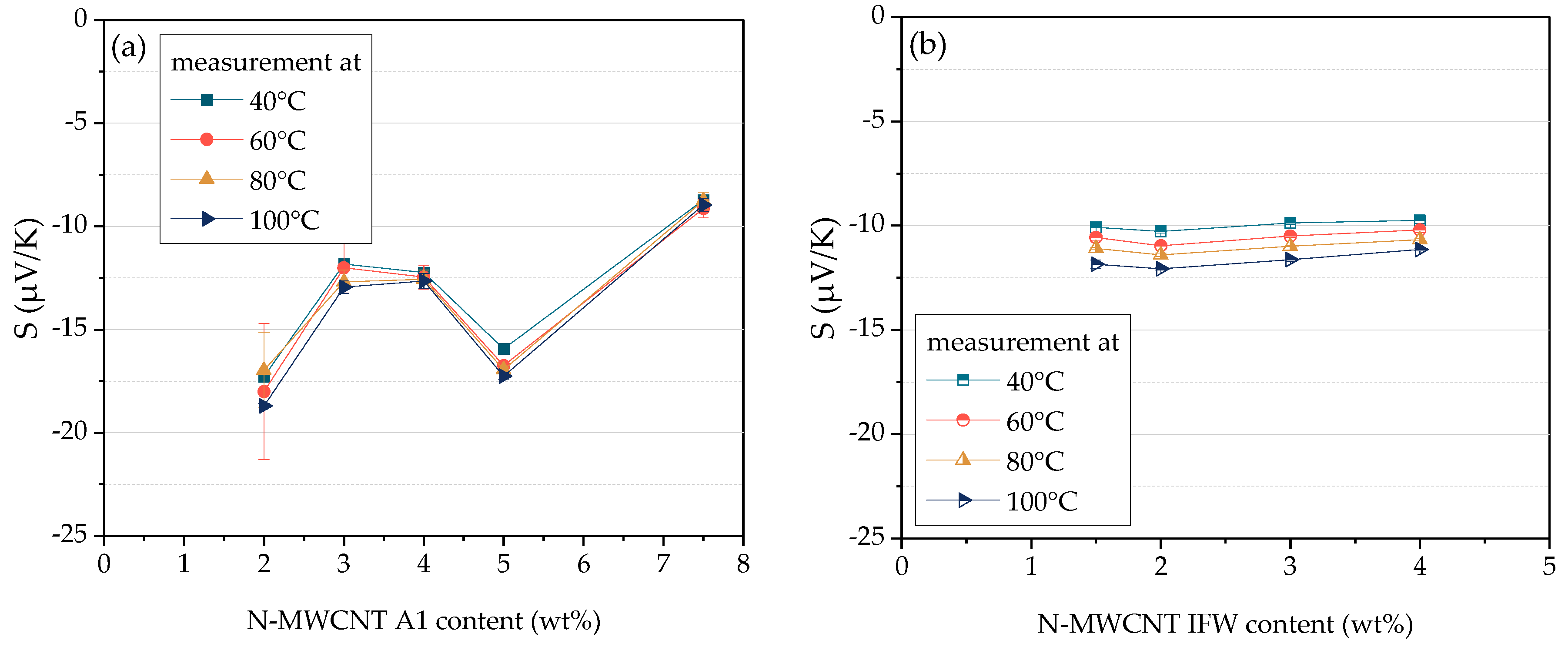

3.1.2. Measurements at Elevated Temperatures

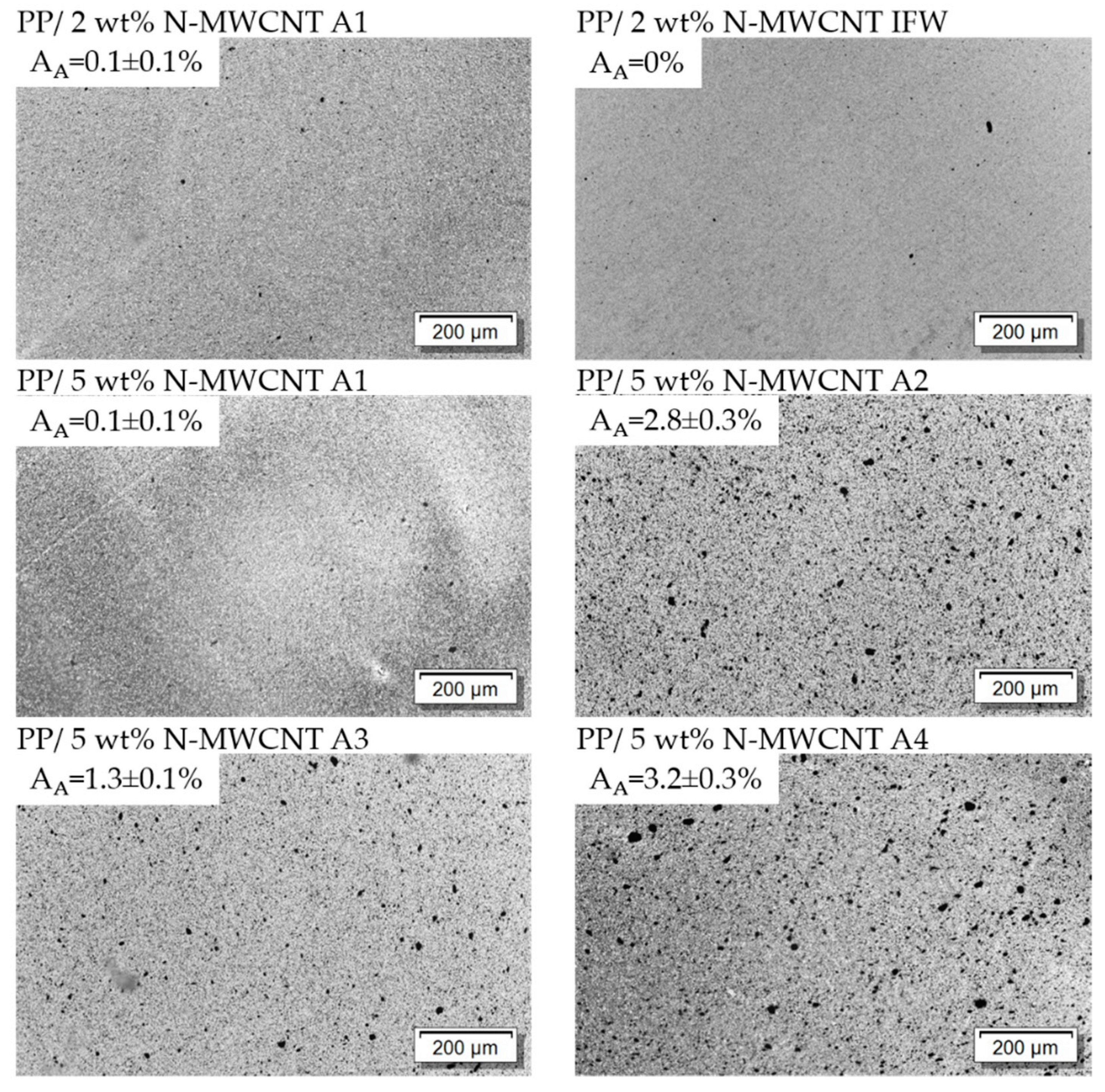

3.2. Macrodispersion of Nitrogen-Doped Multi-Walled Carbon Nanotubes (N-MWCNT) in Polypropylene (PP) Composites

3.3. Comparison of TE Properties of Composites with Buckypapers or Powder Packages of N-MWCNTs and Undoped CNTs

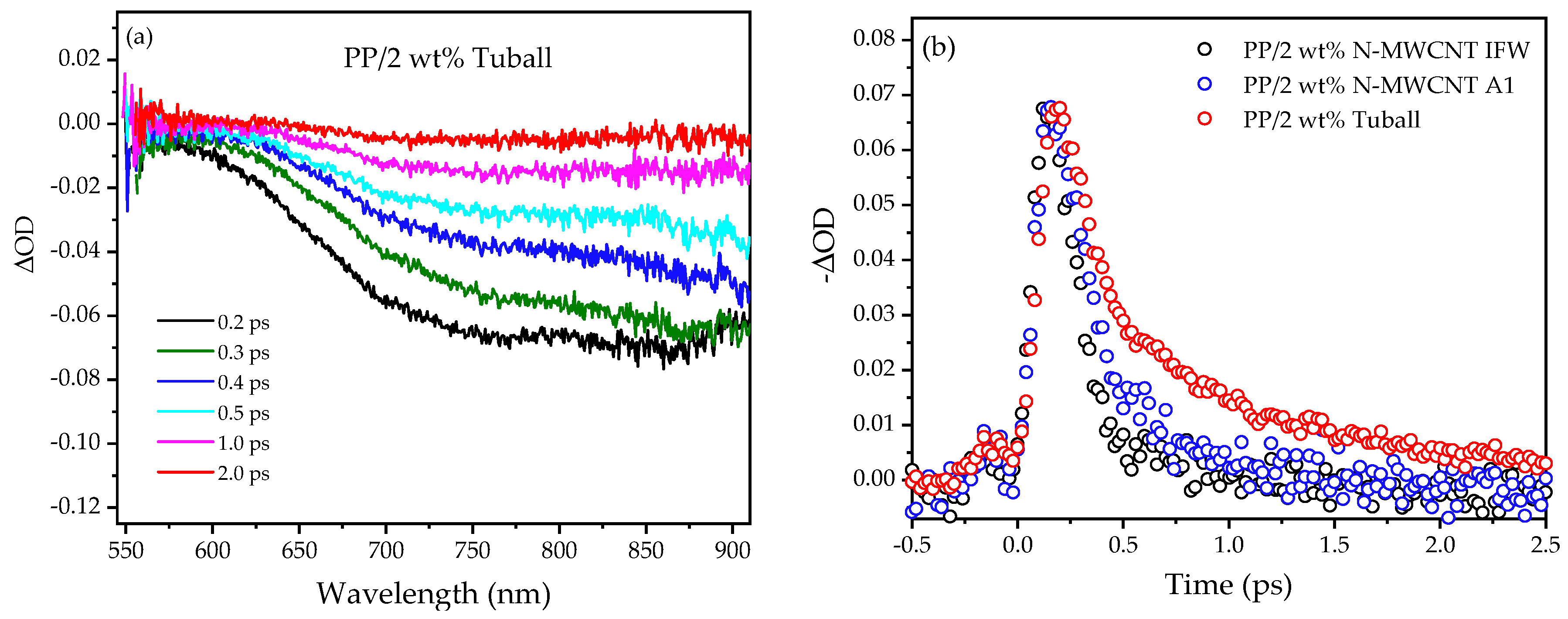

3.4. Transient Absorption Spectroscopy (TAS) Measurement of PP Composites Filled with N-Doped or Undoped CNTs

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mater. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Caballero-Calero, O.; Martín-González, M. Thermoelectric nanowires: A brief prospective. Scr. Mater. 2016, 111, 54–57. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- McGrail, B.T.; Sehirlioglu, A.; Pentzer, E. Polymer composites for thermoelectric applications. Angew. Chem. Int. Ed. 2015, 54, 1710–1723. [Google Scholar] [CrossRef]

- Collins, P.G.; Bradley, K.; Ishigami, M.; Zettl, A. Extreme oxygen sensitivity of electronic properties of carbon nanotubes. Science 2000, 287, 1801–1804. [Google Scholar] [CrossRef]

- Liebscher, M.; Gärtner, T.; Tzounis, L.; Mičušík, M.; Pötschke, P.; Stamm, M.; Heinrich, G.; Voit, B. Influence of the MWCNT surface functionalization on the thermoelectric properties of melt-mixed polycarbonate composites. Compos. Sci. Technol. 2014, 101, 133–138. [Google Scholar] [CrossRef]

- Tzounis, L.; Gartner, T.; Liebscher, M.; Pötschke, P.; Stamm, M.; Voit, B.; Heinrich, G. Influence of a cyclic butylene terephthalate oligomer on the processability and thermoelectric properties of polycarbonate/MWCNT nanocomposites. Polymer 2014, 55, 5381–5388. [Google Scholar] [CrossRef]

- Latil, S.; Roche, S.; Mayou, D.; Charlier, J.-C. Mesoscopic transport in chemically doped carbon nanotubes. Phys. Rev. Lett. 2004, 92, 256805. [Google Scholar] [CrossRef]

- Terrones, M.; Ajayan, P.M.; Banhart, F.; Blase, X.; Carroll, D.L.; Charlier, J.C.; Czerw, R.; Foley, B.; Grobert, N.; Kamalakaran, R.; et al. N-doping and coalescence of carbon nanotubes: Synthesis and electronic properties. Appl. Phys. A 2002, 74, 355–361. [Google Scholar] [CrossRef]

- Kumanek, B.; Stando, G.; Wróbel, P.S.; Krzywiecki, M.; Janas, D. Thermoelectric properties of composite films from multi-walled carbon nanotubes and ethyl cellulose doped with heteroatoms. Synth. Met. 2019, 257, 116190. [Google Scholar] [CrossRef]

- Brownlie, L.; Shapter, J. Advances in carbon nanotube n-type doping: Methods, analysis and applications. Carbon 2018, 126, 257–270. [Google Scholar] [CrossRef]

- Dörling, B.; Sandoval, S.; Kankla, P.; Fuertes, A.; Tobias, G.; Campoy-Quiles, M. Exploring different doping mechanisms in thermoelectric polymer/carbon nanotube composites. Synth. Met. 2017, 225, 70–75. [Google Scholar] [CrossRef]

- Piao, M.; Alam, M.R.; Kim, G.; Dettlaff-Weglikowska, U.; Roth, S. Effect of chemical treatment on the thermoelectric properties of single walled carbon nanotube networks. Phys. Status Solidi B 2012, 249, 2353–2356. [Google Scholar] [CrossRef]

- Ryu, Y.; Freeman, D.; Yu, C. High electrical conductivity and n-type thermopower from double-/single-wall carbon nanotubes by manipulating charge interactions between nanotubes and organic/inorganic nanomaterials. Carbon 2011, 49, 4745–4751. [Google Scholar] [CrossRef]

- Liu, Y.; Nitschke, M.; Stepien, L.; Khavrus, V.; Bezugly, V.; Cuniberti, G. Ammonia plasma-induced n-type doping of semiconducting carbon nanotube films: Thermoelectric properties and ambient effects. ACS Appl. Mater. Interfaces 2019, 11, 21807–21814. [Google Scholar] [CrossRef] [PubMed]

- Ayala, P.; Arenal, R.; Rümmeli, M.; Rubio, A.; Pichler, T. The doping of carbon nanotubes with nitrogen and their potential applications. Carbon 2010, 48, 575–586. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, J.; Na, C.W.; Park, J.; Seo, K.; Kim, B. N-doped double-walled carbon nanotubes synthesized by chemical vapor deposition. Chem. Phys. Lett. 2005, 413, 300–305. [Google Scholar] [CrossRef]

- Boncel, S.; Pattinson, S.W.; Geiser, V.; Shaffer, M.S.P.; Koziol, K.K.K. En route to controlled catalytic CVD synthesis of densely packed and vertically aligned nitrogen-doped carbon nanotube arrays. Beilstein J. Nanotechnol. 2014, 5, 219–233. [Google Scholar] [CrossRef]

- Sharifi, T.; Nitze, F.; Barzegar, H.R.; Tai, C.-W.; Mazurkiewicz, M.; Malolepszy, A.; Stobinski, L.; Wagberg, T. Nitrogen doped multi walled carbon nanotubes produced by CVD-correlating xps and Raman spectroscopy for the study of nitrogen inclusion. Carbon 2012, 50, 3535–3541. [Google Scholar] [CrossRef]

- Fuge, R.; Liebscher, M.; Schröfl, C.; Oswald, S.; Leonhardt, A.; Büchner, B.; Mechtcherine, V. Fragmentation characteristics of undoped and nitrogen-doped multiwalled carbon nanotubes in aqueous dispersion in dependence on the ultrasonication parameters. Diam. Relat. Mater. 2016, 66, 126–134. [Google Scholar] [CrossRef]

- Arjmand, M.; Chizari, K.; Krause, B.; Pötschke, P.; Sundararaj, U. Effect of synthesis catalyst on structure of nitrogen-doped carbon nanotubes and electrical conductivity and electromagnetic interference shielding of their polymeric nanocomposites. Carbon 2016, 98, 358–372. [Google Scholar] [CrossRef]

- Czerw, R.; Terrones, M.; Charlier, J.C.; Blase, X.; Foley, B.; Kamalakaran, R.; Grobert, N.; Terrones, H.; Tekleab, D.; Ajayan, P.M.; et al. Identification of electron donor states in n-doped carbon nanotubes. Nano Lett. 2001, 1, 457–460. [Google Scholar] [CrossRef]

- Kang, H.S.; Jeong, S. Nitrogen doping and chirality of carbon nanotubes. Phys. Rev. B 2004, 70, 233411. [Google Scholar] [CrossRef]

- Rocha, A.R.; Padilha, J.E.; Fazzio, A.; da Silva, A.J.R. Transport properties of single vacancies in nanotubes. Phys. Rev. B 2008, 77, 153406. [Google Scholar] [CrossRef]

- Eckert, V.; Leonhardt, A.; Hampel, S.; Büchner, B. Morphology of MWCNT in dependence on n-doping, synthesized using a sublimation-based CVD method at 750 °C. Diam. Relat. Mater. 2018, 86, 8–14. [Google Scholar] [CrossRef]

- Tzounis, L.; Liebscher, M.; Fuge, R.; Leonhardt, A.; Mechtcherine, V. P- and n-type thermoelectric cement composites with CVD grown p- and n-doped carbon nanotubes: Demonstration of a structural thermoelectric generator. Energy Build. 2019, 191, 151–163. [Google Scholar] [CrossRef]

- Ewels, C.P.; Glerup, M. Nitrogen doping in carbon nanotubes. J. Nanosci. Nanotechnol. 2005, 5, 1345–1363. [Google Scholar] [CrossRef]

- Cruz-Silva, E.; Cullen, D.A.; Gu, L.; Romo-Herrera, J.M.; Muñoz-Sandoval, E.; López-Urías, F.; Sumpter, B.G.; Meunier, V.; Charlier, J.-C.; Smith, D.J.; et al. Heterodoped nanotubes: Theory, synthesis, and characterization of phosphorus−nitrogen doped multiwalled carbon nanotubes. ACS Nano 2008, 2, 441–448. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Bellmann, C.; Khavrus, V.; Oswald, S.; Hampel, S.; Leonhardt, A. Surface properties of CNTs and their interaction with silica. J. Colloid Interface Sci. 2014, 413, 43–53. [Google Scholar] [CrossRef]

- Konidakis, I.; Maksudov, T.; Serpetzoglou, E.; Kakavelakis, G.; Kymakis, E.; Stratakis, E. Improved charge carrier dynamics of CH3NH3PBI3 perovskite films synthesized by means of laser-assisted crystallization. ACS Appl. Energy Mater. 2018, 1, 5101–5111. [Google Scholar] [CrossRef]

- Chochos, C.L.; Leclerc, N.; Gasparini, N.; Zimmerman, N.; Tatsi, E.; Katsouras, A.; Moschovas, D.; Serpetzoglou, E.; Konidakis, I.; Fall, S.; et al. The role of chemical structure in indacenodithienothiophene-alt-benzothiadiazole copolymers for high performance organic solar cells with improved photo-stability through minimization of burn-in loss. J. Mater. Chem. A 2017, 5, 25064–25076. [Google Scholar] [CrossRef]

- Serpetzoglou, E.; Konidakis, I.; Maksudov, T.; Panagiotopoulos, A.; Kymakis, E.; Stratakis, E. In situ monitoring of the charge carrier dynamics of CH3NH3PBI3 perovskite crystallization process. J. Mater. Chem. C 2019, 7, 12170. [Google Scholar] [CrossRef]

- Dal Conte, S.; Vidmar, L.; Golež, D.; Mierzejewski, M.; Soavi, G.; Peli, S.; Banfi, F.; Ferrini, G.; Comin, R.; Ludbrook, B.M.; et al. Snapshots of the retarded interaction of charge carriers with ultrafast fluctuations in cuprates. Nat. Phys. 2015, 11, 421. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Rana, F. Ultrafast dynamics of defect-assisted electron–hole recombination in monolayer MoS2. Nano Lett. 2015, 15, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Konidakis, I.; Skoulas, E.; Papadopoulos, A.; Serpetzoglou, E.; Margariti, E.; Stratakis, E. Erasable and rewritable laser-induced gratings on silver phosphate glass. Appl. Phys. A 2018, 124, 839. [Google Scholar] [CrossRef]

- Styers-Barnett, D.J.; Ellison, S.P.; Mehl, B.P.; Westlake, B.C.; House, R.L.; Park, C.; Wise, K.E.; Papanikolas, J.M. Exciton dynamics and biexciton formation in single-walled carbon nanotubes studied with femtosecond transient absorption spectroscopy. J. Phys. Chem. C 2008, 112, 4507–4516. [Google Scholar] [CrossRef]

- Ruzicka, B.A.; Wang, R.; Lohrman, J.; Ren, S.; Zhao, H. Exciton diffusion in semiconducting single-walled carbon nanotubes studied by transient absorption microscopy. Phys. Rev. B 2012, 86, 205417. [Google Scholar] [CrossRef]

- Soavi, G.; Scotognella, F.; Brida, D.; Hefner, T.; Späth, F.; Antognazza, M.R.; Hertel, T.; Lanzani, G.; Cerullo, G. Ultrafast charge photogeneration in semiconducting carbon nanotubes. J. Phys. Chem. C 2013, 117, 10849–10855. [Google Scholar] [CrossRef]

- Bai, Y.; Olivier, J.-H.; Bullard, G.; Liu, C.; Therien, M.J. Dynamics of charged excitons in electronically and morphologically homogeneous single-walled carbon nanotubes. Proc. Natl. Acad. Sci. USA 2018, 115, 674–679. [Google Scholar] [CrossRef]

- Luo, J.; Cerretti, G.; Krause, B.; Zhang, L.; Otto, T.; Jenschke, W.; Ullrich, M.; Tremel, W.; Voit, B.; Pötschke, P. Polypropylene-based melt mixed composites with singlewalled carbon nanotubes for thermoelectric applications: Switching from p-type to n-type by the addition of polyethylene glycol. Polymer 2017, 108, 513–520. [Google Scholar] [CrossRef]

- Luo, J.; Krause, B.; Pötschke, P. Melt-mixed thermoplastic composites containing carbon nanotubes for thermoelectric applications. Aims Mater. Sci. 2016, 3, 1107–1116. [Google Scholar] [CrossRef]

- Luo, J.; Krause, B.; Pötschke, P. Polymer-carbon nanotube composites for thermoelectric applications. Aip Conf. Proc. 2017, 1914, 030001. [Google Scholar]

- Pötschke, P.; Krause, B.; Luo, J. Melt mixed composites of polypropylene with singlewalled carbon nanotubes for thermoelectric applications: Switching from p- to n-type behavior by additive addition. Aip Conf. Proc. 2019, 2055, 090004. [Google Scholar]

- Paleo, A.J.; Vieira, E.M.F.; Wan, K.; Bondarchuk, O.; Cerqueira, M.F.; Goncalves, L.M.; Bilotti, E.; Alpuim, P.; Rocha, A.M. Negative thermoelectric power of melt mixed vapor grown carbon nanofiber polypropylene composites. Carbon 2019, 150, 408–416. [Google Scholar] [CrossRef]

- Pawar, S.P.; Arjmand, M.; Pötschke, P.; Krause, B.; Fischer, D.; Bose, S.; Sundararaj, U. Tuneable dielectric properties derived from nitrogen-doped carbon nanotubes in PVDF-based nanocomposites. ACS Omega 2018, 3, 9966–9980. [Google Scholar] [CrossRef]

- Technical Data Sheet: NC7000™, v08, 12 July 2016; Nanocyl: Sambreville, Belgium, 2007; Available online: https://www.nanocyl.com/wp-content/uploads/2016/07/DM-TI-02-TDS-NC7000-V08.pdf (accessed on 10 December 2019).

- Castillo, F.Y.; Socher, R.; Krause, B.; Headrick, R.; Grady, B.P.; Prada-Silvy, R.; Pötschke, P. Electrical, mechanical, and glass transition behavior of polycarbonate-based nanocomposites with different multi-walled carbon nanotubes. Polymer 2011, 52, 3835–3845. [Google Scholar] [CrossRef]

- Krause, B.; Boldt, R.; Pötschke, P. A method for determination of length distributions of multiwalled carbon nanotubes before and after melt processing. Carbon 2011, 49, 1243–1247. [Google Scholar] [CrossRef]

- Chen, L.; Ozisik, R.; Schadler, L.S. The influence of carbon nanotube aspect ratio on the foam morphology of MWNT/PMMA nanocomposite foams. Polymer 2010, 51, 2368–2375. [Google Scholar] [CrossRef]

- Krause, B.; Barbier, C.; Kunz, K.; Pötschke, P. Comparative study of singlewalled, multiwalled, and branched carbon nanotubes melt mixed in different thermoplastic matrices. Polymer 2018, 159, 75–85. [Google Scholar] [CrossRef]

- TuballTM Graphene Nanotubes. Available online: https://tuball.com/en/about-tuball (accessed on 16 September 2019).

- Krause, B.; Pötschke, P.; Ilin, E.; Predtechenskiy, M. Melt mixed SWCNT-polypropylene composites with very low electrical percolation. Polymer 2016, 98, 45–50. [Google Scholar] [CrossRef]

- Krestinin, A.V.; Dremova, N.N.; Knerel’man, E.I.; Blinova, L.N.; Zhigalina, V.G.; Kiselev, N.A. Characterization of SWCNT products manufactured in Russia and the prospects for their industrial application. Nanotechnol. Russ. 2015, 10, 537–548. [Google Scholar] [CrossRef]

- Gnanaseelan, M.; Chen, Y.; Luo, J.; Krause, B.; Pionteck, J.; Pötschke, P.; Qi, H. Cellulose-carbon nanotube composite aerogels as novel thermoelectric materials. Compos. Sci. Technol. 2018, 163, 133–140. [Google Scholar] [CrossRef]

- Jenschke, W.; Ullrich, M.; Krause, B.; Pötschke, P. Messanlage zur Untersuchung des Seebeck-Effektes in Polymermaterialien–Measuring apparatus for study of Seebeck-effect in polymer materials. Tech. Mess. 2020, 87. [Google Scholar] [CrossRef]

- Krause, B.; Barbier, C.; Levente, J.; Klaus, M.; Pötschke, P. Screening of different carbon nanotubes in melt-mixed polymer composites with different polymer matrices for their thermoelectric properties. J. Compos. Sci. 2019, 3, 106. [Google Scholar] [CrossRef]

- Rzeczkowski, P.; Krause, B.; Pötschke, P. Characterization of highly filled PP/graphite composites for adhesive joining in fuel cell applications. Polymers 2019, 11, 462. [Google Scholar] [CrossRef] [PubMed]

- Krause, B.; Pötschke, P. Electrical and thermal conductivity of polypropylene filled with combinations of carbon fillers. Aip Conf. Proc. 2016, 1779, 040003. [Google Scholar]

- Shklovskii, B.I.; Efros, A.L. Variable-range hopping conduction. In Electronic Properties of Doped Semiconductors; Springer: Berlin/Heidelberg, Germany, 1984; pp. 202–227. [Google Scholar]

- Kasaliwal, G.R.; Pegel, S.; Göldel, A.; Pötschke, P.; Heinrich, G. Analysis of agglomerate dispersion mechanisms of multiwalled carbon nanotubes during melt mixing in polycarbonate. Polymer 2010, 51, 2708–2720. [Google Scholar] [CrossRef]

- Bulusheva, L.G.; Okotrub, A.V.; Kinloch, I.A.; Asanov, I.P.; Kurenya, A.G.; Kudashov, A.G.; Chen, X.; Song, H. Effect of nitrogen doping on Raman spectra of multi-walled carbon nanotubes. Phys. Status Solidi B 2008, 245, 1971. [Google Scholar] [CrossRef]

| N-MWCNT Code and Reference | Catalyst Material | Synthesis Time (min) | Gas Ratio (sccm) | Nitrogen Content (at %) | Dia-Meter (nm) | Length x50 (nm) | ID/IG (-) + |

|---|---|---|---|---|---|---|---|

| A1 [46] | Iron (III) nitrate nanohydrate | 120 | ethane/ammonia/argon: 50/50/50 | 0.88 | 35 ± 15 | 907 | 0.94 ± 0.14 |

| A2 [46] | Iron (III) nitrate nanohydrate | 120 | ethane/ammonia/argon: 50/80/20 | 0.41 | 39 ± 13 | 1312 | 0.98 ± 0.24 |

| A3 [46] | Iron (III) nitrate nanohydrate | 180 | ethane/ammonia/argon: 50/50/50 | 0.56 | 38 ± 14 | 799 | 0.76 ± 0.41 |

| A4 [22] | cobalt nitrate hexahydrate | 120 | ethane/ammonia/argon: 50/50/50 | 2.2 | 25 | 2600 * | 0.79 |

| IFW [21,27] | ferrocene | 20 | argon/hydrogen: 200/200 | 2.3 | 50 | 14,000 * | 1.17 |

| Sample | Volume Conductivity σ (S/m) | Seebeck Coefficient S (µV/K) | Power Factor PF (µW/m·K2) |

|---|---|---|---|

| Undoped MWCNTs | |||

| NC7000 buckypaper [57] | 3125 | 8.0 ± 0.0 | 0.2015 |

| NC7000 powder [57] | 417 | 6.3 ± 0.0 | 0.0165 |

| PP/2 wt% NC7000 [57] | 2 | 9.5 ± 0.1 | 0.0001 |

| CNS-PEG buckypaper [57] | 9622 | 15.3 ± 0.0 | 2.2569 |

| CNS PEG powder [57] | 933 | 10.1 ± 0.0 | 0.0949 |

| PP/2 wt% CNS-PEG [57] | 96 | 17.5 ± 0.0 | 0.0291 |

| Undoped SWCNTs | |||

| Tuball buckypaper [57] | 42,227 | 37.4 ± 0.9 | 59.1933 |

| Tuball powder [57] | 1790 | 39.6 ± 0.2 | 2.8094 |

| PP/2 wt% Tuball [57] | 12 | 47.2 ± 1.9 | 0.0270 |

| N-MWCNTs | |||

| N-MWCNT A1 powder [57] | 86 | −11.6 ± 0.1 | 0.0117 |

| PP/2 wt% N-MWCNT A1 | 8.3 × 10−2 | −17.3 ± 0.4 | 2.5 × 10−5 |

| PP/5 wt% N-MWCNT A1 | 4 | −15.9 ± 0.1 | 1.1 × 10−3 |

| N-MWCNT A2 powder | 250 | −12.3 ± 0.1 | 0.0376 |

| PP/5 wt% N-MWCNT A2 1 | 1.4 × 10−2 | −22.9 ± 1.4 | 7.1 × 10−6 |

| N-MWCNT A3 powder | 122 | −13.8 ± 0.4 | 0.0233 |

| PP/5 wt% N-MWCNT A3 1 | 2.5 × 10−2 | −18.8 ± 2.2 | 8.7 × 10−6 |

| N-MWCNT A4 powder | 340 | 1.0 ± 0.0 | 0.0003 |

| PP/5 wt% N-MWCNT A4 1 | 1.2 × 10−1 | −4.7 ± 1.6 | 2.6 × 10−6 |

| N-MWCNT IFW buckypaper [57] | 2196 | −10.3 ± 0.0 | 0.2348 |

| N-MWCNT IFW buckypaper 2 [27] | 2748 | −43 ± 1.2 | 5.081 |

| N-MWCNT IFW powder [57] | 506 | −12.7 ± 0.1 | 0.0812 |

| PP/2 wt% N-MWCNT IFW [57] | 10 | −10.3 ± 0.1 | 0.0011 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krause, B.; Konidakis, I.; Arjmand, M.; Sundararaj, U.; Fuge, R.; Liebscher, M.; Hampel, S.; Klaus, M.; Serpetzoglou, E.; Stratakis, E.; et al. Nitrogen-Doped Carbon Nanotube/Polypropylene Composites with Negative Seebeck Coefficient. J. Compos. Sci. 2020, 4, 14. https://doi.org/10.3390/jcs4010014

Krause B, Konidakis I, Arjmand M, Sundararaj U, Fuge R, Liebscher M, Hampel S, Klaus M, Serpetzoglou E, Stratakis E, et al. Nitrogen-Doped Carbon Nanotube/Polypropylene Composites with Negative Seebeck Coefficient. Journal of Composites Science. 2020; 4(1):14. https://doi.org/10.3390/jcs4010014

Chicago/Turabian StyleKrause, Beate, Ioannis Konidakis, Mohammad Arjmand, Uttandaraman Sundararaj, Robert Fuge, Marco Liebscher, Silke Hampel, Maxim Klaus, Efthymis Serpetzoglou, Emmanuel Stratakis, and et al. 2020. "Nitrogen-Doped Carbon Nanotube/Polypropylene Composites with Negative Seebeck Coefficient" Journal of Composites Science 4, no. 1: 14. https://doi.org/10.3390/jcs4010014

APA StyleKrause, B., Konidakis, I., Arjmand, M., Sundararaj, U., Fuge, R., Liebscher, M., Hampel, S., Klaus, M., Serpetzoglou, E., Stratakis, E., & Pötschke, P. (2020). Nitrogen-Doped Carbon Nanotube/Polypropylene Composites with Negative Seebeck Coefficient. Journal of Composites Science, 4(1), 14. https://doi.org/10.3390/jcs4010014