Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers

Abstract

:1. Introduction

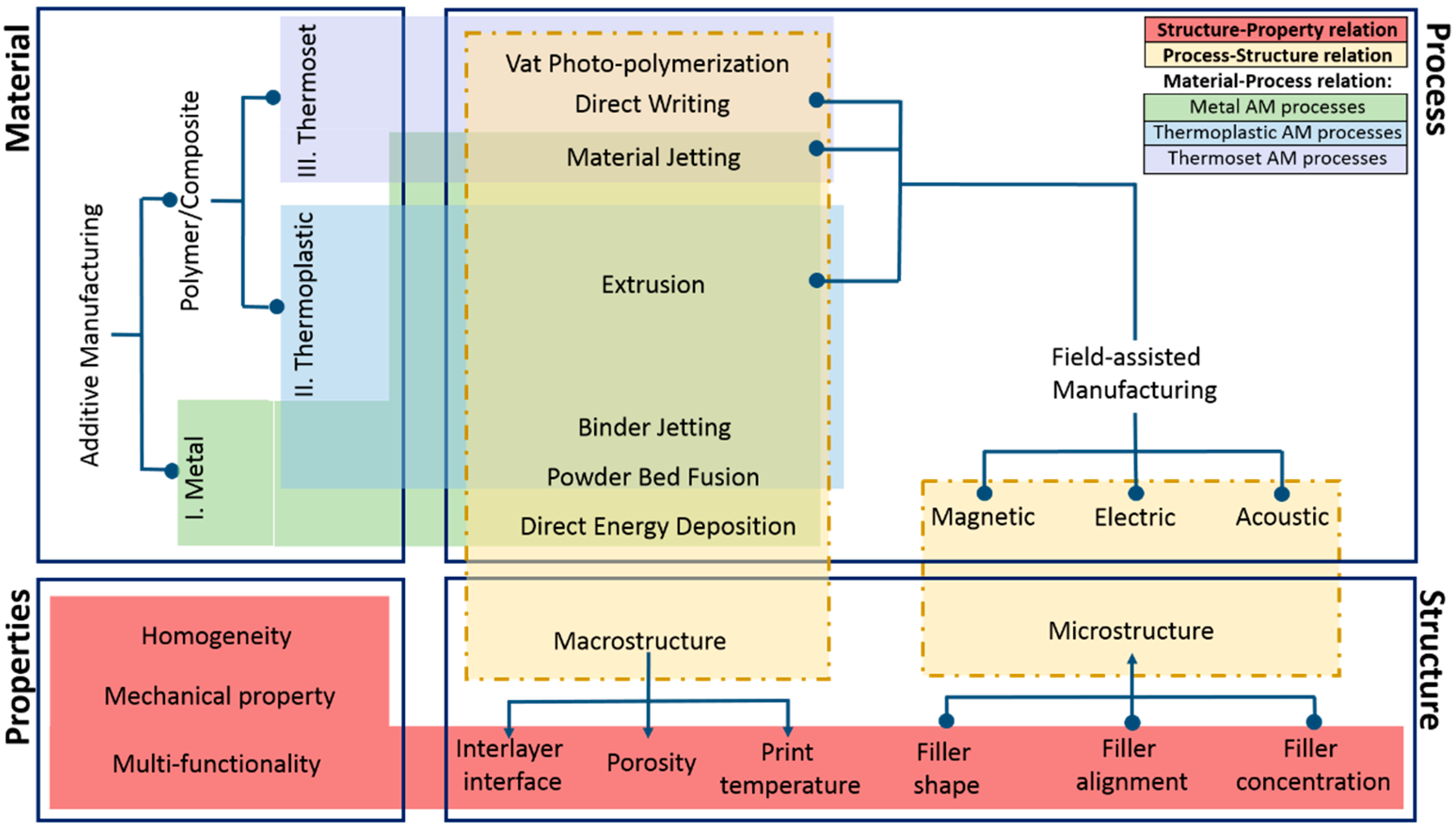

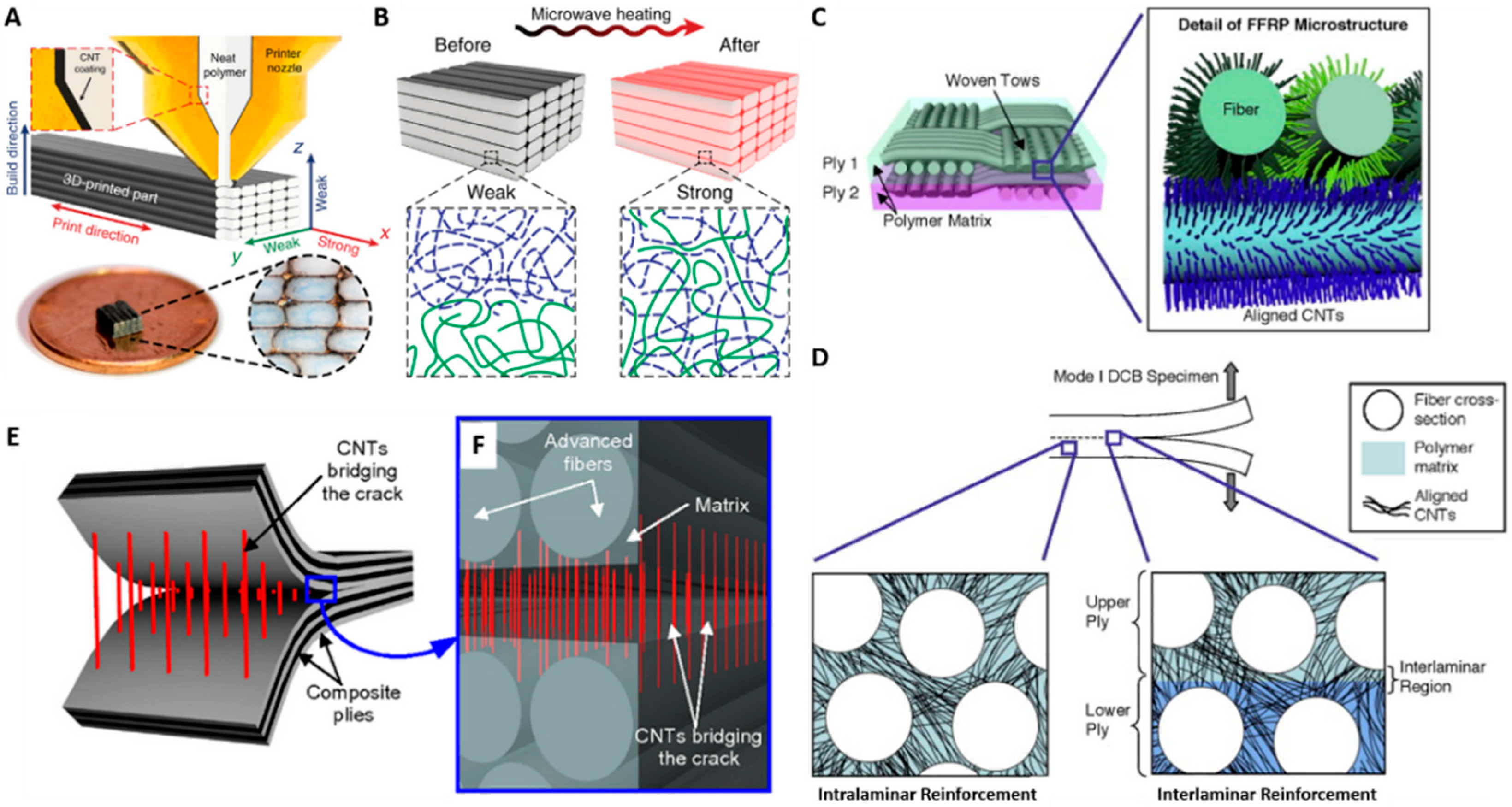

1.1. How Composites Are Finding Their Way into Traditional AM

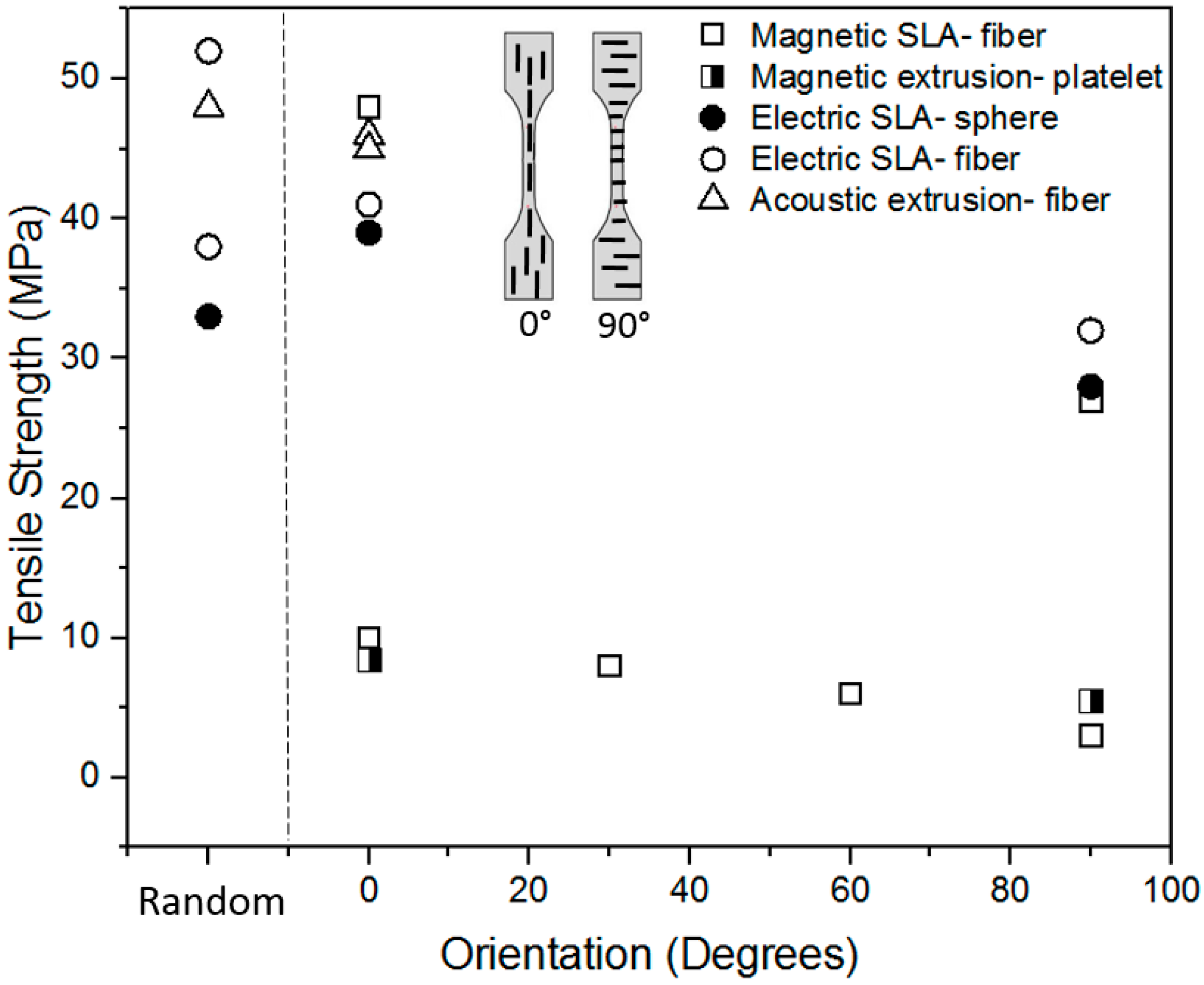

1.2. Need for Fiber Orientation Control in Composite AM

2. Field-Assisted Manufacturing Technologies

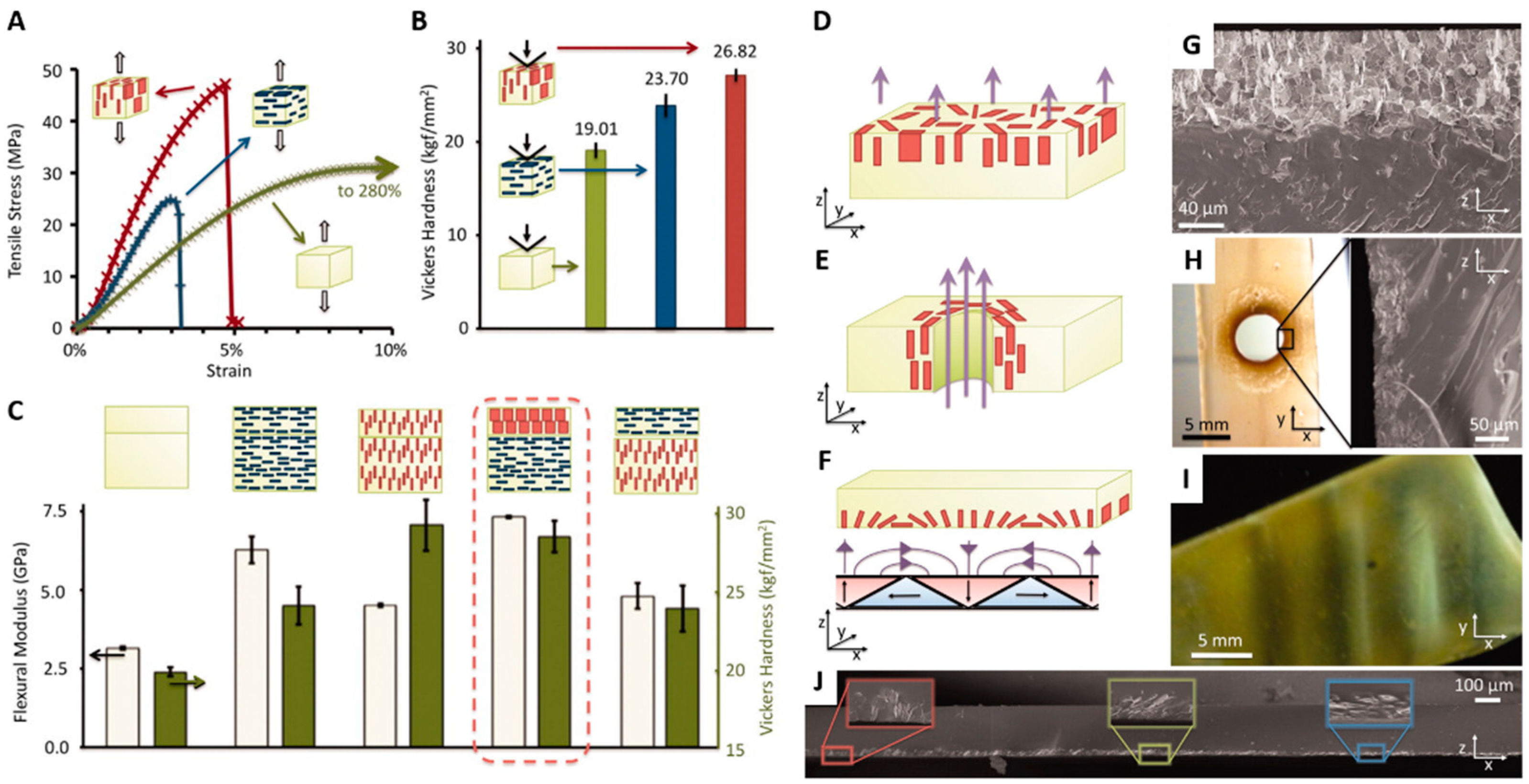

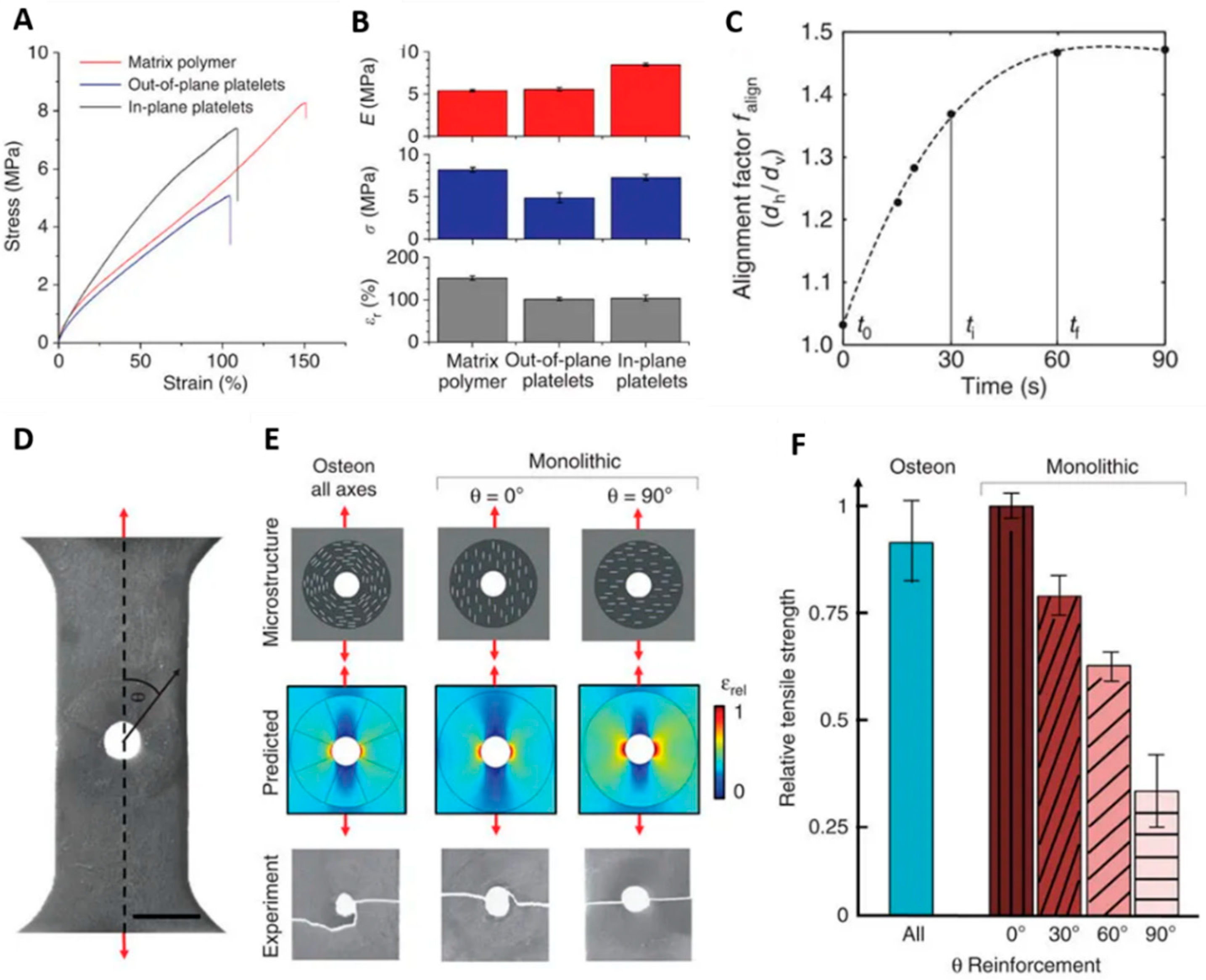

2.1. Magnetic Field-Assisted Additive Manufacturing

2.2. Electric Field Assisted Additive Manufacturing

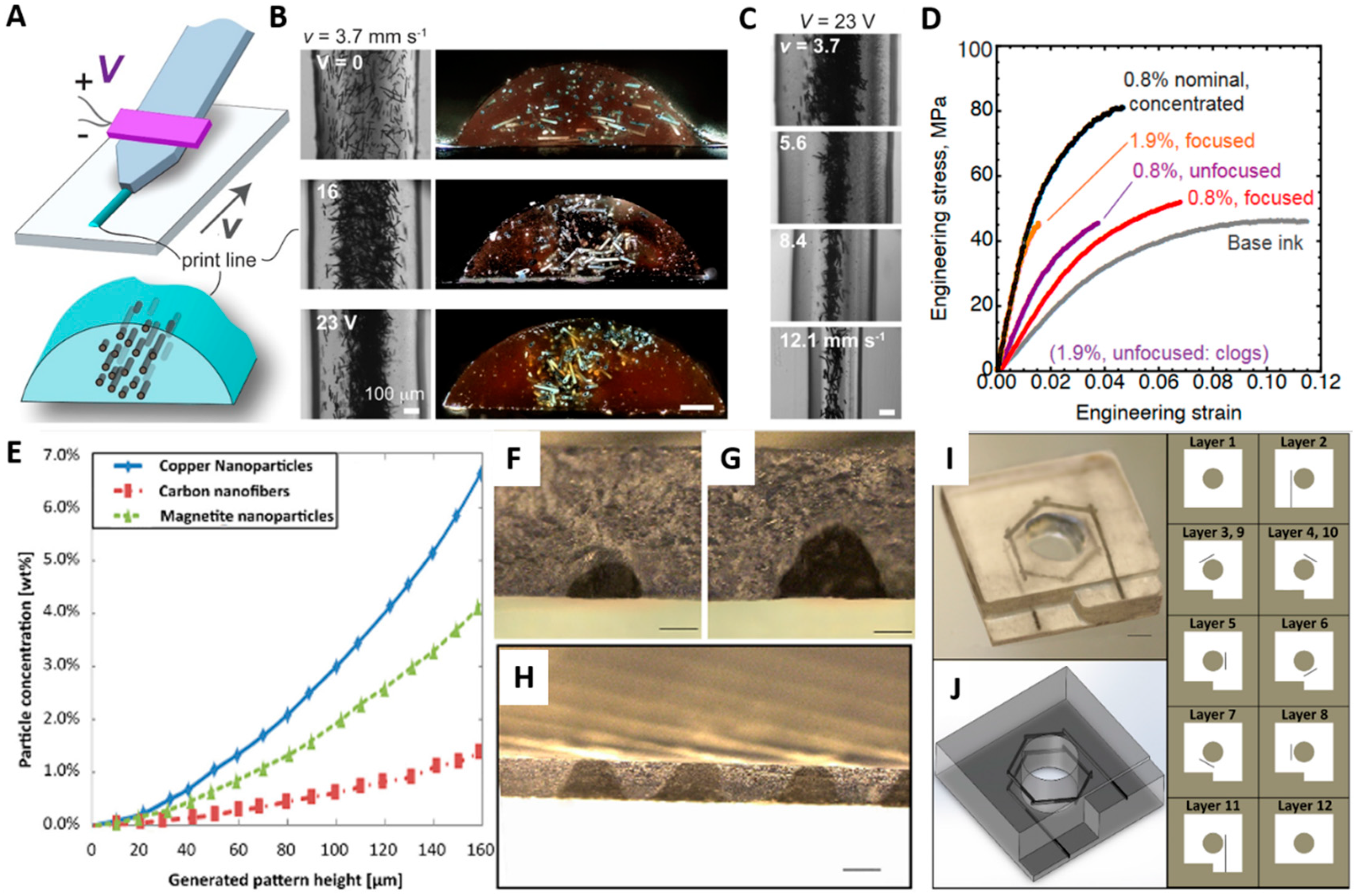

2.3. Acoustic Field-Assisted Additive Manufacturing

2.4. Modeling and Orientation Prediction

3. Challenges and Future Outlook

4. Conclusions

Funding

Conflicts of Interest

References

- Wohlers, T. Annual Worldwide Progress Report; Wohler Associates Inc.: Fort Collins, CO, USA, 2002; p. 4. [Google Scholar]

- Gibson, R.F. A review of recent research on mechanics of multifunctional composite materials and structures. Compos. Struct. 2010, 92, 2793–2810. [Google Scholar] [CrossRef]

- Rengier, F.; Mehndiratta, A.; von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.-U.; Giesel, F.L. 3D printing based on imaging data: review of medical applications. Int. J. Comput. Assist. Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef]

- Pfister, A.; Landers, R.; Laib, A.; Hübner, U.; Schmelzeisen, R.; Mülhaupt, R. Biofunctional rapid prototyping for tissue-engineering applications: 3D bioplotting versus 3D printing. J. Polym. Sci. Part Polym. Chem. 2004, 42, 624–638. [Google Scholar] [CrossRef]

- Moon, S.K.; Tan, Y.E.; Hwang, J.; Yoon, Y.-J. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 223–228. [Google Scholar] [CrossRef]

- Murr, L.E. Frontiers of 3D printing/additive manufacturing: From human organs to aircraft fabrication. J. Mater. Sci. Technol. 2016, 32, 987–995. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Ota, H.; Emaminejad, S.; Gao, Y.; Zhao, A.; Wu, E.; Challa, S.; Chen, K.; Fahad, H.M.; Jha, A.K.; Kiriya, D.; et al. Application of 3D printing for smart objects with embedded electronic sensors and systems. Adv. Mater. Technol. 2016, 1, 1600013. [Google Scholar] [CrossRef] [Green Version]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Moghadam, A.A.A.; Gibson, I.; Kaynak, A. Evolution of 3D printed soft actuators. Sens. Actuators Phys. 2016, 250, 258–272. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- AbouHashem, Y.; Dayal, M.; Savanah, S.; Štrkalj, G. The application of 3D printing in anatomy education. Med. Educ. Online 2015, 20, 29847. [Google Scholar] [CrossRef]

- Canessa, E.; Baruzzo, M.; Fonda, C. Study of Moineau-based pumps for the volumetric extrusion of pellets. Addit. Manuf. 2017, 17, 143–150. [Google Scholar] [CrossRef]

- Birtchnell, T.; Hoyle, W. 3D Printing for Development in the Global South: The 3D 4D Challenge; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 978-1-137-36566-8. [Google Scholar]

- Wu, W.Z.; Geng, P.; Zhao, J.; Zhang, Y.; Rosen, D.W.; Zhang, H.B. Manufacture and thermal deformation analysis of semicrystalline polymer polyether ether ketone by 3D printing. Mater. Res. Innov. 2014, 18, S5-12–S5-16. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Annoni, M.; Giberti, H.; Strano, M. Feasibility Study of an extrusion-based direct metal additive manufacturing technique. Procedia Manuf. 2016, 5, 916–927. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: A review and future perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [Green Version]

- Lieberwirth, C.; Harder, A.; Seitz, H. Extrusion based additive manufacturing of metal parts. J. Mech. Eng. Autom. 2017, 7, 79–83. [Google Scholar]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process parameter optimization of extrusion-based 3D metal printing utilizing PW–LDPE–SA binder system. Materials 2017, 10, 305. [Google Scholar] [CrossRef] [Green Version]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Faes, M.; Valkenaers, H.; Vogeler, F.; Vleugels, J.; Ferraris, E. Extrusion-based 3D printing of ceramic components. Procedia CIRP 2015, 28, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Yang, S.; Chi, X.; Evans, J.R.G. Fine ceramic lattices prepared by extrusion freeforming. J. Biomed. Mater. Res. B Appl. Biomater. 2006, 79B, 116–121. [Google Scholar] [CrossRef]

- Der Klift, F.V.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D printing of continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) tensile test specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef] [Green Version]

- Lewicki, J.P.; Rodriguez, J.N.; Zhu, C.; Worsley, M.A.; Wu, A.S.; Kanarska, Y.; Horn, J.D.; Duoss, E.B.; Ortega, J.M.; Elmer, W.; et al. 3D-printing of meso-structurally ordered carbon fiber/polymer composites with unprecedented orthotropic physical properties. Sci. Rep. 2017, 7, 43401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sand, I.D. Thixotropic, Thermosetting Resins for Use in a Material Extrusion Process in Additive Manufacturing. U.S. Patent 9,707,717, 18 July 2017. [Google Scholar]

- Magasinski, A.; Dixon, P.; Hertzberg, B.; Kvit, A.; Ayala, J.; Yushin, G. High-performance lithium-ion anodes using a hierarchical bottom-up approach. Nat. Mater. 2010, 9, 353–358. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ye, Q.; Cassell, A.; Ng, H.T.; Stevens, R.; Han, J.; Meyyappan, M. Bottom-up approach for carbon nanotube interconnects. Appl. Phys. Lett. 2003, 82, 2491–2493. [Google Scholar] [CrossRef] [Green Version]

- Sial, M.N.; Usman, M.; Zheng, B.; Yu, Y.; Mavrič, A.; Qing, F.; Valant, M.; Wang, Z.M. CVD growth of molybdenum diselenide surface structures with tailored morphology. CrystEngComm 2018, 20, 4867–4874. [Google Scholar] [CrossRef]

- Yang, J.; Downes, R.; Schrand, A.; Park, J.G.; Liang, R.; Xu, C. High electrical conductivity and anisotropy of aligned carbon nanotube nanocomposites reinforced by silicon carbonitride—ScienceDirect. Scr. Mater. 2016, 124, 21–25. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Seifert, T. Additive manufacturing technologies compared: Morphology of deposits of silver ink using inkjet and aerosol jet printing. Ind. Eng. Chem. Res. 2015, 54, 769–779. [Google Scholar] [CrossRef]

- Gibson Lorna, J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 2012, 9, 2749–2766. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired structural materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef]

- Moeller, D.K.; Cho, H.K.; Derenne, K.L.; Shkel, Y.M. Micro-tailoring micro- and nano-composites: Towards variable orthotropy for bio-mimicking materials. In Proceedings of the Smart Structures and Materials 2005: Smart Structures and Integrated Systems; International Society for Optics and Photonics, San Diego, CA, USA, 17 May 2005; Volume 5764, pp. 50–56. [Google Scholar]

- Martin, J.J.; Riederer, M.S.; Krebs, M.D.; Erb, R.M. Understanding and overcoming shear alignment of fibers during extrusion. Soft Matter 2014, 11, 400–405. [Google Scholar] [CrossRef] [PubMed]

- Bonderer, L.J.; Studart, A.R.; Gauckler, L.J. Bioinspired design and assembly of platelet reinforced polymer films. Science 2008, 319, 1069–1073. [Google Scholar] [CrossRef] [PubMed]

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: An additive review of contemporary and modern techniques for advanced materials manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Roy, M.; Dickens, T.J. Additive technology of soluble mold tooling for embedded devices in composite structures: A study on manufactured tolerances. Addit. Manuf. 2017, 15, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Zhong, W.; Li, F.; Zhang, Z.; Song, L.; Li, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Patton, S.T.; Chen, C.; Hu, J.; Grazulis, L.; Schrand, A.M.; Roy, A.K. Characterization of Thermoplastic Polyurethane (TPU) and Ag-carbon black TPU nanocomposite for potential application in additive manufacturing. Polymers 2017, 9, 6. [Google Scholar] [CrossRef] [Green Version]

- Nikzad, M.; Masood, S.H.; Sbarski, I. Thermo-mechanical properties of a highly filled polymeric composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Neff, C.; Elston, E.; Burfeindt, M.; Crane, N.; Schrand, A. A fundamental study of printed ink resiliency for harsh mechanical and thermal environmental applications. Addit. Manuf. 2018, 20, 156–163. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef] [Green Version]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical characterization of metal/polymer composite filaments and printing parameter study for fused deposition modeling in the 3D printing process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Isakov, D.V.; Lei, Q.; Castles, F.; Stevens, C.J.; Grovenor, C.R.M.; Grant, P.S. 3D printed anisotropic dielectric composite with meta-material features. Mater. Des. 2016, 93, 423–430. [Google Scholar] [CrossRef]

- Shemelya, C.M.; Rivera, A.; Perez, A.T.; Rocha, C.; Liang, M.; Yu, X.; Kief, C.; Alexander, D.; Stegeman, J.; Xin, H.; et al. Mechanical, electromagnetic, and X-ray shielding characterization of a 3D printable tungsten–polycarbonate polymer matrix composite for space-based applications. J. Electron. Mater. 2015, 44, 2598–2607. [Google Scholar] [CrossRef]

- Piggott, M.R. Debonding and friction at fibre-polymer interfaces. I: Criteria for failure and sliding. Compos. Sci. Technol. 1987, 30, 295–306. [Google Scholar] [CrossRef]

- Adames, J.M. Characterization of Polymeric Binders for Metal Injection Molding (MIM) Process. Ph.D. Thesis, University of Akron, Akron, OH, USA, 2007. [Google Scholar]

- Muir, E. Innovation in Composite Additive Manufacturing. Master’s Thesis, Lund University, Lund, Sweden, 2015. [Google Scholar]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef] [Green Version]

- Large Scale 3D Printing—Cosine. Available online: https://www.cosineadditive.com (accessed on 19 September 2019).

- Fortify—Manufacturing for the Digital Age. Available online: https://3dfortify.com/ (accessed on 19 September 2019).

- Metal and Carbon Fiber 3D Printers for Manufacturing | Markforged. Available online: https://markforged.com/ (accessed on 19 September 2019).

- Compton, B.G.; Lewis, J.A. 3D-Printing of Lightweight Cellular Composites. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201401804 (accessed on 2 August 2019).

- Nakamoto, T.; Kojima, S. Layered thin film micro parts reinforced with aligned short fibers in laser stereolithography by applying magnetic field. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 849–858. [Google Scholar] [CrossRef] [Green Version]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing bioinspired composite reinforcement architectures via 3D magnetic printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef] [Green Version]

- Erb, R.M.; Sebba, D.S.; Lazarides, A.A.; Yellen, B.B. Magnetic field induced concentration gradients in magnetic nanoparticle suspensions: Theory and experiment. J. Appl. Phys. 2008, 103, 063916. [Google Scholar] [CrossRef]

- Song, H.; Spencer, J.; Jander, A.; Nielsen, J.; Stasiak, J.; Kasperchik, V.; Dhagat, P. Inkjet printing of magnetic materials with aligned anisotropy. J. Appl. Phys. 2014, 115, 17E308. [Google Scholar] [CrossRef]

- Daniel, J.; Ju, L.; Yang, J.; Sun, X.; Gupta, N.; Schrand, A.; Xu, C. Pearl-chain formation of discontinuous carbon fiber under an electrical field. J. Manuf. Mater. Process. 2017, 1, 22. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Guo, Y.; Batra, S.; Wang, E.; Wang, Y.; Liu, X.; Wang, Y.; Cakmak, M. Transparent and through thickness conductive polystyrene films using external magnetic fields for “Z” alignment of nickel nanoparticles. Nanoscale 2015, 7, 14636–14642. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Batra, S.; Chen, Y.; Wang, E.; Cakmak, M. Roll to roll electric field “Z” alignment of nanoparticles from polymer solutions for manufacturing multifunctional capacitor films. ACS Appl. Mater. Interfaces 2016, 8, 18471–18480. [Google Scholar] [CrossRef] [PubMed]

- Qiang, Z.; Guo, Y.; Liu, H.; Cheng, S.Z.D.; Cakmak, M.; Cavicchi, K.A.; Vogt, B.D. Large-scale roll-to-roll fabrication of ordered mesoporous materials using resol-assisted cooperative assembly. ACS Appl. Mater. Interfaces 2015, 7, 4306–4310. [Google Scholar] [CrossRef] [PubMed]

- ASTM International; International Organization for Standardization (ISO). ASTM52900-15 Standard Terminology for Additive Manufacturing—General Principles—Terminology; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Garcia, E.J.; Wardle, B.L.; John Hart, A. Joining prepreg composite interfaces with aligned carbon nanotubes. Compos. Part Appl. Sci. Manuf. 2008, 39, 1065–1070. [Google Scholar] [CrossRef]

- Kruckenberg, T.; Paton, R. Resin Transfer Moulding for Aerospace Structures; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; ISBN 978-94-011-4437-7. [Google Scholar]

- Glenn, F. Fiber insertion process for improved damage tolerance in aircraft laminates. J. Adv. Mater. (USA) 1994, 25, 36–43. [Google Scholar]

- Mohamed, M.H.; Zhang, Z.; Dickinson, L. Manufacture of Multi-Layer Woven Preforms. In Proceedings of the ASME Winter Annual Meeting, Chicago, IL, USA, 27 November–2 December 1988. [Google Scholar]

- Mouritz, A.P.; Bannister, M.K.; Falzon, P.J.; Leong, K.H. Review of applications for advanced three-dimensional fibre textile composites. Compos. Part Appl. Sci. Manuf. 1999, 30, 1445–1461. [Google Scholar] [CrossRef]

- Veedu, V.P.; Cao, A.; Li, X.; Ma, K.; Soldano, C.; Kar, S.; Ajayan, P.M.; Ghasemi-Nejhad, M.N. Multifunctional composites using reinforced laminae with carbon-nanotube forests. Nat. Mater. 2006, 5, 457–462. [Google Scholar] [CrossRef]

- Qian, H.; Greenhalgh, E.S.; Shaffer, M.S.P.; Bismarck, A. Carbon nanotube-based hierarchical composites: A review. J. Mater. Chem. 2010, 20, 4751–4762. [Google Scholar] [CrossRef]

- Erb, R.M.; Libanori, R.; Rothfuchs, N.; Studart, A.R. Composites reinforced in three dimensions by using low magnetic fields. Science 2012, 335, 199–204. [Google Scholar] [CrossRef] [PubMed]

- Duty, C.; Failla, J.; Kim, S.; Smith, T.; Lindahl, J.; Kunc, V. Z-Pinning approach for 3D printing mechanically isotropic materials. Addit. Manuf. 2019, 27, 175–184. [Google Scholar] [CrossRef]

- Islam, M.S.; Prabhakar, P. Interlaminar strengthening of multidirectional laminates using polymer additive manufacturing. Mater. Des. 2017, 133, 332–339. [Google Scholar] [CrossRef]

- Damodaran, V.; Castellanos, A.G.; Milostan, M.; Prabhakar, P. Improving the Mode-II interlaminar fracture toughness of polymeric matrix composites through additive manufacturing. Mater. Des. 2018, 157, 60–73. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Wicks, S.S.; de Villoria, R.G.; Wardle, B.L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos. Sci. Technol. 2010, 70, 20–28. [Google Scholar] [CrossRef]

- Sweeney, C.; Lackey, B.; Saed, M.; Green, M. Microwave Induced Welding of Carbon Nanotube-Thermoplastic Interfaces for Enhanced Mechanical Strength of 3D Printed Parts. In Proceedings of the APS March Meeting, Baltimore, MD, USA, 14–18 March 2016. [Google Scholar]

- Chu, C.; Graf, G.; Rosen, D.W. Design for additive manufacturing of cellular structures. Comput. Aided Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef] [Green Version]

- Sweeney, C.B.; Lackey, B.A.; Pospisil, M.J.; Achee, T.C.; Hicks, V.K.; Moran, A.G.; Teipel, B.R.; Saed, M.A.; Green, M.J. Welding of 3D-printed carbon nanotube–polymer composites by locally induced microwave heating. Sci. Adv. 2017, 3, e1700262. [Google Scholar] [CrossRef] [Green Version]

- Ferrand, H.L.; Bouville, F.; Niebel, T.P.; Studart, A.R. Magnetically-assisted slip casting of bioinspired heterogeneous composites. Nat. Mater. 2015, 14, 1172–1179. [Google Scholar] [CrossRef] [Green Version]

- Holmes, L.R.; Riddick, J.C. Research summary of an additive manufacturing technology for the fabrication of 3D composites with tailored internal structure. JOM 2014, 66, 270–274. [Google Scholar] [CrossRef]

- Collino, R.R.; Ray, T.R.; Fleming, R.C.; Cornell, J.D.; Compton, B.G.; Begley, M.R. Deposition of ordered two-phase materials using microfluidic print nozzles with acoustic focusing. Extrem. Mech. Lett. 2016, 8, 96–106. [Google Scholar] [CrossRef] [Green Version]

- Yunus, D.E.; Sohrabi, S.; He, R.; Shi, W.; Liu, Y. Acoustic patterning for 3D embedded electrically conductive wire in stereolithography. J. Micromech. Microeng. 2017, 27, 045016. [Google Scholar] [CrossRef]

- Vaidyanathan, R. Additive Manufacturing Technologies for Polymers and Composites. Available online: https://www.taylorfrancis.com/ (accessed on 2 August 2019).

- Bakarich, S.E.; Gorkin, R., III; Panhuis, M.; Spinks, G.M. 4D printing with mechanically robust, thermally actuating hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef]

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Bandodkar, A.J.; López, C.S.; Mohan, A.M.V.; Yin, L.; Kumar, R.; Wang, J. All-printed magnetically self-healing electrochemical devices. Sci. Adv. 2016, 2, e1601465. [Google Scholar] [CrossRef] [Green Version]

- Trotsenko, O.; Tokarev, A.; Gruzd, A.; Enright, T.; Minko, S. Magnetic field assisted assembly of highly ordered percolated nanostructures and their application for transparent conductive thin films. Nanoscale 2015, 7, 7155–7161. [Google Scholar] [CrossRef] [Green Version]

- Isaza, J.P.; Avila, A. Iron microparticle deposition at high concentration. Rapid Prototyp. J. 2012, 18, 281–286. [Google Scholar] [CrossRef]

- Vekselman, V.; Sande, L.; Kornev, K.G. Fully magnetic printing by generation of magnetic droplets on demand with a coilgun. J. Appl. Phys. 2015, 118, 224902. [Google Scholar] [CrossRef]

- Fratzl, P.; Weinkamer, R. Nature’s hierarchical materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef] [Green Version]

- Lu, L.; Guo, P.; Pan, Y. Magnetic-field-assisted projection stereolithography for three-dimensional printing of smart structures. J. Manuf. Sci. Eng. 2017, 139, 071008. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D print of polymer bonded rare-earth magnets, and 3D magnetic field scanning with an end-user 3D printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Roh, S.; Okello, L.B.; Golbasi, N.; Hankwitz, J.P.; Liu, J.A.-C.; Tracy, J.B.; Velev, O.D. 3D-printed silicone soft architectures with programmed magneto-capillary reconfiguration. Adv. Mater. Technol. 2019, 4, 1800528. [Google Scholar] [CrossRef] [Green Version]

- Chatzipirpiridis, G.; Gervasoni, S.; Fischer, C.; Ergeneman, O.; Pellicer, E.; Nelson, B.J.; Pané, S. 3D printing of thermoplastic-bonded soft- and hard-magnetic composites: Magnetically tuneable architectures and functional devices. Adv. Intell. Syst. 2019, 1, 1900069. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big area additive manufacturing of high performance bonded NdFeB magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Conner, B.S.; Chi, M.; Elliott, A.M.; Rios, O.; Zhou, H.; Paranthaman, M.P. A novel method combining additive manufacturing and alloy infiltration for NdFeB bonded magnet fabrication. J. Magn. Magn. Mater. 2017, 438, 163–167. [Google Scholar] [CrossRef]

- Li, L.; Post, B.; Kunc, V.; Elliott, A.M.; Paranthaman, M.P. Additive manufacturing of near-net-shape bonded magnets: Prospects and challenges. Scr. Mater. 2017, 135, 100–104. [Google Scholar] [CrossRef]

- Yan, Y.; Ngo, K.D.T.; Mei, Y.; Lu, G.-Q. Additive manufacturing of magnetic components for power electronics integration. In Proceedings of the 2016 International Conference on Electronics Packaging (ICEP), Sapporo, Japan, 20–22 April 2016; pp. 368–371. [Google Scholar]

- Mostafaei, A.; Kimes, K.A.; Stevens, E.L.; Toman, J.; Krimer, Y.L.; Ullakko, K.; Chmielus, M. Microstructural evolution and magnetic properties of binder jet additive manufactured Ni-Mn-Ga magnetic shape memory alloy foam. Acta Mater. 2017, 131, 482–490. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhao, S.; Zhu, M.; Zhu, Y.; Zhang, Y.; Liu, Z.; Zhang, C. 3D-printed magnetic Fe3O4/MBG/PCL composite scaffolds with multifunctionality of bone regeneration, local anticancer drug delivery and hyperthermia. J. Mater. Chem. B 2014, 2, 7583–7595. [Google Scholar] [CrossRef]

- Libanori, R.; Erb, R.M.; Studart, A.R. Mechanics of platelet-reinforced composites assembled using mechanical and magnetic stimuli. ACS Appl. Mater. Interfaces 2013, 5, 10794–10805. [Google Scholar] [CrossRef] [PubMed]

- Grossman, M.; Bouville, F.; Erni, F.; Masania, K.; Libanori, R.; Studart, A.R. Mineral nano-interconnectivity stiffens and toughens nacre-like composite materials. Adv. Mater. 2017, 29, 1605039. [Google Scholar] [CrossRef]

- Kim, G. Field aided technology for local micro-tailoring of polymeric composites with multi-functional response. Ph.D. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2003. [Google Scholar]

- Pinheiro, P.C.; Sousa, C.T.; Araújo, J.P.; Guiomar, A.J.; Trindade, T. Functionalization of nickel nanowires with a fluorophore aiming at new probes for multimodal bioanalysis. J. Colloid Interface Sci. 2013, 410, 21–26. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, M.; Pirota, K.; Hernández-Vélez, M.; Prida, V.M.; Navas, D.; Sanz, R.; Batallán, F.; Velázquez, J. Magnetic properties of densely packed arrays of Ni nanowires as a function of their diameter and lattice parameter. J. Appl. Phys. 2004, 95, 6642–6644. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Petit, T.; Peyer, K.E.; Nelson, B.J. Targeted cargo delivery using a rotating nickel nanowire. Nanomed. Nanotechnol. Biol. Med. 2012, 8, 1074–1080. [Google Scholar] [CrossRef]

- Hultgren, A.; Tanase, M.; Chen, C.S.; Meyer, G.J.; Reich, D.H. Cell manipulation using magnetic nanowires. J. Appl. Phys. 2003, 93, 7554–7556. [Google Scholar] [CrossRef] [Green Version]

- Holmes, J. Micro-Composite Fabrication via Field-Aided Laminar Composite (FALCom) Processing; US Army Research Laboratory: Adelphi, MD, USA, September 2012. [Google Scholar]

- Yang, Y.; Chen, Z.; Song, X.; Zhang, Z.; Zhang, J.; Shung, K.K.; Zhou, Q.; Chen, Y. Biomimetic anisotropic reinforcement architectures by electrically assisted nanocomposite 3D printing. Adv. Mater. 2017, 29, 1605750. [Google Scholar] [CrossRef]

- Kim, G.H. Orthotropic polymeric composites with microstructure tailored by electric field. J. Compos. Mater. 2004, 38, 1895–1909. [Google Scholar] [CrossRef]

- Kim, G.; Shkel, Y.M. Analysis of the electro-orientation of inorganic micro/nano-particles in a liquid polymer considering electrophoresis flow. J. Micromech. Microeng. 2007, 17, 2522. [Google Scholar] [CrossRef]

- Lee, C.; Tarbutton, J.A. Electric poling-assisted additive manufacturing process for PVDF polymer-based piezoelectric device applications. Smart Mater. Struct. 2014, 23, 095044. [Google Scholar] [CrossRef]

- Pascall, A.J.; Qian, F.; Wang, G.; Worsley, M.A.; Li, Y.; Kuntz, J.D. Light-directed electrophoretic deposition: A new additive manufacturing technique for arbitrarily patterned 3D composites. Adv. Mater. 2014, 26, 2252–2256. [Google Scholar] [CrossRef] [PubMed]

- Mora, J.; Dudoff, J.K.; Moran, B.D.; DeOtte, J.R.; Du Frane, W.L.; Kuntz, J.D.; Pascall, A.J. Projection based light-directed electrophoretic deposition for additive manufacturing. Addit. Manuf. 2018, 22, 330–333. [Google Scholar] [CrossRef]

- Sullivan, K.T.; Zhu, C.; Tanaka, D.J.; Kuntz, J.D.; Duoss, E.B.; Gash, A.E. Electrophoretic deposition of thermites onto micro-engineered electrodes prepared by direct-ink writing. J. Phys. Chem. B 2013, 117, 1686–1693. [Google Scholar] [CrossRef] [PubMed]

- Tabellion, J.; Clasen, R. Electrophoretic deposition from aqueous suspensions for near-shape manufacturing of advanced ceramics and glasses—Applications. J. Mater. Sci. 2004, 39, 803–811. [Google Scholar] [CrossRef]

- Hirt, L.; Reiser, A.; Spolenak, R.; Zambelli, T. Additive manufacturing of metal structures at the micrometer scale. Adv. Mater. 2017, 29, 1604211. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Torres, F.; Villagran, D.; Stewart, C.; Lin, Y.; Tseng, T.-L.B. 3D printing of BaTiO3/PVDF composites with electric in situ poling for pressure sensor applications. Macromol. Mater. Eng. 2017, 302, 1700229. [Google Scholar] [CrossRef]

- Gibson, T.; Putthanarat, S.; Fielding, J.C.; Drain, A.; Will, K.; Stoffel, M. Conductive nanocomposites: Focus on lightning strike protection. In Proceedings of the SAMPE Fall Technical Conference and Exhibition, Cincinnati, OH, USA, 29 October–1 November 2007; Volume 66. [Google Scholar]

- Ryan, K.M.; Mastroianni, A.; Stancil, K.A.; Liu, H.; Alivisatos, A.P. Electric-field-assisted assembly of perpendicularly oriented nanorod superlattices. Nano Lett. 2006, 6, 1479–1482. [Google Scholar] [CrossRef] [Green Version]

- Carnell, L.S.; Siochi, E.J.; Wincheski, R.A.; Holloway, N.M.; Clark, R.L. Electric field effects on fiber alignment using an auxiliary electrode during electrospinning. Scr. Mater. 2009, 60, 359–361. [Google Scholar] [CrossRef] [Green Version]

- Park, C.; Wilkinson, J.; Banda, S.; Ounaies, Z.; Wise, K.E.; Sauti, G.; Lillehei, P.T.; Harrison, J.S. Aligned single-wall carbon nanotube polymer composites using an electric field. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 1751–1762. [Google Scholar] [CrossRef]

- Takahashi, T.; Murayama, T.; Higuchi, A.; Awano, H.; Yonetake, K. Aligning vapor-grown carbon fibers in polydimethylsiloxane using dc electric or magnetic field. Carbon 2006, 44, 1180–1188. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Bafekrpour, E.; Ghorbani, K.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 2015, 94, 607–618. [Google Scholar] [CrossRef] [Green Version]

- Kavre, I.; Kostevc, G.; Kralj, S.; Vilfan, A.; Babič, D. Fabrication of magneto-responsive microgears based on magnetic nanoparticle embedded PDMS. RSC Adv. 2014, 4, 38316–38322. [Google Scholar] [CrossRef]

- Zhang, L.; Petit, T.; Lu, Y.; Kratochvil, B.E.; Peyer, K.E.; Pei, R.; Lou, J.; Nelson, B.J. Controlled propulsion and cargo transport of rotating nickel nanowires near a patterned solid surface. ACS Nano 2010, 4, 6228–6234. [Google Scholar] [CrossRef] [PubMed]

- Campbell, T.A.; Ivanova, O.S. 3D printing of multifunctional nanocomposites. Nano Today 2013, 8, 119–120. [Google Scholar] [CrossRef]

- Baur, J.; Silverman, E. Challenges and opportunities in multifunctional nanocomposite structures for aerospace applications. MRS Bull. 2007, 32, 328–334. [Google Scholar] [CrossRef]

- Li, C.; Thostenson, E.T.; Chou, T.-W. Sensors and actuators based on carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2008, 68, 1227–1249. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Park, G.; Rosing, T.; Todd, M.D.; Farrar, C.R.; Hodgkiss, W. Energy harvesting for structural health monitoring sensor networks. J. Infrastruct. Syst. 2008, 14, 64–79. [Google Scholar] [CrossRef] [Green Version]

- Ratna, D.; Karger-Kocsis, J. Recent advances in shape memory polymers and composites: A review. J. Mater. Sci. 2008, 43, 254–269. [Google Scholar] [CrossRef]

- Ahmed, S.; Lauff, C.; Crivaro, A.; McGough, K.; Sheridan, R.; Frecker, M.; von Lockette, P.; Ounaies, Z.; Simpson, T.; Lien, J.-M.; et al. Multi-field Responsive Origami Structures: Preliminary Modeling and Experiments. In Proceedings of the ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Volume 6B: 37th Mechanisms and Robotics Conference. Portland, OR, USA, 4–7 August 2013. [Google Scholar]

- Lauff, C.; Simpson, T.W.; Frecker, M.; Ounaies, Z.; Ahmed, S.; von Lockette, P.; Strzelec, R.; Sheridan, R.; Lien, J.-M. Differentiating Bending From Folding in Origami Engineering Using Active Materials. In Proceedings of the ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Volume 5B: 38th Mechanisms and Robotics Conference. Buffalo, NY, USA, 17–20 August 2014. [Google Scholar]

- Huang, C.-Y.; Wu, C.-C. The EMI shielding effectiveness of PC/ABS/nickel-coated-carbon-fibre composites. Eur. Polym. J. 2000, 36, 2729–2737. [Google Scholar] [CrossRef]

- Jiang, H.; Moon, K.; Li, Y.; Wong, C.P. Surface functionalized silver nanoparticles for ultrahigh conductive polymer composites. Chem. Mater. 2006, 18, 2969–2973. [Google Scholar] [CrossRef]

- Gkourmpis, T. Electrically Conductive Polymer Nanocomposites; Mitchell, G., Tojeira, A., Eds.; Springer: Cham, Switzerland, 2016; pp. 209–236. [Google Scholar]

- Collino, R.R.; Ray, T.R.; Friedrich, L.M.; Cornell, J.D.; Meinhart, C.D.; Begley, M.R. Scaling relationships for acoustic control of two-phase microstructures during direct-write printing. Mater. Res. Lett. 2018, 6, 191–198. [Google Scholar] [CrossRef] [Green Version]

- Llewellyn-Jones, T.M.; Drinkwater, B.W.; Trask, R.S. 3D printed components with ultrasonically arranged microscale structure. Smart Mater. Struct. 2016, 25, 02LT01. [Google Scholar] [CrossRef]

- Parsons, E.M. Lightweight cellular metal composites with zero and tunable thermal expansion enabled by ultrasonic additive manufacturing: Modeling, manufacturing, and testing. Compos. Struct. 2019, 223, 110656. [Google Scholar] [CrossRef]

- Ram, G.D.J.; Robinson, C.; Yang, Y.; Stucker, B.E. Use of ultrasonic consolidation for fabrication of multi-material structures. Rapid Prototyp. J. 2007, 13, 226–235. [Google Scholar]

- Scholz, M.-S.; Drinkwater, B.W.; Trask, R.S. Ultrasonic assembly of anisotropic short fibre reinforced composites. Ultrasonics 2014, 54, 1015–1019. [Google Scholar] [CrossRef]

- Yamahira, S.; Hatanaka, S.; Kuwabara, M.; Asai, S. Orientation of fibers in liquid by ultrasonic standing waves. Jpn. J. Appl. Phys. 2000, 39, 3683. [Google Scholar] [CrossRef]

- Mitri, F.G.; Garzon, F.H.; Sinha, D.N. Characterization of acoustically engineered polymer nanocomposite metamaterials using x-ray microcomputed tomography. Rev. Sci. Instrum. 2011, 82, 034903. [Google Scholar] [CrossRef]

- Saito, M.; Daian, T.; Hayashi, K.; Izumida, S. Fabrication of a polymer composite with periodic structure by the use of ultrasonic waves. J. Appl. Phys. 1998, 83, 3490–3494. [Google Scholar] [CrossRef]

- Tuziuti, T.; Masuda, Y.; Yasui, K.; Kato, K. Two-dimensional patterning of inorganic particles in resin using ultrasound-induced plate vibration. Jpn. J. Appl. Phys. 2011, 50, 088006. [Google Scholar] [CrossRef]

- Hahnlen, R.; Dapino, M.J. NiTi–Al interface strength in ultrasonic additive manufacturing composites. Compos. Part B Eng. 2014, 59, 101–108. [Google Scholar] [CrossRef]

- Monaghan, T.; Capel, A.J.; Christie, S.D.; Harris, R.A.; Friel, R.J. Solid-state additive manufacturing for metallized optical fiber integration. Compos. Part Appl. Sci. Manuf. 2015, 76, 181–193. [Google Scholar] [CrossRef] [Green Version]

- Folgar, F.; Tucker, C.L. Orientation behavior of fibers in concentrated suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Bay, R.S. Fiber Orientation in Injection-Molded Composites: A Comparison of Theory and Experiment. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 1991. [Google Scholar]

- Kenig, S. Fiber orientation development in molding of polymer composites. Polym. Compos. 1986, 7, 50–55. [Google Scholar] [CrossRef]

- Young, W.B.; Fong, K.H.L.H.; Lee, L.J. Flow simulation in molds with preplaced fiber mats. Polym. Compos. 1991, 12, 391–403. [Google Scholar] [CrossRef]

- Foss, P.H.; Tseng, H.-C.; Snawerdt, J.; Chang, Y.-J.; Yang, W.-H.; Hsu, C.-H. Prediction of fiber orientation distribution in injection molded parts using Moldex3D simulation. Polym. Compos. 2014, 35, 671–680. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Vallury, S.; Lin, K.; Yang, A. A study on warpage behavior of EMC in post-mold cure stage using Moldex3D. Addit. Pap. Present. 2016, 2016, 826–850. [Google Scholar]

- Šercer, M.; Godec, D.; Bujanić, B. Application of Moldex3D for Thin-Wall Injection Moulding Simulation. AIP Conf. Proc. 2007, 908, 1067. [Google Scholar] [CrossRef]

- Chang, H.; Lin, T. Long Fiber Orientation and Structural Analysis Using Moldex3D, Digimat and ABAQUS Simulations; SPE ANTEC: Anaheim, CA, USA, 2017. [Google Scholar]

- Composite Engineering and Manufacturing. Available online: https://www.plm.automation.siemens.com/global/en/products/mechanical-design/composite-engineering-manufacturing.html (accessed on 19 September 2019).

- Jeffery, G.B. The motion of ellipsoidal particles immersed in a viscous fluid. Proc. R. Soc. Lond. Ser. Contain. Pap. Math. Phys. Character 1922, 102, 161–179. [Google Scholar] [CrossRef] [Green Version]

- Blaeser, A.; Filipa Duarte Campos, D.; Puster, U.; Richtering, W.; Stevens, M.; Fischer, H. Controlling shear stress in 3D bioprinting is a key factor to balance printing resolution and stem cell integrity. Adv. Healthc. Mater. 2015, 5, 326–333. [Google Scholar] [CrossRef]

- Ciambella, J.; Stanier, D.C.; Rahatekar, S.S. Magnetic alignment of short carbon fibres in curing composites. Compos. Part B Eng. 2017, 109, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Erb, R.M.; Segmehl, J.; Schaffner, M.; Studart, A.R. Temporal response of magnetically labeled platelets under dynamic magnetic fields. Soft Matter 2013, 9, 498–505. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wu, S.; Kinloch, A.J.; Wang, C.H.; Mouritz, A.P. The electric field alignment of short carbon fibres to enhance the toughness of epoxy composites. Compos. Part Appl. Sci. Manuf. 2018, 106, 11–23. [Google Scholar] [CrossRef]

- Tang, H.; Malakooti, M.H.; Sodano, H.A. Relationship between orientation factor of lead zirconate titanate nanowires and dielectric permittivity of nanocomposites. Appl. Phys. Lett. 2013, 103, 222901. [Google Scholar] [CrossRef]

- Bowland, C.C.; Malakooti, M.H.; Zhou, Z.; Sodano, H.A. Highly aligned arrays of high aspect ratio barium titanate nanowires via hydrothermal synthesis. Appl. Phys. Lett. 2015, 106, 222903. [Google Scholar] [CrossRef]

- Mahajan, C.G. Aligning Carbon Fibers in Micro-Extruded Composite Ink. Ph.D. Thesis, Rochester Institute of Technology, New York, NY, USA, 2014. [Google Scholar]

- Mahajan, C.; Cormier, D. 3D Printing of Carbon Fiber Composites with Preferentially Aligned Fibers. In Proceedings of the 2015 Industrial and Systems Engineering Research Conferences, Rochester, NY, USA, 30 May–2 June 2015. [Google Scholar]

- Akula, S. Peridynamic modeling of dynamic fracture in bio-inspired structures for high velocity impacts. Ph.D. Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 2018. [Google Scholar]

- Chen, Z.; Niazi, S.; Zhang, G.; Bobaru, F. Peridynamic functionally graded and porous materials: modeling fracture and damage. In Handbook of Nonlocal Continuum Mechanics for Materials and Structures; Voyiadjis, G.Z., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–35. ISBN 978-3-319-22977-5. [Google Scholar]

- Silling, S.A.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

| AM Process | Specific Approach | Field | Filler Form | Concentration | Alignment |

|---|---|---|---|---|---|

| SLA/Vat photo polymerization | Ref. [58] | Magnetic | Ferromagnetic short fibers | 0.5 vol.% | Unspecified |

| Ref. [59] | Magnetic | Alumina particles/platelets coated with iron oxide nanoparticle, Fe3O4 | 10, 15 vol.% | Unspecified | |

| Ref. [110] | Electric | Ceramic micro spheres; pseudo-fibers | 5 vol.% | In-plane, 0, 90, and random | |

| Ref. [110] | Electric | Glass fiber | 5 vol.% | In-plane, 0, 90, and random | |

| Ref. [115] | Electric | Multi-walled CNT | 0.1 vol.% | In-plane | |

| Ref. [115] | Electric | Aluminum microparticles; pseudo-fibers | 1 vol.% | In-plane | |

| Ref. [87] | Acoustic | Magnetite and copper nanoparticles, carbon nanofibers | 0–9 wt.% | In-plane, 0, and 90 | |

| Extrusion | Ref. [35] | Magnetic | Calcium Phosphate rods with Fe3O4 NP coating | 0.2 vol.% | In-plane; Perpendicular to print direction |

| Ref. [53] | Magnetic | Magnetized anisotropic stiff platelets, non-magnetic (alumina platelets) particles with iron oxide NP | Tunable concentration | In-plane; custom alignment due to rotating field | |

| Ref. [86] | Acoustic | SiC fibers, solid BaTiO3 spheres, hollow SiO2 spheres | 0.8 vol.% | Focused in-plane | |

| Ref. [146] | Acoustic | Glass microfibers | Unspecified | In-plane, 0, 45, and 90 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, M.; Tran, P.; Dickens, T.; Schrand, A. Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers. J. Compos. Sci. 2020, 4, 1. https://doi.org/10.3390/jcs4010001

Roy M, Tran P, Dickens T, Schrand A. Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers. Journal of Composites Science. 2020; 4(1):1. https://doi.org/10.3390/jcs4010001

Chicago/Turabian StyleRoy, Madhuparna, Phong Tran, Tarik Dickens, and Amanda Schrand. 2020. "Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers" Journal of Composites Science 4, no. 1: 1. https://doi.org/10.3390/jcs4010001

APA StyleRoy, M., Tran, P., Dickens, T., & Schrand, A. (2020). Composite Reinforcement Architectures: A Review of Field-Assisted Additive Manufacturing for Polymers. Journal of Composites Science, 4(1), 1. https://doi.org/10.3390/jcs4010001