Influence of Mixing Procedures, Rubber Treatment, and Fibre Additives on Rubcrete Performance

Abstract

1. Introduction

2. Experimental Programme

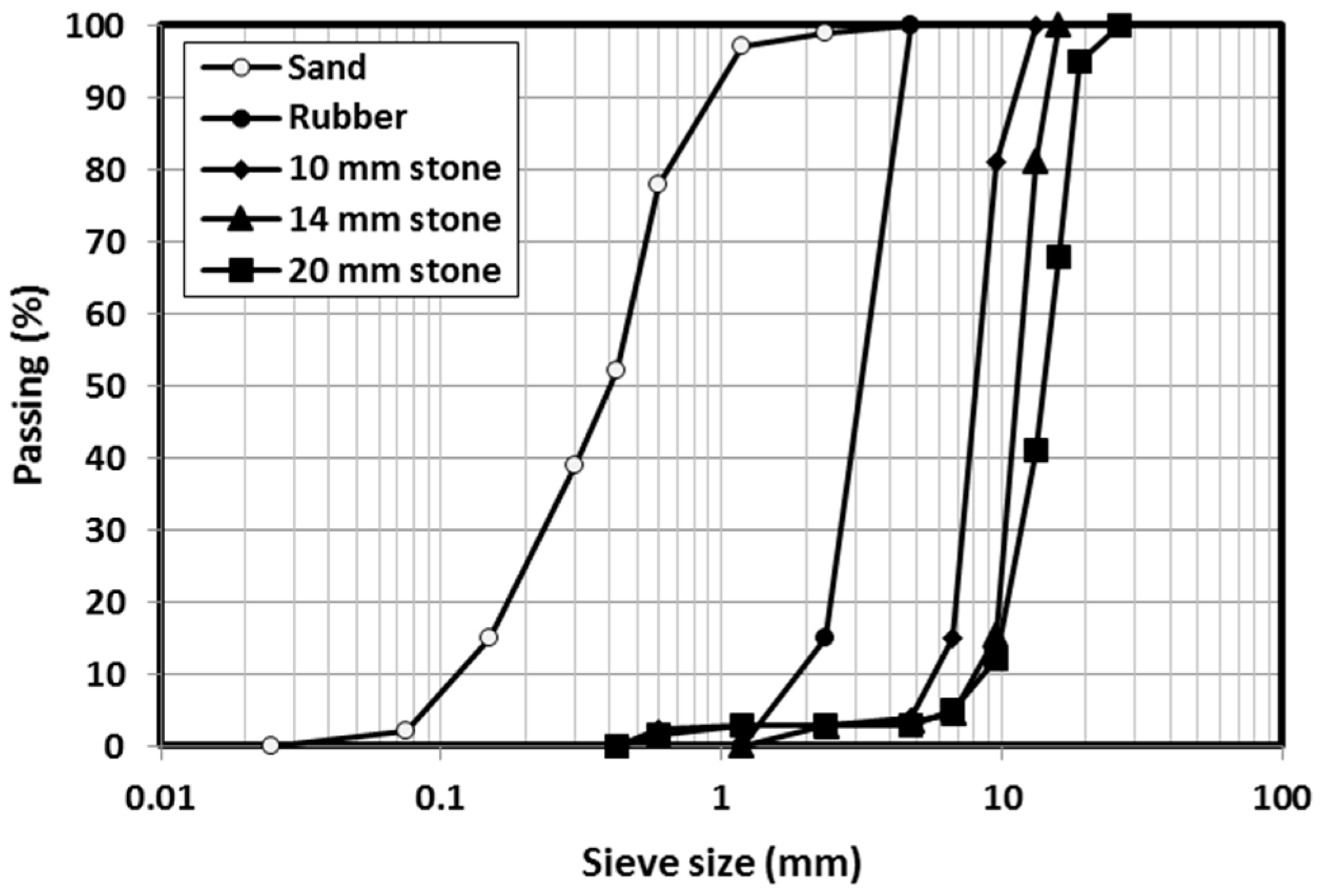

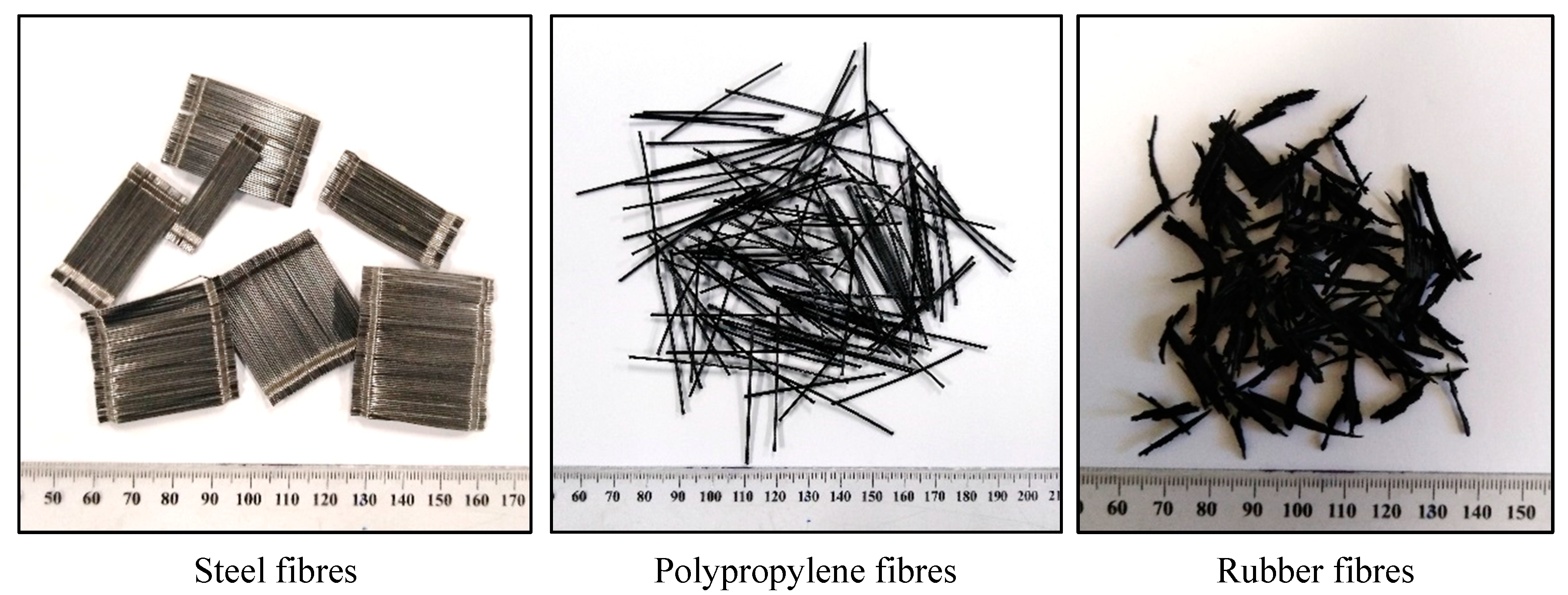

2.1. Concrete Materials and Variables

2.2. Concrete mix Designs and Proposed Mixing Procedures

- Procedure 1 (P1): Mix dry stone, sand, and rubber for 1 min; add ½ water and mix for 1 min; rest for 2 min; add cement, ½ water, and SP, and then mix for 2 min.

- Procedure 2 (P2): Mix dry stone, sand, rubber, and ½ water for 0.5 min; add cement, water, and SP and mix for 2 min; rest for 2 min; and then mix for 2 min.

- Procedure 3 (P3): Mix dry stone, sand, rubber, and cement for 1 min; add water and SP and then mix for 3 min.

- Procedure 4 (P4): Mix dry stone and sand for 1 min; add ½ water and mix for 1 min; rest for 2 min; add rubber, cement, ½ water, and SP, and then mix for 2 min. In P4, the rubber was mixed first with dry cement in a different container before being added to the concrete mix.

- Procedure 5 (P5): Mix stone, sand, rubber, cement, water, and SP for 2 min; rest for 2 min; and then mix for 2 min.

- Procedure 6 (P6): Mix dry stone and sand for 1 min; add ½ water and mix for 1 min; rest for 2 min; add rubber, cement, ½ water, and SP, and then mix for 2 min. In P6, the rubber was mixed with water and SP in a different container before being added to the concrete mix.

2.3. Rubber Particle Pre-Treatment

2.4. Preparation and Testing of Specimens

3. Experimental Results and Discussion

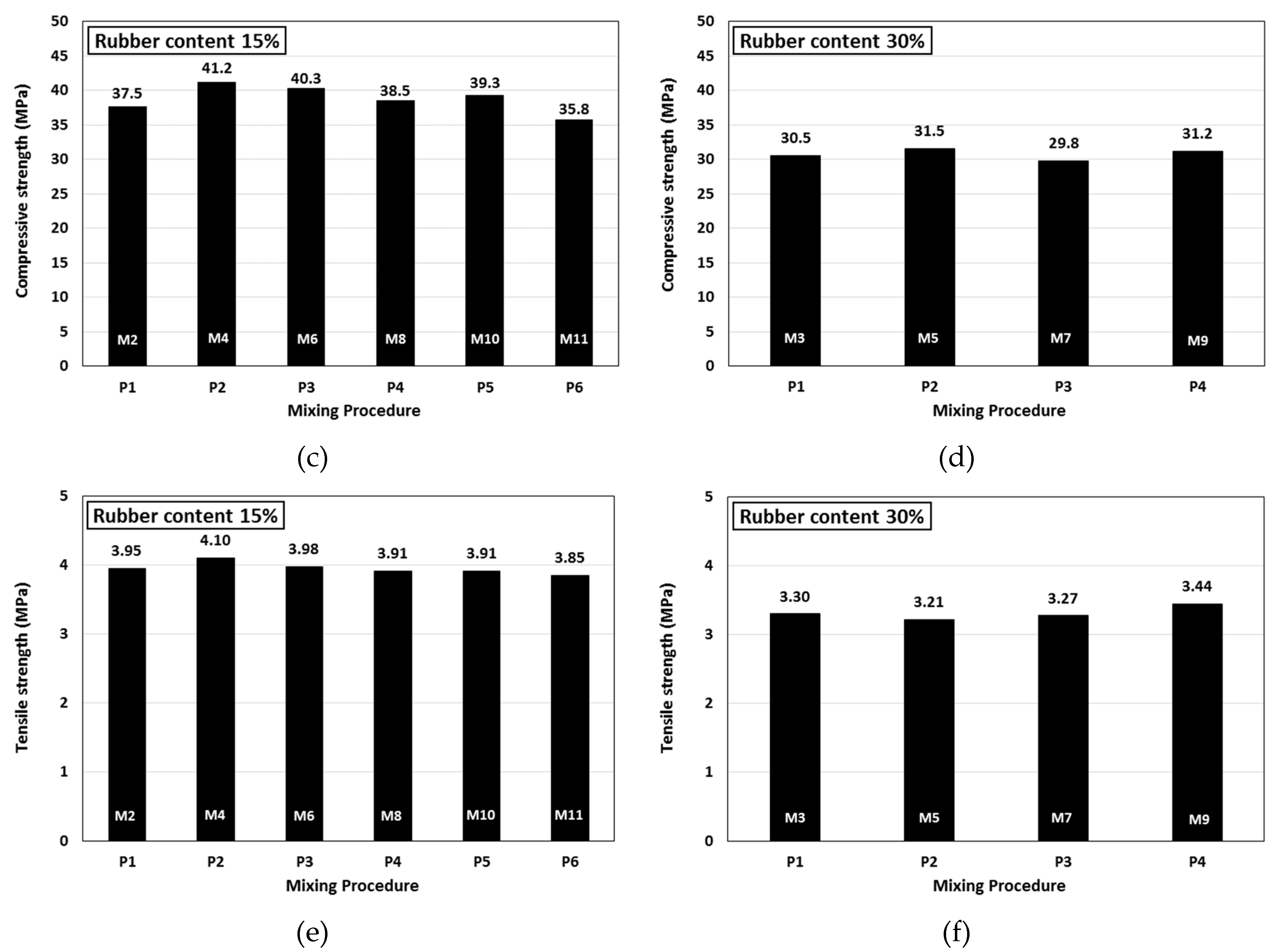

3.1. Effect of Rubcrete Mixing Procedures.

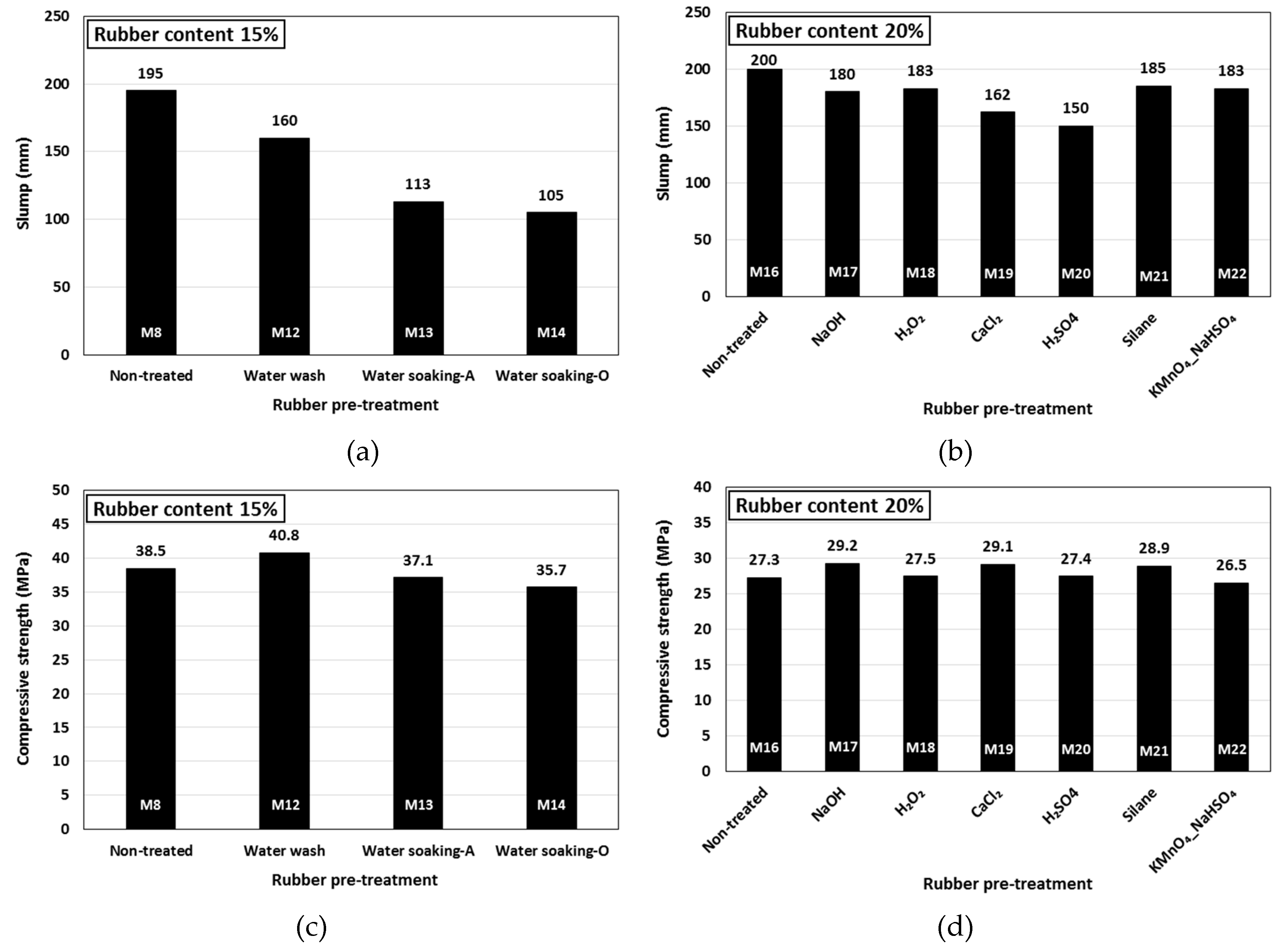

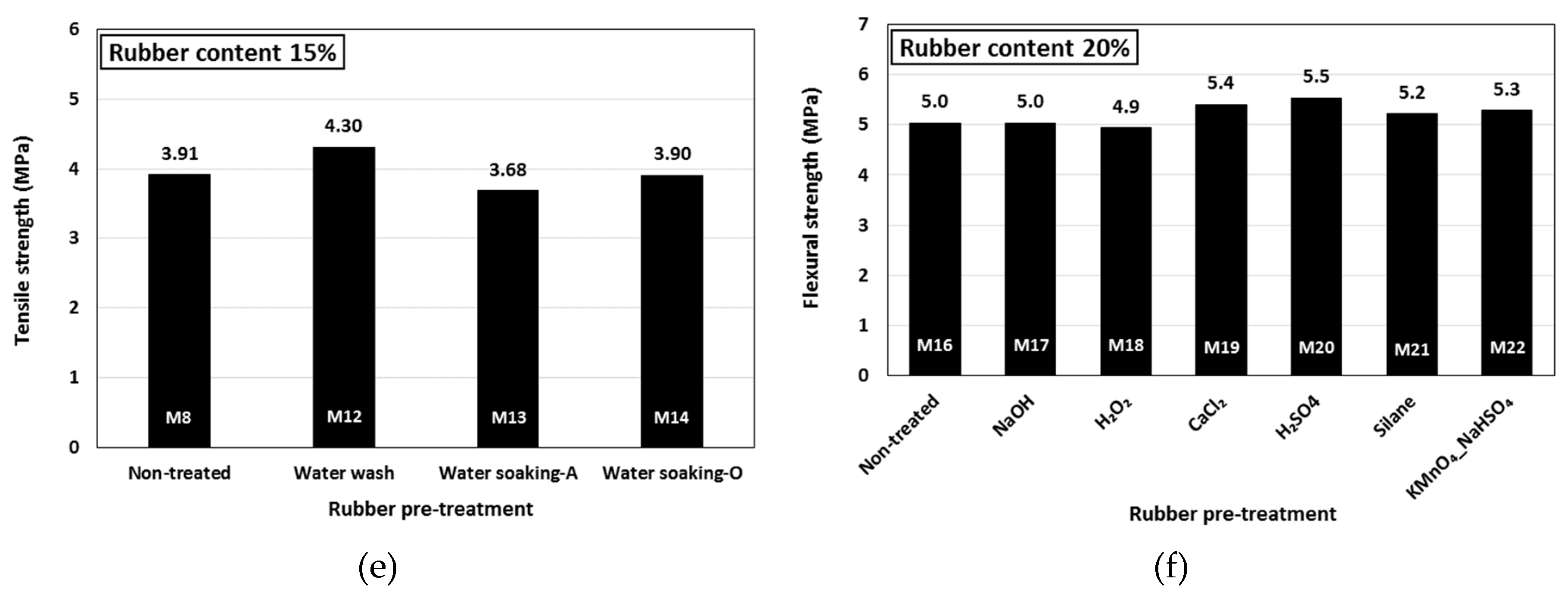

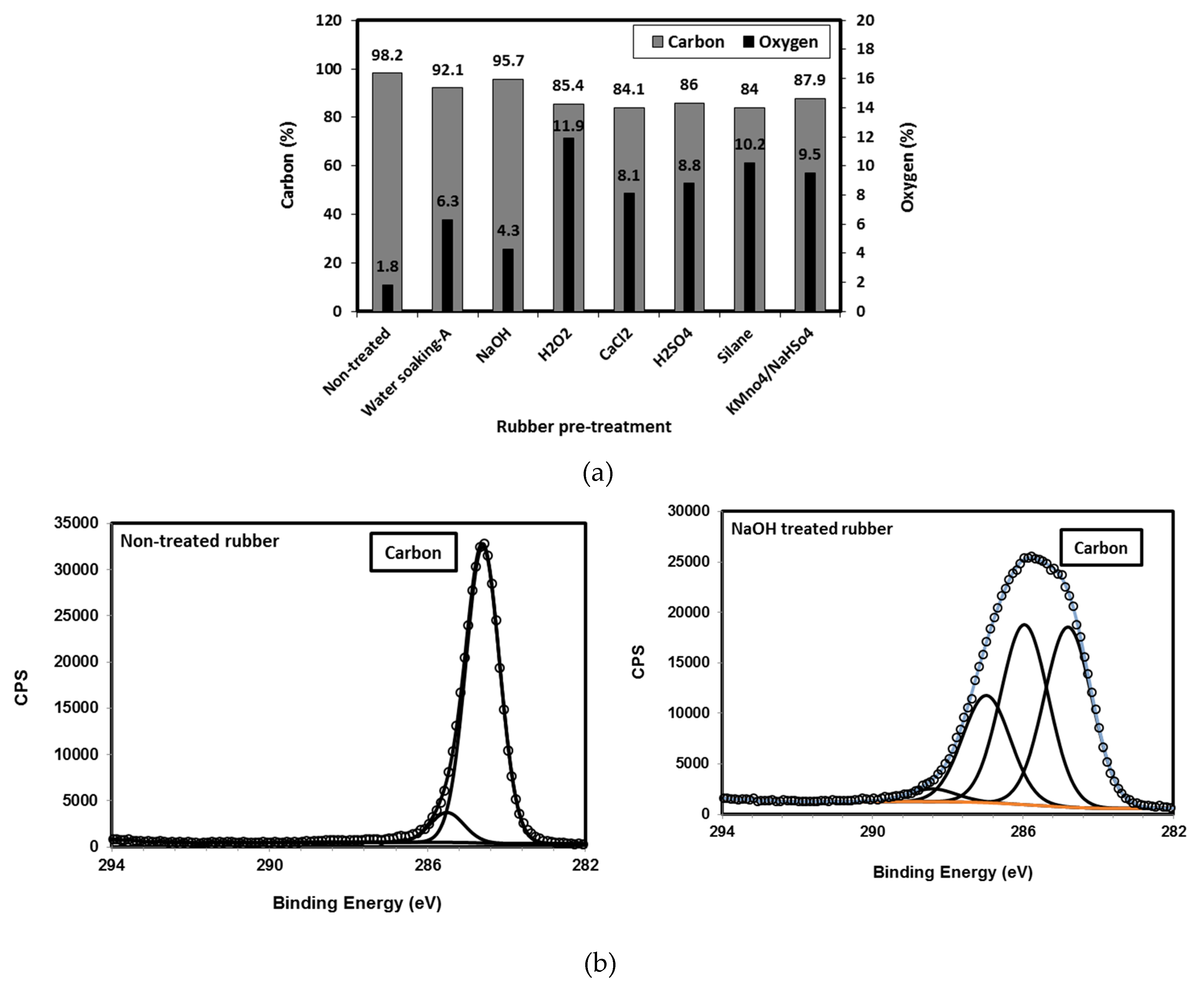

3.2. Effect of Rubber Pre-Treatment

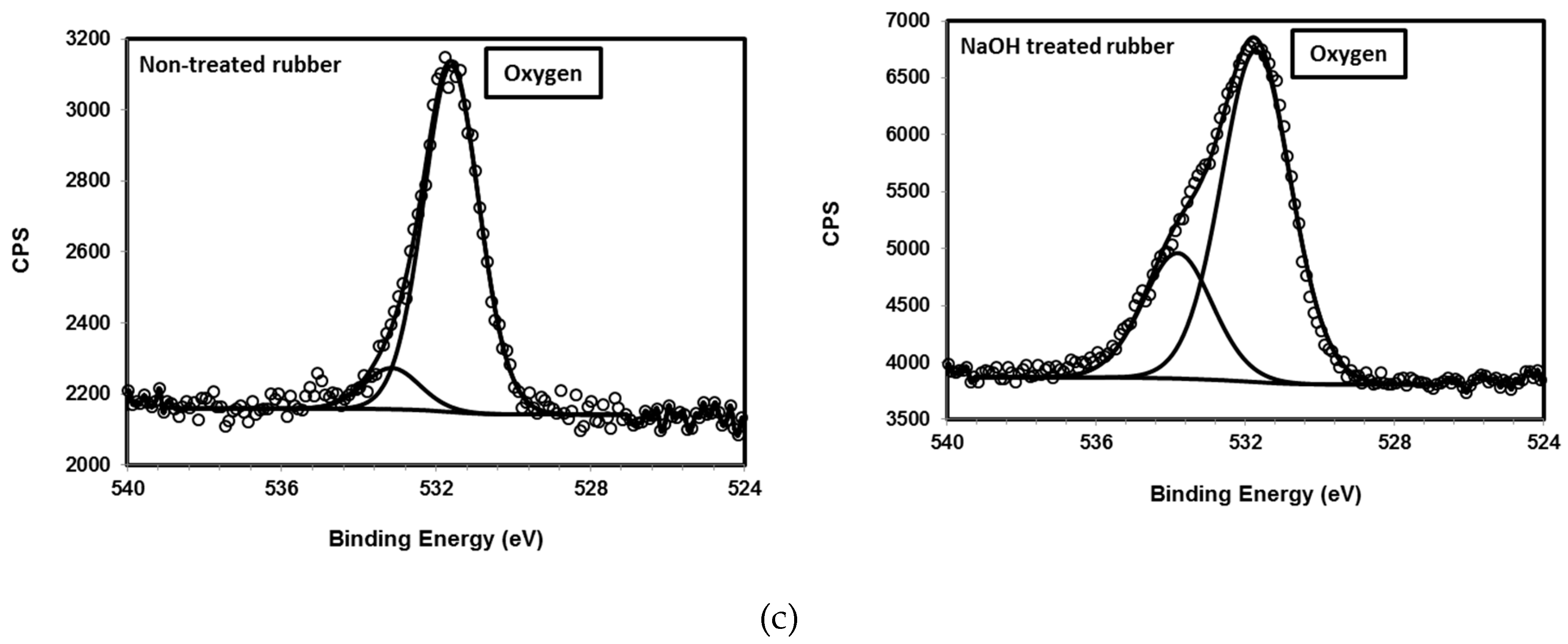

3.3. Effect of Fibre Additives

4. Summary and Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Tyre Stewardship Australia. Tyre Product Stewardship Scheme. 2019. Available online: https://www.tyrestewardship.org.au/about-tsa/tyre-product-stewardship-scheme (accessed on 12 November 2018).

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. Analytical Modeling of the Main characteristics of Crumb Rubber Concrete. Aci-Spec. Publ. 2017, 314, 1–18. [Google Scholar]

- ETRMA—European Tyre Rubber Manufactures Association. European tyre and rubber industry—Statistics. 2014. Available online: http://www.etrma.org/statistics-2 (accessed on 20 November 2018).

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Li, G.; Garrick, G.; Eggers, J.; Abadie, C.; Stubblefield, M.A.; Pang, S.S. Waste tire fiber modified concrete. Compos. Part B Eng. 2004, 35, 305–312. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.; Ma, X.; Zhuge, Y. Cyclic Performance of Steel–Concrete–Steel Sandwich Beams with Rubcrete and LECA Concrete Core. J. Compos. Sci. 2019, 3, 5. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Experimental investigations of reinforced rubberised concrete structural members. J. Build. Eng. 2017, 10, 149–165. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Bakar, B.A.; Ismail, H.; Akil, H.M. Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberised -normal concrete under impact load: Experiment and simulation. J. Clean. Prod. 2013, 59, 284–289. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Experimental investigation of crumb rubber concrete columns under seismic loading. Structures 2015, 3, 13–27. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Static cyclic behaviour of FRP-confined crumb rubber concrete columns. Eng. Struct. 2016, 113, 371–387. [Google Scholar] [CrossRef]

- Elchalakani, M. High strength rubberised concrete containing silica fume for the construction of sustainable road side barriers. Structures 2015, 1, 20–38. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Experimental and modelling studies on high strength concrete containing waste tire rubber. Sustain. Cities Soc. 2015, 19, 68–73. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Seismic Performance of Precast Posttensioned Segmental FRP-Confined and Unconfined Crumb Rubber Concrete Columns. J. Compos. Constr. 2017, 21, 04017006. [Google Scholar] [CrossRef]

- Balaha, M.; Badawy, A.; Hashish, M. Effect of using ground waste tire rubber as fine aggregate on the behaviour of concrete mixes. Indian J. Eng. Mater. Sci. 2007, 14, 427. [Google Scholar]

- Youssf, O.; ElGawady, M.A.; Mills, J.E.; Ma, X. An experimental investigation of crumb rubber concrete confined by fibre reinforced polymer tubes. Constr. Build. Mater. 2014, 53, 522–532. [Google Scholar] [CrossRef]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar] [CrossRef]

- Pelisser, F.; Zavarise, N.; Longo, T.A.; Bernardin, A.M. Concrete made with recycled tire rubber: Effect of alkaline activation and silica fume addition. J. Clean. Prod. 2011, 19, 757–763. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberised concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Mohammadi, I.; Khabbaz, H.; Vessalas, K. Enhancing mechanical performance of rubberised concrete pavements with sodium hydroxide treatment. Mater. Struct. 2015, 49, 813–827. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of crumb rubber concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ghataora, G.S.; Dirar, S. Surface modified used rubber tyre aggregates: Effect on recycled concrete performance. Mag. Concr. Res. 2015, 67, 680–691. [Google Scholar] [CrossRef]

- Hamza, D.M.; Ghedan, R.H. Effect Of Rubber Treatment On Compressive Strength And Thermal Conductivity Of Modified Rubberised Concrete. J. Eng. Dev. 2011, 15, 21–29. [Google Scholar]

- Azevedo, F.; Pacheco-Torgal, F.; Jesus, C.; De Aguiar, J.B.; Camões, A.F. Properties and durability of HPC with tyre rubber wastes. Constr. Build. Mater. 2012, 34, 186–191. [Google Scholar] [CrossRef]

- Raffoul, S.; Garcia, R.; Pilakoutas, K.; Guadagnini, M.; Medina, N.F. Optimisation of rubberised concrete with high rubber content: An experimental investigation. Constr. Build. Mater. 2016, 124, 391–404. [Google Scholar] [CrossRef]

- Deshpande, N.E.; Kulkarni, S.S.; Pawar, T.E.; Gunde, V.I. Experimental investigation on strength characteristics of concrete using tyre rubber as aggregates in concrete. Int. J. Appl. Eng. Res. Dev. 2014, 4, 97–108. [Google Scholar]

- Tian, S.; Zhang, T.; Li, Y. Research on Modifier and Modified Process. for Rubber-Particle Used in Rubberised Concrete for Road. Adv. Mater. Res. 2011, 243–249, 4125–4130. [Google Scholar] [CrossRef]

- Li, G.; Stubblefield, M.A.; Garrick, G.; Eggers, J.; Abadie, C.; Huang, B. Development of waste tire modified concrete. Cem. Concr. Res. 2004, 34, 2283–2289. [Google Scholar] [CrossRef]

- Turatsinze, A.; Bonnet, S.; Granju, J.-L. Potential of rubber aggregates to modify properties of cement based-mortars: Improvement in cracking shrinkage resistance. Constr. Build. Mater. 2007, 21, 176–181. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Reyes, J.; Feliu, J.L.; Hernández, M. Influence of scrap rubber addition to Portland I concrete composites: Destructive and non-destructive testing. Compos. Struct. 2005, 71, 439–446. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Cao, J. A two-staged surface treatment to improve properties of rubber modified cement composites. Constr. Build. Mater. 2013, 40, 270–274. [Google Scholar] [CrossRef]

- Dong, Q.; Huang, B.; Shu, X. Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr. Build. Mater. 2013, 48, 116–123. [Google Scholar] [CrossRef]

- Abdulla, A.I.; Ahmed, S.H. Effect of Rubber Treated by Acidic Solution on Some Mechanical Properties of Rubberize Cement Mortar. Eng. Technol. J. 2011, 29, 2793–2806. [Google Scholar]

- Xiong, G.; Luo, B.; Wu, X.; Li, G.; Chen, L. Influence of silane coupling agent on quality of interfacial transition zone between concrete substrate and repair materials. Cem. Concr. Compos. 2006, 28, 97–101. [Google Scholar] [CrossRef]

- He, L.; Ma, Y.; Liu, Q.; Mu, Y. Surface modification of crumb rubber and its influence on the mechanical properties of rubber-cement concrete. Constr. Build. Mater. 2016, 120, 403–407. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Salim, R.W.; Kupolati, W.K. The impact of rubber crumb on the mechanical and chemical properties of concrete. Eng. Struct. Technol. 2015, 7, 197–204. [Google Scholar] [CrossRef]

- Carroll, J.C.; Helminger, N. Fresh and hardened properties of fiber-reinforced rubber concrete. J. Mater. Civ. Eng. 2016, 28, 04016027. [Google Scholar] [CrossRef]

- Hesami, S.; Hikouei, I.S.; Emadi, S.A.A. Mechanical behavior of self-compacting concrete pavements incorporating recycled tire rubber crumb and reinforced with polypropylene fiber. J. Clean. Prod. 2016, 133, 228–234. [Google Scholar] [CrossRef]

- Standards Australia. General Purpose and Blended Cements, AS 3972; Standards Australia Limited: Sydney, Australia, 2010. [Google Scholar]

- Standards Australia. Methods for Testing Concrete, Preparation of Concrete Mixes in the Laboratory AS 1012.2; Standards Australia Limited: Sydney, Australia, 2014. [Google Scholar]

- Standards Australia. Methods for Testing Concrete, Determination of Properties Related to the Consistency of Concrete—Slump Test AS 1012.3.1; Standards Australia Limited: Sydney, Australia, 2014. [Google Scholar]

- Standards Australia. Methods for Sampling and Testing Aggregates, Method for Making and Curing Concrete—Compression and Indirect Tensile Test Specimens, AS1012.8.1; Standards Australia Limited: Sydney, Australia, 2014. [Google Scholar]

- Standards Australia. Methods of Testing Concrete—Compressive Strength Tests—Concrete, Mortar and Grout Specimens, AS 1012.9; Standards Australia Limited: Sydney, Australia, 2014. [Google Scholar]

- Standards Australia. Methods for Testing Concrete, Determination of Indirect Tensile Strength of Concrete Cylinders (Brasil or Splitting Test), AS 1012.10; Standards Australia Limited: Sydney, Australia, 2000. [Google Scholar]

- Standards Australia. Methods of Testing Concrete—Method for the Determination of the Flexural Strength of Concrete Specimens, AS 1012.11; Standards Australia Limited: Sydney, Australia, 1985. [Google Scholar]

- Neville, A. Properties of Concrete PDF eBook; Prentice Hall: Upper Saddle River, NJ, USA, 2012. [Google Scholar]

- Badalyan, A.; Bromball, R.; Pendleton, P.; Skinner, W. An assessment of activated carbon cloth microporosity change due to chemical activation. Carbon 2010, 48, 1004–1011. [Google Scholar] [CrossRef]

| Mix Code | Rs (%) | Mixing Procedures* | Pre-treatment | Mix Proportions (kg/m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Stone (mm) | Rubber | Water | SP | Fibre | ||||||||

| 10 | 14 | 20 | SF | PF | RF | |||||||||

| M1 | 0 | P1 | -- | 400 | 817 | -- | 493 | 493 | -- | 200 | 2.37 | -- | -- | -- |

| M2 | 15 | P1 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M3 | 30 | P1 | -- | 400 | 572 | -- | 493 | 493 | 89.7 | 200 | 2.37 | -- | -- | -- |

| M4 | 15 | P2 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M5 | 30 | P2 | -- | 400 | 572 | -- | 493 | 493 | 89.7 | 200 | 2.37 | -- | -- | -- |

| M6 | 15 | P3 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M7 | 30 | P3 | -- | 400 | 572 | -- | 493 | 493 | 89.7 | 200 | 2.37 | -- | -- | -- |

| M8 | 15 | P4 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M9 | 30 | P4 | -- | 400 | 572 | -- | 493 | 493 | 89.7 | 200 | 2.37 | -- | -- | -- |

| M10 | 15 | P5 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M11 | 15 | P6 | -- | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M12 | 15 | P4 | Water wash | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M13 | 15 | P4 | Water soaking-A | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M14 | 15 | P4 | Water soaking-O | 400 | 695 | -- | 493 | 493 | 44.9 | 200 | 2.37 | -- | -- | -- |

| M15 | 0 | P1 | -- | 340 | 826 | 458 | -- | 550 | -- | 204 | 1.36 | -- | -- | -- |

| M16 | 20 | P1 | -- | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M17 | 20 | P1 | NaOH | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M18 | 20 | P1 | H2O2 | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M19 | 20 | P1 | CaCl2 | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M20 | 20 | P1 | H2SO4 | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M21 | 20 | P1 | Silane | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M22 | 20 | P1 | KMnO4_NaHSO4 | 340 | 661 | 458 | -- | 550 | 62.0 | 204 | 1.36 | -- | -- | -- |

| M23 | 20 | P1 | -- | 338 | 658 | 456 | -- | 547 | 61.7 | 203 | 1.35 | 39.6 | ||

| M24 | 20 | P1 | -- | 337 | 654 | 453 | -- | 544 | 61.4 | 202 | 1.34 | 79.3 | ||

| M25 | 20 | P1 | -- | 335 | 651 | 451 | -- | 542 | 61.1 | 201 | 1.33 | 118.9 | ||

| M26 | 20 | P1 | -- | 338 | 658 | 456 | -- | 547 | 61.7 | 203 | 1.35 | -- | 4.5 | |

| M27 | 20 | P1 | -- | 337 | 654 | 453 | -- | 544 | 61.4 | 202 | 1.34 | -- | 9.1 | |

| M28 | 20 | P1 | -- | 335 | 651 | 451 | -- | 542 | 61.1 | 201 | 1.33 | -- | 13.6 | |

| M29 | 15 | P1 | -- | 396 | 688 | -- | 488 | 488 | 44.4 | 198 | 2.35 | -- | -- | 9.7 |

| M30 | 15 | P1 | -- | 392 | 681 | -- | 483 | 483 | 43.9 | 196 | 2.32 | -- | -- | 19.4 |

| M31 | 15 | P1 | -- | 388 | 674 | -- | 478 | 478 | 43.5 | 194 | 2.30 | -- | -- | 29.1 |

| Rs PF | Per cent of sand volume replaced by rubber. Polypropylene fibre. | SP RF | Superplasticizer dosage. Rubber fibre. | SF Steel fibre. | ||||||||||

| * Mixing procedures description is show in Section 2.2 | ||||||||||||||

| Fibre Type | Diameter (mm) | Length (mm) | Specific Gravity | Tensile Strength (MPa) |

|---|---|---|---|---|

| Steel fibres | 0.55 | 35 | 7.93 | 1300 |

| polypropylene fibres | 0.80 | 45 | 0.91 | 800 |

| Rubber fibres | 0.5–1.3 | 15–30 | 0.97 | N/A |

| Mixing Procedure | Mixing Stage 1 | Mixing Stage 2 | Rest Time (min) | Mixing Stage 3 | Overall Mixing Time (min) | Net Mixing Time of all Constituents, Tn (min) | |||

|---|---|---|---|---|---|---|---|---|---|

| Constituents | Time (min) | Other Constituents | Time (min) | Other Constituents | Time (min) | ||||

| P1 | Stone, sand, rubber | 1.0 | ½ water | 1.0 | 2.0 | Cement, ½ water, SP | 2.0 | 6.0 | 2.0 |

| P2 | Stone, sand, rubber, ½ water | 0.5 | Cement, water, SP | 2.0 | 2.0 | -- | 2.0 | 6.5 | 4.0 |

| P3 | Stone, sand, rubber, cement | 1.0 | Water, SP | 3.0 | -- | -- | -- | 4.0 | 3.0 |

| P4 | Stone, sand | 1.0 | ½ water | 1.0 | 2.0 | (Rubber+cement), ½ water, SP | 2.0 | 6.0 | 2.0 |

| P5 | Stone, sand, rubber, cement, water, SP | 2.0 | -- | -- | 2.0 | -- | 2.0 | 6.0 | 4.0 |

| P6 | Stone, sand | 1.0 | ½ water | 1.0 | 2.0 | (Rubber+SP+½ water), cement | 2.0 | 6.0 | 2.0 |

| Mix Code | Rs (%) | Mixing Procedures | Pre-treatment | Slump (mm) | Compressive Strength (MPa) | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|---|---|---|---|

| M1 | 0 | P1 | -- | 145 | 53.3 | 4.62 | -- |

| M2 | 15 | P1 | -- | 155 | 37.5 | 3.95 | -- |

| M3 | 30 | P1 | -- | 203 | 30.5 | 3.30 | -- |

| M4 | 15 | P2 | -- | 215 | 41.2 | 4.10 | -- |

| M5 | 30 | P2 | -- | 230 | 31.5 | 3.21 | -- |

| M6 | 15 | P3 | -- | 210 | 40.3 | 3.98 | -- |

| M7 | 30 | P3 | -- | 220 | 29.8 | 3.27 | -- |

| M8 | 15 | P4 | -- | 195 | 38.5 | 3.91 | -- |

| M9 | 30 | P4 | -- | 220 | 31.2 | 3.44 | -- |

| M10 | 15 | P5 | -- | 225 | 39.3 | 3.91 | -- |

| M11 | 15 | P6 | -- | 190 | 35.8 | 3.85 | -- |

| M12 | 15 | P4 | Water wash | 160 | 40.8 | 4.30 | -- |

| M13 | 15 | P4 | Water soaking-A | 113 | 37.1 | 3.68 | -- |

| M14 | 15 | P4 | Water soaking-O | 105 | 35.7 | 3.90 | -- |

| M15 | 0 | P1 | -- | 135 | 41.5 | -- | 6.0 |

| M16 | 20 | P1 | -- | 200 | 27.3 | -- | 5.0 |

| M17 | 20 | P1 | NaOH | 180 | 29.2 | -- | 5.0 |

| M18 | 20 | P1 | H2O2 | 183 | 27.5 | -- | 4.9 |

| M19 | 20 | P1 | CaCl2 | 162 | 29.1 | -- | 5.4 |

| M20 | 20 | P1 | H2SO4 | 150 | 27.4 | -- | 5.5 |

| M21 | 20 | P1 | Silane | 185 | 28.9 | -- | 5.2 |

| M22 | 20 | P1 | KMnO4_NaHSO4 | 183 | 26.5 | -- | 5.3 |

| M23 | 20 | P1 | -- | 120 | 28.6 | -- | 5.8 |

| M24 | 20 | P1 | -- | 65 | 24.4 | -- | 5.4 |

| M25 | 20 | P1 | -- | 32 | 26.9 | -- | 8.3 |

| M26 | 20 | P1 | -- | 120 | 28.0 | -- | 5.2 |

| M27 | 20 | P1 | -- | 75 | 27.9 | -- | 4.6 |

| M28 | 20 | P1 | -- | 45 | 25.6 | -- | 7.0 |

| M29 | 15 | P1 | -- | 150 | 35.7 | 3.66 | -- |

| M30 | 15 | P1 | -- | 125 | 31.7 | 3.35 | -- |

| M31 | 15 | P1 | -- | 113 | 30.7 | 3.36 | -- |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Youssf, O.; Hassanli, R.; Mills, J.E.; Skinner, W.; Ma, X.; Zhuge, Y.; Roychand, R.; Gravina, R. Influence of Mixing Procedures, Rubber Treatment, and Fibre Additives on Rubcrete Performance. J. Compos. Sci. 2019, 3, 41. https://doi.org/10.3390/jcs3020041

Youssf O, Hassanli R, Mills JE, Skinner W, Ma X, Zhuge Y, Roychand R, Gravina R. Influence of Mixing Procedures, Rubber Treatment, and Fibre Additives on Rubcrete Performance. Journal of Composites Science. 2019; 3(2):41. https://doi.org/10.3390/jcs3020041

Chicago/Turabian StyleYoussf, Osama, Reza Hassanli, Julie E. Mills, William Skinner, Xing Ma, Yan Zhuge, Rajeev Roychand, and Rebecca Gravina. 2019. "Influence of Mixing Procedures, Rubber Treatment, and Fibre Additives on Rubcrete Performance" Journal of Composites Science 3, no. 2: 41. https://doi.org/10.3390/jcs3020041

APA StyleYoussf, O., Hassanli, R., Mills, J. E., Skinner, W., Ma, X., Zhuge, Y., Roychand, R., & Gravina, R. (2019). Influence of Mixing Procedures, Rubber Treatment, and Fibre Additives on Rubcrete Performance. Journal of Composites Science, 3(2), 41. https://doi.org/10.3390/jcs3020041