Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art

Abstract

1. Introduction

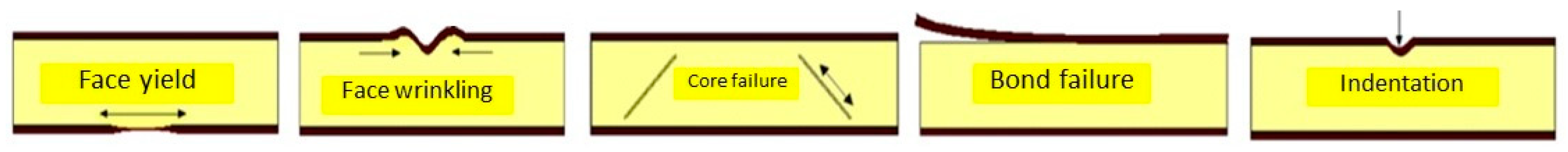

2. Energy Absorption and Dynamic Behaviour

3. Bending and Shear Behaviour

4. Edgewise and Flatwise Compressive/Tensile Behaviour

5. Delamination and Debonding

6. Miscellaneous Themes

7. Conclusions

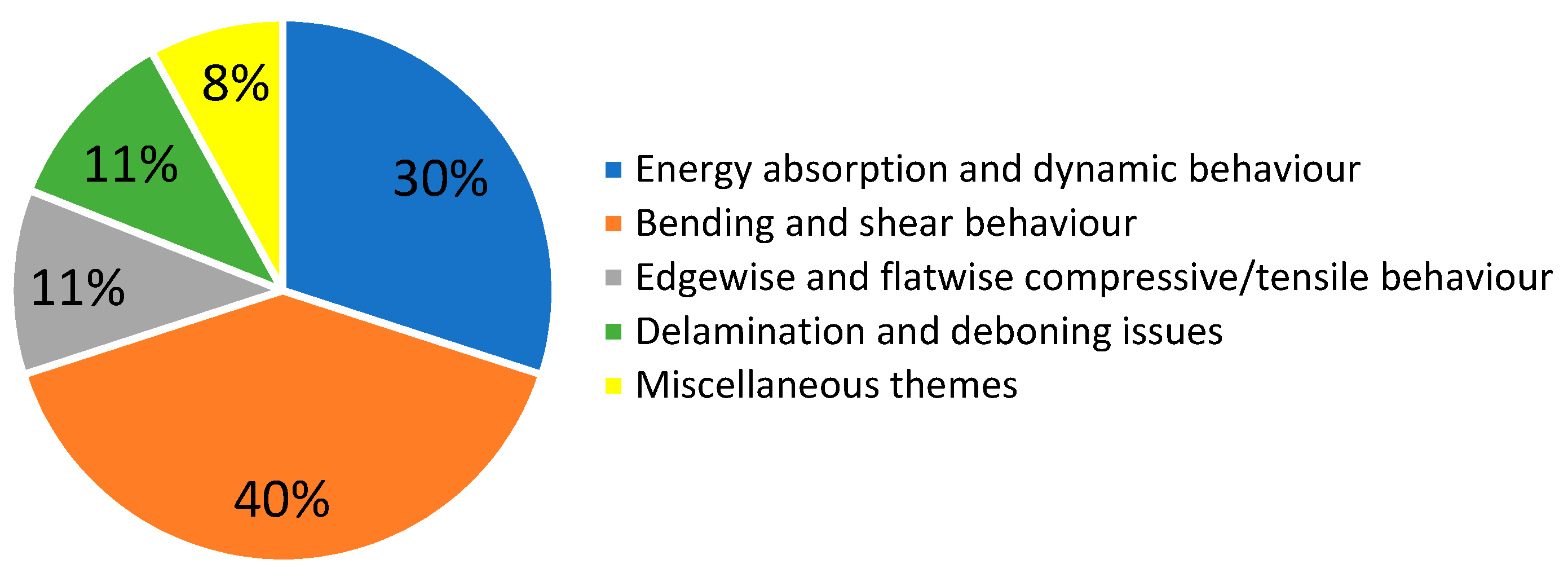

- Energy absorption and dynamic behaviour, bending and shear behaviour, edgewise and flatwise compression/tension behaviour and delamination/deboning themes comprise 30%, 40%, 11% and 11% of related studies, respectively, over the last two decades. Also, 8% of related studies over the last two decades are related to the whole of other themes (Figure 23).

- First two categories represent the 70% of the studies. The direct use of the results of these two categories of studies in the seismic design of building panels can be a reasonable reason for this amount of studies.

- Energy absorbing capacity, flexural stiffness and shear strength of composite panels account 27%, 15% and 12% of studied parameters, respectively.

- Torsional behaviour of foam-filled panels and their connections are neglected absolutely and could be suggested for future researches.

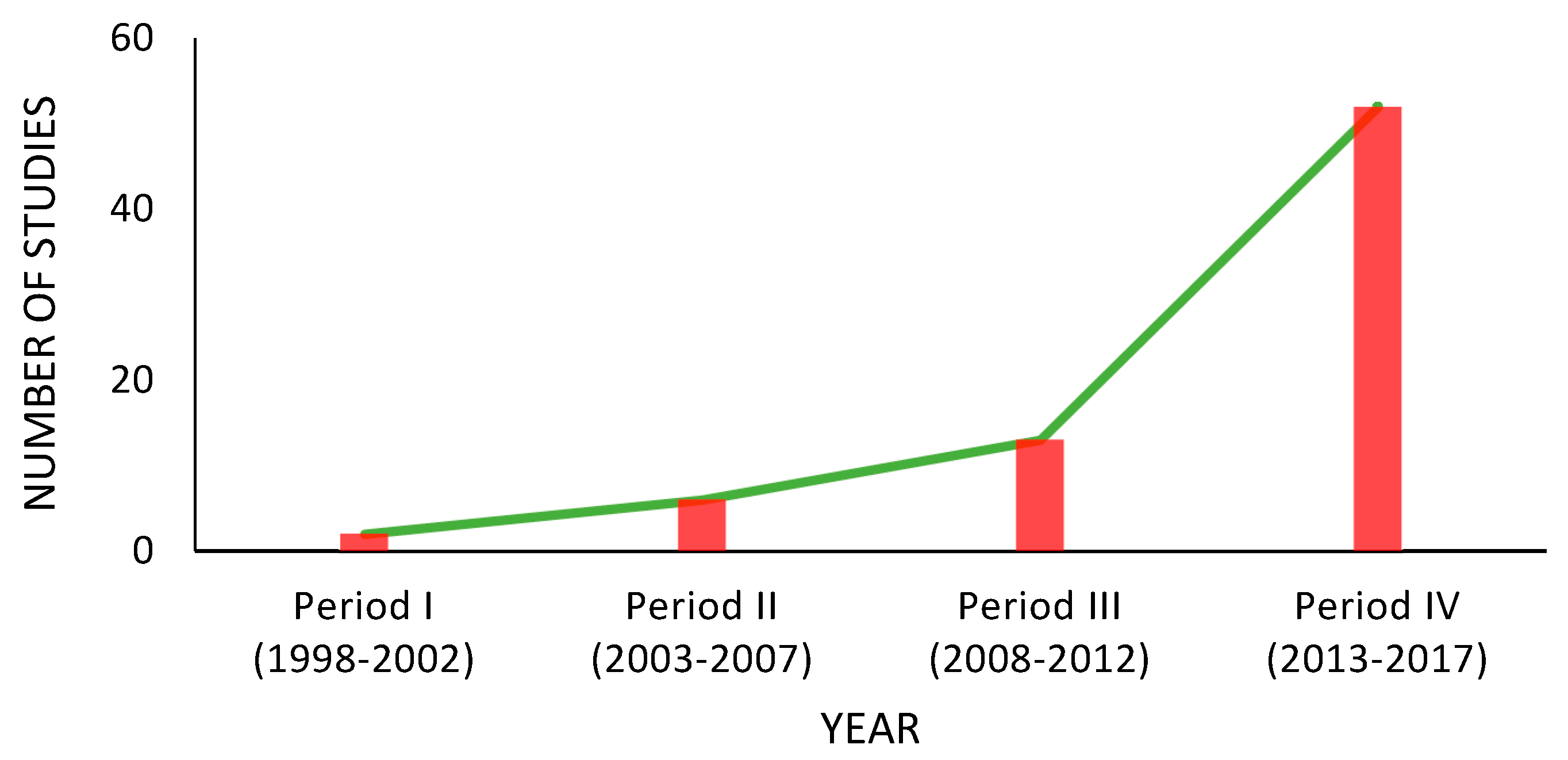

- Over the past 22 years, the number of these studies has increased by at least two hundred percent during each five-year period relative to the previous period. However, over the past five years, this increase was approximately four hundred percent, indicating the interest and attention of researchers to the importance of the structural performance of foam-filled composite panels (Figure 24).

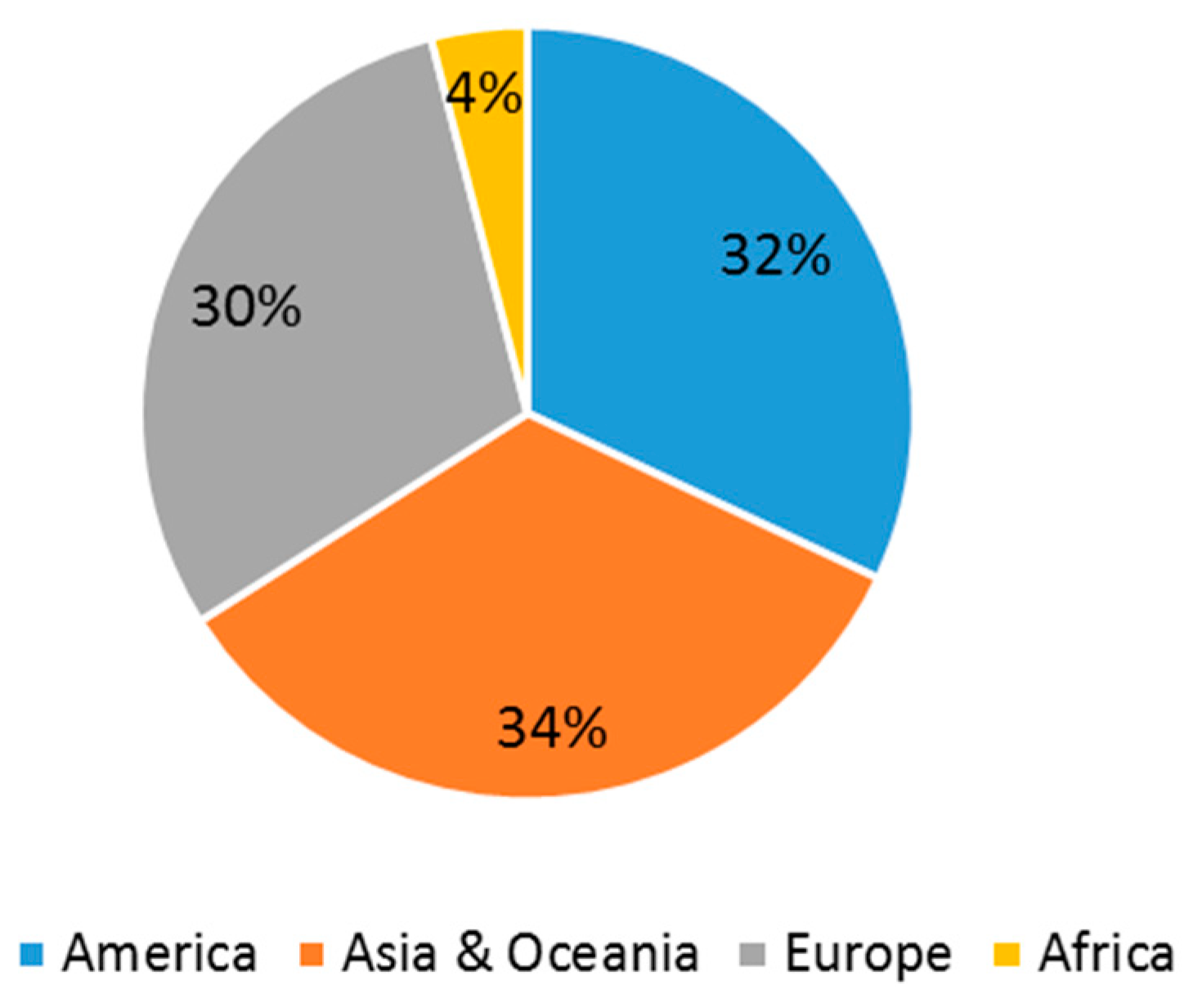

- Studies on the structural performance of foam-filled composite panels from 1998 to 2017 have a uniform continental distribution between America, Asia & Oceania and Europe (Figure 25).

Author Contributions

Funding

Conflicts of Interest

References

- Bomberg, M.T.; Lstiburek, J.W. Spray Polyurethane Foam in External Envelopes of Buildings; Taylor & Francis: Abingdon, UK, 1998. [Google Scholar]

- Cousins, K. Polymers in Building and Construction; Rapra Technology Limited: Shropshire, UK, 2002. [Google Scholar]

- Sharafi, P.; Samali, B.; Ronagh, H.; Ghodrat, M. Automated spatial design of multi-story modular buildings using a unified matrix method. Autom. Constr. 2017, 82, 31–42. [Google Scholar] [CrossRef]

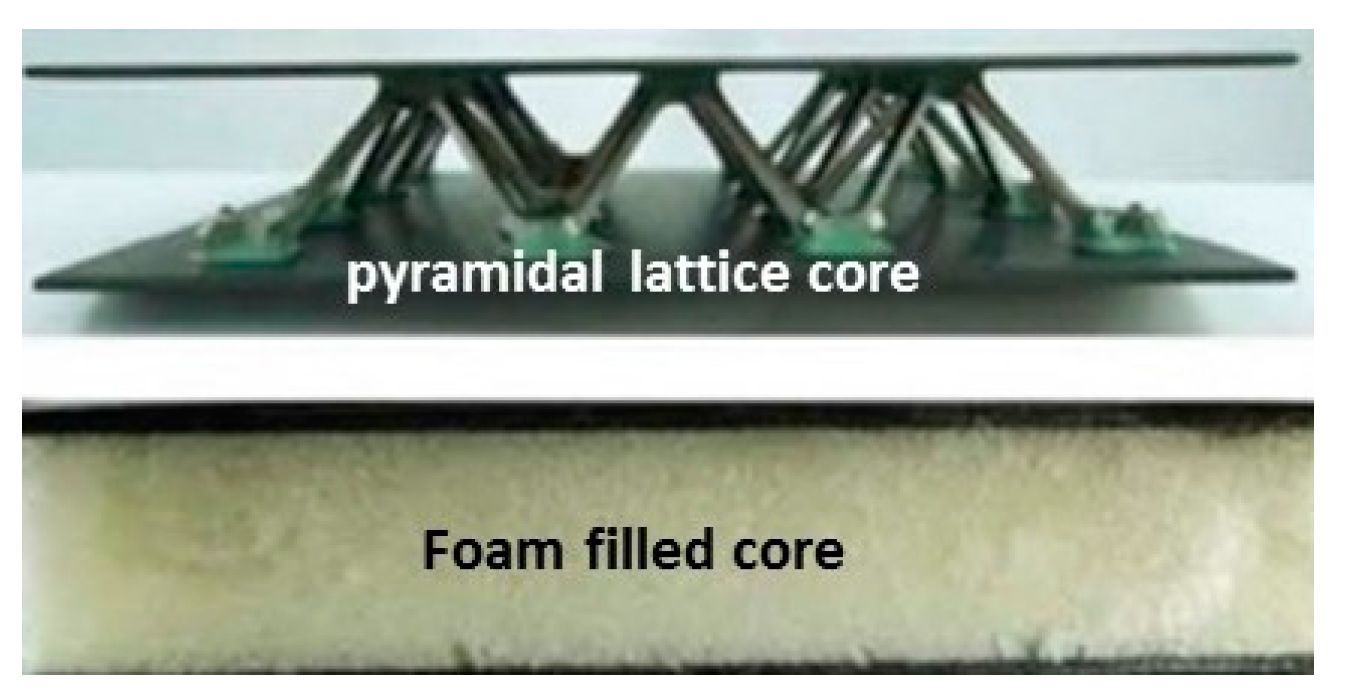

- Wu, Z.; Liu, W.; Wang, L.; Fang, H.; Hui, D. Theoretical and experimental study of foam-filled lattice composite panels under quasi-static compression loading. Compos. Part B Eng. 2014, 60, 329–340. [Google Scholar] [CrossRef]

- Nasirzadeh, R.; Sabet, A.R. Study of foam density variations in composite composite panels under high velocity impact loading. Int. J. Impact Eng. 2014, 63, 129–139. [Google Scholar] [CrossRef]

- Wang, J.; Waas, A.M.; Wang, H. Experimental study on the low-velocity impact behavior of foam-core composite panels. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Wang, J.; Waas, A.M.; Wang, H. Experimental and numerical study on the low-velocity impact behavior of foam-core composite panels. Compos. Struct. 2013, 96, 298–311. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, B.; Ma, L.; Wu, L.; Pan, S.; Yang, J. Energy absorption and low velocity impact response of polyurethane foam filled pyramidal lattice core composite panels. Compos. Struct. 2014, 108, 304–310. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Long, S.; Yao, X.; He, L. Dynamic mechanical behavior of foam-core composite composite structures subjected to low-velocity impact. Arch. Appl. Mech. 2016, 86, 1605–1619. [Google Scholar] [CrossRef]

- Rizov, V.; Shipsha, A.; Zenkert, D. Indentation study of foam core composite composite panels. Compos. Struct. 2005, 69, 95–102. [Google Scholar] [CrossRef]

- Sachse, S.; Poruri, M.; Silva, F.; Michalowski, S.; Pielichowski, K.; Njuguna, J. Effect of nanofillers on low energy impact performance of composite structures with nanoreinforced polyurethane foam cores. J. Compos. Struct. Mater. 2014, 16, 173–194. [Google Scholar]

- Hua, Y.; Akula, P.K.; Gu, L. Experimental and numerical investigation of carbon fiber composite panels subjected to blast loading. Compos. Part B Eng. 2014, 56, 456–463. [Google Scholar] [CrossRef]

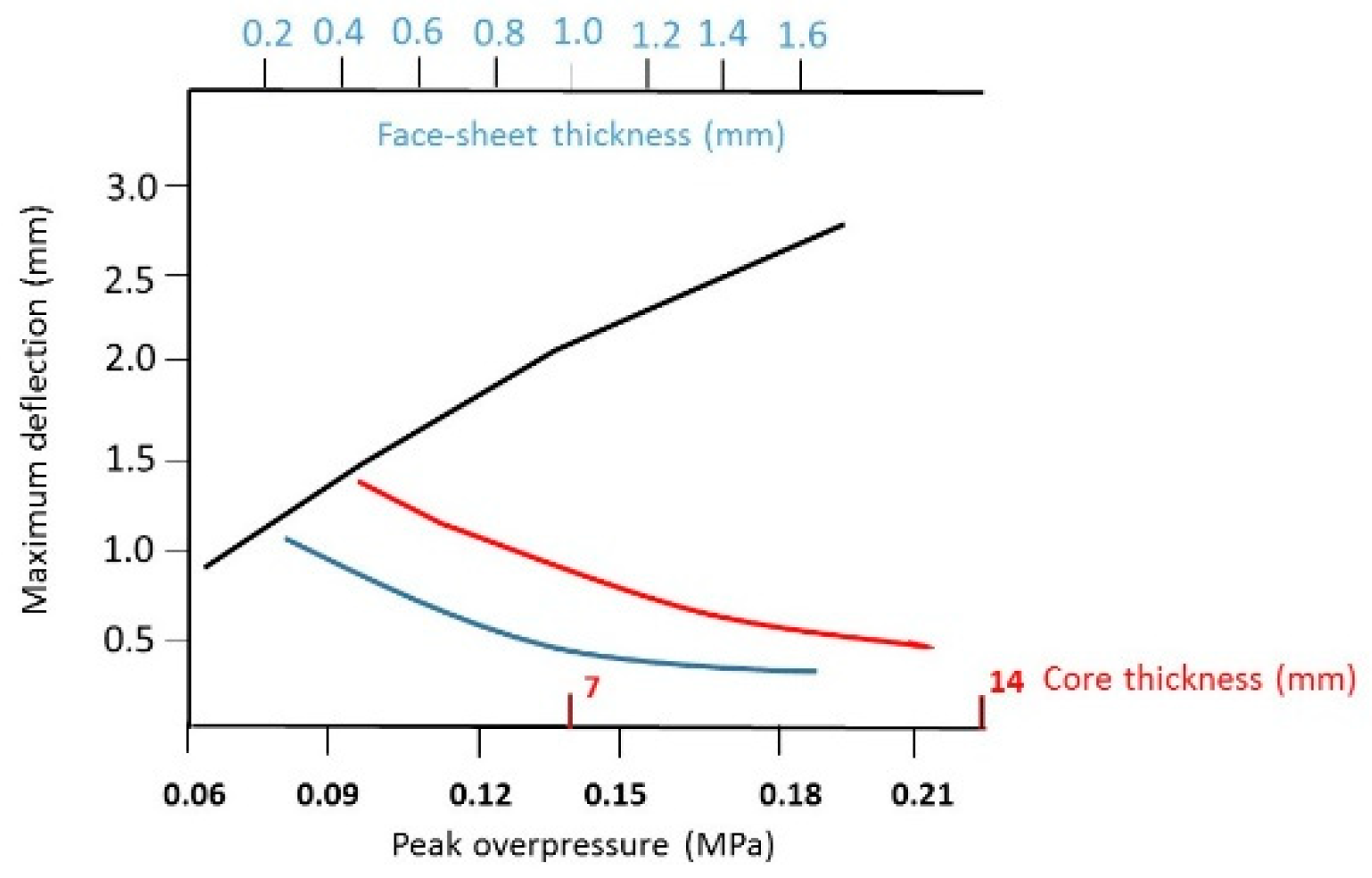

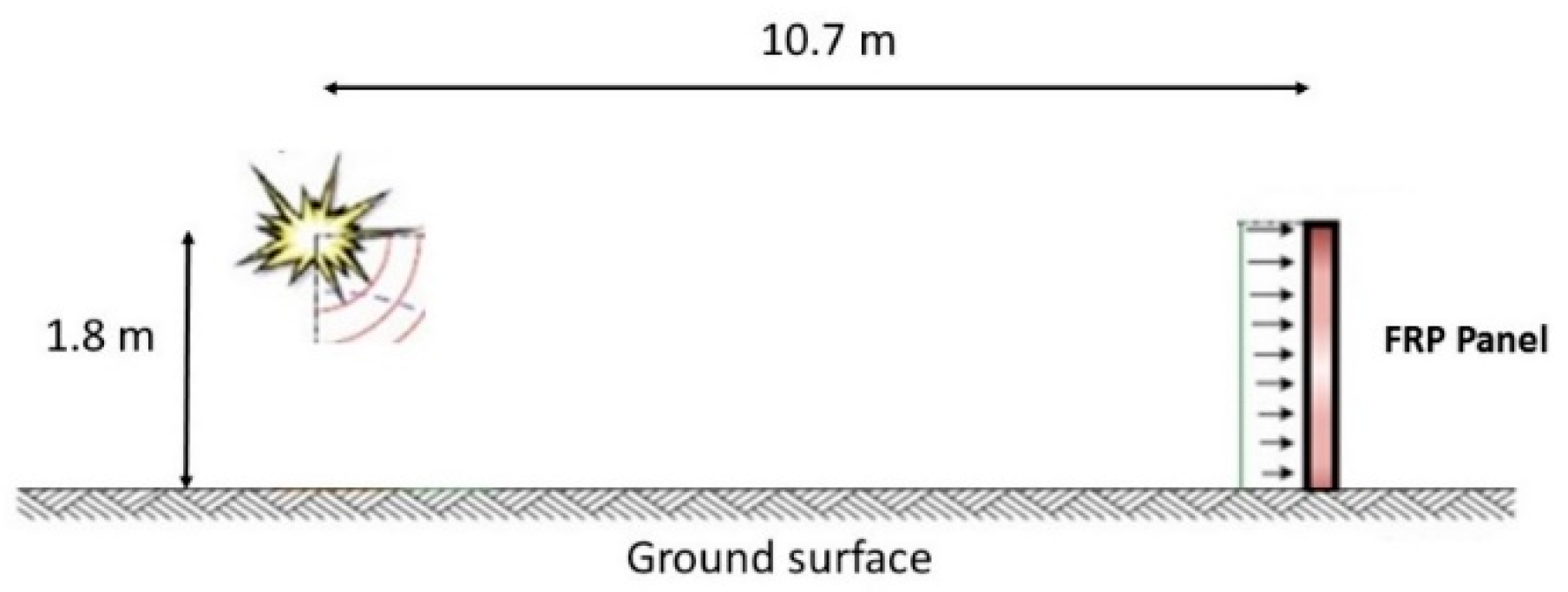

- Ahmed, S.; Galal, K. Effectiveness of FRP composite panels for blast resistance. Compos. Struct. 2017, 163, 454–464. [Google Scholar] [CrossRef]

- Yang, P.; Shams, S.S.; Slay, A.; Brokate, B.; Elhajjar, R. Evaluation of temperature effects on low velocity impact damage in composite composite panels with polymeric foam cores. Compos. Struct. 2015, 129, 213–223. [Google Scholar] [CrossRef]

- Taraghi, I.; Fereidoon, A. Non-destructive evaluation of damage modes in nanocomposite foam-core composite panel subjected to low-velocity impact. Compos. Part B Eng. 2016, 103, 51–59. [Google Scholar] [CrossRef]

- Kavianiboroujeni, A.; Cloutier, A.; Rodrigue, D. Low Velocity Impact Behaviour of Asymmetric Three-layer Composite Composite Structures with and Without Foam Core. Polym. Polym. Compos. 2017, 25, 381. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Lou, C.W.; Yan, R.; Lin, Q.; Li, T.T.; Chen, Y.S.; Lin, J.H. Investigation on structure and impact-resistance property of polyurethane foam filled three-dimensional fabric reinforced composite flexible composites. Compos. Part B Eng. 2017, 131, 43–49. [Google Scholar] [CrossRef]

- Feli, S.; Mahdipour Jalilian, M. Three-dimensional solution of low-velocity impact on composite panels with hybrid nanocomposite face sheets. Mech. Adv. Mater. Struct. 2017, 25, 579–591. [Google Scholar] [CrossRef]

- Feli, S.; Jalilian, M. Theoretical model of low-velocity impact on foam-core composite panels using finite difference method. J. Compos. Struct. Mater. 2017, 19, 261–290. [Google Scholar]

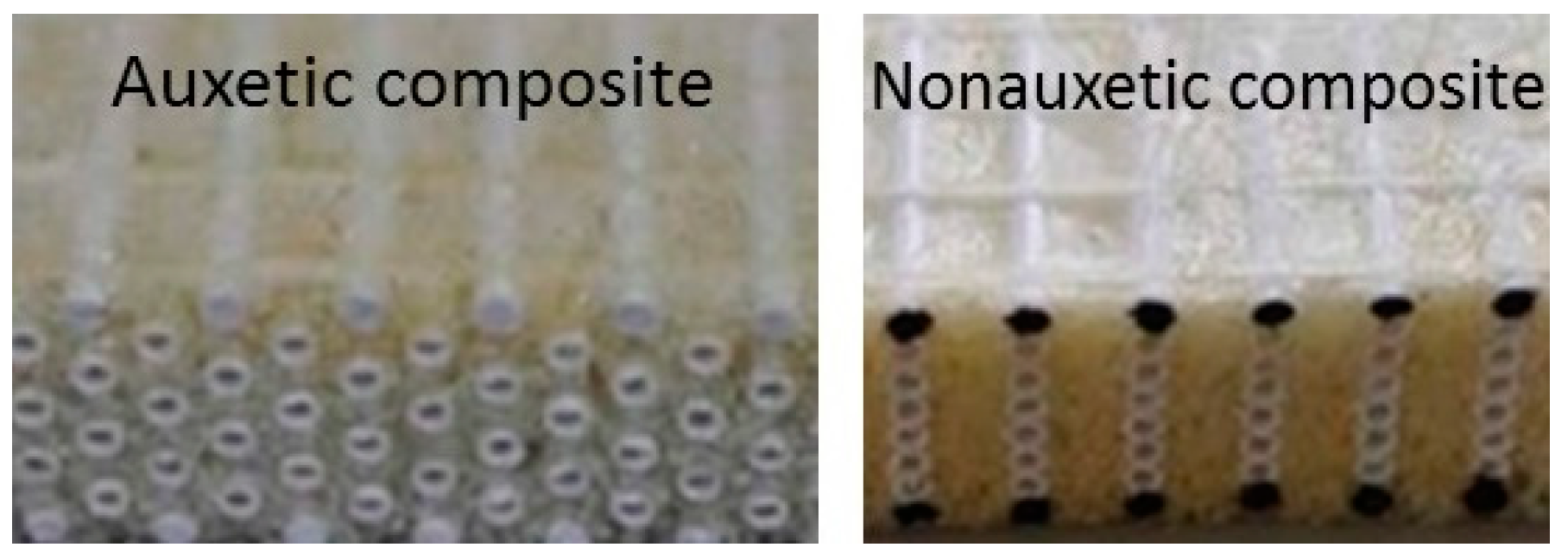

- Jiang, L.; Hu, H. Low-velocity impact response of multilayer orthogonal structural composite with auxetic effect. Compos. Struct. 2017, 169, 62–68. [Google Scholar] [CrossRef]

- Yan, R.; Wang, R.; Lou, C.W.; Huang, S.Y.; Lin, J.H. Quasi-static and dynamic mechanical responses of hybrid laminated composites based on high-density flexible polyurethane foam. Compos. Part B Eng. 2015, 83, 253–263. [Google Scholar] [CrossRef]

- Ghalami-Choobar, M.; Sadighi, M. Investigation of high velocity impact of cylindrical projectile on composite panels with fiber–metal laminates skins and polyurethane core. Aerosp. Sci. Technol. 2014, 32, 142–152. [Google Scholar] [CrossRef]

- Velecela, O.; Soutis, C. Prediction of crushing morphology of GRP composite composite panels under edgewise compression. Compos. Part B Eng. 2007, 38, 914–923. [Google Scholar] [CrossRef]

- Mamalis, A.; Manolakos, D.E.; Ioannidis, M.B.; Papapostolou, D.P. On the crushing response of composite composite panels subjected to edgewise compression: Experimental. Compos. Struct. 2005, 71, 246–257. [Google Scholar] [CrossRef]

- George, T.; Deshpande, V.S.; Sharp, K.; Wadley, H.N. Hybrid core carbon fiber composite composite panels: Fabrication and mechanical response. Compos. Struct. 2014, 108, 696–710. [Google Scholar] [CrossRef]

- Rostamiyan, Y.; Norouzi, H. Flatwise Compression Strength and Energy Absorption of Polyurethane Foam-Filled Lattice Core Composite Panels. Strength Mater. 2016, 48, 801–810. [Google Scholar] [CrossRef]

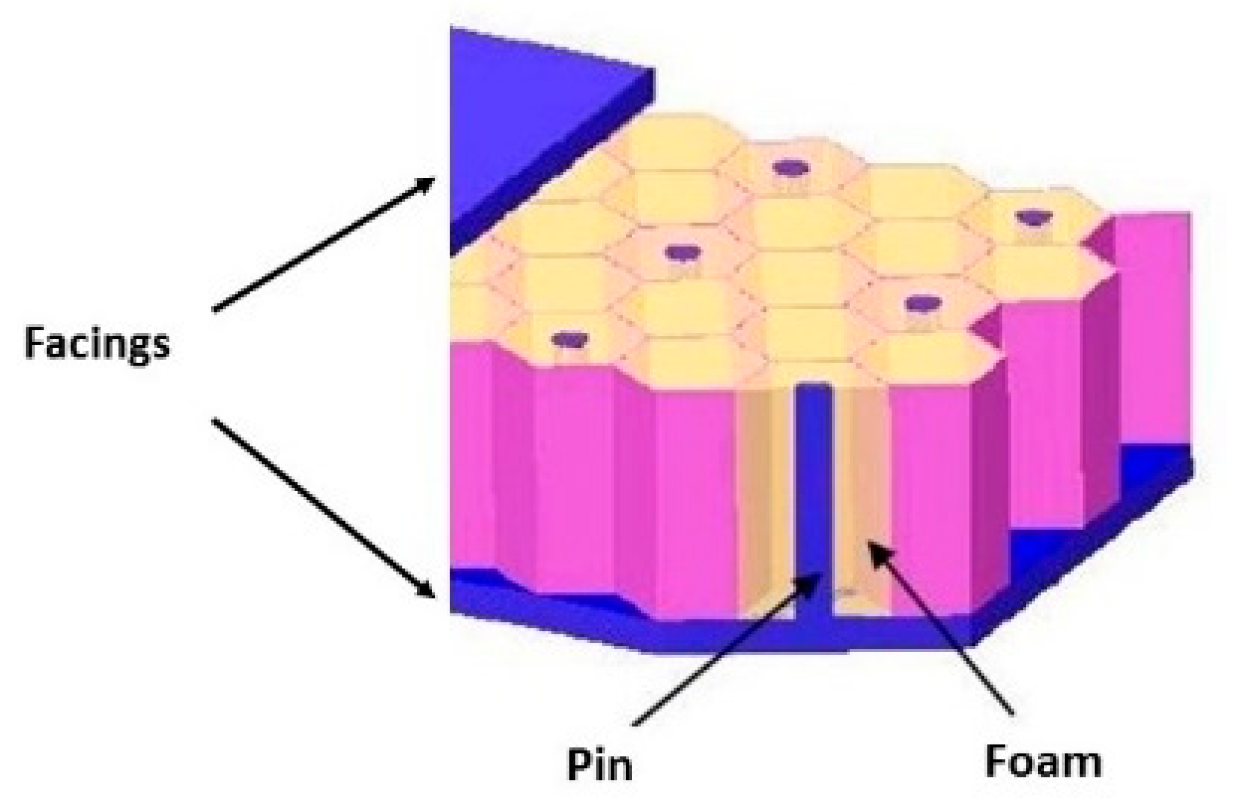

- Abdi, B.; Azwan, S.; Abdullah, M.R.; Ayob, A.; Yahya, Y. Comparison of foam core composite panel and through—Thickness polymer pin–reinforced foam core composite panel subject to indentation and flatwise compression loadings. Polym. Compos. 2016, 37, 612–619. [Google Scholar] [CrossRef]

- Mirzapour, A.; Beheshty, M.H.; Vafayan, M. The response of composite panels with rigid polyurethane foam cores under flexural loading. Iran. Polym. J. 2005, 14, 1082–1088. [Google Scholar]

- Sharaf, T.; Shawkat, W.; Fam, A. Structural performance of composite wall panels with different foam core densities in one-way bending. J. Compos. Mater. 2010, 44, 2249–2263. [Google Scholar] [CrossRef]

- Manalo, A. Structural behaviour of a prefabricated composite wall system made from rigid polyurethane foam and Magnesium Oxide board. Constr. Build. Mater. 2013, 41, 642–653. [Google Scholar] [CrossRef]

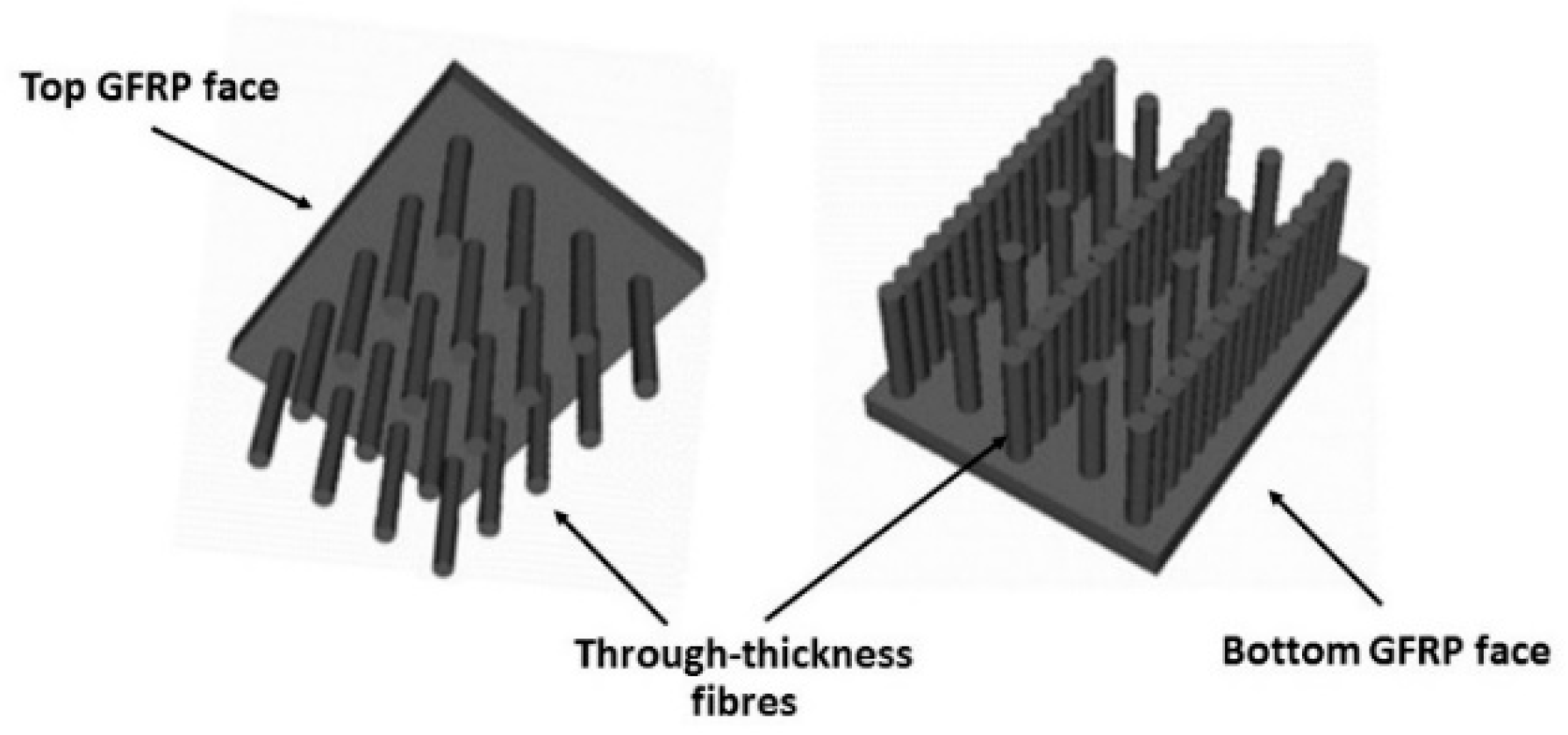

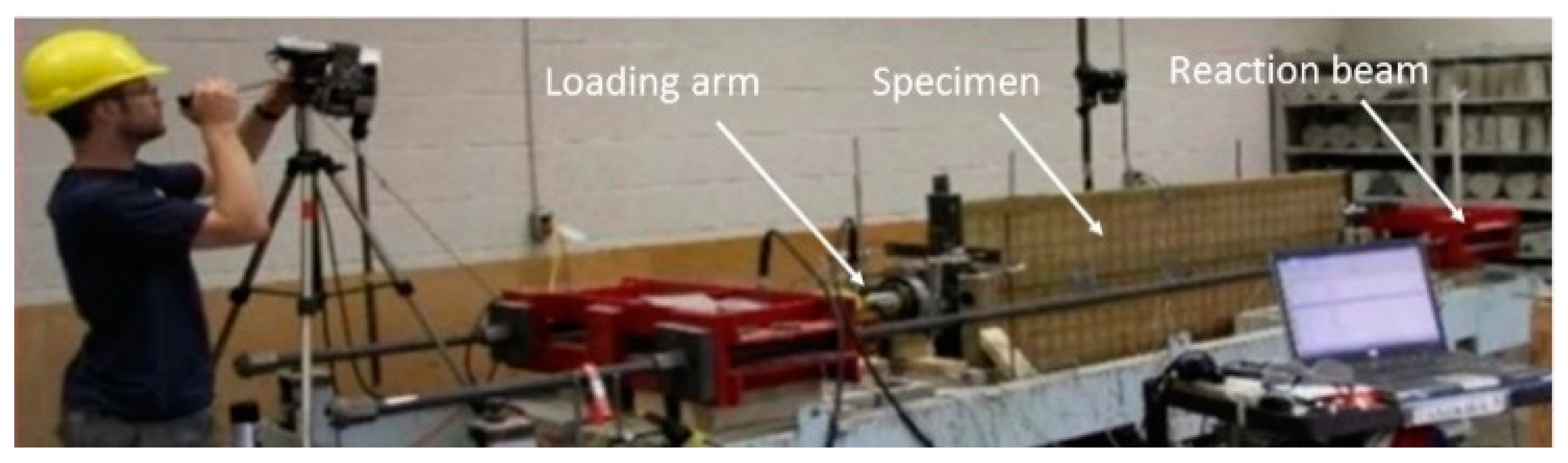

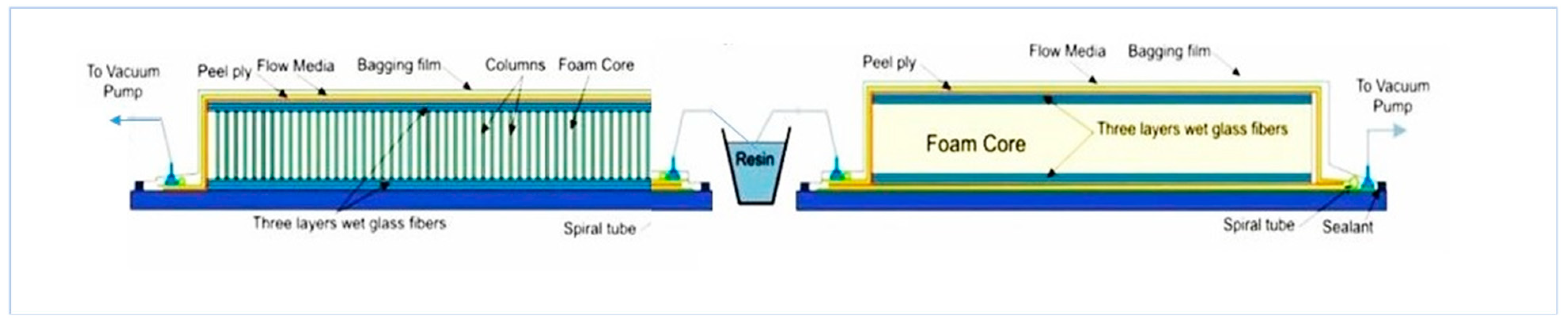

- Dawood, M.; Taylor, E.; Ballew, W.; Rizkalla, S. Static and fatigue bending behavior of pultruded GFRP composite panels with through-thickness fiber insertions. Compos. Part B Eng. 2010, 41, 363–374. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Wan, L.; Fang, H.; Hui, D. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling. Compos. Part B Eng. 2014, 67, 270–279. [Google Scholar] [CrossRef]

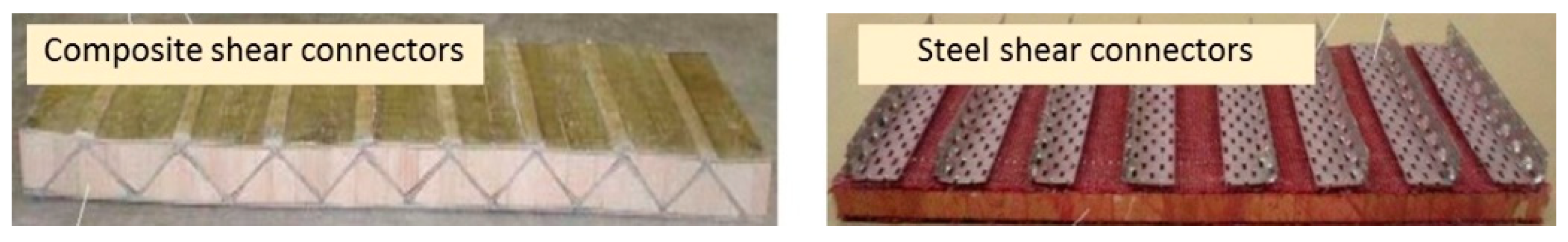

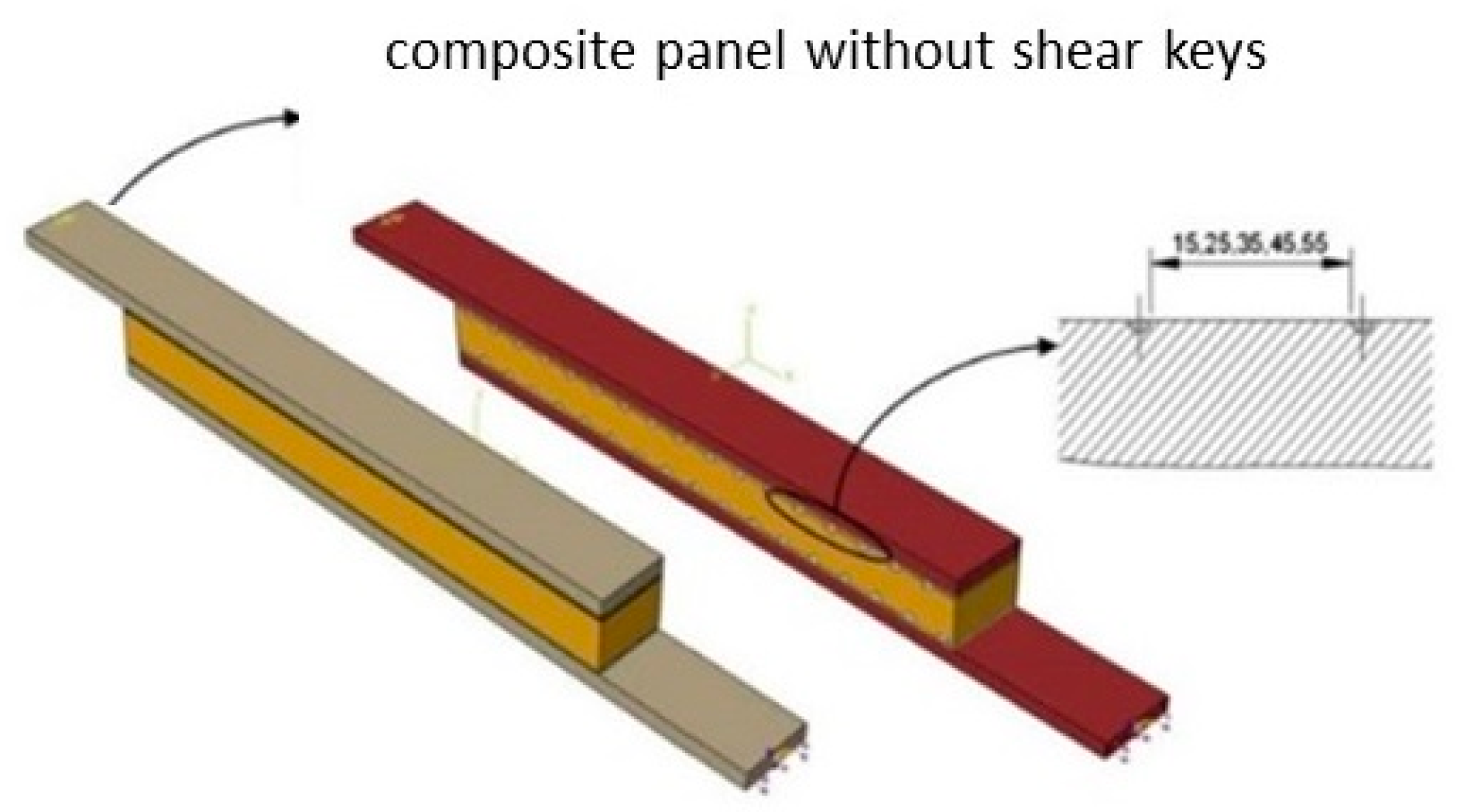

- Mostafa, A.; Shankar, K.; Morozov, E. Independent analytical technique for analysis of the flexural behaviour of the composite composite panels incorporated with shear keys concept. Mater. Struct. 2015, 48, 2455–2474. [Google Scholar] [CrossRef]

- Mostafa, A.; Shankar, K.; Morozov, E. Behaviour of PU-foam/glass-fibre composite composite panels under flexural static load. Mater. Struct. 2015, 48, 1545–1559. [Google Scholar] [CrossRef]

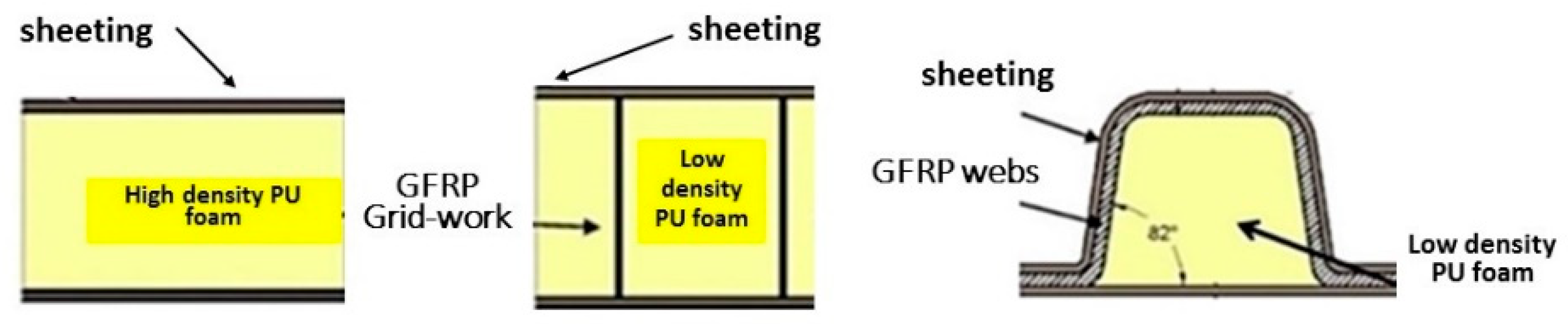

- Tuwair, H.; Hopkins, M.; Volz, J.; ElGawady, M.A.; Mohamed, M.; Chandrashekhara, K.; Birman, V. Evaluation of composite panels with various polyurethane foam-cores and ribs. Compos. Part B Eng. 2015, 79, 262–276. [Google Scholar] [CrossRef]

- Mathieson, H.; Fam, A. High cycle fatigue under reversed bending of composite panels with GFRP skins and polyurethane foam core. Compos. Struct. 2014, 113, 31–39. [Google Scholar] [CrossRef]

- Kumar, M.V.; Soragaon, B. Fabrication and evaluation of multilayered polyurethane foam core composite panels for static flexural stiffness. Procedia Eng. 2014, 97, 1227–1236. [Google Scholar] [CrossRef][Green Version]

- Garrido, M.; Correia, J.R.; Keller, T.; Cabral-Fonseca, S. Creep of Composite Panels with Longitudinal Reinforcement Ribs for Civil Engineering Applications: Experiments and Composite Creep Modeling. J. Compos. Constr. 2016, 21, 04016074. [Google Scholar] [CrossRef]

- Junes, A.; Larbi, A.S. An indirect non-linear approach for the analysis of composite panels with TRC facings. Constr. Build. Mater. 2016, 112, 406–415. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Khazabi, M.; Maynard, K.; Sain, M.; Kwon, O.S. Soy-based polyurethane spray foam insulations for light weight wall panels and their performances under monotonic and static cyclic shear forces. Ind. Crops Prod. 2015, 74, 1–8. [Google Scholar] [CrossRef]

- Mostafa, A. Numerical analysis on the effect of shear keys pitch on the shear performance of foamed composite panels. Eng. Struct. 2015, 101, 216–232. [Google Scholar] [CrossRef]

- Sharaf, T. Flexural Behaviour of Composite Panels Composed of Polyurethane Core and GFRP Skins and Ribs. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2010. [Google Scholar]

- Sharaf, T.; Fam, A. Experimental investigation of large-scale cladding composite panels under out-of-plane transverse loading for building applications. J. Compos. Constr. 2010, 15, 422–430. [Google Scholar] [CrossRef]

- Sharaf, T.; Fam, A. Numerical modelling of composite panels with soft core and different rib configurations. J. Reinf. Plast. Compos. 2012, 31, 771–784. [Google Scholar] [CrossRef]

- Sharaf, T.; Fam, A. Analysis of large scale cladding composite panels composed of GFRP skins and ribs and ribs and polyurethane foam core. Thin-Walled Struct. 2013, 71, 91–101. [Google Scholar] [CrossRef]

- Mastali, M.; Valente, I.B.; Barros, J.A.; Gonçalves, D.M. Development of innovative hybrid composite panel slabs: Experimental results. Compos. Struct. 2015, 133 (Suppl. C), 476–498. [Google Scholar] [CrossRef]

- Mastali, M.; Valente, I.B.; Barros, A.O. Development of innovative hybrid composite panel slabs: Advanced numerical simulations and parametric studies. Compos. Struct. 2016, 152 (Suppl. C), 362–381. [Google Scholar] [CrossRef]

- Mastali, M.; Valente, I.; Barros, J.A. Flexural performance of innovative hybrid composite panels with special focus on the shear connection behavior. Compos. Struct. 2017, 160, 100–117. [Google Scholar] [CrossRef]

- Dawood, M.; Taylor, E.; Rizkalla, S. Two-way bending behavior of 3-D GFRP composite panels with through-thickness fiber insertions. Compos. Struct. 2010, 92, 950–963. [Google Scholar] [CrossRef]

- Amir Fam, T.S. Flexural performance of composite panels comprising polyurethane core and GFRP skins and ribs of various configurations. Compos. Struct. 2010, 92, 2927–2935. [Google Scholar]

- Garrido, M.; Correia, J.R.; Keller, T. Effects of elevated temperature on the shear response of PET and PUR foams used in composite composite panels. Constr. Build. Mater. 2015, 76, 150–157. [Google Scholar] [CrossRef]

- Garrido, M.; Correia, J.R.; Keller, T. Effect of service temperature on the shear creep response of rigid polyurethane foam used in composite composite floor panels. Constr. Build. Mater. 2016, 118, 235–244. [Google Scholar] [CrossRef]

- Shams, A.; Stark, A.; Hoogen, F.; Hegger, J.; Schneider, H. Innovative composite structures made of high performance concrete and foamed polyurethane. Compos. Struct. 2015, 121, 271–279. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, Y.S.; Park, B.J.; Kim, D.H. Evaluation of durability and strength of stitched foam-cored composite structures. Compos. Struct. 1999, 47, 543–550. [Google Scholar] [CrossRef]

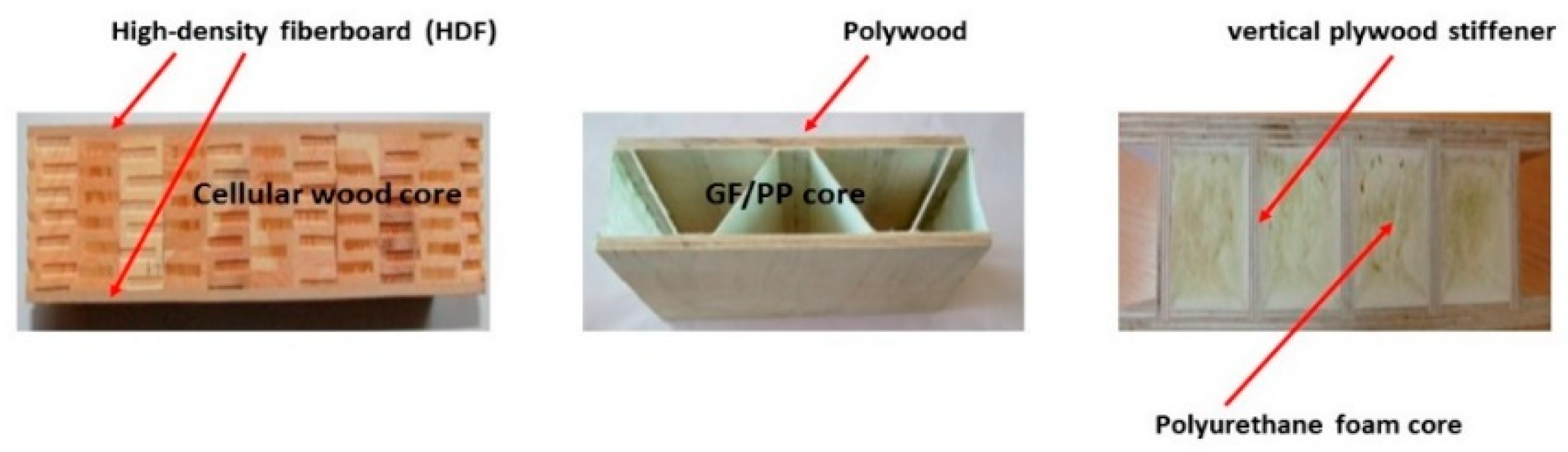

- Labans, E.; Kalnins, K.; Bisagni, C. Flexural behavior of composite panels with cellular wood, plywood stiffener/foam and thermoplastic composite core. J. Compos. Struct. Mater. 2017, 1099636217699587. [Google Scholar] [CrossRef]

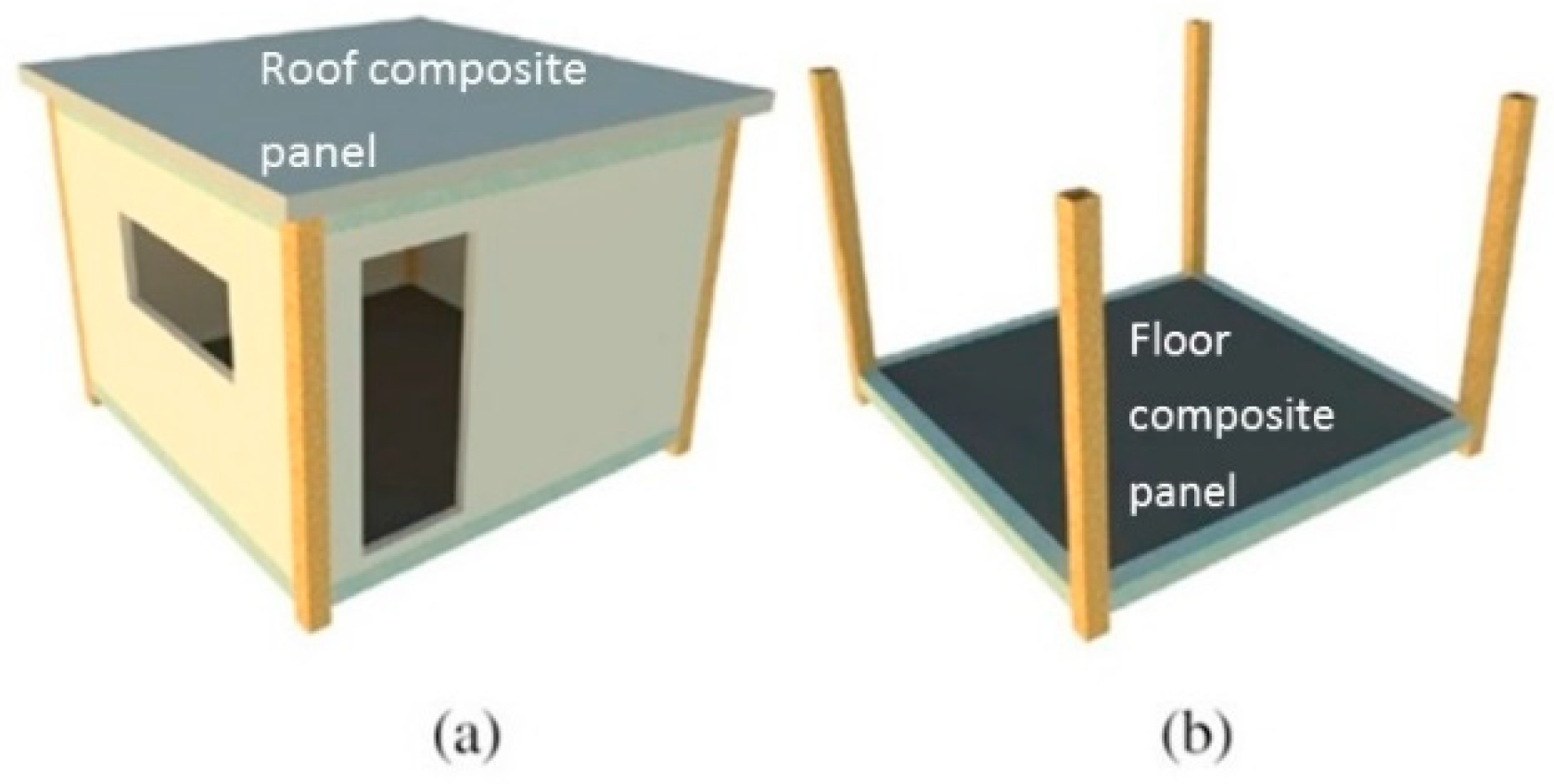

- Abdolpour, H.; Kalnins, K.; Bisagni, C. Development of a composite prototype with GFRP profiles and composite panels used as a floor module of an emergency house. Compos. Struct. 2016, 153, 81–95. [Google Scholar] [CrossRef]

- Jayaram, R.; Nagarajan, V.A.; Kumar, K.P. Polyester Pinning Effect on Flexural and Vibrational Characteristics of Foam Filled Honeycomb Composite Panels. Latin Am. J. Solids Struct. 2017, 14, 1314–1326. [Google Scholar] [CrossRef]

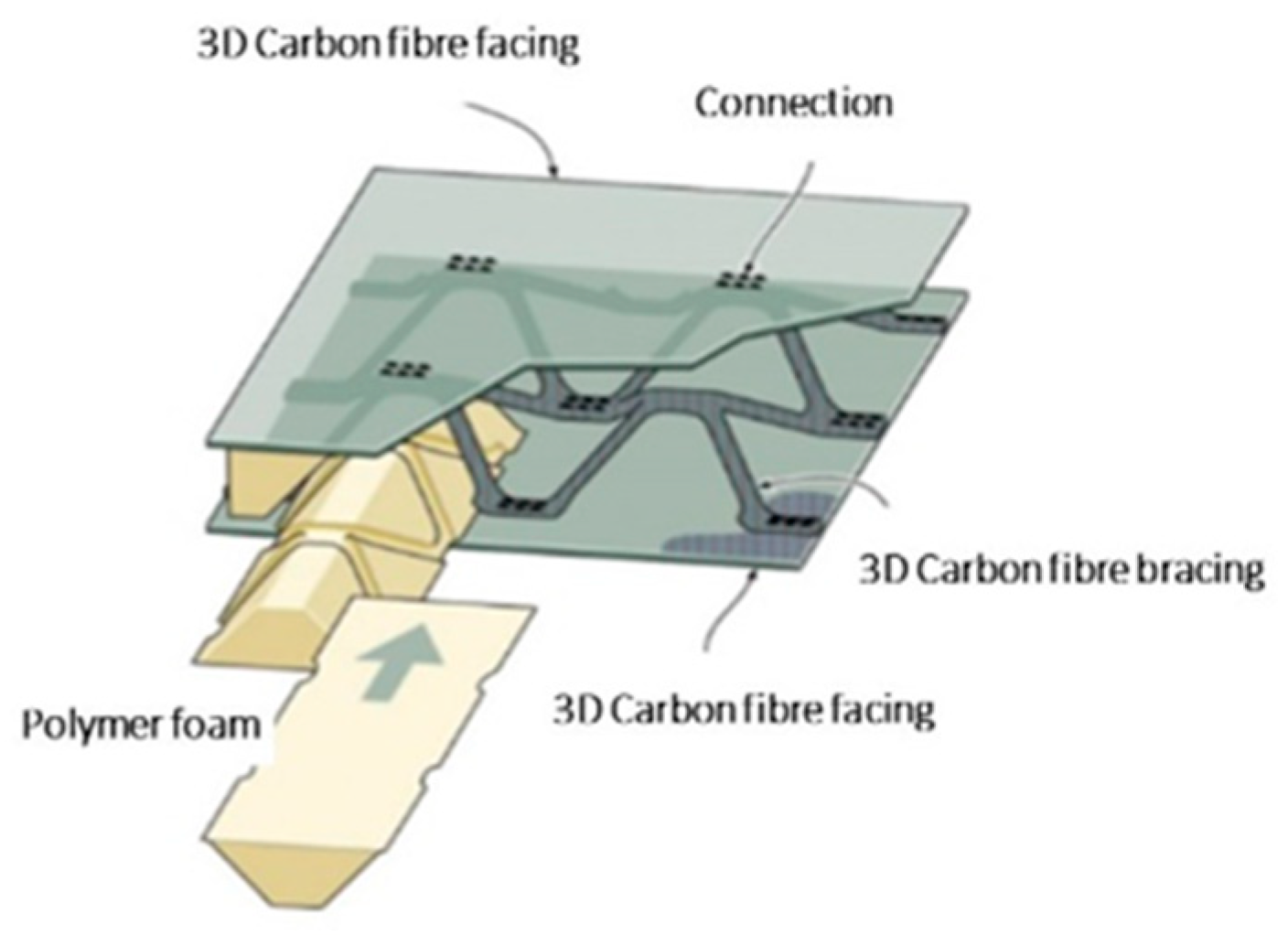

- Reis, E.M.; Rizkalla, S.H. Material characteristics of 3-D FRP composite panels. Constr. Build. Mater. 2008, 22, 1009–1018. [Google Scholar] [CrossRef]

- Mathieson, H.; Fam, A. Numerical modeling and experimental validation of axially loaded slender sandwich panels with soft core and various rib configurations. Eng. Struct. 2016, 118, 195–209. [Google Scholar] [CrossRef]

- Mohamed, M.; Anandan, S.; Huo, Z.; Birman, V.; Volz, J.; Chandrashekhara, K. Manufacturing and characterization of polyurethane based composite composite structures. Compos. Struct. 2015, 123, 169–179. [Google Scholar] [CrossRef]

- Abdi, B.; Azwan, S.; Abdullah, M.R.; Ayob, A.; Yahya, Y.; Xin, L. Flatwise compression and flexural behavior of foam core and polymer pin-reinforced foam core composite composite panels. Int. J. Mech. Sci. 2014, 88, 138–144. [Google Scholar] [CrossRef]

- Saeed Nemati, P.S. Bijan Samali, Shahab Khakpour, Compressive Behaviour of Modular Polyurethane Foam-Filled Composite Panels with 3-D High Density Polyethylene Skins; Centre for Infrastructures Engineering (CIE), Western Sydney University: Sydney, Australia, 2017; pp. 1–21. [Google Scholar]

- Koissin, V.; Shipsha, A.; Skvortsov, V. Compression strength of composite panels with sub-interface damage in the foam core. Compos. Sci. Technol. 2009, 69, 2231–2240. [Google Scholar] [CrossRef]

- Jakobsen, J.; Bozhevolnaya, E.; Thomsen, O.T. New peel stopper concept for composite structures. Compos. Sci. Technol. 2007, 67, 3378–3385. [Google Scholar] [CrossRef]

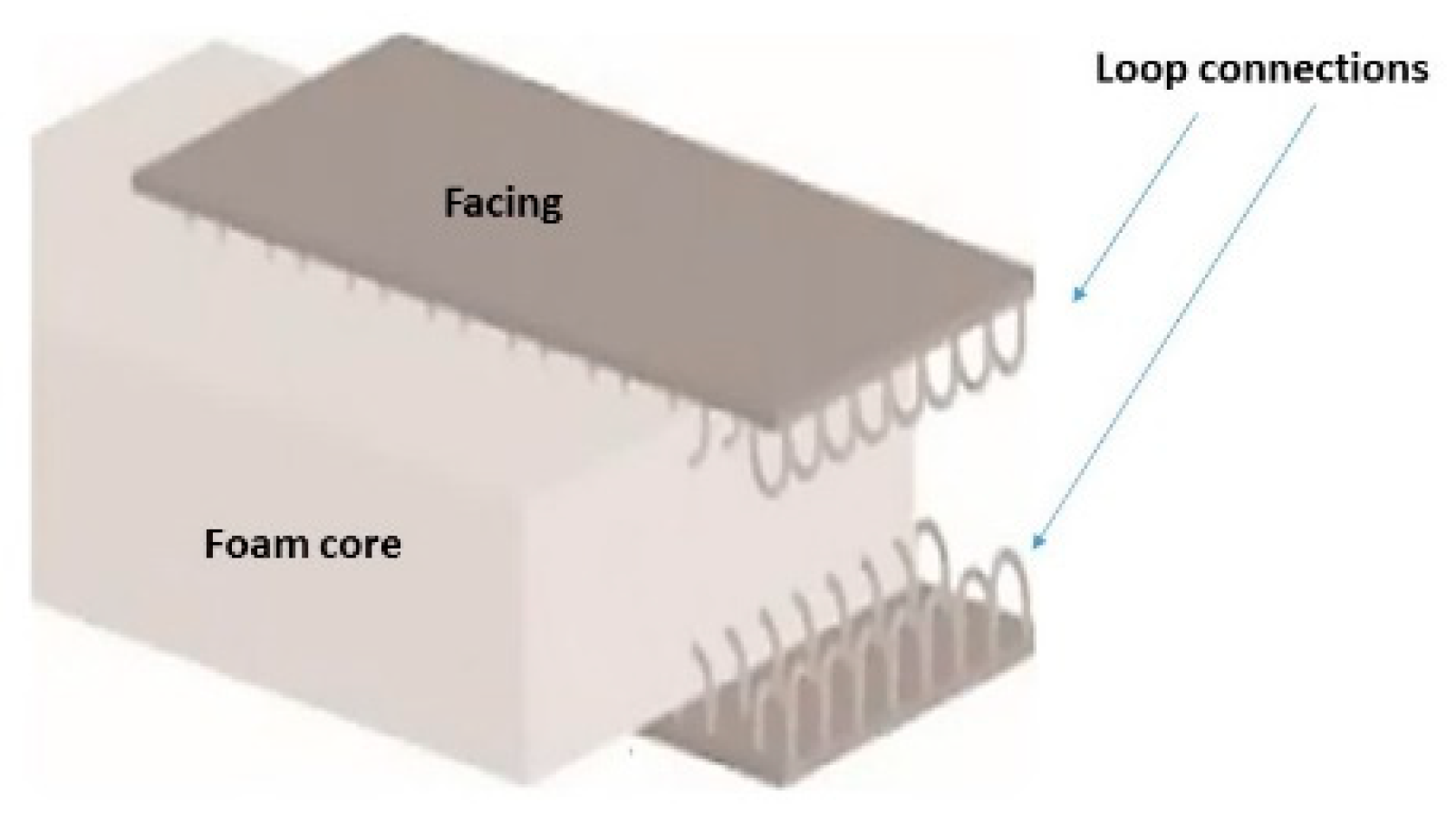

- Chen, M.; Zhou, G.; Wang, J. On mechanical behavior of looped fabric reinforced foam composite. Compos. Struct. 2014, 118, 159–169. [Google Scholar] [CrossRef]

- Miron, M.C.; Constantinescu, D.M. Strain fields at an interface crack in a composite composite. Mech. Mater. 2011, 43, 870–884. [Google Scholar] [CrossRef]

- Sharma, R.S.; Raghupathy, V. Influence of core density, core thickness, and rigid inserts on dynamic characteristics of sandwich panels with polyurethane foam as core. J. Reinf. Plast. Compos. 2010, 29, 3226–3236. [Google Scholar] [CrossRef]

- Sharma, S.; Krishna, M.; Murthy, H.N. Delamination during drilling in polyurethane foam composite composite structures. J. Mater. Eng. Perform. 2006, 15, 306–310. [Google Scholar] [CrossRef]

- Mostafa, A.; Shankar, K.; Morozov, E. Effect of shear keys diameter on the shear performance of composite composite panel with PVC and PU foam core: FE study. Compos. Struct. 2013, 102, 90–100. [Google Scholar] [CrossRef]

- Rodrigo Lameiras, J.B.; Isabel Valente, B.; Miguel, A. Development of composite panels combining fibre reinforced concrete layers and fibre reinforced polymer connectors. Part I: Conception and pull-out tests. Compos. Struct. 2013, 105, 446–459. [Google Scholar] [CrossRef]

- Yanes-Armas, S.; de Castro, J.; Keller, T. Long-term design of FRP-PUR web-core composite structures in building construction. Compos. Struct. 2017, 181, 214–228. [Google Scholar] [CrossRef]

- Chan, K.E. Experimental and numerical studies of sustainable composite bio-composites derived from plant-based resources. J. Compos. Struct. Mater. 2017, 19, 192–215. [Google Scholar] [CrossRef]

- Azmi, M.A.; Abdullah, H.; Idris, M.I. Properties of polyurethane foam/coconut coir fiber as a core material and as a composite composites component. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2013. [Google Scholar]

- Reany, J.; Grenestedt, J.L. Corrugated skin in a foam core composite panel. Compos. Struct. 2009, 89, 345–355. [Google Scholar] [CrossRef]

- Kam, T.; Lai, F.; Chao, T. Optimum design of laminated composite foam-filled composite plates subjected to strength constraint. Int. J. Solids Struct. 1999, 36, 2865–2889. [Google Scholar] [CrossRef]

- Arruda, M. Numerical modelling of the creep behaviour of GFRP composite panels using the Carrera Unified Formulation and Composite Creep Modelling. Compos. Struct. 2017, 183, 103–113. [Google Scholar] [CrossRef]

| Ref. | Goal | Investigated Parameters | Variables |

|---|---|---|---|

| [4] | Increasing the peak load and energy absorption capacity of composite panels |

|

|

| [5] | Determination of effects of foam density on composite panels energy absorption |

|

|

| [6,7] | Determination of low-velocity impact behaviour of foam-core composite panels |

|

|

| [8] | Study on the response of foam core composite panels to indentation |

|

|

| [9] | Determination of the dynamic response of foam-core composite plates subjected to low-velocity impact |

|

|

| [10] | Improvement the energy absorption |

|

|

| [11] | Determination of effects of nanoclay on polyurethane foam-filled composite panels energy absorption |

|

|

| [12] | Study on the structural response of carbon fibre composite panels subjected to blast loading |

|

|

| [13] | Conduction a numerical model to study the effectiveness of fibre-reinforced polymer (FRP) composite panels under blast effect |

|

|

| [14] | Study on the response of foam core composite panels under low-velocity impacts. |

|

|

| [15] | Improvement of absorbed energy and penetration threshold of the foam-core composite panels |

|

|

| [16] | Experimental investigation of the impact behaviour of three-layer composite structures made of high-density polyethylene (HDPE) and hemp, with and without a foam core |

|

|

| [17] | Investigation of the static bursting and low-velocity impact property of the composite flexible composites |

|

|

| [18,19] | Modelling of low-velocity impact on the composite panels with hybrid nanocomposite face sheets |

|

|

| [20] | Study on the low-velocity drop-weight impact tests of composites |

|

|

| [21] | Study on hybrid laminated composites energy absorption |

|

|

| [22] | Investigation of high-velocity impact on composite panels |

|

|

| [23] | Use of FE analysis for the simulation of the crushing response of composite panels aimed to absorb collision energy |

|

|

| [24] | Study on compressive properties, collapse modes and crushing characteristics of various types of composite panels in edgewise compression tests. |

|

|

| [25] | Study on composite panels fabricated using a fixed carbon fibre-reinforced polymer (CFRP) truss and a variety of closed-cell polymer and syntactic foams |

|

|

| [26] | Investigation of the effect of the polyurethane foam-filled lattice core composite panel on the energy absorption and the compression strength |

|

|

| [27] | Comparison between the indentation and compression behaviour of PRFCS and common traditional composite panels |

|

|

| Ref. | Goal | Investigated Parameters | Variables |

|---|---|---|---|

| [28] | Optimisation of processing conditions in the fabrication of the composite structures designed for flexural applications |

|

|

| [29] | Study on the flexural behaviour of a new composite panel proposed for cladding of buildings |

|

|

| [30] | Identification of the behaviour of an emerging prefabricated wall system |

|

|

| [31] | Study on static and fatigue bending behaviour of composite panels |

|

|

| [32] | Study on the bending behaviour of an innovative composite panel |

|

|

| [33] | Analysis of flexural behaviour of the composite composite panels |

|

|

| [34] | Study of composite panel flexural behaviour |

|

|

| [35] | Evaluation of three core alternatives for GFRP foam-core composite panels |

|

|

| [36] | Study of composite panel fatigue behaviour |

|

|

| [37] | Study on the effect of facing thickness on composite panels flexural behaviour |

|

|

| [38] | Presentation of an experimental assessment and analytical modelling of the viscoelastic response of composite panels |

|

|

| [39] | providing a nonlinear calculation procedure of textile reinforced concrete (TRC) facings composite panels |

|

|

| [40] | Study on the strengthening of soy-based PU foam cores, neat and composite foams containing wood fibre on the performance of small-scale wooden wall panels under monotonic and static cyclic shear loads |

|

|

| [41] | Study on effects of semicircular shear keys on composite panels shear strength |

|

|

| [42,43] | Experimental, numerical and analytical investigations on the flexural performance of composite panels composed of a polyurethane foam core and GFRP skins |

|

|

| [44] | Numerical modelling of the flexural behaviour of composite panels composed of woven glass fibre-reinforced polymer skins and polyurethane foam core |

|

|

| [45] | Numerical modelling and large-scale testing of lightweight composite panels intended for cladding of buildings in order to satisfy design code requirements in terms of strength and stiffness |

|

|

| [46,47,48] | Evaluation of the flexural performance of hybrid composite panels |

|

|

| [49] | Evaluation of the two-way bending behaviour of 3-D GFRP composite panels |

|

|

| [50] | Feasibility study of fabrication and flexural performance of composite panels of low-density PU foam and GFRP skins |

|

|

| [51] | Study on the effects of elevated temperature on the shear response of PET and PUR foams used in composite panels |

|

|

| [52] | Experimental/analytical study on the effect of temperature on the shear creep response of a rigid PUR foam at composite panels |

|

|

| [53] | Presenting the possible applications, the production method, and the major results of experimental investigations on the load-bearing behaviour of composite panels with textile-reinforced concrete (TRC) and ultrahigh performance fibre reinforced concrete |

|

|

| [54] | Investigation of the static and fatigue characteristics of nonstitched, stitched and stiffened PU filled composite panels |

|

|

| [55] | Mechanical evaluation of novel composite panels for application in lightweight mobile housing |

|

|

| [56] | Performing a series of experimental tests on a composite prototype to be used as a floor module of an emergency house |

|

|

| [57] | Increase the interfacial strength between the faces and core |

|

|

| [58] | Introducing a new 3D fibre-reinforced polymer (FRP) panels designed to overcome delamination |

|

|

| Ref. | Goal | Investigated Parameters | Variables |

|---|---|---|---|

| [24] | Study on compressive properties, collapse modes and crushing characteristics of various types of composite panels in edgewise compression tests. |

|

|

| [25] | Study on composite panels fabricated using a fixed carbon fibre-reinforced polymer (CFRP) truss and a variety of closed-cell polymer and syntactic foams |

|

|

| [26] | Investigation of the effect of the polyurethane foam-filled lattice core composite panel on the energy absorption and the compression strength |

|

|

| [27] | Comparison between the indentation and compression behaviour of PRFCS and common traditional composite panels |

|

|

| [59] | Experimental and analytical investigations of axially loaded composite panels |

|

|

| [60] | Core shear, flatwise and edgewise compression studies of three designs of glass reinforced composite composite panels |

|

|

| [61] | Study on the effect of composite panels’ foam core pin reinforcement under flexural and flatwise compression loadings |

|

|

| [62] | Study on edgewise and flatwise compression behaviour of an innovative composite panel |

|

|

| [63] | Study on the effect of a local quasi-static indentation or a low-velocity impact on the residual strength of foam core composite panels subjected to edgewise compression |

|

|

| Ref. | Goal | Investigated Parameters | Variables |

|---|---|---|---|

| [57] | Increase the interfacial strength between the faces and core |

|

|

| [58] | Introducing a new 3D fibre-reinforced polymer (FRP) panels designed to overcome delamination |

|

|

| [64] | presenting a new peel stopper concept for composite structures |

|

|

| [65] | Study on interface mechanical properties of Looped fabric reinforced foam composite (U-core) panels |

|

|

| [66] | Numerical and experimental study on interface damage characterisation and interlaminar failure of composite panels |

|

|

| [67] | Study on dynamic characteristics of composite panels |

|

|

| [68] | Study on the influence of drilling on the delamination of PU composite panels |

|

|

| [69] | Improvement of debonding failure between skin and core is highly important composite panels |

|

|

| [70] | Introducing an innovative and thermally efficient composite panel for the structural walls |

|

|

|

| Ref. | Goal | Investigated parameters | Variables |

|---|---|---|---|

| [71] | studying on structural creep behaviour of GFRP-polyurethane web-core composite structures subjected to sustained loading |

|

|

| [72] | Experimental and numerical studies of sustainable composite biocomposites |

|

|

| [73] | To characterise the physical and mechanical properties and to elucidate the effect of coconut coir fibres in polyurethane foam cores and composite panels |

|

|

| [74] | Study on composite panels with one corrugated and one flat skin in order to find configurations with higher strength and/or stiffness and reduced weight |

|

|

| [75] | Introducing a new method for optimum design of laminated composite panels |

|

|

| [76] | Numerical investigations on the creep behaviour of composite panels |

|

|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samali, B.; Nemati, S.; Sharafi, P.; Tahmoorian, F.; Sanati, F. Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art. J. Compos. Sci. 2019, 3, 40. https://doi.org/10.3390/jcs3020040

Samali B, Nemati S, Sharafi P, Tahmoorian F, Sanati F. Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art. Journal of Composites Science. 2019; 3(2):40. https://doi.org/10.3390/jcs3020040

Chicago/Turabian StyleSamali, Bijan, Saeed Nemati, Pezhman Sharafi, Farzaneh Tahmoorian, and Farshad Sanati. 2019. "Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art" Journal of Composites Science 3, no. 2: 40. https://doi.org/10.3390/jcs3020040

APA StyleSamali, B., Nemati, S., Sharafi, P., Tahmoorian, F., & Sanati, F. (2019). Structural Performance of Polyurethane Foam-Filled Building Composite Panels: A State-Of-The-Art. Journal of Composites Science, 3(2), 40. https://doi.org/10.3390/jcs3020040