Wear Behavior of Copper–Graphite Composites Processed by Field-Assisted Hot Pressing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Fabrication

2.3. Microstructure Characterization

2.4. Hardness Testing

2.5. Tribological Performance Testing

2.6. Wear Characterization

3. Results and Discussion

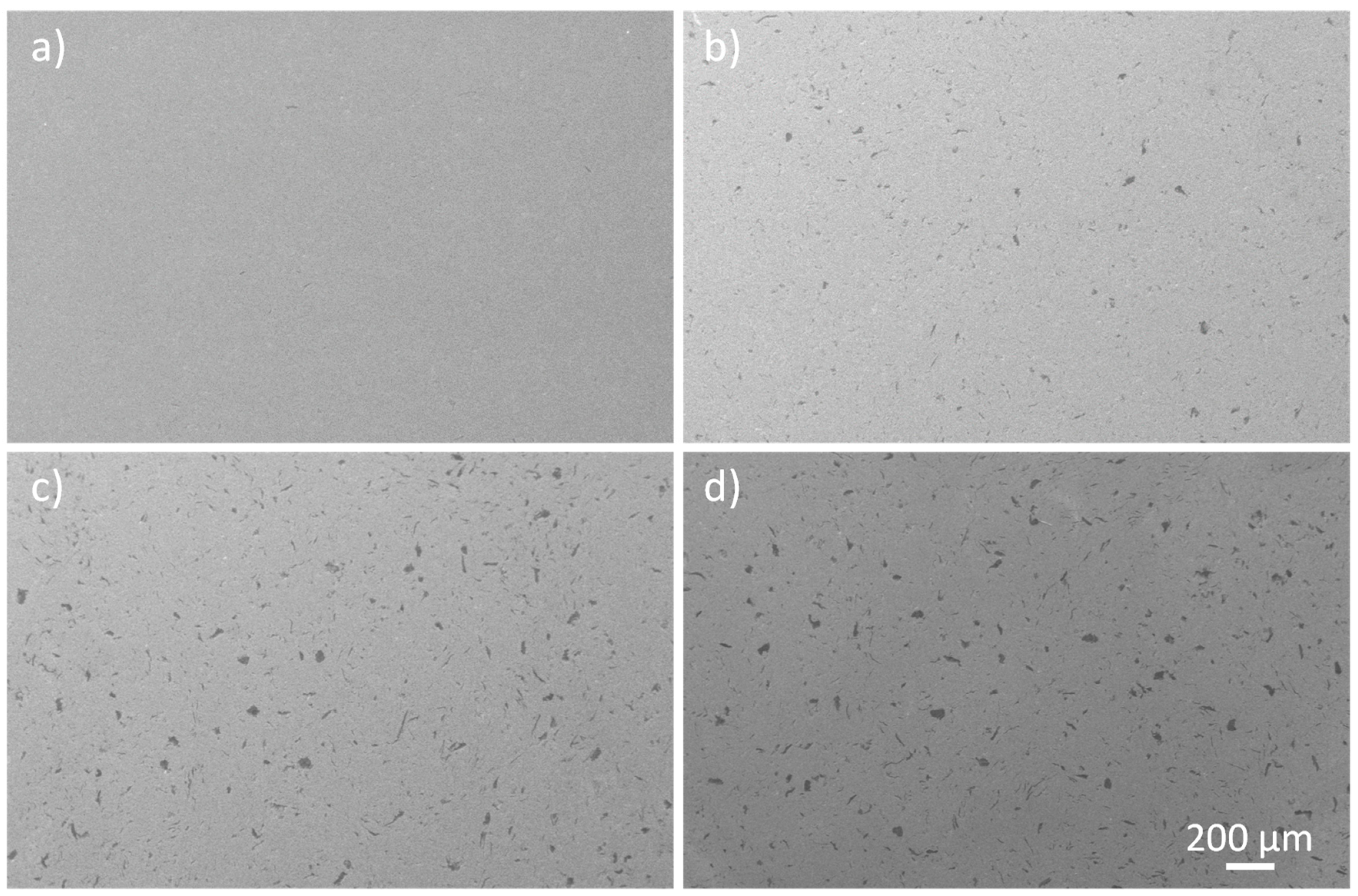

3.1. Microstructure and Properties of Composites

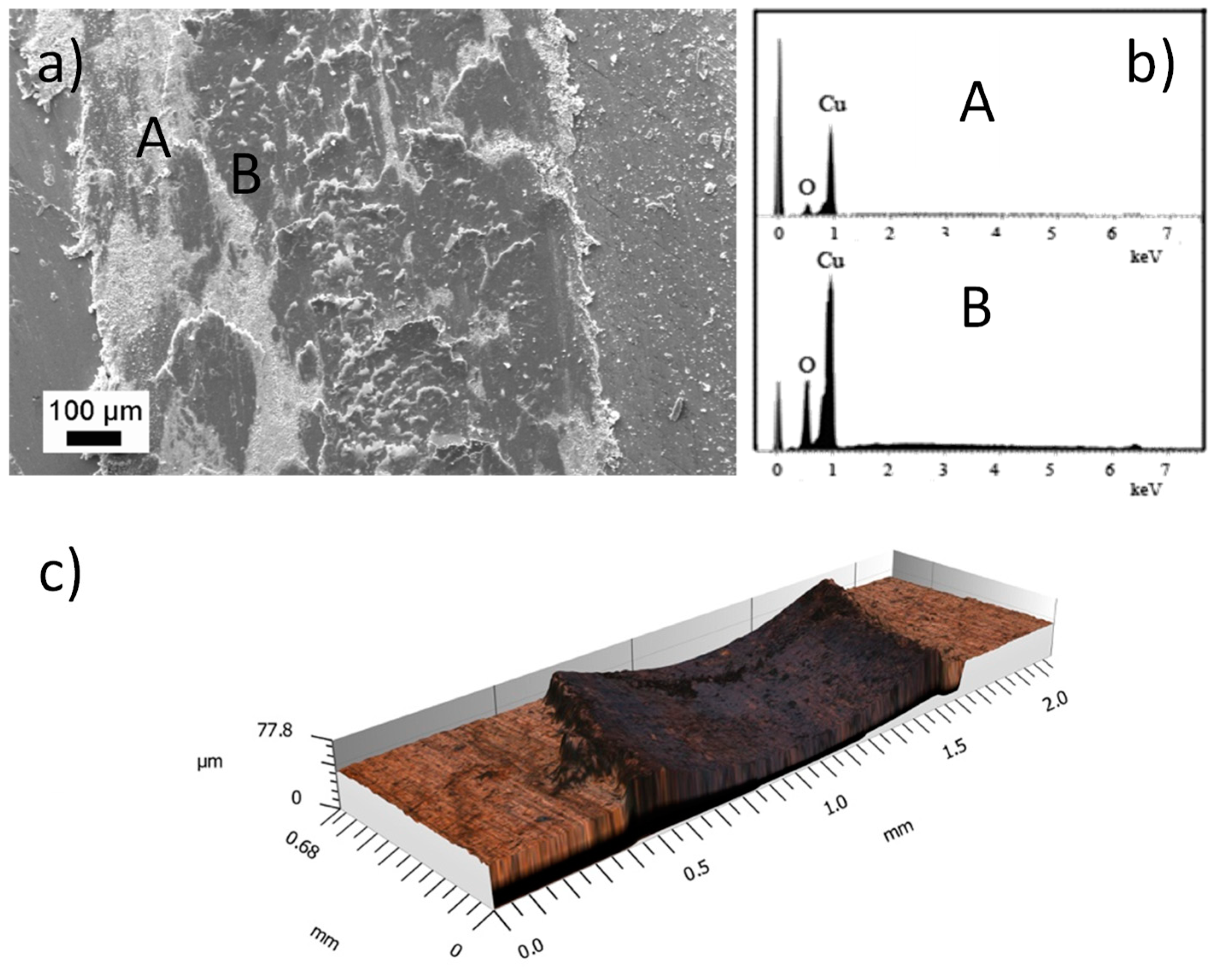

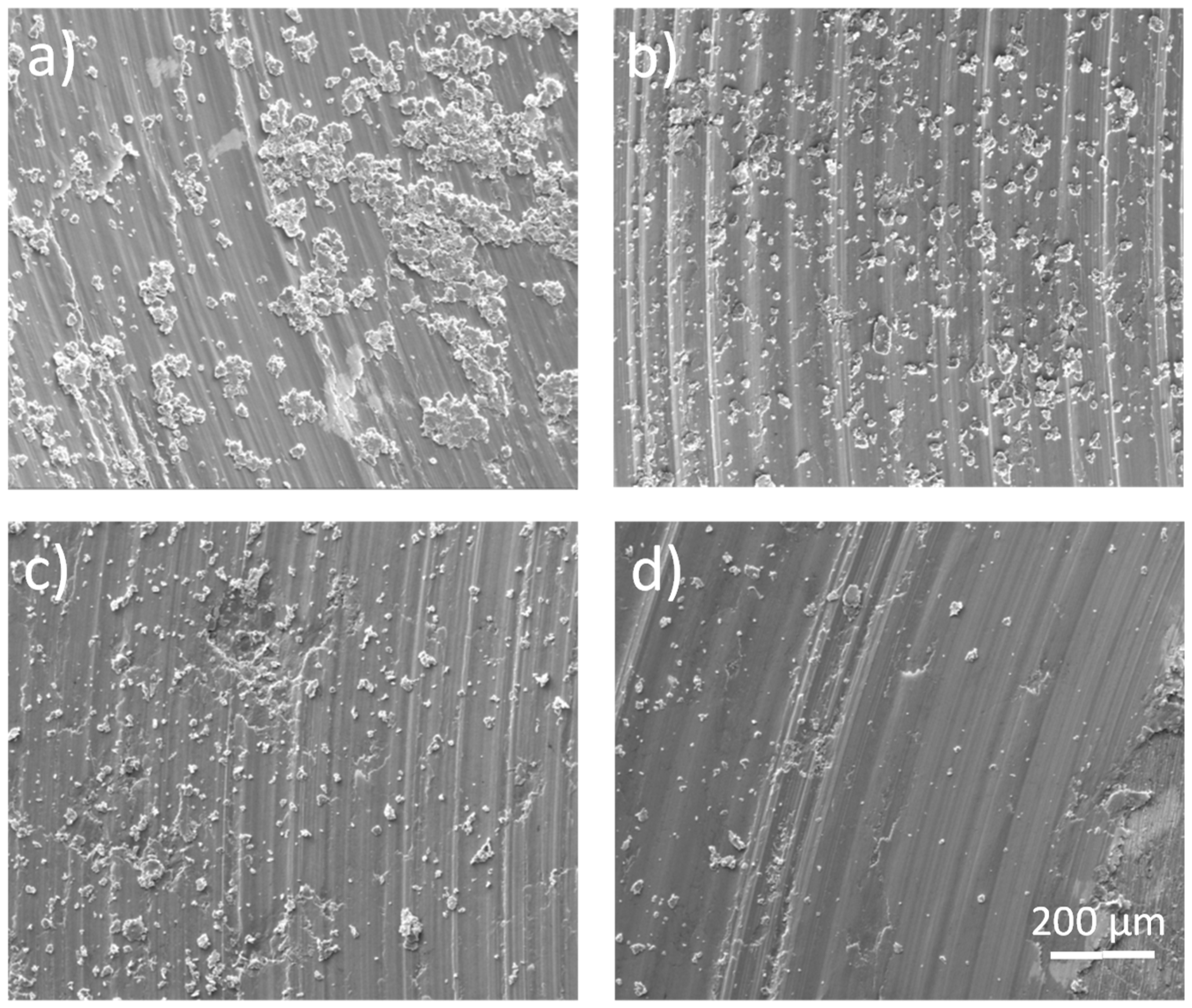

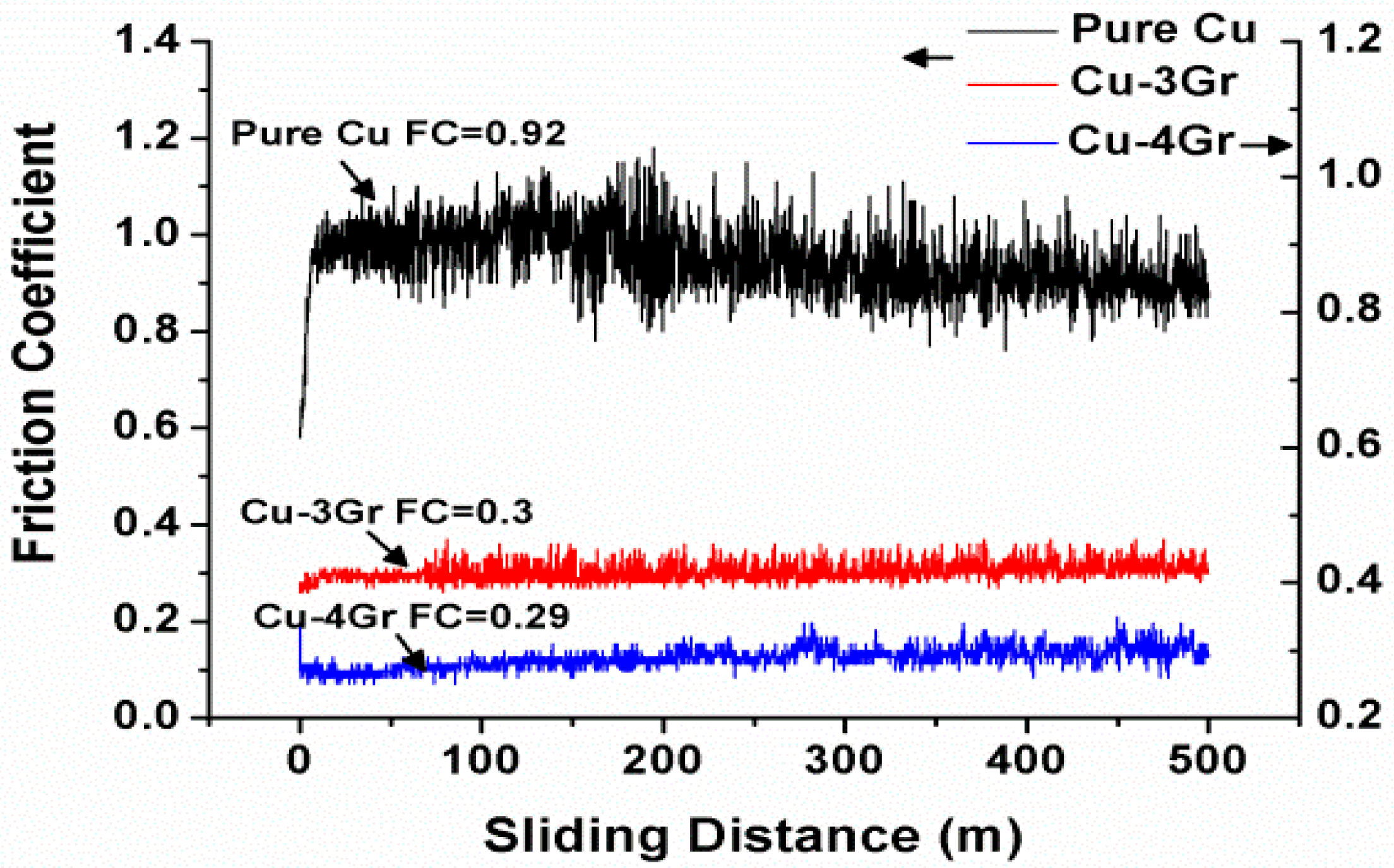

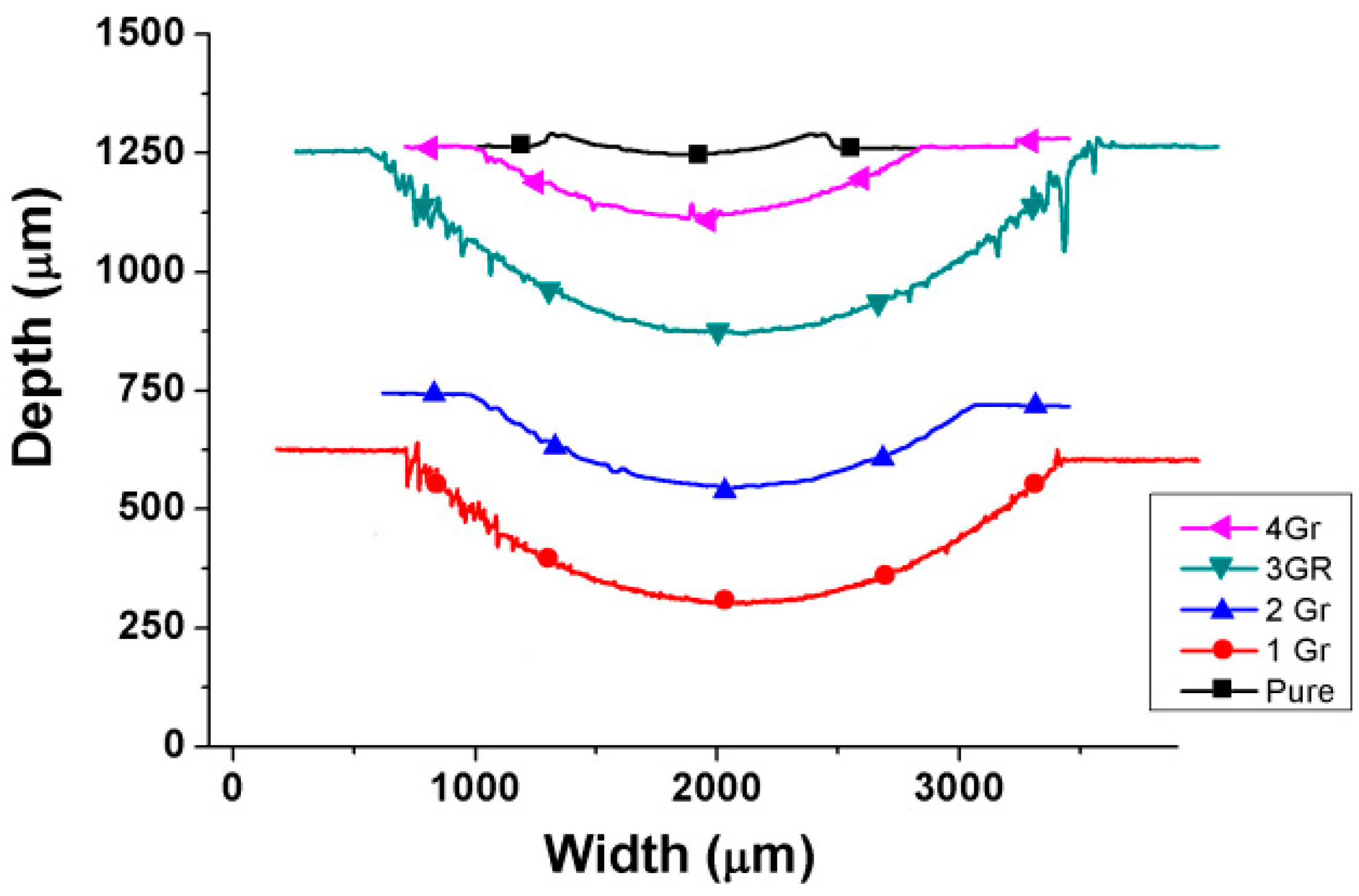

3.2. Friction and Wear Behavior

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zahran, R.R.; Ibrahim, I.H.M.; Sedahmed, G.H. The corrosion of graphite/copper composites in different aqueous environments. Mater. Lett. 1996, 28, 237–244. [Google Scholar] [CrossRef]

- Kestursatya, M.; Kim, J.K.; Rohatgi, P.K. Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 2003, 339, 150–158. [Google Scholar] [CrossRef]

- Ma, X.; He, G.; He, D.; Chen, C.; Hu, Z. Sliding wear behavior of copper–graphite composite material for use in maglev transportation system. Wear 2008, 265, 1087–1092. [Google Scholar] [CrossRef]

- Moustafa, S.; El-Badry, S.; Sanad, A.; Kieback, B. Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders. Wear 2002, 253, 699–710. [Google Scholar] [CrossRef]

- Kováčik, J.; Emmer, Š.; Bielek, J.; Keleši, L. Effect of composition on friction coefficient of Cu–graphite composites. Wear 2008, 265, 417–421. [Google Scholar] [CrossRef]

- Rajkumar, K.; Aravindan, S. Tribological behavior of microwave processed copper–nanographite composites. Tribol. Int. 2013, 57, 282–296. [Google Scholar] [CrossRef]

- Nayak, D.; Debata, M. Effect of composition and milling time on mechanical and wear performance of copper-graphite composites processed by powder metallurgy route. Powder Metall. 2014, 57, 265–273. [Google Scholar] [CrossRef]

- Sarmadi, H.; Kokabi, A.; Reihani, S.S. Friction and wear performance of copper–graphite surface composites fabricated by friction stir processing (FSP). Wear 2013, 304, 1–12. [Google Scholar] [CrossRef]

- Samal, C.; Parihar, J.; Chaira, D. The effect of milling and sintering techniques on mechanical properties of Cu–graphite metal matrix composite prepared by powder metallurgy route. J. Alloys Compd. 2013, 569, 95–101. [Google Scholar] [CrossRef]

- Chu, K.; Wu, Q.Y.; Jia, C.C.; Liang, X.B.; Nie, J.H.; Tian, W.H.; Gai, G.S.; Guo, H. Fabrication and effective thermal conductivity of multi-walled carbon nanotubes reinforced Cu matrix composites for heat sink applications. Compos. Sci. Technol. 2010, 70, 298–304. [Google Scholar] [CrossRef]

- Daoush, W.M.; Lim, B.K.; Mo, C.B.; Nam, D.H.; Hong, S.H. Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater. Sci. Eng. A 2009, 513–514, 247–253. [Google Scholar] [CrossRef]

- Czichos, H.; Klaffke, D.; Santner, E.; Woydt, M. Advances in tribology: The materials point of view. Wear 1995, 190, 155–161. [Google Scholar] [CrossRef]

- Sule, R.; Olubambi, P.; Sigalas, I.; Asante, J.; Garrett, J. Effect of SPS consolidation parameters on submicron Cu and Cu–CNT composites for thermal management. Powder Technol. 2014, 258, 198–205. [Google Scholar] [CrossRef]

- Liu, Q.; He, X.B.; Ren, S.B.; Zhang, C.; Liu, T.T.; Qu, X.H. Thermophysical properties and microstructure of graphite flake/copper composites processed by electroless copper coating. J. Alloys Compd. 2014, 587, 255–259. [Google Scholar] [CrossRef]

- Zhan, Y.; Zhang, G. Friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles. Tribol. Lett. 2004, 17, 91–98. [Google Scholar] [CrossRef]

- Akhlaghi, F.; Zare-Bidaki, A. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024–graphite composites produced by in situ powder metallurgy method. Wear 2009, 266, 37–45. [Google Scholar] [CrossRef]

- Hocheng, H.; Yen, S.; Ishihara, T.; Yen, B. Fundamental turning characteristics of a tribology-favored graphite/aluminum alloy composite material. Compos. Part A 1997, 28, 883–890. [Google Scholar] [CrossRef]

- Riahi, A.; Alpas, A. The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear 2001, 251, 1396–1407. [Google Scholar] [CrossRef]

- Teoh, S.; Thampuran, R.; Seah, W. Coefficient of friction under dry and lubricated conditions of a fracture and wear resistant P/M titanium-graphite composite for biomedical applications. Wear 1998, 214, 237–244. [Google Scholar] [CrossRef]

- Li, J.L.; Xiong, D.S. Tribological properties of nickel-based self-lubricating composite at elevated temperature and counterface material selection. Wear 2008, 265, 533–539. [Google Scholar] [CrossRef]

| Ref. | System | Graphite Content | Microhardness (HV) | Friction Test Conditions (Load, Speed) | Friction Coefficient | Wear Rate (10−4 mm3/Nm) |

|---|---|---|---|---|---|---|

| [4] | Coated, cold pressing sintering | 8 wt % | 19.3 (BH) * | pin-on-ring 100 N 0.2 m/s | 0.35 | 0.13 |

| 15 wt % | 16.4 (BH) * | 0.25 | 0.14 | |||

| 20 wt % | 12.5 (BH) * | 0.2 | 0.11 | |||

| [5] | Hot isostatic pressing | 30 vol % | - | pin-on-disc 30 N, 0.5 m/s | 0.15 | 16 |

| 50 vol % | - | 0.15 | 5.7 | |||

| [6] | Microwave sintering | 15 vol % | 72 | pin-on-disc 12 N, 0.77 m/s | 0.22 | 0.5 |

| 15 vol % (Nanographite) | 81.5 | 0.16 | 0.33 | |||

| [7] | Ball milling, cold pressing, sintering | 5 vol % | 51 | block-on-ring 30 N, 1 m/s | - | 4.97 |

| 10 vol % | 42 | - | 1.11 | |||

| 15 vol % | 36 | - | 0.85 | |||

| [8] | Friction stir processing | 0 vol % | pin-on-disc 10 N 0.3 m/s | 0.81 | 22.4 | |

| 6.54 vol % | - | 0.45 | 15.4 | |||

| 10.89 vol % | - | 0.30 | 12.7 | |||

| 16.70 vol % | 0.22 | 11.3 | ||||

| 22.12 vol % | - | 0.17 | 9.4 | |||

| [9] | Conventional sintering | 1 vol % | 70 | - | - | - |

| 3 vol % | 70 | - | - | |||

| 5 vol % | 42 | - | - | |||

| 10 vol % | 50 | - | - | |||

| Field-assisted sintering | 1 vol % | 100 | - | - | ||

| 5 vol % | 100 | - | - |

| Material | Graphite Content (wt %) | Density (g/cm3) | Relative Density (%) | Hardness (HV) | Friction Coefficient | Wear Rate (10−4 mm3/Nm) |

|---|---|---|---|---|---|---|

| Pure copper | 0 | 8.76 0.06 | 98.4 | 94 ± 3 | 0.92 ± 0.09 | 0.03 ± 0.06 |

| Cu–1Gr | 1 | 8.41 ± 0.06 | 98.2 | 75 ± 2 | 0.33 ± 0.01 | 30.0 ± 2.7 |

| Cu–2Gr | 2 | 8.07 ± 0.02 | 97.8 | 72 ± 2 | 0.29 ± 0.02 | 14.6 ± 3.4 |

| Cu–3Gr | 3 | 7.90 ± 0.03 | 99.3 | 71.1 ± 1.4 | 0.3 ± 0.01 | 12.7 ± 3.8 |

| Cu–4Gr | 4 | 7.61 ± 0.06 | 98.9 | 69.7 ± 0.8 | 0.29 0.02 | 13.7 ± 3.0 |

| Material | Weight% | Atomic% | ||

|---|---|---|---|---|

| C | Cu | C | Cu | |

| Cu–1Gr | 2.11 | 97.89 | 9.55 | 90.45 |

| Cu–2Gr | 5.64 | 94.36 | 24.02 | 75.98 |

| Cu–3Gr | 8.06 | 91.94 | 31.68 | 68.32 |

| Cu–4Gr | 12.56 | 87.44 | 46.53 | 53.47 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Castillo-Rodríguez, M.; Galisteo, A.J.; Guzmán de Villoria, R.; Torralba, J.M. Wear Behavior of Copper–Graphite Composites Processed by Field-Assisted Hot Pressing. J. Compos. Sci. 2019, 3, 29. https://doi.org/10.3390/jcs3010029

Liu Q, Castillo-Rodríguez M, Galisteo AJ, Guzmán de Villoria R, Torralba JM. Wear Behavior of Copper–Graphite Composites Processed by Field-Assisted Hot Pressing. Journal of Composites Science. 2019; 3(1):29. https://doi.org/10.3390/jcs3010029

Chicago/Turabian StyleLiu, Qian, Miguel Castillo-Rodríguez, Antonio Julio Galisteo, Roberto Guzmán de Villoria, and José Manuel Torralba. 2019. "Wear Behavior of Copper–Graphite Composites Processed by Field-Assisted Hot Pressing" Journal of Composites Science 3, no. 1: 29. https://doi.org/10.3390/jcs3010029

APA StyleLiu, Q., Castillo-Rodríguez, M., Galisteo, A. J., Guzmán de Villoria, R., & Torralba, J. M. (2019). Wear Behavior of Copper–Graphite Composites Processed by Field-Assisted Hot Pressing. Journal of Composites Science, 3(1), 29. https://doi.org/10.3390/jcs3010029