Preparation and Mechanical Properties of Graphene/Carbon Fiber-Reinforced Hierarchical Polymer Composites

Abstract

1. Introduction

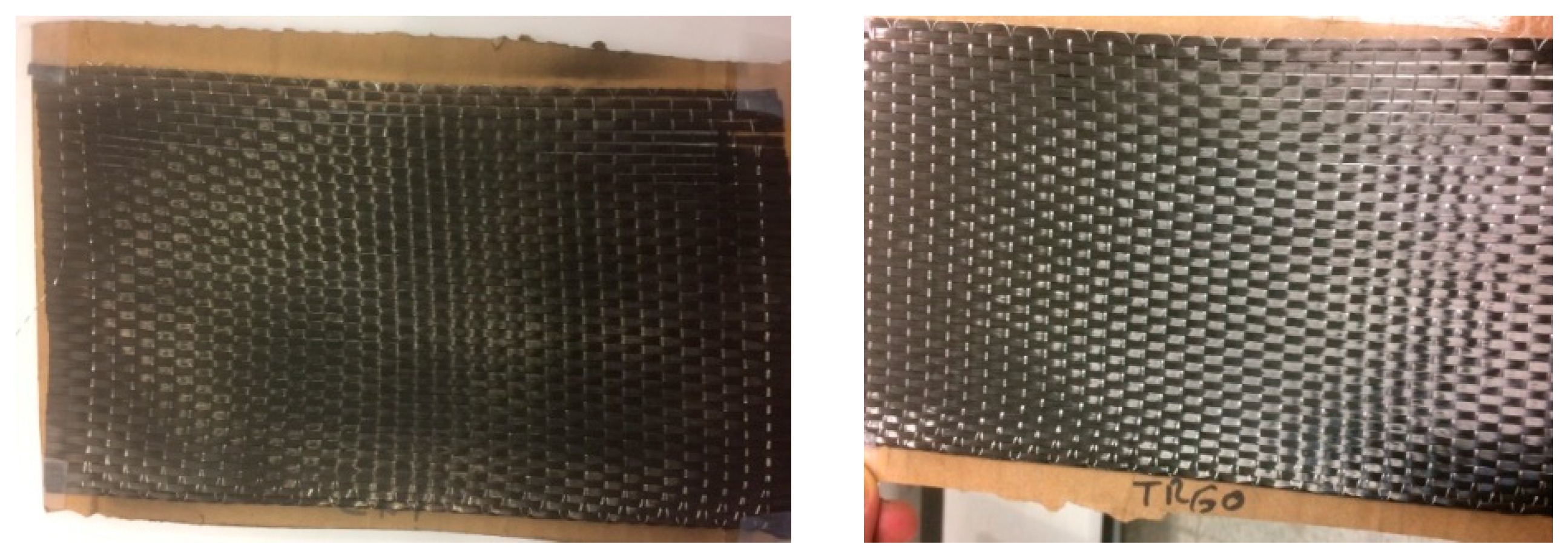

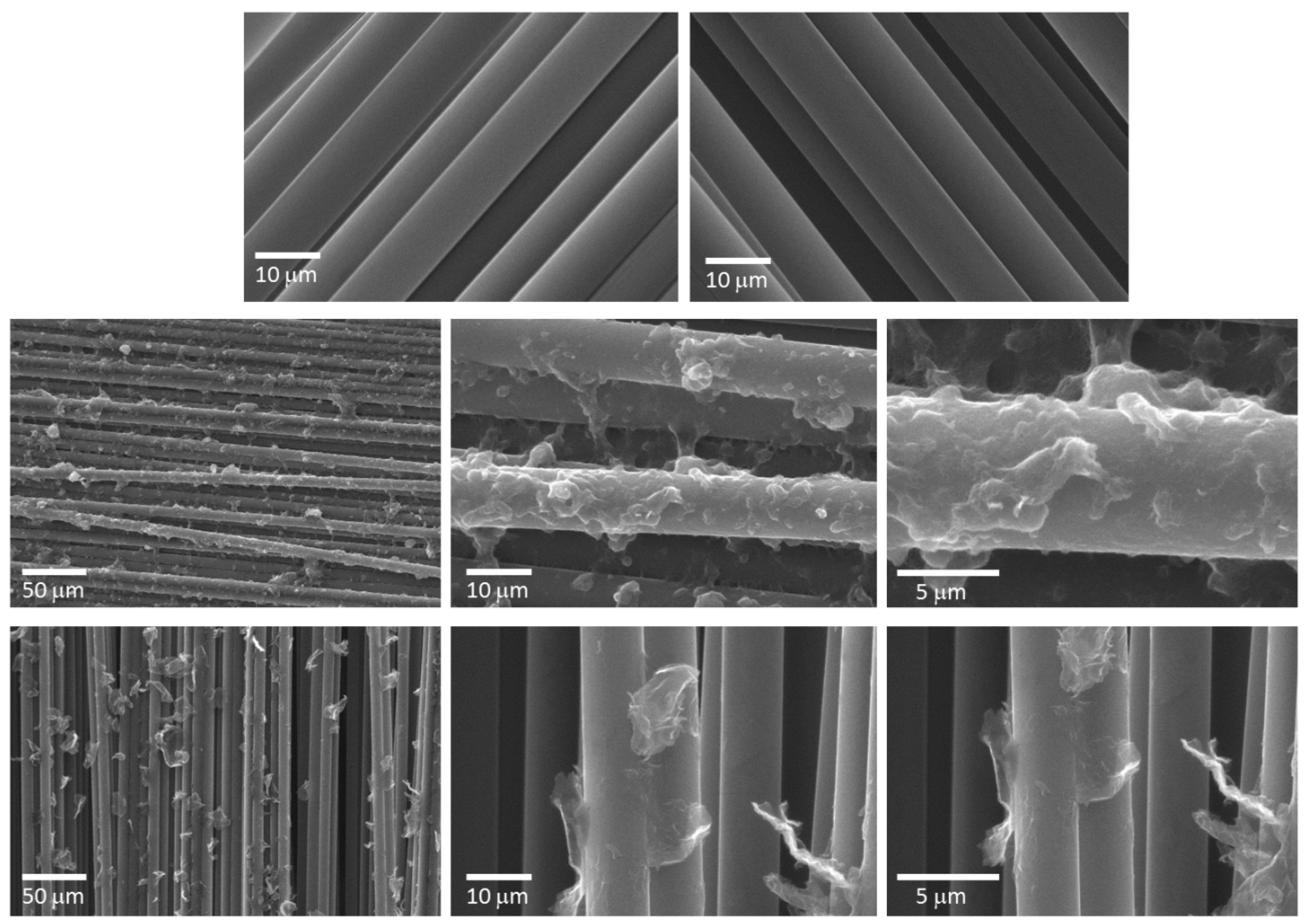

2. Materials and Methods

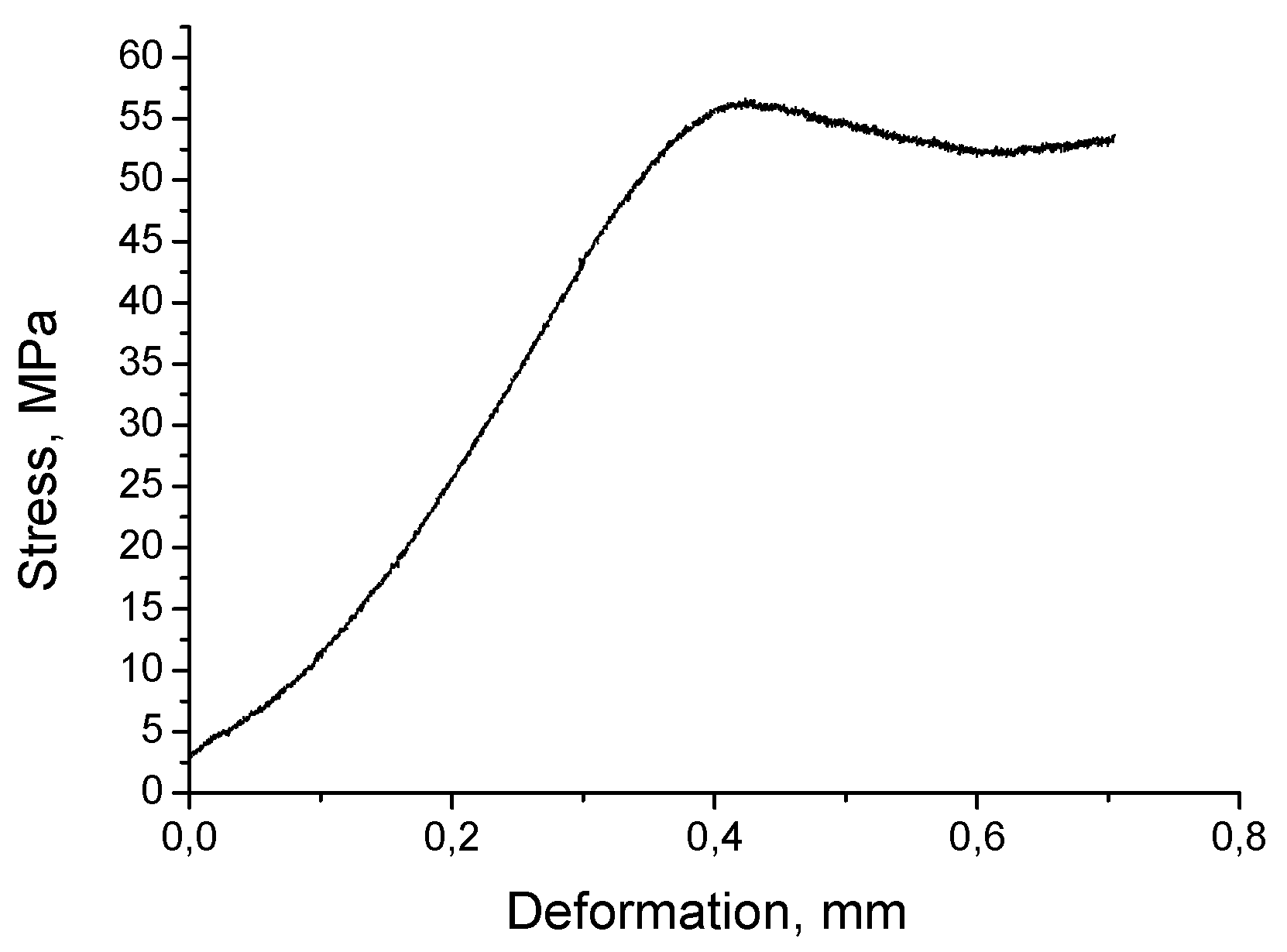

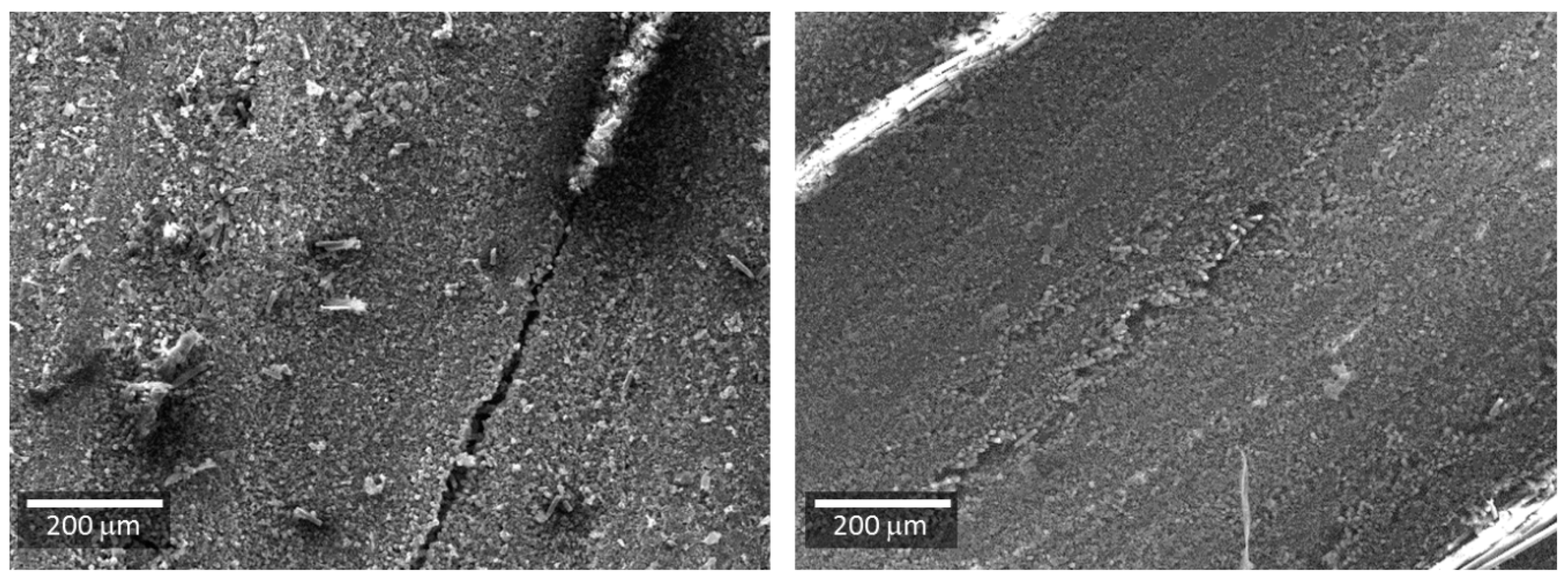

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mallick, P.K. Fiber-Reinforced Composites. Materials, Manufacturing and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Jain, R.; Lee, L. Fiber Reinforced Polymer (FRP) Composites for Infrastructure Applications; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bai, J. Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Ozgur Seydibeyoglu, M.; Mohanty, A.K.; Misra, M. Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- Borri, A.; Castori, G.; Corradi, M.; Speranzini, E. Durability analysis for FRP and SRG composites in civil applications. Key Eng. Mater. 2015, 624, 421–428. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Righetti, L.; Speranzini, E. Uncertainty analysis of FRP reinforced timber beams. Compos. Part B 2017, 113, 174–184. [Google Scholar] [CrossRef]

- Corradi, M.; Borri, A.; Castori, G.; Speranzini, E. Fully reversible reinforcement of softwood beams with unbounded composite plates. Compos. Struct. 2016, 149, 54–68. [Google Scholar] [CrossRef]

- Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.; Wang, M.; Wang, F.; Jiang, Z.; Huang, Y. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Tong, L.; Mouritz, A.P.; Bannister, M.K. 3D Fibre Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Vautard, F.; Ozcan, S.; Meyer, H. Properties of thermo-chemically Surface treated carbon fibers and of their epoxy and vinyl ester composites. Compos. Part A 2012, 43, 1120–1133. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.G.; Zhang, S.; Lin, X. Effect of surface modification on carbon fibre and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.L.; Mader, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Major, L.; Janusz, M.; Kot, M.; Lackner, J.M.; Major, B. Development and complex characterization of bio-tribological Cr/CrNplus A-C:H (Doped Cr) nano-multilayer protective coatings for carbon fibre composite materials. RSC Adv. 2015, 5, 9405–9415. [Google Scholar] [CrossRef]

- Qian, H.; Greenhalgh, E.S.; Shaffer, M.S.P.; Bismarck, A. Carbon nanofiber –base hierarchical composites: A review. J. Mater. Chem. 2010, 20, 4751–4762. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2010, 73, 1–43. [Google Scholar] [CrossRef]

- Ghasemi-Nejhad, M.N. Hierarchical multifunctional nanocomposites. SPIE 2014, 9058, 905801–905816. [Google Scholar]

- Qin, W.; Vautard, F.; Drzal, L.T.; Yu, J. Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber–matrix interphase. Compos. Part B 2015, 69, 335–341. [Google Scholar] [CrossRef]

- Zhang, R.L.; Gao, B.; Ma, Q.H.; Zhang, J.; Cui, H.Z.; Liu, L. Directly grafting graphene oxide onto carbon fiber and the effect on the mechanical properties of carbon fiber composites. Mater. Des. 2016, 93, 364–369. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Yu, J.; Sun, S.; Li, X.; Xie, F.; Jiang, B.; Wu, G. Grafting of size-controlled graphene oxide sheets onto carbon fiber for reinforcement of carbon fiber/epoxy composite interfacial strength. Compos. Part A 2015, 101, 511–520. [Google Scholar] [CrossRef]

- Liu, L.; Yan, F.; Li, M.; Zhang, M.; Xiao, L.; Shang, L.; Ao, Y. Improving interfacial properties of hierarchical reinforcement carbon fibers modified by graphene oxide with different bonding types. Compos. Part A 2018, 107, 616–625. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Verdejo, R.; Bernal, M.M.; Romasanta, L.J.; Lopez-Manchado, M.A. Graphene filled polymer nanocomposites. J. Mater. Chem. 2011, 21, 3301–3310. [Google Scholar] [CrossRef]

- Botas, C.; Álvarez, P.; Blanco, C.; Santamaría, R.; Granda, M.; Ares, P.; Rodríguez-Reinoso, F.; Menéndez, R. The Effect of the parent graphite on the structure of graphene oxide. Carbon 2012, 50, 275–282. [Google Scholar] [CrossRef]

- Botas, C.; Álvarez, P.; Blanco, P.; Granda, M.; Blanco, C.; Santamaría, R.; Romasanta, L.J.; Verdejo, R.; López-Manchado, M.A.; Menéndez, R. Graphene materials with different structures prepared from the same graphite by the Hummers and Brodie methods. Carbon 2013, 65, 156–164. [Google Scholar] [CrossRef]

- Vazquez-Moreno, J.M.; Yuste-Sanchez, V.; Sanchez-Hidalgo, R.; Verdejo, R.; Lopez-Manchado, M.A.; Fernández-García, L.; Blanco, C.; Menéndez, R. Customizing thermally-reduced graphene oxides for electrically conductive or mechanical reinforced epoxy nanocomposites. Eur. Polym. J. 2017, 93, 1–7. [Google Scholar] [CrossRef]

- Sánchez-Hidalgo, R.; Yuste-Sanchez, V.; Verdejo, R.; Blanco, C.; Lopez-Manchado, M.A.; Menéndez, R. Main structural features of graphene materials controlling the transport properties of epoxy resin-based composites. Eur. Polym. J. 2018, 101, 56–65. [Google Scholar] [CrossRef]

- Iwahori, Y.; Ishiwata, S.; Sumizawa, T.; Ishikawa, T. Mechanical properties improvements in two-phase and three-phase composites using carbon nano-fiber dispersed resin. Compos. Part A 2005, 36, 1430–1439. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, C.; Wang, B.; Liang, R. Carbon nanotube integrated multifunctional multiscale composites. Nanotechnology 2007, 18, 275708. [Google Scholar] [CrossRef]

- Godara, A.; Mezzo, L.; Luizi, F.; Warrier, A.; Lomov, S.V.; van Vuure, A.W.; Gorbatikh, L.; Moldenaers, P.; Verpoest, I. Influence of carbon nanotube reinforcement on the processing and the mechanical behaviour of carbon fiber/epoxy composites. Carbon 2009, 47, 2914–2923. [Google Scholar] [CrossRef]

- Sánchez-Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part B 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Ci, L.; Bai, J. The reinforcement role of carbon nanotubes in epoxy composites with different matrix stiffness. Compos. Sci. Technol. 2006, 66, 599–603. [Google Scholar] [CrossRef]

- Chandrasekaran, V.C.S.; Advani, S.G.; Santare, M.H. Role of processing on interlaminar shear strength enhancement of epoxy/glass fiber/multi-walled carbon nanotube hybrid composites. Carbon 2010, 48, 3692–3699. [Google Scholar] [CrossRef]

- Wu, G.; Ma, L.; Liu, L.; Wang, Y.; Xie, F.; Zhong, Z.; Zhao, M.; Jiang, B.; Huang, Y. Interfacially reinforced methylphenylsilicone resin composites by chemically grafting multiwall carbon nanotubes onto carbon fibers. Compos. Part B 2015, 82, 50–58. [Google Scholar] [CrossRef]

- Rong, H.; Dahmen, K.H.; Garmestani, H.; Yu, M.; Jacob, K.I. Comparison of chemical vapor deposition and chemical grafting for improving the mechanical properties of carbon fiber/epoxy composites with multi-wall carbon nanotubes. J. Mater. Sci. 2013, 48, 4834–4842. [Google Scholar] [CrossRef]

- Fan, W.; Wang, Y.; Wang, C.; Chen, J.; Wang, Q.; Yuan, Y.; Niu, F. High efficient preparation of carbon nanotube-grafted carbon fibers with the improved tensile strength. Appl. Surf. Sci. 2016, 364, 539–551. [Google Scholar] [CrossRef]

| Laminate | Tensile Tests | ILSS, τ13, MPa | |||||

|---|---|---|---|---|---|---|---|

| 0° | 90° | ±45° | |||||

| Young’s Modulus, E1, GPa | Maximum Strength, MPa | Young’s Modulus, E2, GPa | Maximum Strength, MPa | Modulus, G12, MPa | Strength, MPa | ||

| Cblank | 128.2 ± 4.2 | 1630.7 ± 58.8 | 9.7 ± 0.6 | 45.6 ± 0.9 | 4249.6 ± 109.7 | 32.3 ± 0.3 | 52.2 ± 1.6 |

| CG05 | 126.8 ± 4.8 | 1726.0 ± 20.4 | 8.6 ± 0.5 | 41.5 ± 1.6 | 4458.6 ± 112.4 | 28.2 ± 0.2 | 52.6 ± 1.2 |

| CG1 | 126.1 ± 3.2 | 1715.4 ± 49.6 | 9.3 ± 0.2 | 48.6 ± 1.1 | 5077.9 ± 123.7 | 33.1 ± 0.5 | 55.2 ± 1.1 |

| CCNT05 | 134.0 ± 2.4 | 1723.5 ± 46.1 | 8.8 ± 0.2 | 48.0 ± 0.9 | 4938.2 ± 63.8 | 32.0 ± 0.2 | 57.4 ± 1.0 |

| SG05 | 120.7 ± 4.0 | 1562.5 ± 73.2 | 9.6 ± 0.2 | 46.0 ± 1.5 | 4937.0 ± 88.7 | 31.3 ± 0.2 | 57.7 ± 1.5 |

| SG1 | 125.2 ± 1.6 | 1660.1 ± 73.2 | 8.8 ± 0.3 | 44.8 ± 0.5 | 4257.3 ± 71.4 | 29.0 ± 0.4 | 54.2 ± 2.2 |

| SCNT05 | 127.5 ± 6.5 | 1640.0 ± 49.3 | 9.4 ± 0.5 | 48.9 ± 0.5 | 4648.0 ± 151.1 | 31.2 ± 0.3 | 60.3 ± 1.4 |

| SCNT1 | 119.8 ± 5.7 | 1514.0 ± 36.9 | 8.7 ± 0.2 | 48.0 ± 1.5 | 4286.4 ± 82.1 | 28.2 ± 0.2 | 56.5 ± 1.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vázquez-Moreno, J.M.; Sánchez-Hidalgo, R.; Sanz-Horcajo, E.; Viña, J.; Verdejo, R.; López-Manchado, M.A. Preparation and Mechanical Properties of Graphene/Carbon Fiber-Reinforced Hierarchical Polymer Composites. J. Compos. Sci. 2019, 3, 30. https://doi.org/10.3390/jcs3010030

Vázquez-Moreno JM, Sánchez-Hidalgo R, Sanz-Horcajo E, Viña J, Verdejo R, López-Manchado MA. Preparation and Mechanical Properties of Graphene/Carbon Fiber-Reinforced Hierarchical Polymer Composites. Journal of Composites Science. 2019; 3(1):30. https://doi.org/10.3390/jcs3010030

Chicago/Turabian StyleVázquez-Moreno, Jose M., Ruben Sánchez-Hidalgo, Estela Sanz-Horcajo, Jaime Viña, Raquel Verdejo, and Miguel A. López-Manchado. 2019. "Preparation and Mechanical Properties of Graphene/Carbon Fiber-Reinforced Hierarchical Polymer Composites" Journal of Composites Science 3, no. 1: 30. https://doi.org/10.3390/jcs3010030

APA StyleVázquez-Moreno, J. M., Sánchez-Hidalgo, R., Sanz-Horcajo, E., Viña, J., Verdejo, R., & López-Manchado, M. A. (2019). Preparation and Mechanical Properties of Graphene/Carbon Fiber-Reinforced Hierarchical Polymer Composites. Journal of Composites Science, 3(1), 30. https://doi.org/10.3390/jcs3010030