Finite Element Analysis and Experimental Characterisation of SMC Composite Car Hood Specimens under Complex Loadings

Abstract

1. Introduction

2. Experimental Methodology

2.1. Material and Manufacturing Process

2.2. Specimen Preparation

2.3. Uniaxial Tensile Testing

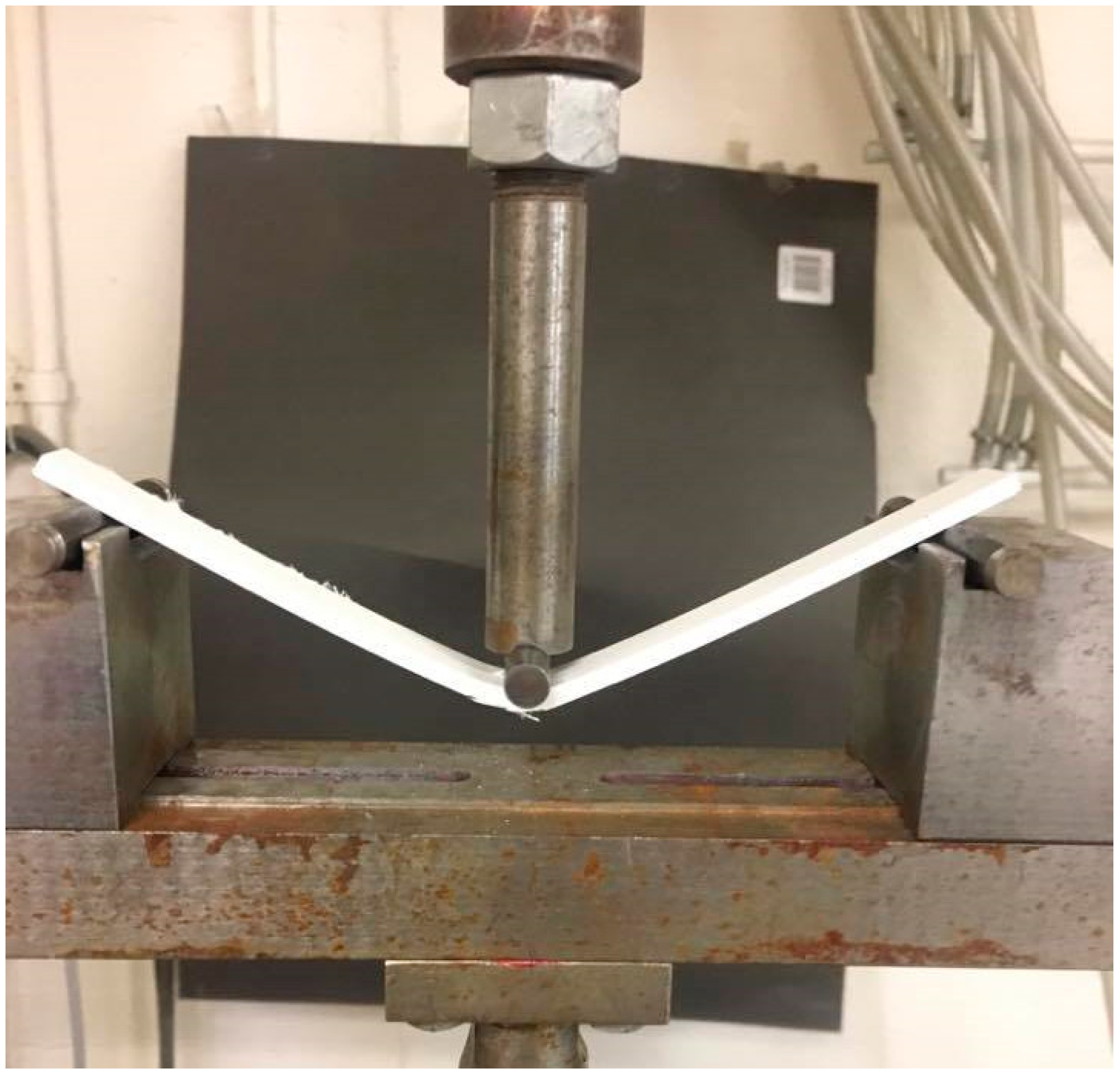

2.4. Flexural Testing

2.5. Scanning Electron Microscopy

3. Experimental Results and Discussion

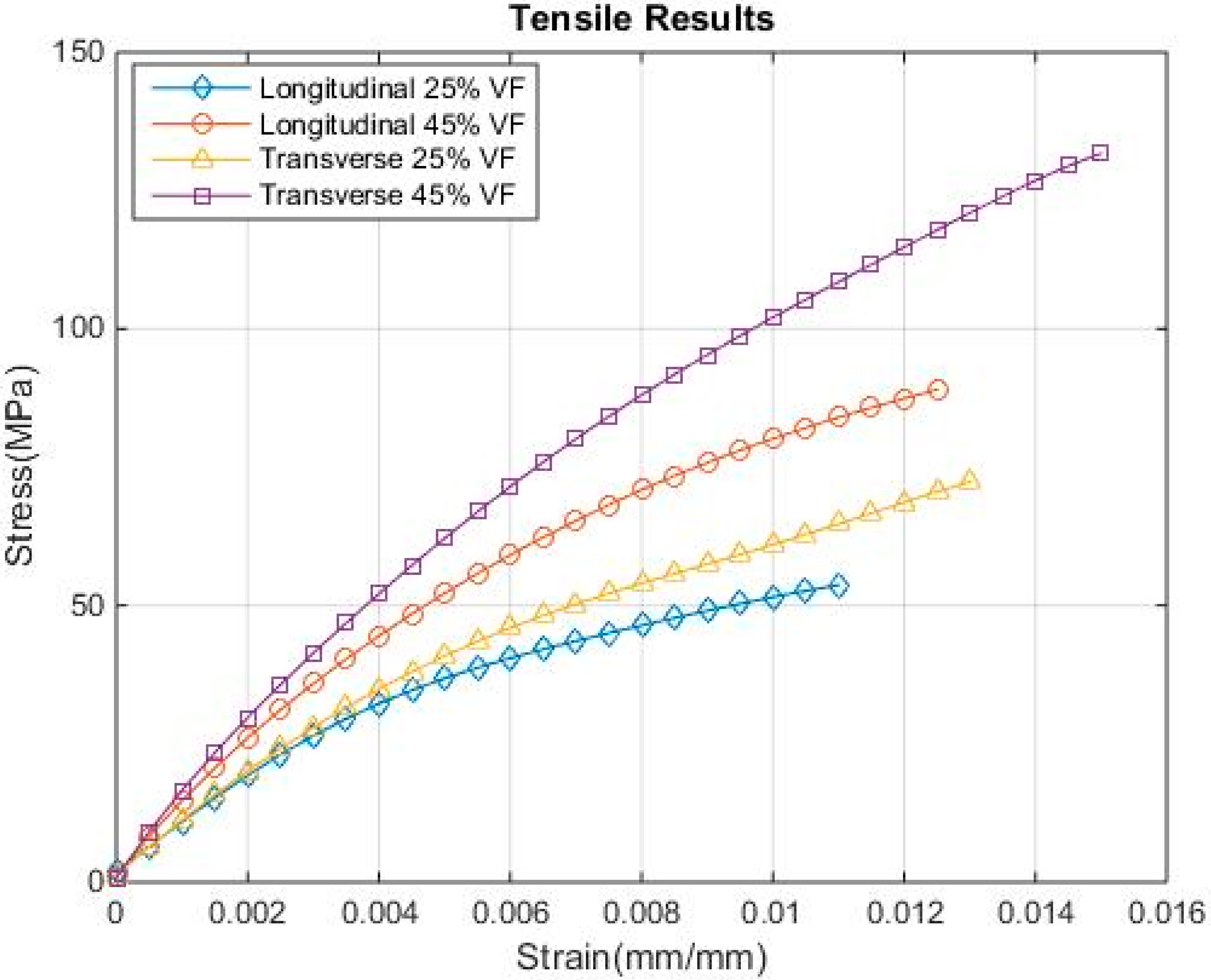

3.1. Uniaxial Tensile Test Results

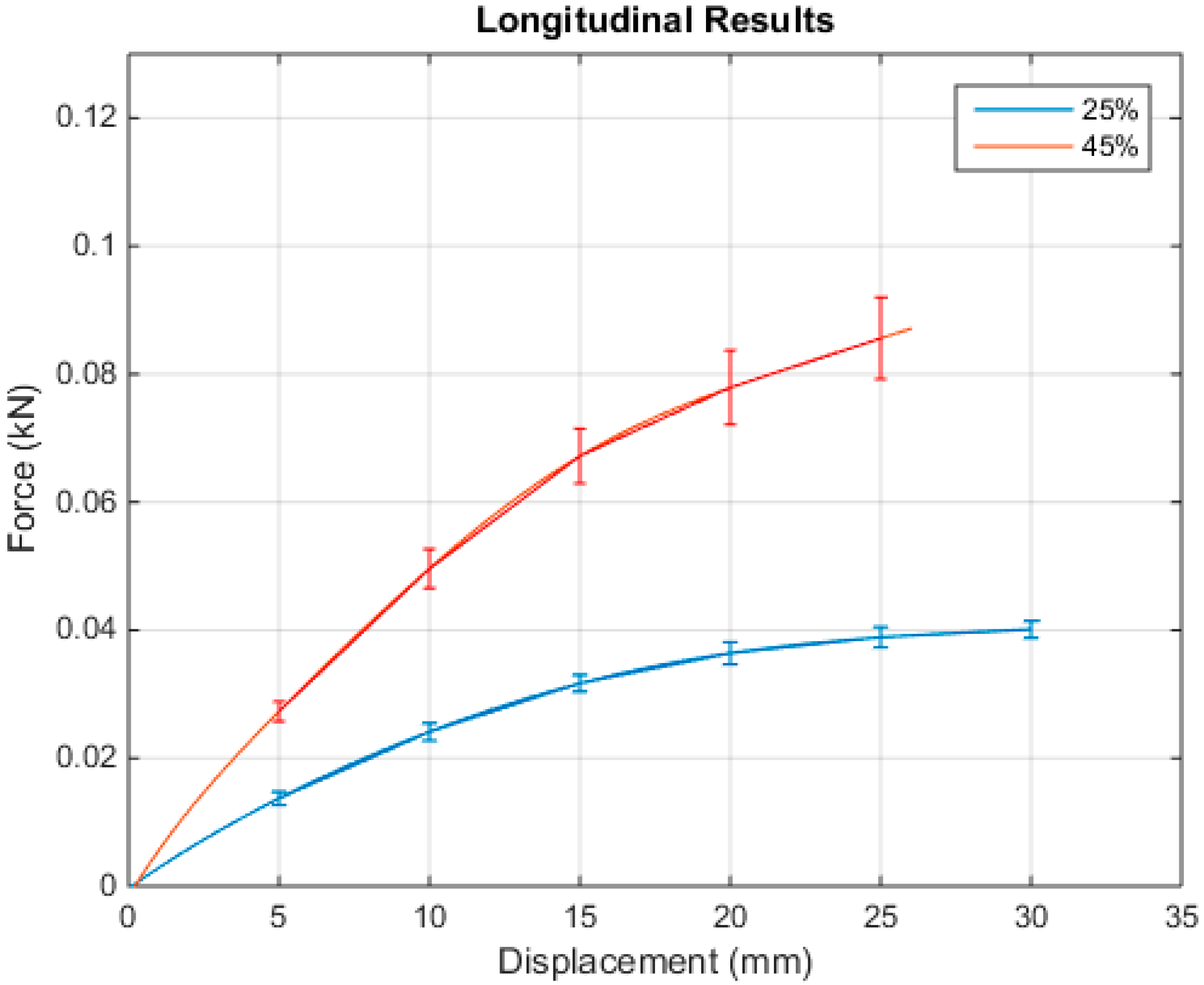

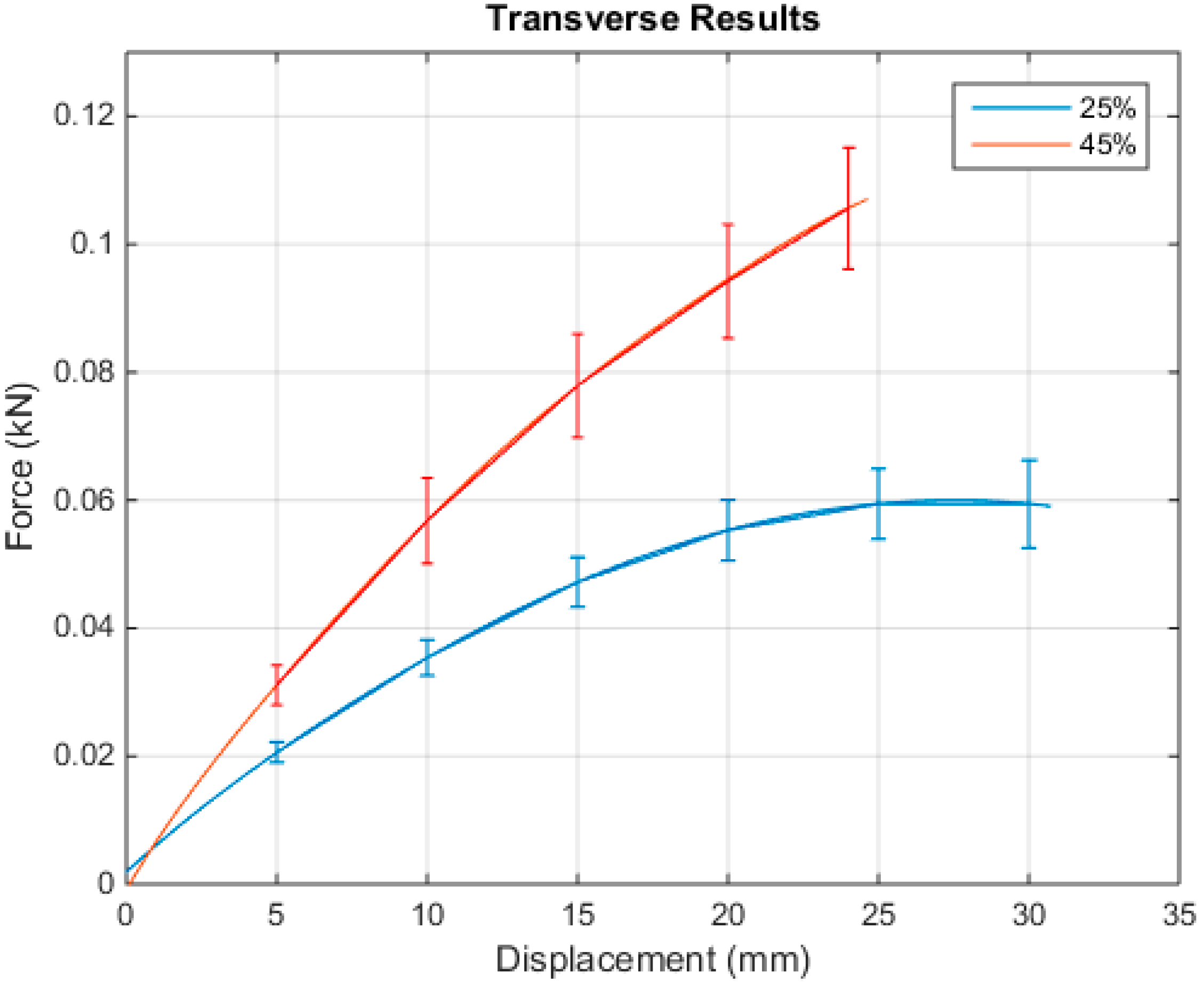

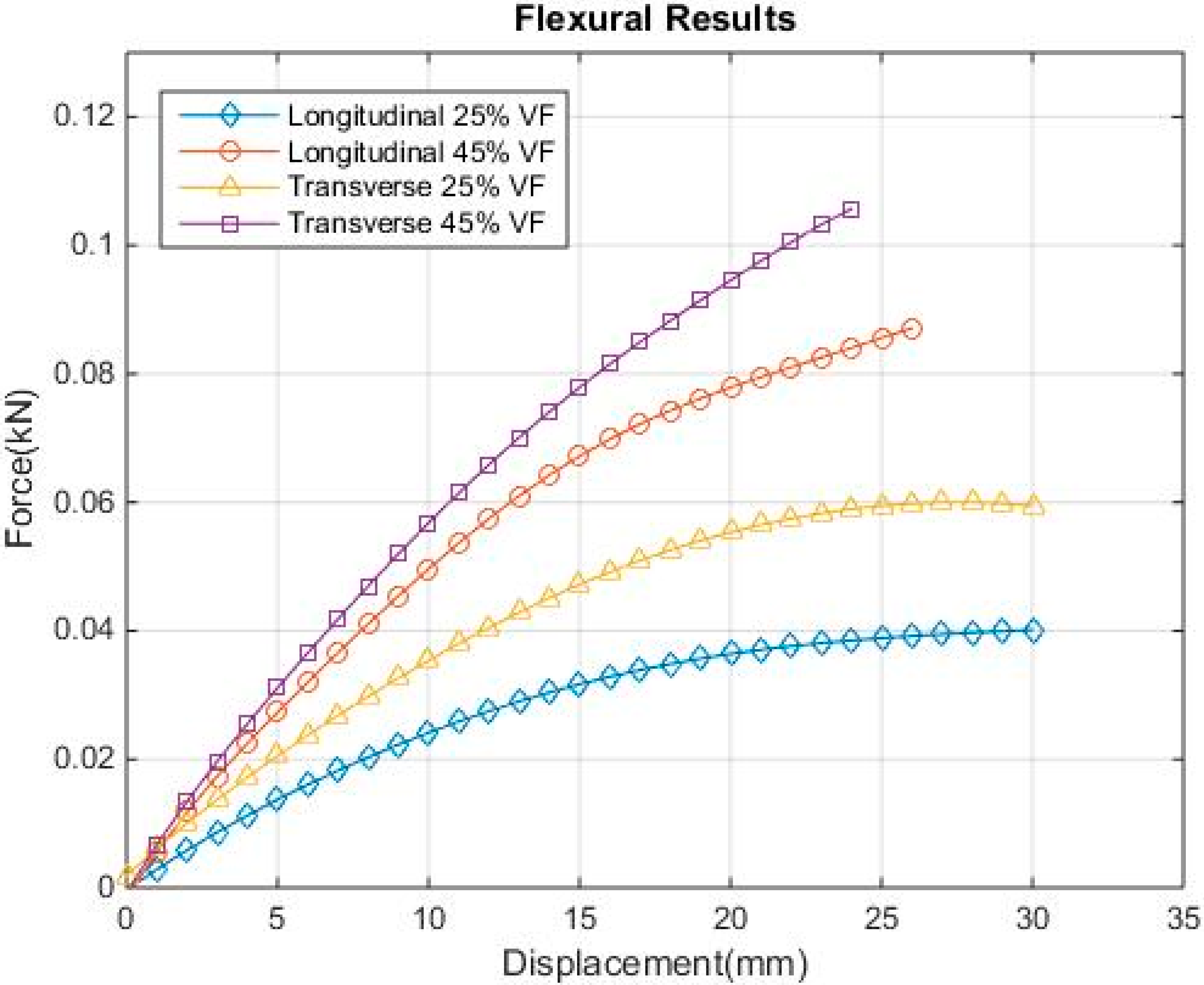

3.2. Three-Point Bending Test Results

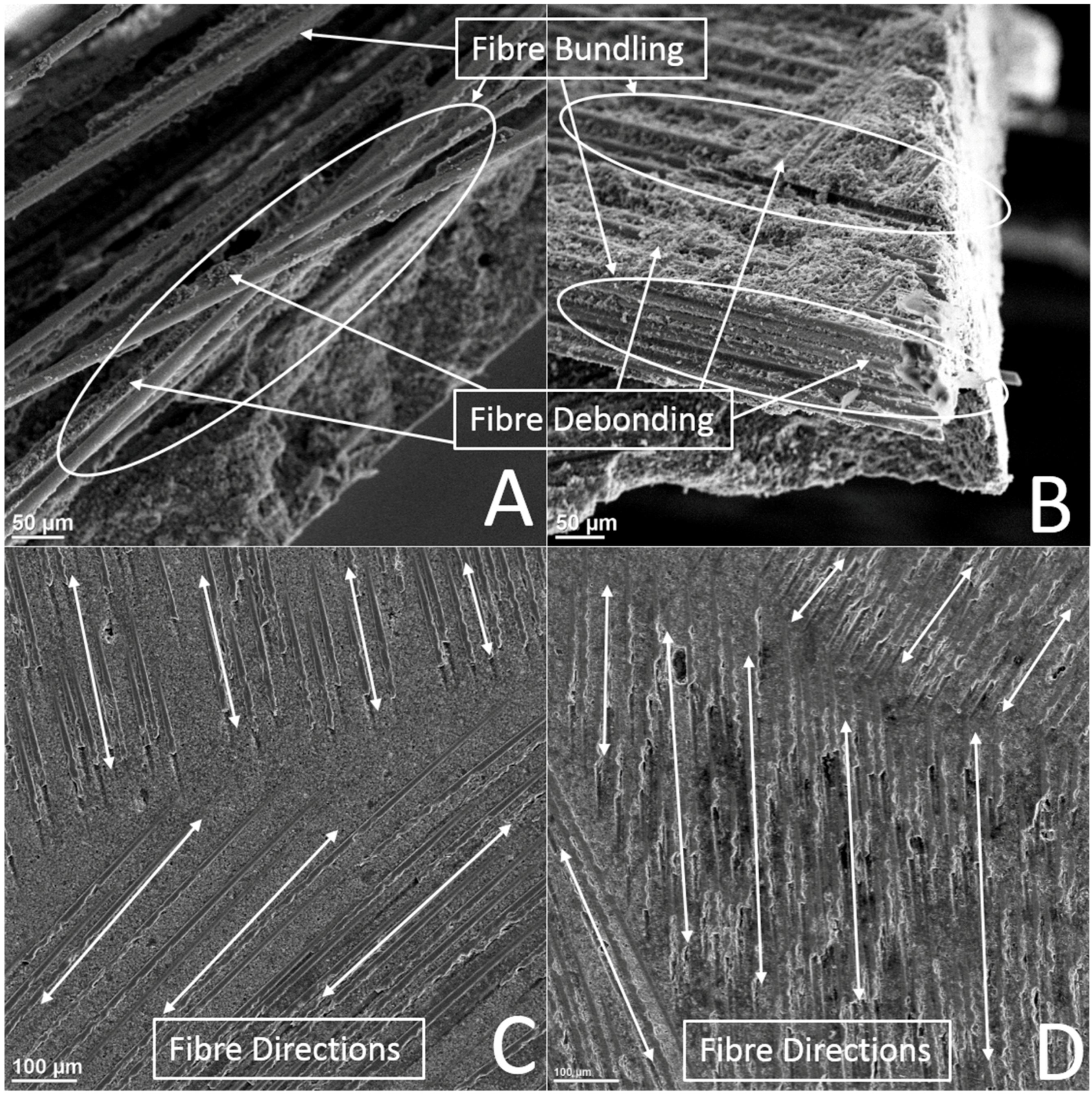

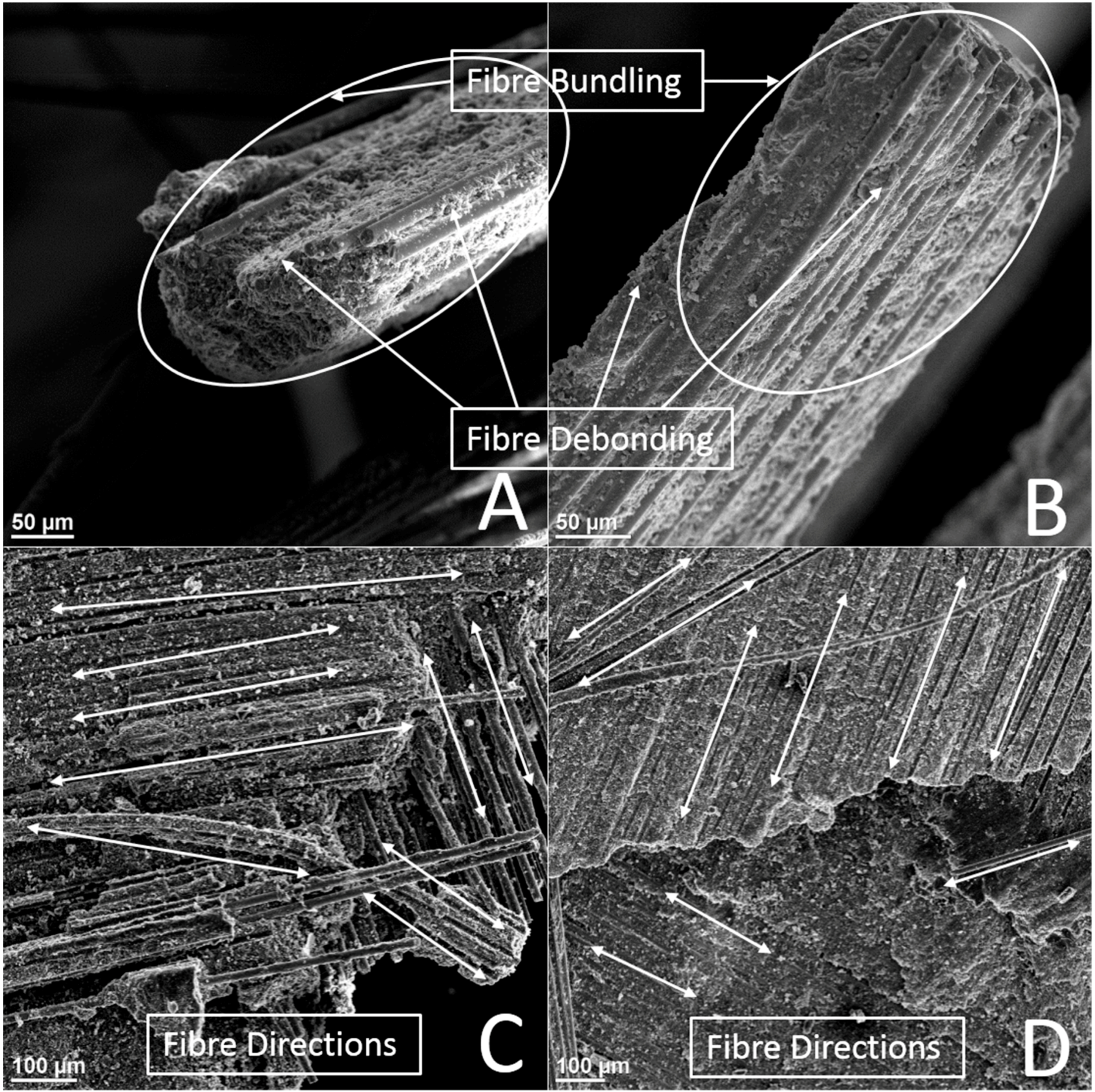

3.3. Scanning Electron Microscopy Analysis

3.4. Remarks on Fracture

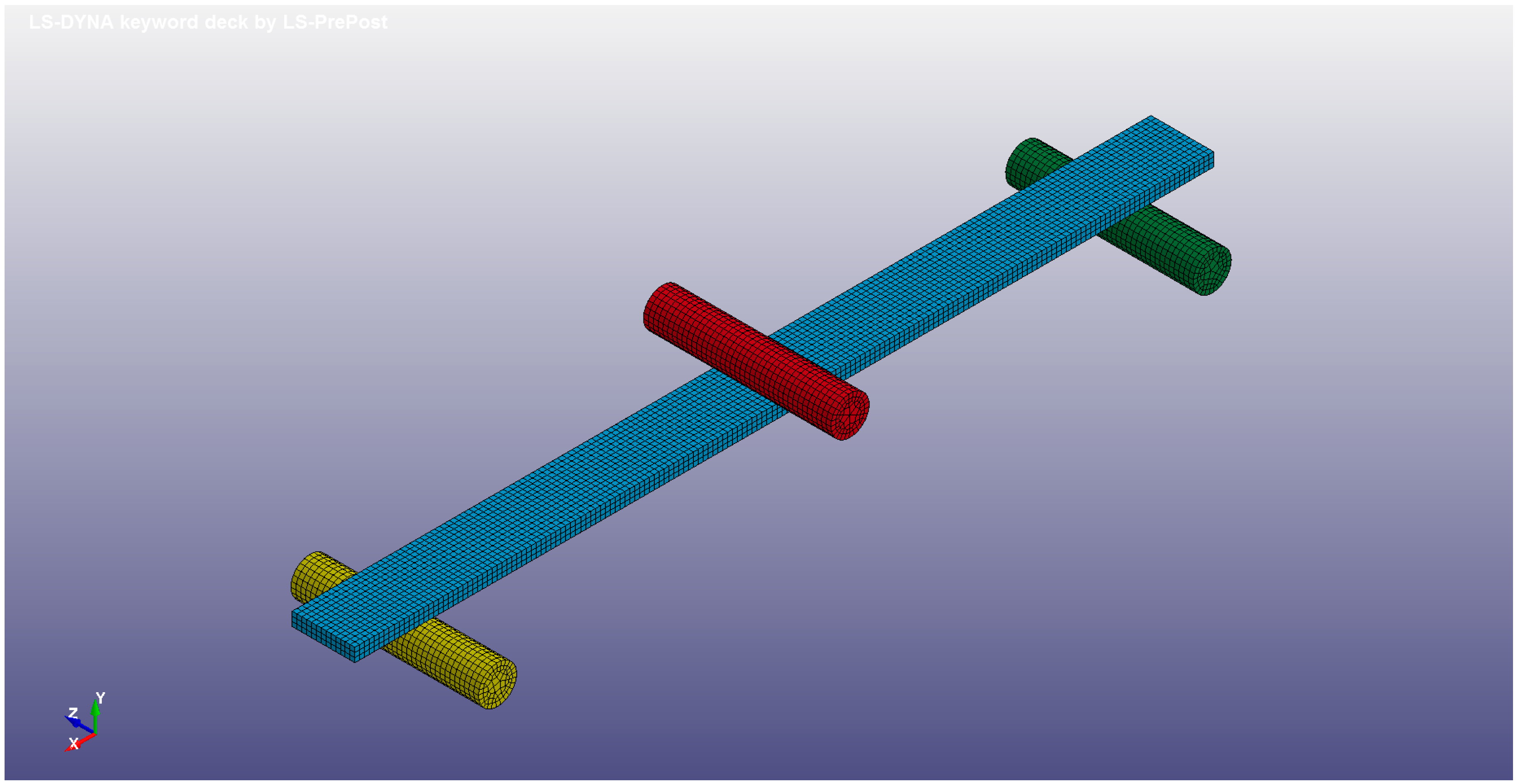

4. Finite Element Model Development

4.1. Model Development and Calibration

4.2. Mesh Sensitivity

4.3. Overview

5. Model Validation and Further Discussion

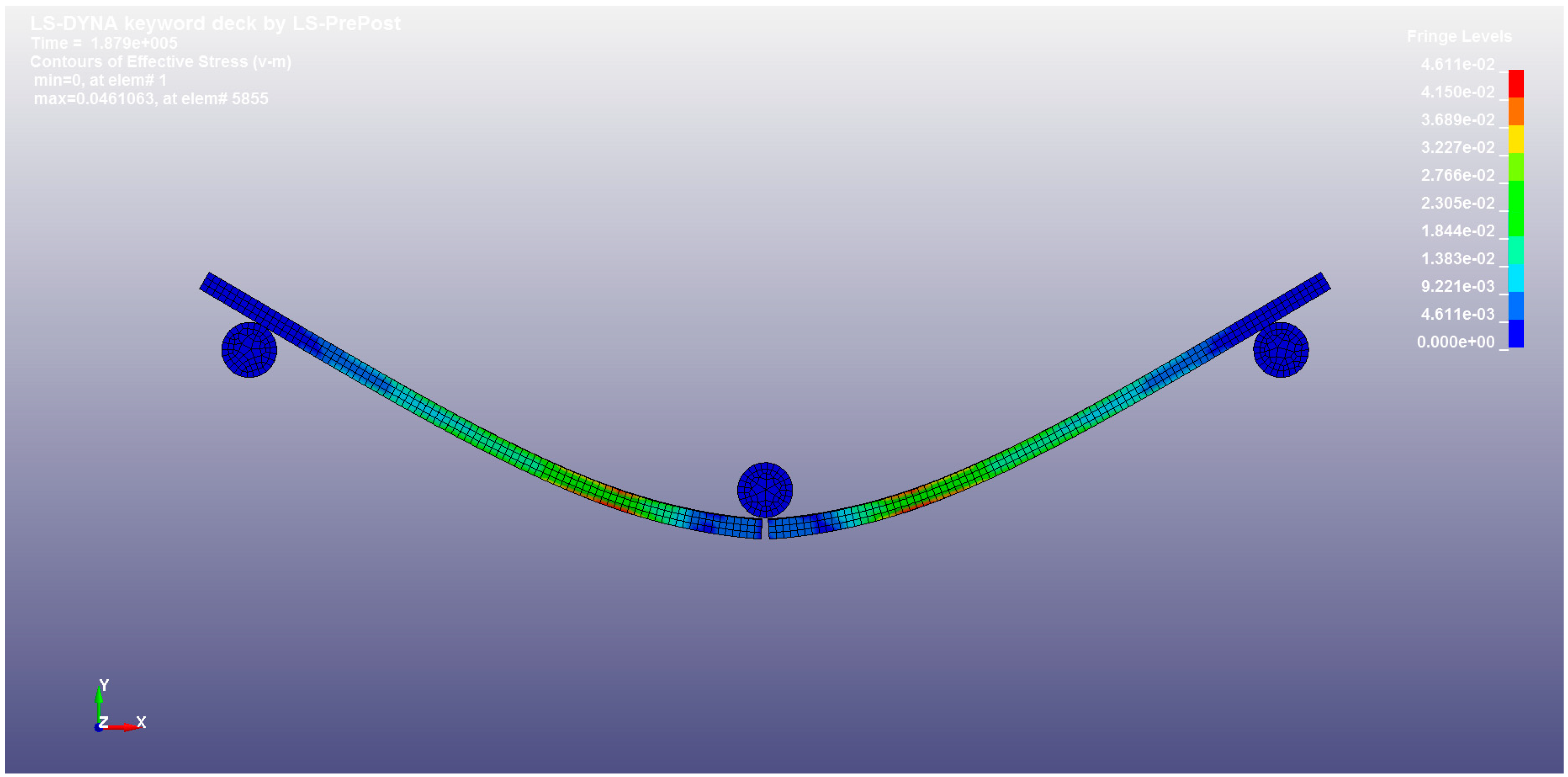

5.1. Flexural Model Setup

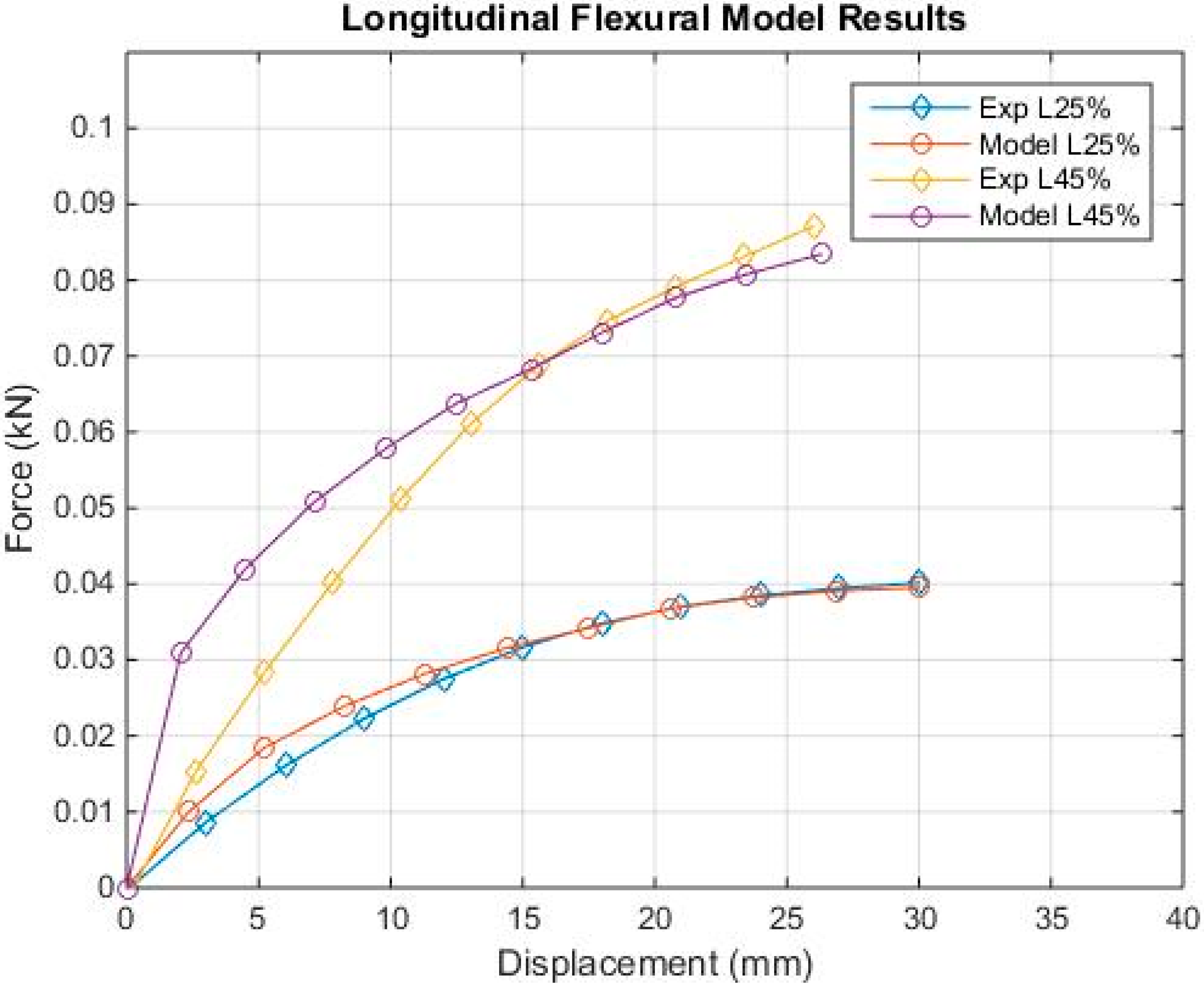

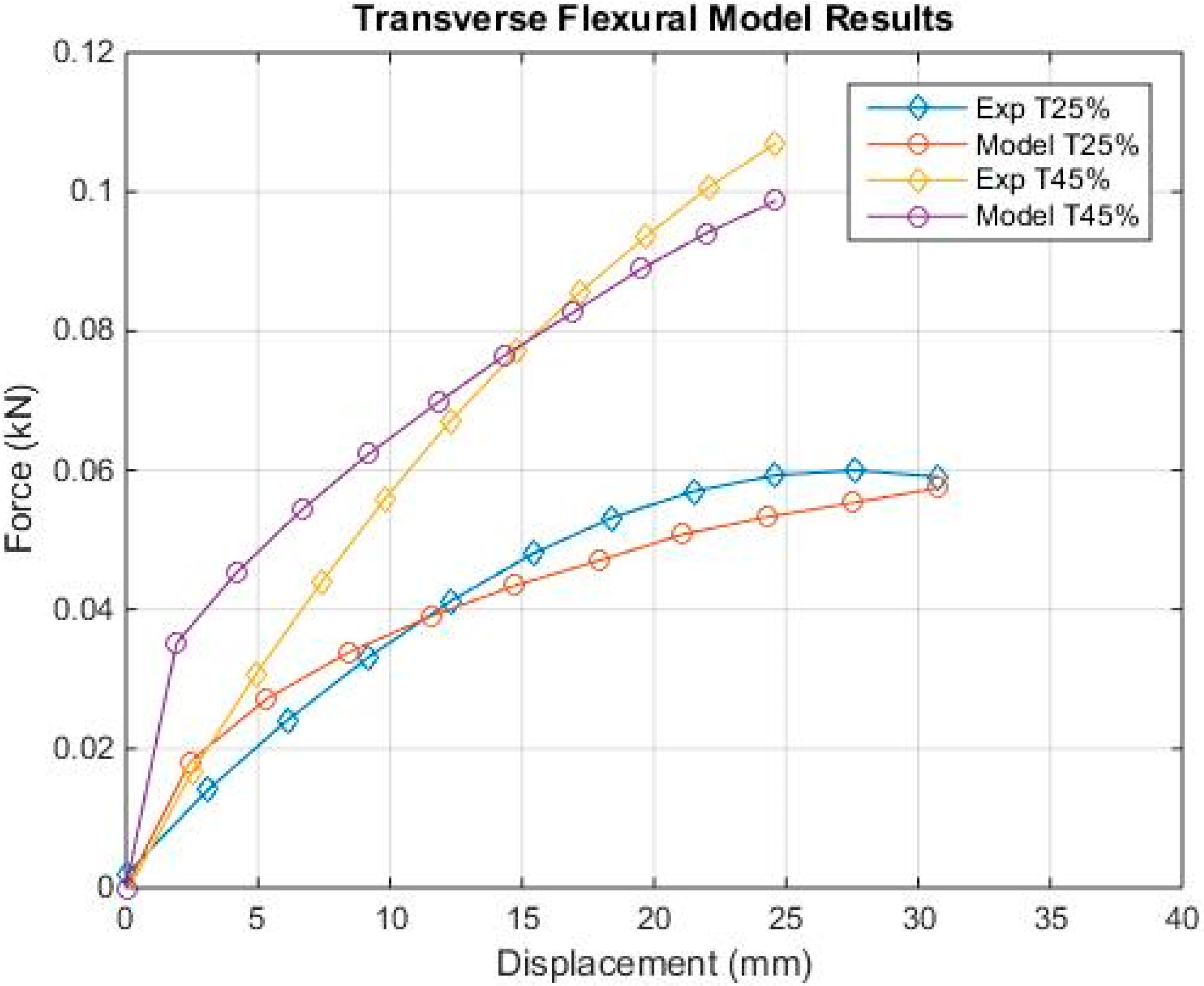

5.2. Flexural Test Simulations

5.3. Remarks on the Accuracy of the Results

6. Conclusions

- Throughout the tensile tests, the higher volume fractions led to a higher UTS and failure strain, while the transverse direction was stronger than the longitudinal direction. The flexural test saw similar results, with the higher volume fraction specimens reaching a higher failure force, but the failure displacement was less than that seen in the lower volume fraction tests; however, again, the transverse direction proved to be stronger than the longitudinal direction.

- The SEM images taken lead to the conclusion that fibre bundling leading to matrix debonding is the primary failure mode of fracture in both the 25% and 45% volume fraction specimens, for the tensile and flexural tests.

- A linear piecewise plasticity material model was able to simulate very well the tensile stress–strain data for calibration, and provide good results. The model was then validated by simulating the three-point bending tests along with the experimental flexural data. The lower volume fraction simulation was more accurate than the higher volume fraction simulation, with a maximum error of 3.5% for the 25% volume fraction tests, and 6.6% for the 45% volume fraction tests. The reason that the 45% volume fraction simulations are less accurate is that the model cannot account for the uneven loading of fibres experienced at the beginning of the flexural tests. This is an area that should be investigated further in future work using micromechanics-based models.

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A. Uniaxial Tensile Tests with Error Bars

Appendix B. Flexural Bending Tests with Error Bars

References

- Jayasree, N.A.; Airale, A.G.; Ferraris, A.; Messana, A.; Sisca, L.; Carello, M. Process analysis for structural optimisation of thermoplastic composite component using the building block approach. Compos. Part B 2017, 126, 119–132. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Liu, P.F.; Zheng, J.Y. Recent developments on damage modeling and finite element analysis for composite laminates: A review. Mater. Des. 2010, 31, 3825–3834. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.L. Mechanics of Solid Materials; Cambridge Unitversity Press: Cambridge, UK, 1990. [Google Scholar]

- Ristinmaa, M.; Ottosen, N.S. Viscoplasticity based on a additive split of the conjugated forces. Eur. J. Mech. A/Solids 1998, 17, 207–235. [Google Scholar] [CrossRef]

- Schapery, R.A. A theory of mechanical behaviour of elastic media with growing damage and other changes in structure. J. Mech. Phys. Solids 1990, 38, 215–253. [Google Scholar] [CrossRef]

- Murakami, S.; Kamiya, K. Constitutive and damage evolution equations of elastic-brittle materials based on irreversible thermodynamics. Int. J. Mech. Sci. 1997, 39, 473–486. [Google Scholar] [CrossRef]

- Hayakawa, K.; Murakami, S.; Liu, Y. An irreversible thermodynamics theory for elastic-plastic-damage materials. Eur. J. Mech. A/Solids 1998, 17, 13–32. [Google Scholar] [CrossRef]

- Qing, H.; Liu, T. Micromechanical analysis of SiC/Al metal matrix composites: Finite element modeling and damage simulation. Int. J. Appl. Mech. 2015, 7, 1550023. [Google Scholar] [CrossRef]

- Olsson, M.; Ristinmaa, M. Damage Evolution in Elasto-plastic Materials–Material Response Due to Different Concepts. Int. J. Damage Mech. 2003, 12, 115–140. [Google Scholar] [CrossRef]

- Matzenmiller, A.; Lubliner, J.; Taylor, R.L. A constitutive model for anisotropic damage in fiber-composites. Mech. Mater. 1995, 20, 125–152. [Google Scholar] [CrossRef]

- Maa, R.H.; Cheng, J.H. A CDM-based failure model for predicting strength of notched composite laminates. Compos. Part B 2002, 33, 479–489. [Google Scholar] [CrossRef]

- Camanho, P.P.; Maimi, P.; Davila, C.G. Prediction of size effects in notched laminates using continuum damage mechanics. Compos. Sci. Technol. 2007, 67, 2715–2727. [Google Scholar] [CrossRef]

- Perreux, D.; Robinet, P.; Chapelle, D. The effect of internal stress on the identification of the mechanical behaviour of composite pipes. Compos. Part A 2006, 37, 630–635. [Google Scholar] [CrossRef]

- Liu, P.F.; Zheng, J.Y. Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics. Mater. Sci. Eng. A 2008, 485, 711–717. [Google Scholar] [CrossRef]

- Lin, W.P.; Hu, H.T. Nonlinear Analysis of Fiber-Reinforced Composite Laminates Subjected to Uniaxial Tensile Load. J. Compos. Mater. 2002, 36, 1429–1451. [Google Scholar] [CrossRef]

- Tsai, S.W.; Wu, E.M. A General Theory of Strength for Anisotropic Materials. J. Compos. Mater. 1971, 5, 58–81. [Google Scholar] [CrossRef]

- Hashin, Z. Failure criteria for unidirectional fiber composites. J. Appl. Mech. 1980, 47, 329–363. [Google Scholar] [CrossRef]

- Hoffman, O. The Brittle Strength of Orthotropic Materials. J. Compos. Mater. 1967, 1, 200–207. [Google Scholar] [CrossRef]

- Yamada, S.E.; Sun, C.T. Analysis of Laminate Strength and its Distribution. J. Compos. Mater. 1978, 12, 275–285. [Google Scholar] [CrossRef]

- Padhi, G.S.; Shenoi, R.A.; Moy, S.S.J.; Hawkins, G.L. Progressive failure and ultimate collapse of laminated composite plates in bending. Compos. Struct. 1998, 40, 277–291. [Google Scholar] [CrossRef]

- Tay, T.E.; Tan, S.; Tan, V.; Gosse, J.H. Damage progression by the finite element-failure method (EFM) and strain invariant failure theory (SIFT). Compos. Sci. Technol. 2005, 65, 935–944. [Google Scholar] [CrossRef]

- Tay, T.E.; Liu, G.; Yudhanto, A.; Tan, V.B.C. A Micro-Macro Approach to Modeling Progressive Damage in Composite Structures. Int. J. Damage Mech. 2008, 17, 5–29. [Google Scholar] [CrossRef]

- Li, R.; Kelly, D. Application of a First Invariant Strain Criterion for Matrix Failure in Composite Materials. J. Compos. Mater. 2003, 37, 1977–2001. [Google Scholar] [CrossRef]

- Mayes, J.S.; Hansen, A.C. Composite laminate failure analysis using multicontinuum theory. Compos. Sci. Technol. 2004, 64, 379–394. [Google Scholar] [CrossRef]

- Mayes, J.S.; Hansen, A.C. A comparison of multicontinuum theory based failure simulation with experimental results. Compos. Sci. Technol. 2004, 64, 517–527. [Google Scholar] [CrossRef]

- Zhu, H.; Sankar, B.V.; Marrey, R.V. Evaluation of Failure Criteria for Fiber Composites Using Finite Element Micromechanics. J. Compos. Mater. 1998, 32, 766–783. [Google Scholar] [CrossRef]

- Ha, S.K.; Jin, K.K.; Huang, Y. Micro-Mechanics of Failure (MMF) for Continuous Fiber Reinforced Composites. J. Compos. Mater. 2008, 42, 1873–1896. [Google Scholar]

- Rybicki, E.F.; Kanninen, M.F. A Finite Element Calculation of Stress Intensity Factors by a Modified Crack Closure Integral. Eng. Fract. Mech. 1977, 9, 931–938. [Google Scholar] [CrossRef]

- Rybicki, E.F.; Schmueser, D.W.; Fox, J. An Energy Release Rate Approach for Stable Crack Growth in the Free-Edge Delamination Problem. J. Compos. Mater. 1977, 11, 470–488. [Google Scholar] [CrossRef]

- Irwin, G.R. Fracture dynaimcs, fracturing of metals. Am. Soc. Met. 1948, 8, 147–203. [Google Scholar]

- Rice, J.R. A path independant integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 1968, 2, 379–465. [Google Scholar] [CrossRef]

- Krueger, R. Virtual crack closure technique: History, approach, and applications. Appl. Mech. Rev. 2004, 57, 109–144. [Google Scholar] [CrossRef]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Barenblatt, I. Mathematical thoery of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 1962, 7, 55–129. [Google Scholar]

- Hutchinson, J.W.; Suo, Z. Mixed mode cracking in layered materials. Adv. Appl. Mech. 1992, 29, 63–191. [Google Scholar]

- Tvergaard, V.; Hutchinson, J.W. Effect of strain-dependent cohesive zone model on predictions of crack growth resistance. Pergamon 1995, 33, 261–269. [Google Scholar] [CrossRef]

- Allen, D.H.; Searcy, C.R. Numerical Aspects of a Micromechanical Model of a Cohesive Zone. J. Reinf. Plast. Compos. 2000, 19, 240–249. [Google Scholar] [CrossRef]

- Camanho, P.P.; Davila, C.G.; de Moura, M.F. Numerical Simulation of Mixed-mode Progressive Delamination in Composite Materials. J. Compos. Mater. 2003, 37, 1415–1439. [Google Scholar] [CrossRef]

- Xie, D.; Waas, A.M. Discrete cohesive zone model for mixed-mode fracture using finite element analysis. Eng. Fract. Mech. 2006, 73, 1783–1796. [Google Scholar] [CrossRef]

- Shin, C.S.; Wang, C.M. An Improved Cohesive Zone Model for Residual Notched Strength Prediction of Composite Laminates with Different Orthotropic Lay-ups. J. Compos. Mater. 2004, 38, 713–737. [Google Scholar] [CrossRef]

- Rami, H.A. Cohesive micromechanics: A new approach for progressive damage modeling in laminated composites. Int. J. Damage Mech. 2009, 8, 691–719. [Google Scholar]

- Sabiston, T.; Mohammadi, M.; Cherkaoui, M.; Levesque, J.; Inal, K. Micromechanics for a long fibre reinforced composite model with a functionally graded interphase. Compos. Part B Eng. 2016, 84, 188–199. [Google Scholar] [CrossRef]

- Mohammadi, M.; Saha, G.C.; Akbarzadeh, A.H. Elastic field in composite cylinders made of functionally graded coatings. Int. J. Eng. Sci. 2016, 101, 156–170. [Google Scholar] [CrossRef]

- Sabiston, T.; Mohammadi, M.; Cherkaoui, M.; Levesque, J.; Inal, K. Micromechanics based elasto-visco-plastic response of long fibre composites using functionally graded interphases at quasi-static and moderate strain rates. Compos. Part B Eng. 2016, 100, 31–43. [Google Scholar] [CrossRef]

- Tay, T.E.; Liu, G.; Tan, V.B.; Sun, X.S.; Pham, D.C. Progressive Failure Analysis of Composites. J. Compos. Mater. 2008, 42, 1921–1967. [Google Scholar] [CrossRef]

- Gao, Y.F.; Bower, A.F. A simple technique for avoiding convergence problems in finite element simulations of crack nucleation and growth on cohesive interfaces. Model. Simul. Mater. Sci. Eng. 2004, 12, 453–463. [Google Scholar] [CrossRef]

- Xu, X.P.; Needleman, A. Numerical Simulations of Fast Crack Growth in Brittle Solids. J. Mech. Phys. Solids 1994, 42, 1397–1434. [Google Scholar] [CrossRef]

- Riks, E. An Incremental Approach to the Solution of Snapping and Buckling Problems. Int. J. Solid Struct. 1979, 15, 529–551. [Google Scholar] [CrossRef]

- Ramm, E. Strategies for Tracing the Nonlinear Response Near Limit Points. Nonlinear Finite Elem. Anal. Struct. Mater. 1981, 63–89. [Google Scholar] [CrossRef]

- Crisfield, M.A. An arc-length method including line searches and accelerations. Int. J. Numer. Methods Eng. 1983, 19, 1269–1358. [Google Scholar] [CrossRef]

- Bednarcyk, B.A.; Arnold, S.M. A Framework for Performing Multiscale Stochastic Progressive Failure Analysis of Composite Structures; NASA Center for Aerospace Information: Hanover, MD, USA, 2007; pp. 1–16.

- Van der Meer, F.P.; Sluys, L.J. Continuum Models for the Analysis of Progressive Failure in Composite Laminates. J. Compos. Mater. 2009, 43, 2131–2156. [Google Scholar] [CrossRef]

- Robbins, D.H., Jr.; Reddy, J.N. Adaptive Hierarchical Kintematics in Modeling Progress Damage and Global Failure in Fiber-reinforced Composite Laminates. J. Compos. Mater. 2008, 42, 43–173. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–621. [Google Scholar] [CrossRef]

- Moes, N.; Dolbow, J.; Belytschko, T. A finite element method for crack growth without remeshing. Int. J. Numer. Methods Eng. 1999, 46, 131–181. [Google Scholar] [CrossRef]

- Moes, N.; Belytschko, T. Extended finite element method for cohesive crack growth. Eng. Fract. Mech. 2002, 69, 813–833. [Google Scholar] [CrossRef]

- Dolbow, J.; Moes, N.; Belytschko, T. Discontinuous enrichment in finite element with a partition of unity method. Finite Elem. Anal. Des. 2000, 36, 235–260. [Google Scholar] [CrossRef]

- Guidault, P.A.; Allix, O.; Champaney, L.; Cornuault, C. A multiscale extended finite element method for crack propagation. Comput. Methods Appl. Mech. Eng. 2008, 197, 381–399. [Google Scholar] [CrossRef]

- Huynh, D.B.; Belytschko, T. The extended finite element method for fracture in composite materials. Int. J. Numer. Methods Eng. 2008, 77, 214–239. [Google Scholar] [CrossRef]

- Kelly, J.; Mohammadi, M. Uniaxial tensile behavior of sheet molded composite car hoods with different fibre contents under quasi-static strain rates. Mech. Res. Commun. 2018, 87, 42–52. [Google Scholar] [CrossRef]

- Western University. (2015) Thermoset Sheet Moulding Copound (SMC). Available online: http://www.eng.uwo.ca/fraunhofer/pdf/FPC_Western_D-SMC_2015.pdf (accessed on 7 July 2018).

- Standard Test Method for Tensile Properties of Plastics; ASTM D638-14; ASTM International: West Conshohocken, PA, USA, 2014.

- Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM D790-15; ASTM International: West Conshohocken, PA, USA, 2015.

- Mohammadi, M.; Salimi, H.R. Failure analysis of a gas turbine marriage bolt. J. Fail. Anal. Prev. 2007, 7, 81–86. [Google Scholar] [CrossRef]

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yue, C.Y.; Hu, X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Kuriger, R.J.; Alam, M.K.; Anderson, D.P. Strength prediction of partially aligned discontinuous fiber-reinforced composites. J. Mater. Res. 2001, 16, 226–232. [Google Scholar] [CrossRef]

- Lu, Y. Mechanical Properties of Random Discontinuous Fiber Composites Manufactured from Wetlay Process; Virginia Tech: Blacksburg, Virginia, 2002. [Google Scholar]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part A 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Baxter, W.J. The strength of metal matrix composites reinforced with randomly oriented discontinuous fibers. Metall. Trans. A 1992, 23A, 3045–3053. [Google Scholar] [CrossRef]

- Aboudi, J.; Arnold, S.M.; Bednarcyk, B.A. Micromechanics of Composite Materials; ELSEVIER: Oxford, UK, 2013. [Google Scholar]

- Huberth, F.; Hiermaier, S.; Neumann, M. Material Models for Polymers under Crash Loads Existing LS-DYNA Models and Perspective; Fraunhofer: Bamberg, Germany, 2005. [Google Scholar]

- More, S.T.; Bindu, R.S. Effect of Mesh Size on Finite Element Analysis of Plate Structure. Int. J. Eng. Sci. Innov. Technol. 2015, 4, 181–185. [Google Scholar]

- Chandrupatla, T.R.; Belegundu, A.D. Introduction to Finite Elements in Engineering, 4th ed.; Pearson: London, UK, 2012. [Google Scholar]

- Aboudi, J.; Arnold, S.M.; Bednarcyk, B.A. Micromechanics of Composite Materials: A Generalized Multiscale Analysis Approach; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Shin, D.K.; Kim, H.C.; Lee, J.J. Numerical analysis of the damage behavior of an aluminum/CFRP hybrid beam under three point bending. Compos. Part B Eng. 2014, 56, 397–407. [Google Scholar] [CrossRef]

- Pineda, E.; Waas, A.; Bednarcyk, B.; Collier, C.; Yarrington, P. Progressive damage and failure modeling in notched laminated fiber reinforced composites. Int. J. Fract. 2009, 158, 125–143. [Google Scholar] [CrossRef]

- Germain, N.; Besson, J.; Feyel, F. Composite layered materials: Anisotropic nonlocal damage models. Comput. Methods Appl. Mech. Eng. 2007, 196, 4272–4282. [Google Scholar] [CrossRef]

- Giner, E.; Sukumar, N.; Tarancon, J.E.; Fuenmayor, F.J. An Abaqus implementation of the extended finite element method. Eng. Fract. Mech. 2009, 76, 347–368. [Google Scholar] [CrossRef]

| Volume Fraction | Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio | Yield Stress (MPa) | Failure Strain (mm/mm) |

|---|---|---|---|---|---|

| L25% | 1910 | 10.3 | 0.30 | 5.5 | 0.98% |

| L45% | 1910 | 17.1 | 0.30 | 5.5 | 1.15% |

| T25% | 1910 | 12.55 | 0.30 | 5.4 | 1.13% |

| T45% | 1910 | 21.4 | 0.30 | 5.94 | 1.34% |

| Volume Fraction | UTS (MPa) Experiential | UTS (MPa) Simulation | % Difference | Fracture Experimental | Fracture Simulation | % Difference | RMS Error (MPa) |

|---|---|---|---|---|---|---|---|

| L25% | 53.7 | 54.3 | 1.10% | 1.10% | 1.10% | 0% | 0.99 |

| L45% | 89 | 90.7 | 1.90% | 1.25% | 1.25% | 0% | 2.98 |

| T25% | 72.4 | 71.7 | 1.00% | 1.30% | 1.30% | 0% | 1.97 |

| T45% | 131.7 | 131 | 0.50% | 1.50% | 1.50% | 0% | 4 |

| Mesh Size | UTS (MPa) | Fracture |

|---|---|---|

| Rough Mesh | 54.9 | 1.13% |

| Model Mesh | 54.4 | 1.10% |

| Fine Mesh | 54.4 | 1.10% |

| Flexural Specimen | Static Friction Coefficient | Dynamic Friction Coefficient |

|---|---|---|

| Loading Nose/Specimen | 0.3 | 0.2 |

| Supports/Specimen | 0.3 | 0.2 |

| Volume Fraction | Tensile | Flexural |

|---|---|---|

| L25% | 0.98% | 1.95% |

| L45% | 1.25% | 1.65% |

| T25% | 1.13% | 1.63% |

| T45% | 1.34% | 1.34% |

| Volume Fraction | Failure Force (N) Experiential | Failure Force (N) Simulation | % Difference | Displacement (mm) Experimental | Displacement (mm) Simulation | % Difference | RMS Error (N) |

|---|---|---|---|---|---|---|---|

| L25% | 40.1 | 39.5 | 1.50% | 30 | 30 | 0% | 1.53 |

| L45% | 87.1 | 83.4 | 4.20% | 26 | 26.3 | 1.20% | 6.22 |

| T25% | 59.5 | 57.4 | 3.50% | 30 | 30.7 | 2.30% | 3.39 |

| T45% | 105.7 | 98.7 | 6.60% | 24 | 24.6 | 2.50% | 6.74 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelly, J.; Cyr, E.; Mohammadi, M. Finite Element Analysis and Experimental Characterisation of SMC Composite Car Hood Specimens under Complex Loadings. J. Compos. Sci. 2018, 2, 53. https://doi.org/10.3390/jcs2030053

Kelly J, Cyr E, Mohammadi M. Finite Element Analysis and Experimental Characterisation of SMC Composite Car Hood Specimens under Complex Loadings. Journal of Composites Science. 2018; 2(3):53. https://doi.org/10.3390/jcs2030053

Chicago/Turabian StyleKelly, Josh, Edward Cyr, and Mohsen Mohammadi. 2018. "Finite Element Analysis and Experimental Characterisation of SMC Composite Car Hood Specimens under Complex Loadings" Journal of Composites Science 2, no. 3: 53. https://doi.org/10.3390/jcs2030053

APA StyleKelly, J., Cyr, E., & Mohammadi, M. (2018). Finite Element Analysis and Experimental Characterisation of SMC Composite Car Hood Specimens under Complex Loadings. Journal of Composites Science, 2(3), 53. https://doi.org/10.3390/jcs2030053