On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Synthesis of Composite

2.2. Characterization of Composite

3. Results and Discussion

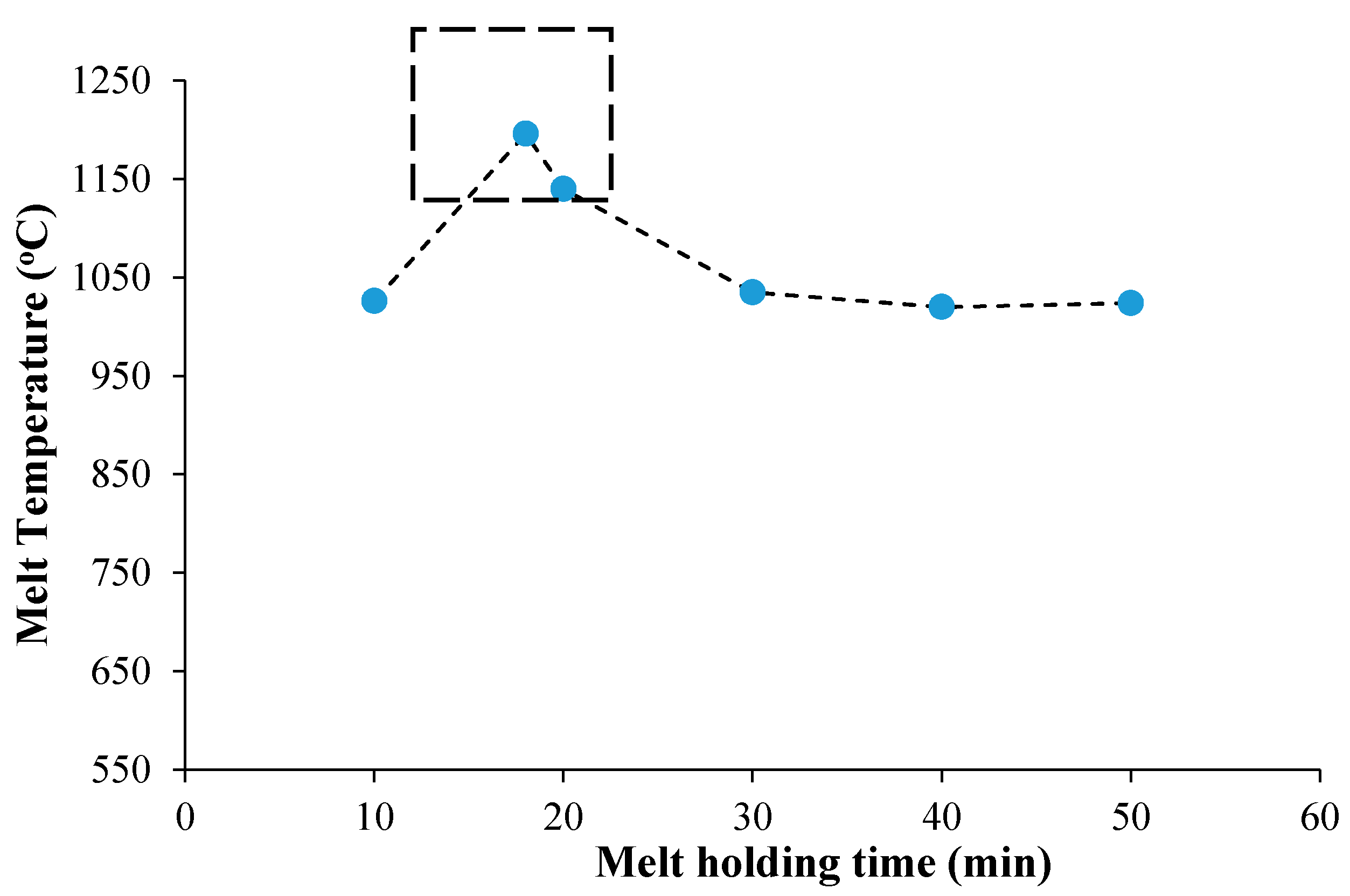

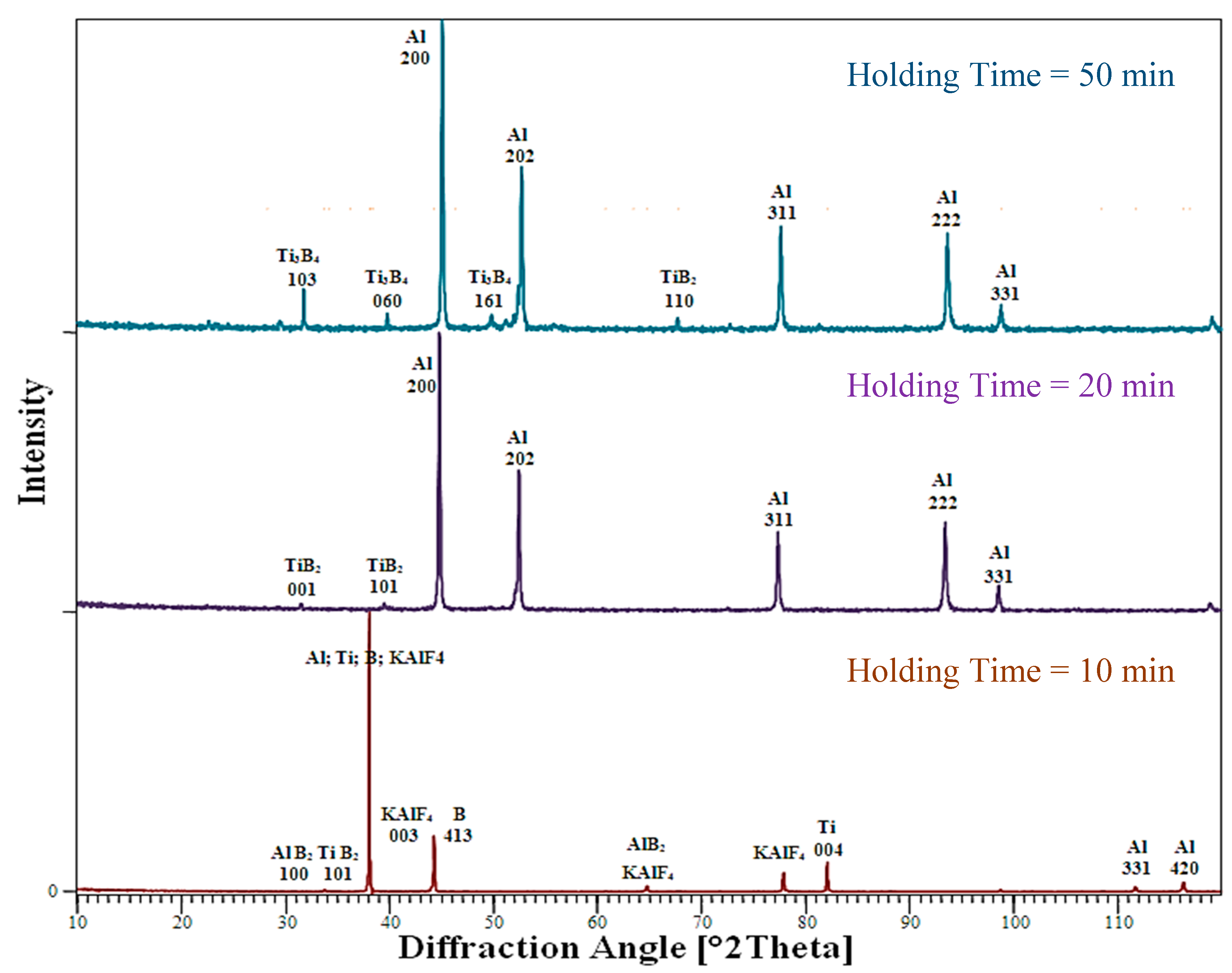

3.1. Exothermic Reaction Synthesis

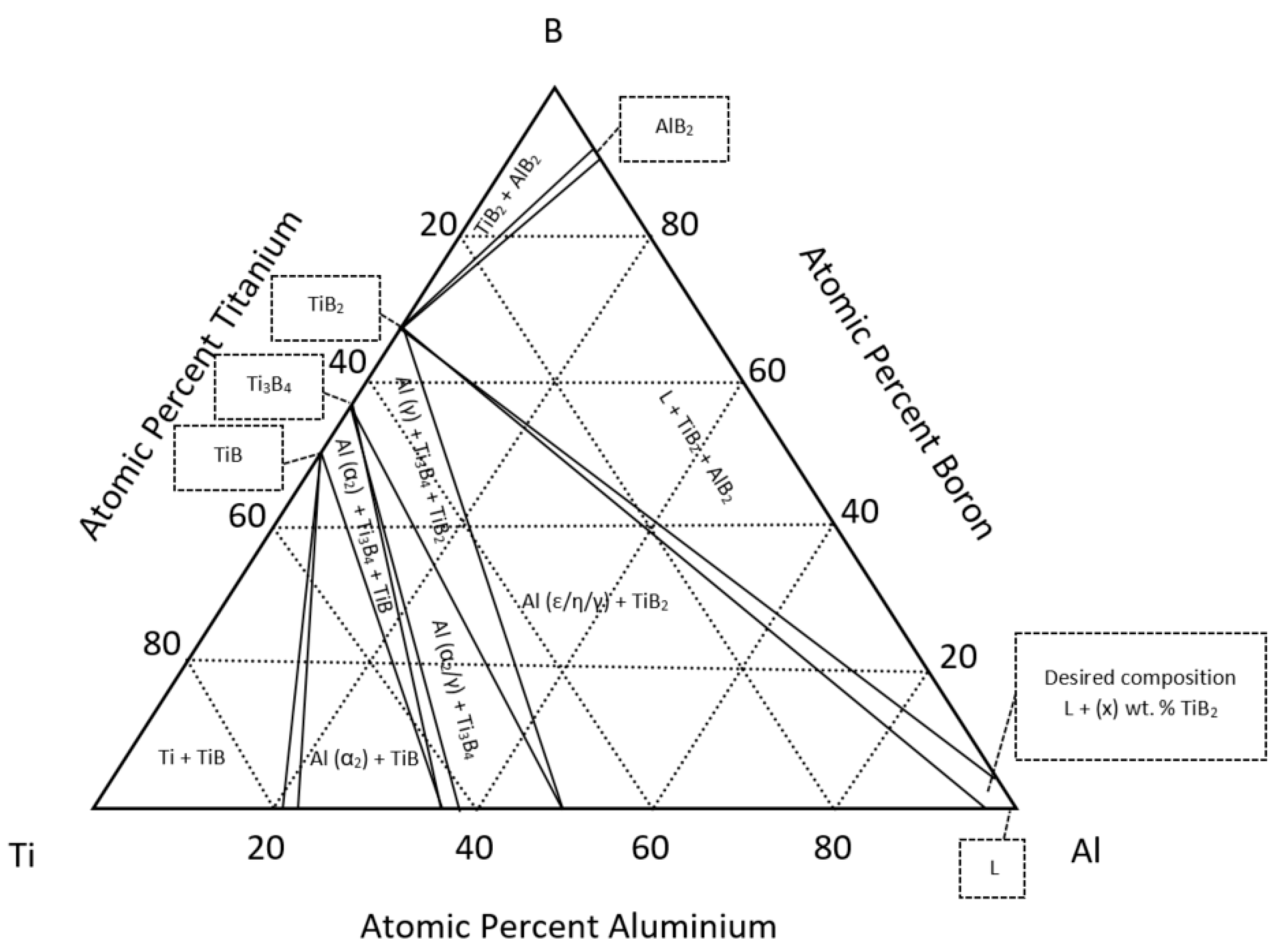

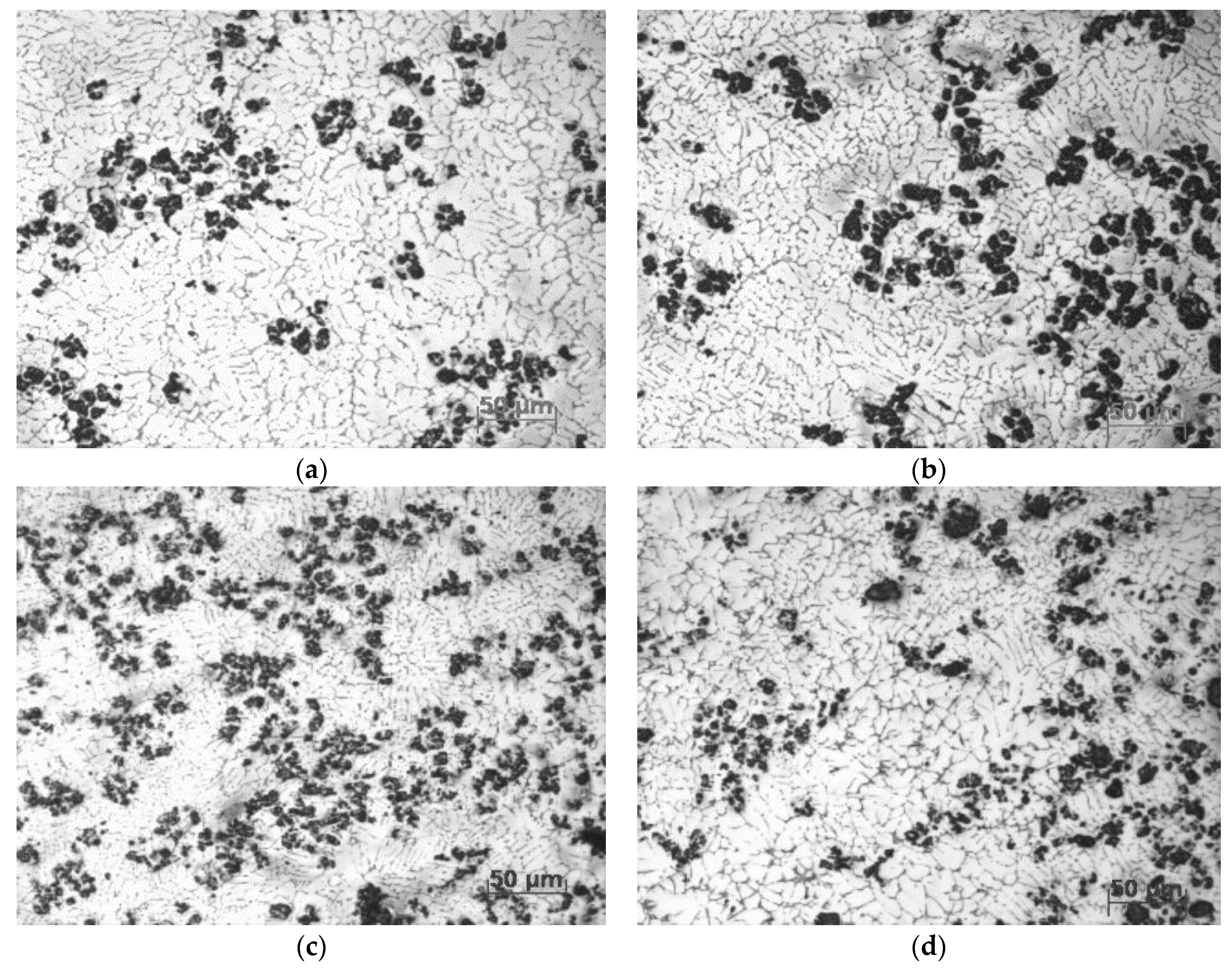

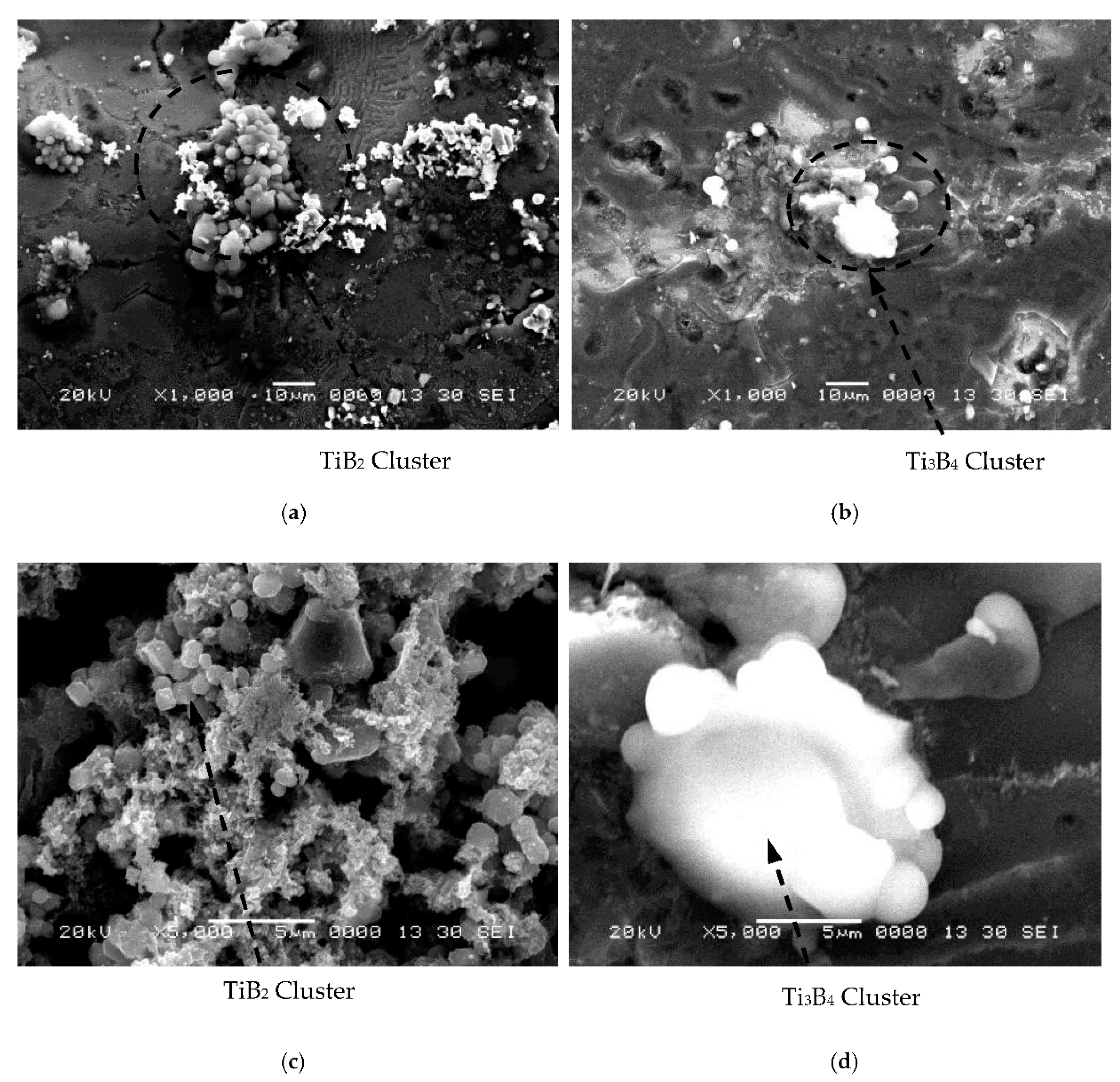

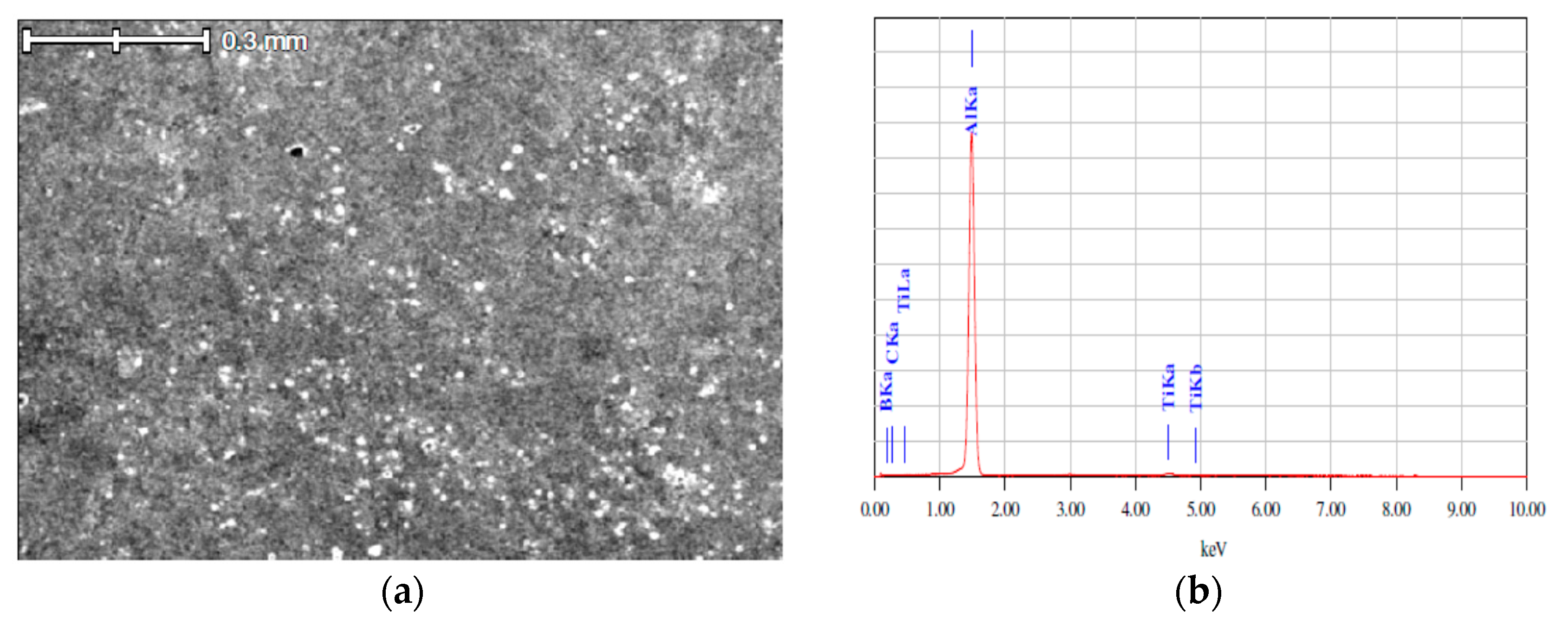

3.2. Formation and Distribution of TiB2 Phases

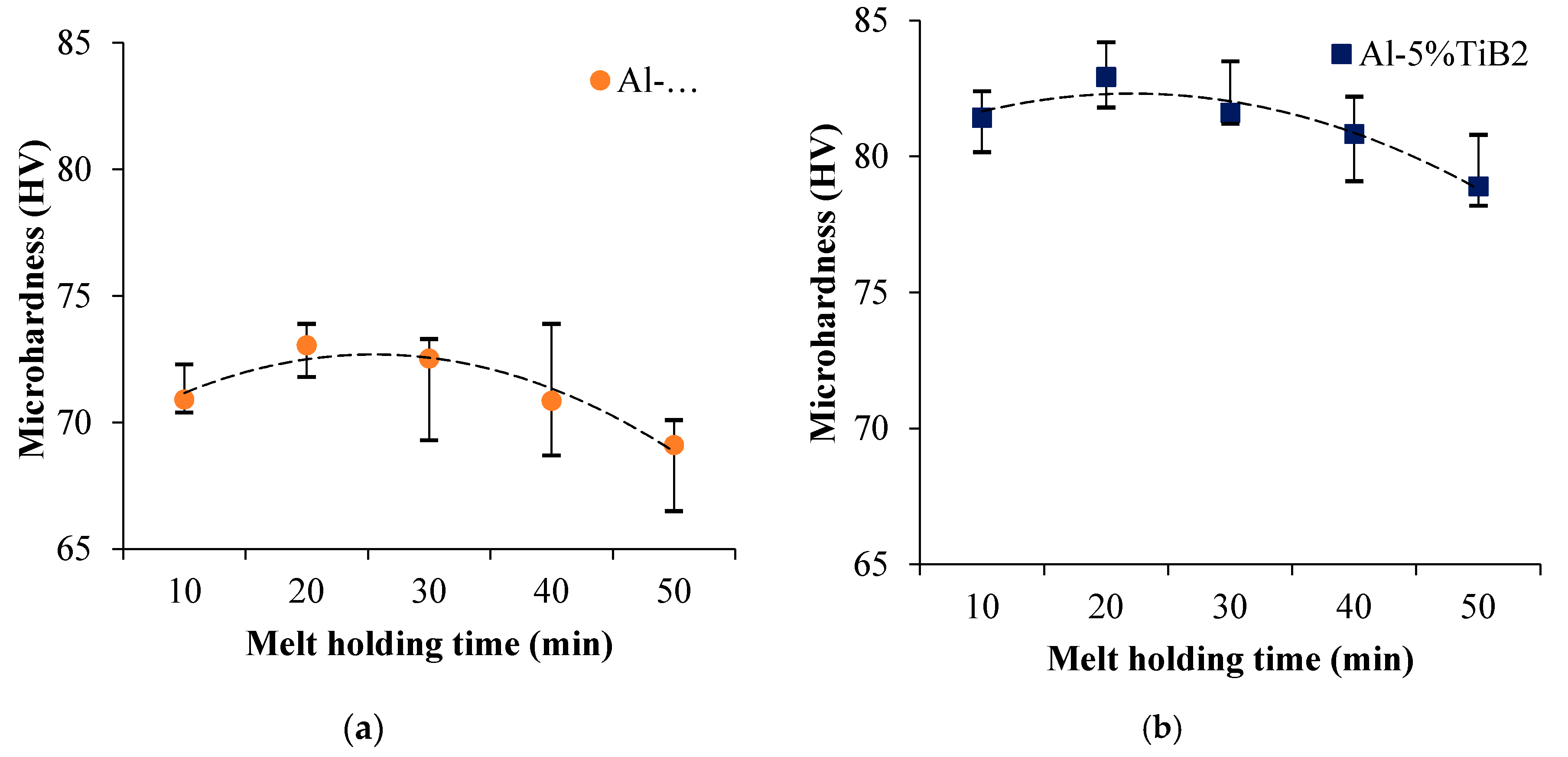

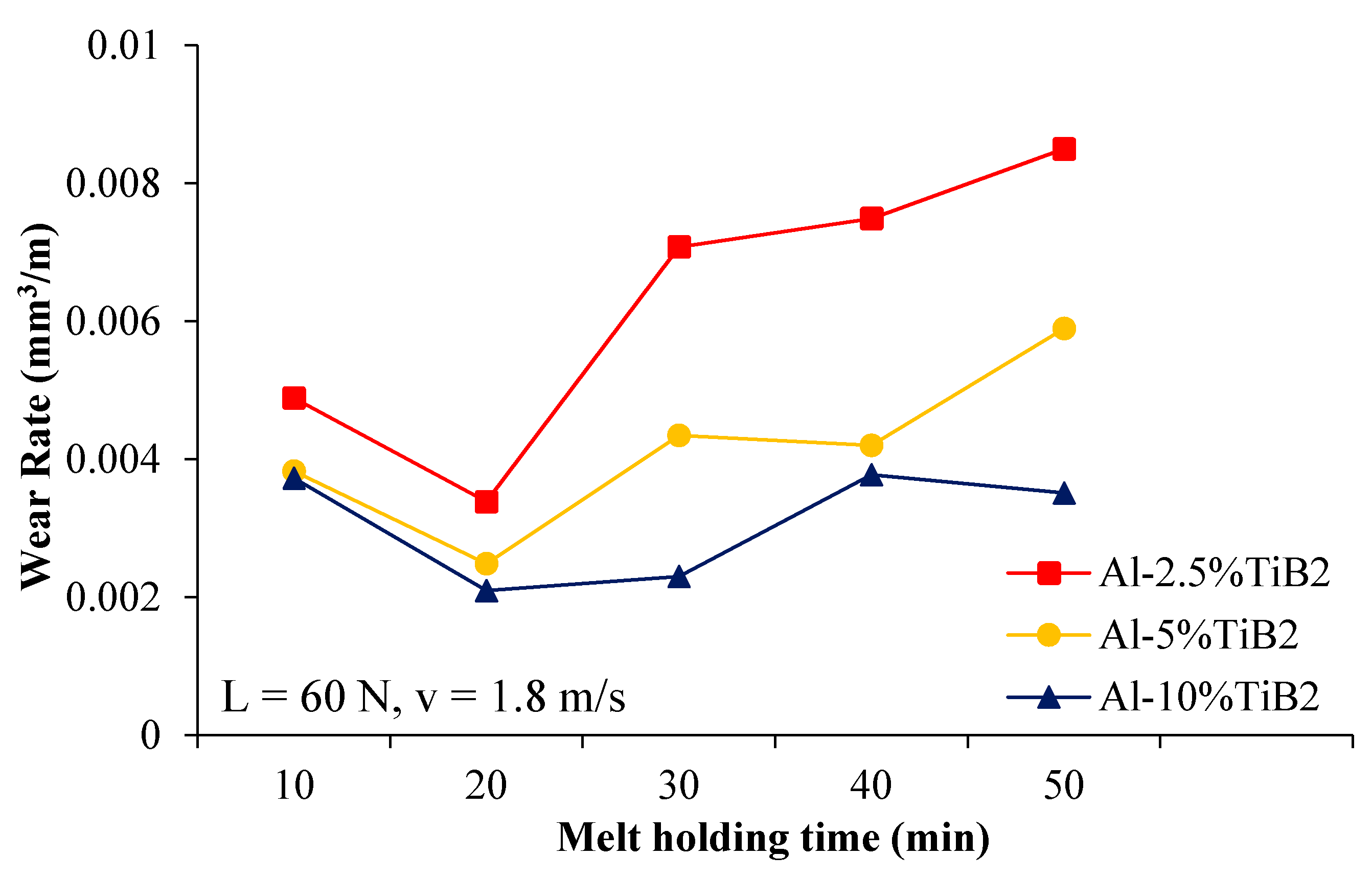

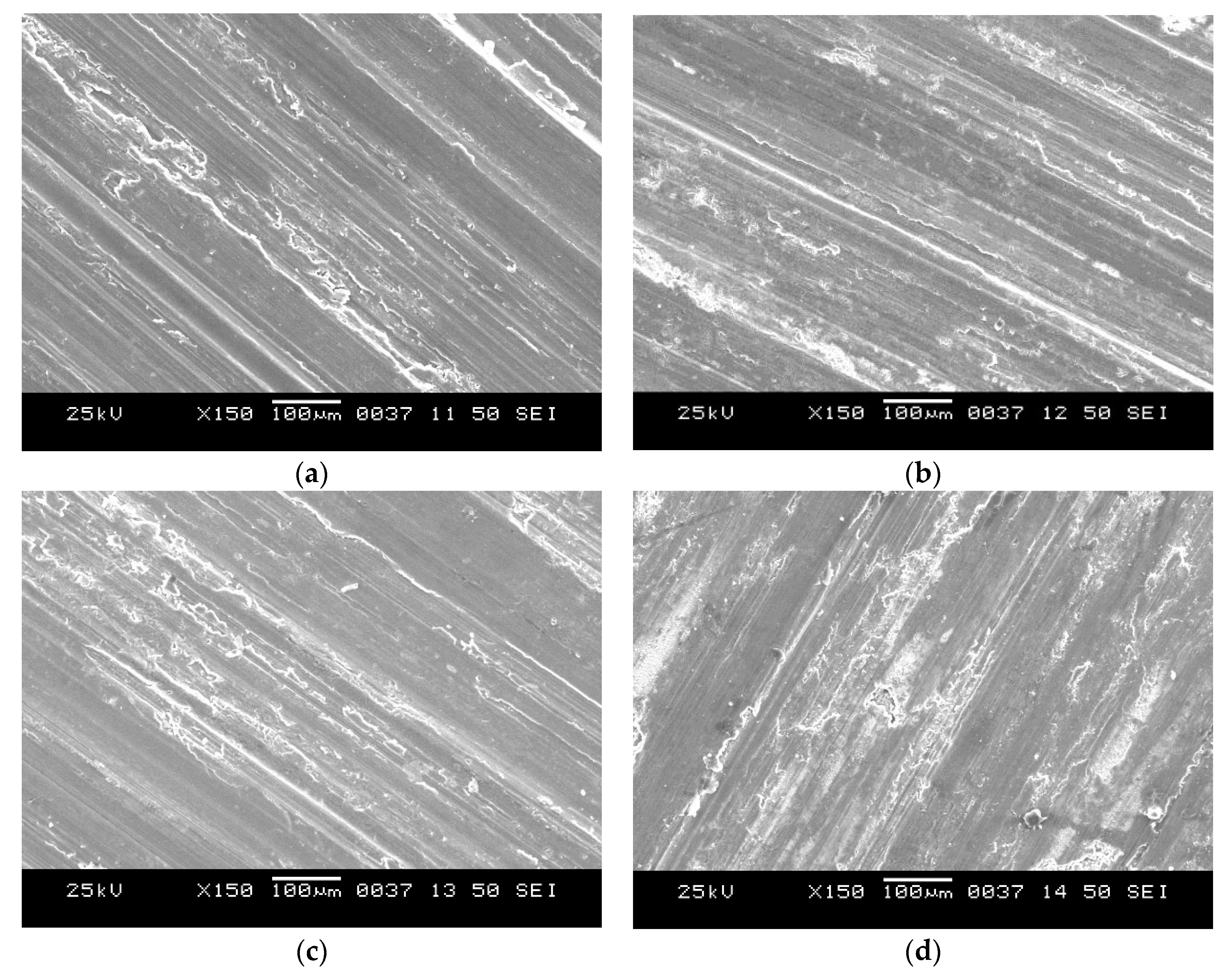

3.3. Strengthening of the Composite by TiB2 Reinforcement

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Clyne, T.W.; Robert, M.H. Stability of intermetallic aluminides in liquid aluminium and implications for grain refinement. Met. Technol. 1980, 7, 177–185. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal Matrix Composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Yue, N.L.; Lu, L.; Lai, M.O. Application of thermodynamic calculation in the in-situ process of Al/TiB2. Compos. Struct. 1999, 47, 691–694. [Google Scholar] [CrossRef]

- Sivaprasad, K.; Babu, S.P.K.; Natarajan, S. Study on abrasive and erosive wear behaviour of Al 6063/TiB2 in situ composites. Mater. Sci. Eng. A 2008, 498, 495–500. [Google Scholar] [CrossRef]

- Luo, A. Processing, microstructure and mechanical behavior of cast magnesium metal matrix composites. Met. Mater. Trans. A 1995, 26, 2445–2455. [Google Scholar] [CrossRef]

- Han, Y.; Liu, X.; Bian, X. In situ TiB2 particulate reinforced near eutectic Al-Si alloy composites. Compos. Part A 2002, 33, 439–444. [Google Scholar] [CrossRef]

- Koczak, M.J.; Premkumar, M.K. Emerging technologies for the in situ production of MMCs. JOM 1993, 45, 44–48. [Google Scholar] [CrossRef]

- Tjonga, S.C.; Wub, S.Q.; Zhu, H.G. Wear behavior of in situ TiB2·Al2O3/Al and TiB2·Al2O3/Al-Cu composites. Compos. Sci. Technol. 1999, 59, 1341–1347. [Google Scholar] [CrossRef]

- Shi, L.; Gu, Y.; Chen, L. A convenient solid-state reaction route to nanocrystalline TiB2. Compos. Part A 2005, 36, 1177–1187. [Google Scholar] [CrossRef]

- Wang, F.-C.; Zhang, Z.-H.; Luo, J.; Huang, C.-C.; Lee, S.-K. A novel rapid route for in situ synthesizing TiB–TiB2 composites. Compos. Sci. Technol. 2009, 69, 2682–2687. [Google Scholar] [CrossRef]

- Jha, A.; Dometakis, U.C. The dispersion mechanism of TiB2 ceramic phase in molten aluminium and its alloys. Mater. Des. 1997, 18, 297–301. [Google Scholar] [CrossRef]

- Christy, T.V.; Murugan, N.; Kumar, S. A comparative study on the microstructures and mechanical properties of Al 6061 alloy and the MMC Al 6061/TiB2. J. Miner. Mater. Charact. Eng. 2010, 9, 57–65. [Google Scholar]

- Kennedy, A.R.; Wyatt, S.M. Effect of processing on the mechanical properties and interfacial strength of aluminium TiC MMCs. Compos. Sci. Technol. 2000, 60, 307–314. [Google Scholar] [CrossRef]

- Lu, L.; Lai, M.O.; Su, V.; Teo, H.L. In-situ TiB2 reinforced Al alloy composites. Scr. Mater. 2001, 45, 1017–1023. [Google Scholar] [CrossRef]

- Watson, I.G.; Forster, M.F.; Lee, P.D.; Dashwood, R.J.; Hamilton, R.W.; Chirazi, A. Investigation of the clustering behavior of titanium diboride particles in aluminium. Compos. Part A 2005, 36, 1177–1187. [Google Scholar] [CrossRef]

- Smalcerz, A.; Przylucki, R. Impact of electromagnetic field upon temperature measurement of induction heated charges. Int. J. Thermophys. 2013, 34, 667–679. [Google Scholar] [CrossRef]

- Gagnoud, A.; Leclercq, I. Electromagnetic modelling of induction melting devices in cold crucible. IEEE Trans. Magn. 1988, 24, 573–575. [Google Scholar] [CrossRef]

- Youssef, Y.M.; Dashwood, R.J.; Lee, P.D. Effect of clustering on particle pushing and solidification behavior in TiB2 reinforced aluminium PMMCs. Compos. Part A 2005, 36, 747–763. [Google Scholar] [CrossRef]

- Dhokey, N.B.; Ghule, S.; Rane, K.; Ranade, R.S. Effect of KBF4 and K2TiF6 on precipitation kinetics of TiB2 in aluminium matrix composite. J. Adv. Mater. Lett. 2011, 2, 210–216. [Google Scholar] [CrossRef]

- Raghavan, V. Al-B-Ti (Aluminum-Boron-Titanium), phase diagram evaluations: Section II. J. Phase Equilib. Diffus. 2009, 30, 610–613. [Google Scholar] [CrossRef]

- Ma, X.; Li, C.; Du, Z.; Zang, W. Thermodynamic assessment of the Ti-B system. J. Alloys Compd. 2004, 370, 149–158. [Google Scholar] [CrossRef]

- Brodkin, D.; Zavaliangos, A.; Kalidindi, S.; Barsoum, M. Transient Plastic Phase Processing of Titanium Carbide-Titanium Boride Composites: Reaction Paths and Microstructural Evolution; No. CONF-9409291; OSTI: Oak Ridge, TN, USA, 1994; pp. 58–59. [Google Scholar]

- Lawrance, C.A.; Prabhu, P.S. Al 6061-TiB2 metal matrix composite synthesized with different reaction holding times by in-situ method. Int. J. Compos. Mater. 2015, 5, 97–101. [Google Scholar]

- Murty, B.S.; Kori, S.A.; Venkateswarlu, K.; Bhat, R.R.; Chakraborty, M. Manufacture of Al–Ti–B master alloys by the reaction of complex halide salts with molten aluminium. J. Mater. Process. Technol. 1999, 89–90, 152–158. [Google Scholar] [CrossRef]

- Poria, S.; Sahoo, P.; Sutradhar, G. Tribological characterization of stir-cast aluminium-TiB2 metal matrix composites. Silicon 2016, 8, 591–599. [Google Scholar] [CrossRef]

- Dhokey, N.B.; Rane, K.K. Wear behavior and its correlation with mechanical properties of TiB2 reinforced aluminium-based composites. Adv. Tribol. 2011, 2011. [Google Scholar] [CrossRef]

- Suh, N.P.; Archard, J.F.T. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar]

| Composite | Reactants | Products | ||||

|---|---|---|---|---|---|---|

| Aluminium | K2TiF6 | KBF4 | 120% KBF4 | Aluminium | TiB2 | |

| Al-2.5%TiB2 | 201.47 | 17.24 | 18.07 | 21.68 | 195 | 5 |

| Al-5%TiB2 | 202.94 | 34.14 | 36.14 | 43.36 | 190 | 10 |

| Al-10%TiB2 | 205.73 | 72.29 | 56.89 | 68.26 | 180 | 20 |

| Element | (KeV) | Mass% | At% |

|---|---|---|---|

| B | - | - | - |

| C | - | - | - |

| Al | 1.486 | 97.67 | 98.67 |

| Ti | 4.508 | 2.33 | 1.33 |

| Total | - | 100 | 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rane, K.; Dhokey, N. On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites. J. Compos. Sci. 2018, 2, 52. https://doi.org/10.3390/jcs2030052

Rane K, Dhokey N. On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites. Journal of Composites Science. 2018; 2(3):52. https://doi.org/10.3390/jcs2030052

Chicago/Turabian StyleRane, Kedarnath, and Narendra Dhokey. 2018. "On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites" Journal of Composites Science 2, no. 3: 52. https://doi.org/10.3390/jcs2030052

APA StyleRane, K., & Dhokey, N. (2018). On the Formation and Distribution of In Situ Synthesized TiB2 Reinforcements in Cast Aluminium Matrix Composites. Journal of Composites Science, 2(3), 52. https://doi.org/10.3390/jcs2030052