Hybrid Laminate Design for Forming and Molding of D-Shaped Composite Beams

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

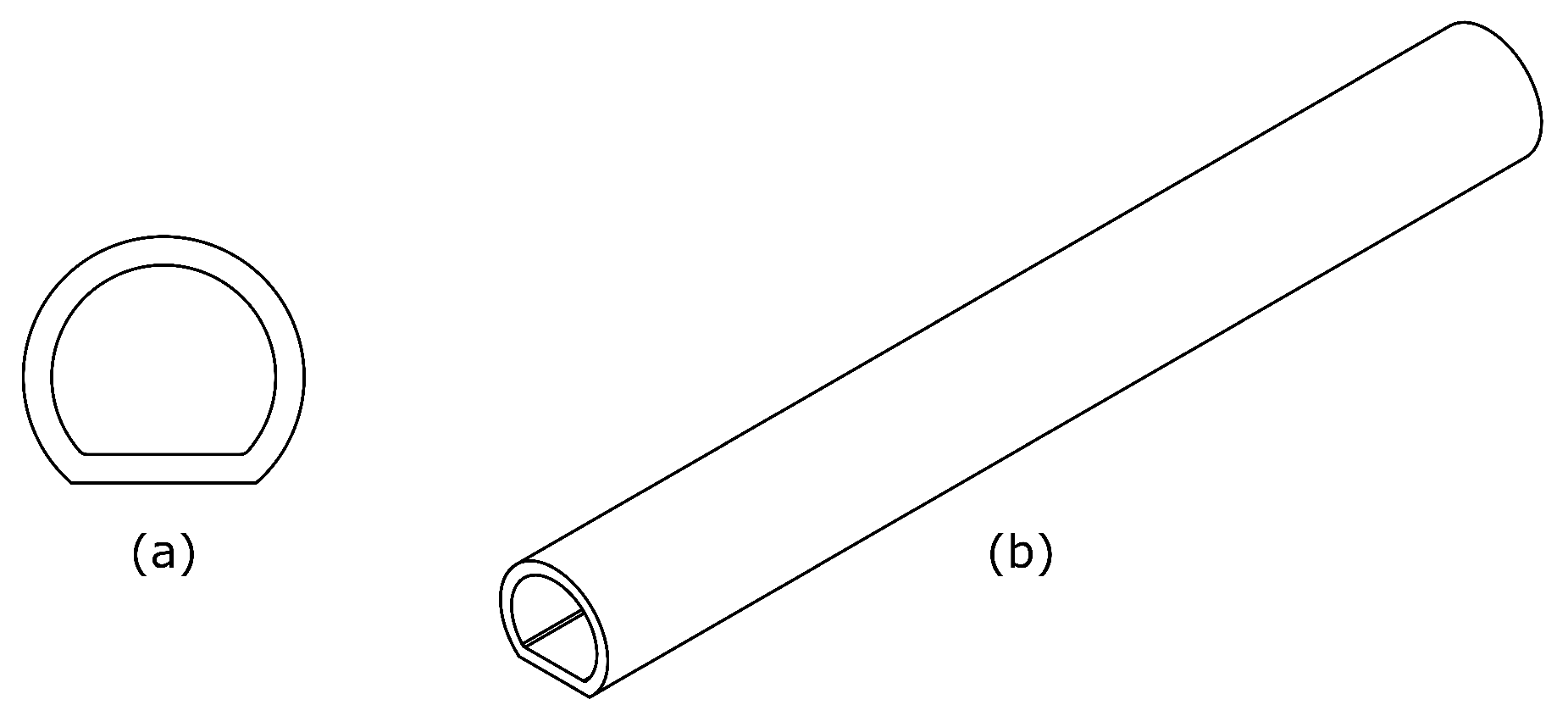

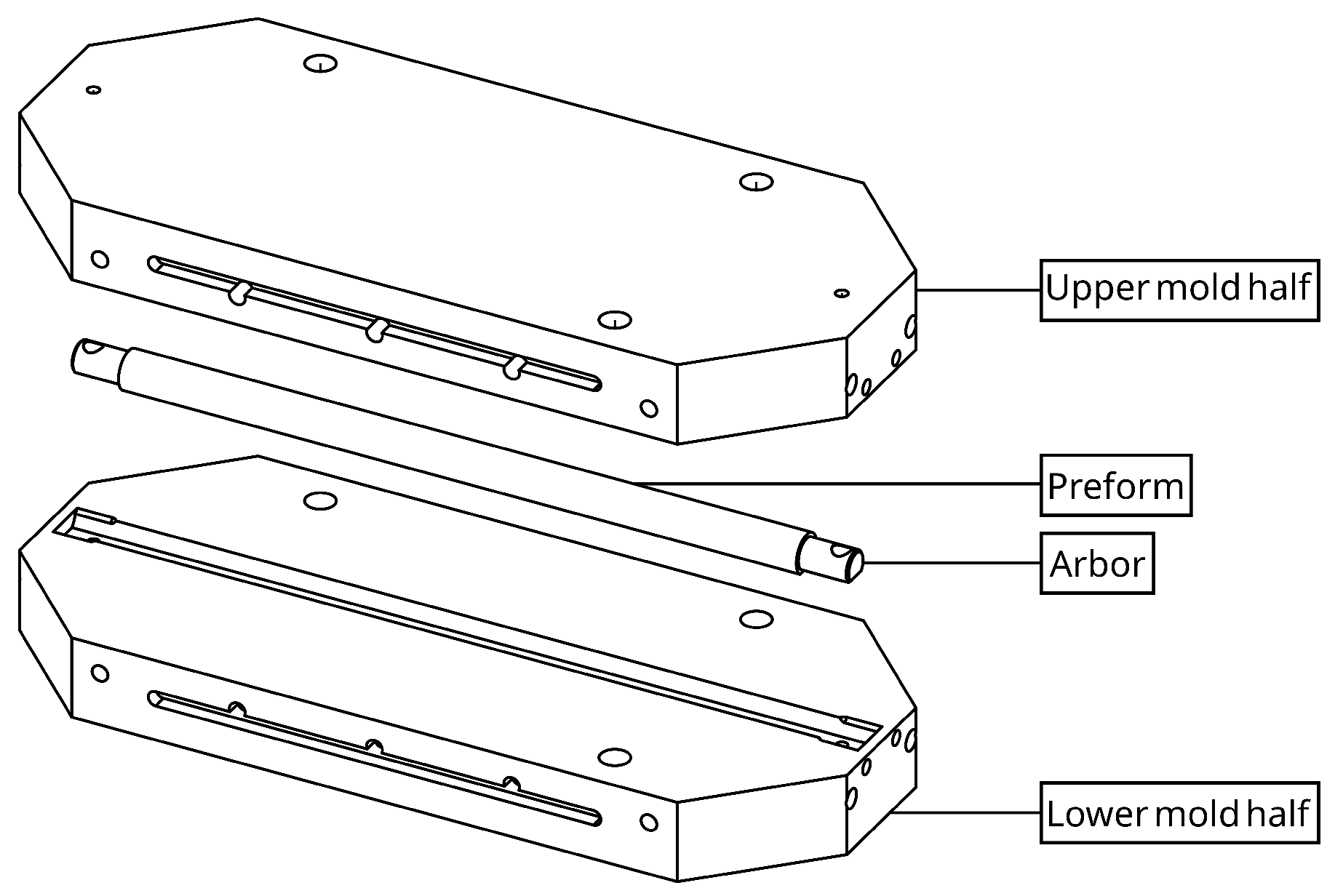

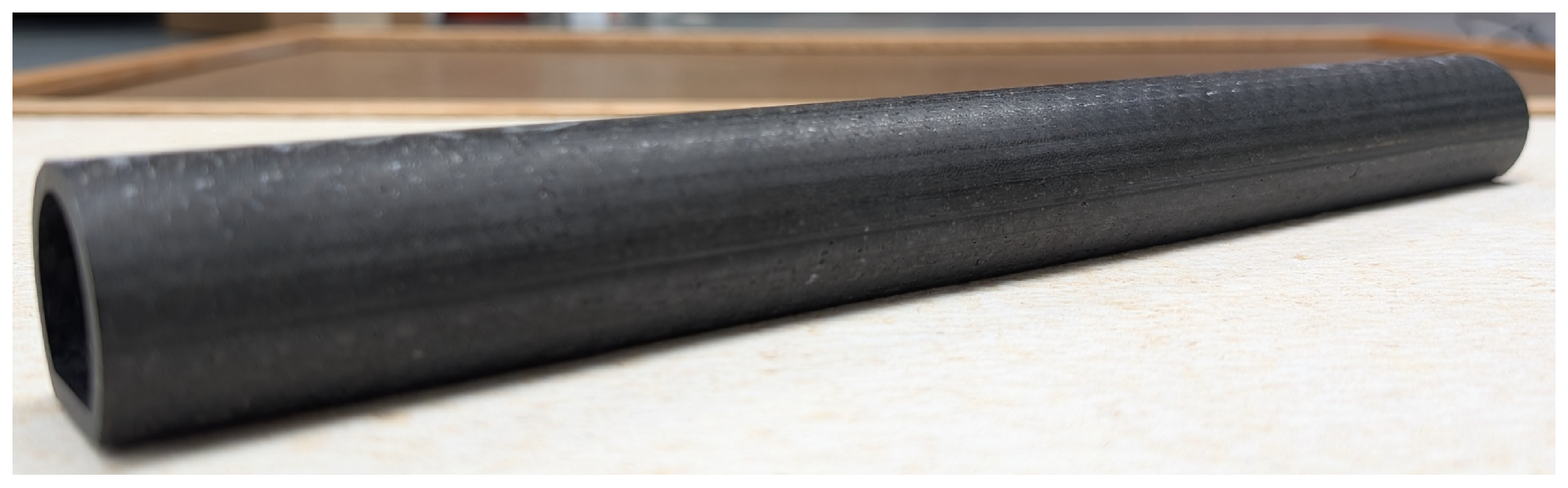

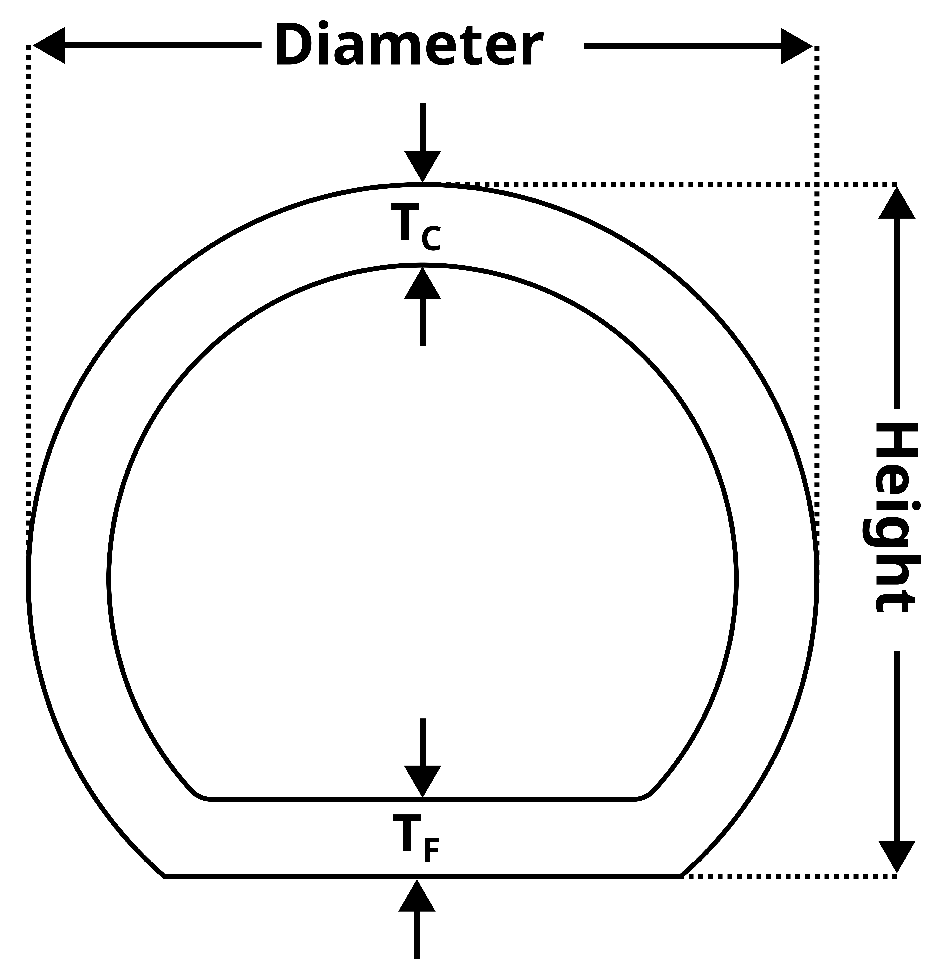

2.2. Design and Fabrication

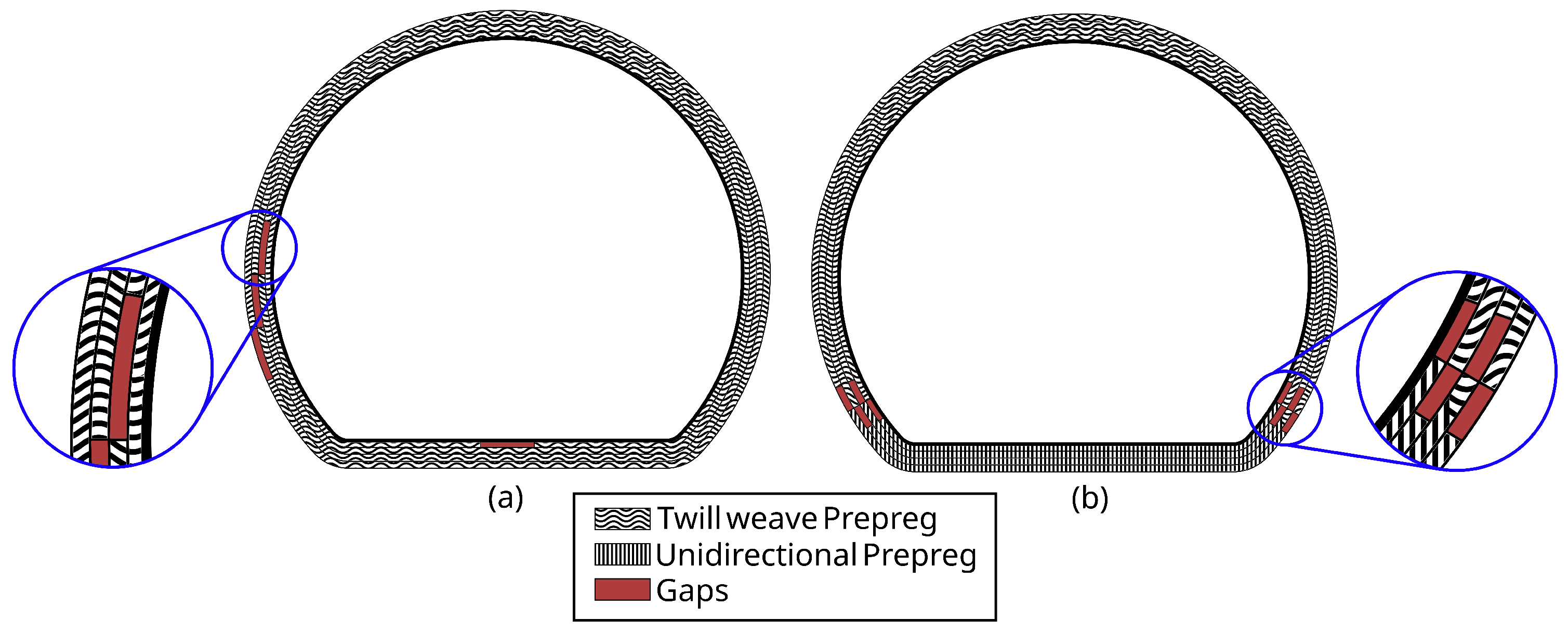

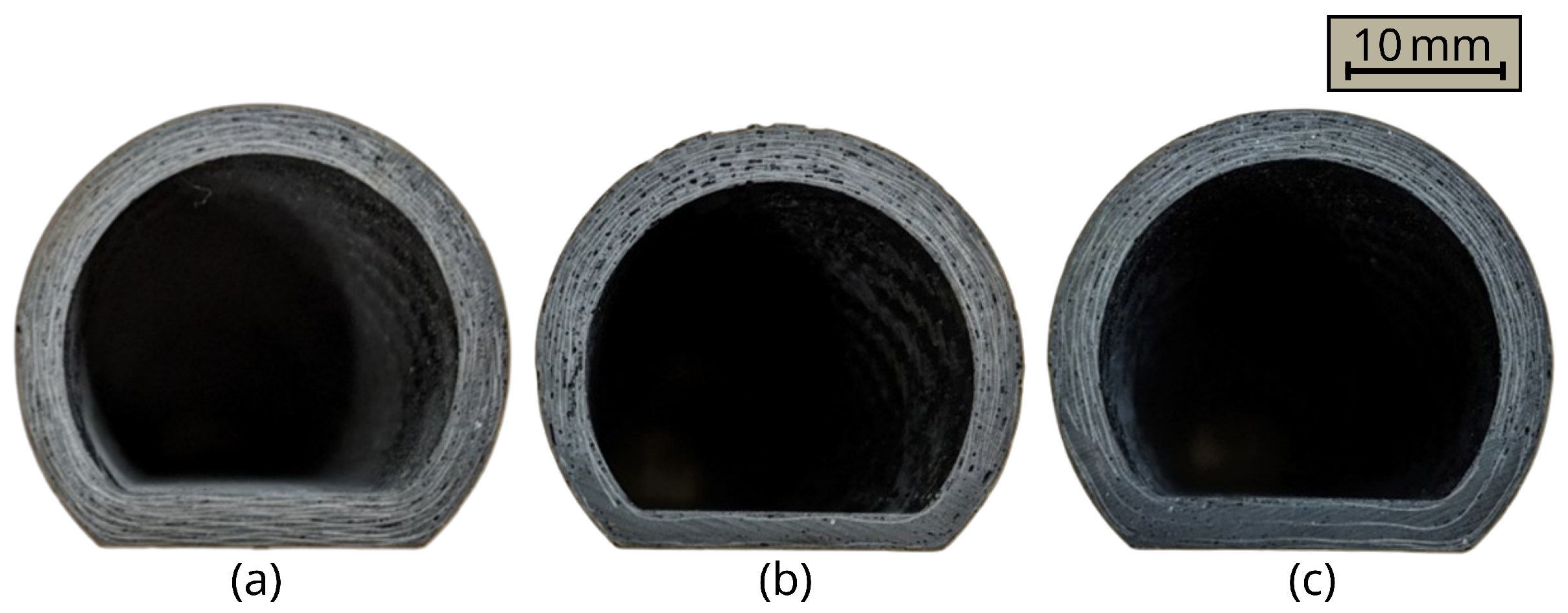

2.3. Prepreg Layup

- All twill (AT), with 14 plies of twill-weave fabric.

- MA1, using 10 UD plies around the flat and 14 twill plies around the curved section.

- MA2, using 13 UD plies around the flat and 14 twill plies around the curved section.

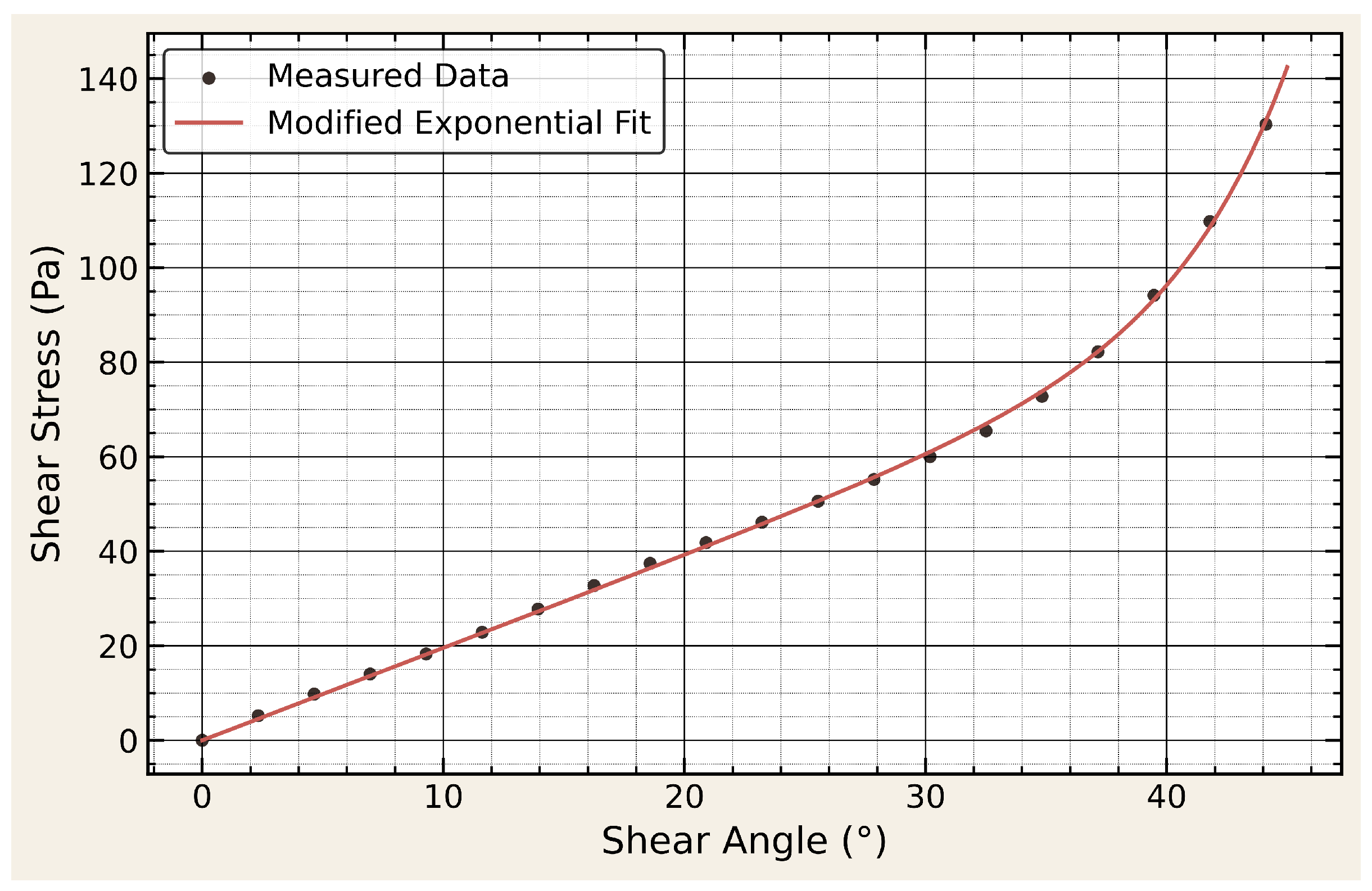

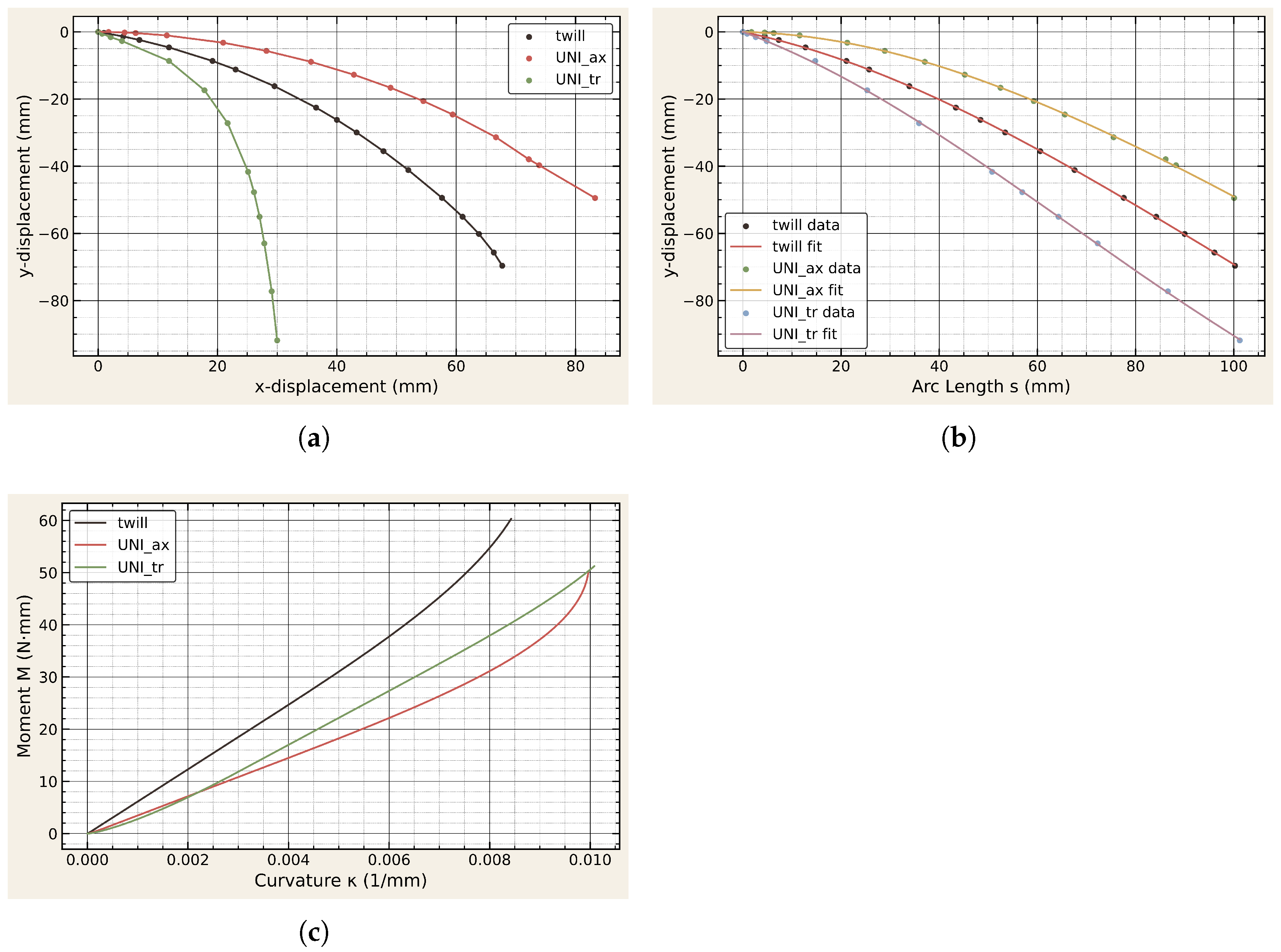

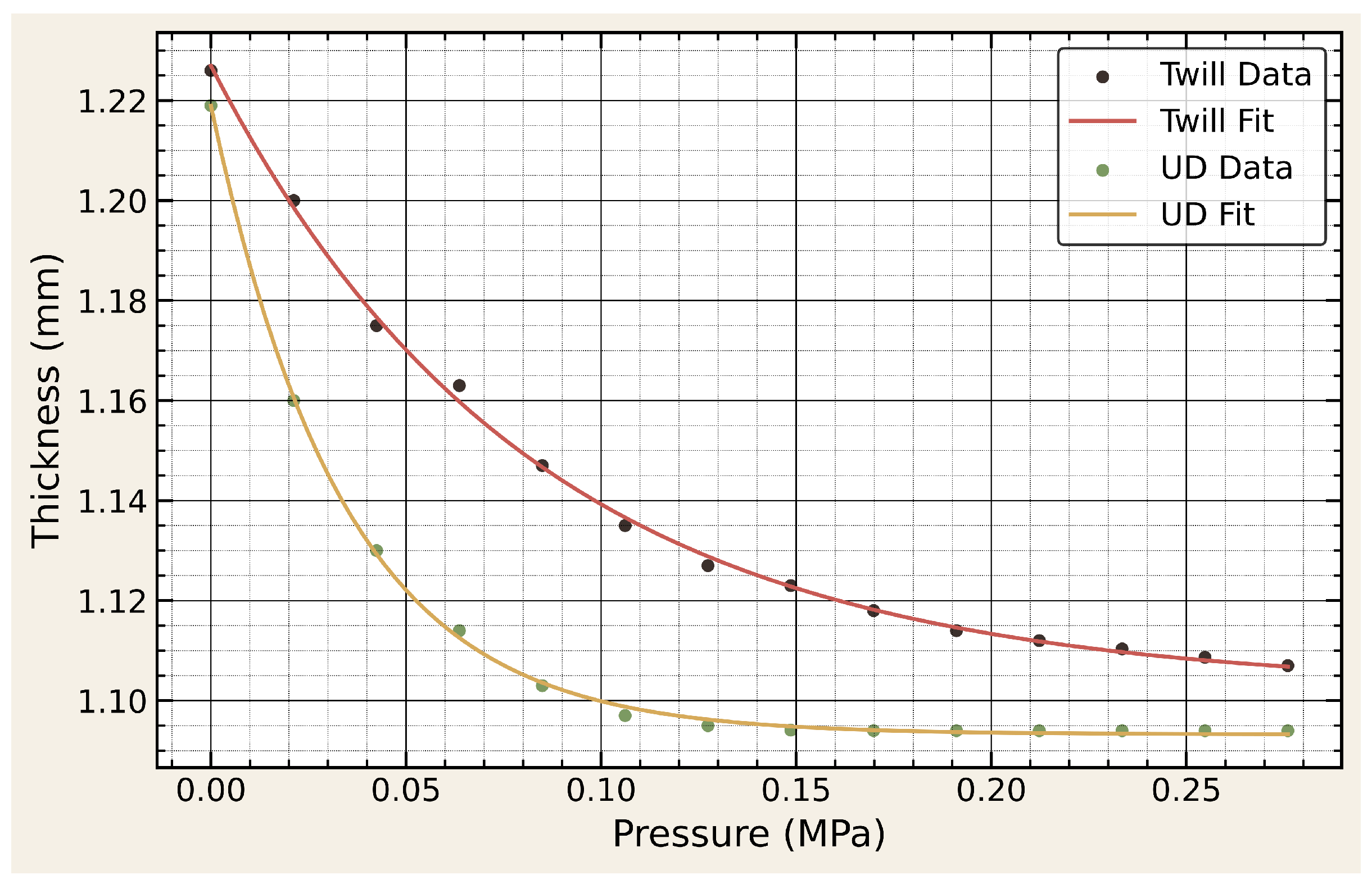

2.4. Mechanical Characterization

2.5. Thermal Characterization

2.6. Forming, Molding, and Cooling

3. Model Simulations

3.1. Forming, Compaction, and Contact Modeling

3.2. Curing

3.3. Cooling, Demolding, and Distortion

4. Results and Discussion

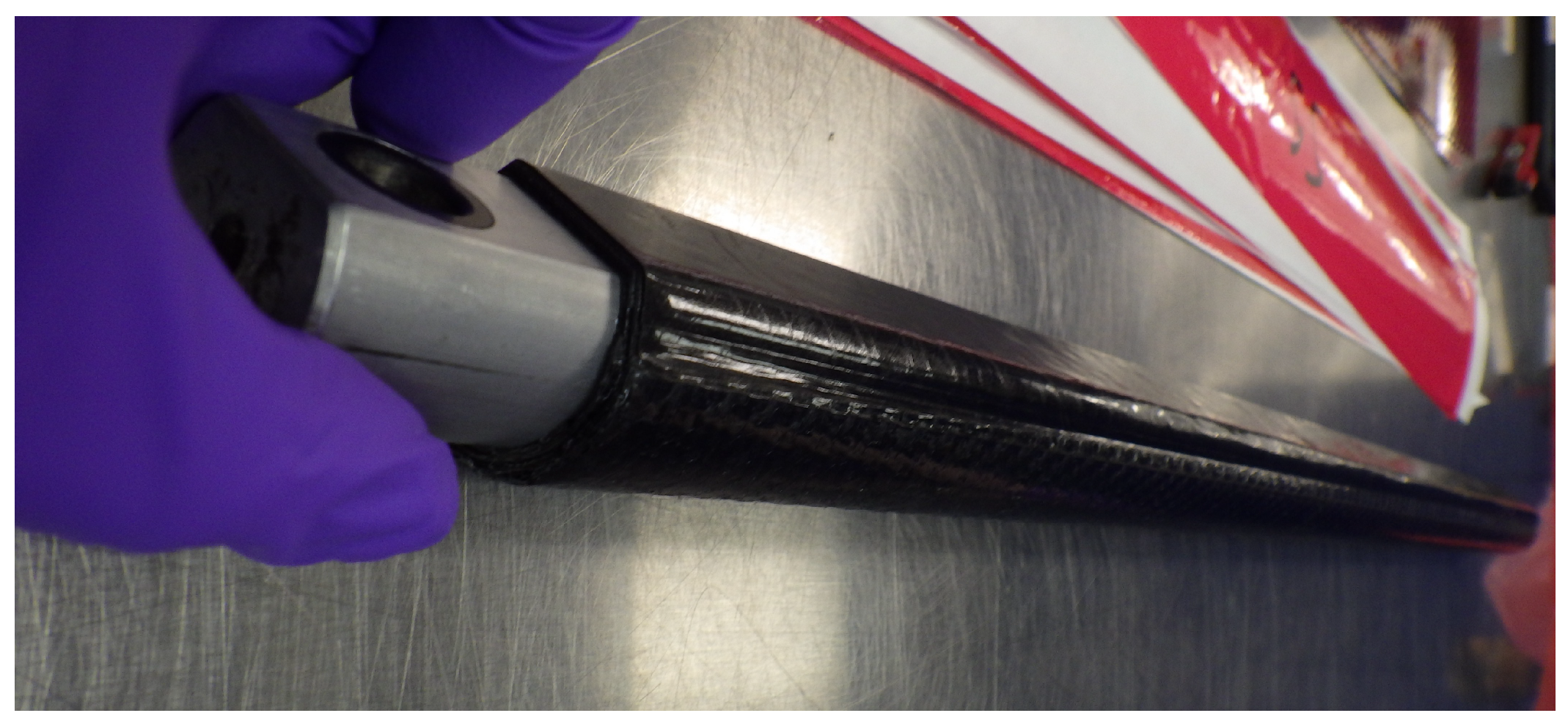

4.1. Experimental Characterization of Molded Parts

4.2. Experimental Inputs for Forming Simulations

4.3. Predicted and Measured Part Dimensions

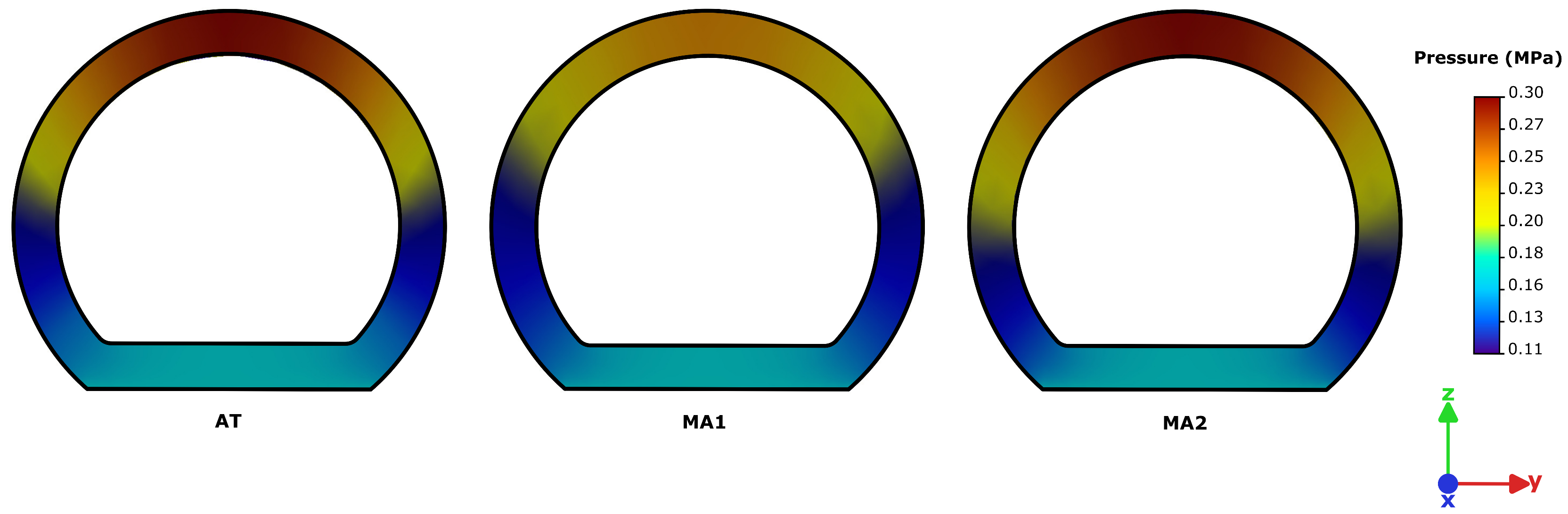

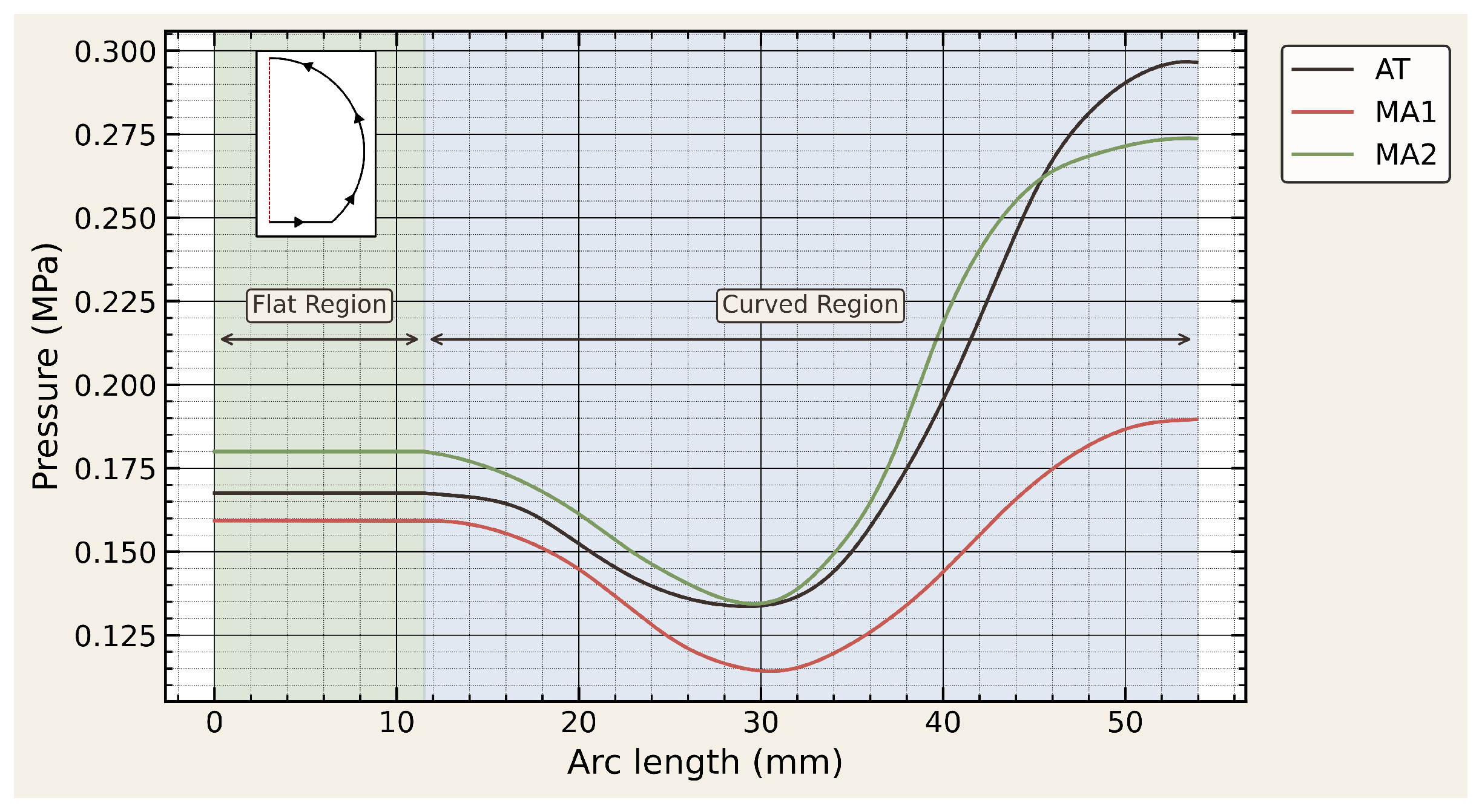

4.4. Pressure Distributions from Simulations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Material Property Inputs for Cure and Distortion Simulations

| Material | Property | Value |

|---|---|---|

| Resin | Density | 1.25 g/cc |

| Thermal Conductivity | 0.15 W/(m.K) | |

| Specific Heat Capacity | 1100 J/(kg.K) | |

| Heat of Reaction | 114.68 J/g | |

| 64,054 J/mol | ||

| 77,684 J/mol | ||

| s−1 | ||

| s−1 | ||

| m | 0.36 | |

| n | 1.64 | |

| Fiber | Density | 1.80 g/cc |

| Thermal Conductivity || | 150 W/(m.K) | |

| Thermal Conductivity ⊥ | 15 W/(m.K) | |

| Specific Heat Capacity | 0.71 J/(g.K) |

| Property | Twill Weave | UD |

|---|---|---|

| Density (g/cc) | 1.50 | 1.55 |

| Fiber Volume Fraction (%) | 44.9 | 54.2 |

| Gel-Point Conversion (%) | 55 | |

| Tg0 (K) | 260.15 | |

| (K) | 476.65 | |

| Below | ||

| Young’s Modulus [x] (GPa) | 7.9 | 19.6 |

| Young’s Modulus [y] (GPa) | 7.9 | 4.7 |

| Young’s Modulus [z] (GPa) | 6.5 | 4.7 |

| Poisson’s Ratio [xy] | 0.22 | 0.31 |

| Poisson’s Ratio [yz] | 0.18 | 0.23 |

| Poisson’s Ratio [xz] | 0.18 | 0.23 |

| Shear Modulus [xy] (GPa) | 3.24 | 2.48 |

| Shear Modulus [yz] (GPa) | 2.35 | 2.17 |

| Shear Modulus [xz] (GPa) | 2.35 | 2.17 |

| CTE [x] (µm/m°C) | 1.4 | 0.7 |

| CTE [y] (µm/m°C) | 1.4 | 48.6 |

| CTE [z] (µm/m°C) | 43.9 | 48.6 |

| Above | ||

| Young’s Modulus [x] (GPa) | 303.7 | 453.1 |

| Young’s Modulus [y] (GPa) | 303.7 | 126.7 |

| Young’s Modulus [z] (GPa) | 270.6 | 126.7 |

| Poisson’s Ratio [xy] | 0.28 | 0.34 |

| Poisson’s Ratio [yz] | 0.25 | 0.31 |

| Poisson’s Ratio [xz] | 0.25 | 0.31 |

| Shear Modulus [xy] (GPa) | 118.6 | 169.1 |

| Shear Modulus [yz] (GPa) | 121.5 | 48.4 |

| Shear Modulus [xz] (GPa) | 121.5 | 48.4 |

| CTE [x] (µm/m°C) | 2.3 | 1.87 |

| CTE [y] (µm/m°C) | 2.3 | 123 |

| CTE [z] (µm/m°C) | 107 | 123 |

References

- Han, N.; Ahmed, I.; Parsons, A.J.; Harper, L.; Scotchford, C.A.; Scammell, B.E.; Rudd, C.D. Influence of screw holes and gamma sterilization on properties of phosphate glass fiber-reinforced composite bone plates. J. Biomater. Appl. 2013, 27, 990–1002. [Google Scholar] [CrossRef] [PubMed]

- Chua, C.Y.X.; Liu, H.C.; Di Trani, N.; Susnjar, A.; Ho, J.; Scorrano, G.; Rhudy, J.; Sizovs, A.; Lolli, G.; Hernandez, N.; et al. Carbon fiber reinforced polymers for implantable medical devices. Biomaterials 2021, 271, 120719. [Google Scholar] [CrossRef] [PubMed]

- Morris, R.H.; Geraldi, N.R.; Stafford, J.L.; Spicer, A.; Hall, J.; Bradley, C.; Newton, M.I. Woven Natural Fibre Reinforced Composite Materials for Medical Imaging. Materials 2020, 13, 1684. [Google Scholar] [CrossRef]

- Scholz, M.S.; Blanchfield, J.P.; Bloom, L.D.; Coburn, B.H.; Elkington, M.; Fuller, J.D.; Gilbert, M.E.; Muflahi, S.A.; Pernice, M.F.; Rae, S.I.; et al. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Lee, J.M.; Lee, C.J.; Kim, B.M.; Ko, D.C. Design of Prepreg Compression Molding for Manufacturing of CFRTP B-pillar Reinforcement with Equivalent Mechanical Properties to Existing Steel Part. Int. J. Precis. Eng. Manuf. 2020, 21, 545–556. [Google Scholar] [CrossRef]

- Gong, Y.; Xu, P.; Peng, X.; Wei, R.; Yao, Y.; Zhao, K. A lamination model for forming simulation of woven fabric reinforced thermoplastic prepregs. Compos. Struct. 2018, 196, 89–95. [Google Scholar] [CrossRef]

- Boisse, P.; Hamila, N.; Madeo, A. Modelling the development of defects during composite reinforcements and prepreg forming. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150269. [Google Scholar] [CrossRef] [PubMed]

- Bae, D.; Kim, S.; Lee, W.; Yi, J.W.; Um, M.K.; Seong, D.G. Experimental and Numerical Studies on Fiber Deformation and Formability in Thermoforming Process Using a Fast-Cure Carbon Prepreg: Effect of Stacking Sequence and Mold Geometry. Materials 2018, 11, 857. [Google Scholar] [CrossRef]

- Dodwell, T.; Butler, R.; Hunt, G. Out-of-plane ply wrinkling defects during consolidation over an external radius. Compos. Sci. Technol. 2014, 105, 151–159. [Google Scholar] [CrossRef]

- Tamagawa, T.; Mori, Y.; Minakuchi, S. Consolidation mechanism of composite corners cured on convex and concave tools. Compos. Part A Appl. Sci. Manuf. 2023, 169, 107500. [Google Scholar] [CrossRef]

- Bae, J.H.; Han, M.G.; Chang, S.H. Formability of complex composite structures with ribs made of long carbon-fiber-reinforced prepregs. Compos. Struct. 2017, 168, 56–64. [Google Scholar] [CrossRef]

- Potter, K. In-plane and out-of-plane deformation properties of unidirectional preimpregnated reinforcement. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1469–1477. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Summerscales, J. Woven Fabrics for Composite Reinforcement: A Review. J. Compos. Sci. 2024, 8, 280. [Google Scholar] [CrossRef]

- Kim, J.Y.; Hwang, Y.T.; Baek, J.H.; Song, W.Y.; Kim, H.S. Study on inter-ply friction between woven and unidirectional prepregs and its effect on the composite forming process. Compos. Struct. 2021, 267, 113888. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.G.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part B Eng. 2018, 136, 101–118. [Google Scholar] [CrossRef]

- Kim, S.; Shin, H.; Lee, K.; Ha, S. Enhancing Product Performance via a Modified Double-Diaphragm Forming (mDDF) Preform Method for Prepreg Compression Molding of Fiber-Reinforced Polymer Composites. Polymers 2025, 17, 1489. [Google Scholar] [CrossRef] [PubMed]

- Mulye, P.D.; Morançay, L.; Binetruy, C.; Comas-Cardona, S.; Leygue, A.; Guillon, D. Unified numerical process modeling of forming and consolidation for thermoplastic composites with prepreg patches. Front. Mater. 2023, 10, 1176482. [Google Scholar] [CrossRef]

- Pasco, C. Prepreg Forming Numerical Analysis and Experimental Characterisation for a Novel High-Volume Forming Process. Ph.D. Thesis, University of Warwick, Coventry, UK, 2018. [Google Scholar]

- Kogiso, N.; Watson, L.T.; Gürdal, Z.; Haftka, R.T. Genetic algorithms with local improvement for composite laminate design. Struct. Optim. 1994, 7, 207–218. [Google Scholar] [CrossRef]

- Callahan, K.J.; Weeks, G.E. Optimum design of composite laminates using genetic algorithms. Compos. Eng. 1992, 2, 149–160. [Google Scholar] [CrossRef]

- Almeida, F.S.; Awruch, A.M. Design optimization of composite laminated structures using genetic algorithms and finite element analysis. Compos. Struct. 2009, 88, 443–454. [Google Scholar] [CrossRef]

- Park, J.H.; Hwang, J.H.; Lee, C.S.; Hwang, W. Stacking sequence design of composite laminates for maximum strength using genetic algorithms. Compos. Struct. 2001, 52, 217–231. [Google Scholar] [CrossRef]

- Albazzan, M.A.; Harik, R.; Tatting, B.F.; Gürdal, Z. Efficient design optimization of nonconventional laminated composites using lamination parameters: A state of the art. Compos. Struct. 2019, 209, 362–374. [Google Scholar] [CrossRef]

- Hochard, C. Optimum design of laminated composite structures. Compos. Struct. 2004, 63, 159–165. [Google Scholar] [CrossRef]

- Belnoue, J.P.H.; Nixon-Pearson, O.; Ivanov, D.; Hallet, S.R. Numerical and experimental investigation of prepreg compaction for defect formation mechanisms. In Design, Manufacturing and Applications of Composites, Proceedings of the Tenth Joint Canada–Japan Workshop on Composites, Vancouver, BC, Canada, 4–6 August 2014; DEStech Publications, Inc.: Lancaster, PA, USA, 2015. [Google Scholar]

- Gangloff, J.J.; Simacek, P.; Sinha, S.; Advani, S.G. A process model for the compaction and saturation of partially impregnated thermoset prepreg tapes. Compos. Part A Appl. Sci. Manuf. 2014, 64, 234–244. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Vidal-Sallé, E.; Boisse, P.; Park, C.H.; Saouab, A.; Bréard, J.; Hivet, G. Mesoscopic scale analyses of textile composite reinforcement compaction. Compos. Part B Eng. 2013, 44, 231–241. [Google Scholar] [CrossRef]

- Xiong, H. Simulation of Forming, Compaction and Consolidation of Thermoplastic Composites Based on Solid Shell Elements. Ph.D. Thesis, Université de Lyon, Lyon, France, 2017. [Google Scholar]

- Rashidi, A.; Belnoue, J.P.H.; Thompson, A.J.; Hallett, S.R.; Milani, A.S. Consolidation-driven wrinkling in carbon/epoxy woven fabric prepregs: An experimental and numerical study. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106298. [Google Scholar] [CrossRef]

- Hallander, P.; Akermo, M.; Mattei, C.; Petersson, M.; Nyman, T. An experimental study of mechanisms behind wrinkle development during forming of composite laminates. Compos. Part A Appl. Sci. Manuf. 2013, 50, 54–64. [Google Scholar] [CrossRef]

- Bai, R.; Chen, B.; Colmars, J.; Boisse, P. Physics-based evaluation of the drapability of textile composite reinforcements. Compos. Part B Eng. 2022, 242, 110089. [Google Scholar] [CrossRef]

- Hubert, P.; Kratz, J. Tool interface pressure during the forming of model composite corners. Compos. Part A Appl. Sci. Manuf. 2021, 151, 106639. [Google Scholar] [CrossRef]

- Maes, V.K.; Minakuchi, S.; Chandarana, N.; Kratz, J. Shape change of composite corners due to tooling pressure distribution effects. Compos. Part A Appl. Sci. Manuf. 2025, 196, 108924. [Google Scholar] [CrossRef]

- Walczyk, D.; Kuppers, J.; Hoffman, C. Curing and Consolidation of Advanced Thermoset Composite Laminate Parts by Pressing Between a Heated Mold and Customized Rubber-Faced Mold. J. Manuf. Sci. Eng. 2011, 133, 011002. [Google Scholar] [CrossRef]

- Garofalo, J.; Walczyk, D.; Kuppers, J. Rapid Consolidation and Curing of Vacuum-Infused Thermoset Composite Parts. J. Manuf. Sci. Eng. 2016, 139, 021010. [Google Scholar] [CrossRef]

- D8067/D8067M-17; Standard Test Method for In-Plane Shear Properties of Sandwich Panels Using a Picture Frame Fixture. ASTM International: West Conshohocken, PA, USA, 2017; reapproved 2025.

- D1388-23; Standard Test Method for Stiffness of Fabrics. ASTM International: West Conshohocken, PA, USA, 2023.

- ISO 13934-1:2013; Textiles—Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017; reapproved 2025.

- D7078/D7078M-20; Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method. ASTM International: West Conshohocken, PA, USA, 2020; reapproved 2025.

- E831-25; Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis. ASTM International: West Conshohocken, PA, USA, 2025.

- E2585-09; Standard Practice for Thermal Diffusivity by the Flash Method. ASTM International: West Conshohocken, PA, USA, 2009; reapproved 2022.

- Poodts, E.; Minak, G.; Mazzocchetti, L.; Giorgini, L. Fabrication, process simulation and testing of a thick CFRP component using the RTM process. Compos. Part B Eng. 2014, 56, 673–680. [Google Scholar] [CrossRef]

- Zhang, Y.; An, L.; Zhao, C. Enhancing the Forming Accuracy of CFRP through a Global Compensation Method by Introducing an Optimal Profile. Polymers 2024, 16, 1792. [Google Scholar] [CrossRef] [PubMed]

- Qian, C.; Weare, R.; Pasco, C.; Kourra, N.; Attridge, A.; Williams, M.; Kendall, K. Numerical and Experimental Studies of Multi-ply Woven Carbon Fibre Prepreg Forming Process. Procedia Manuf. 2020, 47, 93–99. [Google Scholar] [CrossRef]

- Lee, W.; Um, M.K.; Byun, J.H.; Boisse, P.; Cao, J. Numerical study on thermo-stamping of woven fabric composites based on double-dome stretch forming. Int. J. Mater. Form. 2010, 3, 1217–1227. [Google Scholar] [CrossRef]

- Nguyen, D.T.A.; Li, L.; Ji, H. Stable and accurate numerical methods for generalized Kirchhoff–Love plates. J. Eng. Math. 2021, 130, 6. [Google Scholar] [CrossRef]

- Ozenda, O.; Virga, E.G. On the Kirchhoff-Love Hypothesis (Revised and Vindicated). J. Elast. 2021, 143, 359–384. [Google Scholar] [CrossRef]

- Kiendl, J.; Bletzinger, K.U.; Linhard, J.; Wüchner, R. Isogeometric shell analysis with Kirchhoff–Love elements. Comput. Methods Appl. Mech. Eng. 2009, 198, 3902–3914. [Google Scholar] [CrossRef]

- Nguyen-Thanh, N.; Valizadeh, N.; Nguyen, M.N.; Nguyen-Xuan, H.; Zhuang, X.; Areias, P.; Zi, G.; Bazilevs, Y.; De Lorenzis, L.; Rabczuk, T. An extended isogeometric thin shell analysis based on Kirchhoff–Love theory. Comput. Methods Appl. Mech. Eng. 2015, 284, 265–291. [Google Scholar] [CrossRef]

- Yu, W. A unified theory for constitutive modeling of composites. J. Mech. Mater. Struct. 2016, 11, 379–411. [Google Scholar] [CrossRef]

- Kamal, M.R.; Sourour, S. Kinetics and thermal characterization of thermoset cure. Polym. Eng. Sci. 1973, 13, 59–64. [Google Scholar] [CrossRef]

- Shree, S.; Jayaraman, K.; Dereims, A.; Raveendra, R. Performance of additively manufactured composite mold with uniform fiber orientation. Int. J. Adv. Manuf. Technol. 2024, 131, 4297–4305. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Ren, H.; Huang, Z.; Geng, F.; Li, Y.; Zhu, Z. An Analytical Model for the Tension-Shear Coupling of Woven Fabrics with Different Weave Patterns under Large Shear Deformation. Appl. Sci. 2020, 10, 1551. [Google Scholar] [CrossRef]

- Kahavita, K.D.H.N.; McCarthy, E.D.; Zhang, M.; Brádaigh, C.M.Ó.; Harrison, P. Characterising the shear resistance of a unidirectional non-crimp glass fabric using modified picture frame and uniaxial bias extension test methods. Int. J. Mater. Form. 2023, 16, 49. [Google Scholar] [CrossRef]

- Alshahrani, H.; Hojjati, M. A new test method for the characterization of the bending behavior of textile prepregs. Compos. Part A Appl. Sci. Manuf. 2017, 97, 128–140. [Google Scholar] [CrossRef]

- Li, Z.; Song, Q.; Liu, J.; Liu, W.; Chen, P.; Yue, G. Modeling of Preforming Process for Unidirectional Prepreg Composites Using Simplified Linear Friction Model and Fiber-Tracking Method. Polymers 2025, 17, 1321. [Google Scholar] [CrossRef]

- Hubert, P.; Poursartip, A. A method for the direct measurement of the fibre bed compaction curve of composite prepregs. Compos. Part A Appl. Sci. Manuf. 2001, 32, 179–187. [Google Scholar] [CrossRef]

| Part | Diameter (mm) | Height (mm) | (mm) | (mm) | Flat Width (mm) |

|---|---|---|---|---|---|

| Design | 34.9 | 30.8 | 3.56 | 3.50 | 22.9 |

| AT | 35.2 | 30.9 | 3.58 | 3.69 | 23.1 |

| MA1 | 33.5 | 29.2 | 3.82 | 2.49 | 21.4 |

| MA2 | 35.0 | 30.6 | 3.53 | 3.43 | 23 |

| Attribute | AT | MA1 | MA2 | |||

|---|---|---|---|---|---|---|

| Diameter (mm) | +0.3 | (0.9%) | −1.4 | (−4.0%) | +0.1 | (0.3%) |

| Height (mm) | +0.1 | (0.3%) | −1.6 | (−5.2%) | −0.2 | (−0.6%) |

| (mm) | +0.02 | (0.6%) | +0.26 | (+7.3%) | −0.03 | (−0.8%) |

| (mm) | +0.19 | (5.4%) | −1.01 | (−29%) | −0.07 | (−2%) |

| Flat Width (mm) | +0.2 | (0.9%) | −1.5 | (−6.6%) | +0.1 | (0.5%) |

| Part Description | Flexural Modulus (GPa) | Flexural Strength (MPa) | |

|---|---|---|---|

| AT | 0.45 | 7.7 | 45.2 |

| MA1 | 0.47 | 8.2 | 45.3 |

| MA2 | 0.48 | 8.3 | 45.4 |

| Parameter | Twill Weave (Vf = 0.45) | UD (Vf = 0.45) |

|---|---|---|

| A (mm) | 4.5411 | 4.2511 || |

| 8.7519 ⊥ | ||

| B (mm/mm) | 0.3082 | 0.0343 || |

| 0.5463 ⊥ | ||

| C (1/mm) | 0.0029 | 0.0037 || |

| 0.0018 ⊥ |

| Prepreg Type | (mm) | (mm) | a (1/MPa) |

|---|---|---|---|

| Twill Weave | 1.227 | 0.125 | 12.19 |

| UD | 1.219 | 0.126 | 29.43 |

| Attribute | AT (Pred/Meas/ ) | MA1 (Pred/Meas/ ) | MA2 (Pred/Meas/ ) |

|---|---|---|---|

| Diameter (mm) | 35.13/35.2/−0.2% | 33.29/33.5/−0.6% | 34.97/35/−0.1% |

| Height (mm) | 30.9/30.9/0% | 29.12/29.2/−0.3% | 30.88/30.6/0.9% |

| TC (mm) | 3.57/3.58/−0.3% | 3.80/3.82/−0.5% | 3.55/3.53/0.6% |

| TF (mm) | 3.67/3.69/−0.5% | 2.52/2.49/+1.2% | 3.49/3.43/1.7% |

| Flat Width (mm) | 23/23.1/−0.4% | 20.89/21.4/−2.4% | 23/23/0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Shree, S.; Jayaraman, K. Hybrid Laminate Design for Forming and Molding of D-Shaped Composite Beams. J. Compos. Sci. 2026, 10, 4. https://doi.org/10.3390/jcs10010004

Shree S, Jayaraman K. Hybrid Laminate Design for Forming and Molding of D-Shaped Composite Beams. Journal of Composites Science. 2026; 10(1):4. https://doi.org/10.3390/jcs10010004

Chicago/Turabian StyleShree, Swayam, and Krishnamurthy Jayaraman. 2026. "Hybrid Laminate Design for Forming and Molding of D-Shaped Composite Beams" Journal of Composites Science 10, no. 1: 4. https://doi.org/10.3390/jcs10010004

APA StyleShree, S., & Jayaraman, K. (2026). Hybrid Laminate Design for Forming and Molding of D-Shaped Composite Beams. Journal of Composites Science, 10(1), 4. https://doi.org/10.3390/jcs10010004