Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions

Abstract

1. Introduction

2. Materials and Methods

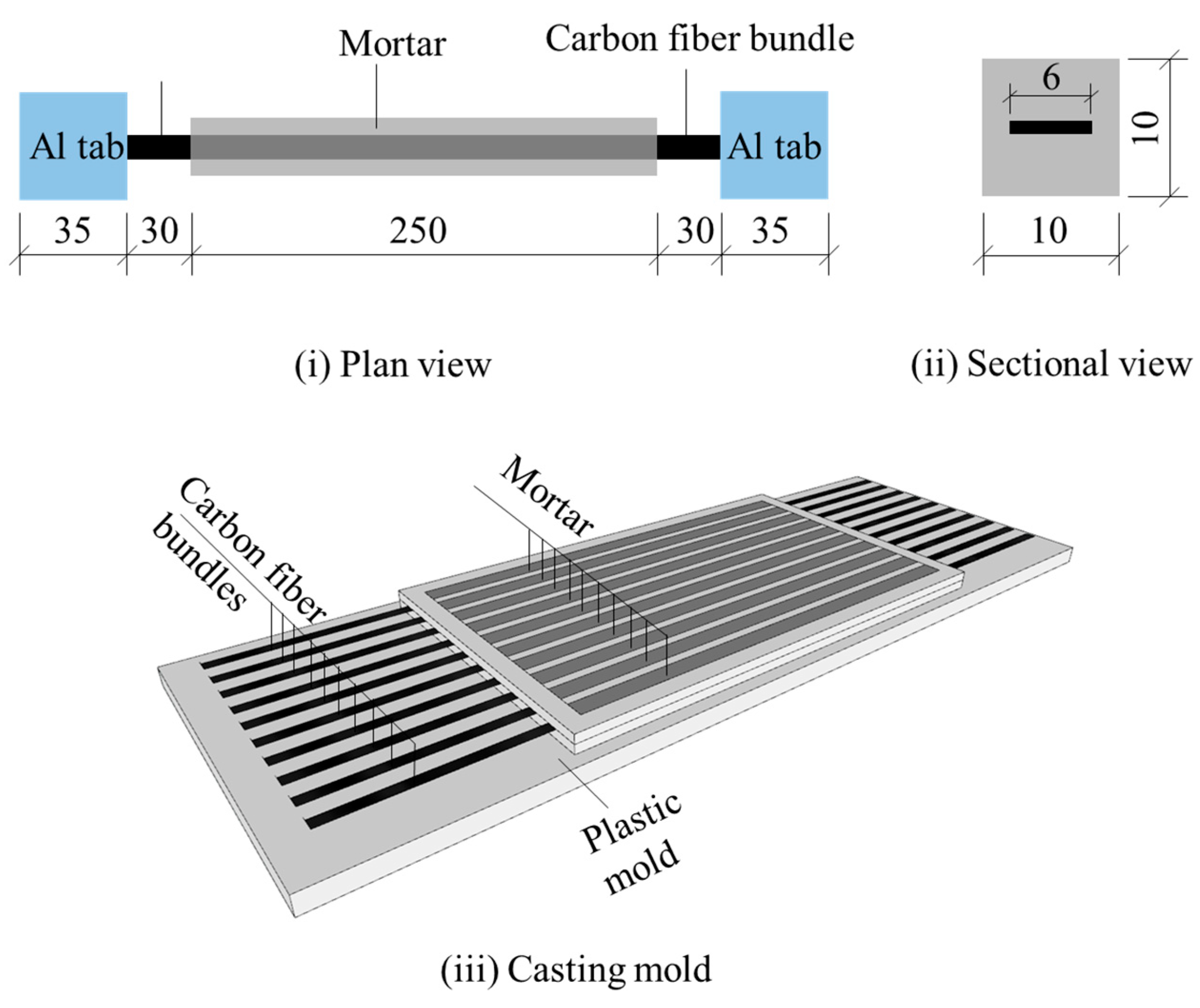

2.1. Raw Materials and Specimen Preparation

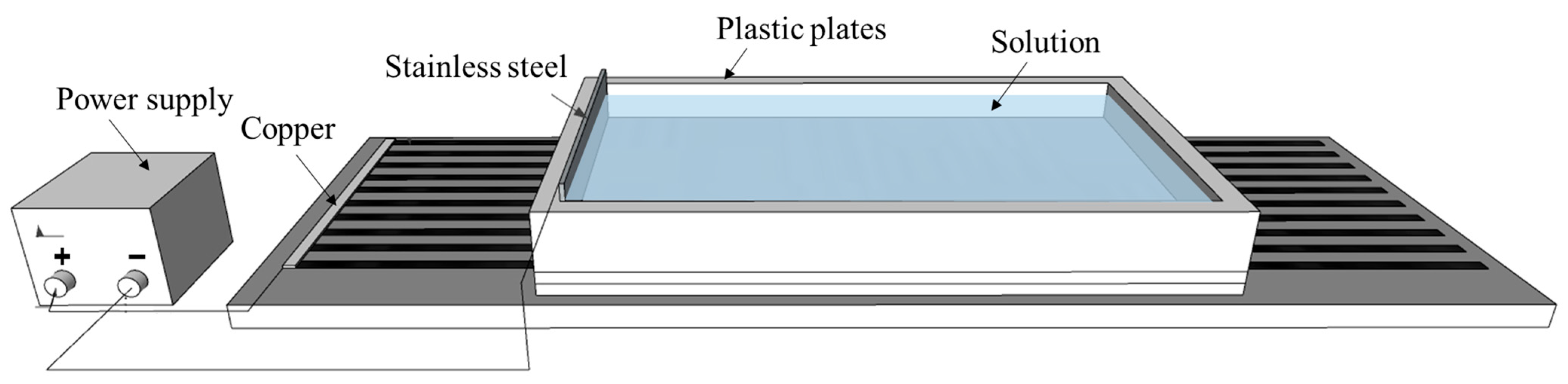

2.2. Implementation of Anodic Polarization

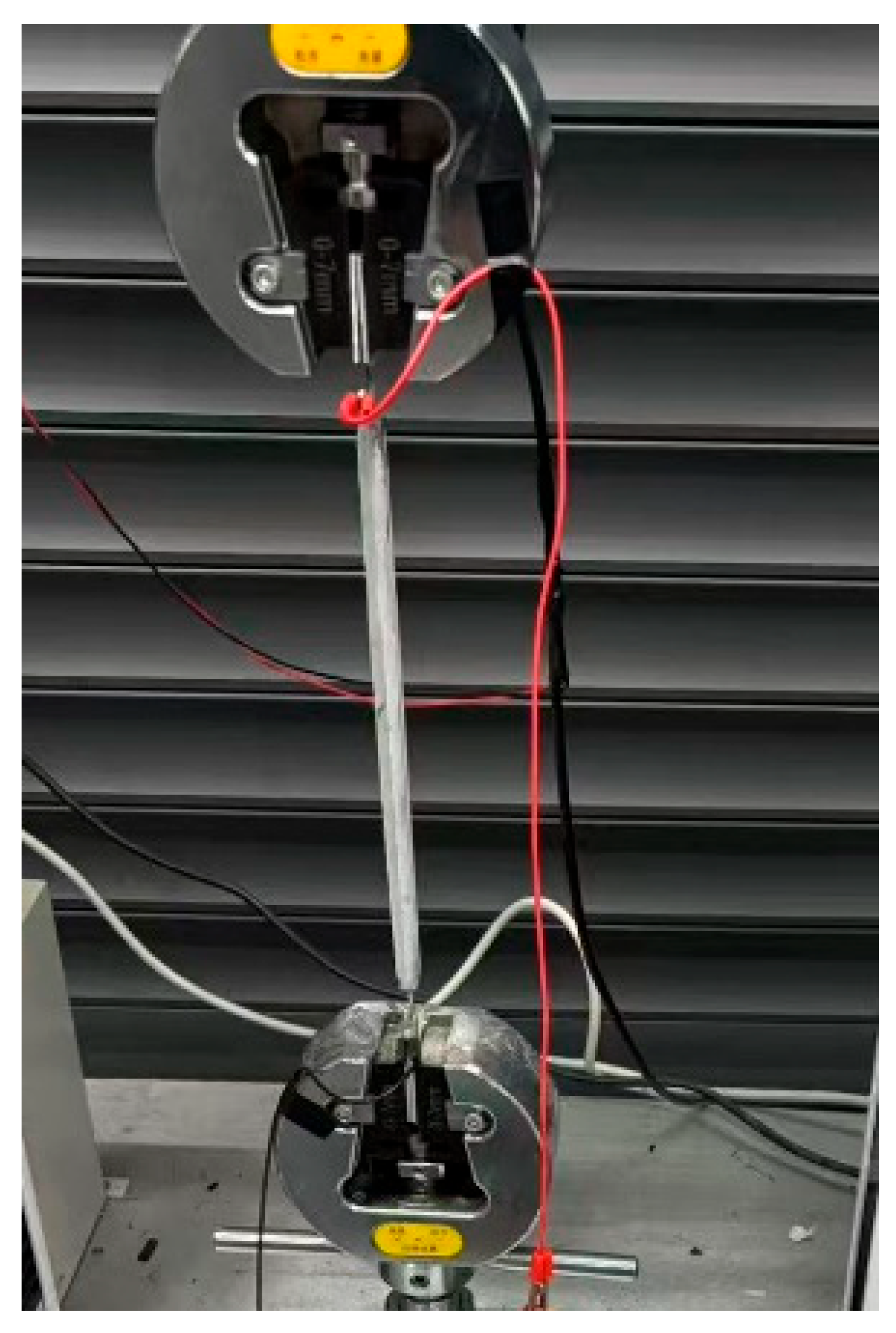

2.3. Tensile Tests

3. Results

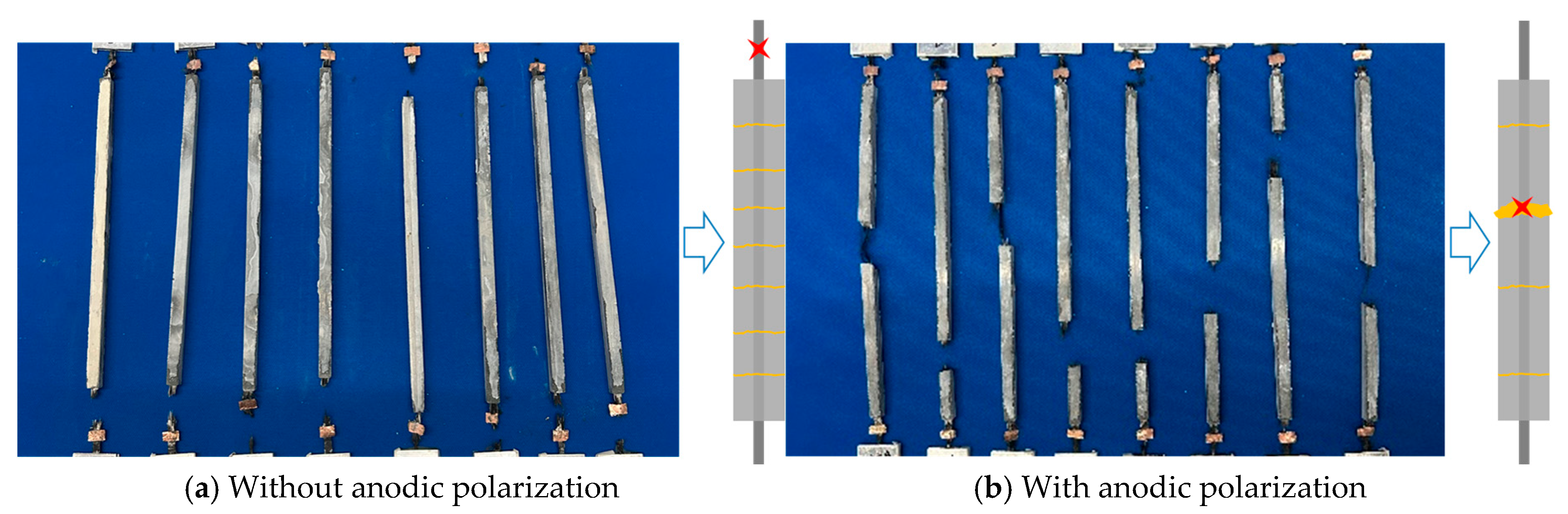

3.1. Failure Modes

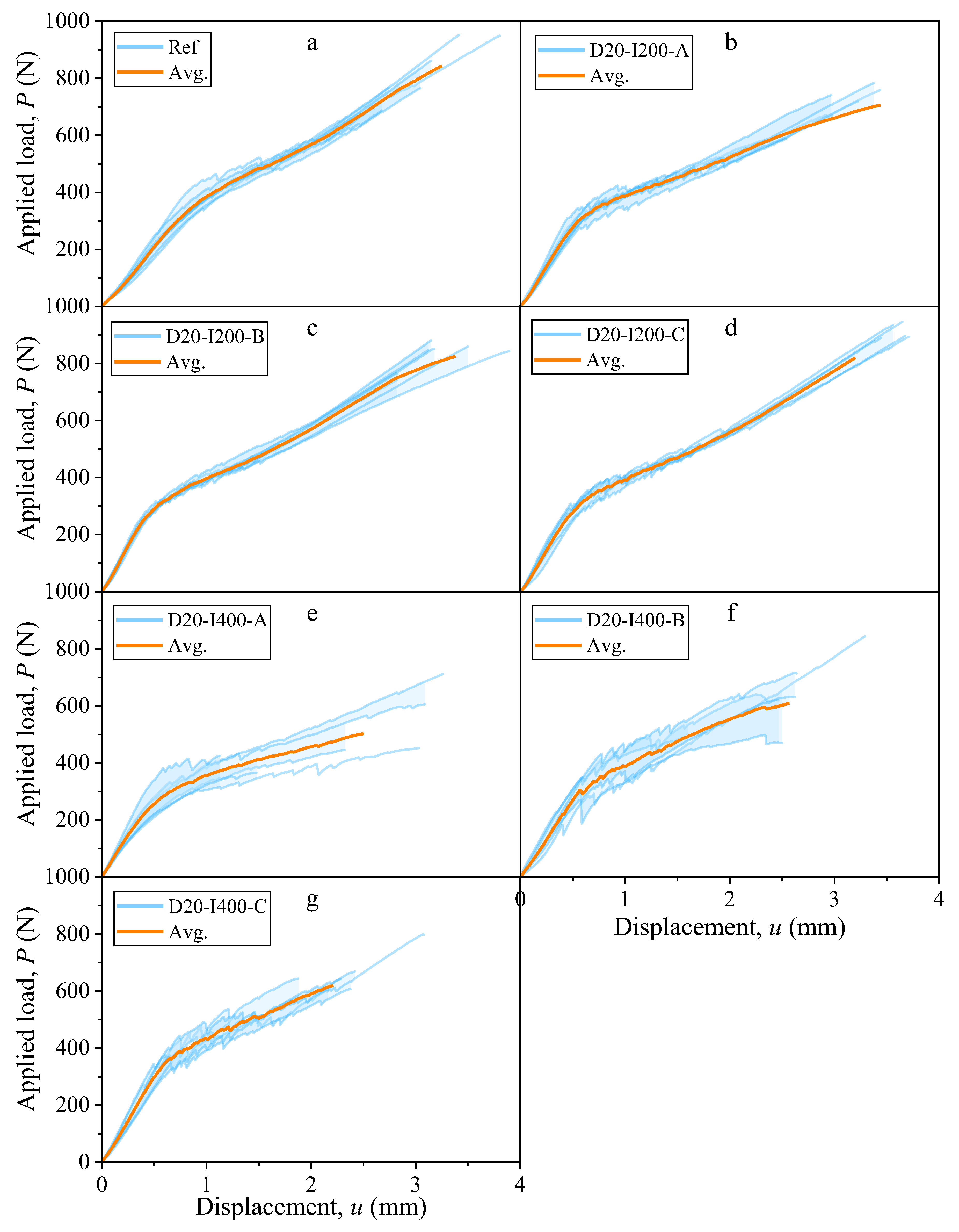

3.2. Load–Displacement Curves

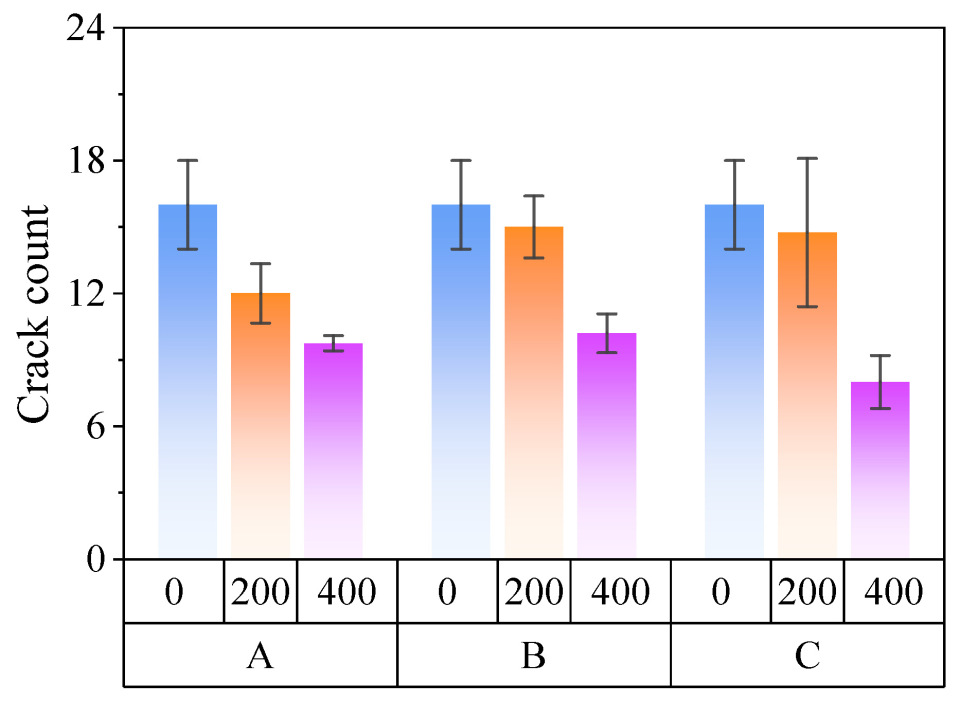

3.3. The Number of Cracks Within Mortar

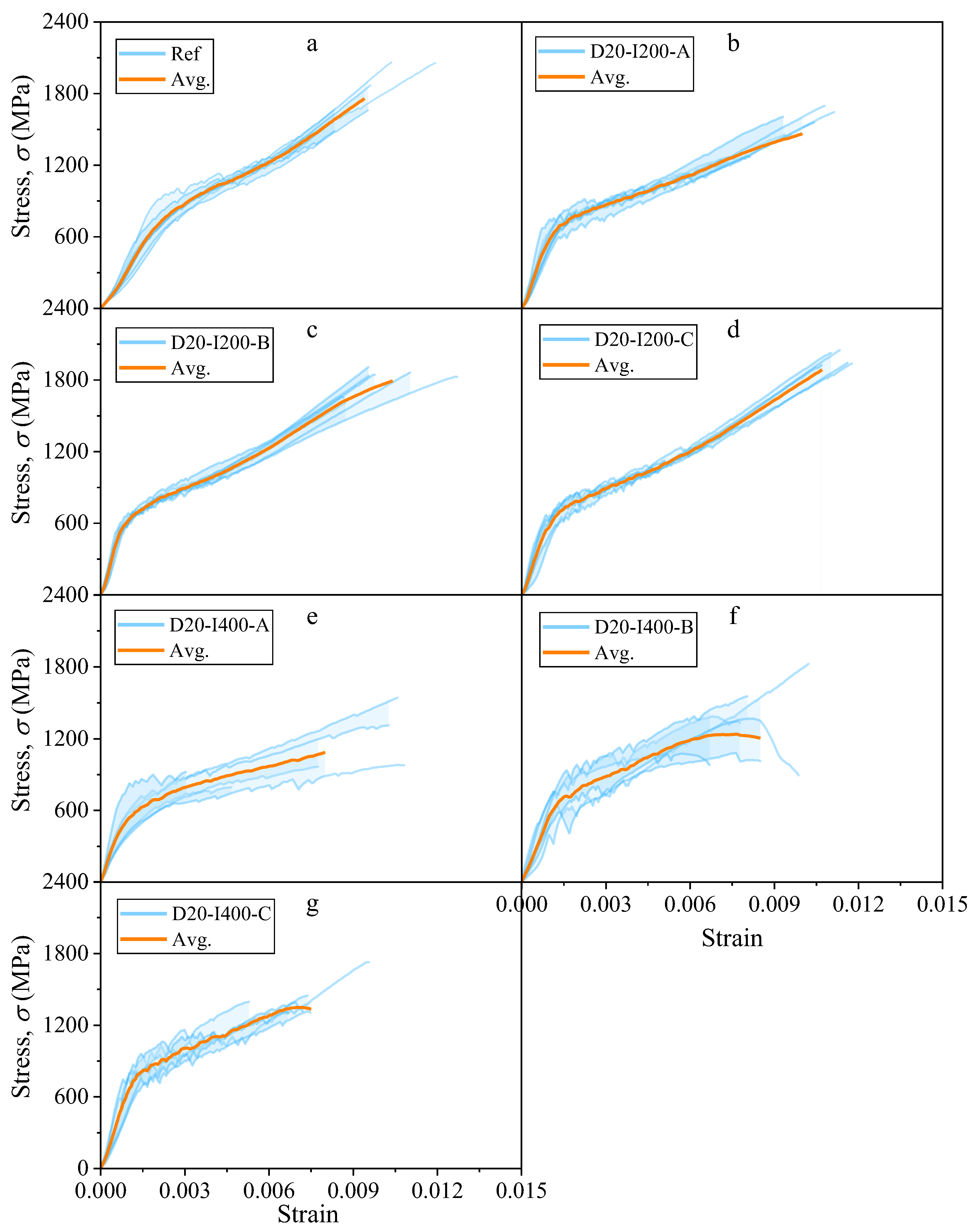

3.4. Tensile Stress–Strain Constitutive Relationship

3.5. Comparison of Tensile Strength: Bare Carbon Fiber Bundles vs. CFRCM-Embedded Bundles

4. Conclusions

- (1)

- The anodic polarization treatment altered the tensile failure mode of the CFRCM specimens. In the non-polarized control specimens, the rupture of the exposed carbon fiber bundle occurred outside the mortar matrix. In contrast, after anodic polarization, the rupture of the carbon fiber bundle consistently occurred within a crack inside the mortar matrix. This indicates that the anodic polarization process caused degradation at the carbon fiber-mortar interface and within the carbon fibers themselves, prompting a shift in the location of fiber rupture.

- (2)

- Compared to the control group, the polarized specimens exhibited a reduced number of cracks and an increased average crack spacing. This confirms that anodic polarization weakened the interfacial bond strength between the fibers and the mortar matrix.

- (3)

- All specimens exhibited typical strain-hardening behavior. However, the slope of the load-deformation curve in the crack-widening stage was noticeably reduced after anodic polarization. This indicates that anodic polarization not only reduced the peak strength of the material but also impaired its stiffness during the primary service stage (post-cracking stage).

- (4)

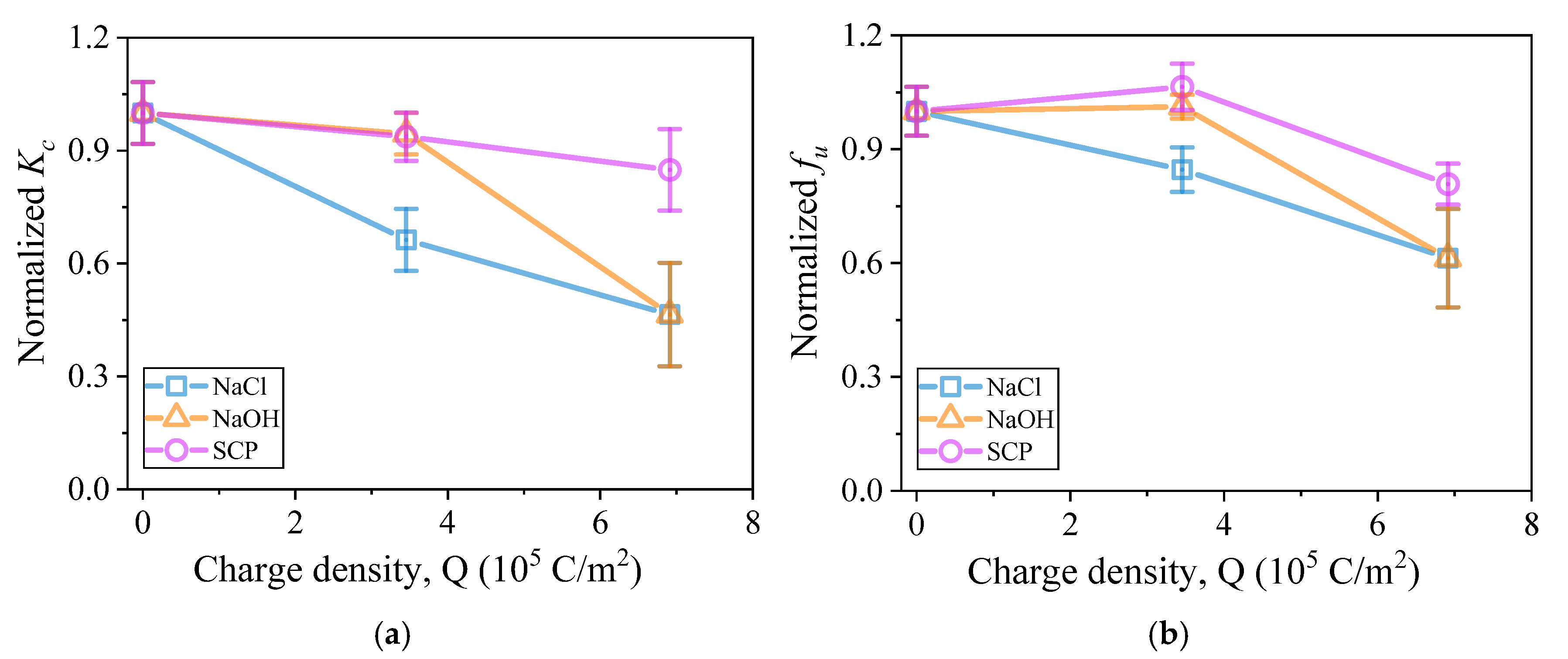

- The degrading effect of anodic polarization on the post-cracking modulus and peak strength of CFRCM composites was positively correlated with the charge density (the product of current density and polarization time) and was significantly modulated by the type of electrolyte solution. At a charge density of 691,200 C/m2, the property degradation was most pronounced in the NaCl solution (A: 54.5% reduction in modulus, 38.7% reduction in strength), while it was least significant in the simulated pore solution (C: 15.1% reduction in modulus, 19.2% reduction in strength).

- (5)

- Comparison with bare carbon fiber bundles directly exposed to the solutions revealed that the strength degradation of the bundles embedded within CFRCM composites was more severe. This highlights a critical issue caused by the mortar matrix: non-uniform current distribution. This non-uniformity induces more significant localized damage, thereby exacerbating the overall degradation of mechanical performance. Therefore, the non-uniform polarization effect resulting from the matrix must be considered in the durability assessment of CFRCM composite for long-term applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Broomfield, J.P. Corrosion of Steel in Concrete; CRC Press: London, UK, 2022; ISBN 9781003223016. [Google Scholar]

- Duan, L.; Wang, C.; Brühwiler, E.; Wang, Q. Experiments on the Flexural Behavior of Full-Scale PC Box Girders with Service Damage Strengthened by Prestressed CFRP Plates. Compos. Struct. 2023, 312, 116864. [Google Scholar] [CrossRef]

- Kotynia, R.; Oller, E.; Marí, A.; Kaszubska, M. Efficiency of Shear Strengthening of RC Beams with Externally Bonded FRP Materials—State-of-the-Art in the Experimental Tests. Compos. Struct. 2021, 267, 113891. [Google Scholar] [CrossRef]

- Hu, W.; Li, Y.; Yuan, H. Review of Experimental Studies on Application of FRP for Strengthening of Bridge Structures. Adv. Mater. Sci. Eng. 2020, 2020, 1–21. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-Reinforced Polymer Composites in Strengthening Reinforced Concrete Structures: A Critical Review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Byrne, A.; Norton, B.; Holmes, N. State-of-the-Art Review of Cathodic Protection for Reinforced Concrete Structures. Mag. Concr. Res. 2016, 68, 664–677. [Google Scholar] [CrossRef]

- Bertolini, L.; Pedeferri, P.; Redaelli, E.; Pastore, T. Repassivation of Steel in Carbonated Concrete Induced by Cathodic Protection. Mater. Corros. 2003, 54, 163–175. [Google Scholar] [CrossRef]

- Bhuiyan, S. Effectiveness of Impressed Current Cathodic Protection in Concrete Following Current Interruption. Master’s Thesis, University of Sheffield, Sheffield, UK, 2015. [Google Scholar]

- Polder, R.; Peelen, W. Cathodic Protection of Steel in Concrete—Experience and Overview of 30 Years Application. MATEC Web Conf. 2018, 199, 01002. [Google Scholar] [CrossRef]

- Cheaitani, A. Review of Cathodic Protection Systems for Concrete Structures in Australia. In Proceedings of the CORROSION 2017, New Orleans, LA, USA, 26–30 March 2017; pp. 3–4. [Google Scholar]

- Pedeferri, P. Cathodic Protection and Cathodic Prevention. Constr. Build. Mater. 1996, 10, 391–402. [Google Scholar] [CrossRef]

- Mietz, J.; Fischer, J.; Isecke, B. Cathodic Protection of Steel-Reinforced Concrete Structures—Results from 15 Years’ Experience. Mater. Perform. 2001, 40, 22–26. [Google Scholar]

- Polder, R.B.; Peelen, W.H.A. Service Life Aspects of Cathodic Protection of Concrete Structures; Taylor & Francis Group: Abingdon, UK, 2008. [Google Scholar]

- Zhu, J.; Su, M.-N.; Huang, J.; Ueda, T.; Xing, F. The ICCP-SS Technique for Retrofitting Reinforced Concrete Compressive Members Subjected to Corrosion. Constr. Build. Mater. 2018, 167, 669–679. [Google Scholar] [CrossRef]

- Su, M.; Liang, H.; Wei, L.; Ueda, T.; Xing, F.; Zhu, J.; Zeng, Z.W. Experimental Investigation on the ICCP-SS Technique for Sea-Sand RC Beams. In Proceedings of the Sixth International Conference on Durability of Concrete Structures, Leeds, UK, 18–20 July 2018. [Google Scholar]

- Su, M.; Wei, L.; Zeng, Z.; Ueda, T.; Xing, F.; Zhu, J.-H. A Solution for Sea-Sand Reinforced Concrete Beams. Constr. Build. Mater. 2019, 204, 586–596. [Google Scholar] [CrossRef]

- Sun, H.; Wei, L.; Zhu, M.; Han, N.; Zhu, J.; Xing, F. Corrosion Behavior of Carbon Fiber Reinforced Polymer Anode in Simulated Impressed Current Cathodic Protection System with 3% NaCl Solution. Constr. Build. Mater. 2016, 112, 538–546. [Google Scholar] [CrossRef]

- Zhu, J.; Guo, G.; Wei, L.; Zhu, M.; Chen, X. Dual Function Behavior of Carbon Fiber-Reinforced Polymer in Simulated Pore Solution. Materials 2016, 9, 103. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.-H.; Wei, L.; Moahmoud, H.; Redaelli, E.; Xing, F.; Bertolini, L. Investigation on CFRP as Dual-Functional Material in Chloride-Contaminated Solutions. Constr. Build. Mater. 2017, 151, 127–137. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, L.; Zhu, M.; Sun, H.; Tang, L.; Xing, F. Polarization Induced Deterioration of Reinforced Concrete with CFRP Anode. Materials 2015, 8, 4316–4331. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, J.-H.; Dong, Z.; Liu, J.; Liu, W.; Su, M.; Xing, F. Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials 2020, 13, 222. [Google Scholar] [CrossRef]

- Sun, H.; Memon, S.A.; Gu, Y.; Zhu, M.; Zhu, J.; Xing, F. Degradation of Carbon Fiber Reinforced Polymer from Cathodic Protection Process on Exposure to NaOH and Simulated Pore Water Solutions. Mater. Struct. 2016, 49, 5273–5283. [Google Scholar] [CrossRef]

- Mazzuca, P.; Ombres, L.; Guglielmi, M.; Verre, S. Residual Mechanical Properties of PBO FRCM Composites after Elevated Temperature Exposure: Experimental and Comparative Analysis. J. Mater. Civ. Eng. 2023, 35, 04023383. [Google Scholar] [CrossRef]

- Mazzuca, P.; Micieli, A.; Campolongo, F.; Ombres, L. Influence of Thermal Exposure Scenarios on the Residual Mechanical Properties of a Cement-Based Composite System. Constr. Build. Mater. 2025, 466, 140304. [Google Scholar] [CrossRef]

- Ombres, L.; Mazzuca, P.; Micieli, A.; Candamano, S.; Campolongo, F. FRCM–Masonry Joints at High Temperature: Residual Bond Capacity. J. Mater. Civ. Eng. 2025, 37, 04025012. [Google Scholar] [CrossRef]

- Asghari, H.; Omeman, Z.; Noel, M.; Hajiloo, H. Tensile Properties of Carbon Fabric-Reinforced Cementitious Matrix (FRCM) at High Temperatures. Structures 2023, 55, 85–96. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Bond between Textile-Reinforced Mortar (TRM) and Concrete Substrates: Experimental Investigation. Compos. Part B 2016, 98, 350–361. [Google Scholar] [CrossRef]

- Bencardino, F.; Carloni, C.; Condello, A.; Focacci, F.; Napoli, A.; Realfonzo, R. Flexural Behaviour of RC Members Strengthened with FRCM: State-of-the-Art and Predictive Formulas. Compos. Part B 2018, 148, 132–148. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U. Bond Characteristics of Different FRCM Systems. Constr. Build. Mater. 2018, 175, 610–620. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical Characterization of Textile Reinforced Inorganic-Matrix Composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Arboleda, D. Fabric Reinforced Cementitious Matrix (FRCM) Composites for Infrastructure Strengthening and Rehabilitation: Characterization Methods. Ph.D. Thesis, University of Miami, Coral Gables, FL, USA, 2014. [Google Scholar]

- Al-Lami, K.; D’Antino, T.; Colombi, P. Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review. Appl. Sci. 2020, 10, 1714. [Google Scholar] [CrossRef]

- Daneshvar, K.; Moradi, M.J.; Roshan, N.; Noel, M.; Hajiloo, H. Enhancing Flexural and Shear Capacities of RC T-Beams with FRCM Incorporating a Full FRCM-Concrete Bond. Constr. Build. Mater. 2025, 471, 140687. [Google Scholar] [CrossRef]

- Irandegani, M.A.; Zhang, D.; Shadabfar, M.; Kontoni, D.P.N.; Iqbal, M. Failure Modes of RC Structural Elements and Masonry Members Retrofitted with Fabric-Reinforced Cementitious Matrix (FRCM) System: A Review. Buildings 2022, 12, 653. [Google Scholar] [CrossRef]

- Liu, X.; Figueredo, G.P.; Gordon, G.S.D.; Thermou, G.E. Data-Driven Shear Strength Prediction of RC Beams Strengthened with FRCM Jackets Using Machine Learning Approach. Eng. Struct. 2025, 325, 119485. [Google Scholar] [CrossRef]

- Sheng, J.; Dou, G.; Bi, X.; Zhu, J.; Yu, Z. Experimental Study on the Flexural Fatigue Performance of TRC-Strengthened Corroded RC Beams. J. Build. Eng. 2025, 110, 113065. [Google Scholar] [CrossRef]

- Bertolli, V.; Sneed, L.H.; Focacci, F.; D’Antino, T. Shear Strengthening of RC Beams with U-Wrapped FRCM Composites: State of the Art and Assessment of Available Analytical Models. J. Compos. Constr. 2025, 29, 04024091. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Wang, Z.; Su, M.; Ueda, T.; Xing, F. C-FRCM Jacket Confinement for RC Columns under Impressed Current Cathodic Protection. J. Compos. Constr. 2020, 24, 4020001. [Google Scholar] [CrossRef]

- Elnassar, Z.; Abed, F.; Refai, A.E.; El-Maaddawy, T. FRCM Confinement of Concrete Columns: A Review of Strength and Ductility Enhancements. Compos. Struct. 2025, 370, 119389. [Google Scholar] [CrossRef]

- Jawdhari, A.; Adheem, A.H.; Kadhim, M.M.A. Parametric 3D Finite Element Analysis of FRCM-Confined RC Columns under Eccentric Loading. Eng. Struct. 2020, 212, 110504. [Google Scholar] [CrossRef]

- Kumar, P.; Arora, H.C.; Chidambaram, R.S.; Kumar, A. Prediction of Confined Compressive Strength of Concrete Column Strengthened with FRCM Composites. Struct. Concr. 2025, 26, 879–908. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Hofer, L.; Pellegrino, C. Experimental Behavior of Reinforced Concrete Columns Confined with Carbon-FRCM Composites. Constr. Build. Mater. 2020, 243, 118296. [Google Scholar] [CrossRef]

- Zhu, M.; Zhu, J.; Ueda, T.; Matsumoto, K. Degradation Behavior of Multifunctional Carbon Fabric-Reinforced Cementitious Matrix Composites under Anodic Polarization. Constr. Build. Mater. 2022, 341, 127751. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, C.; Song, G.; Zheng, D.; Guo, Y.; Huang, X. Electrochemical Activity and Damage of Single Carbon Fiber. Materials 2021, 14, 1758. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, Y.; Yang, C. Stripping Mechanism of PAN-Based Carbon Fiber during Anodic Oxidation in NaOH Electrolyte. Appl. Surf. Sci. 2019, 486, 128–136. [Google Scholar] [CrossRef]

- Zhu, J.-H.; Li, Q.; Pei, C.; Yu, H.; Xing, F. Evolution Mechanism of Carbon Fiber Anode Properties for Functionalized Applications: Impressed Current Cathodic Protection and Structural Strengthening. Engineering 2025, in press. [Google Scholar] [CrossRef]

- Pei, C.; Yu, H.; Zhu, J.; Xing, F. Efficient Multifunctional Modification of Commercial Carbon Fiber Through Tailored Carbon Layer Structure. Engineering 2024, 55, 191–203. [Google Scholar] [CrossRef]

- Yu, H.; Li, Q.; Zhu, J.-H.; Xing, F. Anodic Degradation Behaviour of Carbon Fibre in CFRP at High-Chloride and -Alkali Condition. Constr. Build. Mater. 2024, 417, 135241. [Google Scholar] [CrossRef]

- Zhu, J.H.; Wu, X.Y.; Mohamed, I.M.A.; Xing, F. Electrochemical and Microstructural Evaluation of Acidification Damage Induced by Impressed Current Cathodic Protection after Incorporating a Hydroxy Activated-Mg/Al-Double Oxide in the External Anode Mortar. Constr. Build. Mater. 2021, 309, 125116. [Google Scholar] [CrossRef]

- Koster, T.; Peelen, W.; Larbi, J.; de Rooij, M.; Polder, R. Numerical Model of Ca(OH)2 Transport in Concrete Due to Electrical Currents. Mater. Corros. 2010, 61, 518–523. [Google Scholar] [CrossRef]

- Guo, W.; Hu, J.; Ma, Y.; Huang, H.; Yin, S.; Wei, J.; Yu, Q. The Application of Novel Lightweight Functional Aggregates on the Mitigation of Acidification Damage in the External Anode Mortar during Cathodic Protection for Reinforced Concrete. Corros. Sci. 2020, 165, 108366. [Google Scholar] [CrossRef]

- Zeng, C.; Qin, S.; Deng, Z.; Zhu, M. In Situ Monitoring of Anodic Acidification Process Using 3D μ-XCT Method. Materials 2024, 17, 5662. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Liu, J.; Zhang, D.; Xie, Z.; Hong, J. Effect of ICCP on Bond Performance and Piezoresistive Effect of Carbon Fiber Bundles in Cementitious Matrix. Cem. Concr. Compos. 2024, 152, 105645. [Google Scholar] [CrossRef]

- Feng, R.; Zhang, J.; Zhu, J.-H.; Xing, F. Experimental Study on Interface Bonding Fatigue Behavior of C-FRCM Composites in ICCP. Constr. Build. Mater. 2020, 259, 120655. [Google Scholar] [CrossRef]

- Feng, R.; Zhang, J.; Zhu, J.-H.; Xing, F. Experimental Study on the Behavior of Carbon-Fabric Reinforced Cementitious Matrix Composites in Impressed Current Cathodic Protection. Constr. Build. Mater. 2020, 264, 120655. [Google Scholar] [CrossRef]

- Wei, L.L.; Zhu, J.-H.; Ueda, T.; Su, M.; Liu, J.; Liu, W.; Tang, L.-P.; Xing, F. Tensile Behaviour of Carbon Fabric Reinforced Cementitious Matrix Composites as Both Strengthening and Anode Materials. Compos. Struct. 2020, 234, 111675. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, D.; Tao, Y.; Xie, Z.; Yi, B. Effect of ICCP on Tensile Performance and Piezoresistive Effect of CFRCM Plates. Eng. Struct. 2024, 313, 118317. [Google Scholar] [CrossRef]

- Wei, L.; Zheng, Y.; Tian, J.; Shen, H.; Zhu, J. Effects of Hybrid Fibers and Anodic Polarization on Mechanical Performance of Carbon Fabric Reinforced Cementitious Matrix (C-FRCM). Eng. Struct. 2025, 336, 120302. [Google Scholar] [CrossRef]

- NACE TM0294-2016; Testing of Embeddable Impressed Current Anodes for Use in Cathodic Protection of Atmospherically Exposed Steel-Reinforced Concrete. AMPP: Houston, TX, USA, 2016.

- ISO 19097-1:2018; Accelerated Life Test Method of Mixed Metal Oxide Anodes for Cathodic Protection—Part 1: Application in Concrete. ISO: Geneva, Switzerland, 2018.

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013; p. 69.

- Brameshuber, W. Recommendation of RILEM TC 232-TDT: Test Methods and Design of Textile Reinforced Concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- ASTM D638-10; Test Method for Tensile Properties of Plastics. ASTM Int.: West Conshohocken, PA, USA, 2010; pp. 1–16.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhu, M.; Zhang, Y.; Chen, H.; Deng, J.; Zeng, C. Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions. J. Compos. Sci. 2026, 10, 16. https://doi.org/10.3390/jcs10010016

Zhu M, Zhang Y, Chen H, Deng J, Zeng C. Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions. Journal of Composites Science. 2026; 10(1):16. https://doi.org/10.3390/jcs10010016

Chicago/Turabian StyleZhu, Miaochang, Yawen Zhang, Haorui Chen, Jun Deng, and Chaoqun Zeng. 2026. "Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions" Journal of Composites Science 10, no. 1: 16. https://doi.org/10.3390/jcs10010016

APA StyleZhu, M., Zhang, Y., Chen, H., Deng, J., & Zeng, C. (2026). Degradation of Tensile Properties in CFRCM Composites Under Anodic Polarization: Role of Standardized Electrolyte Solutions. Journal of Composites Science, 10(1), 16. https://doi.org/10.3390/jcs10010016