1. Introduction

Shot peening is a surface treatment widely used in the aerospace industry to enhance the fatigue strength of metal structural components [

1]. It works by bombarding the surface of a metal part with small steel pellets called “shot” at high velocities. The impacts of the shot with the surface of the material results in localized plastic deformation and compressive residual stresses which help to prevent the initiation of cracks [

2]. Though most aerospace components are sufficiently stiff so the residual stresses imparted by shot peening have little effect on their shape, this is not the case for thin metal panels such as wing skins [

3]. In fact, it is common in the aerospace industry to use shot peening specifically as a process to contour thin metal parts, as it allows for more continuous contours than a traditional procedure such as brake forming [

4].

Historically, generating the “recipes” to form metal panels with shot peening has relied primarily on trial and error. The intensity of a shot peen operation describes the extent of plastic deformation in the material and thus the residual stress distribution [

5,

6]. As such, obtaining a shot peen forming recipe requires a map of intensity vs. position on the surface of a panel which, when carried out, obtains a desired contour of the part. In order to streamline the laborious process of obtaining these recipes through trial and error, a number of authors have investigated predictive models of the shot peen process. Two early approaches to modeling shot peen forming are [

7], where the exact characteristics of the residual stress distribution are ignored in favor of a linear elastic model incorporating stress resultants, and [

8], in which temperature inputs are used to model experimentally determined residual stress distributions. The benefit of the first approach is that only the net force and moment resultants of the residual stress distribution are required, but this may come at the cost of accuracy of the simulated solution. Variants of the latter approach—where a high-fidelity model of the shot peen process is used to make predictions of the deformed contour—make up the majority of follow-up works.

In the spirit of high-fidelity simulations of the shot peen process, many subsequent works have opted to directly simulate the collisions themselves in place of imposing the residual stress distribution that arises from the collisions. In [

9], up to 1000 impacts involving plastic deformation of the shot with the panel are directly simulated. In [

10], a smaller number of collisions are used to estimate the effects of shot peening. The authors in [

11] aspire to make these impact models more scalable by coupling discrete and continuum models of the shot peen process. Another explicit collision simulation work is [

12], where the shot peen process is implemented in a commercial finite element code. While highly representative of the underlying physics of the shot peen process, these collision simulations are extremely expensive due to their dynamical nature and the nonlinearity introduced by contact and plastic deformation. This computational expense tends to render the inverse problem intractable. We note that it is possible to break the problem into two steps by first simulating plastic collisions and then using the resulting strain field as an input to a static model [

13].

An alternative to directly simulating collisions is the so-called “eigenstrain” method, in which an experimentally characterized residual strain field can be introduced as a source term in the governing equations for stress equilibrium [

14,

15]. Our review suggests that methods which use experimental results on the through-thickness stress and/or strain distribution as source terms in a numerical simulation are the most popular. For example, in [

16], though not an eigenstrain method, a known residual stress distribution is introduced to the governing equations in order to predict the deformation. Some other works use thermal loads as a tool to introduce an experimentally determined plastic strain distribution [

17,

18]. Using these methods, a recent work has proposed a pipeline for total automation of the shot peen forming process [

19]. The experiments required to obtain the residual stress and strain profiles require complex machinery and processing techniques [

20,

21,

22] and thus represent a bottleneck in building predictive models of shot peen forming.

Because shot peen forming recipes need to be designed on a part-by-part basis, it is important for any modeling approach to be able to solve the inverse problem, which maps a desired displacement field to a specific intensity distribution over the part’s surface. In one work, the eigenstrain method is used to solve the inverse problem for the peening distribution of interest [

23]. In [

24], a novel non-Euclidean plate model is used to solve the inverse problem [

24]. Finally, some recent works have made use of neural networks as surrogate models for the relation between intensity and deformation, which, due to the low cost of a forward evaluation, are useful for solving inverse problems [

25,

26].

In this paper, we return to the ideas of one of the foundational early studies on modeling shot peen forming, where only resultants of the through-thickness stress distribution are used to predict deformation [

7]. However, unlike past works, we rely only on the moment resultant from the through-thickness stress distribution, which can be estimated from simple measurements taken from uniformly shot peened plates. This obviates the more complex experimental efforts required to obtain the full residual stress and/or strain distribution in the peened material. Thus, our contributions in this work are as follows:

We use thermoelasticity to derive the governing equations for bending of a Kirchhoff plate driven by an applied torque distribution;

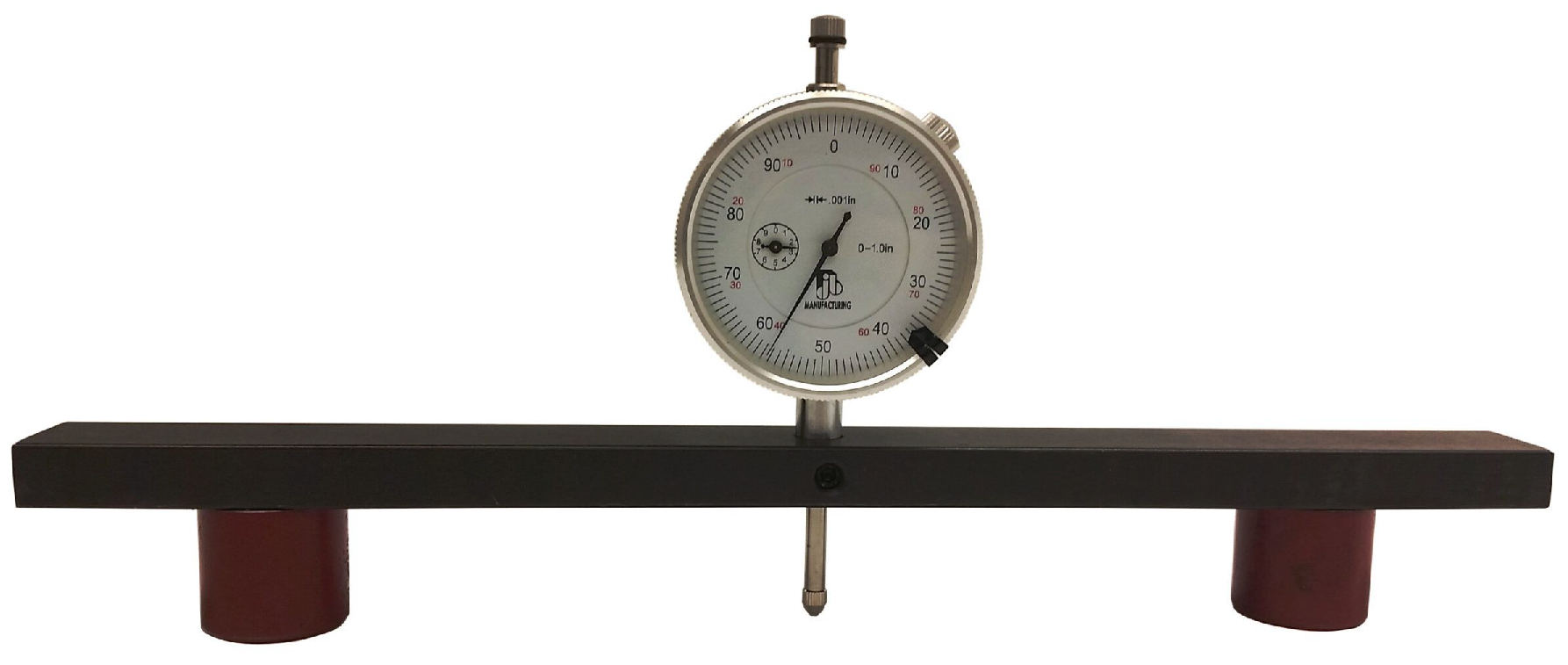

We devise a simple, non-invasive experiment to calibrate the thermal model to the shot peen process by extracting an “effective torque” parameter;

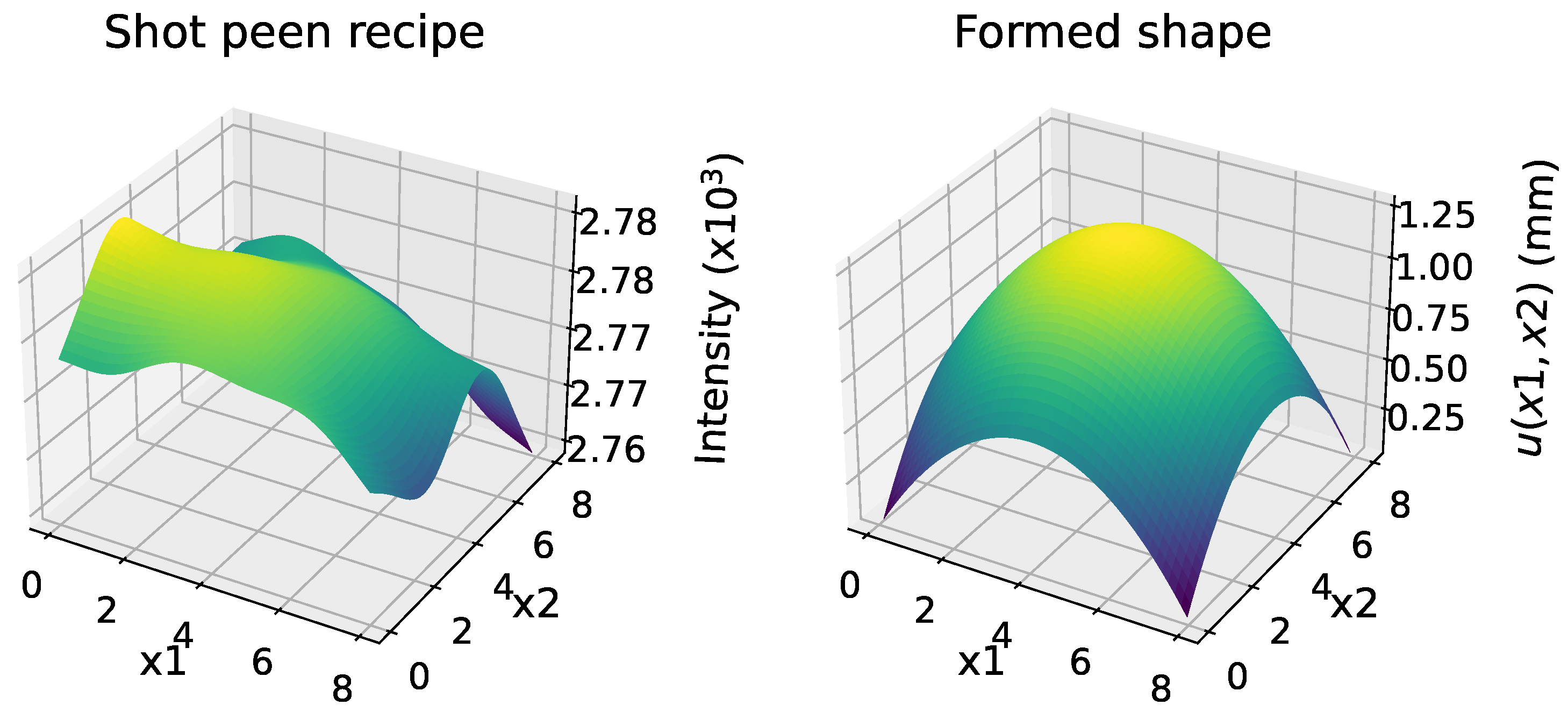

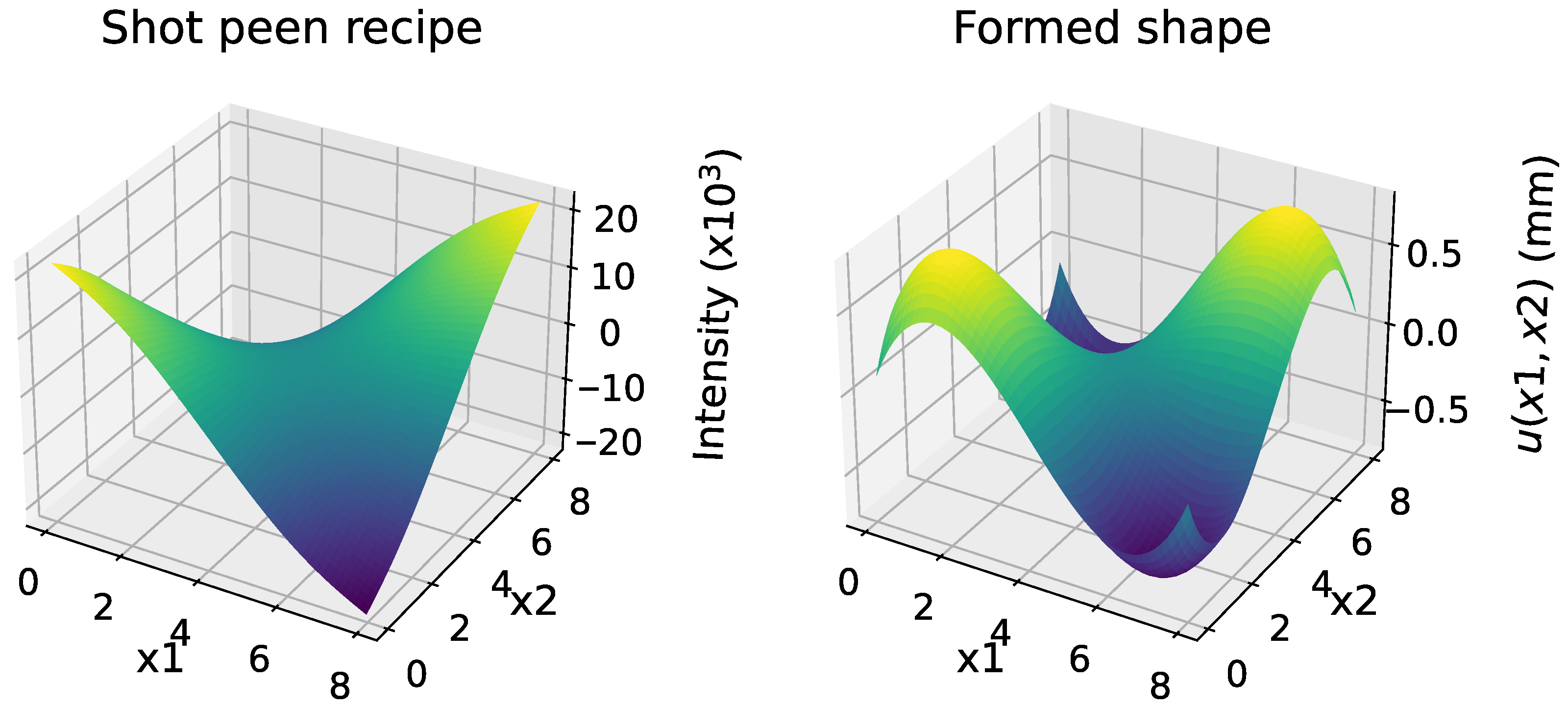

We introduce a novel regularization of the inverse problem which encourages shot peening recipes which can be realized by existing shot peen machines;

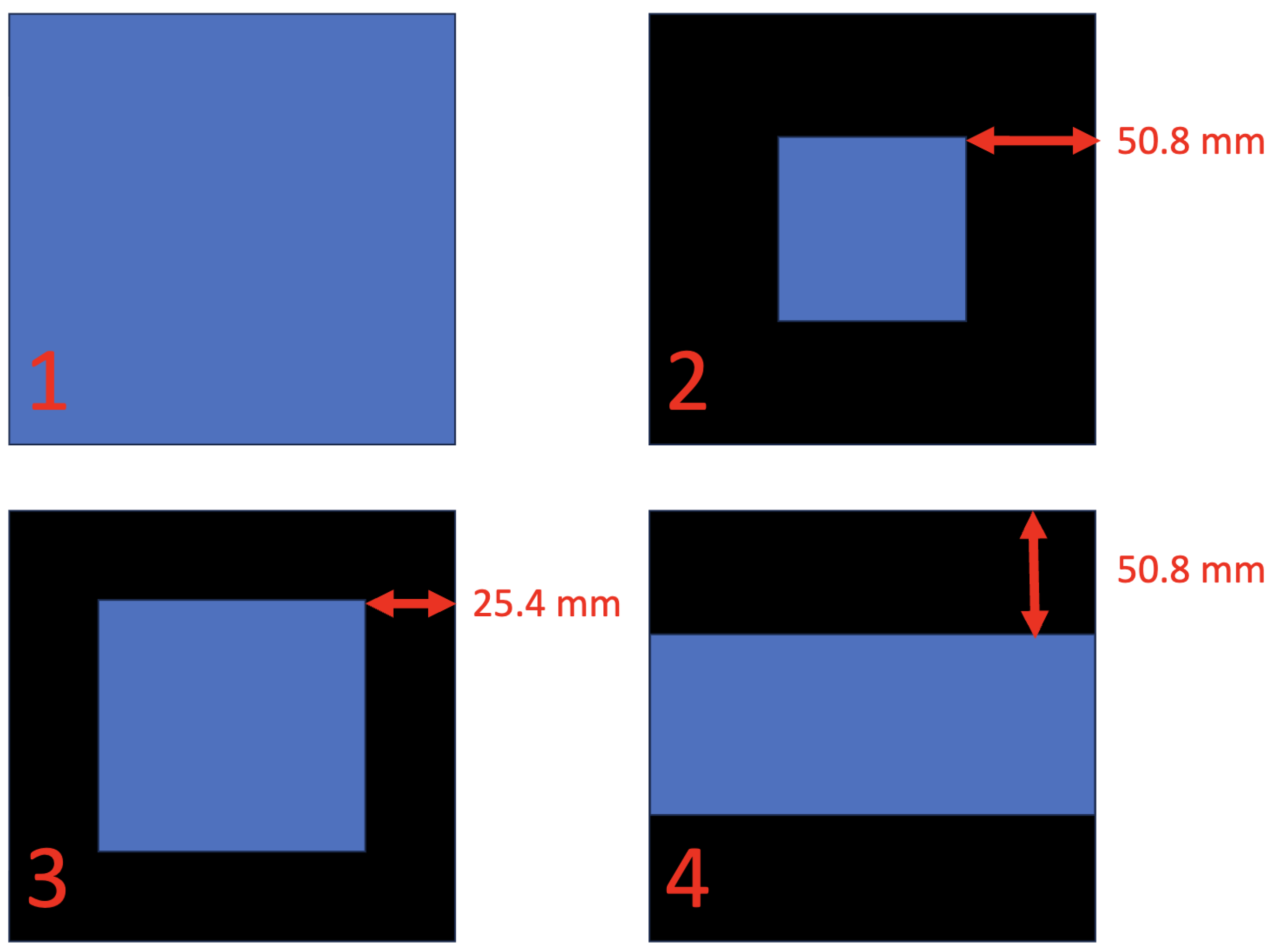

We compare the predictions of our calibrated model to experimental results obtained from the application of spatially varying shot peen distributions to test samples.

The rest of this paper is organized as follows. In

Section 2, we introduce the constitutive relation for a thermoelastic material and the kinematic assumptions of Kirchhoff plate bending. With these in hand, we then derive the variational energy functional whose minimum governs the solution. In

Section 3, we develop an experimental test which is used to connect the modeling framework of temperature distributions to real shot peen operations. In

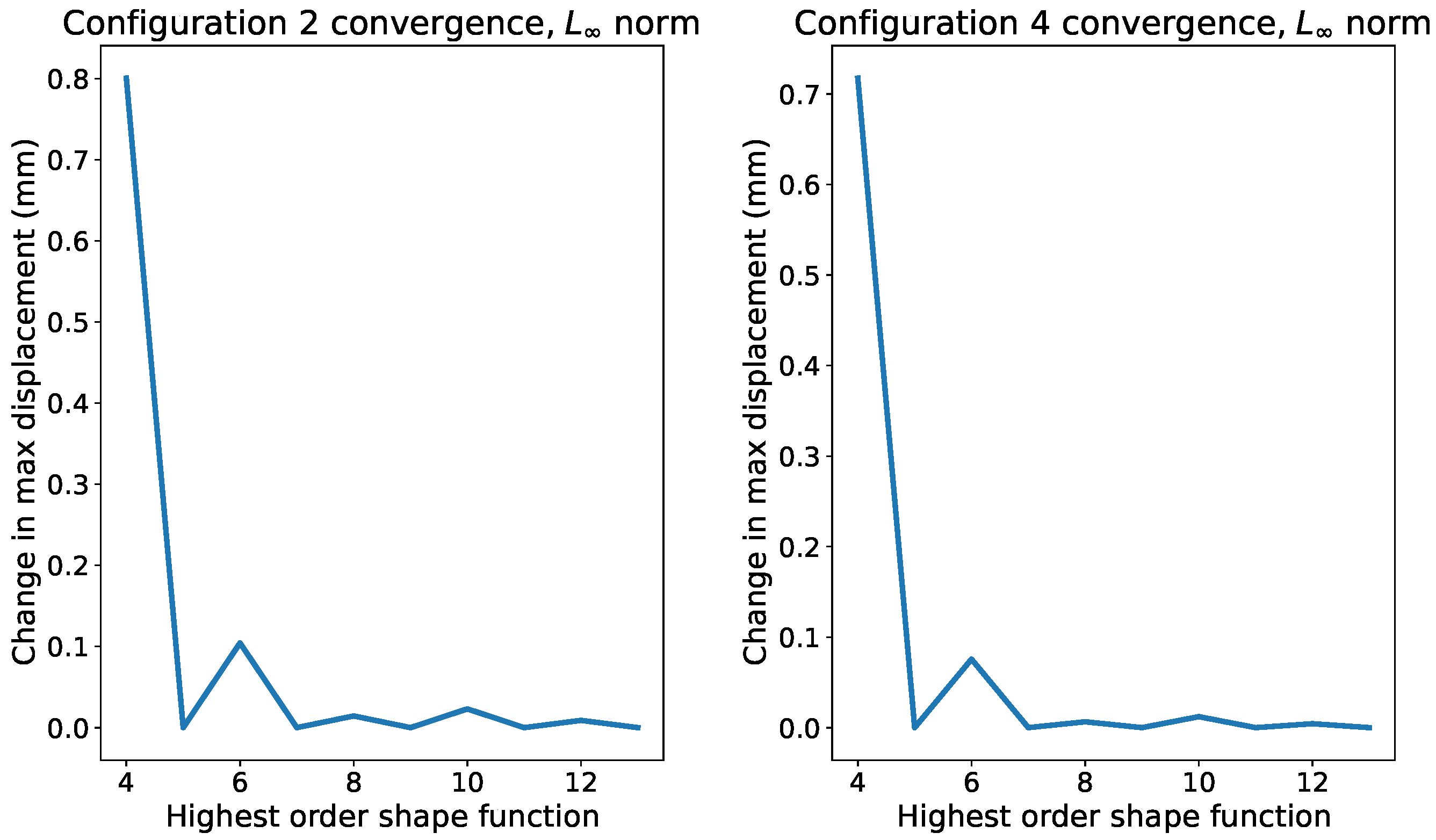

Section 4, we derive the numerical solution procedure and a technique for handling the unconventional boundary conditions used in modeling shot peen forming. In

Section 5, we devise a method for treating inverse problems through which a physically realizable peening distribution required to obtain specified displacements. In

Section 6, we outline our experimental set up and the results of the experiment conducted to validate the proposed model. In

Section 7, we discuss the agreement of the model predictions with the experiment and close with concluding remarks and directions for future work.

3. Moment–Intensity Relation

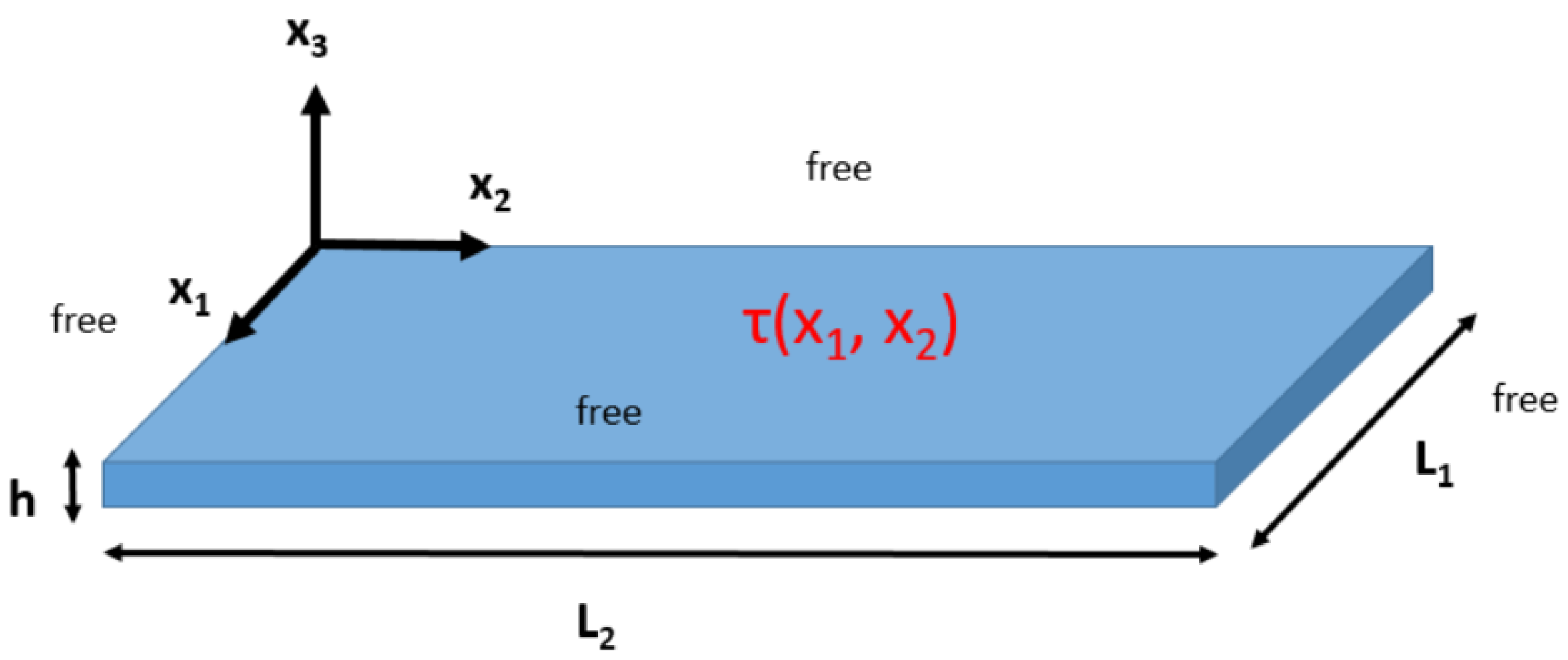

We seek to design an experiment to extract the thermal moment which corresponds to shot peening a thin plate at a given intensity. This forms the link between the real shot peening operation and the thermoelastic plate model. We assume that the thermal moment is only a function of the intensity of the shot peening operation. This means that a uniformly peened plate has a spatially constant thermal moment. In order to proceed, let us look at the bending moment distribution within the plate:

The bending moments associated with the through-thickness stress distribution are zero because there are no applied external forces or moments. With a constant thermal moment

in Equation (

6), it is necessary that the transverse displacement has the following form:

where we assume in this section that the origin of the coordinate system is at the center of the plate (as opposed to a corner) in order to avoid linear terms in the displacement of Equation (

7). This form of bending displacement is a consequence of the ansatz that a uniformly peened plate has spatially constant thermal moment. Now, plugging Equation (

7) into Equation (

6), we obtain the following system of equations:

which immediately shows that

. Using the definitions of

and

, these equations can be solved to find that

. Thus, the relation between the displacement and thermal moment is

We now can conduct an experiment to determine the connection between the shot peening operation and the thermal moment. We consider a test sample with side lengths

and

. The thickness

h of the test sample should be the same as the plate we ultimately wish to model, as the thermal moment associated with shot peening may depend on the plate thickness. This is equivalent to the observation that the details of the through-thickness residual stress distribution from shot peening depend on the sample thickness [

20]. The geometry of the test sample is unimportant so long as it is rectangular. The maximum displacement is obtained at the corner of the plate (given our choice of coordinate system), which allows us to calculate the relation between the thermal moment and the maximum displacement. Looking only at the magnitude of the displacement in Equation (

8), the relation between the maximum displacement, the sample geometry, and the thermal moment is

In practice,

is the height the sample rises to after being uniformly peened on one side. This is a quantity which is straightforward to measure experimentally, thus Equation (

9) provides a procedure to calibrate the thermoelastic model to the shot peening operation. In other words, we only need to measure the maximum displacement of a uniformly peened plate in order to extract the thermal moment corresponding to shot peening at a given intensity. In general, we expect that the thermal moment depends on the plate material and thickness. Thus, in order to calculate the thermal moment associated with shot peening for a given material and thickness, a series of tests can be carried out where a plate is fully peened at different intensities and the maximum displacement is measured. This displacement is then related to the thermal moment

and stored as in

Table 1.

The intensity

I of the shot peen procedure is defined as the maximum displacement (in inches) of a standardized steel “Almen” strip after being uniformly peened on one side [

28], so for these plates,

. Assuming there is still a linear relationship between intensity and displacement for other materials and plate thicknesses, we can write

where the constant of proportionality

K combines the empirical intensity–displacement and the analytical displacement–moment relationships. With this assumption of linearity, the experiments used to calibrate the model are tasked with estimating the slope

K for given thicknesses and materials. We note that the assumed linear relationship between intensity and displacement need not hold beyond Almen strips. Approximating this relationship as linear is parsimonious in the sense that few shot peen tests are required, but whether it is sufficiently fine-grained depends on the needs of the analyst. We note also that the sign of the thermal moment can be controlled by shot peening different sides of the plate.

5. Inverse Problem

Given that shot peen forming is used as a technique to obtain pre-specified contours in metal plates, a model for the shot peen process should be well equipped to solve inverse problems, where the inverse problem finds a shot peen distribution that gives rise to a specified plate geometry. Until now, we have treated the thermal moment as a known input and the displacement as the unknown response. Equation (

15) is equally valid in both directions, meaning that we can input a known displacement field to solve for the required loads. However, the relationship between displacements specified at a finite set of points and corresponding shot peen distributions is non-unique, which suggests that the inverse problem needs to be regularized. We assume that the target displacement is stored at a discrete set of points in space. We wish to regularize the inverse problem in such a way that the peening distributions we obtain are “physical” in the sense that they can be realized on real shot peen machines. This translates to minimizing gradients of the intensity, as it is difficult in practice to peen a plate with complex, high-frequency intensity distributions.

We begin our treatment of the inverse problem by making the dependence of the displacement constraints on the thermal moment explicit. Given that the force vector in Equation (

13) can be decomposed into a matrix-vector product, we can rewrite Equation (

15) as

where

is the matrix which takes the coefficients on the thermal moment

to the force vector

per Equation (

13). The matrix

is

with three rows of zero appended to the bottom and it is introduced to isolate the thermal moment coefficients. Now, we introduce a truncation operator

which takes a vector of length

to length

by removing the final three entries. The displacement coefficients can then be written as an explicit function of the thermal moment:

Assuming that the displacement field is specified at

P points given by

, we use the discretization of the displacement to write the constraints as

This system of equations can be cast in matrix form by defining the matrix

. The constraint equation is then

where

. Finally, we use

to denote the inverse of the expanded system matrix in Equation (

16). The constraints can then be written as a function of the moment coefficients via a series of matrix operations:

Having written the displacement constraints in terms of the thermal moment, we can now introduce the regularization for the inverse problem. We seek to minimize a functional of the thermal moment

which encourages physically realizable shot peen distributions subject to the constraints of Equation (

17). In practice, we cannot apply arbitrarily large shot peen intensities, nor arbitrarily complex intensity distributions. The optimal shot peen distribution is both small in magnitude and as close to constant as possible. This suggests choosing a functional which penalizes large values of both

and its derivatives. The chosen regularization functional

takes combinations of the square of the thermal moment and all its derivatives up to the second order:

The plate side lengths are used to scale the derivatives and to normalize units. Using the discretization of the thermal moment, this expression becomes

which is a quadratic form in the thermal moment coefficients. We call the matrix which specifies our measure of the thermal moment

, so that Equation (

18) becomes

. Thus, we seek a minimum to Equation (

18) subject to Equation (

17). The method of Lagrange multipliers states that we extremize the Lagrange function given by

where

are the Lagrange multipliers. We set the gradient of this function with respect to the coefficients on the thermal moment and the Lagrange multipliers to zero in order to obtain the condition for a stationary point. This reads

The two systems of equations can be combined into a single system using block matrices with

The coefficients on the thermal moment can be calculated by solving Equation (

19). We note that the size of the discretization for the thermal moment (

) and the number of constraints on the displacement (

P) cannot be chosen independently of each other. A solution to Equation (

19) may cease to exist when there are more constraints on the displacement than there are degrees of freedom in the thermal moment discretization. Equation (

19) defines a conceptually straightforward and computationally inexpensive approach to constructing recipes for shot peen forming of unconstrained plates.

7. Conclusions

We hypothesized a model for shot peen forming which allows plasticity to be neglected and which avoids reliance on complex experiments to obtain the residual stress/strain distribution in the material. In particular, we hypothesized that shot peen forming can be modeled with spatially varying applied torques. We opted to use the modeling framework of thermoelasticity in order to introduce these spatially varying torques. With the caveat that this relationship is dependent on both the material and thickness of the plate, a test was devised to extract the effective torque corresponding to shot peening at a given intensity. In order to simplify the experimental procedure, we assumed that the relationship between shot peen intensity and forming displacement in the calibration sample was linear, which, as demonstrated in the inverse problem, meant that only one intensity setting was needed for the thermoelastic model. Then, a numerical method was developed and implemented in order to solve the thermoelastic equations for the fully free boundary conditions relevant to shot peen forming. An inverse method was formulated in order to generate shot peen forming recipes from the desired contour of a plate. Finally, an experiment was designed by which to test the proposed thermoelastic model and uncertainty quantification was used to carefully compare model predictions to the results of the experiment.

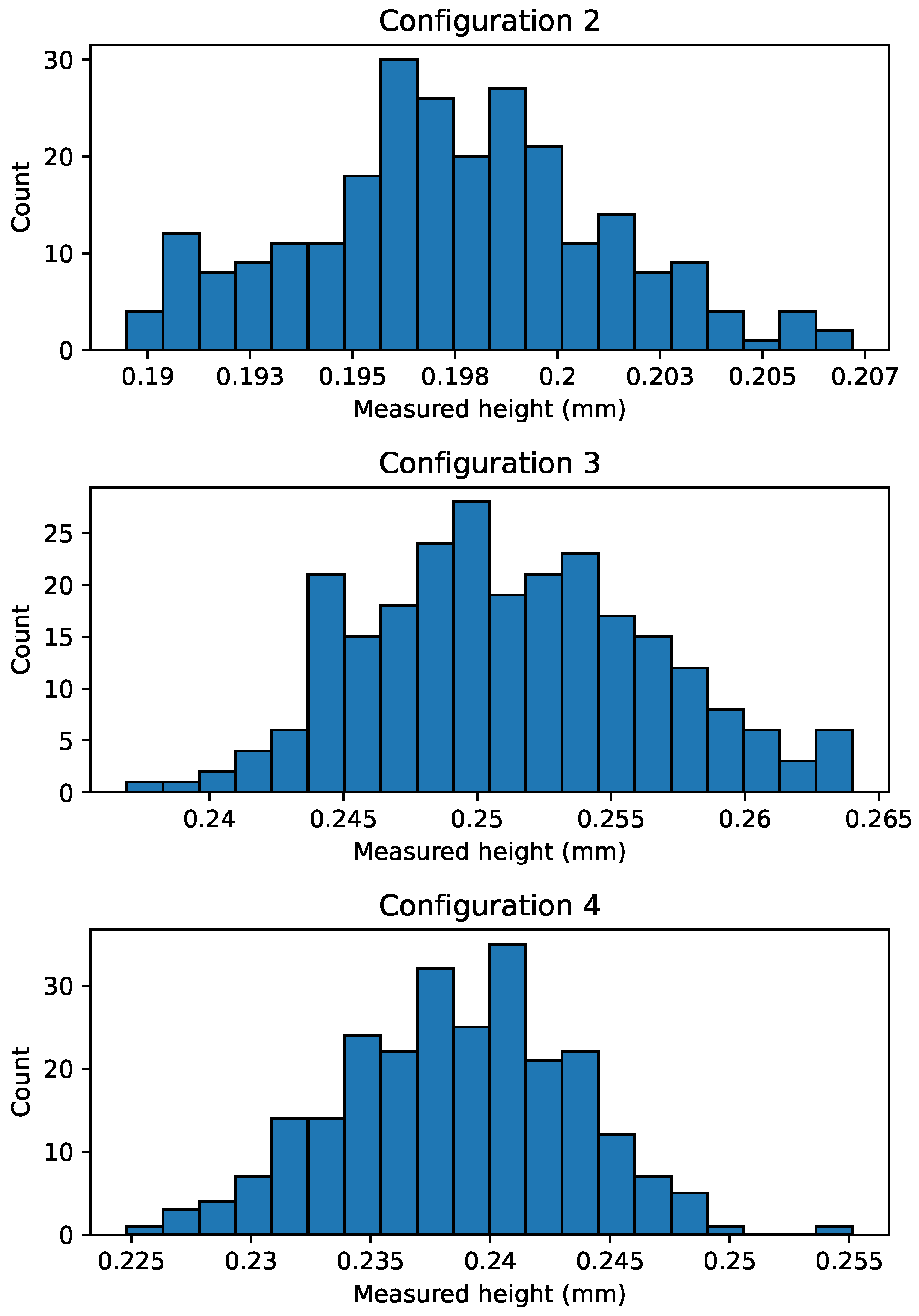

Figure 8 shows the comparison of our model to measurements taken from the test samples. We see that three values of the measured height of the test samples fall within the two standard deviation range of uncertainty on the model predictions. Five measurements were larger than the model predictions and one smaller. The data suggest that the model tends to underestimate the experimental measurements, though for Configuration 4 especially we observed significant variation underlying the shot peen process. Taking the average of the test data and comparing to the mean theoretical prediction, the model exhibits 10% relative error. While avoiding complex residual stress experiments, this level of error is on par with eigenstrain methods such as [

15]. However, the error our model obtains is notably greater than direct collision simulations such as [

10]. Though direct collision simulations may yield predictions for the forming displacement with an order of magnitude greater accuracy, by resolving the sample with a 3D finite element mesh and nonlinear constitutive models, the computational cost increases by multiple orders of magnitude. Whether the increased accuracy is worth the computational cost depends entirely on the needs of the analyst.

More testing is required to understand if the observed patterns are true systematic shifts in the model or simply artifacts of variation in the shot peen process. This should involve using different sample dimensions, materials, and further replication. By conducting calibration tests at more intensity settings, it is possible to either verify or relax the assumption of linearity between shot peen intensity and forming displacement, thus providing a higher degree of confidence in the accuracy of the implementation of our proposed model. In order to accommodate the anisotropic material properties introduced in the manufacturing process of many metal plates, the thermoelastic model could be extended to handle different material moduli in different directions. Thick plate bending models, such as that of Reissner and Mindlin, could be employed to extend the validity of our torque-based model to a wider class of panel geometries. Another direction of future work is to devise regularization schemes for the inverse problem which enforce locally constant shot peen intensities, as this is the most practical for many factory settings. Finally, in order to extend this model to larger plates, it is necessary to incorporate a distributed bending force to the model to account for the part’s own weight. In order to extend the effective torque approach to existing thermoelastic finite element codes, a through-thickness temperature distribution can be obtained from the measured thermal moment, which is discussed in

Appendix D. Such an extension to finite element analysis would enable the modeling of peened plates with more complex geometries.