Optimising WC-25Co Feedstock and Parameters for Laser-Directed Energy Deposition

Abstract

1. Introduction

2. Materials and Methods

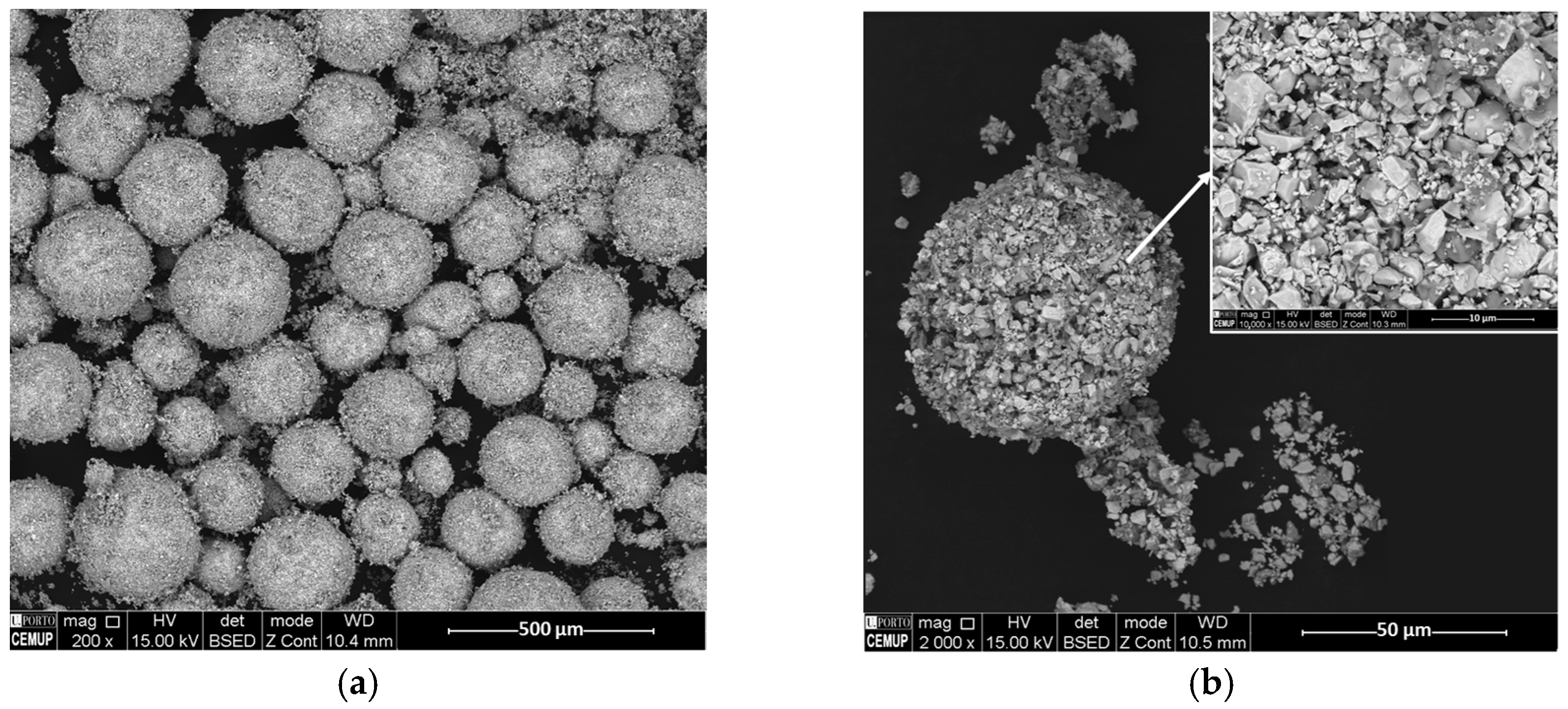

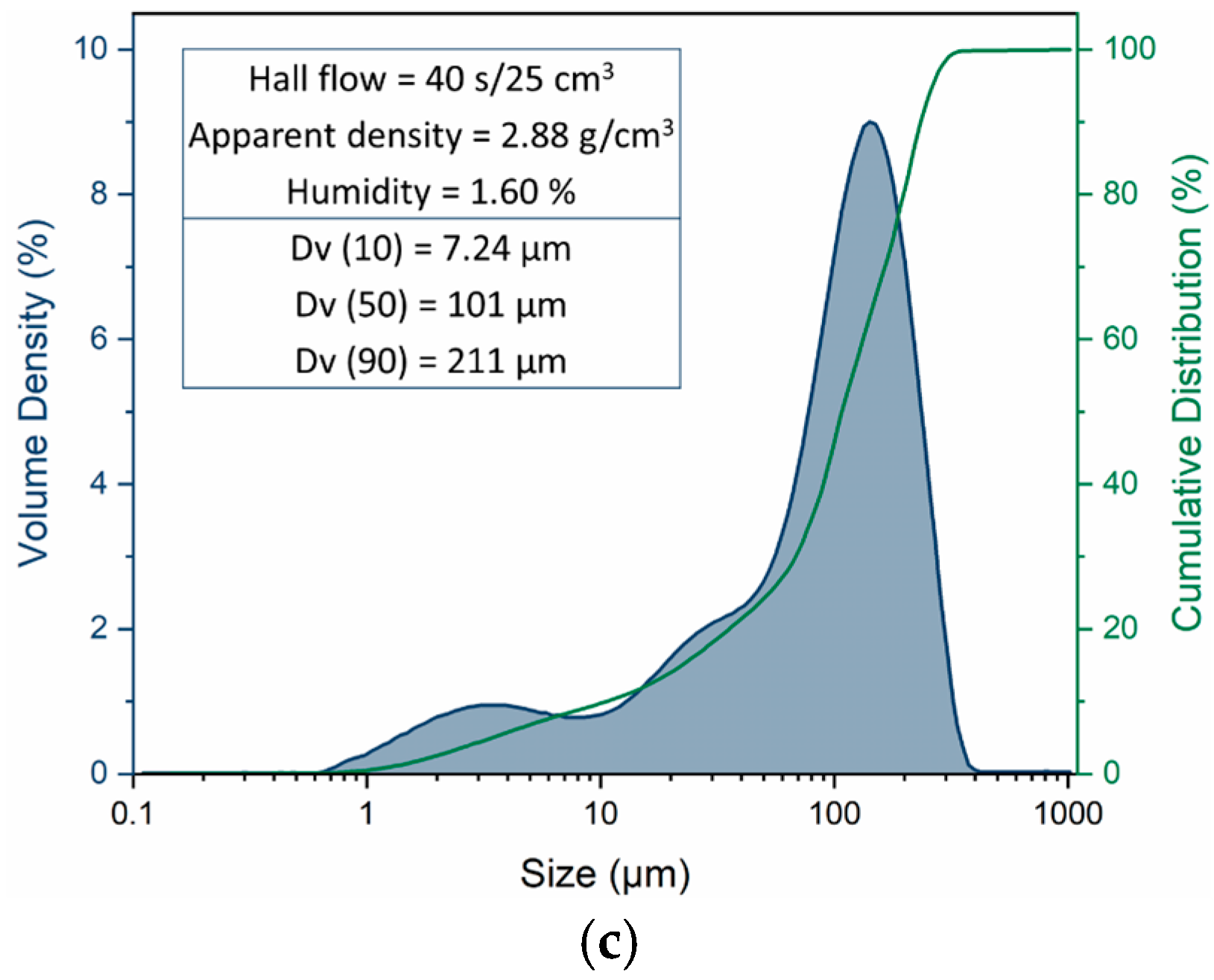

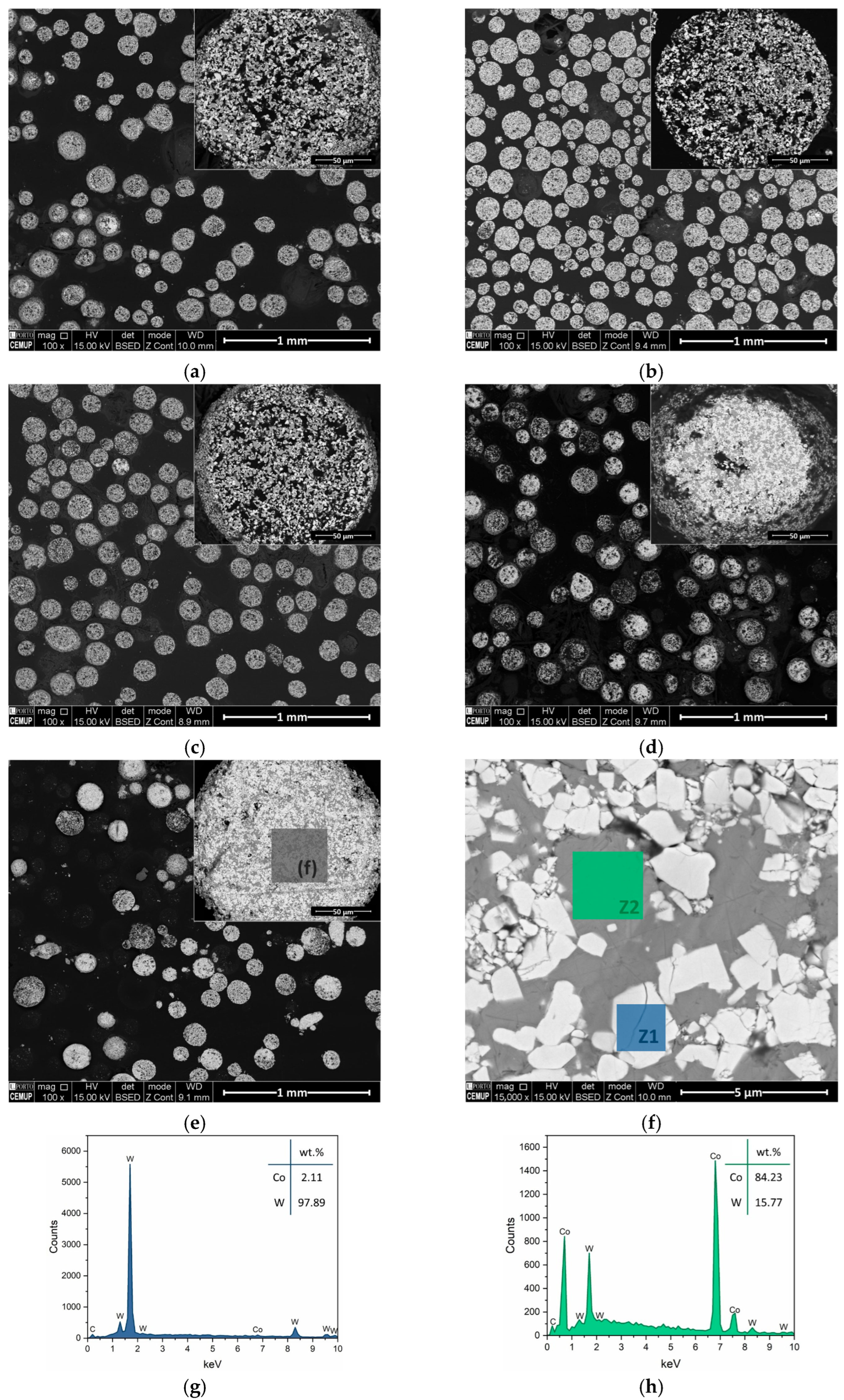

2.1. WC-Co Granules

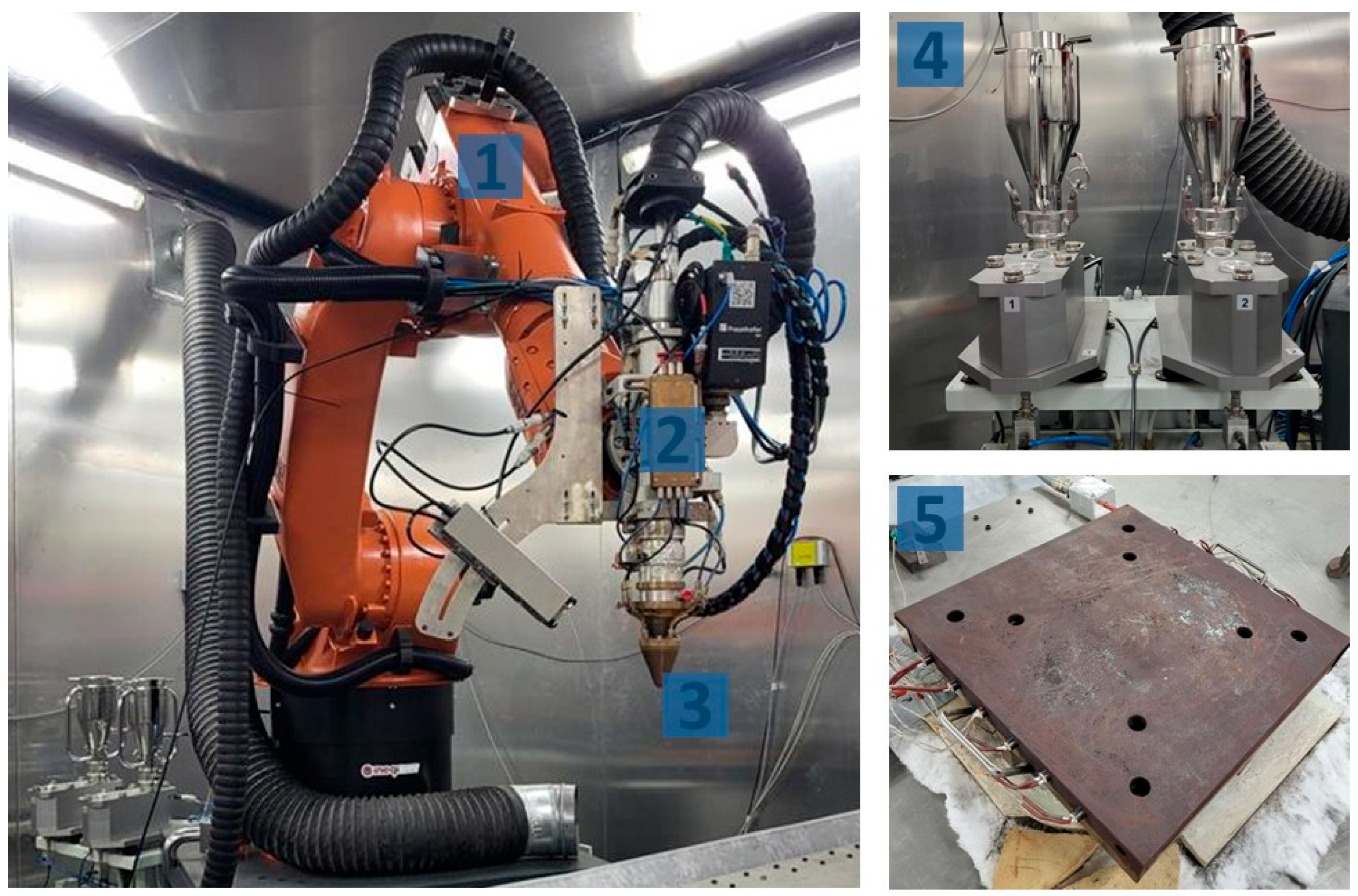

2.2. DED Deposition

- Six-axis KUKA industrial robot (Augsburg, Germany), on which the nozzle and powder splitter are assembled (1);

- Powder splitter from Fraunhoffer IWS (Dresden, Germany), used to distribute the powder through four output channels (2);

- COAX12V6 nozzle head from Fraunhoffer IWS (Germany), featuring cooling capacity up to 6000 W, when working in continuous mode (3);

- Two Medicoat AG disc powder feeders (Mägenwil, Switzerland), that allow smooth powder flow (without pulsation) between 0.5 g/min and 100 g/min (4);

- Coherent Highlight FL3000 laser source (Santa Clara, CA, USA), capable of delivering 3000 W in continuous wave, producing a laser with a spot size of 2.1 mm.

- Argon as shielding gas regulated to 6 bar pressure and a constant flow of 10 L/min in all deposits;

2.3. Taguchi Metodology

2.4. Material Characterisation

3. Results and Discussion

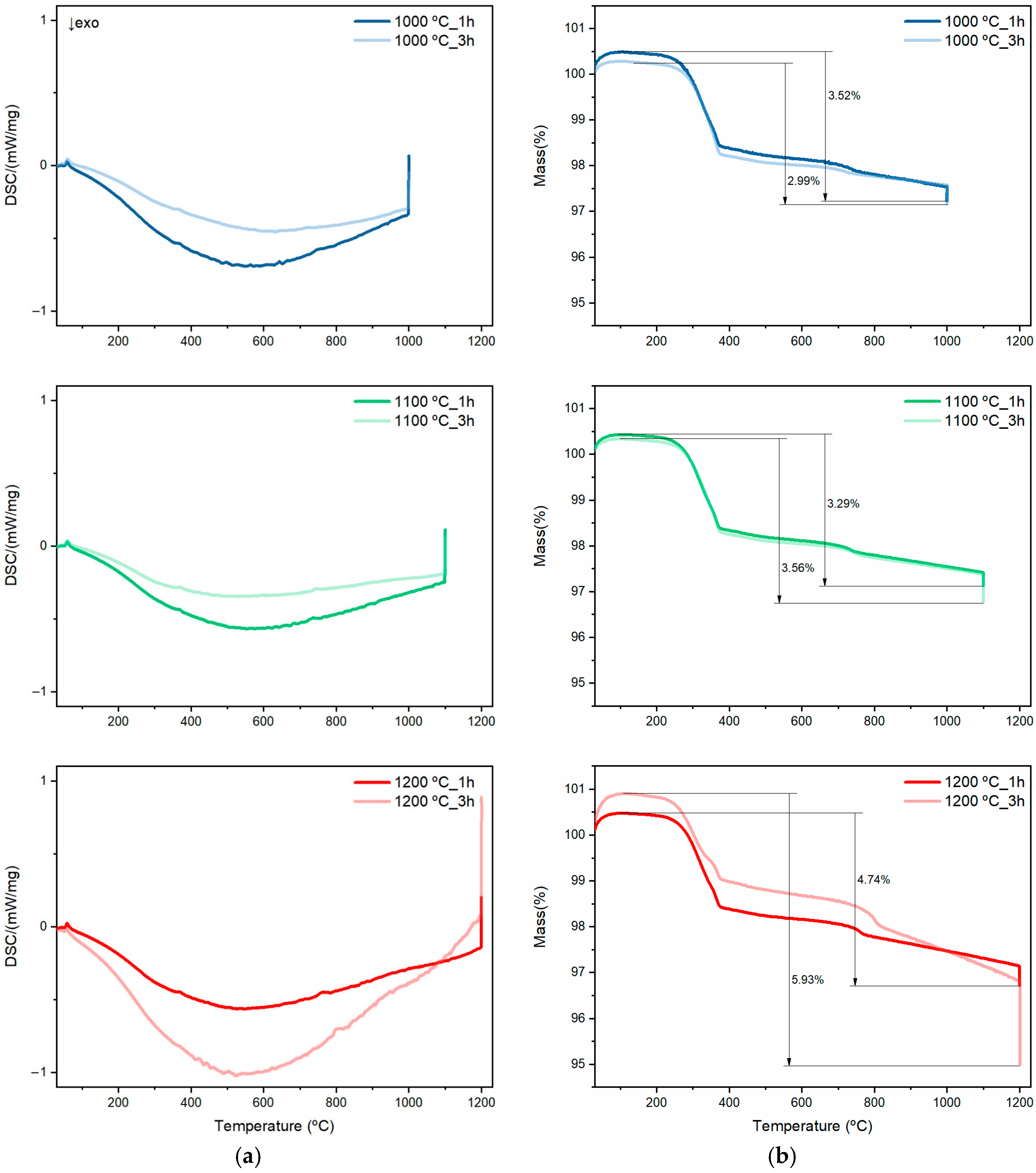

3.1. Thermal Treatment

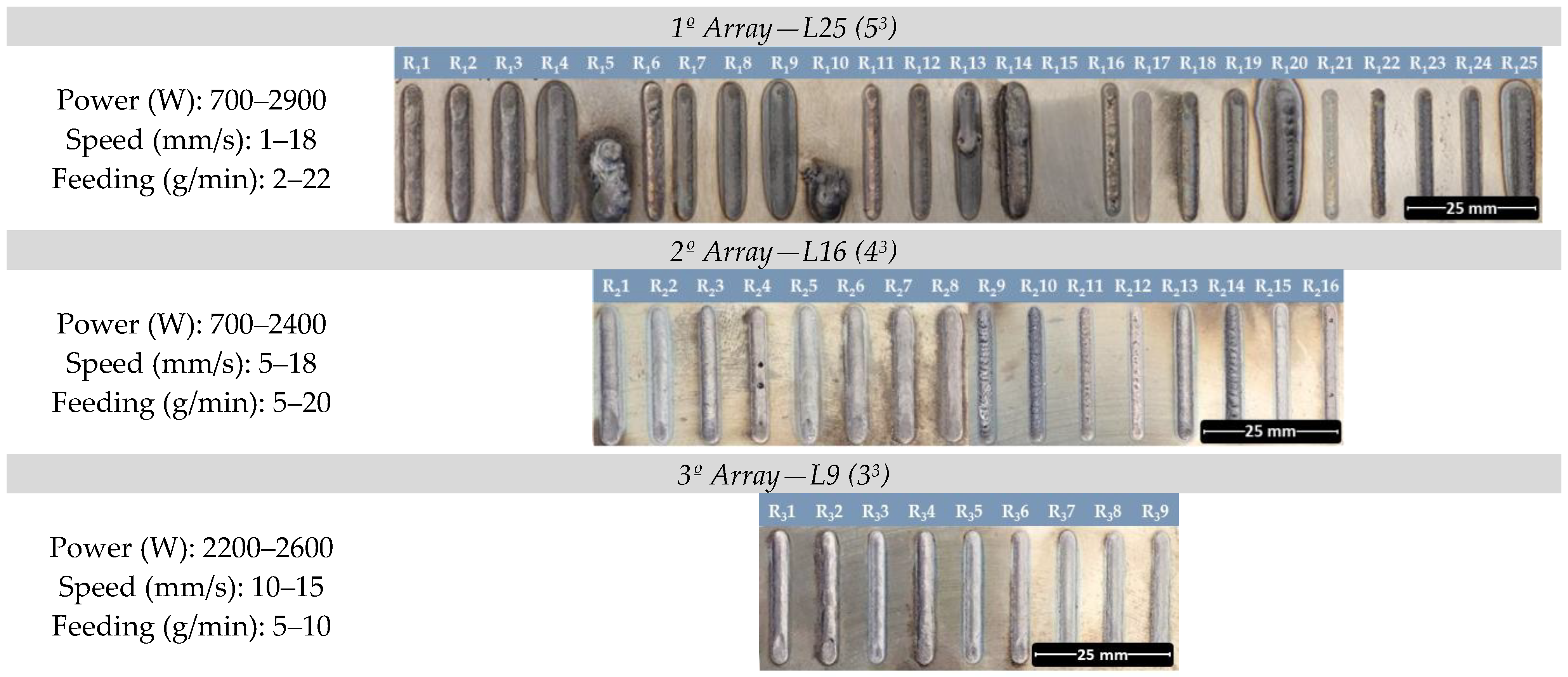

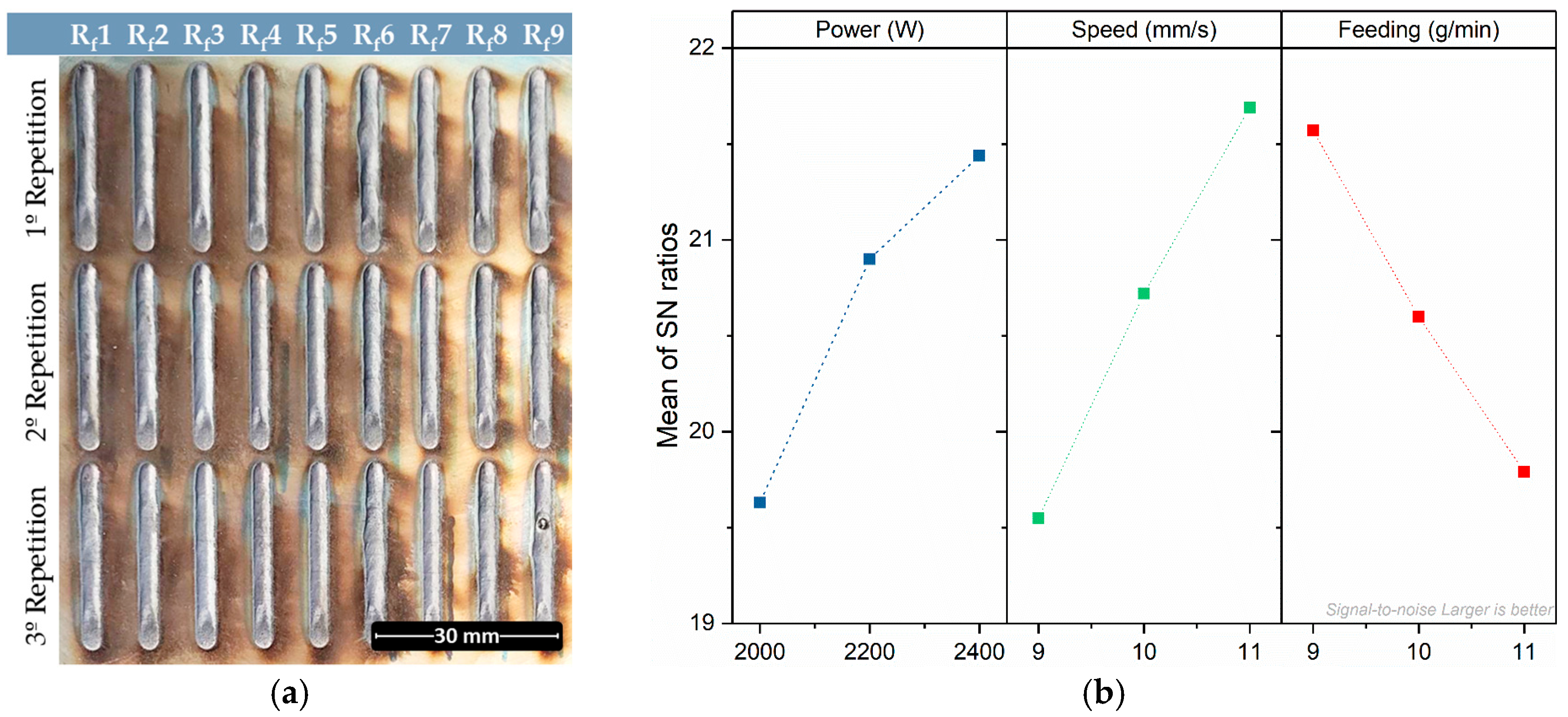

3.2. DED Depositing Optimisation

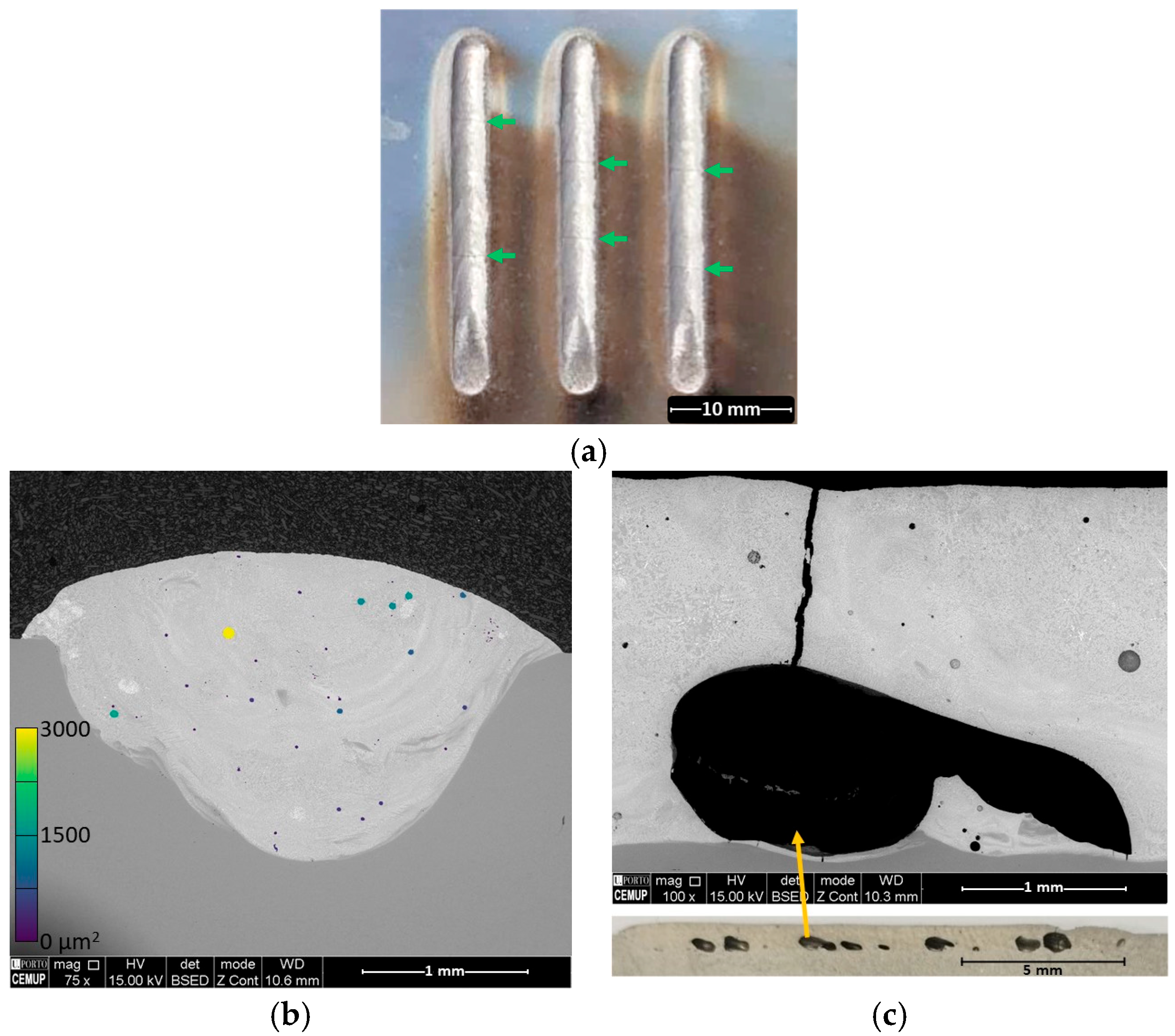

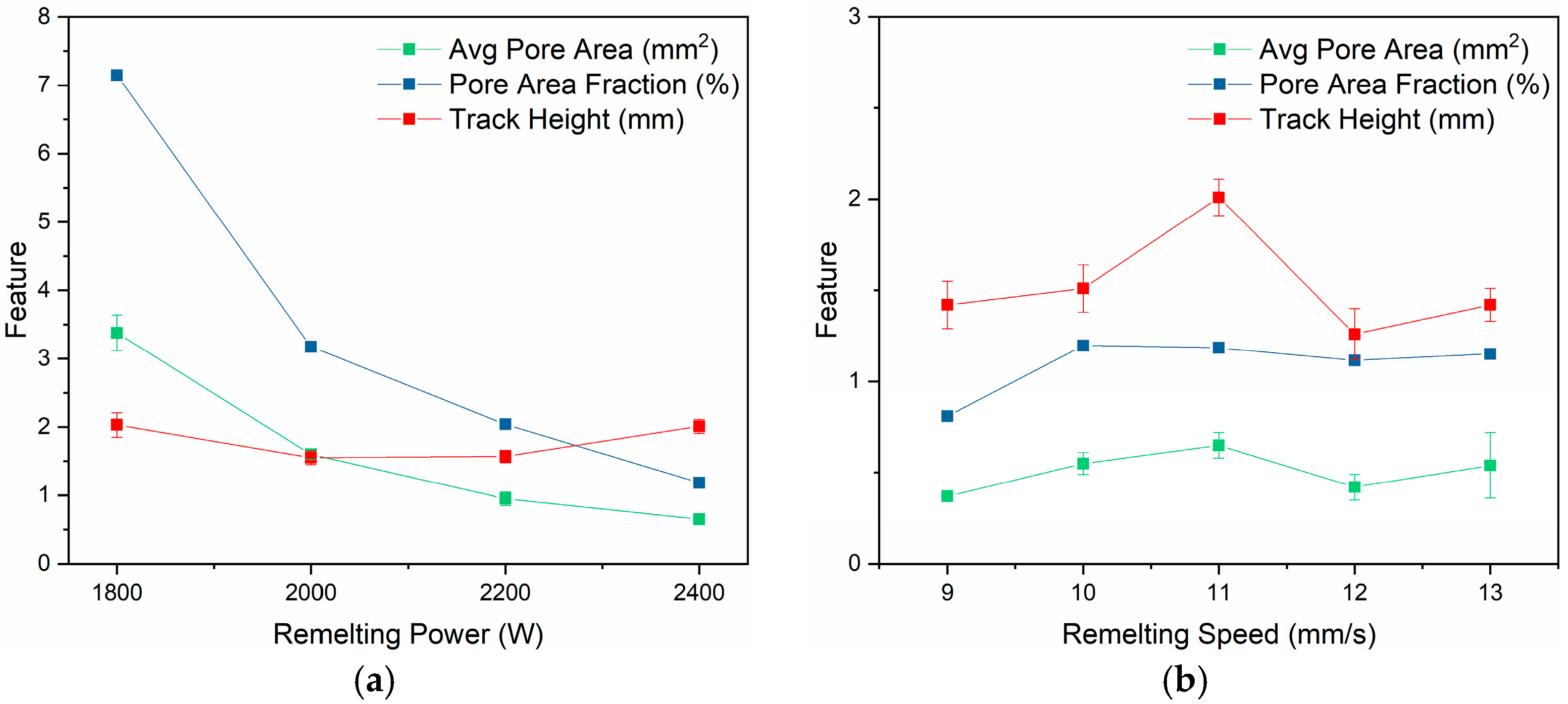

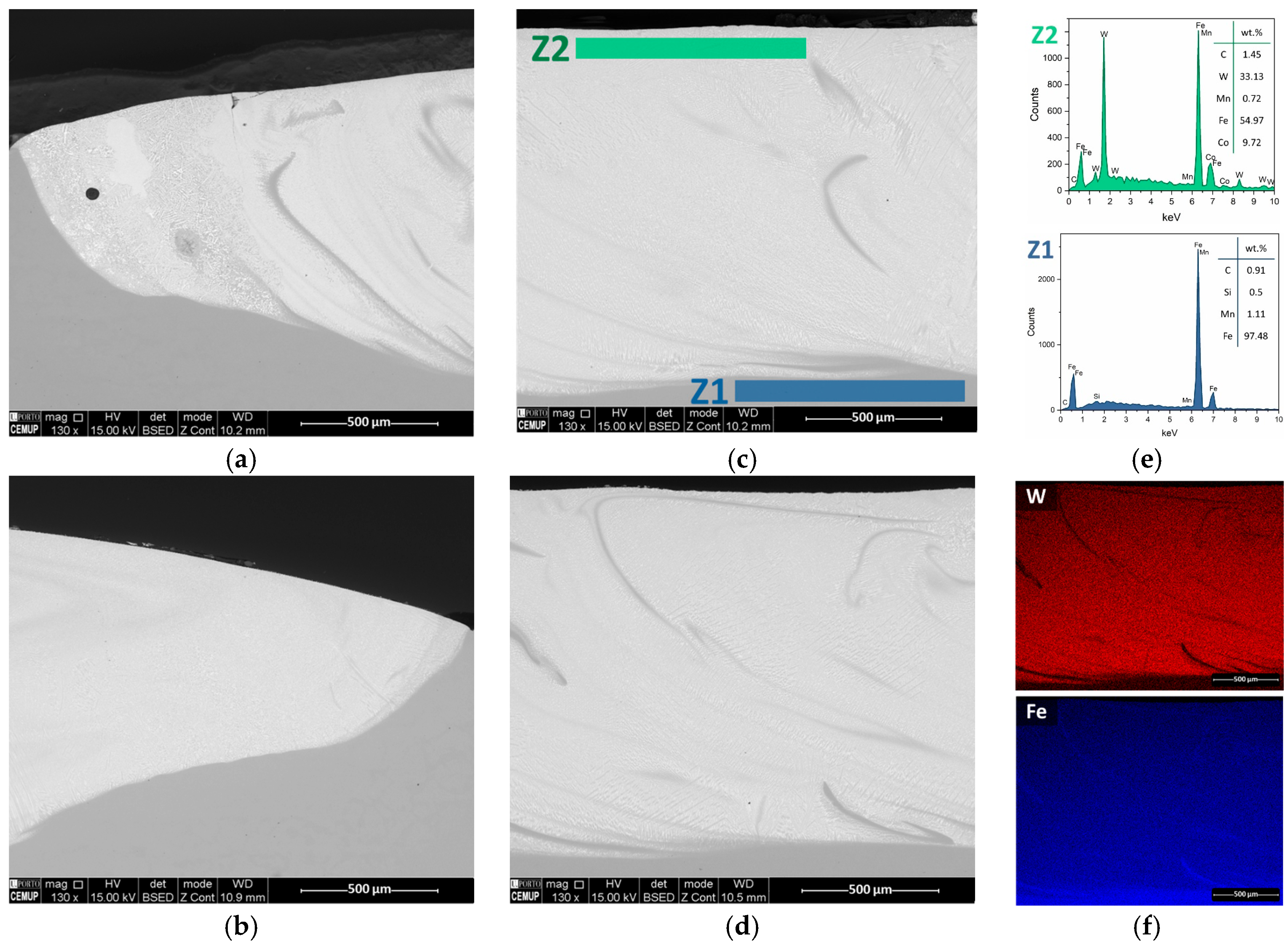

3.3. Remelting Strategies

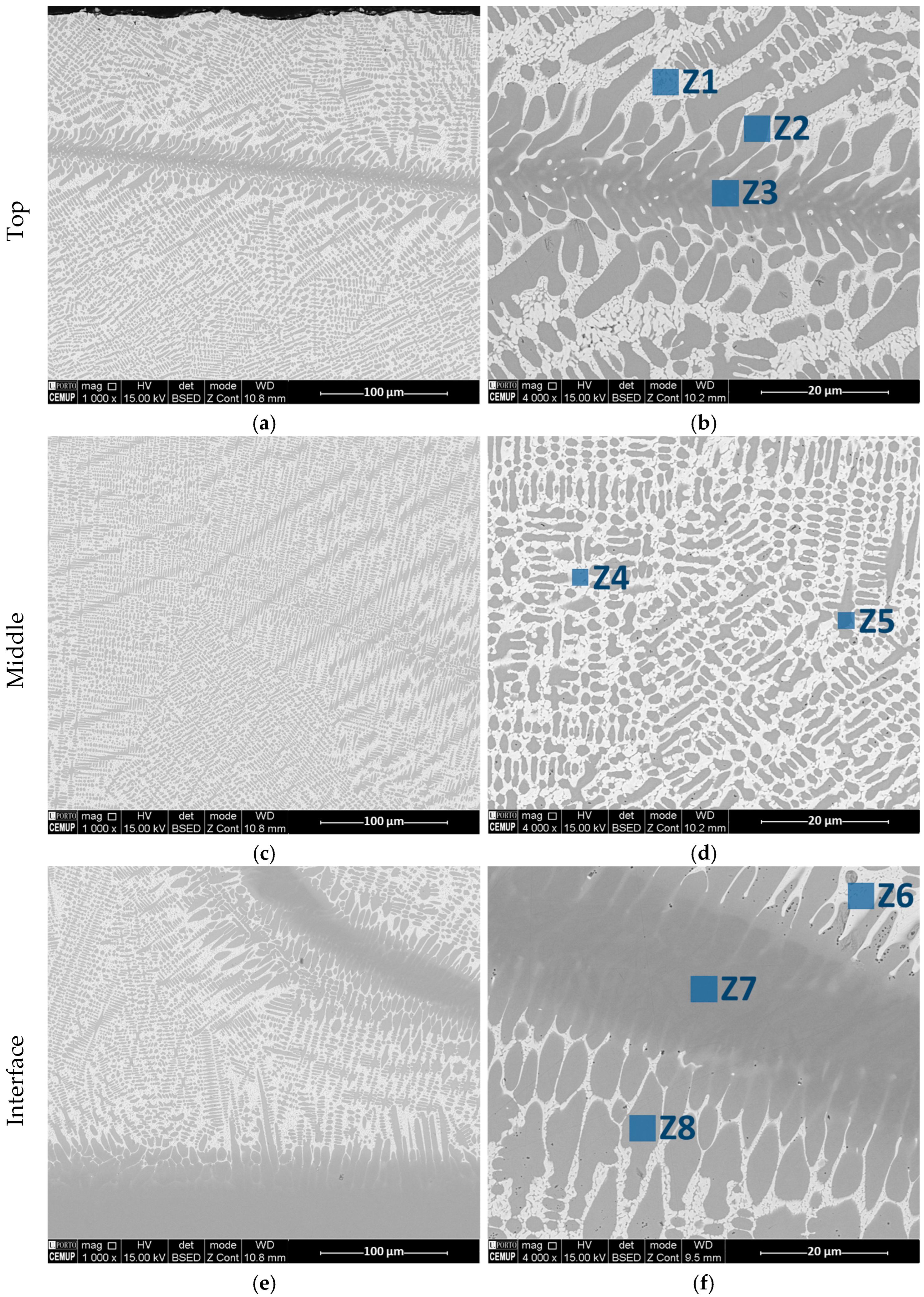

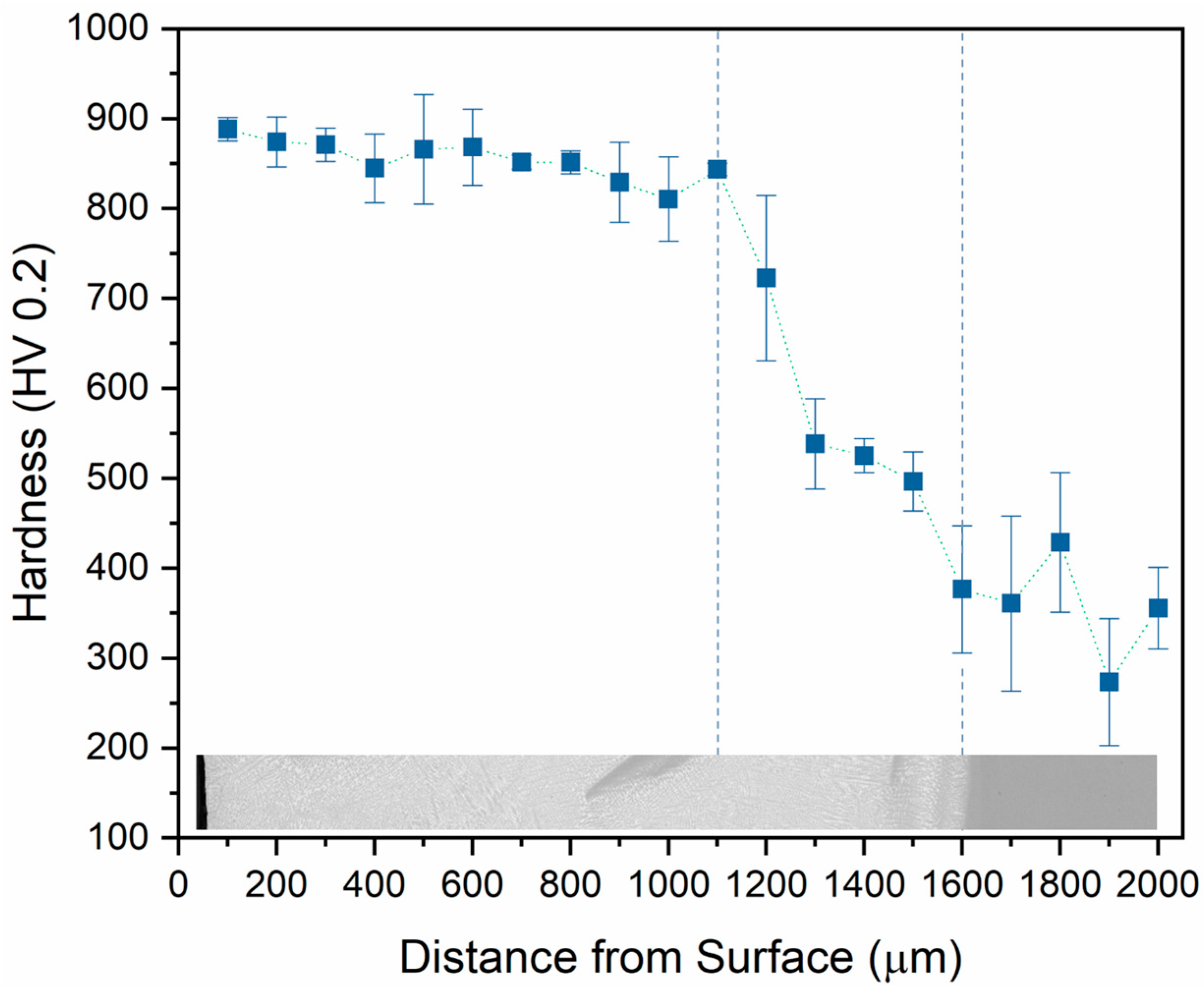

3.4. Final Optimal Line Characterisation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| L-DED | Laser-Directed Energy Deposition |

| DoE | Design of Experiments |

| DSC | Differential Scanning Calorimetry |

| TGA | Thermogravimetric Analysis |

| PSD | Particle Size Distribution |

| GED | Global Energy Density |

| RTP | Ready-to-press |

| SN | Signal-to-noise |

References

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Ortner, H.M.; Ettmayer, P.; Kolaska, H. The history of the technological progress of hardmetals. Int. J. Refract. Met. Hard Mater. 2014, 44, 148–159. [Google Scholar] [CrossRef]

- He, J.; Schoenung, J.M. A review on nanostructured WC–Co coatings. Surf. Coat. Technol. 2002, 157, 72–79. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, N.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 1653–1673. [Google Scholar] [CrossRef]

- Zhao, Z.; Ni, X.; Hu, Z.; Yang, W.; Deng, X.; Wu, S.; Li, Y.; Nie, G.; Wu, H.; Liu, J.; et al. A Short Review of Advancements in Additive Manufacturing of Cemented Carbides. Crystals 2025, 15, 146. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Shoja-Razavi, R. An empirical-statistical model for laser cladding of WC-12Co powder on AISI 321 stainless steel. Opt. Laser Technol. 2017, 97, 180–186. [Google Scholar] [CrossRef]

- Al-Thamir, M.; McCartney, D.G.; Simonelli, M.; Hague, R.; Clare, A. Processability of Atypical WC-Co Composite Feedstock by Laser Powder-Bed Fusion. Materials 2020, 13, 50. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.K.; Bal, K.S.; Dey, D.; Das, A.K.; Pal, A.R.; Pratihar, D.K.; Choudhury, A.R. Experimental investigation and parametric optimization for minimization of dilution during direct laser metal deposition of tungsten carbide and cobalt powder mixture on SS304 substrate. Powder Technol. 2021, 390, 339–353. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H. Influence of using electroless Ni-P coated WC-Co powder on laser cladding of stainless steel. Surf. Coat. Technol. 2018, 348, 41–54. [Google Scholar] [CrossRef]

- Kim, G.; Kim, Y.-C.; Cho, J.-E.; Yim, C.-H.; Yun, D.-S.; Lee, T.-G.; Park, N.-K.; Chung, R.-H.; Hong, D.-G. Microstructural Evolution, Hardness and Wear Resistance of WC-Co-Ni Composite Coatings Fabricated by Laser Cladding. Materials 2024, 17, 2116. [Google Scholar] [CrossRef] [PubMed]

- Angelastro, A.; Campanelli, S.L. Direct laser metal deposition of WC/Co/Cr powder by means of the functionally graded materials strategy. Surf. Topogr. Metrol. Prop. 2017, 5, 044002. [Google Scholar] [CrossRef]

- Liverani, E.; Ascari, A.; Fortunato, A. Multilayered WC–Co coatings by Direct Energy Deposition-based cladding: Effect of laser remelting on interface defects. Surf. Coat. Technol. 2023, 464, 129556. [Google Scholar] [CrossRef]

- Heydari, L.; Lietor, P.F.; Corpas-Iglesias, F.A.; Laguna, O.H. Ti(C,N) and WC-Based Cermets: A Review of Synthesis, Properties and Applications in Additive Manufacturing. Materials 2021, 14, 6786. [Google Scholar] [CrossRef]

- Nie, H.; Zhang, T. Development of manufacturing technology on WC–Co hardmetals. Tungsten 2019, 1, 198–212. [Google Scholar] [CrossRef]

- Kresse, T.; Meinhard, D.; Bernthaler, T.; Schneider, G. Hardness of WC-Co hard metals: Preparation, quantitative microstructure analysis, structure-property relationship and modelling. Int. J. Refract. Met. Hard Mater. 2018, 75, 287–293. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Queguineur, A.; Valtonen, K.; Lamikiz, A.; Ituarte, I.F. Influence of process parameters on the particle–matrix interaction of WC-Co metal matrix composites produced by laser-directed energy deposition. Mater. Des. 2022, 223, 111172. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. Diamond-reinforced cutting tools using laser-based additive manufacturing. Addit. Manuf. 2021, 37, 101602. [Google Scholar] [CrossRef]

- Kim, K.-W.; Ham, G.-S.; Park, S.-H.; Cho, J.-W.; Lee, K.-A. Direct energy deposition of ultrastrong WC-12Co cemented carbide: Fabrication, microstructure and compressive properties. Int. J. Refract. Met. Hard Mater. 2021, 99, 105591. [Google Scholar] [CrossRef]

- Morales, C.; Fortini, A.; Soffritti, C.; Merlin, M. Effect of Post-Fabrication Heat Treatments on the Microstructure of WC-12Co Direct Energy Depositions. Coatings 2023, 13, 1459. [Google Scholar] [CrossRef]

- Yamashita, Y.; Nakamura, M.; Kunimine, T.; Sato, Y.; Funada, Y.; Tsukamoto, M. Effects of WC ratios on bead size and crack initiation in forming WC-Co cemented carbides by the laser metal deposition. J. Laser Appl. 2023, 35, 042010. [Google Scholar] [CrossRef]

- Liu, Z.; Jian, L.; Tao, W. Preparation of WC–Co composite powder by electroless plating and its application in laser cladding. Mater. Lett. 2006, 60, 1956–1959. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Shoja-Razavi, R. Kinetics and oxidation behavior of laser clad WC-Co and Ni/WC-Co coatings. Ceram. Int. 2018, 44, 12805–12814. [Google Scholar] [CrossRef]

- You, A.; Wang, N.; Chen, Y.; Jiang, C.; Zhang, Y.; Zhao, Q.; Shi, Y.; Li, Y.; Zhang, F.; Zhao, Y. Effect of linear energy density on microstructure and wear resistance of WC-Co-Cr composite coating by laser cladding. Surf. Coat. Technol. 2023, 454, 129185. [Google Scholar] [CrossRef]

- Wang, J.; Meng, H.; Yu, H.; Fan, Z.; Sun, D. Surface hardening of Fe-based alloy powders by Nd:YAG laser cladding followed by electrospark deposition with WC-Co cemented carbide. Rare Met. 2010, 29, 380–384. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Ajdelsztajn, L.; Schoenung, J.M. Fabrication of WC–Co cermets by laser engineered net shaping. Mater. Sci. Eng. A 2008, 493, 261–266. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Schoenung, J.M. The influence of working distance on laser deposited WC–Co. J. Mater. Process. Technol. 2009, 209, 4935–4941. [Google Scholar] [CrossRef]

- Angelastro, A.; Campanelli, S.L.; Casalino, G.; Ludovico, A.D. Optimization of Ni-Based WC/Co/Cr Composite Coatings Produced by Multilayer Laser Cladding. Adv. Mater. Sci. Eng. 2013, 2013, 615464. [Google Scholar] [CrossRef]

- Valsecchi, B.; Previtali, B.; Vedani, M.; Vimercati, G. Fiber Laser Cladding with High Content of WC-Co Based Powder. Int. J. Mater. Form. 2010, 3, 1127–1130. [Google Scholar] [CrossRef]

- Kunimine, T.; Miyazaki, R.; Yamashita, Y.; Funada, Y. Effects of Laser-Beam Defocus on Microstructural Features of Compositionally Graded WC/Co-Alloy Composites Additively Manufactured by Multi-Beam Laser Directed Energy Deposition. Sci. Rep. 2020, 10, 8975. [Google Scholar] [CrossRef]

- Xu, M.; Tang, J.; Ye, N.; Chen, X.; Hu, M. Microstructure and mechanical properties of laser-cladded WC–Co composite coatings on Ti–6Al–4V. Mater. Res. Express 2019, 6, 1265k2. [Google Scholar] [CrossRef]

- Hazzan, K.E.; Pacella, M.; See, T.L. Understanding the surface integrity of laser surface engineered tungsten carbide. Int. J. Adv. Manuf. Technol. 2022, 118, 1141–1163. [Google Scholar] [CrossRef]

- Bidare, P.; Jiménez, A.; Hassanin, H.; Essa, K. Porosity, cracks, and mechanical properties of additively manufactured tooling alloys: A review. Adv. Manuf. 2022, 10, 175–204. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, Y.W.; Jang, K.M.; Lee, J.W.; Park, M.-S.; Koo, H.Y.; Ha, G.-H.; Kang, Y.C. Phase control of WC–Co hardmetal using additive manufacturing technologies. Powder Metall. 2022, 65, 13–21. [Google Scholar] [CrossRef]

- Konyashin, I.; Hinners, H.; Ries, B.; Kirchner, A.; Klöden, B.; Kieback, B.; Nilen, R.; Sidorenko, D. Additive manufacturing of WC-13%Co by selective electron beam melting: Achievements and challenges. Int. J. Refract. Met. Hard Mater. 2019, 84, 105028. [Google Scholar] [CrossRef]

- Sykora, J.; Sedlmajer, M.; Schubert, T.; Merkel, M.; Kroft, L.; Kucerova, L.; Rehor, J. Additive Manufacturing of WC-Co Specimens with Internal Channels. Materials 2023, 16, 3907. [Google Scholar] [CrossRef]

- Ibe, H.; Kato, Y.; Yamada, J.; Kato, M.; Suzuki, A.; Takata, N.; Kobashi, M. Controlling WC/Co two-phase microstructure of cemented carbides additive-manufactured by laser powder bed fusion: Effect of powder composition and post heat-treatment. Mater. Des. 2021, 210, 110034. [Google Scholar] [CrossRef]

- Bricín, D.; Kříž, A. Processability of WC-CO Powder Mixtures Using SLM Additive Technology. MM Sci. J. 2019, 2019, 2939–2945. [Google Scholar] [CrossRef]

- Liu, J.; Chen, J.; Lu, Y.; Deng, X.; Wu, S.; Lu, Z. WC Grain Growth Behavior During Selective Laser Melting of WC–Co Cemented Carbides. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 949–961. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Contuzzi, N.; Posa, P.; Angelastro, A. Printability and Microstructure of Selective Laser Melting of WC/Co/Cr Powder. Materials 2019, 12, 2397. [Google Scholar] [CrossRef] [PubMed]

- Uhlmann, E.; Bergmann, A.; Gridin, W. Investigation on Additive Manufacturing of Tungsten Carbide-cobalt by Selective Laser Melting. Procedia CIRP 2015, 35, 8–15. [Google Scholar] [CrossRef]

- Grigoriev, S.; Tarasova, T.; Gusarov, A.; Khmyrov, R.; Egorov, S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials 2019, 12, 3425. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Huang, M.; Fang, Z.Z.; Koopman, M.; Liu, W.; Deng, X.; Zhao, Z.; Chen, S.; Wu, S.; Liu, J.; et al. Microstructure analysis of high density WC-Co composite prepared by one step selective laser melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 104980. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, H.; Zhang, L.; Li, X.; Guo, Z.; Zhang, J.; Yi, D.; Liu, B.; Bai, P. Study on the microstructure and properties of WC-12Co cemented carbide fabricated by selective laser melting. J. Mater. Res. Technol. 2022, 20, 3512–3521. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Shevchukov, A.P.; Gusarov, A.V.; Tarasova, T.V.; Grigoriev, S.N. Phase composition and microstructure of WC–Co alloys obtained by selective laser melting. Mech. Ind. 2017, 18, 714. [Google Scholar] [CrossRef]

- Agyapong, J.; Czekanski, A.; Boakye-Yiadom, S. Effect of Process Parameters on Part Quality, Microstructure, and Mechanical Properties of a WC-Co-Hexagonal Boron Nitride Alloy Prepared by Laser Power Bed Fusion Process. J. Mater. Eng. Perform. 2024, 33, 410–426. [Google Scholar] [CrossRef]

- Schaak, C.; Kleszczynski, S.; Tillmann, W.; Witt, G. Investigation of LBM-processed bimodal powder mixtures of the nickel base alloy HX and WC–Co. Prog. Addit. Manuf. 2019, 4, 43–54. [Google Scholar] [CrossRef]

- Fries, S.; Vogelpoth, A.; Kaletsch, A.; Broeckmann, C. Influence of post heat treatment on microstructure and fracture strength of cemented carbides manufactured using laser-based additive manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 111, 106085. [Google Scholar] [CrossRef]

- Fries, S.; Genilke, S.; Wilms, M.B.; Seimann, M.; Weisheit, A.; Kaletsch, A.; Bergs, T.; Schleifenbaum, J.H.; Broeckmann, C. Laser-Based Additive Manufacturing of WC–Co with High-Temperature Powder Bed Preheating. Steel Res. Int. 2020, 91, 1900511. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Ferreira, T.; Hiner, M.; Rueden, C.; Miura, K.; Eglinger, J.; Chef, B. tferr/Scripts: BAR 1.5.1.; Zenodo: Geneva, Switzerland, 2017. [Google Scholar] [CrossRef]

- ISO 6507-1; Metallic Materials—Vickers Hardness Test, in Part 1, Test Method. ISO: Geneva, Switzerland, 2023.

- Eso, O.O. Densification and sintering shrinkage of Zinc Reclaimed WC-Co. Int. J. Refract. Met. Hard Mater. 2016, 54, 445–454. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Hagino, H. Effects of the ambient oxygen concentration on WC-12Co cermet coatings fabricated by laser cladding. Opt. Laser Technol. 2021, 139, 106922. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Tanaka, K.; Suyama, T. In-situ observation of CO gas bubble behavior in molten pool during direct laser deposition of WC-Co cermet material. Opt. Laser Technol. 2025, 180, 111561. [Google Scholar] [CrossRef]

- Li, M.; Huang, K.; Yi, X. Crack Formation Mechanisms and Control Methods of Laser Cladding Coatings: A Review. Coatings 2023, 13, 1117. [Google Scholar] [CrossRef]

- Liu, T.; Qu, X.; Zheng, Y.; Wang, Y.; Yu, C.; Lu, H. Revealing multiphysics effects on microstructure characteristics in powder-fed laser cladding based on a comprehensive model. J. Mater. Res. Technol. 2024, 29, 3673–3685. [Google Scholar] [CrossRef]

- Hu, M.; Tang, J.-C.; Chen, X.-G.; Ye, N.; Zhao, X.-Y.; Xu, M.-M. Microstructure and properties of WC-12Co composite coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China 2020, 30, 1017–1030. [Google Scholar] [CrossRef]

- Dosta, S.; Couto, M.; Guilemany, J.M. Cold spray deposition of a WC-25Co cermet onto Al7075-T6 and carbon steel substrates. Acta Mater. 2013, 61, 643–652. [Google Scholar] [CrossRef]

- Yin, S.; Ekoi, E.J.; Lupton, T.L.; Dowling, D.P.; Lupoi, R. Cold spraying of WC-Co-Ni coatings using porous WC-17Co powders: Formation mechanism, microstructure characterization and tribological performance. Mater. Des. 2017, 126, 305–313. [Google Scholar] [CrossRef]

| 1 º Array—L25 (53) | 2 º Array—L16 (43) | 3 º Array—L9 (33) | Final Array—L9 (33) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Run (R1) | Power | Speed | Feed | GED | QI | Run (R2) | Power | Speed | Feed | GED | QI | Run (R3) | Power | Speed | Feed | GED | QI | Run (Rf) | Power | Speed | Feed | GED | QI |

| 1 | 2900 | 18 | 22 | 77 | 7 | 1 | 2400 | 18 | 20 | 63 | 10 | 1 | 2600 | 15 | 10 | 83 | 13 | 1 | 2400 | 11 | 11 | 104 | 12.0 ±1.0 |

| 2 | 13 | 18 | 106 | 7 | 2 | 13 | 15 | 88 | 9 | 2 | 12 | 8 | 103 | 13 | 2 | 10 | 10 | 114 | 11.8 ± 1.2 | ||||

| 3 | 8 | 14 | 173 | 7 | 3 | 8 | 10 | 143 | 12 | 3 | 10 | 5 | 124 | 14 | 3 | 9 | 9 | 127 | 11.8 ± 1.2 | ||||

| 4 | 5 | 8 | 276 | 7 | 4 | 5 | 5 | 229 | 15 | 4 | 2400 | 15 | 8 | 76 | 10 | 4 | 2200 | 11 | 10 | 95 | 12.7 ± 0.8 | ||

| 5 | 1 | 22 | 1381 | 1 | 5 | 2200 | 18 | 15 | 50 | 9 | 5 | 12 | 5 | 95 | 9 | 5 | 10 | 9 | 105 | 12.3 ± 0.8 | |||

| 6 | 2400 | 18 | 18 | 63 | 8 | 6 | 13 | 10 | 70 | 12 | 6 | 10 | 10 | 114 | 11 | 6 | 9 | 11 | 116 | 9.2 ± 2.3 | |||

| 7 | 13 | 14 | 88 | 9 | 7 | 8 | 5 | 113 | 11 | 7 | 2200 | 15 | 5 | 70 | 11 | 7 | 2000 | 11 | 9 | 87 | 12.0 ± 1.0 | ||

| 8 | 8 | 8 | 143 | 10 | 8 | 5 | 20 | 181 | 10 | 8 | 12 | 10 | 87 | 8 | 8 | 10 | 11 | 95 | 9.0 ± 1.0 | ||||

| 9 | 5 | 2 | 229 | 8 | 9 | 1200 | 18 | 10 | 32 | 9 | 9 | 10 | 8 | 105 | 9 | 9 | 9 | 10 | 106 | 8.3 ± 0.7 | |||

| 10 | 1 | 22 | 1143 | 1 | 10 | 13 | 5 | 44 | 14 | ||||||||||||||

| 11 | 1900 | 18 | 14 | 50 | 8 | 11 | 8 | 20 | 71 | 8 | |||||||||||||

| 12 | 13 | 8 | 70 | 9 | 12 | 5 | 15 | 114 | 9 | ||||||||||||||

| 13 | 8 | 2 | 113 | 6 | 13 | 700 | 18 | 5 | 19 | 3 | |||||||||||||

| 14 | 5 | 22 | 181 | 6 | 14 | 13 | 20 | 26 | 5 | ||||||||||||||

| 15 | 1 | 18 | 905 | 0 | 15 | 8 | 15 | 42 | 5 | ||||||||||||||

| 16 | 1200 | 18 | 8 | 32 | 7 | 16 | 5 | 10 | 67 | 3 | |||||||||||||

| 17 | 13 | 2 | 44 | 5 | |||||||||||||||||||

| 18 | 8 | 22 | 71 | 9 | |||||||||||||||||||

| 19 | 5 | 18 | 114 | 10 | |||||||||||||||||||

| 20 | 1 | 14 | 571 | 4 | |||||||||||||||||||

| 21 | 700 | 18 | 2 | 19 | 4 | ||||||||||||||||||

| 22 | 13 | 22 | 26 | 4 | |||||||||||||||||||

| 23 | 8 | 18 | 42 | 4 | |||||||||||||||||||

| 24 | 5 | 14 | 67 | 4 | |||||||||||||||||||

| 25 | 1 | 8 | 333 | 7 | |||||||||||||||||||

| 1º Test—Varying Speed | 2º Test—Varying Power | ||

|---|---|---|---|

| Laser Power (W) | Scanning Speed (mm/s) | Laser Power (W) | Scanning Speed (mm/s) |

| Constant at 2400 | 9 | 1800 | Constant at 11 |

| 10 | 2000 | ||

| 12 | 2200 | ||

| 13 | 2400 | ||

| Zone | W | Co | Fe | Mn | Si | C |

|---|---|---|---|---|---|---|

| Z1 | 48.01 | 7.09 | 43.74 | - | - | 1.15 |

| Z2 | 17.84 | 12.21 | 69.05 | - | - | 0.89 |

| Z3 | 12.4 | 5.83 | 80.83 | - | - | 0.93 |

| Z4 | 47.6 | 7.52 | 43.52 | - | - | 1.36 |

| Z5 | 21.53 | 12.76 | 64.03 | 0.7 | - | 0.98 |

| Z6 | 45.95 | 5.49 | 46.79 | 0.78 | - | 6.46 |

| Z7 | - | - | 97.31 | 1.1 | 0.77 | 0.81 |

| Z8 | 12.93 | 6.96 | 77.92 | 0.69 | 0.58 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, H.; Nhanga, J.; Regueiras, L.; Reis, A.; Vieira, M.F.; Guimarães, B.; Figueiredo, D.; Fernandes, C.; Emadinia, O. Optimising WC-25Co Feedstock and Parameters for Laser-Directed Energy Deposition. J. Manuf. Mater. Process. 2025, 9, 279. https://doi.org/10.3390/jmmp9080279

Nunes H, Nhanga J, Regueiras L, Reis A, Vieira MF, Guimarães B, Figueiredo D, Fernandes C, Emadinia O. Optimising WC-25Co Feedstock and Parameters for Laser-Directed Energy Deposition. Journal of Manufacturing and Materials Processing. 2025; 9(8):279. https://doi.org/10.3390/jmmp9080279

Chicago/Turabian StyleNunes, Helder, José Nhanga, Luís Regueiras, Ana Reis, Manuel F. Vieira, Bruno Guimarães, Daniel Figueiredo, Cristina Fernandes, and Omid Emadinia. 2025. "Optimising WC-25Co Feedstock and Parameters for Laser-Directed Energy Deposition" Journal of Manufacturing and Materials Processing 9, no. 8: 279. https://doi.org/10.3390/jmmp9080279

APA StyleNunes, H., Nhanga, J., Regueiras, L., Reis, A., Vieira, M. F., Guimarães, B., Figueiredo, D., Fernandes, C., & Emadinia, O. (2025). Optimising WC-25Co Feedstock and Parameters for Laser-Directed Energy Deposition. Journal of Manufacturing and Materials Processing, 9(8), 279. https://doi.org/10.3390/jmmp9080279