1. Introduction

Additive manufacturing, commonly known as 3D printing, has revolutionized numerous industries—from aerospace and healthcare to automotive and architecture—through its ability to fabricate complex geometries with precision, flexibility, and material efficiency. In recent years, this transformative technology has begun to make inroads into the culinary sector, giving rise to an emerging field known as 3D food printing. Three-dimensional food printing utilizes computer-aided design models and customized extrusion mechanisms to deposit edible materials in a layer-by-layer fashion, enabling the creation of intricate, personalized, and nutritionally tailored food products. The application of 3DFP holds significant promise in a variety of domains. In high-end gastronomy, it offers chefs and food designers a new medium for culinary artistry and novel sensory experiences. In nutritional science, it provides the potential to address individual dietary needs through precise macronutrient control, portion sizing, and functional food incorporation. Additionally, in sectors such as space travel, elderly care, and emergency relief, 3DFP may offer innovative solutions for food preservation, palatability, and distribution. Despite its growing potential, 3D food printing faces critical technical and practical challenges. Unlike traditional AM processes that rely on thermoplastics or metals, food-based materials present a high degree of variability in terms of rheology, structural integrity, and post-processing requirements. Ingredients must be carefully formulated to ensure both extrudability and shape retention, while also maintaining desirable organoleptic qualities after cooking or consumption. Moreover, the integration of automation, nutrition, and digital design within a single platform demands interdisciplinary expertise across food science, mechanical engineering, material science, and human-centered design. This paper explores the state of the art in 3D food printing, with a specific focus on the formulation and printability of protein-rich food pastes, using chicken-based mixtures and a chocolate mixture as a case study. Through experimental formulation, print testing, and evaluation, this study aims to contribute to the growing body of knowledge on how AM technologies can shape the future of food—not just in function and nutrition, but in form, experience, and artistry.

The primary objective of this study is to investigate the feasibility and optimization of 3D food printing using meat- and chocolate-based formulations tailored for children’s nutritional needs. Specifically, the study aims to evaluate how key printing parameters, such as print speed and flow rate, influence the geometric fidelity, structural stability, and printability of these food constructs using a modified FDM 3D printer. This research also seeks to contribute practical insights into the design of personalized, nutritious snacks using additive manufacturing technologies.

2. Materials and Methods

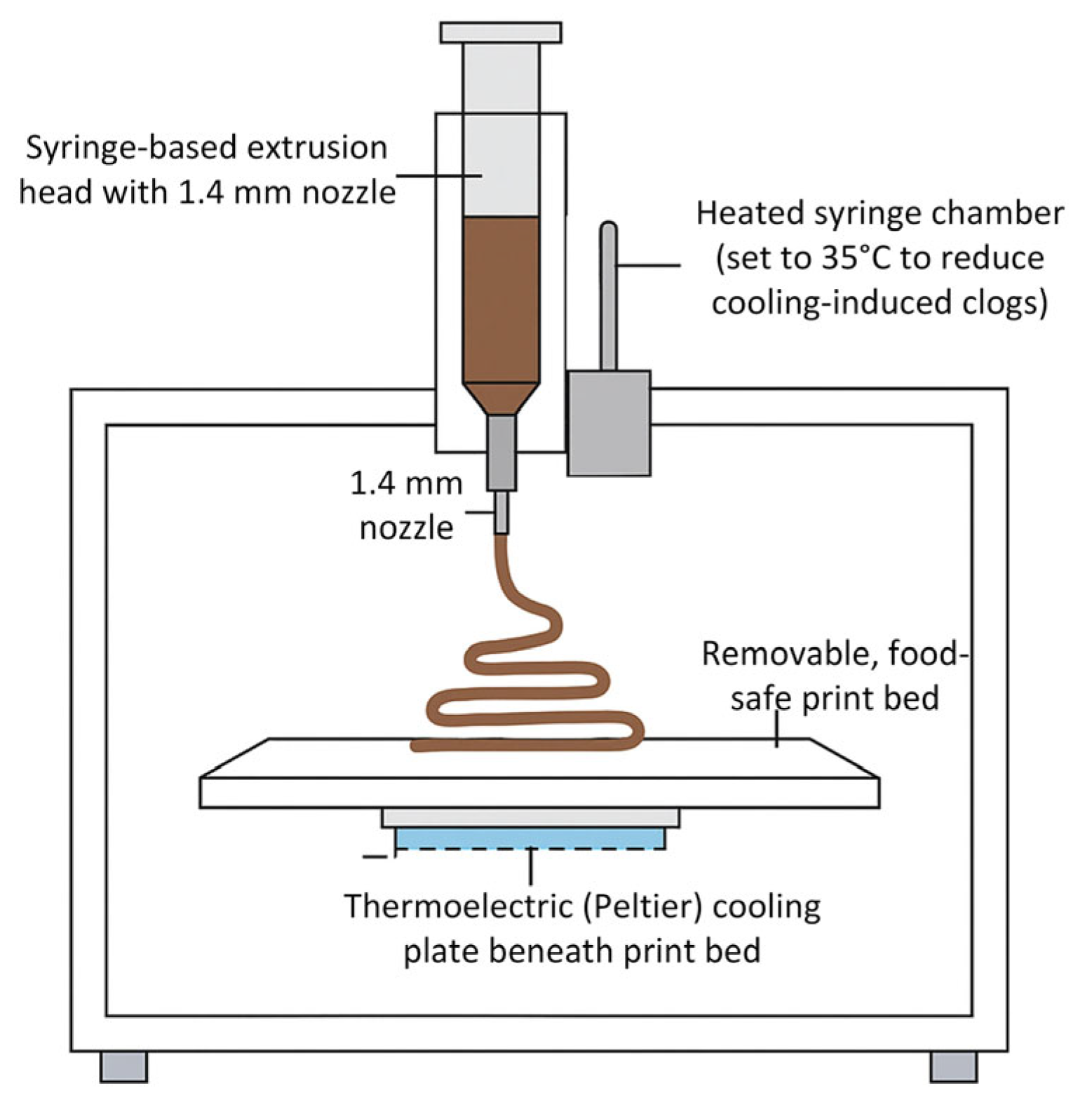

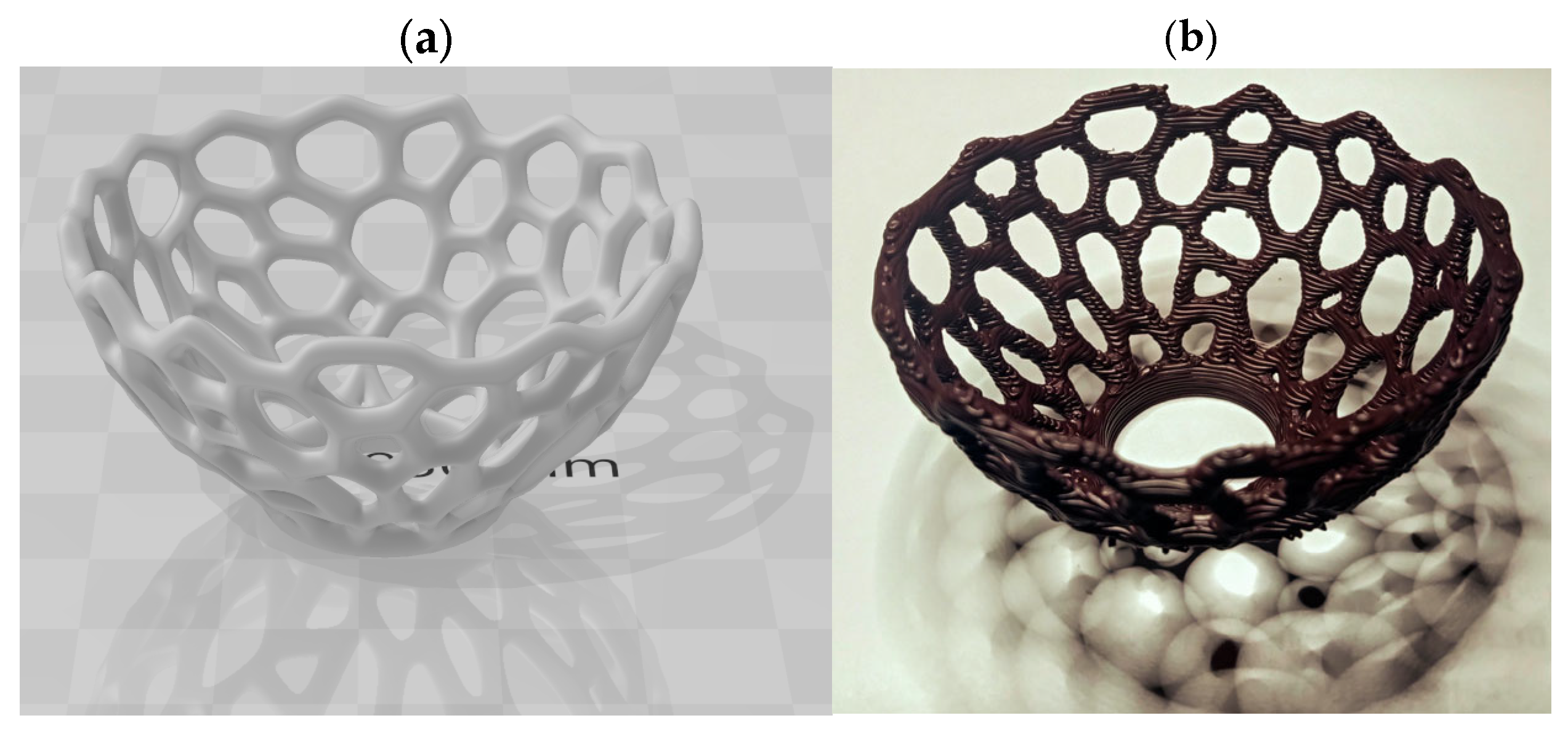

For the purpose of testing the recipes, three different recipes for chicken nuggets and two chocolate recipes were developed that proved to be suitable for printing chocolate decorative elements. The 3D printer was extensively modified to successfully form the chicken nuggets using a homogenized meat mass layer by layer [

10]. A special container was developed for the purpose of tempering the chocolate mass, which ensures a constant temperature of the chocolate mass for successful printing, as depicted in

Figure 1. The 3D printer used in this study was modified from a Creality Ender 3 Pro, from Shenzhen Creality 3D Technology Co, Ltd. (Shenzhen, China) which operates using an open-source firmware platform—Marlin. This firmware was adjusted to support syringe-based extrusion rather than thermoplastic filament. Marlin’s open-source nature allows for full customization of motion control, extrusion parameters, and temperature regulation, making it ideal for experimental setups such as food printing.

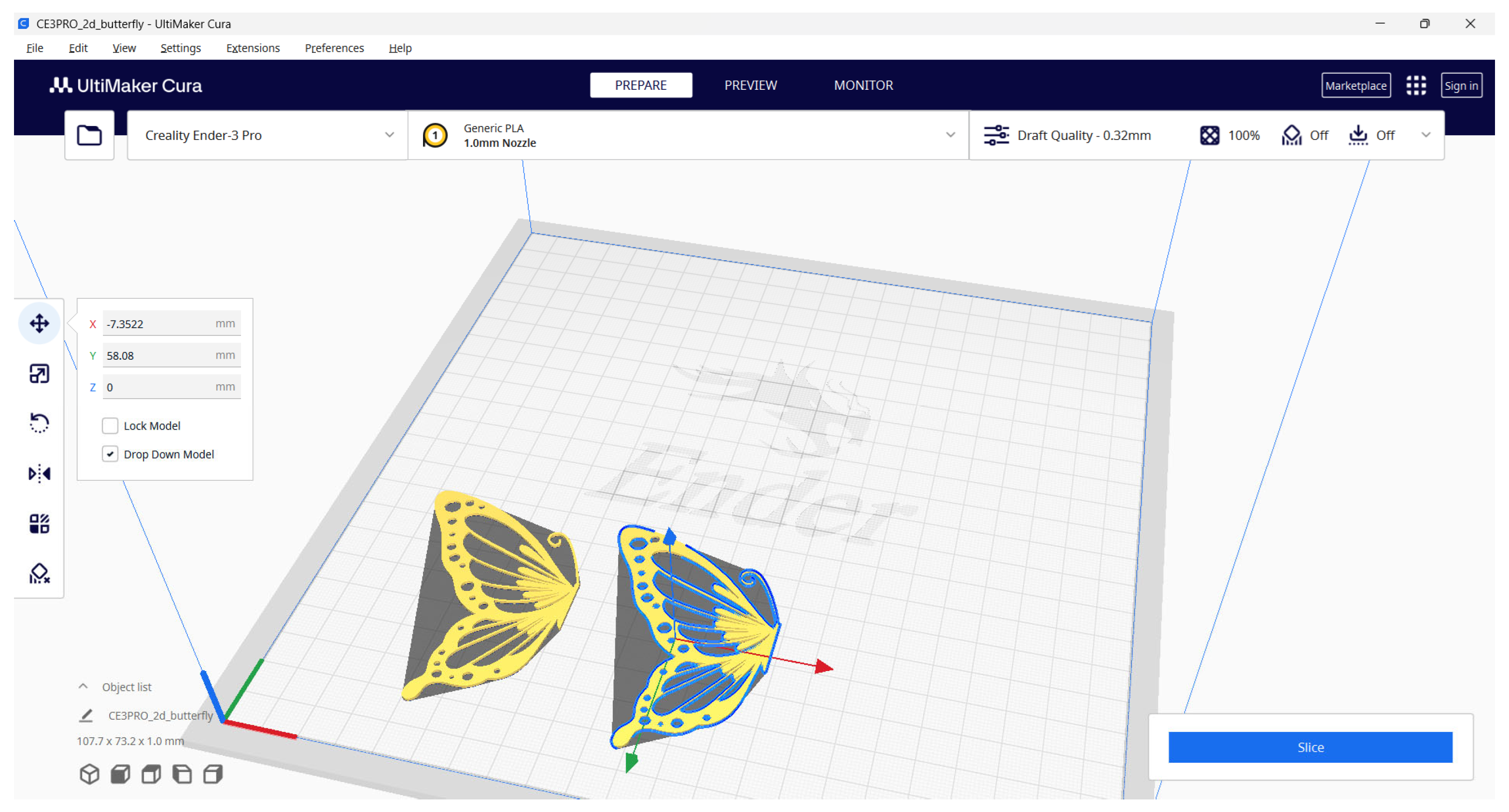

For slicing and G-code generation, Ultimaker Cura 5.6.0, also open-source, was employed with customized material profiles and extrusion parameters tailored for food paste viscosities. Cura’s flexibility enabled precise control over flow rate, print speed, retraction, and layer height, which are critical for food texture fidelity and print stability. The use of open-source software in both the firmware and slicer stages ensures that the conversion process is fully transparent, reproducible, and modifiable by other researchers or practitioners seeking to replicate or expand upon this work.

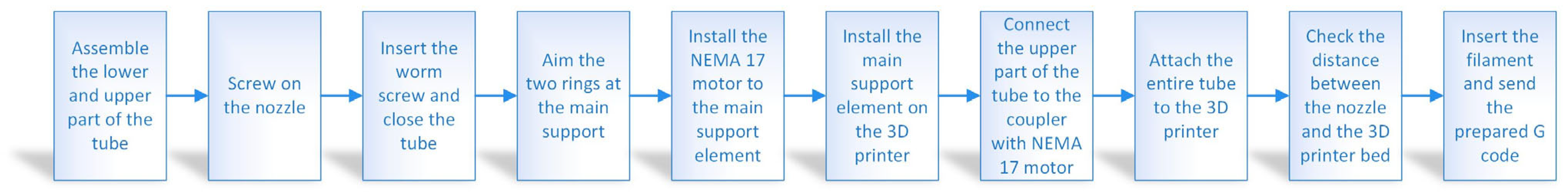

Figure 2 shows a flowchart that explains, step by step, all the details involved in converting a conventional 3D printer to a food 3D printer.

This setup ensured consistent flow, reduced premature hardening of chocolate within the extruder, and allowed for finer control over printed geometry. A low-wattage resistive heater was implemented directly around the nozzle and maintained a stable temperature range of 30–32 °C. The mixture was preheated slightly above the extrusion temperature before loading. A modified G-code was implemented to include a short delay after retraction. The retraction distance was reduced in order to minimize backflow, with rest time allowed between layers for surface settling.

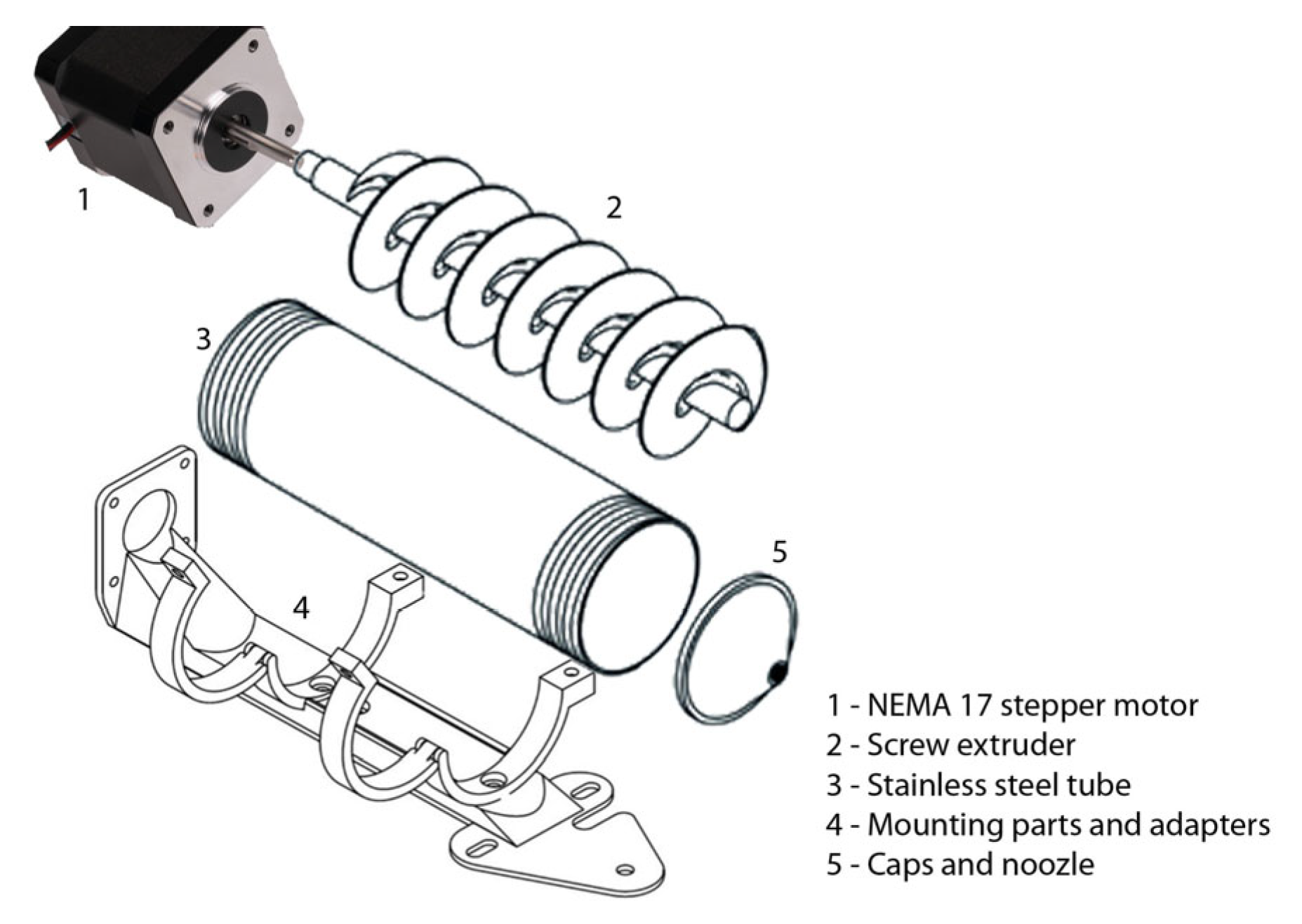

Figure 3 shows a modified version of the extruder, and includes a food-grade syringe extruder (2, 3, 5), mounting parts and adapters (4), and a NEMA 17 stepper motor (1).

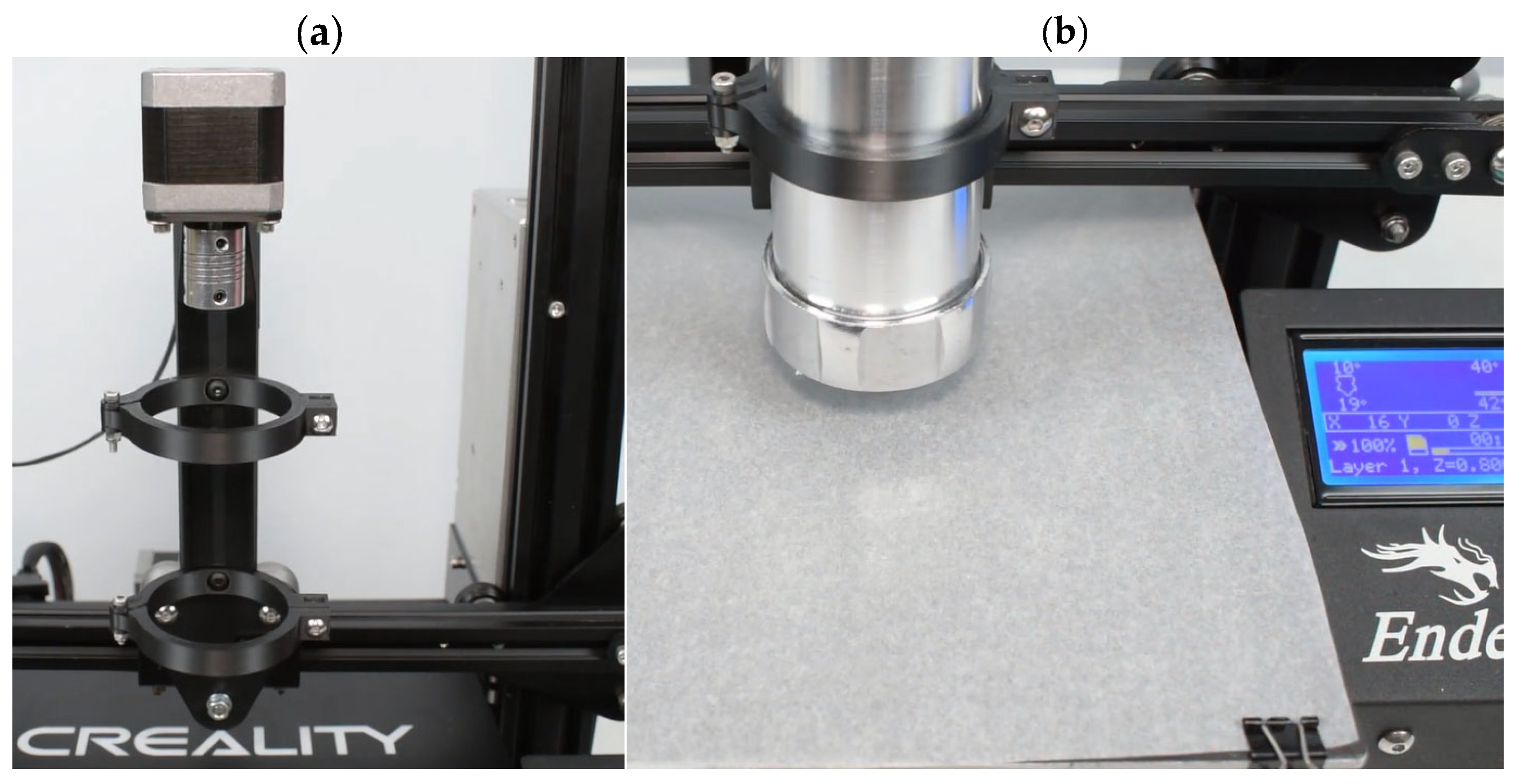

Modifying a Creality Ender 3 Pro 3D printer with the proposed food printing extruder allows for converting the desktop filament printer into a machine capable of extruding paste-based food materials such as chocolate or a homogenized meat mass. The extrusion process of a 3D food printer adapted from a conventional FDM (Fused Deposition Modeling) printer like the Creality Ender Pro 3 relies on a coordinated set of mechanical, electrical, and software components. These elements ensure the precise deposition of food pastes such as chocolate or homogenized meat mass. The extrusion motor is a NEMA 17 stepper motor, chosen for its precision and torque control, regulated via stepper drivers on the mainboard, and synchronizing with X Y Z movement. The syringe or cartridge holder is made of stainless steel, attached to the print head or carriage using custom 3D-printed brackets. The extrusion piston applies pressure on the food paste to extrude it through the nozzle. A nozzle with a size of 0.8 mm directs the paste into precise layers on the print bed (see

Figure 4). G-code control manages extrusion rate, travel speed, retraction, and layer height via Ultimaker Cura 5.6.0.

To install a modified extruder, the existing hotend and extruder assembly need to be removed. Extruder must be attached to the X-axis carriage where the original hotend was installed. After the proper installation of the adapter, the food-safe syringe is inserted into its holder. The NEMA 17 type stepper motor on the syringe extruder is inserted into the E0 stepper motor port on the mainboard which replaces the original filament extruder stepper. To allow extrusion at low/no temperature, a G-code command “M302 S0” is used. For the G-code preparation, slicer software (like Ultimaker Cura 5.6.0) with paste printing profiles can be used as depicted in

Figure 5. In Cura, different colored arrows can be seen. These arrows are used to manipulate the 3D model along the X, Y, and Z axes. Red indicates the X-axis, Green represents the Y-axis and Blue signifies the Z-axis. The syringe and any parts which come into contact with food must always be cleaned thoroughly after use to maintain hygiene.

Cura 5.6.0 is applicable in 3D food printing by enabling precise control over print speed, layer height, flow rate, and nozzle movement—critical for paste-based materials. It allows users to customize G-code for extruding food pastes like chocolate or dough, with settings for cold extrusion. While primarily used for thermoplastics, its advanced slicing capabilities and open material profiles make it adaptable for food-safe 3D printing experiments.

Rheological measurements were carried out to evaluate the viscoelastic and flow properties of the food mixtures intended for 3D printing. The tests were conducted using an Anton Paar MCR 501 Rheometer, which is equipped with a temperature-controlled Peltier system to ensure consistent thermal conditions throughout the measurements. All analyses were performed at a constant temperature of 25 ± 0.1 °C, which corresponds to the extrusion conditions used in the printing experiments. A parallel plate geometry with a 25 mm diameter was employed, and the gap between the plates was set to 1 mm for all samples. The sample pastes were carefully loaded to avoid introducing air bubbles, and excess material was trimmed. To prevent moisture loss during testing, the exposed edges were sealed with low-viscosity mineral oil. Two types of rheological tests were performed for each food paste formulation. The first is an oscillatory amplitude sweep (to determine the linear viscoelastic region, LVR), followed by a Frequency sweep in the LVR range to determine the storage modulus (G′), loss modulus (G″), and the damping factor (tan δ = G″/G′). These parameters indicate the relative elasticity and viscosity of the material, which are crucial for predicting its ability to extrude and hold shape during and after printing. Additionally, flow tests were conducted by applying a shear rate sweep from 0.01 s−1 to 100 s−1 to assess the shear-thinning behaviour, which is desirable in extrusion-based printing. All tests were performed in triplicate for statistical reliability, and average values with standard deviations were recorded. The rheological data were used to establish correlations between material behaviour and printability outcomes, including structural fidelity, flow consistency, and resolution of printed features.

2.1. Printing of Chicken Nuggets

Three distinct chicken nugget formulations were developed for evaluation in 3D food printing applications. Ingredients were selected based on their functional roles in texture, printability, binding, and nutritional profile.

Common Ingredients Across Recipes:

Chicken (breast or thigh): Protein-rich base, pre-cooked (steamed/poached) for safety and texture optimization.

Binding Agents: Egg white, starches, or flaxseed gel were used to enhance structural integrity.

Moisturizers and Emulsifiers: Cream cheese, yogurt, olive oil, or silken tofu contributed to smooth extrusion.

Flavourings: Mild spices and condiments (e.g., garlic powder, mustard) were incorporated for palatability.

Optional Fortifiers: Nutritional yeast or vegetable purees (carrot, pumpkin) were used to enhance nutritional diversity.

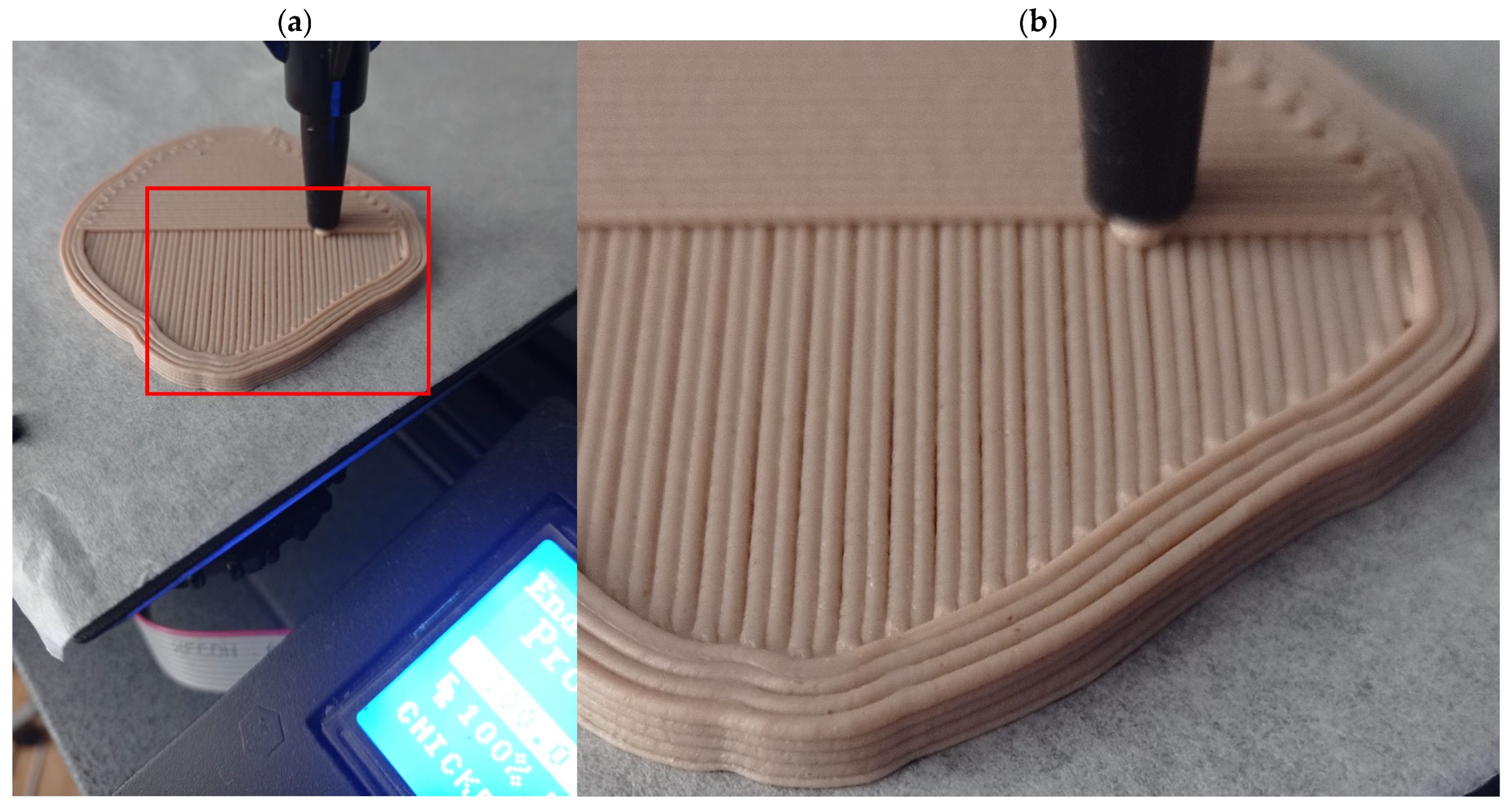

As shown in

Figure 6, the homogenized meat mass is formed into the shape of a 3D model layer by layer using a heavily modified 3D printer.

All ingredients were sourced fresh, prepared hygienically, and blended under food-safe laboratory conditions. The development of printable chicken nugget mixtures involves a multifaceted balance between printability, nutrition, structural integrity, and sensory quality. The three formulations evaluated in this study—Classic Chicken Nugget Mix, Chicken–Vegetable Blend, and Gluten-Free Protein-Enhanced Mix—each present unique strengths and limitations. Key considerations in their design focused on optimizing extrusion behaviour, post-print cooking performance, and consumer appeal.

2.1.1. Preparation of Mixtures

Each recipe was homogenized using a high-speed food processor to produce a consistent paste with minimal particulate matter. Consistency was verified visually and manually to ensure flow through a 3D printer extrusion nozzle (1.4 mm diameter). Mixtures were refrigerated (4 °C) for 15 min before loading into the 3D printer to enhance viscosity and print precision.

2.1.2. Three-Dimensional-Printing Process

A customized food-grade extrusion-based 3D printer was used. STL files were generated via Autodesk Tinkercad, a free web app for 3D design CAD software and converted into G-code with simplified pathing to test basic shapes (cups, nuggets, lattice forms). Parameters were optimized for each mixture:

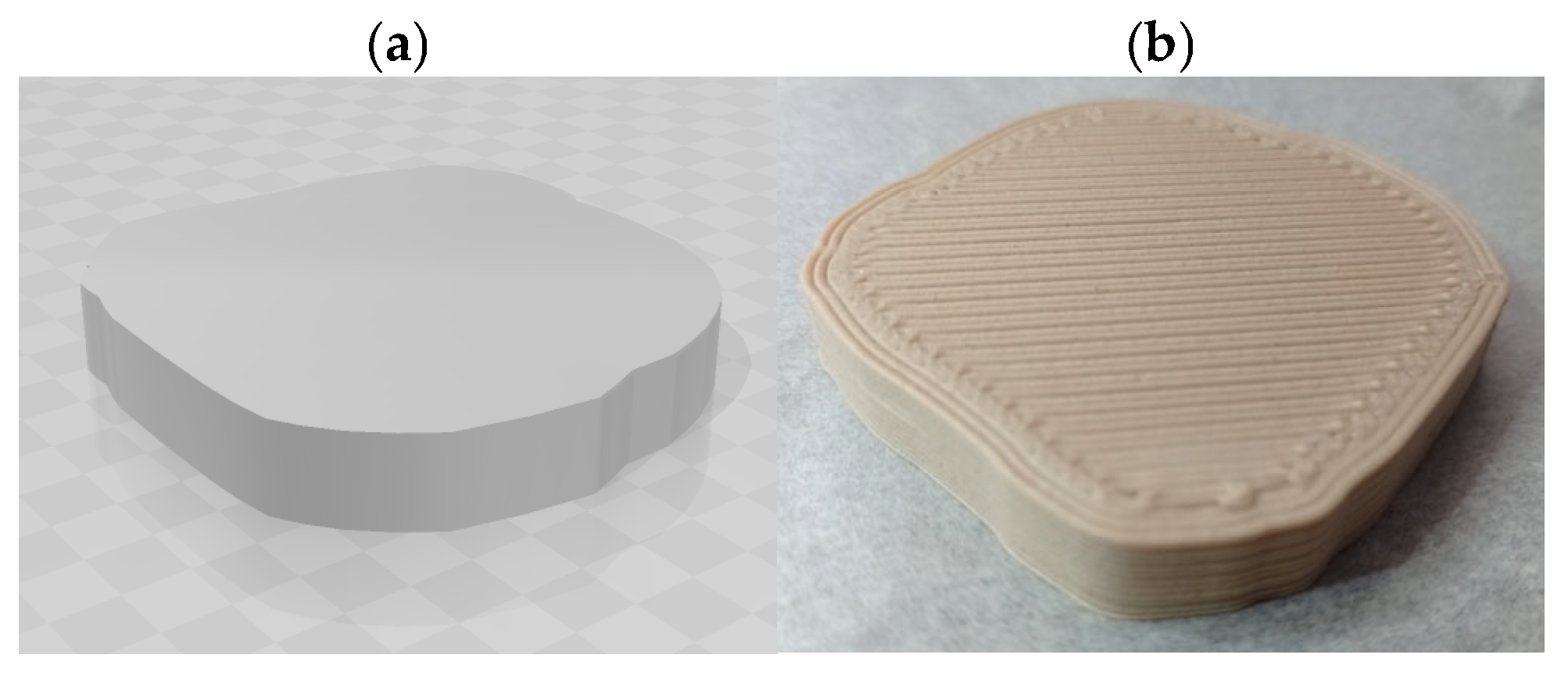

After printing the chicken nuggets model using homogenized meat mass, it is manually breaded, then baked in the air fryer. The designed model of the chicken nuggets and 3D-printed elements are depicted in

Figure 7.

2.1.3. Post-Processing

All printed samples were thermally treated after deposition to ensure microbial safety:

Baking: 180 °C for 15–20 min;

Air Frying (optional): For texture and surface browning;

Steaming: Evaluated for soft-texture variants.

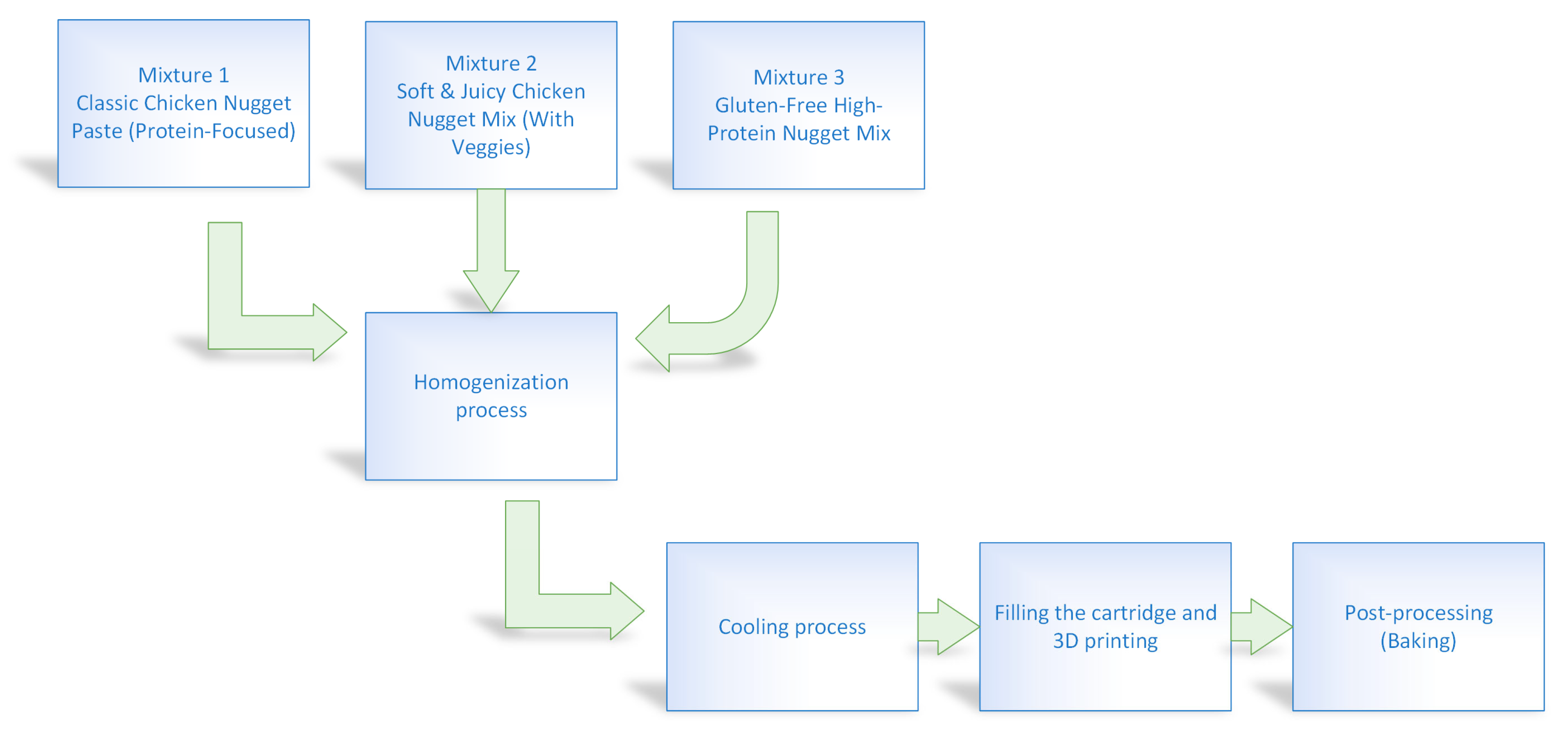

The procedural scheme of creating the 3D-printed chicken nuggets is shown in

Figure 8 with three different mixtures.

Three chicken nugget mixture recipes were designed to be suitable for 3D food printing, as given in

Table 1. These mixtures are formulated with printability in mind, focusing on smooth texture, extrusion-friendly consistency, and shape-holding capability.

Each mixture was assessed based on the following parameters:

Printability: Flow consistency, nozzle clogging, and shape retention.

Structural Integrity: Stability during and after printing.

Texture and Sensory Quality: Evaluated after cooking.

Nutritional Profile: Estimated using USDA food database references.

The success of these mixtures in 3D food printing lies in balancing ingredient function (binders, moisturizers, emulsifiers), flow behaviour, and post-print cooking compatibility. Each mixture can be customized further based on user needs, printer design, and targeted nutritional outcomes, demonstrating the versatility of additive manufacturing in personalized food production. After printing the homogenized meat mass comes the breading phase, followed by thermal processing. As we can see in

Figure 9, the printed elements change shape depending on the recipe of the homogenized meat mass during thermal processing, which, in this case, involves cooking in an air fryer at 180 degrees Celsius for 20 min.

2.2. Printing of Decorative Chocoloate Elements

Two types of chocolate formulations were prepared to evaluate their suitability for decorative 3D printing applications:

Milk Chocolate Paste: Composed of 200 g milk chocolate (36% cocoa), 50 g heavy cream, 10 g glucose syrup, and 5 g cocoa butter.

Dark Chocolate Paste: Composed of 200 g dark chocolate (70% cocoa), 20 g cocoa butter, 30 g coconut cream, and 5 g invert sugar.

All chocolate materials were food-grade and sourced from certified suppliers. Emulsifiers such as glucose or invert sugar were incorporated to improve flow properties and prevent crystallization during extrusion. Cocoa butter was added to both formulations to reduce viscosity and enhance flow control.

Table 2 gives an overview of the chocolate mixtures.

Chocolate mixtures were prepared using a double boiler system to ensure gentle, uniform melting. Ingredients were combined and heated to 40–45 °C, then stirred continuously to form a smooth and homogenous paste. After emulsification, mixtures were cooled to 28–30 °C to reach optimal extrusion viscosity. The consistency was adjusted based on flow behaviour suitable for syringe-based extrusion (soft paste consistency without separation or clogging) by maintaining the nozzle temperature at 30–32 °C during printing for continuous flow.

Three-Dimensional-Printing Process

A customized extrusion-based 3D printer was used, which included the following modifications for food-grade chocolate printing:

Food-grade stainless steel or silicone extrusion syringe;

Temperature-controlled nozzle (30–32 °C);

Heated syringe holder (35 °C set point);

Cooling plate (optional, 18–20 °C) to aid post-print solidification.

The CAD Modeling of the decorative geometries (e.g., flower, butterfly, 3D cup) were created in Tinker CAD and exported as STL files. The STL files were sliced using Cura with custom settings optimized for low-speed extrusion.

The printer settings are as follows:

The process of 3D printing chocolate involves unique challenges that differ significantly from traditional filament-based additive manufacturing. Chocolate is a temperature-sensitive material with complex rheological properties, requiring precise control over flow, solidification, and structural stability [

11]. During experimentation with decorative chocolate printing, several recurring technical issues were identified. These included nozzle clogging, inconsistent extrusion, layer deformation, and the presence of air bubbles in the syringe system. Addressing these challenges was critical for achieving reliable print quality and maintaining the integrity of fine decorative designs.

Figure 10,

Figure 11 and

Figure 12 show the 3D test models and the appropriate printed versions.

One of the most common issues encountered was nozzle clogging, which typically occurred when the temperature at the nozzle tip dropped below the minimum flow threshold for chocolate (approximately 30 °C). Chocolate would begin to solidify prematurely at the nozzle, leading to interruptions or complete blockage. To mitigate this, a low-wattage resistive heater was integrated directly into the nozzle assembly, regulated by a PID controller. This ensured a constant extrusion temperature of 30–32 °C. Additionally, the chocolate paste was pre-warmed before loading, reducing thermal shock and encouraging smoother flow from the outset. Air bubble entrapment within the syringe was identified as a key factor causing inconsistent extrusion and structural voids. These bubbles formed during the loading of the chocolate mixture, especially when the paste was too thick or introduced hastily. To counter this, the chocolate was degassed manually by tapping the filled syringe and applying slow, uniform pressure during loading. This significantly improved extrusion reliability by eliminating sudden pressure drops caused by trapped air.

As we can see in the picture, the thin elements of the model can easily break off. Care must be taken when removing from the printer platform to avoid damaging the freshly printed chocolate model. Another frequent problem was inconsistent flow, characterized by sudden stops in extrusion or post-deposition oozing. These inconsistencies were linked to both mechanical and material factors, such as pressure instability in the syringe system and the chocolate’s natural tendency to drip when warm. To address this, the G-code was customized to introduce a slight delay after retraction commands, allowing for better flow management. Retraction distance was minimized, and the print speed was reduced to 5 mm/s to prevent overshooting during delicate patterns. These adjustments helped maintain a controlled and continuous flow, which was essential for achieving fine details and clean edges.

Layer deformation and collapse also present significant challenges, especially during multi-layered prints. The semi-solid nature of warm chocolate meant that successive layers often lacked the rigidity to support the structure above, leading to slumping or smearing. This issue was addressed by introducing brief pauses between layer depositions and activating localized cooling via a small fan or thermoelectric (Peltier) cooling element. In some cases, the use of a chilled print bed at approximately 18–20 °C helped solidify each layer faster, thereby enhancing vertical stability and shape retention. The final products can look truly impressive. A great degree of creativity is required, and the result can be on a par with the creations of the greatest pastry chefs. By systematically identifying and resolving these issues, the printing process became more predictable and reproducible, laying the foundation for high-resolution, artistic chocolate creations with both aesthetic and structural fidelity as shown in

Figure 13.

The optimization of the chocolate 3D-printing process required a combination of mechanical, thermal, and procedural refinements.

3. Results

In extrusion-based 3D food printing, the nozzle diameter plays a crucial role in determining flow rate, resolution, and structural stability of the printed material. The 1.4 mm nozzle was selected for this study as an optimal mid-range size that offers a practical balance between detail and extrusion stability, particularly when working with textured food pastes like chicken nugget mixtures [

12]. Three nutritionally and functionally distinct recipes were evaluated: Mixture 1 (Classic Chicken Nugget Paste), Mixture 2 (Soft and Juicy Chicken with Veggies), and Mixture 3 (Gluten-Free Protein-eEnhanced Mix).

3.1. Mixture 1: Classic Chicken Nugget Paste (Protein-Focused)

This formulation, consisting of finely ground cooked chicken, egg white, breadcrumb, cream cheese, and seasoning, demonstrated excellent compatibility with the 1.4 mm nozzle. Its smooth, cohesive texture and moderate viscosity allowed for consistent, clog-free extrusion. The mixture’s structural behaviour was well-suited for layered deposition, retaining vertical stability during and after printing without the need for chilling between layers. The inclusion of cream cheese and egg white provided effective emulsification and binding, which helped maintain line precision and prevented material deformation. The nozzle allowed intricate designs such as nugget shapes with ridged surfaces or layered core fillings to be printed reliably. This mixture achieved the best balance of print quality, nutritional value, and post-processing integrity, making it highly suitable for both commercial and personalized applications.

3.2. Mixture 2: Soft and Juicy Chicken Nugget Mix (With Veggies)

This variant included steamed carrots and olive oil, introducing higher moisture content and reduced density. While the mixture printed reasonably well through the 1.4 mm nozzle, it exhibited a slightly softer consistency, which posed challenges for maintaining vertical shape definition in taller structures. The extrusion flow was smooth and even, but minor spreading occurred after deposition, leading to reduced edge sharpness compared to Mixture 1. Despite the softness, the nozzle size allowed for adequate control, especially when lower print speeds (4–5 mm/s) and intermediate cooling pauses were used. The benefits of this formulation included enhanced colour contrast, nutritional diversity, and a more tender bite, making it suitable for populations with chewing difficulties. However, it may require post-print structural reinforcement (e.g., partial freezing) prior to cooking.

3.3. Mixture 3: Gluten-Free Protein-Enhanced Nugget Mix

This formulation featured ground chicken, quinoa flakes, flaxseed gel, and egg white. The presence of plant-based binders and fibrous elements introduced moderate extrusion resistance, but the 1.4 mm nozzle effectively prevented clogging while still producing fine detail. The mixture was designed to be allergen-friendly, specifically formulated without common allergens such as gluten, dairy, eggs, and nuts. This mixture required a slightly higher extrusion pressure and benefited from consistent stirring and pre-loading to prevent clumping within the syringe. Despite its grainy texture, the nozzle diameter provided a good compromise between resolution and flow, enabling successful printing of moderate-complexity nugget geometries. The mixture held its shape well, and upon baking, maintained a dense, meaty texture. It performed best when slightly warmed prior to printing (28–30 °C) to reduce viscosity and improve adhesion between layers.

Table 3 gives a comparative evaluation of the chicken nuggets mixtures.

Additive manufacturing of chocolate presents unique challenges due to its rheological behaviour, sensitivity to temperature, and rapid phase transition from liquid to solid. Nozzle diameter plays a critical role in managing flow rate, extrusion control, and shape fidelity. The use of a 1.4 mm nozzle provides a versatile middle ground that balances print resolution with flow reliability, making it well-suited for printing moderately detailed edible designs. This discussion evaluates the performance of two formulations—Milk Chocolate Paste and Dark Chocolate Paste—when extruded through a 1.4 mm nozzle.

3.4. Mixture 1: Milk Chocolate Paste

Milk chocolate typically contains a higher proportion of milk solids, sugar, and fat, which makes it softer and more pliable at lower temperatures compared to dark chocolate. This composition contributed to excellent flow behaviour through the 1.4 mm nozzle at an extrusion temperature of approximately 30–31 °C. The nozzle diameter allowed for smooth, continuous extrusion with minimal pulsation or clogging. However, milk chocolate’s lower viscosity posed a slight risk of post-deposition spreading, especially when printing fine features or unsupported overhangs. To mitigate this, the print speed was optimized to 5–6 mm/s, and a controlled cooling system (e.g., Peltier-cooled plate or ambient fan) was employed to initiate rapid surface solidification after each layer. With these optimizations, the milk chocolate paste produced clean, layered structures suitable for decorative elements like letters, curved edges, and low-relief textures. One limitation was its lower melting point, which reduced the thermal tolerance during handling and post-print storage. As such, printed objects required immediate refrigeration or setting in a cooled environment to preserve dimensional accuracy.

3.5. Mixture 2: Dark Chocolate Paste

Dark chocolate, characterized by a higher cocoa solid content and lower sugar/fat ratio, presented a more viscous and robust material profile. This resulted in slightly more resistance during extrusion, yet the 1.4 mm nozzle maintained a reliable flow rate when the temperature was maintained between 32 and 33 °C. The higher viscosity provided greater shape retention and structural rigidity, which was especially beneficial for complex geometries or multi-layered forms. Because of its stiffer consistency, dark chocolate exhibited sharper edge definition and less spreading upon deposition. It performed better under ambient conditions and was more resistant to deformation during handling or plating. However, its increased hardness and reduced fat content also meant it was less forgiving to nozzle imperfections or inconsistent temperature control, requiring fine-tuned PID heating elements and stable feed rates. While dark chocolate’s higher cocoa content enhances antioxidant properties and consumer appeal, it may also limit the sweetness and mouthfeel preferred by some users. Nevertheless, from a mechanical perspective, it proved ideal for precise, high-stability prints using the 1.4 mm nozzle.

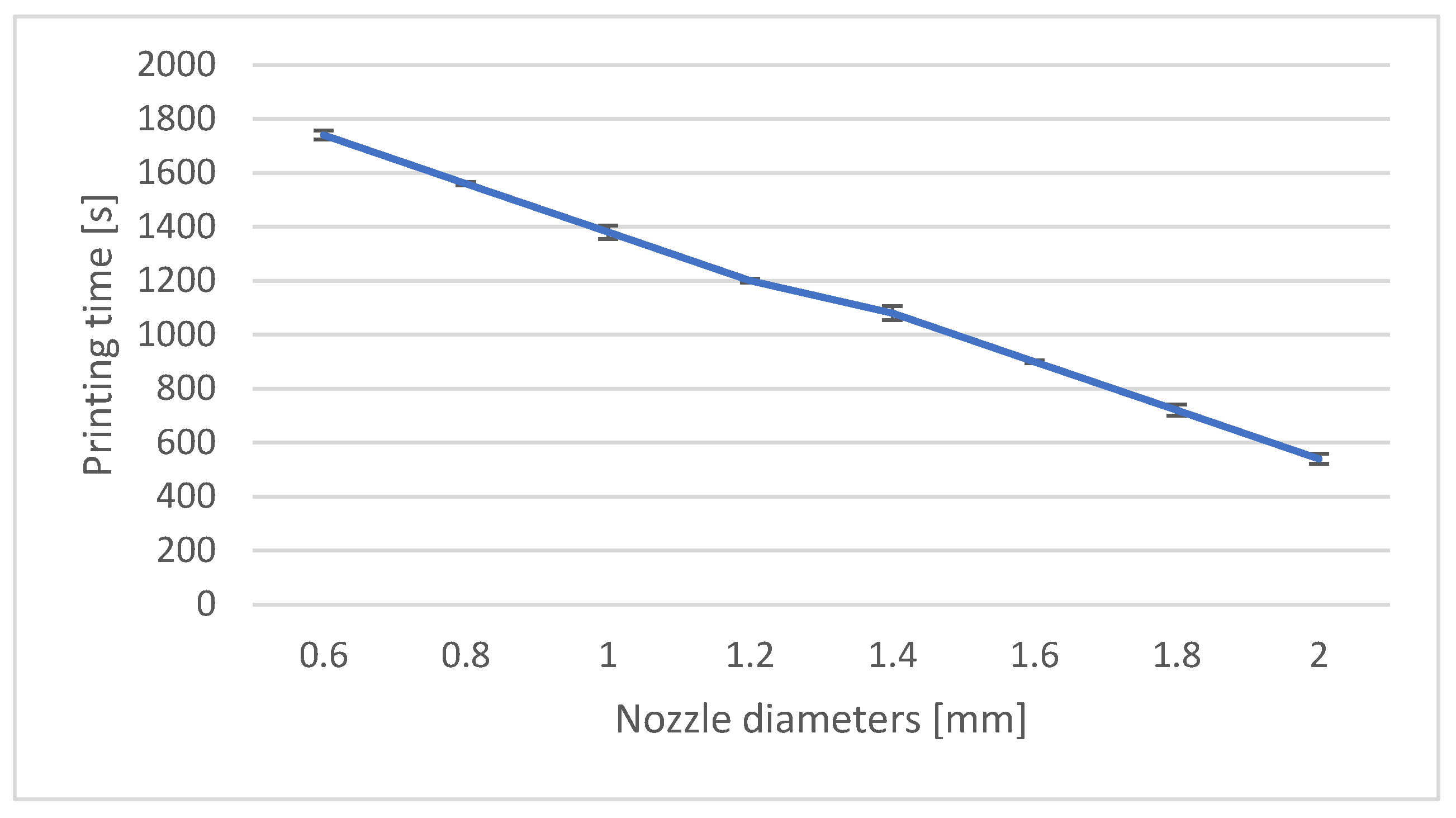

3.6. The Nozzle Diameter Test Using Chocolate Paste

The nozzle diameter is a critical parameter in extrusion-based 3D food printing, directly influencing material flow, resolution, print speed, and structural accuracy. In chocolate 3D printing, where the material exhibits temperature-dependent viscosity and a narrow solidification window, nozzle selection becomes even more vital. This discussion examines the effects of nozzle diameters ranging from 0.6 mm to 2 mm on the printability and quality of decorative chocolate elements using a modified 3D printer (see

Figure 14). The test was conducted using a butterfly model shown in

Figure 11.

Smaller nozzles (0.6 mm, 0.8 mm, and 1.0 mm) offer a higher resolution, making them suitable for intricate designs such as text, filigree, or fine lattice structures. However, these nozzles presented notable challenges with flow consistency and clogging, especially in ganache-based mixtures containing cream or inclusions. The chocolate mixture required a highly refined texture—fully melted, emulsified, and free of particulates—to avoid blockages. Extrusion through smaller nozzles also demanded tighter thermal control. A slight drop in nozzle temperature caused rapid solidification, impeding flow. Flow rates had to be reduced significantly (as low as 1–2 mm3/s), which increased overall print time. Additionally, higher extrusion pressures were needed, leading to mechanical strain on stepper motors and syringes. Despite these limitations, fine nozzles yielded excellent edge definition when used under optimal conditions, making them suitable for precision chocolate sculpting.

Nozzles in the 1.2 mm to 1.4 mm range offered the best balance between detail and reliability. These diameters allowed for smoother extrusion, reduced clogging risk, and still maintained acceptable resolution for most decorative applications. Layer adhesion was strong, and the structures held their shape without post-deposition collapse, especially when cooling was applied between layers. Print speed could be moderately increased (up to 4–5 mm

3/s), making this range ideal for medium-complexity chocolate designs, including logos, basic figurines, and layered confections, as can be seen in

Figure 15. These nozzles proved forgiving with minor formulation inconsistencies, making them the preferred choice for reliable, repeatable results in both prototype and production environments.

The repeatability of chocolate 3D printing was evaluated by printing identical samples using fixed parameters across multiple trials. Key metrics included dimensional consistency, surface smoothness, and extrusion stability. The results showed high repeatability, particularly at 1.4 mm nozzle size, with minimal variance (<5%) in layer height and shape accuracy. Printer reliability was confirmed through consistent motor response, temperature control, and material flow over extended use.

Larger nozzles (1.6 mm, 1.8 mm, and 2.0 mm) provided superior flow and greatly minimized clogging, which was particularly beneficial when printing chocolate mixtures with added solids (e.g., nuts, fruit particles, or textured cocoa nibs). These nozzles allowed high-volume extrusion rates (8–10 mm3/s), reducing print time for large-scale decorative elements or filled molds. However, this came at the cost of reduced precision and surface smoothness. Edges appeared rounded, and overhangs were less defined. These nozzles are most appropriate for bulk chocolate deposition, base layers, or simple 3D forms where resolution is secondary to throughput.

3.7. Rheological Characterization Using Developed Mixtures

Rheological characterization outlines the key rheological parameters needed to validate material behaviour and printability performance of the chicken nugget and chocolate pastes developed for 3D food printing.

Formulation Overview of Chicken Nugget Pastes for 3D Printing:

Mixture 1: Classic Chicken Nugget Paste (Protein-Focused)—This formulation emphasizes a high protein content and minimal fat, using cooked chicken breast as the base. The inclusion of egg white improves protein structure and contributes to post-print binding, while cream cheese or yogurt aids in paste cohesiveness and smooth extrusion. Breadcrumb or oat flour serves as a mild thickening agent to support stackable layer consistency.

Mixture 2: Soft and Juicy Chicken Nugget Mix (With Veggies)—Designed for enhanced moisture retention and a child-friendly flavour, this mix uses raw chicken thigh for a higher fat content and softer texture. Mashed steamed vegetables (carrot or pumpkin) add micronutrients and natural binding properties, while starch improves printability by increasing viscosity. Olive oil or broth balances extrusion flow with added lubrication and taste.

Mixture 3: Gluten-Free, Protein-Enhanced Nugget Mix—Targeting dietary restrictions and protein enrichment, this recipe replaces conventional binders with quinoa or chickpea flour for a gluten-free structure. Nutritional yeast adds depth in flavour and nutritional complexity. The use of Greek yogurt or silken tofu aids smoothness, while flaxseed gel provides an egg-free binding alternative. The blend’s rheology is optimized for extrusion through higher protein and starch synergy.

Formulation Overview of Chocolate-Based Pastes for 3D Printing:

Mixture 1: Classic Milk Chocolate Paste—This formulation is optimized for a mild flavour and smooth extrudability. The blend consists of 200 g high-quality milk chocolate (35–40% cocoa content) as the base matrix, enriched with 50 g heavy cream (35% fat) to enhance flowability and reduce brittleness during post-deposition cooling. Next, 5 g cocoa butter is added to further adjust viscosity and promote a glossy finish, while 10 g corn syrup or glucose (optional) acts as a humectant and anti-crystallization agent, improving extrusion stability and preventing graininess. A pinch of salt enhances flavour complexity without impacting rheology.

Mixture 2: Dark Chocolate Paste—Formulated for a richer flavour and enhanced antioxidant content, this mixture uses 200 g dark chocolate (60–70% cocoa) for its robust structure. To fine-tune flow behaviour, 20 g cocoa butter is incorporated as a plasticizer, ensuring smooth nozzle deposition. The addition of 30 g coconut cream or full-fat coconut milk imparts creaminess and improved spreadability without excessive softening. Further, adding 5 g honey or invert sugar (optional) helps regulate plasticity and contributes to a pleasant mouthfeel post-printing.

Table 4 shows the rheological values of the three chicken nugget mixtures and two chocolate pastes. Significant progress was made toward personalized nutrition by systematically investigating how water content and macronutrient composition influence the rheological properties of multi-component mixtures intended for 3D food printing.

In 3D printing, materials exhibiting shear-thinning behaviour are advantageous, as they flow readily under high shear rates during extrusion and regain their structure upon deposition.

Table 4 presents the rheological stability and behaviour of the tested mixtures, as evaluated using a microrheological approach. Measurements were conducted with an Anton Paar MCR 501 Rheometer. The mechanical integrity of each sample was assessed through its storage modulus (G′) and loss modulus (G″), which reflect the elastic and viscous components, respectively. Mixtures demonstrating higher G′ values possess greater mechanical strength, translating to enhanced self-supporting capability during and after printing. This contributes to reduced deformation and higher precision in printed structures. The viscoelastic nature of the samples was further analyzed using the damping factor (tan δ), calculated as the ratio of G″ to G′. A tan δ greater than 1 indicates a material predominantly exhibiting viscous behaviour, whereas values less than 1 suggest an elastic-dominant material. These values support discussions around printability, layer stability, and customization potential for both savory and sweet formulations. Since the tactile and structural characteristics of printed food are influenced by both viscosity and elasticity, mixtures with higher values in these parameters tend to be more shape-retentive and resistant to mechanical deformation. Such rheological traits are critical in ensuring print fidelity and achieving structurally stable and well-defined edible constructs.

4. Discussion

The choice of nozzle diameter in chocolate 3D printing should be guided by the intended application. Smaller nozzles (≤1 mm) are ideal for detailed artistic work but demand high precision in formulation and thermal control. Mid-range nozzles (1.2–1.4 mm) strike the best balance for general-purpose decorative printing [

13,

14,

15,

16]. Larger nozzles (≥1.6 mm) excel in speed and reliability but are limited in resolution. Ultimately, matching nozzle size with material behaviour and design complexity is essential for successful edible fabrication using 3D printing technology.

4.1. Personalized Nutrition Through 3D Food Printing Technology

As dietary needs become increasingly individualized due to medical conditions, lifestyle choices, age, and performance goals, personalized nutrition has emerged as a key trend in health and food science. Three-dimensional food printing—a form of additive manufacturing—offers unprecedented opportunities to deliver customized meals that cater to specific nutritional profiles, preferences, and even genetic markers. This technology’s ability to precisely control ingredient composition, portion size, and structure enables food to be tailored in ways that traditional preparation methods cannot easily achieve. At the heart of 3D food printing’s potential for personalized nutrition lies its layer-by-layer deposition approach, which allows for micron-level precision in the distribution of macronutrients (proteins, carbohydrates, fats) and micronutrients (vitamins, minerals). This precision makes it possible to design meals for individuals with specific dietary restrictions, such as gluten intolerance, lactose sensitivity, or low-sodium requirements, as well as for those with clinical conditions like diabetes, cardiovascular disease, or cancer. For example, a 3D printer can be programmed to produce a high-protein, low-carb breakfast for an athlete, while printing a fibre-rich, easily chewable meal for an elderly patient suffering from dysphagia. Furthermore, patients undergoing recovery can receive texturized, visually appealing meals that meet medical nutrition therapy guidelines, reducing mealtime refusal and enhancing quality of life [

17]. These personalized formulations can even be enhanced with bioactive compounds, probiotics, or controlled-release nutrients, giving food a functional role beyond basic sustenance. Another advantage lies in the ability to create portion-controlled meals, addressing global health concerns like obesity and malnutrition. By precisely depositing specific amounts of ingredients, 3D food printing helps in calorie control and ensures balanced nutrient intake. When integrated with wearable health monitors or dietary tracking apps, future systems could automatically generate food designs in response to real-time biometrics such as blood sugar or hydration levels, creating a closed-loop nutrition ecosystem. Despite its promise, several challenges must be addressed. The formulation of printable food pastes with both suitable rheology and desirable nutritional profiles remains complex. Many healthy ingredients, such as whole grains, leafy vegetables, or lean meats, are difficult to extrude unless blended with binders or emulsifiers, which can alter their nutritional value. Additionally, the temperature sensitivity of nutrients during the printing and post-processing stages may lead to degradation, especially for heat-labile vitamins. Consumer acceptance is also a crucial factor. While personalization appeals to health-conscious and tech-savvy consumers, skepticism remains regarding the “artificial” nature of printed food. Ensuring transparency in ingredient sourcing, improving aesthetic and sensory quality, and promoting culinary creativity through design may help bridge this gap [

18,

19,

20,

21].

4.2. Challenges in the Acceptance of 3D-Printed Food Technology

While 3D food printing represents a cutting-edge intersection of culinary arts, food science, and digital technology, its widespread acceptance still faces a number of challenges. These barriers span consumer perception, sensory quality, technological limitations, cost, cultural attitudes, and regulatory uncertainties, all of which influence how this novel technology is adopted in both domestic and commercial food environments [

22]. One of the most prominent obstacles is consumer skepticism. For many individuals, food is not just a source of nutrition—it is deeply tied to tradition, identity, and sensory experience. The idea of food being created by a machine rather than by hand often evokes a sense of artificiality. Consumers may question the safety, freshness, and naturalness of printed meals, especially when the ingredients are not immediately recognizable in their raw form. The lack of familiarity with extrusion-based food production processes contributes to a perception that printed food is overly processed or synthetic, even when made from real, wholesome components [

23]. Aesthetic and textural limitations also pose challenges. Although 3D printers can produce visually striking designs, early prototypes often failed to replicate the flavour complexity and mouthfeel of traditionally prepared foods. Especially with protein- or vegetable-based formulations, achieving the right balance between printability and palatability remains technically demanding. Without improvements in sensory quality, even nutritionally optimized meals may not gain traction with users who value taste, aroma, and visual appeal equally. From a technical standpoint, 3D food printing still faces limitations in terms of speed, scalability, and reliability. Printing a multi-ingredient dish can take significantly longer than traditional cooking, which hampers its appeal for quick-service environments. Moreover, the development of food-grade printable materials that are both nutritionally dense and structurally stable remains an active area of research. Many healthy ingredients—such as fibrous vegetables, whole grains, or lean meats—must be highly processed or mixed with additives to be printable, which may counteract the health benefits or alter natural flavour profiles. Cost is another significant factor. The current price of specialized food printers, cartridges, and maintenance places the technology out of reach for most consumers and small businesses. Until devices become more affordable and user-friendly, 3D-printed food will remain largely confined to niche markets such as luxury dining, scientific research, or space missions [

24,

25,

26,

27,

28]. Cultural and psychological barriers also play a role. In many societies, food preparation is a communal or family activity. Delegating this task to a machine may reduce emotional engagement with food and create resistance based on values of tradition and craftsmanship. Furthermore, there may be generational gaps in acceptance, with younger tech-savvy users more open to experimentation than older demographics. Finally, regulatory and safety concerns remain unresolved. The standardization of printing materials, cleaning protocols, and food safety regulations specific to 3D-printed consumables is still developing [

29,

30,

31,

32]. Clear guidance from food authorities is essential to foster consumer trust and industry confidence.

Rheological properties are fundamental in determining the printability and structural integrity of food inks used in extrusion-based 3D printing. In this study, both chocolate and chicken nugget formulations were characterized by their viscoelastic behaviour—quantified via storage modulus (G′), loss modulus (G″), and damping factor (tan δ)—to evaluate their suitability for maintaining shape fidelity post-deposition. These properties were analyzed in conjunction with printing behaviour using different nozzle diameters, emphasizing the practical relevance of rheology to the 3D-printing process. All three chicken nugget pastes and the two chocolate formulations exhibited shear-thinning behaviour, which is essential for smooth flow through the nozzle under shear stress while ensuring rapid solidification post-extrusion. Among the mixtures, the Gluten-Free Protein-Enhanced Nugget Mix displayed the highest G′ value, indicating superior elasticity and shape retention, consistent with reports in [

33], who emphasize that higher G′ values correlate with better shape fidelity in printed food constructs. In contrast, the Soft and Juicy chicken mixture, while printable, had a lower G′ and a higher tan δ (>1), suggesting a more viscous than elastic behaviour, which could lead to structural collapse during layer buildup—an observation supported in [

34]. For the chocolate mixtures, the addition of cocoa butter significantly influenced flowability and microstructure. The dark chocolate mixture, with a higher cocoa content and lower tan δ, showed improved elastic recovery and reduced spreading upon deposition, corroborating the findings of [

33], where optimal viscoelastic balance was shown to support high-resolution chocolate printing. The milk chocolate formulation, while softer, benefited from the inclusion of glucose and cream, improving flow at the expense of shape accuracy, similar to the patterns observed in prior research [

35]. Furthermore, the comparison of our rheological values with benchmarks in the literature illustrates that the tested mixtures fall within the desirable rheological window for 3D food printing. For example, ideal 3D-printable food materials generally possess G′ values in the range of 100–1000 Pa and tan δ < 1 to ensure a dominant elastic behaviour [

34]. Our results align with this range, particularly for the protein-focused chicken mixture and the dark chocolate paste. In combination with extrusion behaviour across different nozzle diameters (discussed in

Figure 14), the rheological measurements also explain the observed trade-offs between flow ease and print resolution. Larger nozzles allowed faster printing but diminished fine detail, especially in softer mixtures. These findings emphasize that rheological tailoring must align with hardware parameters, reinforcing the need for integrative optimization in 3D food printing.

5. Conclusions

Chocolate production is complex and requires several technological operations and processes to achieve the desired product quality. During processing, the physical and rheological properties and sensory perception of chocolate are largely influenced by processing techniques, particle size distribution, and recipe. In order to improve the quality of chocolate in terms of appearance, texture, taste, and aroma, the solid particle size distribution and ingredient composition can be manipulated to modify physical, rheological, and sensory properties. In recent years, several improvements in chocolate quality have been made using different processing and recipe strategies. However, using particle size distribution and recipe as tools to change the rheological and sensory properties of chocolate still requires a better understanding of the fundamental principles and factors that influence changes in flow behaviour and other physical quality characteristics.

Three-dimensional food printing presents a revolutionary tool for delivering precision nutrition at scale. By merging food science, digital design, and health data, this technology opens a path toward truly individualized diets, tailored to the physiological, psychological, and lifestyle needs of the user. As formulation techniques and device accessibility improve, personalized nutrition powered by additive manufacturing could transform how we approach food—shifting it from a generic product to a custom-engineered component of healthcare and wellbeing.

While the potential of 3D food printing is vast, especially in personalized nutrition and sustainable production, its broader acceptance hinges on addressing both technical challenges and human factors. Bridging the gap between innovation and tradition, and science and culture, will be key to bringing 3D-printed food from the lab and showroom into everyday life.

One major area for future investigation involves the stability and bioavailability of nutrients throughout the printing and post-processing stages. The application of thermal and mechanical stress during extrusion may compromise the integrity of heat-sensitive micronutrients such as vitamin C, certain B-complex vitamins, and bioactive compounds. A second important research direction is the sensory evaluation and behavioural impact of 3D-printed food, particularly in specific target groups. Although personalization allows for appealing shapes and creative presentations, taste, mouthfeel, and aroma remain fundamental to user acceptance. Future studies should incorporate multi-sensory analysis using standardized sensory panels, along with behavioural studies involving children to assess their preferences, eating behaviour, and emotional responses to printed food products. Another promising avenue lies in the development of hybrid, multi-material printing systems capable of producing foods with multiple textures, ingredients, and nutritional zones in a single build. Most current 3D food printers are limited to an extrusion of homogenous pastes. Innovations in multi-head or multi-cartridge systems could allow for layer-by-layer inclusion of diverse food types, such as a protein core encased in a sweet or crunchy shell.