Influence of Laser Energy Variation on the Composition and Properties of Gradient-Structured Cemented Carbide Layers Produced by LP-DED

Abstract

1. Introduction

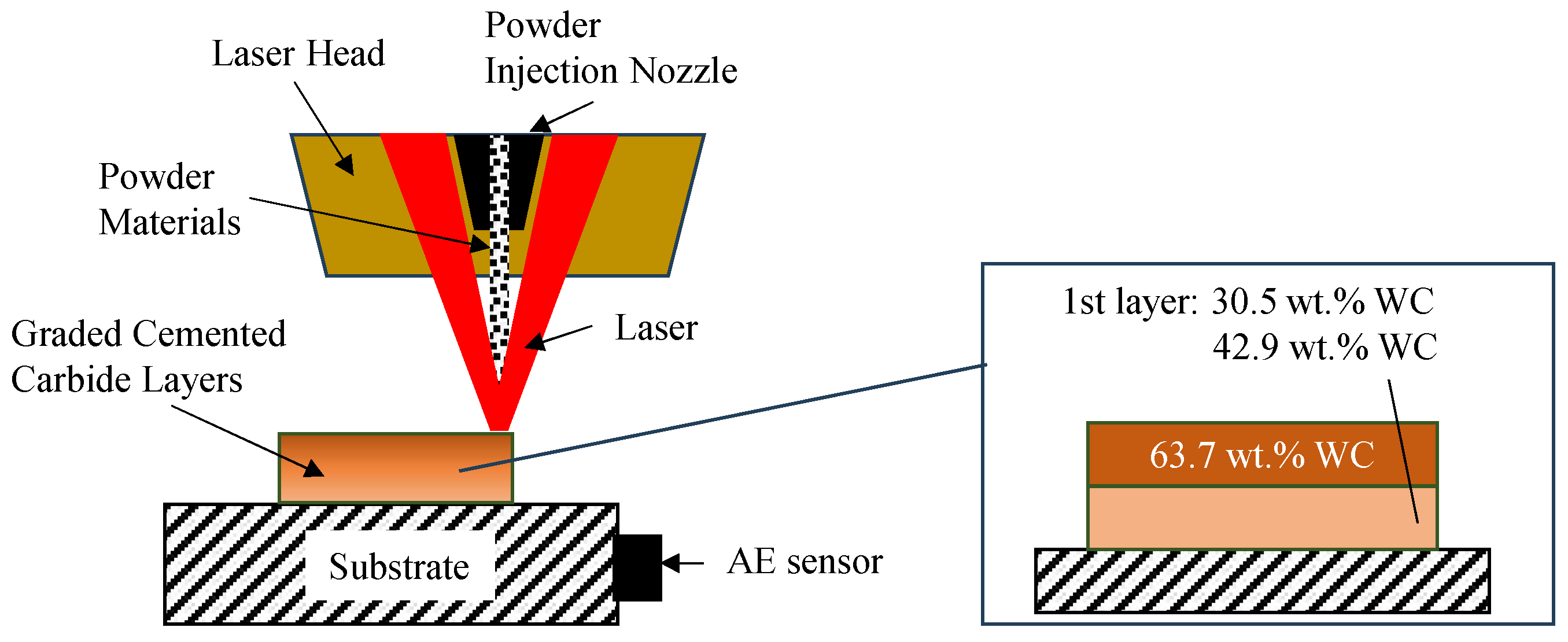

2. Materials and Methods

3. Results and Discussion

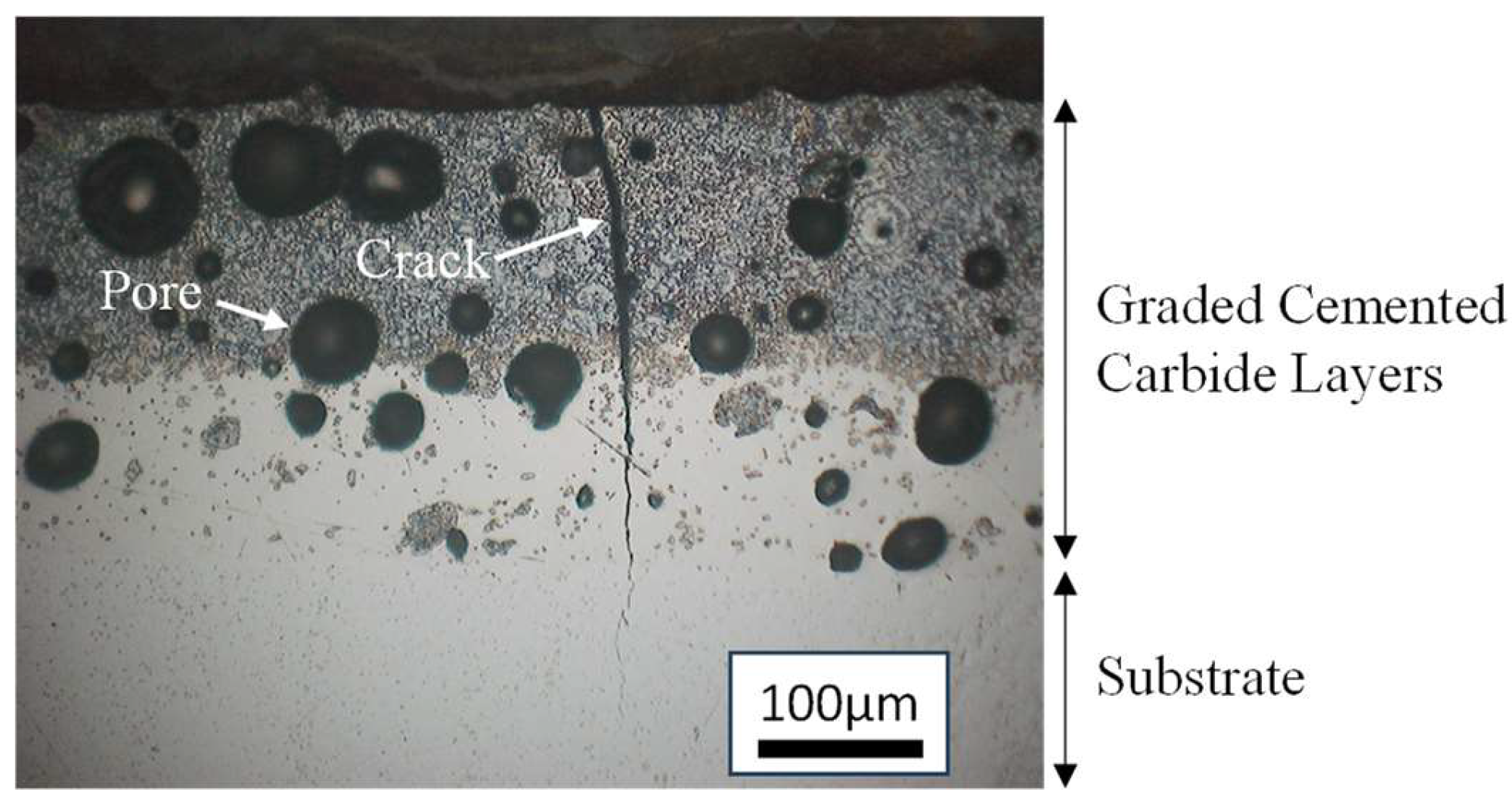

3.1. Crack Evaluation of Graded Composition Cemented Carbide Layers

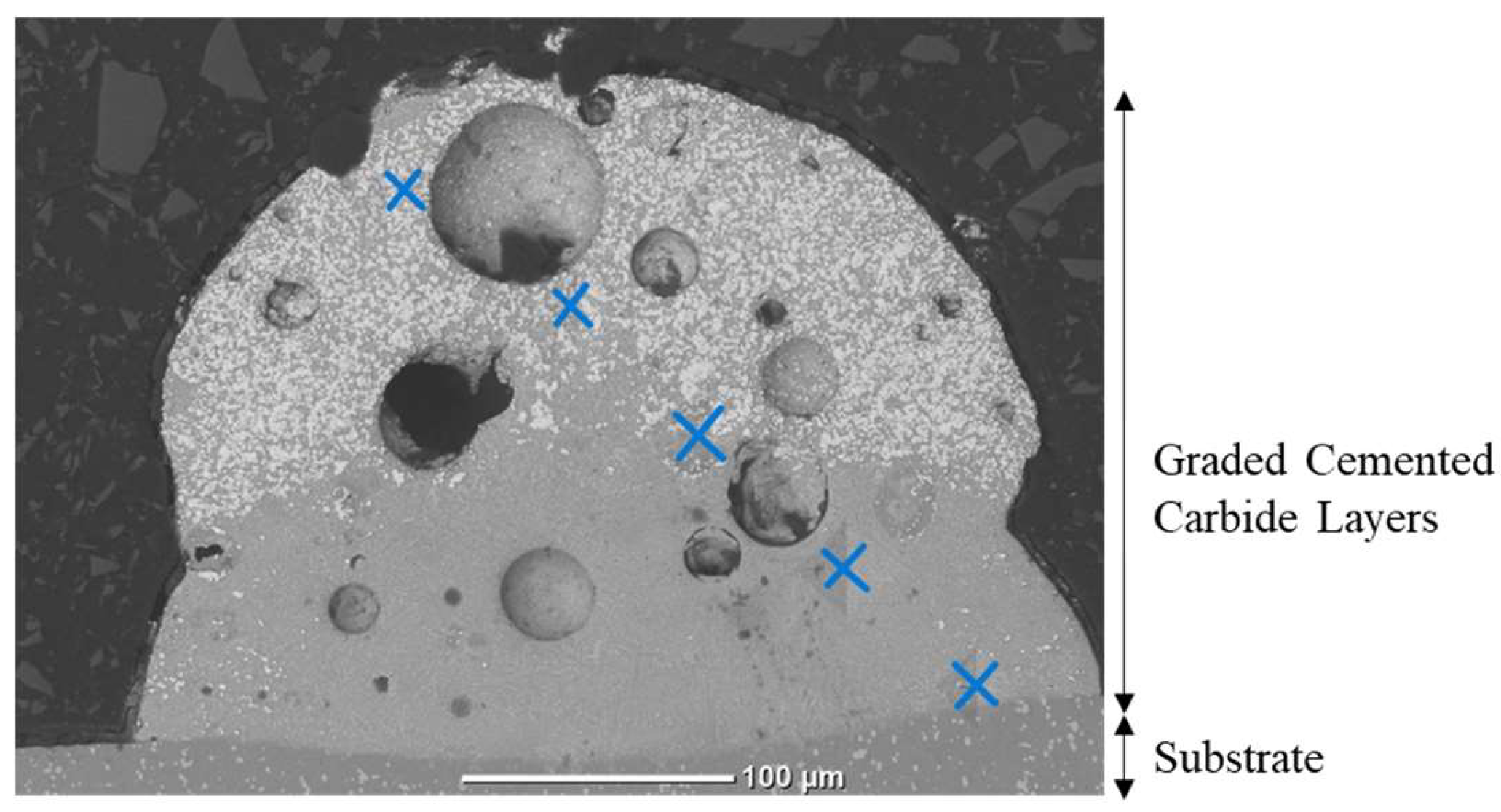

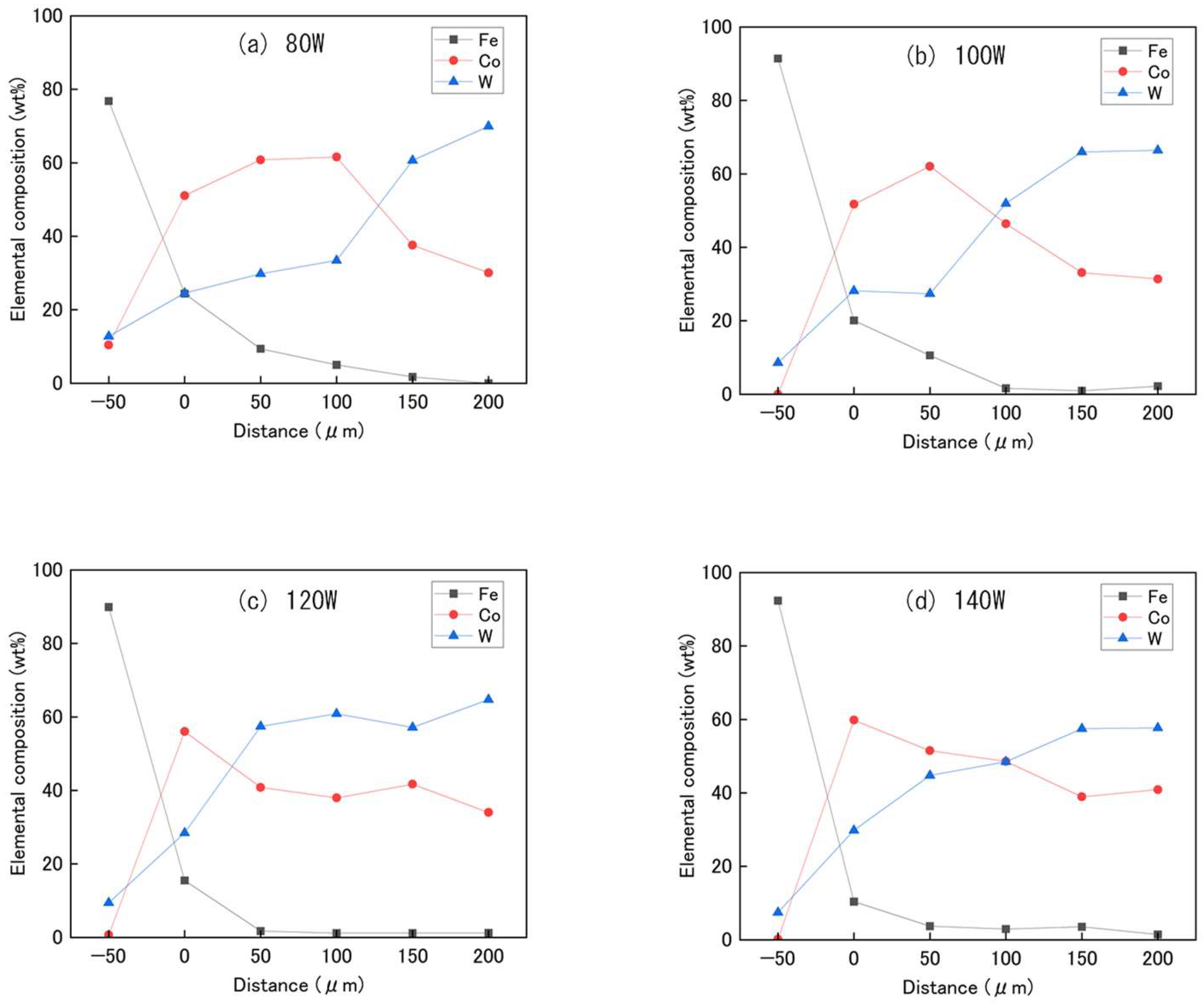

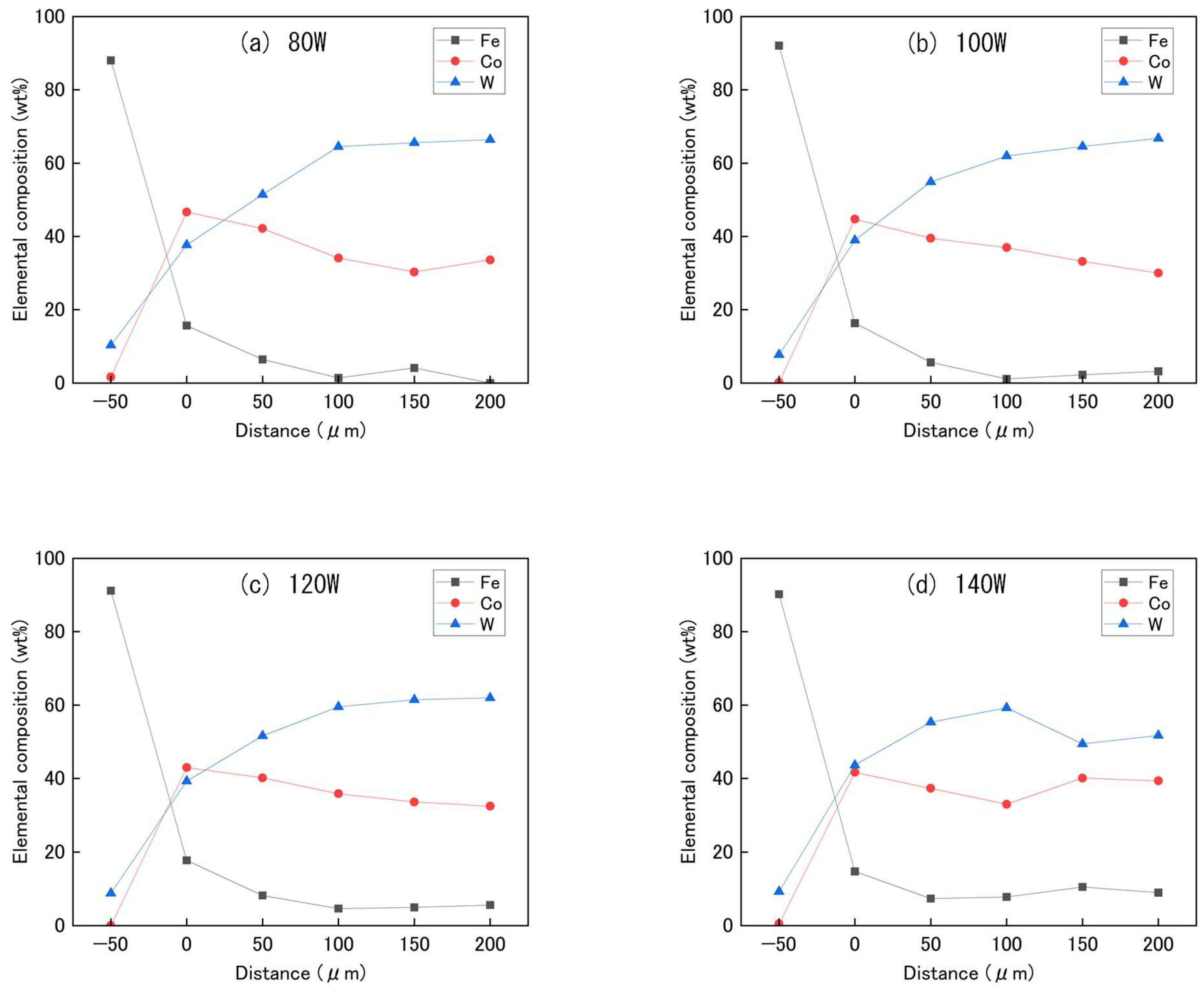

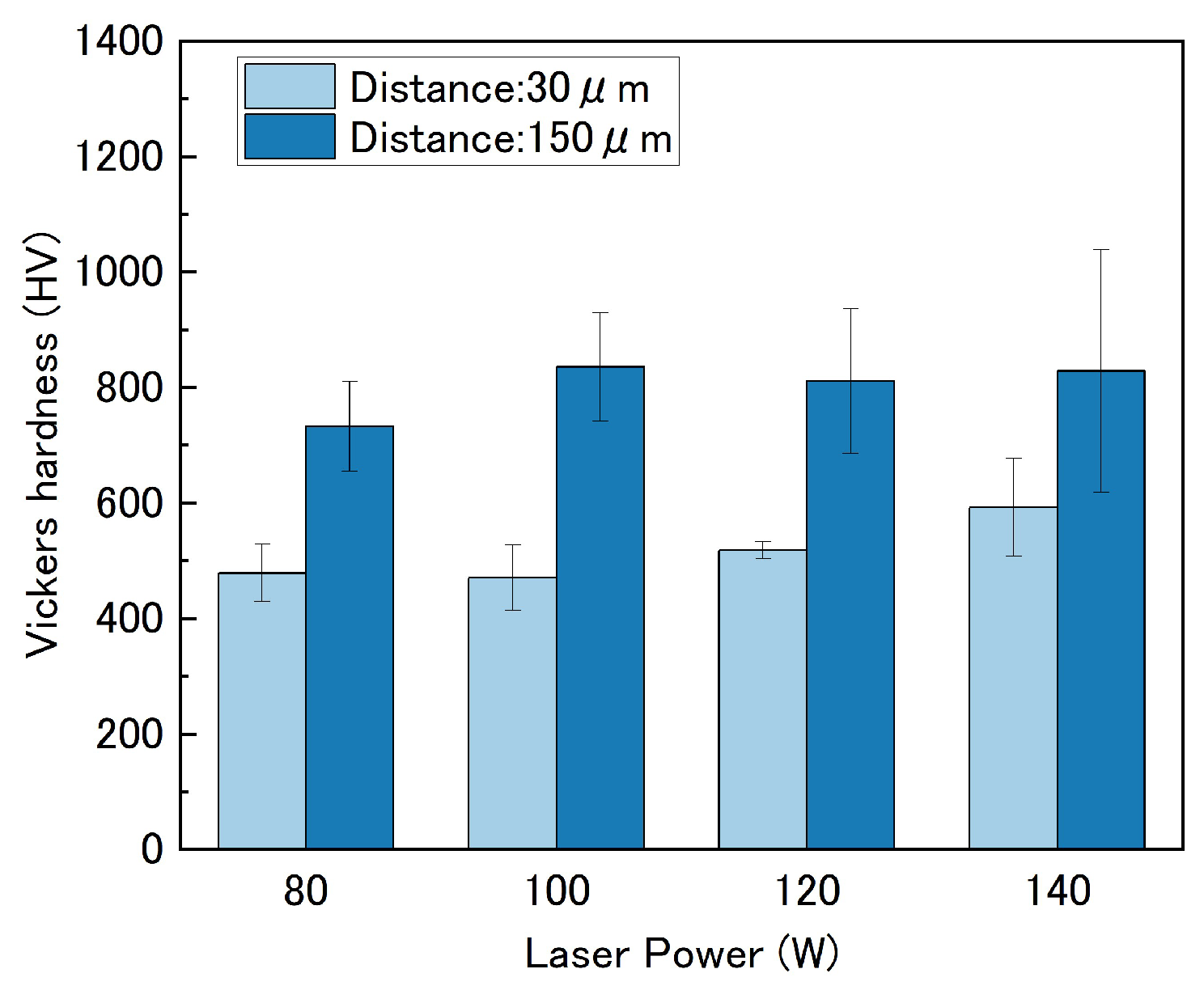

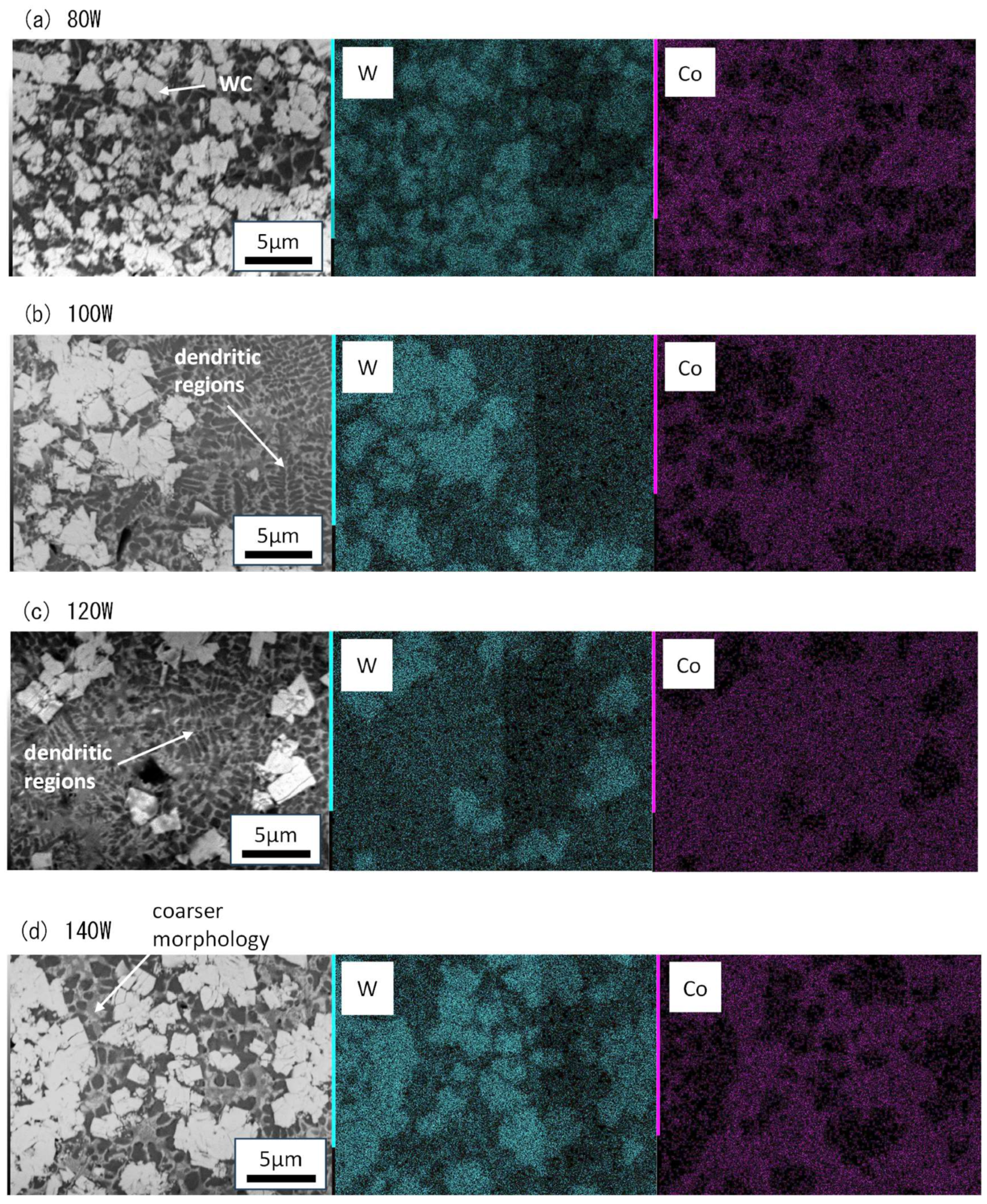

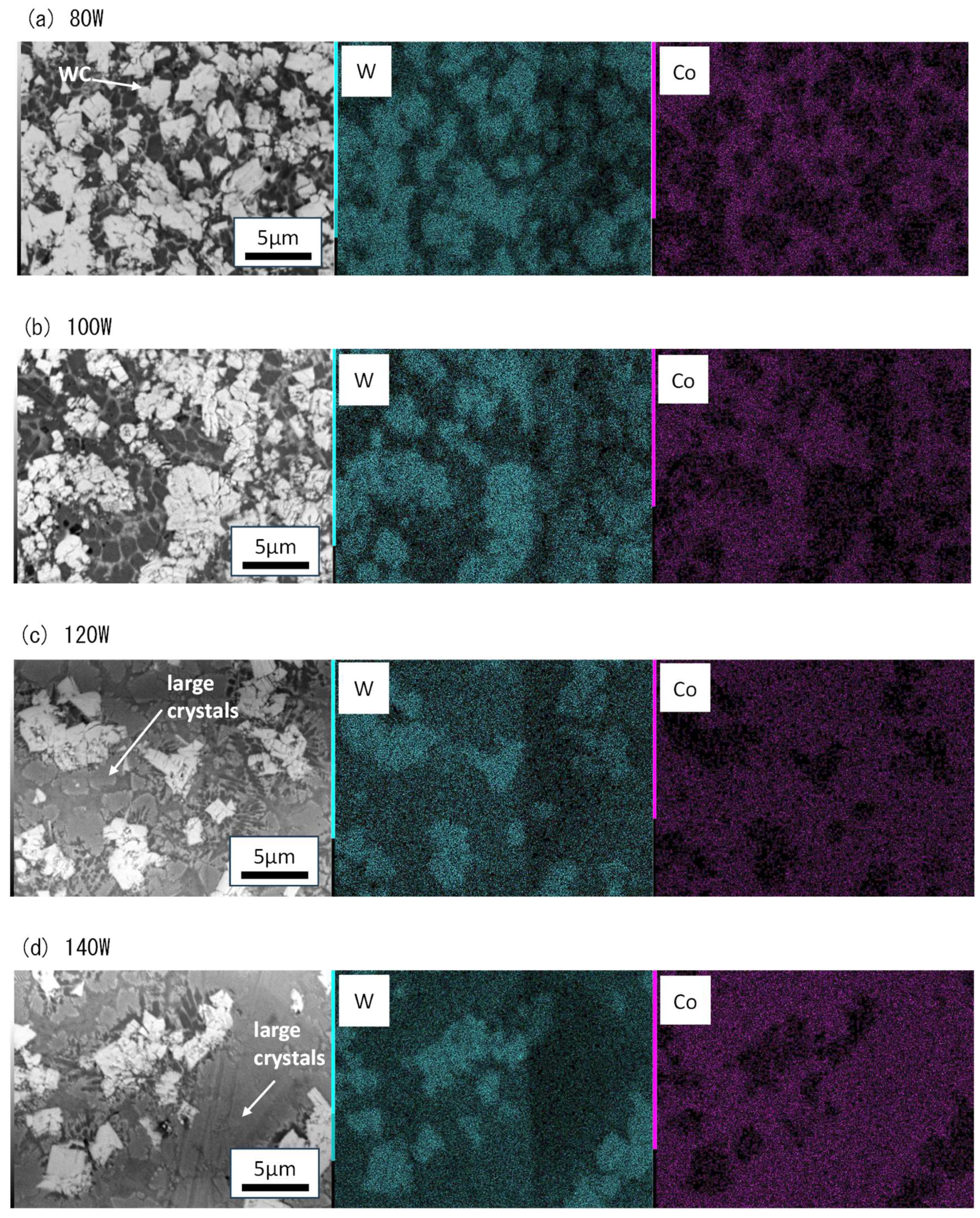

3.2. Evaluation of Elemental Composition and Hardness Characteristics

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef] [PubMed]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for Additive Manufacturing: A Systematic Review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Energy Deposition for additive manufacturing. Addit. Manuf. 2015, 8, 36–43. [Google Scholar] [CrossRef]

- Pinkerton, A.J. Lasers in additive manufacturing. Opt. Laser Technol. 2016, 78, 25–32. [Google Scholar] [CrossRef]

- da Silva, L.J.; Pacheco, J.T.; Moura, E.I.F.; de Araújo, D.B.; Reis, R.P.; D’Oliveira, A.S.C.M. Metal Matrix Composite Coatings Deposited by Laser Cladding: On the Effectiveness of WC Reinforcement for Wear Resistance and its Synergy with the Matrix Material (Ni Versus Co Alloys). Coatings 2025, 15, 468. [Google Scholar] [CrossRef]

- Novichenko, D.; Marants, A.; Thivillon, L.; Bertrand, P.; Smurov, I. Metal Matrix Composite Material by Direct Metal Deposition. Phys. Procedia 2011, 12, 296–302. [Google Scholar] [CrossRef]

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research Status of Laser Additive Manufacturing for Metal: A Review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Ben-Artzy, A.; Reichardt, A.; Borgonia, J.-P.; Dillon, R.P.; McEnerney, B.; Shapiro, A.A.; Hosemann, P. Compositionally Graded SS316 to C300 Maraging Steel Using Additive Manufacturing. arXiv 2021, arXiv:2101.08209. [Google Scholar] [CrossRef]

- Koizumi, M. FGM activities in Japan. Compos. Part B. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive Manufacturing of Functionally Graded Materials: A Review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Yamashita, Y.; Nakamura, M.; Kunimine, T.; Sato, Y.; Funada, Y.; Tsukamoto, M. Effects of WC Ratios on Bead Size and Crack Initiation in Forming WC-Co Cemented Carbides by the Laser Metal Deposition. J. Laser Appl. 2023, 35, 042010. [Google Scholar] [CrossRef]

- Kunimine, T.; Miyazaki, R.; Yamashita, Y.; Funada, Y. Effects of Laser-Beam Defocus on Microstructural Features of Compositionally Graded WC/Co-Alloy Composites Additively Manufactured by Multi-Beam Laser Directed Energy Deposition. Sci. Rep. 2020, 10, 8975. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual stress in metal additive manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Singh, D.D.; Arjula, S.; Reddy, A.R. Functionally Graded Materials Manufactured by Direct Energy Deposition: A Review. Mater. Today Proc. 2021, 47, 2450–2456. [Google Scholar] [CrossRef]

- Ostolaza, M.; Arrizubieta, J.I.; Lamikiz, A.; Plaza, S.; Ortega, N. Latest Developments to Manufacture Metal Matrix Composites and Functionally Graded Materials through AM: A State-of-the-Art Review. Materials 2023, 16, 1746. [Google Scholar] [CrossRef]

- Ostolaza, M.; Zabala, A.; Arrizubieta, J.I.; Llavori, I.; Otegi, N.; Lamikiz, A. High-Temperature Tribological Performance of Functionally Graded Stellite 6/WC Metal Matrix Composite Coatings Manufactured by Laser-Directed Energy Deposition. Friction 2024, 12, 522–538. [Google Scholar] [CrossRef]

- ISO 4957; Tool steels. International Organization for Standardization: Geneva, Switzerland, 2018.

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and materials in selective laser sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Ghaem, E.N.; Dorranian, D.; Sari, A.H. Characterization of cobalt oxide nanoparticles produced by laser ablation method: Effects of laser fluence. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 115, 113670. [Google Scholar] [CrossRef]

- Ochiai, H.; Ukai, T. Weld Residual Stress Analysis of WC-Ni Cemented Carbide Using Thermo-Elastoplasticity. J. Jpn. Soc. Des. Eng. 2005, 40, 410–415. [Google Scholar]

- The Japan Society of Mechanical Engineers (JSME). JSME Data Book: Heat Transfer, 5th ed.; Maruzen Publishing: Tokyo, Japan, 2009. [Google Scholar]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Barekat, M. Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method. Int. J. Refract. Met. Hard Mater. 2020, 88, 105199. [Google Scholar] [CrossRef]

- Gietzelt, T.; Eichhorn, L. Mechanical Micromachining by Drilling, Milling and Slotting. In Micromachining Techniques for Fabrication of Micro and Nano Structures; Kahrizi, M., Ed.; InTech: Rijeka, Croatia, 2012; pp. 157–182. [Google Scholar] [CrossRef][Green Version]

- Kubota, H. Recent Advances in Cemented Carbides (III). Shinpo Sosetsu 1968, 19, A-104–A-106. (In Japanese) [Google Scholar]

- Li, C.-J.; Yang, G.-J. Relationships between feedstock structure, particle parameter, coating deposition, microstructure and properties for thermally sprayed conventional and nanostructured WC–Co. Int. J. Refract. Met. Hard Mater. 2013, 39, 2–17. [Google Scholar] [CrossRef]

- Matthews, S.; Ansbro, J.; Berndt, C.C.; Ang, A.S.M. Carbide dissolution in WC–17Co thermal spray coatings: Part 1—Project concept and as-sprayed coatings. J. Alloy. Compd. 2021, 856, 157464. [Google Scholar] [CrossRef]

- Yamashita, Y.; Ilman, K.A.; Kunimine, T.; Sato, Y. Temperature Evaluation of Cladding Beads and the Surrounding Area during the Laser Metal Deposition Process. J. Manuf. Mater. Process. 2023, 7, 192. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | |||

|---|---|---|---|---|---|

| Laser power | W | 80 | 100 | 120 | 140 |

| Scan Speed | mm/s | 20 | |||

| Powder Feed Rate | mg/s | 20 | |||

| Laser wavelength | nm | 975 | |||

| Focused spot diameter | mm | 0.3 | |||

| Layer Thickness | mm | 0.1 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamashita, Y.; Kawabata, K.; Mori, H.; Ose, E.; Kunimine, T. Influence of Laser Energy Variation on the Composition and Properties of Gradient-Structured Cemented Carbide Layers Produced by LP-DED. J. Manuf. Mater. Process. 2025, 9, 218. https://doi.org/10.3390/jmmp9070218

Yamashita Y, Kawabata K, Mori H, Ose E, Kunimine T. Influence of Laser Energy Variation on the Composition and Properties of Gradient-Structured Cemented Carbide Layers Produced by LP-DED. Journal of Manufacturing and Materials Processing. 2025; 9(7):218. https://doi.org/10.3390/jmmp9070218

Chicago/Turabian StyleYamashita, Yorihiro, Kenta Kawabata, Hayato Mori, Eito Ose, and Takahiro Kunimine. 2025. "Influence of Laser Energy Variation on the Composition and Properties of Gradient-Structured Cemented Carbide Layers Produced by LP-DED" Journal of Manufacturing and Materials Processing 9, no. 7: 218. https://doi.org/10.3390/jmmp9070218

APA StyleYamashita, Y., Kawabata, K., Mori, H., Ose, E., & Kunimine, T. (2025). Influence of Laser Energy Variation on the Composition and Properties of Gradient-Structured Cemented Carbide Layers Produced by LP-DED. Journal of Manufacturing and Materials Processing, 9(7), 218. https://doi.org/10.3390/jmmp9070218