Statistical Correlation Analysis of Surface Roughness of Micromilled 316L Stainless Steel Components Fabricated by FDM–FFF Hybrid Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Selection and Feedstock Preparation

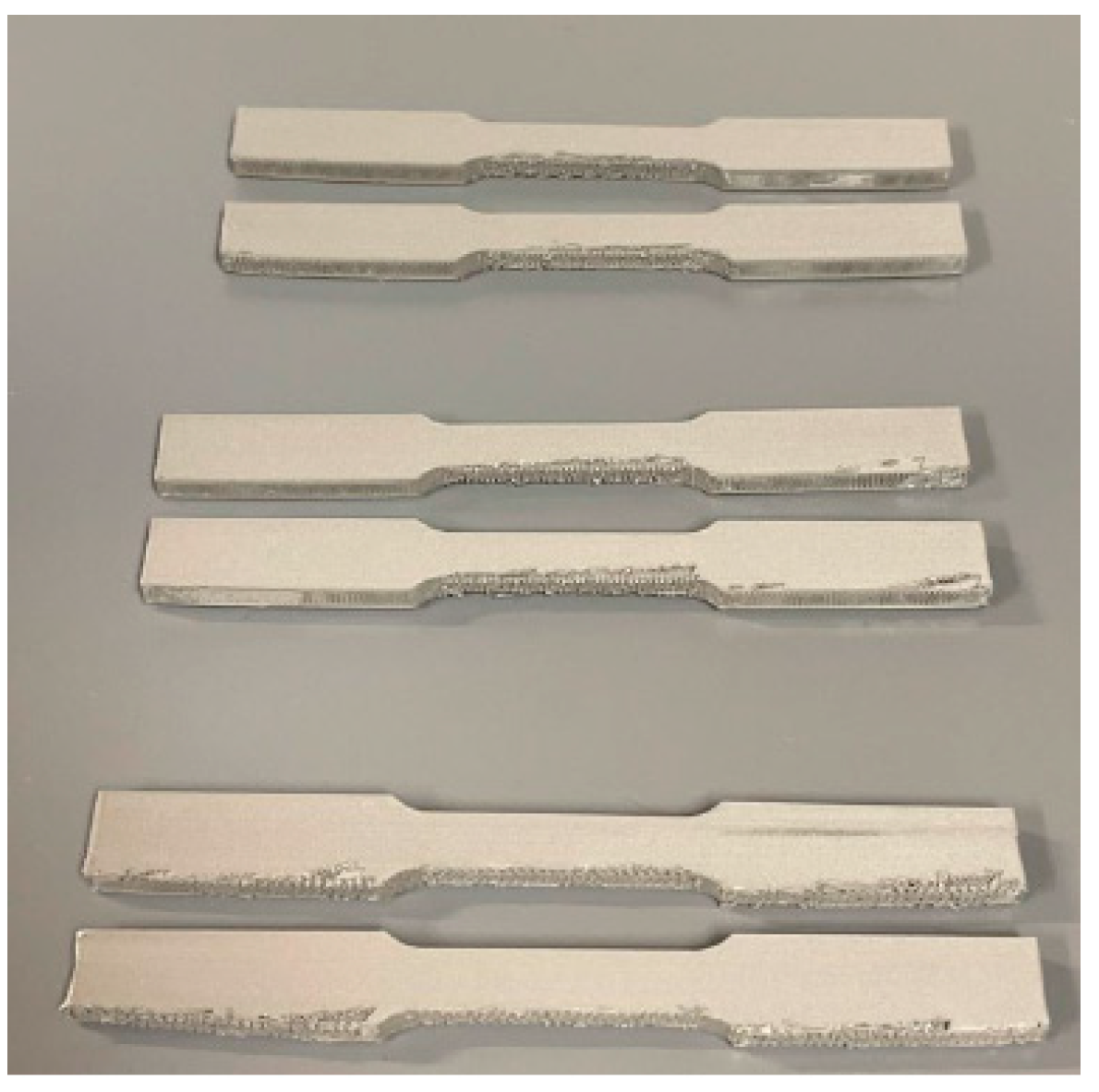

2.2. Additive Manufacturing Process

2.3. Sample Design and Experimental Matrix

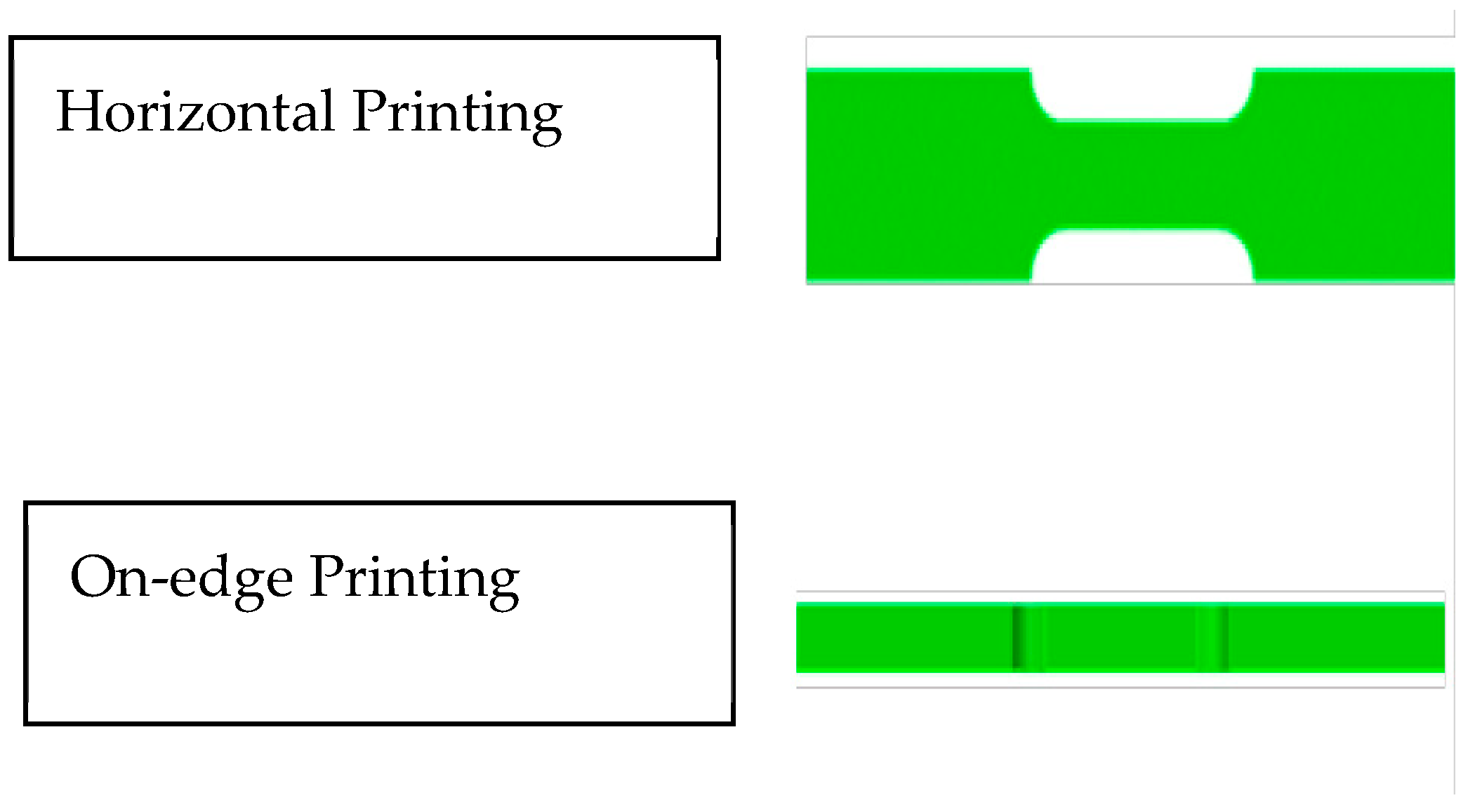

- Fabrication Direction (Input 3: FD): Macro-build orientation relative to the print bed. Affects grain alignment, porosity distribution, and residual stresses after sintering. Vertically fabricated parts tend to have higher Ra due to perpendicular layer-step ridges; creating a staircase effect that inherently increases the pre-machined surface roughness. In the correlation analysis, part orientation typically emerges as a significant factor affecting final roughness values. Horizontally fabricated parts present smoother surfaces before machining because layer deposition results in minimal visible staircase effects [8,9,17].

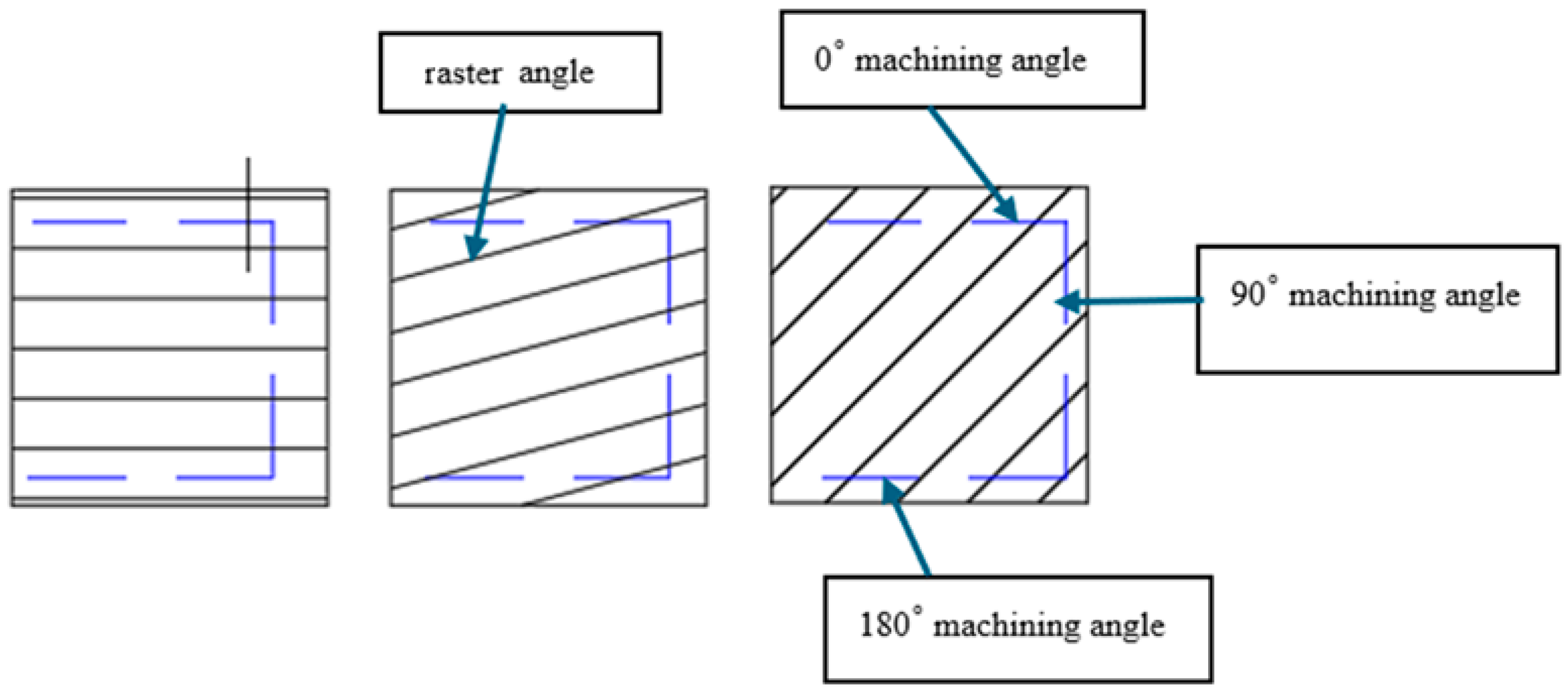

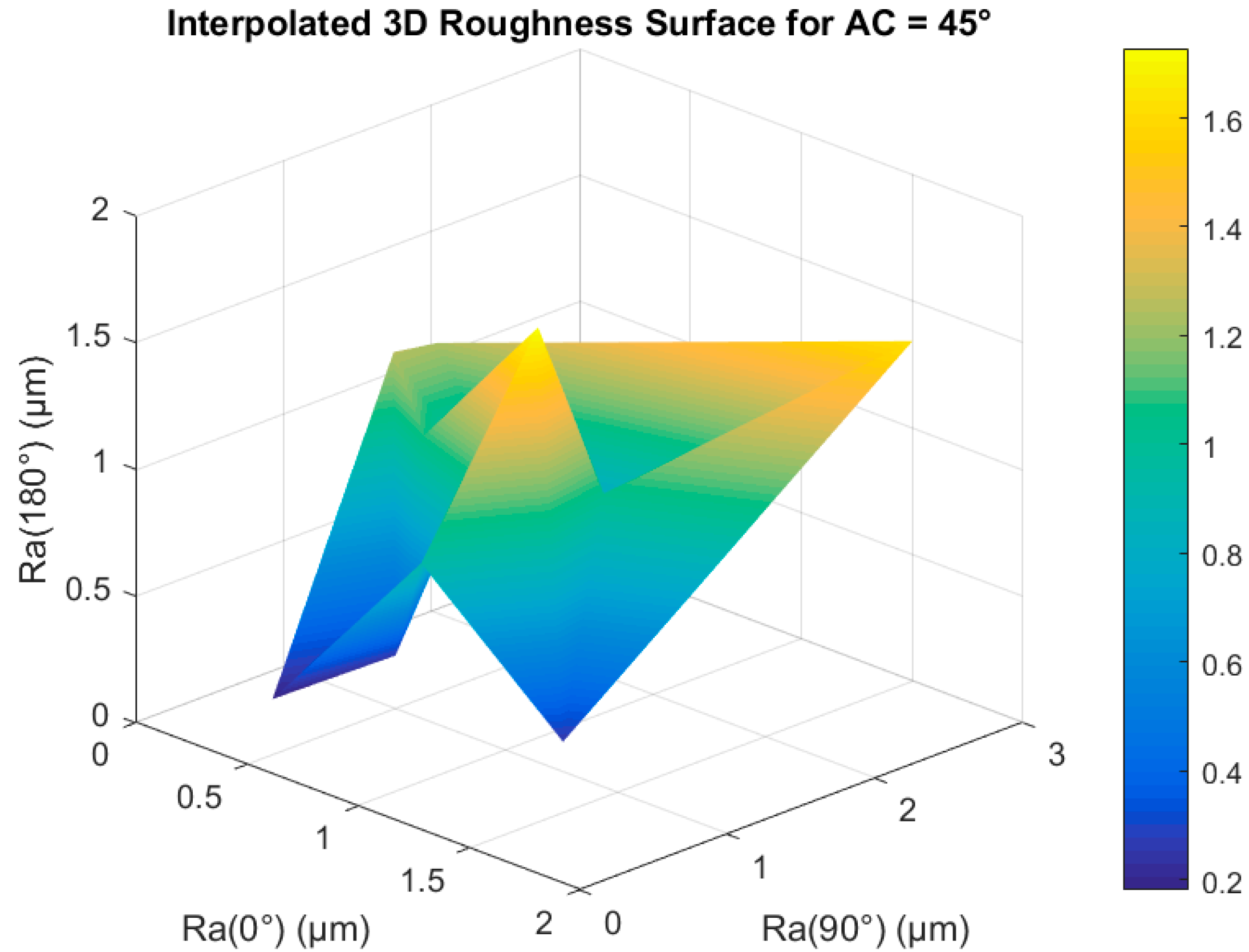

- Angle Cut (Input 4: AC): Tool-feed angle during micromilling (0°, 90°, 180°). Determines anisotropic machining response due to print-induced texture and porosity gradients; influences chip formation and surface morphology.

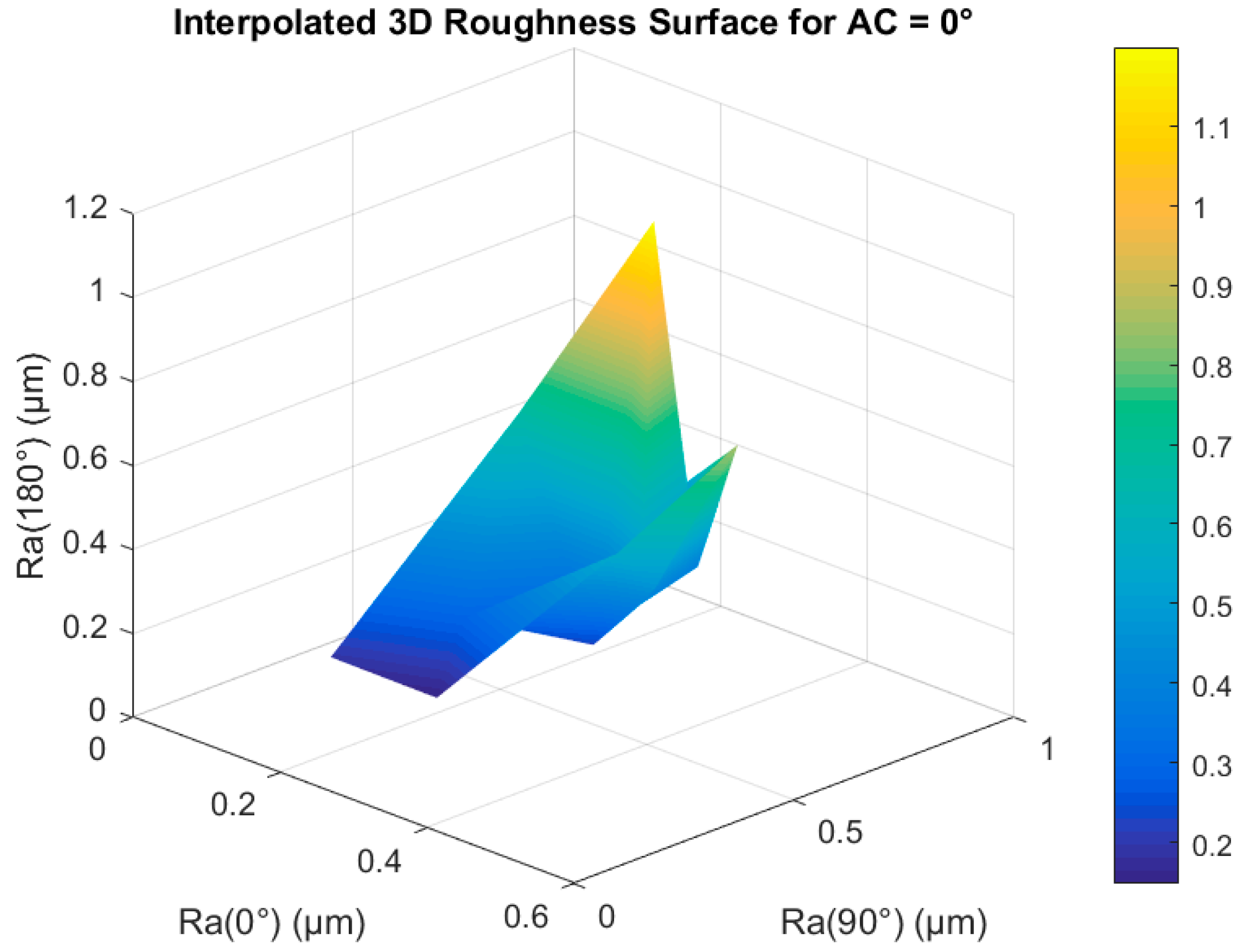

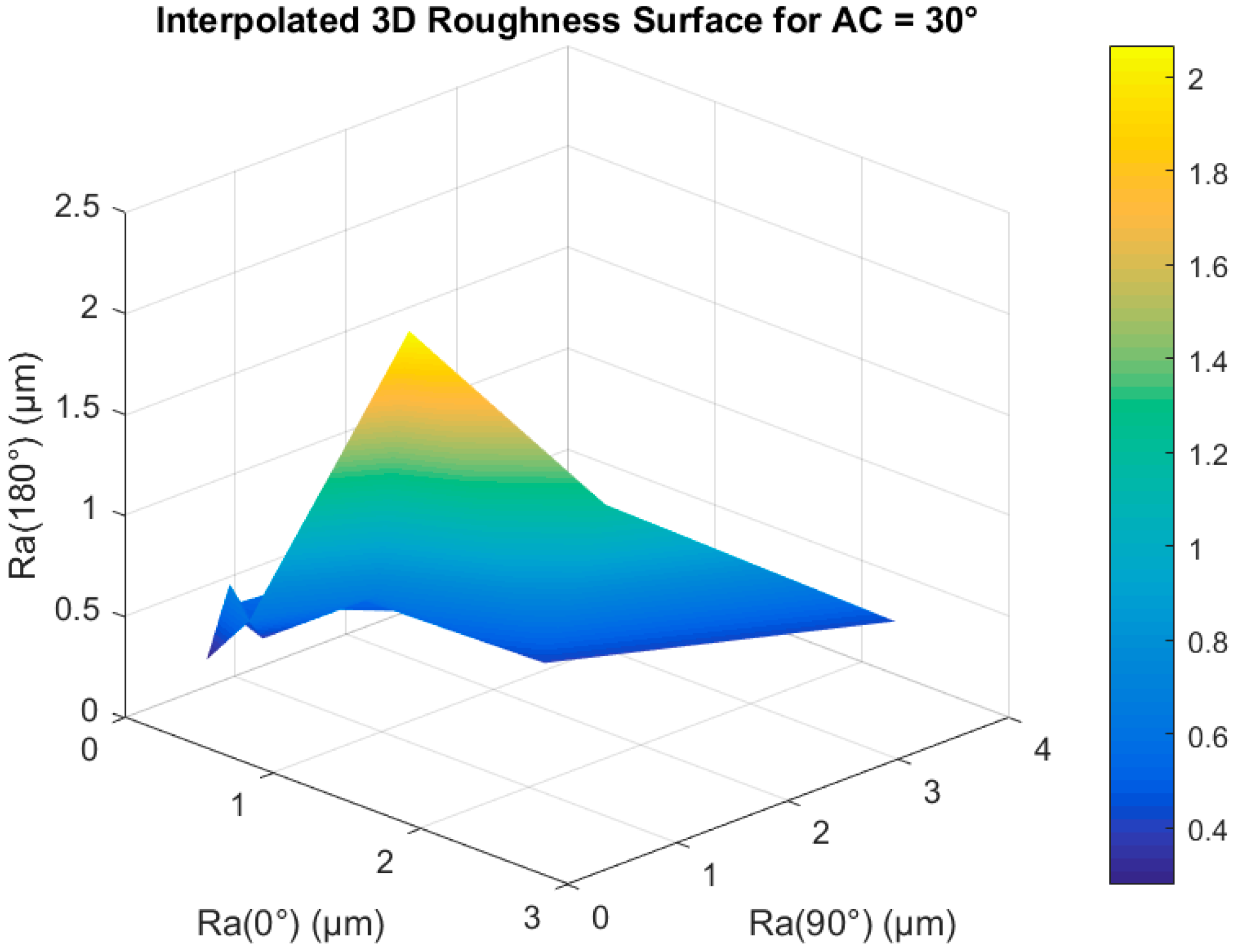

- Output Variables: Ra (0°), Ra (90°), and Ra (180°) measured with a Mitutoyo SJ-410 profilometer; maximum Ra was used as the overall surface-quality index (Raoverall), capturing combined additive–subtractive effects.

2.4. Post-Processing and Micromilling Procedure

2.5. Density and Mechanical Testing

2.6. Surface Roughness Measurement and Characterization

2.7. Data Analysis and Statistical Evaluation

2.7.1. Analysis of Variance (ANOVA)

2.7.2. Correlation Analysis

2.7.3. Regression Modeling

2.7.4. Data Readiness for AI Modeling

2.8. Experimental Factors Summary

2.9. Section Summary

3. Results and Discussion

3.1. Effect of Process Parameters on Surface Roughness

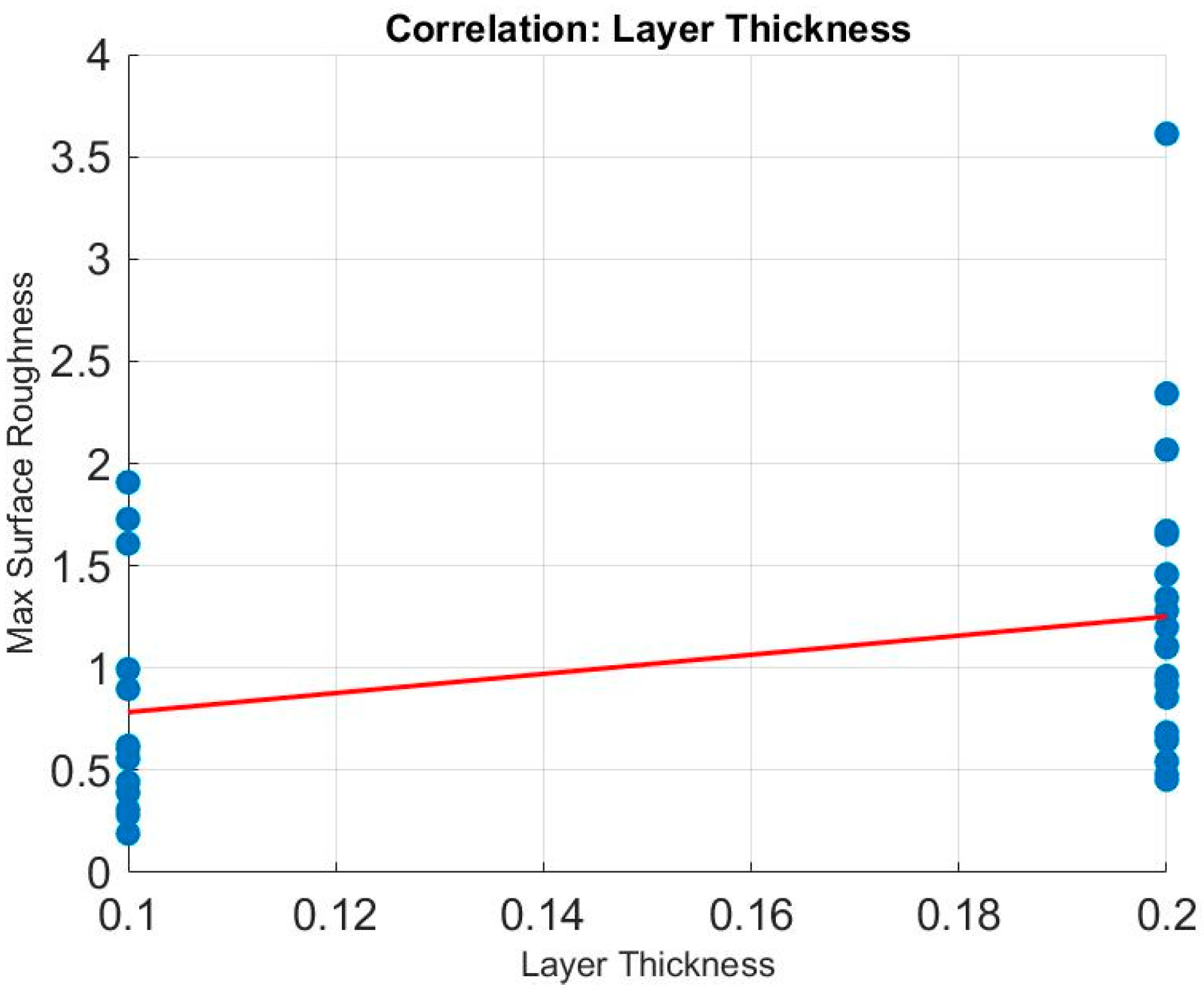

3.1.1. Layer Thickness

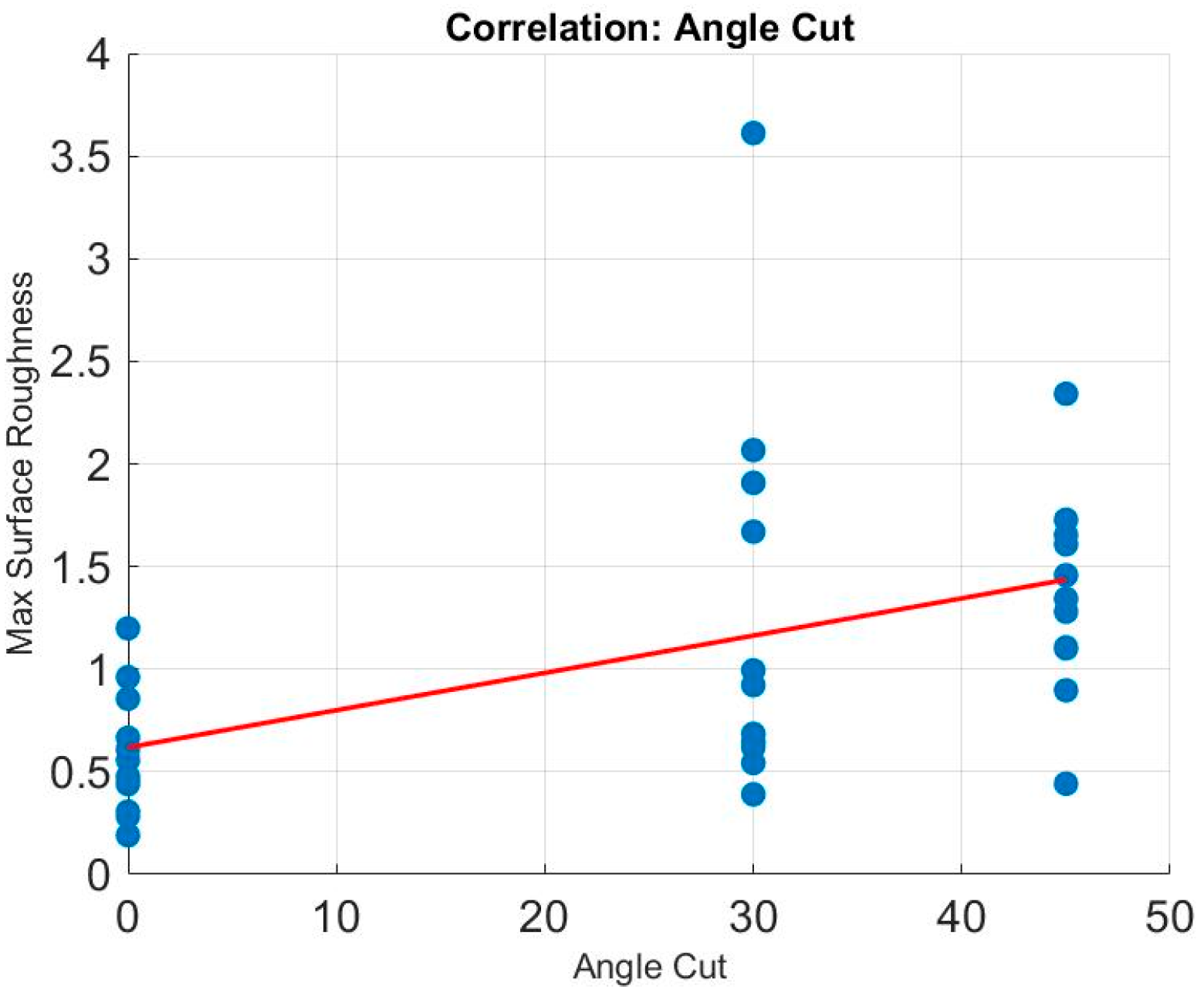

3.1.2. Cutting Direction (Angle Cut)

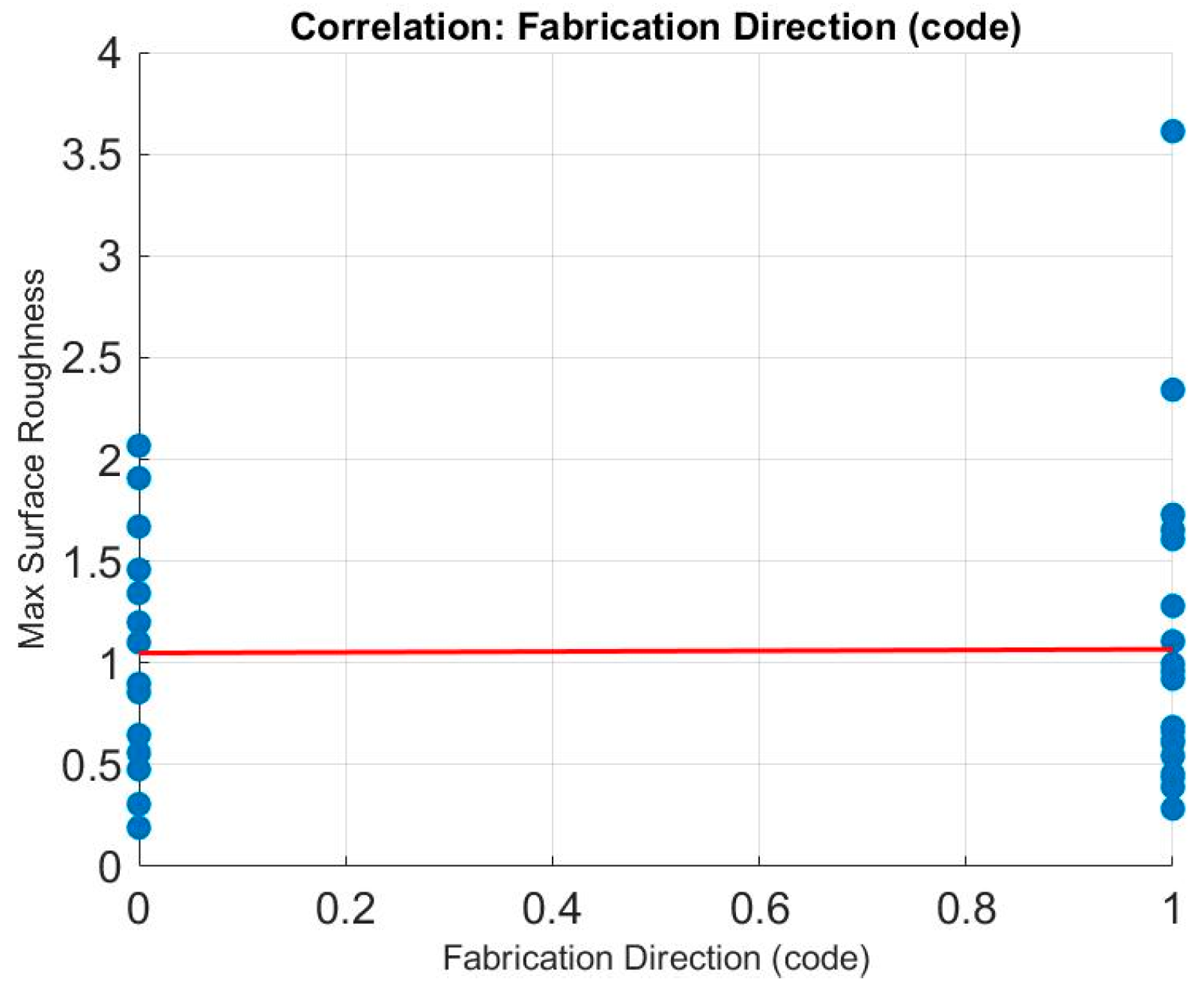

3.1.3. Fabrication Direction

3.1.4. Raster Angle

3.2. Regression Modeling and Quantitative Interpretation

3.3. Comparative Analysis with Literature

3.4. Implications for Hybrid Process Optimization

- (i)

- Fine-layer deposition (<0.1 mm) and

- (ii)

- Toolpath alignment with filament orientation during cutting.

4. Conclusions

- Layer thickness exhibited a moderate positive correlation with surface roughness (r = 0.326, p = 0.060), indicating that thicker layers tend to produce rougher post-machined surfaces due to increased staircase effects and nonuniform interlayer bonding. Finer layers enhance chip stability and microstructural uniformity during finishing, consistent with observations by Boschetto et al. [1] and Caminero et al. [2].

- Cutting direction (angle cut) was identified as the dominant factor, showing a strong correlation with roughness (r = 0.486, p = 0.004). Machining parallel to the filament deposition path yielded the smoothest surfaces, validating the anisotropic cutting behavior observed in micromilling studies of AM metals [17,19].

- Fabrication direction and raster angle demonstrated a weak statistical influence on surface roughness (r = 0.013, p = 0.942 and r = –0.130, p = 0.466, respectively). Their limited contribution suggests that sintering effectively homogenizes internal porosity, making machining orientation the dominant factor governing surface response. Similar behavior was reported by O’Connor et al. [9] and Kurose et al. [21].

- The multiple linear regression model achieved R2 = 0.335 (p = 0.0158), confirming that approximately one-third of the surface roughness variation can be captured by the linear effects of process parameters. The remaining variance reflects the nonlinear and thermomechanical interactions characteristic of hybrid AM–machining systems, consistent with the findings in [45,47,48,54].

- The study provides a quantitative framework for optimizing hybrid FDM–micromilling processes. Fine-layer deposition combined with directionally aligned cutting can reduce the Ra below 1.2 µm without secondary polishing. Incorporating data-driven monitoring and machine-learning-based prediction can further improve adaptive control, surface consistency, and process repeatability.

4.1. Practical Applications of Study

4.2. Limitations and Outlook for Future Work

4.3. Novel Contributions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| FFF | Fused Filament Fabrication |

| FDM | Fused Deposition Modeling |

| H-AM | Hybrid Additive–Subtractive Manufacturing |

| SLM | Selective Laser Melting |

| DED | Directed Energy Deposition |

| MIM | Metal Injection Molding |

| SEM | Scanning Electron Microscopy |

| UTS | Ultimate Tensile Strength |

| DOE | Design of Experiments |

| RSM | Response Surface Methodology |

| ANOVA | Analysis of Variance |

| ANN | Artificial Neural Network |

| RFR | Random Forest Regression |

| SVM | Support Vector Machine |

| Ra | Arithmetic Mean Surface Roughness |

| R2 | Coefficient of Determination |

| ρa | Apparent Density |

References

- Boschetto, A.; Bottini, L.; Miani, F.; Veniali, F. Roughness investigation of steel 316L parts fabricated by Metal Fused Filament Fabrication. J. Manuf. Process. 2022, 81, 261–280. [Google Scholar] [CrossRef]

- Caminero, M.A.; Romero, A.; Chacón, J.M.; Núñez, P.J.; García-Plaza, E.; Rodríguez, G.P. Additive manufacturing of 316L stainless-steel structures using fused filament fabrication technology. Rapid Prototyp. J. 2021, 27, 583–591. [Google Scholar] [CrossRef]

- Cerlincă, D.-A.; Tamașag, I.; Beșliu-Băncescu, I.; Severin, T.-L.; Dulucheanu, C. Experimental investigation of FDM manufacturing of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2024, 135, 1449–1463. [Google Scholar] [CrossRef]

- Kedziora, S.; Decker, T.; Museyibov, E.; Morbach, J.; Hohmann, S.; Huwer, A.; Wahl, M. Strength properties of 316L and 17-4 PH stainless steel produced with additive manufacturing. Materials 2022, 15, 6278. [Google Scholar] [CrossRef]

- Galati, M.; Minetola, P. Analysis of density, roughness, and accuracy of the ADAM (metal FFF) process for metal parts. Materials 2019, 12, 4122. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Lin, Z.; Zhang, T. Creating metal parts by fused deposition modeling and sintering. Mater. Lett. 2020, 263, 127252. [Google Scholar] [CrossRef]

- Martignoni, L.; Vegro, A.; Candidori, S.; Shaikh, M.Q.; Atre, S.V.; Graziosi, S.; Casati, R. Prototyping and characterisation of 316L stainless steel parts and lattice structures printed via metal fused filament fabrication. Rapid Prototyp. J. 2024, 30, 123–141. [Google Scholar] [CrossRef]

- Obeidat, S.; Basith, I.; Dakeev, U. The impact of printing direction and raster angle on apparent density and mechanical properties of 316L stainless steel parts printed by FDM/FFF technology. Int. J. Mod. Eng. 2024, 24, 29–35. [Google Scholar] [CrossRef]

- O’Connor, H.; Singh, G.; Kumar, A.; Paetzold, R.; Celikin, M.; O’Cearbhaill, E.D. Fused filament fabrication using stainless steel 316L–polymer blend: Analysis and optimization for green density and surface roughness. Polym. Compos. 2024, 45, 10632–10644. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process parameter optimization of extrusion-based 3D metal printing utilizing PW–LDPE–SA binder system. Materials 2017, 10, 305. [Google Scholar] [CrossRef] [PubMed]

- Spiller, S.; Kolstad, S.O.; Razavi, N. Fabrication and characterization of 316L stainless steel components printed with material extrusion additive manufacturing. Procedia Struct. Integr. 2023, 42, 1239–1248. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A simple route for additive manufacturing of 316L stainless steel via fused filament fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Wagner, M.A.; Engel, J.; Hadian, A.; Clemens, F.; Rodríguez-Arbaizar, M.; Carreño-Morelli, E.; Wheeler, J.M.; Spolenak, R. Filament extrusion-based additive manufacturing of 316L stainless steel: Effects of sintering conditions. Addit. Manuf. 2022, 59, 103147. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, surface quality, microhardness and microstructure of SLM 316L after finish machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef]

- Greco, S.; Kieren-Ehses, S.; Kirsch, B.; Aurich, J.C. Micro milling of additively manufactured AISI 316L: Impact of layerwise microstructure. Int. J. Adv. Manuf. Technol. 2021, 112, 361–373. [Google Scholar] [CrossRef]

- Matras, A. Research and optimization of surface roughness in milling of SLM semi-finished parts. Materials 2020, 13, 9. [Google Scholar] [CrossRef]

- He, Q.; Kang, X.; Wu, X. Micro-milling of additively manufactured Al–Si–Mg alloys. Materials 2024, 17, 2668. [Google Scholar] [CrossRef]

- Machno, M.; Zębala, W. Comparative study of the dimensional and shape accuracy of 316L manufactured using SLM and casting after milling and WEDM. Materials 2024, 17, 2907. [Google Scholar] [CrossRef] [PubMed]

- Montalti, A.; Galiè, G.; Pignatelli, E.; Liverani, A. Enhancing surface roughness of material extrusion AM components via innovative ironing process. Virtual Phys. Prototyp. 2024, 19, e2401929. [Google Scholar] [CrossRef]

- Salvi, D.; Ucciardello, N.; Vesco, S. Multi-Head MEX 3D Printing of Self-Recoverable Joule-Heating-Based Shape Memory Polymeric Components. Arab. J. Sci. Eng. 2025. [Google Scholar] [CrossRef]

- Kurose, T.; Abe, Y.; Santos, M.V.A.; Kanaya, Y.; Ishigami, A.; Tanaka, S.; Ito, H. Influence of layer directions on properties of 316L parts fabricated through fused deposition of metals. Materials 2020, 13, 2493. [Google Scholar] [CrossRef]

- Quarto, M.; Carminati, M.; D’Urso, G. Density and shrinkage evaluation of AISI 316L parts printed via FDM process. Mater. Manuf. Process. 2021, 36, 1535–1543. [Google Scholar] [CrossRef]

- Vesco, S.; Salvi, D. Fuzzy skin in fused filament fabrication: Enhancing morphology, wettability, and friction through a full-factorial experimental plan. Prog. Addit. Manuf. 2025, 10, 11233–11257. [Google Scholar] [CrossRef]

- Gorey, T.J.; Stull, J.A.; Hackenberg, R.E.; Clark, C.L.; Hooks, D.E. Enhancing surface finish of AM 316L stainless steel with pulse/pulse reverse electropolishing. J. Miner. 2023, 75, 195–208. [Google Scholar] [CrossRef]

- Behjat, A.; Lannunziata, E.; Gadalińska, E.; Iuliano, L.; Saboori, A. Improving surface quality and mechanical properties of AM AISI 316L by different surface post-treatments. Procedia CIRP 2023, 118, 771–776. [Google Scholar] [CrossRef]

- Chueca de Bruijn, A.; García de la Torre, H.; Gómez-Gras, G.; Pérez-Martínez, M.A. Effect of ball burnishing on fused-filament fabricated parts. Addit. Manuf. 2021, 46, 102133. [Google Scholar] [CrossRef]

- Hassan, W.; Farid, M.A.; Tosi, A.; Rane, K.; Strano, M. Effect of printing parameters on sintered properties of EAM 316L parts. Int. J. Adv. Manuf. Technol. 2021, 114, 3057–3067. [Google Scholar] [CrossRef]

- Zaitceva, M.; Sotov, A.; Popovich, A.; Sufiiarov, V. Stainless steel 316L fabricated by FDM: Microstructure and mechanical properties. J. Manuf. Mater. Process. 2024, 8, 259. [Google Scholar] [CrossRef]

- Soler, D.; Telleria, M.; Belén, M.; Espinosa, E.; Cuesta, M.; Arrazola, P.J. Prediction of surface roughness after finishing processes using ANN. J. Manuf. Mater. Process. 2022, 6, 82. [Google Scholar] [CrossRef]

- Mukherjee, T.; Shen, W.; Liao, Y.; Li, B. Improving deposited surface quality using structured light characterization and modeling. J. Manuf. Mater. Process. 2024, 8, 124. [Google Scholar] [CrossRef]

- Betts, J.L.; Sampson, B.J.; Lindsey, K.; Brinkley, F.M.; Priddy, M.W. Reduction of process-induced porosity for Ultrafuse 316L via parameter optimization. Crystals 2024, 14, 285. [Google Scholar] [CrossRef]

- Suresh, V.; Balasubramaniam, B.; Yeh, L.; Li, B. Recent advances in in situ 3D surface topographical monitoring for AM. J. Manuf. Mater. Process. 2025, 9, 133. [Google Scholar] [CrossRef]

- Tran, N.H.; Phan, N.D.M. Analyzing the Impact of Process Parameters on Surface Roughness and Mechanical Properties in FDM 3D Printing Using Machine Learning. Int. J. Interact. Des. Manuf. 2025, 19, 8709–8728. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Integration of FDM surface quality modeling with process design. Addit. Manuf. 2016, 12, 334–344. [Google Scholar] [CrossRef]

- Rajhi, W.; Ali, A.B.; Jasim, D.J.; Mehrabi, O.; Ben Said, L.; Moradi, M. Mathematical and statistical analysis of FFF parameters via response surface methodology. Mathematics 2024, 12, 3146. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, L. Understanding surface roughness on vertical surfaces of 316L in LPBF AM. Powder Technol. 2022, 411, 117957. [Google Scholar] [CrossRef]

- Dias, Y.E.P.; Lima, J.S.D.; Coêlho, G.D.C.; Maciel, T.M.; Neto, J.F.D.S.; Castro, W.B.D. Quality control, monitoring and techniques for surface quality optimization in wire arc additive manufacturing: A review. Rapid Prototyp. J. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Mushtaq, R.T.; Iqbal, A.; Wang, Y.; Cheok, Q.; Abbas, S. Parametric effects of FFF approach on surface roughness of ABS and Nylon-6. Materials 2022, 15, 5206. [Google Scholar] [CrossRef]

- La Fé-Perdomo, I.; Ramos-Grez, J.A.; Jeria, I.; Guerra, C.; Barrionuevo, G.O. Statistical and ML-based regressors for roughness and properties of SLM 316L. J. Manuf. Process. 2022, 80, 666–682. [Google Scholar] [CrossRef]

- Yang, D.; Tang, J.; Xia, F.; Zhou, W. Rough surface characterization and redundant parameter sets for modeling. Materials 2022, 15, 5971. [Google Scholar] [CrossRef]

- Kim, E.-J.; Lee, C.-M.; Kim, D.-H. Post-processing effects on mechanical characteristics of AM 304L steel. J. Mater. Res. Technol. 2021, 15, 1370–1381. [Google Scholar] [CrossRef]

- Mishra, A.; Kumar, R.; Sharma, A.K.; Gupta, N.K.; Somani, N. Statistical analysis of process parameters for Wood–PLA FDM composites. Int. J. Interact. Des. Manuf. 2024, 18, 1303–1315. [Google Scholar] [CrossRef]

- Kumaresan, R.; Kadirgama, K.; Samykano, M.; Harun, W.S.W.; Thirugnanasambandam, A.; Kanny, K. Optimization of process parameters to enhance strengths of PETG in FDM. J. Mater. Res. Technol. 2025, 37, 397–416. [Google Scholar] [CrossRef]

- Elkaseer, A.; Schneider, S.; Scholz, S.G. Experiment-based process modeling and optimization for resource-efficient FFF. Appl. Sci. 2020, 10, 2899. [Google Scholar] [CrossRef]

- Sharma, A.; Saini, R.S.; Kaushik, A.; Okshah, A.; Kuruniyan, M.S.; Gurumurthy, V.; Vyas, R.; Binduhayyim, R.I.H.; Heboyan, A. ML-based approach for surface roughness prediction in dental prototyping. Sci. Rep. 2025, 15, 32239. [Google Scholar] [CrossRef]

- Chen, H.; Yaseer, A.; Zhang, Y. Top Surface Roughness Modeling for Robotic Wire Arc Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 39. [Google Scholar] [CrossRef]

- Batu, T.; Lemu, H.G.; Shimels, H. Application of AI for surface roughness prediction of AM components. Materials 2023, 16, 6266. [Google Scholar] [CrossRef]

- Natesh, C.P.; Siddeshkumar, N.G.; Srinivasa, G.; Shivaramakrishna, A.; Pruthvi, H.M.; Prasad, C.D.; Shashidhara, Y.M.; Amarendra, H.J.; Tiwari, A.; Aden, A.A. Multi-objective optimization of surface roughness and MRR in 316L steel via Taguchi–RSM–ANN–RFR. Sci. Rep. 2025, 15, 36583. [Google Scholar] [CrossRef]

- Adeniji, D.; Schoop, J.; Gunawardena, S.; Hanson, C.; Jahan, M. Characterization and modeling of surface roughness and burr formation in slot milling. J. Manuf. Mater. Process. 2020, 4, 59. [Google Scholar] [CrossRef]

- Khanafer, K.; Cao, J.; Kokash, H. Condition monitoring in additive manufacturing: A critical review. J. Manuf. Mater. Process. 2024, 8, 95. [Google Scholar] [CrossRef]

- Dinc, A.; Mamedov, A. Optimization of surface quality and machining time in micro-milling of glass. Aircr. Eng. Aerosp. Technol. 2022, 94, 676–686. [Google Scholar] [CrossRef]

- Jacob, J.; Pejak Simunec, D.; Kandjani, A.E.; Trinchi, A.; Sola, A. Review of fused filament fabrication of metal parts: Current developments and challenges. Technologies 2024, 12, 267. [Google Scholar] [CrossRef]

- Mamedov, A.; Dinc, A.; Guler, M.A.; Demiral, M.; Otkur, M. Tool wear in micromilling: A review. Int. J. Adv. Manuf. Technol. 2025, 137, 47–65. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Wafa, F. Surface Roughness Prediction in Additive Manufacturing: Presenting the Power of Neural Networks Compared to Linear Regression. J. Adv. Manuf. Syst. 2025, 24, 69–88. [Google Scholar] [CrossRef]

- Cicek, U.I.; Johnson, A.A. Multi-objective optimization of FDM process parameters using Taguchi-based gray relational analysis. Int. J. Adv. Manuf. Technol. 2025, 137, 3709–3725. [Google Scholar] [CrossRef]

- ISO 4287:1997; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 1997.

| Parameter | Value | Reference Justification |

|---|---|---|

| Nozzle temperature | 245 °C | Typical for metal–polymer composites [6,9,14] |

| Bed temperature | 85 °C | Promotes layer bonding [7,12] |

| Chamber temperature | 60–80 °C | Minimizes thermal gradients [13,15] |

| Layer thickness | 0.10 mm and 0.20 mm | Common in fine and rapid FFF [9,14,33] |

| Raster angles | 0°, 30°, 45° | Investigates anisotropy [17,18,33,40] |

| Infill density | 100% (linear) | Ensures full density [5,8] |

| Print speed | 50 mm · s−1 | Balanced deposition [7,11] |

| Experiment # | Input 1: LT (mm) | Input 2: RA (°) | Input 3: FD | Input 4: AC (°) | Ra (0°) (µm) | Ra (90°) (µm) | Ra (180°) (µm) | Max Overall Ra (µm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.1 | 0 | Horizontal | 0 | 0.284 | 0.217 | 0.148 | 0.284 |

| 2 | 0.1 | 45 | Horizontal | 0 | 0.44 | 0.418 | 0.393 | 0.44 |

| 3 | 0.1 | 30 | Horizontal | 0 | 0.404 | 0.609 | 0.384 | 0.609 |

| 4 | 0.2 | 0 | Horizontal | 0 | 0.22 | 0.508 | 0.666 | 0.666 |

| 5 | 0.2 | 45 | Horizontal | 0 | 0.355 | 0.454 | 0.227 | 0.454 |

| 6 | 0.2 | 30 | Horizontal | 0 | 0.105 | 0.961 | 0.156 | 0.961 |

| 7 | 0.1 | 0 | Vertical | 0 | 0.457 | 0.337 | 0.558 | 0.558 |

| 8 | 0.1 | 45 | Vertical | 0 | 0.267 | 0.306 | 0.291 | 0.306 |

| 9 | 0.1 | 30 | Vertical | 0 | 0.171 | 0.165 | 0.191 | 0.191 |

| 10 | 0.2 | 0 | Vertical | 0 | 0.569 | 0.424 | 0.856 | 0.856 |

| 11 | 0.2 | 45 | Vertical | 0 | 0.477 | 0.394 | 0.471 | 0.477 |

| 12 | 0.2 | 30 | Vertical | 0 | 0.368 | 0.569 | 1.199 | 1.199 |

| 13 | 0.1 | 0 | Horizontal | 30 | 0.964 | 0.994 | 0.662 | 0.994 |

| 14 | 0.1 | 45 | Horizontal | 30 | 0.264 | 0.39 | 0.279 | 0.39 |

| 15 | 0.1 | 30 | Horizontal | 30 | 0.619 | 0.299 | 0.585 | 0.619 |

| 16 | 0.2 | 0 | Horizontal | 30 | 2.516 | 3.612 | 0.424 | 3.612 |

| 17 | 0.2 | 45 | Horizontal | 30 | 0.405 | 0.413 | 0.685 | 0.685 |

| 18 | 0.2 | 30 | Horizontal | 30 | 0.558 | 0.922 | 0.638 | 0.922 |

| 19 | 0.1 | 45 | Vertical | 30 | 1.908 | 1.802 | 1.207 | 1.908 |

| 20 | 0.2 | 0 | Vertical | 30 | 1.245 | 0.912 | 2.067 | 2.067 |

| 21 | 0.2 | 45 | Vertical | 30 | 1.67 | 1.569 | 0.406 | 1.67 |

| 22 | 0.2 | 30 | Vertical | 30 | 0.453 | 0.646 | 0.383 | 0.646 |

| 23 | 0.2 | 45 | Horizontal | 30 | 0.256 | 0.543 | 0.504 | 0.543 |

| 24 | 0.1 | 0 | Horizontal | 45 | 0.442 | 0.263 | 0.181 | 0.442 |

| 25 | 0.1 | 45 | Horizontal | 45 | 0.289 | 1.608 | 1.24 | 1.608 |

| 26 | 0.1 | 30 | Horizontal | 45 | 1.163 | 0.977 | 1.728 | 1.728 |

| 27 | 0.2 | 0 | Horizontal | 45 | 1.257 | 1.28 | 1.037 | 1.28 |

| 28 | 0.2 | 45 | Horizontal | 45 | 0.836 | 1.653 | 0.337 | 1.653 |

| 29 | 0.2 | 30 | Horizontal | 45 | 1.94 | 2.342 | 1.63 | 2.342 |

| 30 | 0.1 | 45 | Vertical | 45 | 0.574 | 0.897 | 0.257 | 0.897 |

| 31 | 0.2 | 0 | Vertical | 45 | 0.564 | 1.101 | 1.076 | 1.101 |

| 32 | 0.2 | 45 | Vertical | 45 | 0.268 | 1.343 | 1.255 | 1.343 |

| 33 | 0.2 | 30 | Vertical | 45 | 1.458 | 0.703 | 0.251 | 1.458 |

| 34 | 0.2 | 45 | Horizontal | 45 | 1.106 | 0.273 | 0.934 | 1.106 |

| Factor | Parameter (Levels) | Category | Objective | Representative References |

|---|---|---|---|---|

| A | Layer thickness (Input 1: LT, 0.10, 0.20 mm) | Additive | Evaluate stair-stepping effect and its influence on surface roughness | [9,14,33] |

| B | Raster angle (Input 2: RA, 0°, 30°, 45°) | Additive | Capture filament-induced anisotropy and directional porosity | [33,40] |

| C | Fabrication direction (Input 3: FD, Horizontal/Vertical) | Additive | Assess gravitational densification, layer stacking, and interlayer bonding effects | [2,3,7] |

| D | Micromilling direction Angle Cut (Input 4: AC, 0°, 90°, 180°) | Subtractive | Examine directional machinability and cutting response relative to filament layup | [17,18,21,25] |

| ρ, UTS | Density, tensile strength | Material Property | Correlate sintered material properties with surface finish and machinability | [27] |

| Factor | Parameter (Levels) | r | p |

|---|---|---|---|

| A | Layer thickness (Input 1: LT, 0.10, 0.20 mm) | 0.326 | 0.060 |

| B | Micromilling direction Angle Cut (Input 4: AC, 0°, 90°, 180°) | 0.486 | 0.004 |

| C | Fabrication direction (Input 3: FD, Horizontal/Vertical) | 0.013 | 0.942 |

| D | Raster angle (Input 2: RA, 0°, 30°, 45°) | −0.130 | 0.466 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinc, A.; Obeidat, S.; Mamedov, A.; Otkur, M.; Nag, K. Statistical Correlation Analysis of Surface Roughness of Micromilled 316L Stainless Steel Components Fabricated by FDM–FFF Hybrid Manufacturing. J. Manuf. Mater. Process. 2025, 9, 406. https://doi.org/10.3390/jmmp9120406

Dinc A, Obeidat S, Mamedov A, Otkur M, Nag K. Statistical Correlation Analysis of Surface Roughness of Micromilled 316L Stainless Steel Components Fabricated by FDM–FFF Hybrid Manufacturing. Journal of Manufacturing and Materials Processing. 2025; 9(12):406. https://doi.org/10.3390/jmmp9120406

Chicago/Turabian StyleDinc, Ali, Suleiman Obeidat, Ali Mamedov, Murat Otkur, and Kaushik Nag. 2025. "Statistical Correlation Analysis of Surface Roughness of Micromilled 316L Stainless Steel Components Fabricated by FDM–FFF Hybrid Manufacturing" Journal of Manufacturing and Materials Processing 9, no. 12: 406. https://doi.org/10.3390/jmmp9120406

APA StyleDinc, A., Obeidat, S., Mamedov, A., Otkur, M., & Nag, K. (2025). Statistical Correlation Analysis of Surface Roughness of Micromilled 316L Stainless Steel Components Fabricated by FDM–FFF Hybrid Manufacturing. Journal of Manufacturing and Materials Processing, 9(12), 406. https://doi.org/10.3390/jmmp9120406