Effect of Hot Isostatic Pressing and Sequenced Heat Treatment on the Mechanical Properties of Hybrid Additive Manufactured Inconel 718 Components

Abstract

1. Introduction

2. Materials and Methods

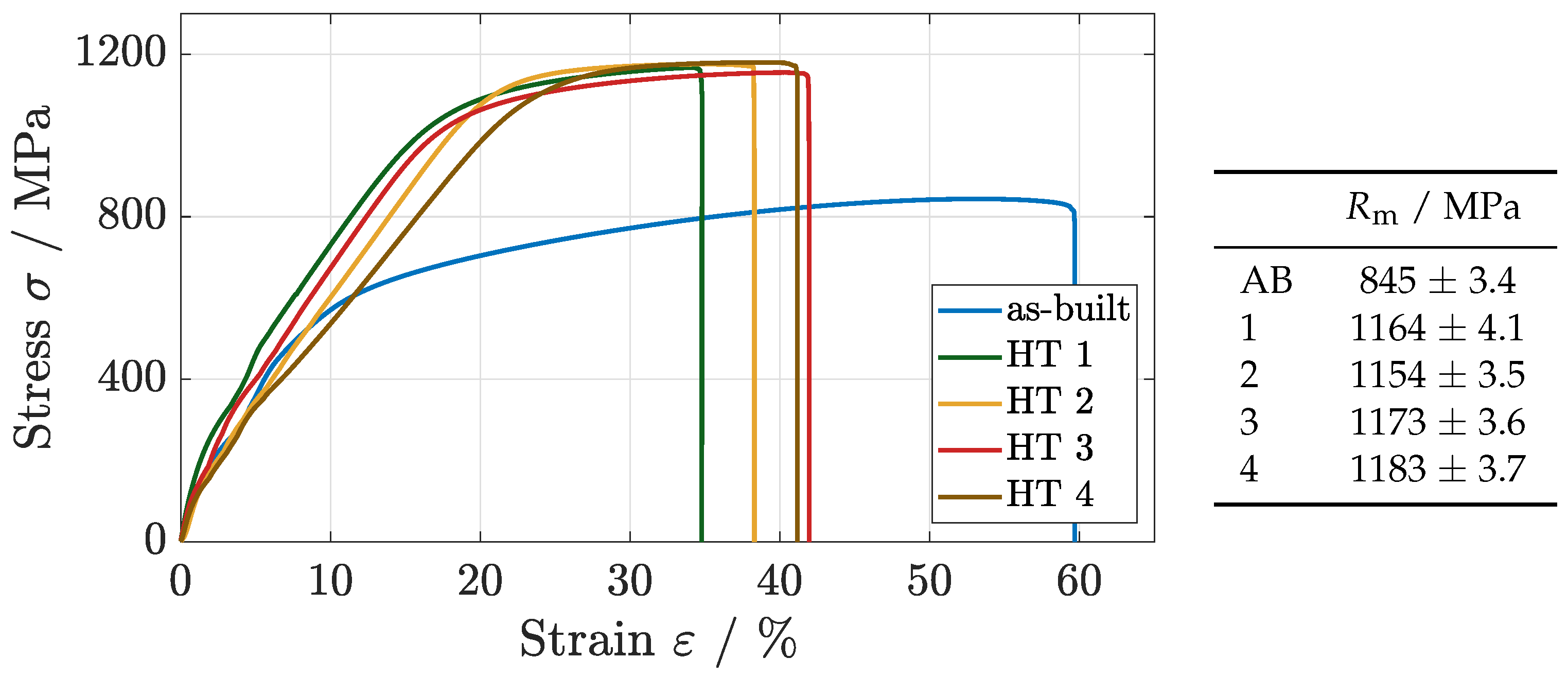

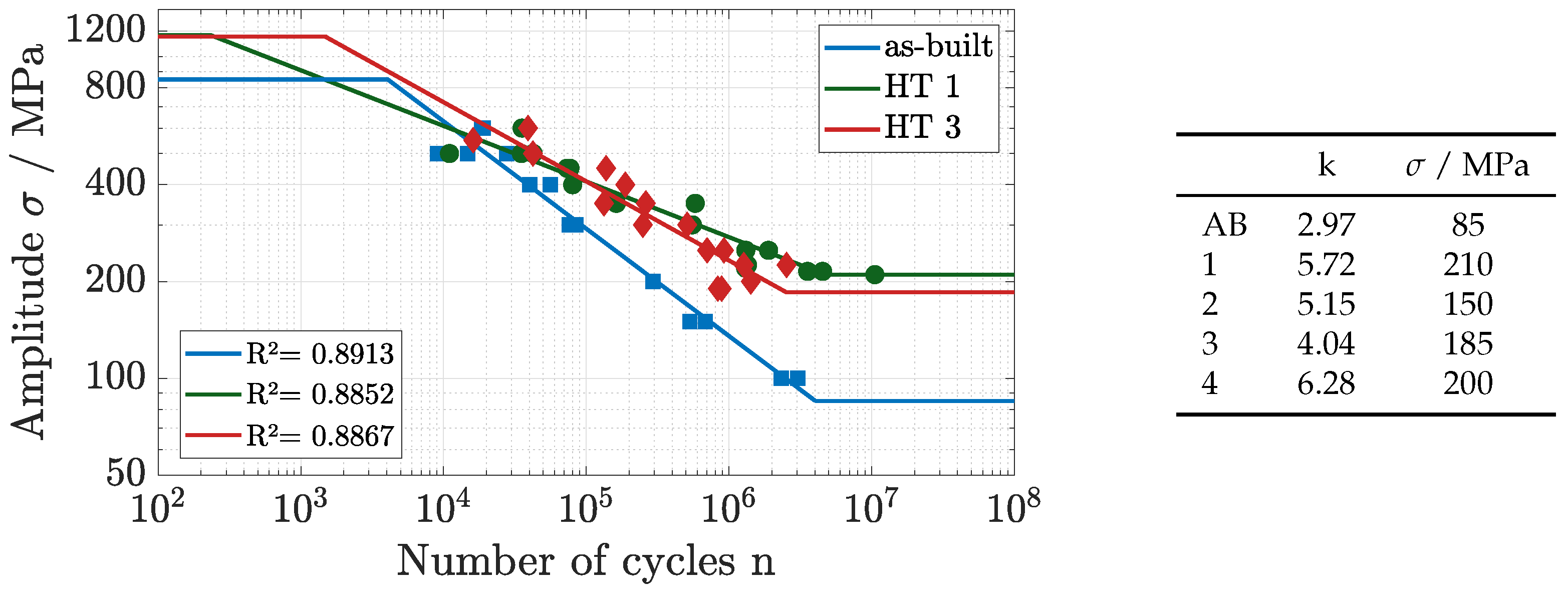

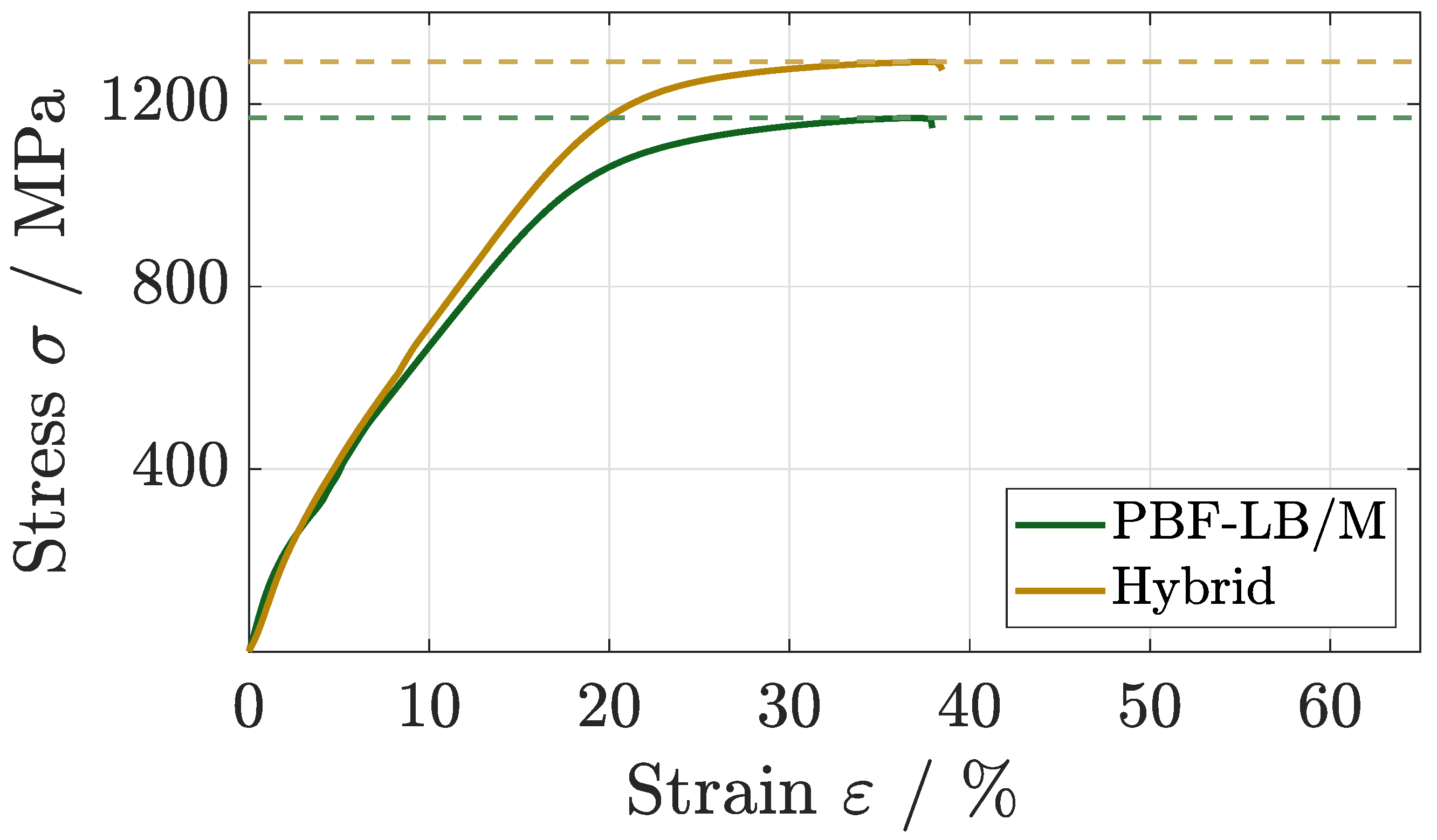

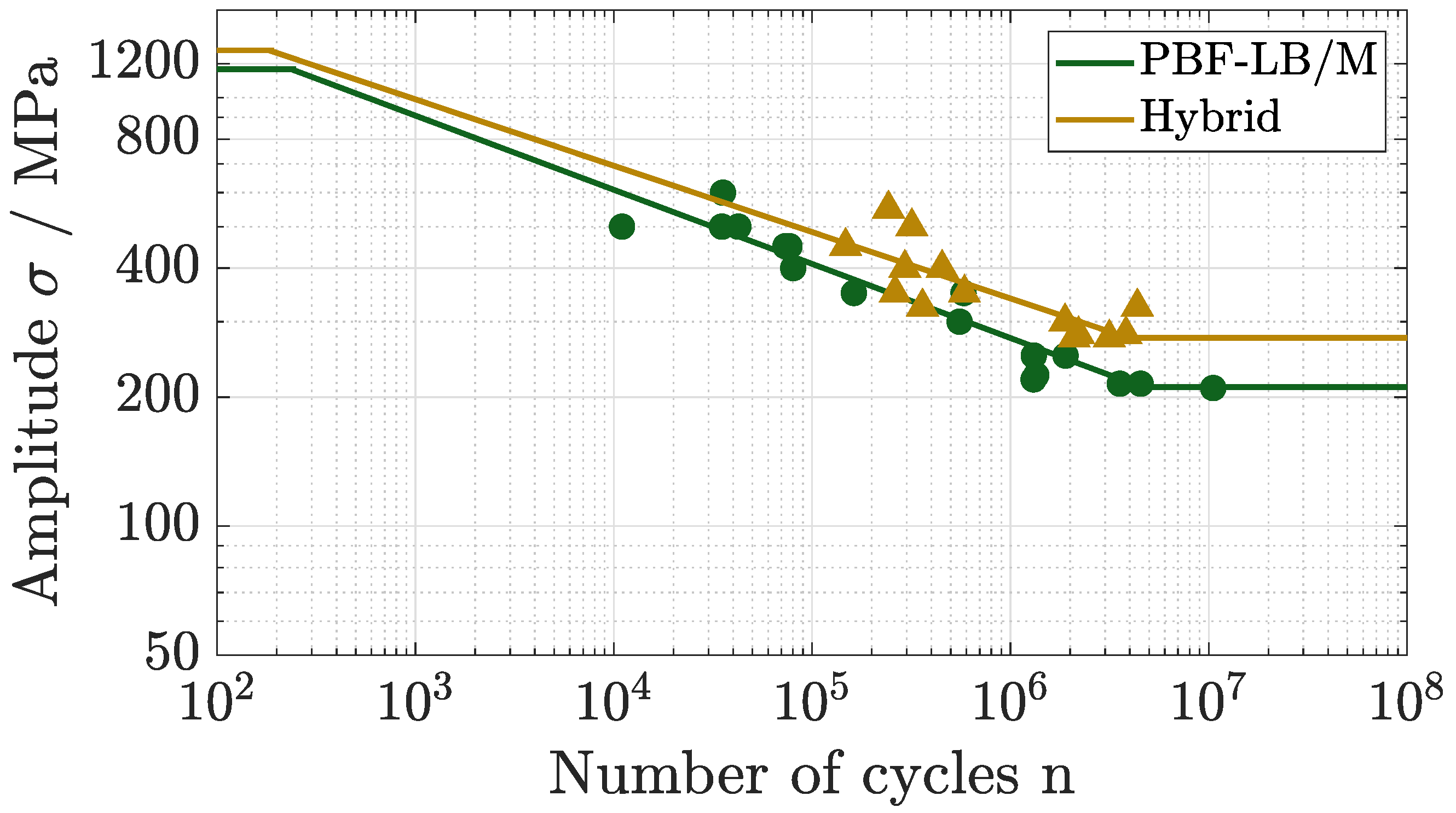

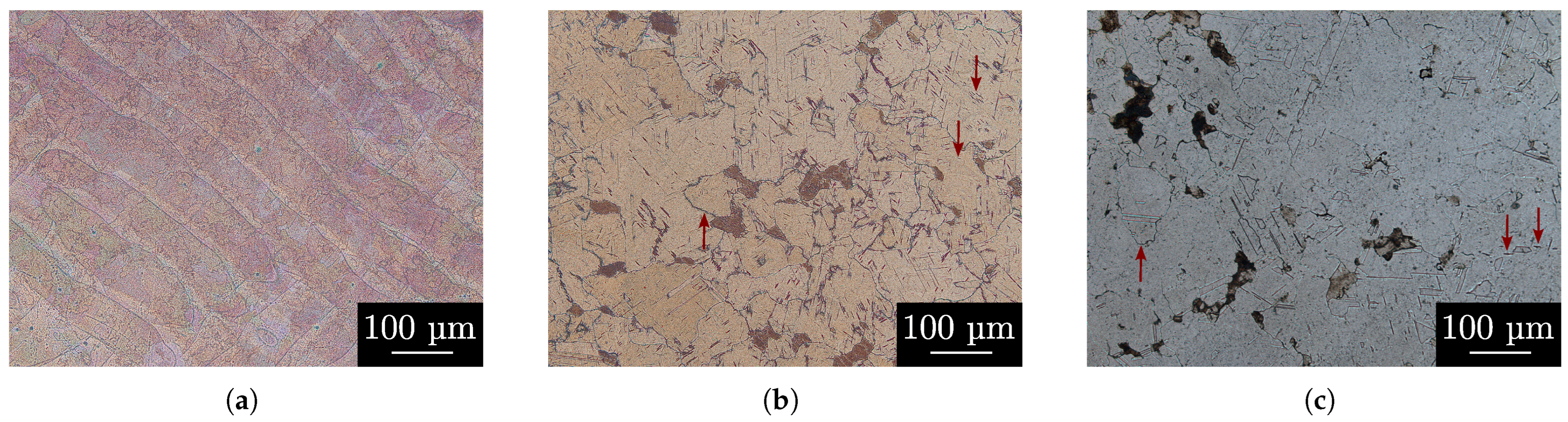

3. Results

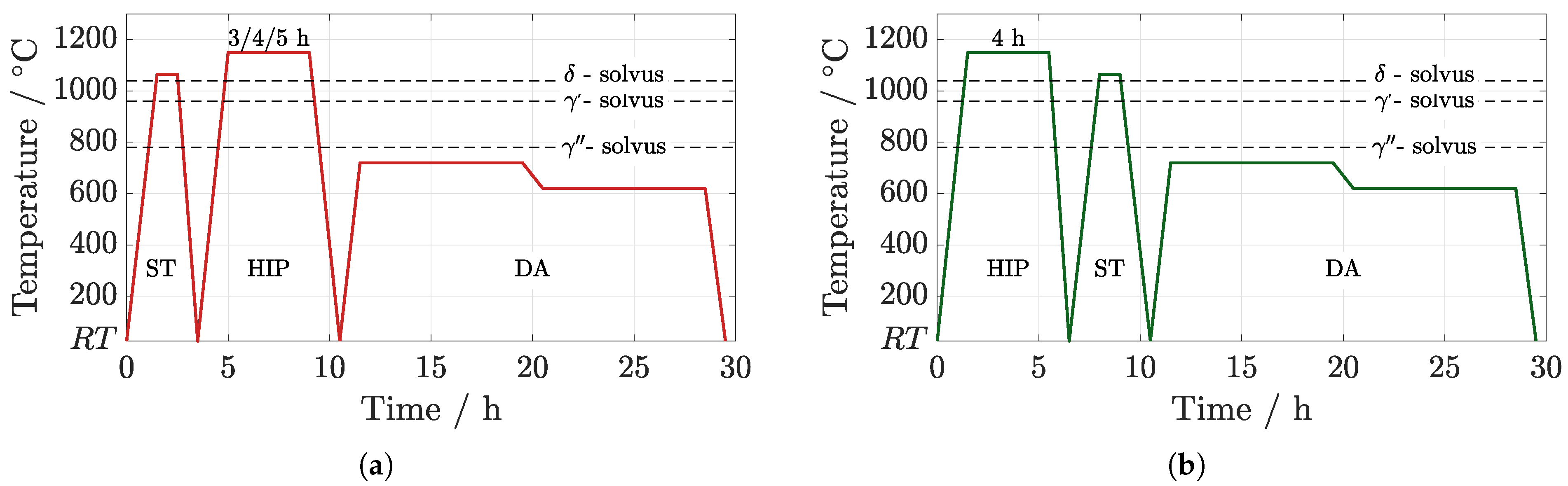

3.1. Hot Isostatic Pressing

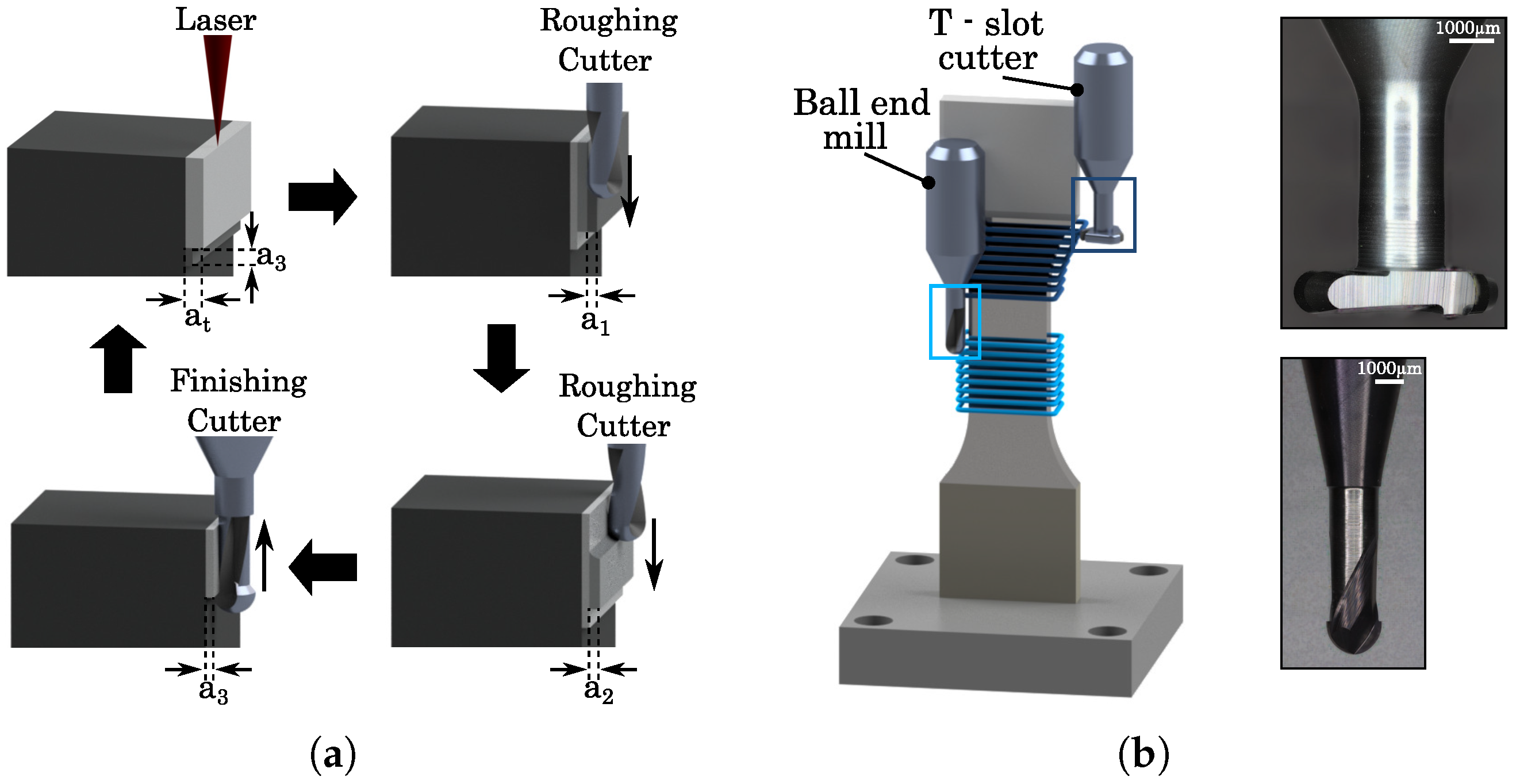

3.2. Hybrid Additive Manufacturing

4. Discussion

4.1. Density

4.2. Hardness and Microstructure

4.3. Surface Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Sefene, E.M.; Hailu, Y.; Asmare, A. Metal hybrid additive manufacturing: State-of-the-art. Prog. Addit. Manuf. 2022, 7, 737–749. [Google Scholar] [CrossRef]

- Sommer, D.; Götzendorfer, B.; Esen, C.; Hellmann, R. Design Rules for Hybrid Additive Manufacturing Combining Selective Laser Melting and Micromilling. Materials 2021, 14, 5753. [Google Scholar] [CrossRef] [PubMed]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Pedro Mortágua, J. Selective laser melting (SLM) and topology optimization for lighter aerospace componentes. Procedia Struct. Integr. 2016, 1, 289–296. [Google Scholar] [CrossRef]

- Adelmann, B.; Schwiddessen, T.; Götzendorfer, B.; Hellmann, R. Evaluation of SLS 3D-Printed Filter Structures Based on Bionic Manta Structures. Materials 2022, 15, 8454. [Google Scholar] [CrossRef] [PubMed]

- Pei, C.; Shi, D.; Yuan, H.; Li, H. Assessment of mechanical properties and fatigue performance of a selective laser melted nickel-base superalloy Inconel 718. Mater. Sci. Eng. A 2019, 759, 278–287. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.; Li, N.; Zhao, L.; Chen, W. Heterogeneities of microstructure and mechanical properties for inconel 718 strut tensile sample fabricated by selective laser melting. J. Mater. Res. Technol. 2021, 12, 2396–2406. [Google Scholar] [CrossRef]

- Großwendt, F.; Röttger, A.; Strauch, A.; Chehreh, A.; Uhlenwinkel, V.; Fechte-Heinen, R.; Walther, F.; Weber, S.; Theisen, W. Additive manufacturing of a carbon-martensitic hot-work tool steel using a powder mixture—Microstructure, post-processing, mechanical properties. Mater. Sci. Eng. A 2021, 827, 142038. [Google Scholar] [CrossRef]

- Monkova, K.; Zetkova, I.; Kučerová, L.; Zetek, M.; Monka, P.; Daňa, M. Study of 3D printing direction and effects of heat treatment on mechanical properties of MS1 maraging steel. Arch. Appl. Mech. 2019, 89, 791–804. [Google Scholar] [CrossRef]

- Weddeling, A.; Wulbieter, N.; Theisen, W. Densifying and hardening of martensitic steel powders in HIP units providing high cooling rates. Powder Metall. 2016, 59, 9–19. [Google Scholar] [CrossRef]

- Qin, S.; Herzog, S.; Kaletsch, A.; Broeckmann, C. Effects of HIP on microstructure and creep properties of Inconel 718 fabricated by laser powder-bed fusion. In Europe’s Annual Powder Metallurgy Congress and Exhibition; Universitätsbibliothek der RWTH Aachen: Aachen, Germany, 2019. [Google Scholar] [CrossRef]

- Holland, S.; Wang, X.; Chen, J.; Cai, W.; Yan, F.; Li, L. Multiscale characterization of microstructures and mechanical properties of Inconel 718 fabricated by selective laser melting. J. Alloys Compd. 2019, 784, 182–194. [Google Scholar] [CrossRef]

- Yamazaki, T. Development of A Hybrid Multi-tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Wüst, P.; Edelmann, A.; Hellmann, R. Areal Surface Roughness Optimization of Maraging Steel Parts Produced by Hybrid Additive Manufacturing. Materials 2020, 13, 418. [Google Scholar] [CrossRef]

- Sommer, D.; Hornung, S.; Esen, C.; Hellmann, R. Surface roughness optimization of hybrid PBF-LB/M-built Inconel 718 using in situ high-speed milling. Int. J. Adv. Manuf. Technol. 2024, 132, 1741–1751. [Google Scholar] [CrossRef]

- Sommer, D.; Hornung, S.; Esen, C.; Hellmann, R. Design Guide for Hybrid-Additive Manufacturing of Inconel 718 Combining PBF-LB/M and In Situ High-Speed Milling. J. Manuf. Mater. Process. 2025, 9, 88. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Pelletier, R.; Atabay, S.E.; Gholipour, J.; Soost, J.; Amos, R.; Patnaik, P. Elevated-Temperature Tensile Behavior and Properties of Inconel 718 Fabricated by In-Envelope Additive—Subtractive Hybrid Manufacturing and Post-Process Precipitation Hardening. J. Manuf. Mater. Process. 2024, 8, 297. [Google Scholar] [CrossRef]

- Sahu, A.K.; Bag, S. Design of a double aging treatment for the improvement of mechanical and microstructural properties of pulse micro-plasma arc welded alloy 718. J. Mater. Sci. 2021, 56, 13400–13415. [Google Scholar] [CrossRef]

- Hasani, N.; Dharmendra, C.; Sanjari, M.; Fazeli, F.; Amirkhiz, B.S.; Pirgazi, H.; Ram, G.J.; Mohammadi, M. Laser powder bed fused Inconel 718 in stress-relieved and solution heat-treated conditions. Mater. Charact. 2021, 181, 111499. [Google Scholar] [CrossRef]

- Calandri, M.; Manfredi, D.; Calignano, F.; Ambrosio, E.P.; Biamino, S.; Lupoi, R.; Ugues, D. Solution Treatment Study of Inconel 718 Produced by SLM Additive Technique in View of the Oxidation Resistance. Adv. Eng. Mater. 2018, 20, 1800351. [Google Scholar] [CrossRef]

- Maurya, A.K.; Kumar, A. Study of Microstructure and Mechanical Properties of As-built and Heat-treated Additive Manufactured Inconel 718 Alloy. ASEAN J. Sci. Technol. Dev. 2021, 38, 6. [Google Scholar] [CrossRef]

- Raghavan, S.; Zhang, B.; Wang, P.; Sun, C.N.; Nai, M.L.S.; Li, T.; Wei, J. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Processes 2017, 32, 1588–1595. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- Rindler, J.J.; Slone, C.E.; Herderick, E.D.; Mills, M.J.; Ramirez, A.J. Investigation on the potential effects of laser stitching and subsequent heat treatment on the microstructure and mechanical properties of Nickel Alloy 718 produced via Laser Powder Bed Fusion (L-PBF). Addit. Manuf. 2022, 57, 102906. [Google Scholar] [CrossRef]

- Ordnung, D.; Mertens, T.; Tacq, J.; Nasab, M.H.; Sinico, M.; Li, G.; Thijs, L.; Vrancken, B.; van Hooreweder, B. Enhancing fatigue life of as-printed martensitic M789 steel produced by laser powder bed fusion via in-process surface integrity improvement and phase change induced compressive residual stresses. Addit. Manuf. 2024, 88, 104263. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, C.S.; Nath, A.K. Effects of different surface modifications on the fatigue life of selective laser melted 15–5 PH stainless steel. Mater. Sci. Eng. A 2019, 762, 138109. [Google Scholar] [CrossRef]

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- DIN 50125; Testing of Metallic Materials-Tensile Test Pieces. DIN: Berlin, Germany, 2016.

- Lin, S. Evaluation of the staircase and the accelerated test methods for fatigue limit distributions. Int. J. Fatigue 2001, 23, 75–83. [Google Scholar] [CrossRef]

- DIN EN ISO 6507-1; Metallic Material—Vickers Hardness Test Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- ASTM E2109-01; Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings. ASTM: West Conshohocken, PA, USA, 2021.

- ISO 4288; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. ISO: Geneva, Switzerland, 1996.

- AMS 5662; ALLOY BARS, FORGINGS, AND RINGS, CORROSION AND HEAT RESISTANT Nickel Base - 19Cr - 3.1Mo - 5.1(Cb + Ta) - 0.90Ti - 0.50Al Consumable Electrode or Vacuum Induction Melted, Solution Treated. AMS: Warrendale, PA, USA, 1965.

- Becker, T.H.; Dimitrov, D. The achievable mechanical properties of SLM produced Maraging Steel 300 components. Rapid Prototyp. J. 2016, 22, 487–494. [Google Scholar] [CrossRef]

- Balbaa, M.; Mekhiel, S.; Elbestawi, M.; McIsaac, J. On selective laser melting of Inconel 718: Densification, surface roughness, and residual stresses. Mater. Des. 2020, 193, 108818. [Google Scholar] [CrossRef]

- Deng, D.; Peng, R.L.; Brodin, H.; Moverare, J. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: Sample orientation dependence and effects of post heat treatments. Mater. Sci. Eng. A 2018, 713, 294–306. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, D.; Cao, M.; Chen, R.; Feng, Z.; Poprawe, R.; Schleifenbaum, J.H.; Ziegler, S. Effect of delta phase on high temperature mechanical performances of Inconel 718 fabricated with SLM process. Mater. Sci. Eng. A 2019, 767, 138327. [Google Scholar] [CrossRef]

| Infeed | Z-Pitch | Spindle Speed | Feed Rate | |

|---|---|---|---|---|

| N/(1/min) | /(mm/min) | |||

| Roughing | 110 | 150 | 4800 | 240 |

| Semi-finishing | 110 | 100 | 4800 | 240 |

| Finishing | 30 | 80 | 9600 | 240 |

| Element | Ni | Cr | Nb | Mo | Ti | Al | C | Mn | Si | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt% | 50–55 | 17–21 | 4.8–5.5 | 2.8–3.3 | 0.7–1.2 | 0.2–0.8 | <0.1 | <0.4 | <0.4 | balance |

| Step 1 | Step 2 | DA | |

|---|---|---|---|

| AB | — | — | — |

| HT 1 | 1150 °C/4 h/150 MPa | 980 °C/60 min | 720 °C/8 h, 620 °C/10 h |

| HT 2 | 1065 °C/90 min | 1150 °C/3 h/175 MPa | 720 °C/8 h, 620 °C/10 h |

| HT 3 | 1065 °C/90 min | 1150 °C/4 h/175 MPa | 720 °C/8 h, 620 °C/10 h |

| HT 4 | 1065 °C/90 min | 1150 °C/5 h/175 MPa | 720 °C/8 h, 620 °C/10 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sommer, D.; Truetsch, B.; Esen, C.; Hellmann, R. Effect of Hot Isostatic Pressing and Sequenced Heat Treatment on the Mechanical Properties of Hybrid Additive Manufactured Inconel 718 Components. J. Manuf. Mater. Process. 2025, 9, 378. https://doi.org/10.3390/jmmp9110378

Sommer D, Truetsch B, Esen C, Hellmann R. Effect of Hot Isostatic Pressing and Sequenced Heat Treatment on the Mechanical Properties of Hybrid Additive Manufactured Inconel 718 Components. Journal of Manufacturing and Materials Processing. 2025; 9(11):378. https://doi.org/10.3390/jmmp9110378

Chicago/Turabian StyleSommer, David, Ben Truetsch, Cemal Esen, and Ralf Hellmann. 2025. "Effect of Hot Isostatic Pressing and Sequenced Heat Treatment on the Mechanical Properties of Hybrid Additive Manufactured Inconel 718 Components" Journal of Manufacturing and Materials Processing 9, no. 11: 378. https://doi.org/10.3390/jmmp9110378

APA StyleSommer, D., Truetsch, B., Esen, C., & Hellmann, R. (2025). Effect of Hot Isostatic Pressing and Sequenced Heat Treatment on the Mechanical Properties of Hybrid Additive Manufactured Inconel 718 Components. Journal of Manufacturing and Materials Processing, 9(11), 378. https://doi.org/10.3390/jmmp9110378