Microstructure, Processability, and Strength of SiC-Reinforced AlSi9Mg Composite After Laser Surface Remelting and Post-Heat Treatment

Abstract

1. Introduction

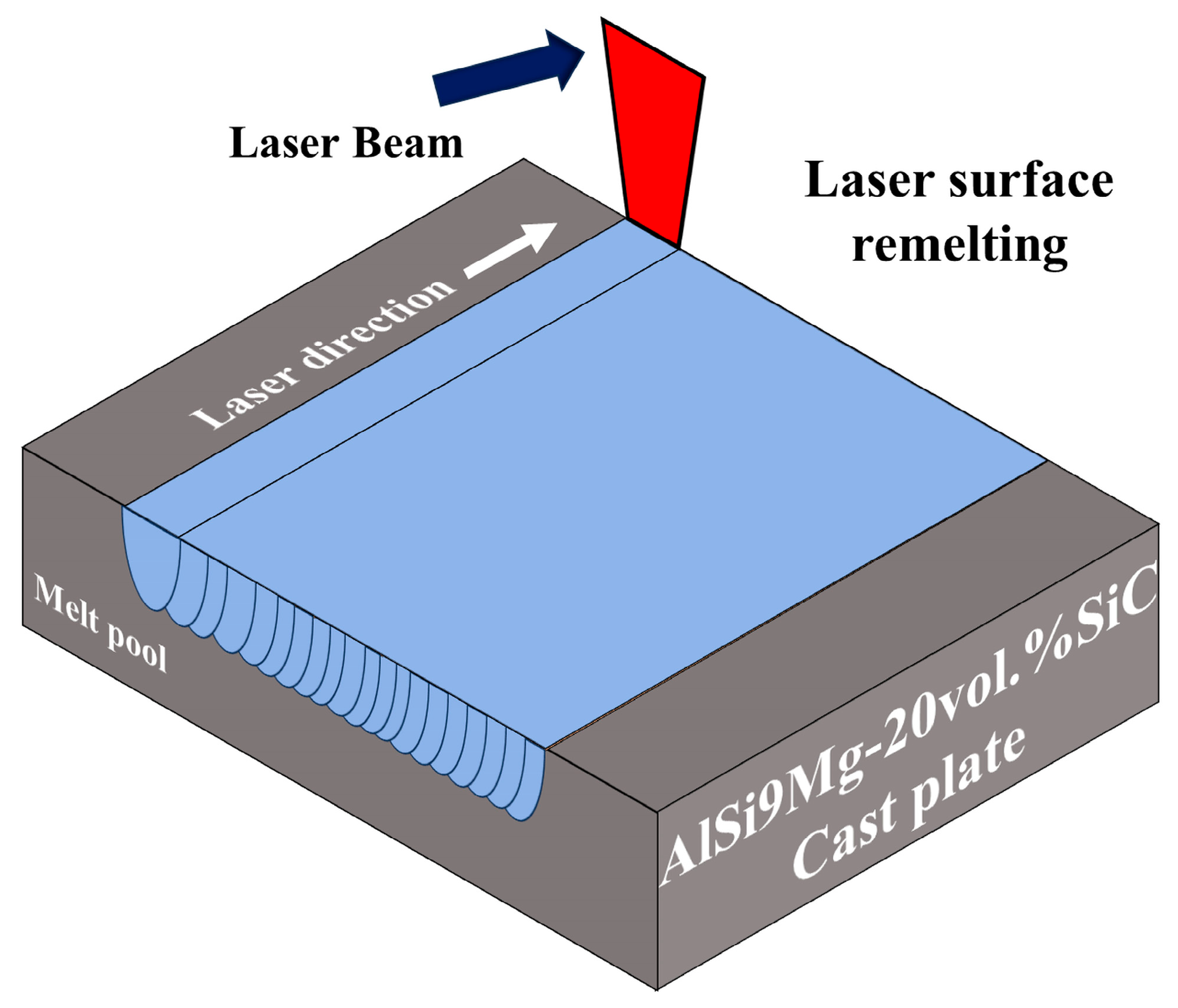

2. Materials and Methods

3. Results

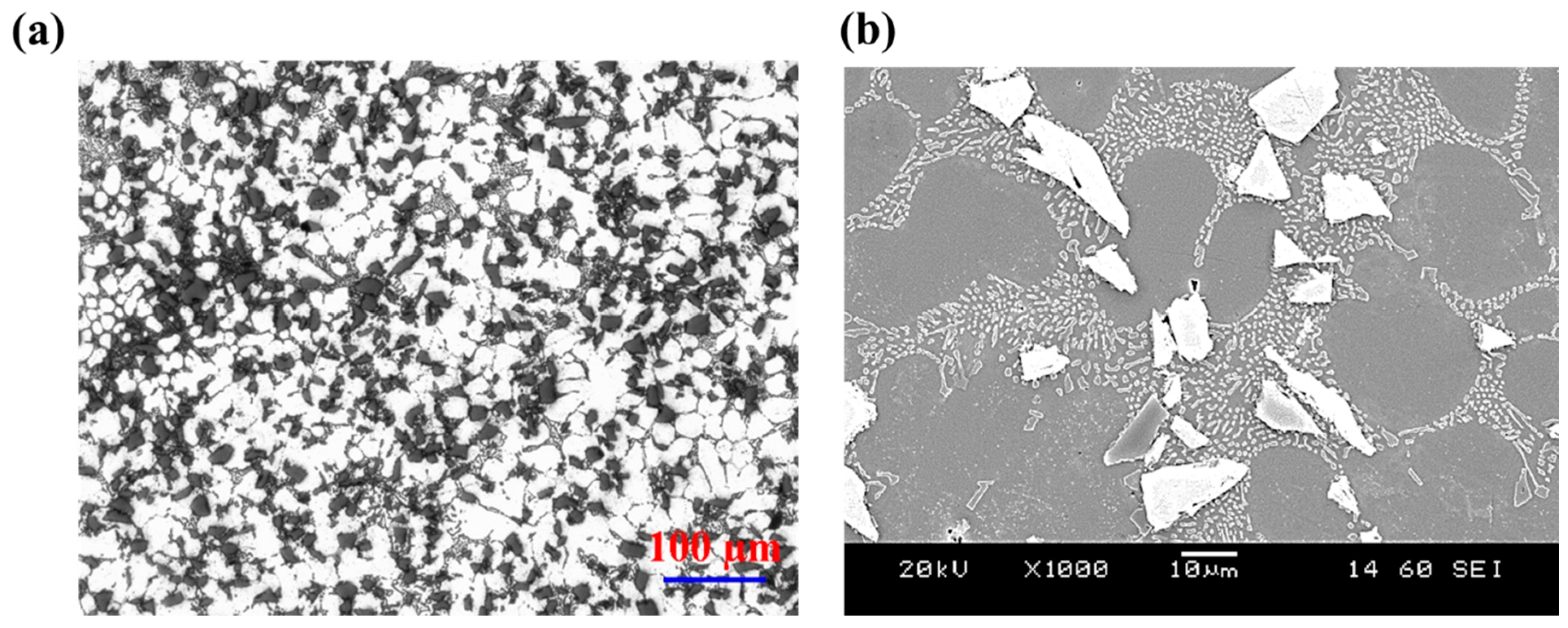

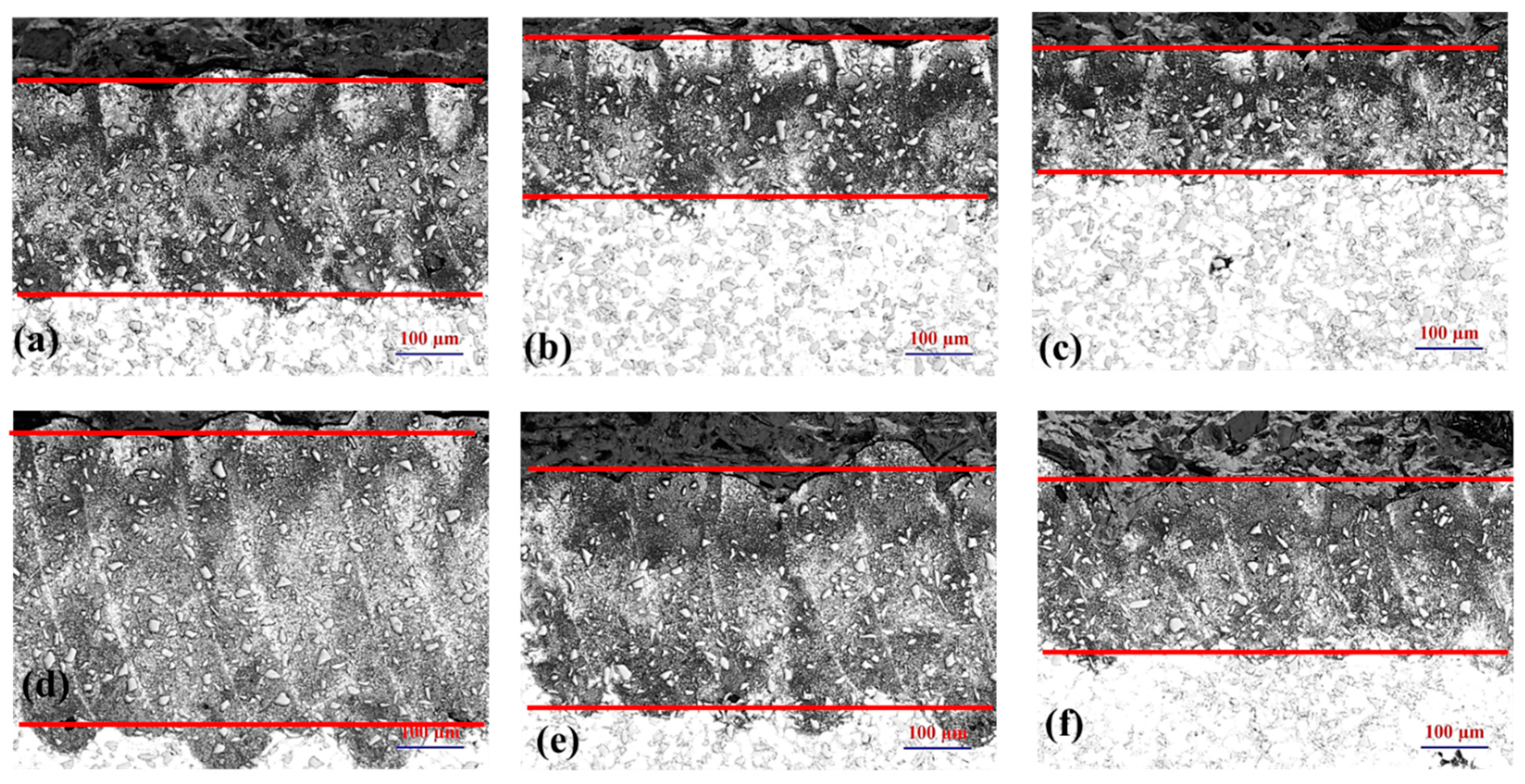

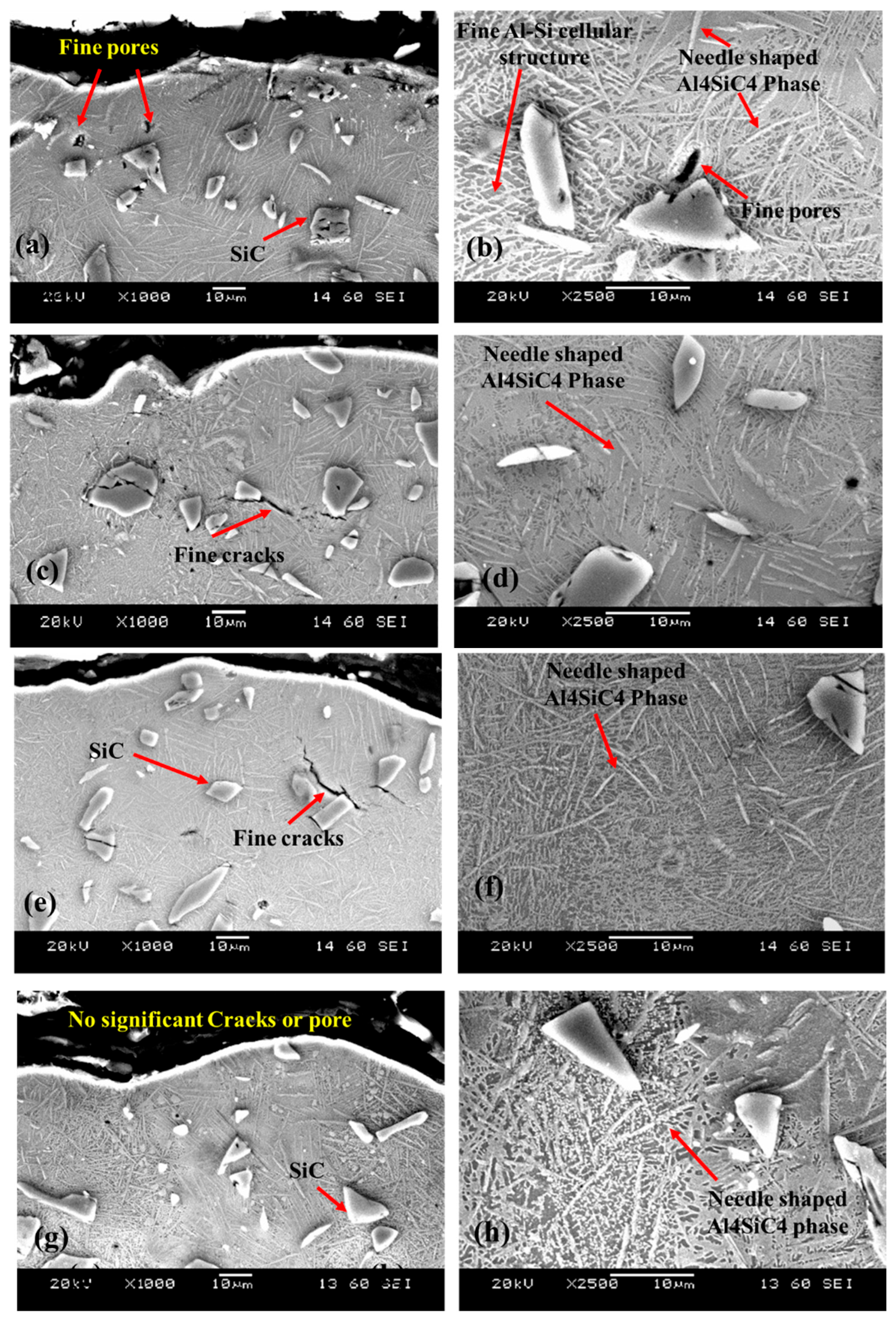

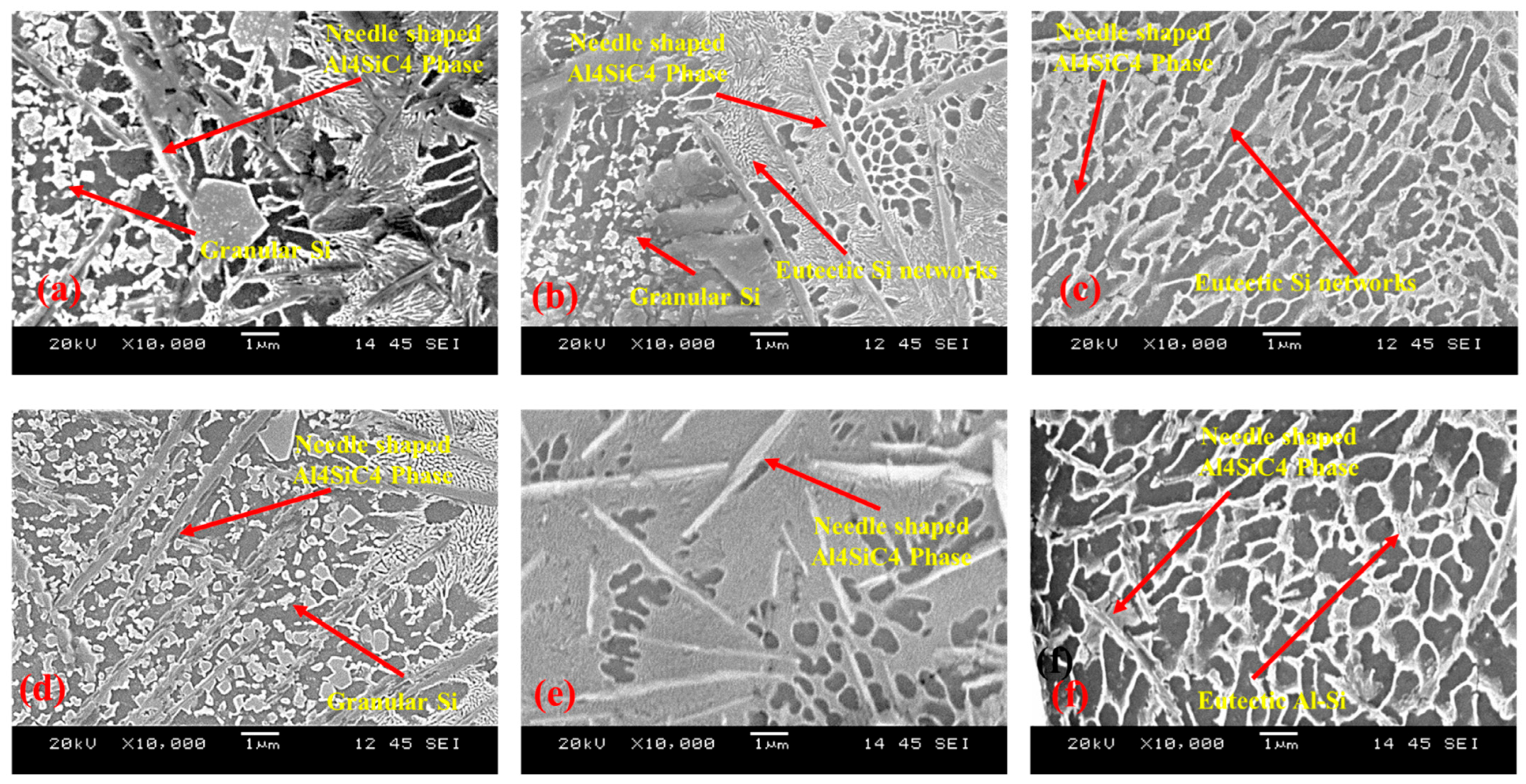

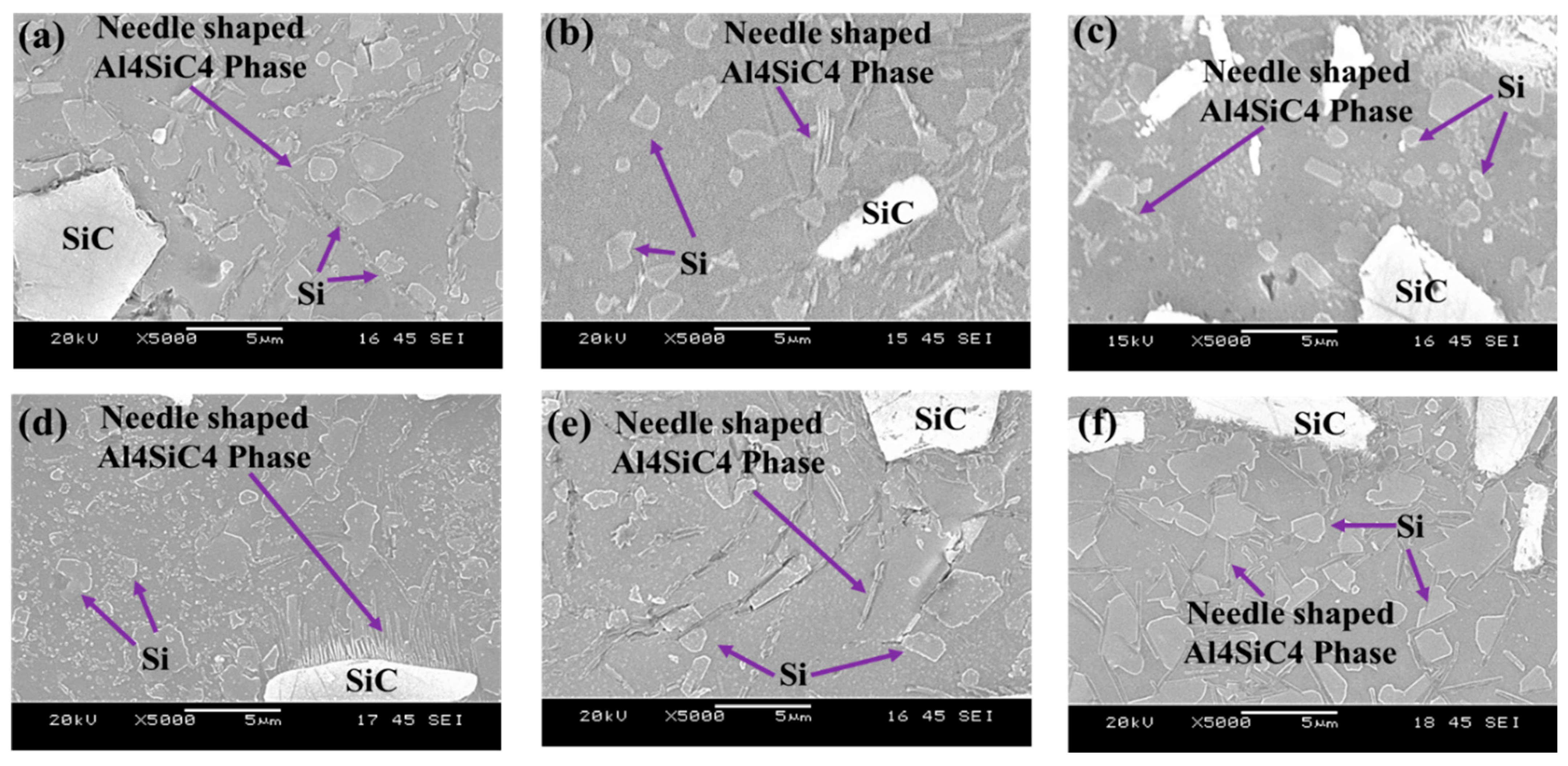

3.1. Microstructures After Casting and Laser Surface Remelting

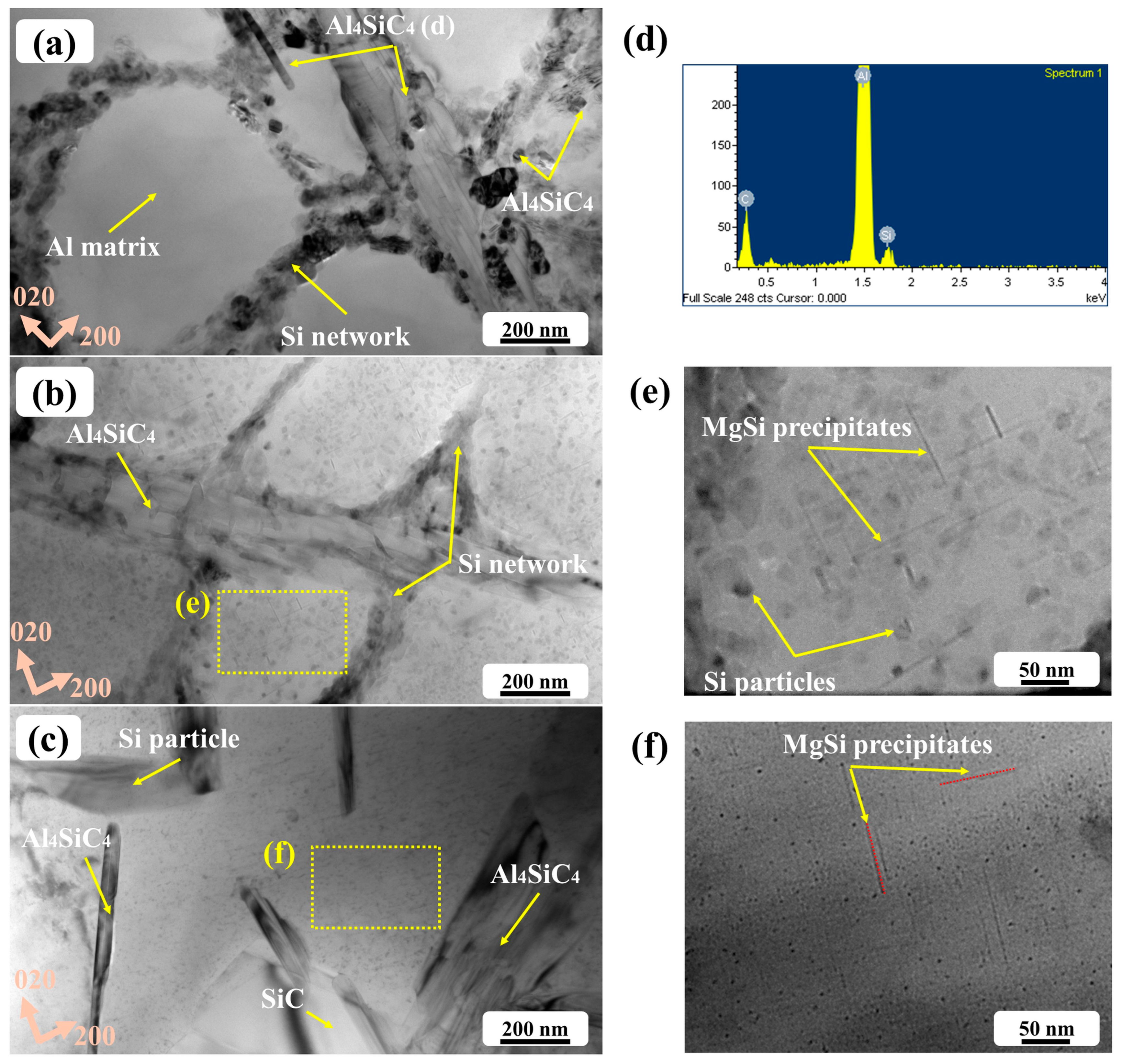

3.2. Microstructure Evolution During T5 and T6 Post-Heat Treatments

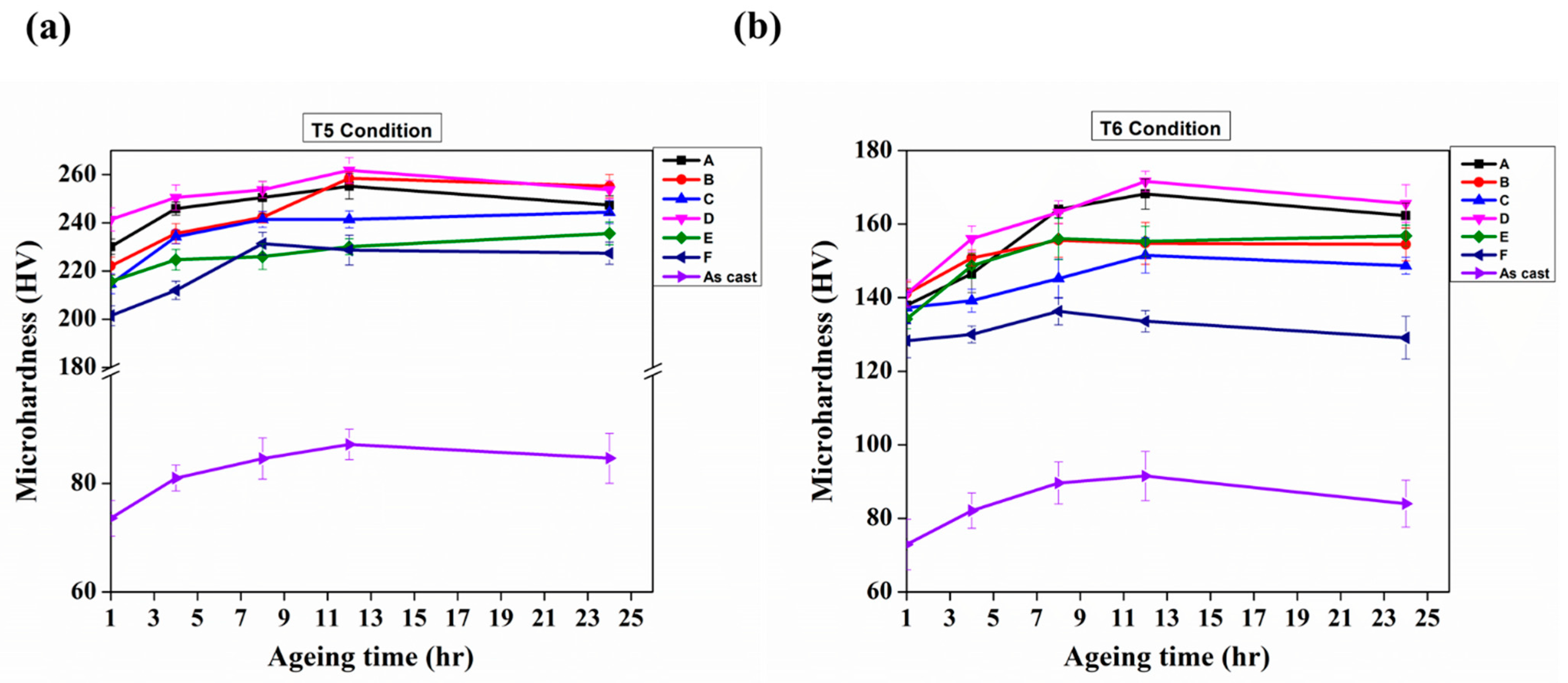

3.3. Microhardness Evolution and Aging Responses During T5 and T6 Treatments

4. Discussion

4.1. Microstructure Evolution of SiC-Reinforced AlSi9Mg Composite During Laser-Based Manufacturing Process

4.2. Comparison of Strength Between AlSi9Mg-20%SiC and Conventional AlSi10Mg

5. Conclusions

- The AlSi9Mg-20%SiC composite generally exhibited good laser processability owing to the lack of macro solidification cracks with the current processing parameters studied. The samples with the highest laser energy density of 0.6–0.8 J/mm and the lowest scan speed of 500 mm/s possessed the best processability for the laser-based processes owing to the elimination of microcracks and pores. The width and cross-section of the melt pools increased with increasing laser energy density.

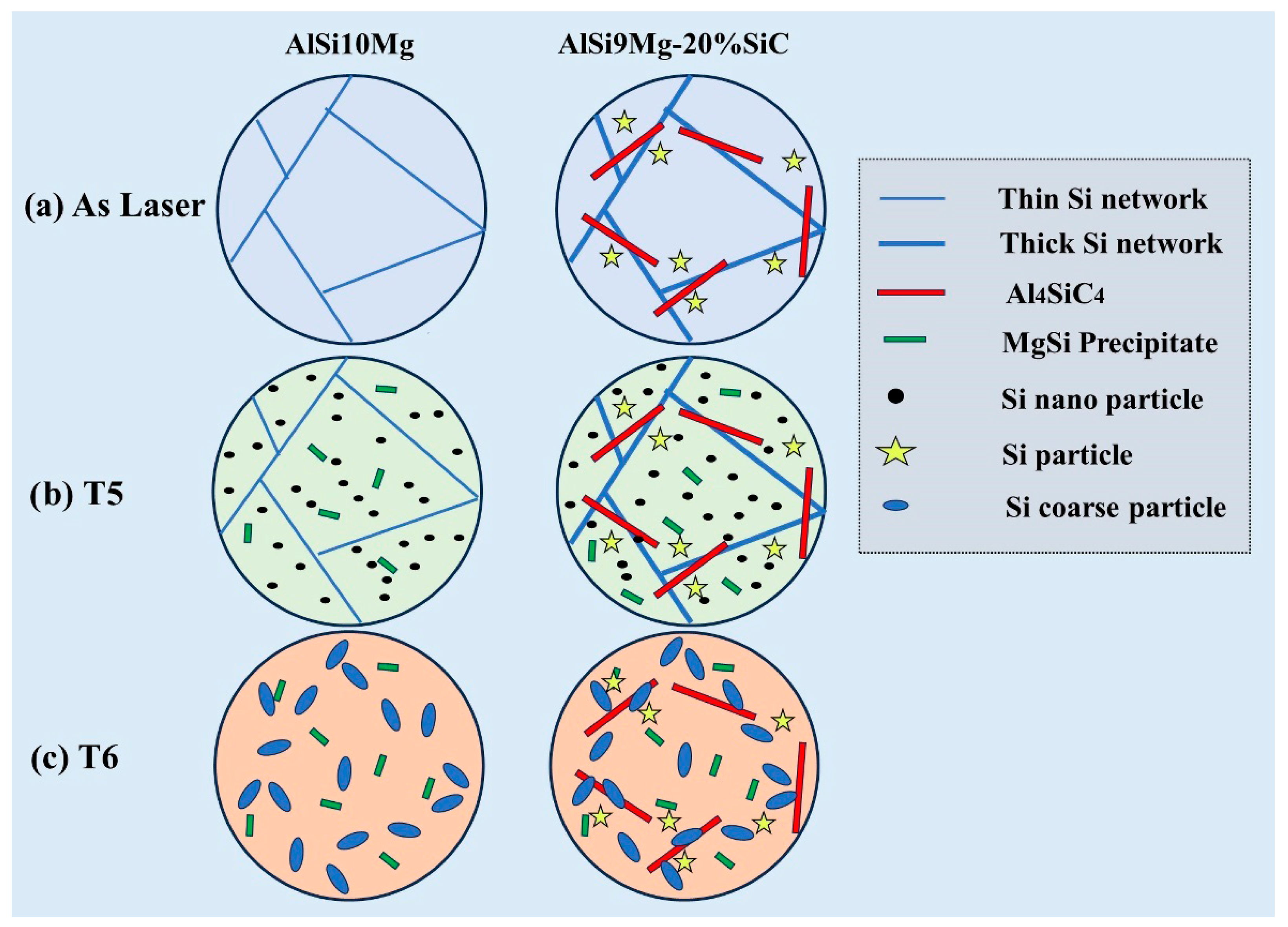

- During the LSR process, all the samples displayed a fine Al-Si cellular structure, in which a supersaturated aluminum matrix was surrounded by eutectic Si networks in the intercellular regions. Owing to the in-situ reaction between the liquid aluminum and SiC particles, a needle-shaped Al4SiC4 phase was formed and randomly distributed in the melt pools of the composite. With increasing laser energy density, the area fraction of these fine Al4SiC4 needles considerably increased, resulting in significantly higher hardness and strength compared to the as-cast samples.

- The T5-treated samples preserved the fine Al-Si cellular structure and the strengthening effect of the fine eutectic network. Additionally, a large number of Si and MgSi nanoparticles were precipitated out upon aging. During T6 solid solution treatment, the Si network was broken down into coarse Si particles, disintegrating the Al-Si cellular structure. Although a number of MgSi precipitates were formed during the subsequent aging, the microhardness was significantly lower than in the as-laser-scanned and T5 conditions. The T5 condition attained the highest level of microhardness and strength when compared to the as-laser-scanned and T6 conditions.

- Compared to conventionally laser-processed AlSi10Mg alloys, the AlSi9Mg-20%SiC composite exhibited a significant increase in microhardness and yield strength, with both values being almost doubled. This significant strengthening effect was attributed to the presence of a large number of ex-situ SiC particles and in-situ Al4SiC4 phase in the matrix, which are known to increase the resistance against deformation and induce internal residual stresses. In future work, the mechanical properties and optimal process parameters of AlSi9Mg-20%SiC composite will be verified with LPBF-manufactured parts to substantiate the findings obtained from LSR in real additive manufacturing contexts.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, S.; Li, B.; Lv, Z.; Yan, X. Microstructures and Mechanical Behaviors of Reinforced Aluminum Matrix Composites with Modified Nano-Sized TiB2/SiC Fabricated by Selective Laser Melting. Compos. Commun. 2023, 37, 101439. [Google Scholar] [CrossRef]

- Karabulut, Y.; Ünal, R. Additive Manufacturing of Ceramic Particle-Reinforced Aluminum–based Metal Matrix Composites: A Review. J. Mater. Sci. 2022, 57, 19212–19242. [Google Scholar] [CrossRef]

- Xue, G.; Ke, L.; Zhu, H.; Liao, H.; Zhu, J.; Zeng, X. Influence of Processing Parameters on Selective Laser Melted SiCp/AlSi10Mg Composites: Densification, Microstructure and Mechanical Properties. Mater. Sci. Eng. A 2019, 764, 138155. [Google Scholar] [CrossRef]

- Zhao, X.; Gu, D.; Ma, C.; Xi, L.; Zhang, H. Microstructure Characteristics and Its Formation Mechanism of Selective Laser Melting SiC Reinforced Al-Based Composites. Vacuum 2019, 160, 189–196. [Google Scholar] [CrossRef]

- Wei, P.; Chen, Z.; Zhang, S.; Li, B.; Han, J.; Lu, B. Microstructure and Mechanical Properties of Graphene and Nano-Zirconia Reinforced AlSi10Mg Composite Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2023, 864, 144574. [Google Scholar] [CrossRef]

- Huang, B.C.; Hung, F.Y. Al2O3 Particle Erosion Induced Phase Transformation: Structure, Mechanical Property, and Impact Toughness of an Slm Al-10si-Mg Alloy. Nanomaterials 2021, 11, 2131. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhuo, L.; Yin, E.; Zhao, Z. Microstructure Evolution and Properties of Nanoparticulate SiC Modified AlSi10Mg Alloys. Mater. Sci. Eng. A 2021, 808, 140864. [Google Scholar] [CrossRef]

- Rio Tinto Alcan Fact Sheet for DuralcanTM. Available online: https://www.riotinto.com/-/media/Content/Documents/Products/Aluminium/RT-Aluminium-Duralcan-fact-sheet.pdf?rev=48ac3c3132294b6cbc5921e6c15aef3d (accessed on 1 January 2025).

- Cyboroń, J.; Karolus, M.; Putyra, P.; Dyzia, M.; Ratuszek, W. Structure Properties of AlSi7Mg/SiC Composite Produced by Stir Casting Method. Acta Phys. Pol. A 2016, 130, 969–971. [Google Scholar] [CrossRef]

- Dehghan Hamedan, A.; Shahmiri, M. Production of A356–1wt% SiC Nanocomposite by the Modified Stir Casting Method. Mater. Sci. Eng. A 2012, 556, 921–926. [Google Scholar] [CrossRef]

- Pourkhorshid, E.; Rometsch, P.; Chen, X.-G. Evolution of Mechanical Properties and Microstructure of Selective Laser Melted AlSi10MgMn Alloy with Different Post Heat Treatments. Mater. Sci. Eng. A 2024, 915, 147249. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Cao, S.; Zhang, K.; Wu, X. Towards a High Strength Aluminium Alloy Development Methodology for Selective Laser Melting. Mater. Des. 2019, 174, 107775. [Google Scholar] [CrossRef]

- Song, X.Y.; Shu, S.L.; Zhang, S.; Yang, H.Y.; Qiu, F.; Jiang, Q.C. Microstructure, Solidification Defects and Mechanical Properties of High-Modulus and High-Strength SiC/AlSi10Mg Composites Fabricated by Selective Laser Melting. Ceram. Int. 2024, 50, 26607–26623. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and Mechanical Property Considerations in Additive Manufacturing of Aluminum Alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective Laser Melting of In-Situ Al4SiC4 + SiC Hybrid Reinforced Al Matrix Composites: Influence of Starting SiC Particle Size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Fox, P.; Pogson, S.; Sutcliffe, C.J.; Jones, E. Interface Interactions between Porous Titanium/Tantalum Coatings, Produced by Selective Laser Melting (SLM), on a Cobalt–Chromium Alloy. Surf. Coat. Technol. 2008, 202, 5001–5007. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Thivillon, L.; Bertrand, P.; Smurov, I. Strategy of Manufacturing Components with Designed Internal Structure by Selective Laser Melting of Metallic Powder. Appl. Surf. Sci. 2007, 254, 980–983. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser Additive Manufacturing of Metallic Components: Materials, Processes and Mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Kürnsteiner, P.; Chao, Q.; Huang, A.; Weyland, M.; Bourgeois, L.; Wu, X. Selective Laser Melting of a High Strength Al-Mn-Sc Alloy: Alloy Design and Strengthening Mechanisms. Acta Mater. 2019, 171, 108–118. [Google Scholar] [CrossRef]

- Carluccio, D.; Bermingham, M.J.; Zhang, Y.; StJohn, D.H.; Yang, K.; Rometsch, P.A.; Wu, X.; Dargusch, M.S. Grain Refinement of Laser Remelted Al-7Si and 6061 Aluminium Alloys with Tibor® and Scandium Additions. J. Manuf. Process. 2018, 35, 715–720. [Google Scholar] [CrossRef]

- Pourkhorshid, E.; Rometsch, P.; Bois-Brochu, A.; Taylor, A.; Marceau, R.K.W.; Grant Chen, X. Effect of Mn on Microstructural Characteristics and Mechanical Behavior of AlSi10Mg Alloys Produced by Laser Powder Bed Fusion. Addit. Manuf. 2025, 110, 104923. [Google Scholar] [CrossRef]

- Kaščák, Ľ.; Varga, J.; Bidulská, J.; Bidulský, R.; Kvačkaj, T. A Review of Simulation Tools Utilization for the Process of Laser Powder Bed Fusion. Materials 2025, 18, 895. [Google Scholar] [CrossRef] [PubMed]

- Kaščák, Ľ.; Varga, J.; Bidulská, J.; Bidulský, R.; Manfredi, D. Weight Factor as a Parameter for Optimal Part Orientation in the L-PBF Printing Process Using Numerical Simulation. Materials 2024, 17, 3604. [Google Scholar] [CrossRef] [PubMed]

- Benoit, M.J.; Whitney, M.A.; Zhu, S.M.; Zhang, D.; Field, M.R.; Easton, M.A. The Beneficial Effect of Minor Iron Additions on the Crack Susceptibility of Rapidly Solidified Aluminum Alloy 6060 toward Additive Manufacturing Applications. Mater. Charact. 2023, 205, 113287. [Google Scholar] [CrossRef]

- Famodimu, O.H.; Stanford, M.; Oduoza, C.F.; Zhang, L. Effect of Process Parameters on the Density and Porosity of Laser Melted AlSi10Mg/SiC Metal Matrix Composite. Front. Mech. Eng. 2018, 13, 520–527. [Google Scholar] [CrossRef]

- Chen, Y.; Jian, Z.; Li, K.; Song, K.; Ren, Y.; Liu, Y.; Dang, B.; Zhu, M.; Gao, Q. Effects of Processing Parameters on the LPBF-Deposited AlSi10Mg/SiCp Composite: Microstructure and Mechanical Properties. Mater. Sci. Technol. 2023, 39, 2501–2514. [Google Scholar] [CrossRef]

- Lu, Q.; Ou, Y.; Zhang, P.; Yan, H. Fatigue Performance and Material Characteristics of SiC/AlSi10Mg Composites by Selective Laser Melting. Mater. Sci. Eng. A 2022, 858, 144163. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Shankar, G. On the Role of Precipitates in Controlling Microstructure and Mechanical Properties of Ag and Sn Added 7075 Alloys during Artificial Ageing. Mater. Sci. Eng. A 2018, 738, 399–411. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M. Tensile and Impact Behaviour of Thermo Mechanically Treated and Micro-Alloyed Medium Carbon Steel Bar. Constr. Build. Mater. 2018, 192, 657–670. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Saha, P. Crack and Wear Behavior of SiC Particulate Reinforced Aluminium Based Metal Matrix Composite Fabricated by Direct Metal Laser Sintering Process. Mater. Des. 2011, 32, 139–145. [Google Scholar] [CrossRef]

- Sahin, Y.; Özdin, K. A Model for the Abrasive Wear Behaviour of Aluminium Based Composites. Mater. Des. 2008, 29, 728–733. [Google Scholar] [CrossRef]

- Wang, M.; Song, B.; Wei, Q.; Shi, Y. Improved Mechanical Properties of AlSi7Mg/Nano-SiCp Composites Fabricated by Selective Laser Melting. J. Alloys Compd. 2019, 810, 151926. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Li, X. Selective Laser Melting of Aluminium and Aluminium Metal Matrix Composites: Review. Mater. Technol. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- Han, Q.; Jiao, Y. Effect of Heat Treatment and Laser Surface Remelting on AlSi10Mg Alloy Fabricated by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2019, 102, 3315–3324. [Google Scholar] [CrossRef]

- Zhou, X.; Chao, P.; Sloan, L.; Lien, H.H.; Hunter, A.H.; Misra, A.; Shahani, A.J. Three-Dimensional Morphology of an Ultrafine Al-Si Eutectic Produced via Laser Rapid Solidification. Scr. Mater. 2023, 232, 115471. [Google Scholar] [CrossRef]

- Kayitmazbatir, M.; Lien, H.-H.; Mazumder, J.; Wang, J.; Misra, A. Effect of Cooling Rate on Nano-Eutectic Formation in Laser Surface Remelted and Rare Earth Modified Hypereutectic Al-20Si Alloys. Crystals 2022, 12, 750. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Cao, S.; Zhang, K.; Huang, A.; Wu, X. Characterisation of AlScZr and AlErZr Alloys Processed by Rapid Laser Melting. Scr. Mater. 2018, 151, 42–46. [Google Scholar] [CrossRef]

- Pourkhorshid, E.; Rometsch, P.; Chen, X.-G. Laser-Based Additive Manufacturing Processability and Mechanical Properties of Al-Cu 224 Alloys with TiB Grain Refiner Additions. Materials 2025, 18, 516. [Google Scholar] [CrossRef]

- Zhang, D.; Yi, D.; Wu, X.; Liu, Z.; Wang, W.; Poprawe, R.; Schleifenbaumc, J.H.; Zieglerd, S. SiC Reinforced AlSi10Mg Composites Fabricated by Selective Laser Melting. J. Alloys Compd. 2022, 894, 162365. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, Precipitates and Hardness of Selectively Laser Melted AlSi10Mg Alloy before and after Heat Treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Van Cauwenbergh, P.; Samaee, V.; Thijs, L.; Nejezchlebová, J.; Sedlák, P.; Iveković, A.; Schryvers, D.; Van Hooreweder, B.; Vanmeensel, K. Unravelling the Multi-Scale Structure–Property Relationship of Laser Powder Bed Fusion Processed and Heat-Treated AlSi10Mg. Sci. Rep. 2021, 11, 6423. [Google Scholar] [CrossRef]

- Tang, H.; Gao, C.; Zhang, Y.; Zhang, N.; Lei, C.; Bi, Y.; Tang, P.; Rao, J.H. Effects of Direct Aging Treatment on Microstructure, Mechanical Properties and Residual Stress of Selective Laser Melted AlSi10Mg Alloy. J. Mater. Sci. Technol. 2023, 139, 198–209. [Google Scholar] [CrossRef]

- Cahoon, J.R.; Broughton, W.H.; Kutzak, A.R. The Determination of Yield Strength from Hardness Measurements. Metall. Trans. 1971, 2, 1979–1983. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, M.; Gudimetla, K.; Kalsar, R.; Kestens, L.A.I.; Kondaveeti, C.S.; Singh Pugazhendhi, B.; Ravisankar, B. Development of Ultrafine Grained Al–Zn–Mg–Cu Alloy by Equal Channel Angular Pressing: Microstructure, Texture and Mechanical Properties. Arch. Civ. Mech. Eng. 2020, 20, 7. [Google Scholar] [CrossRef]

- Chen, B.; Moon, S.K.; Yao, X.; Bi, G.; Shen, J.; Umeda, J.; Kondoh, K. Strength and Strain Hardening of a Selective Laser Melted AlSi10Mg Alloy. Scr. Mater. 2017, 141, 45–49. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain Rate Sensitivity and Fracture Mechanism of AlSi10Mg Parts Produced by Selective Laser Melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Wang, J.J.; Ni, D.R.; Wang, D.; Xiao, B.L.; Ma, Z.Y. Achieving Superior Mechanical Properties of Selective Laser Melted AlSi10Mg via Direct Aging Treatment. J. Mater. Sci. Technol. 2022, 108, 226–235. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in Microstructure of Selectively Laser Melted AlSi10Mg Alloy with Heat Treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The Microstructure and Mechanical Properties of Selectively Laser Melted AlSi10Mg: The Effect of a Conventional T6-like Heat Treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Park, T.H.; Baek, M.S.; Hyer, H.; Sohn, Y.; Lee, K.A. Effect of Direct Aging on the Microstructure and Tensile Properties of AlSi10Mg Alloy Manufactured by Selective Laser Melting Process. Mater. Charact. 2021, 176, 111113. [Google Scholar] [CrossRef]

| Sample ID | Laser Power (W) | Scan Speed (mm/s) | Linear Energy Density (J/mm) |

|---|---|---|---|

| A | 300 | 500 | 0.60 |

| B | 300 | 700 | 0.42 |

| C | 300 | 900 | 0.33 |

| D | 400 | 500 | 0.80 |

| E | 400 | 700 | 0.57 |

| F | 400 | 900 | 0.44 |

| Sample IDs | Linear Energy Density (J/mm) | Area Fraction of Al4SiC4 (%) |

|---|---|---|

| A | 0.60 | 14.55 |

| B | 0.42 | 7.24 |

| C | 0.33 | 4.10 |

| D | 0.80 | 21.29 |

| E | 0.57 | 12.49 |

| F | 0.44 | 8.85 |

| Conditions | Materials | Hardness (HV) | Yield Strength (MPa) | References |

|---|---|---|---|---|

| As-built | AlSi9Mg-20%SiC | 224 * | 461 ** | Present study |

| AlSi10Mg | 120 | 276 | [47] | |

| AlSi10Mg | 135 | 293 | [48] | |

| AlSi10Mg | 125 | 268 | [49] | |

| AlSi10Mg | 135 | 279 | [48] | |

| AlSi10Mg | 128 | 263 | [50] | |

| T5 | AlSi9Mg-20%SiC | 261 * | 678 ** | Present study |

| AlSi10Mg | 130 | 296 | [47] | |

| AlSi10Mg | 145 | 313 | [42] | |

| AlSi10Mg | 139 | 310 | [50] | |

| T6 | AlSi9Mg-20%SiC | 172 * | 446 ** | Present study |

| AlSi10Mg | 123 | 248 | [42] | |

| AlSi10Mg | 103 | 239 | [49] | |

| AlSi10Mg | 75 | 153 | [48] | |

| Permanent mold casting | AlSi9Mg-20%SiC (T6) | 117 | 338 | [8] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, A.; Pourkhorshid, E.; Rometsch, P.; Chen, X.-G. Microstructure, Processability, and Strength of SiC-Reinforced AlSi9Mg Composite After Laser Surface Remelting and Post-Heat Treatment. J. Manuf. Mater. Process. 2025, 9, 379. https://doi.org/10.3390/jmmp9110379

Ghosh A, Pourkhorshid E, Rometsch P, Chen X-G. Microstructure, Processability, and Strength of SiC-Reinforced AlSi9Mg Composite After Laser Surface Remelting and Post-Heat Treatment. Journal of Manufacturing and Materials Processing. 2025; 9(11):379. https://doi.org/10.3390/jmmp9110379

Chicago/Turabian StyleGhosh, Abhishek, Esmaeil Pourkhorshid, Paul Rometsch, and X.-Grant Chen. 2025. "Microstructure, Processability, and Strength of SiC-Reinforced AlSi9Mg Composite After Laser Surface Remelting and Post-Heat Treatment" Journal of Manufacturing and Materials Processing 9, no. 11: 379. https://doi.org/10.3390/jmmp9110379

APA StyleGhosh, A., Pourkhorshid, E., Rometsch, P., & Chen, X.-G. (2025). Microstructure, Processability, and Strength of SiC-Reinforced AlSi9Mg Composite After Laser Surface Remelting and Post-Heat Treatment. Journal of Manufacturing and Materials Processing, 9(11), 379. https://doi.org/10.3390/jmmp9110379