Effects of Printing Angle, Infill Density and Cryogenic Pre-Treatment on the Tensile and Flexural Properties of FFF-Printed PLA

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Test Samples (FFF)

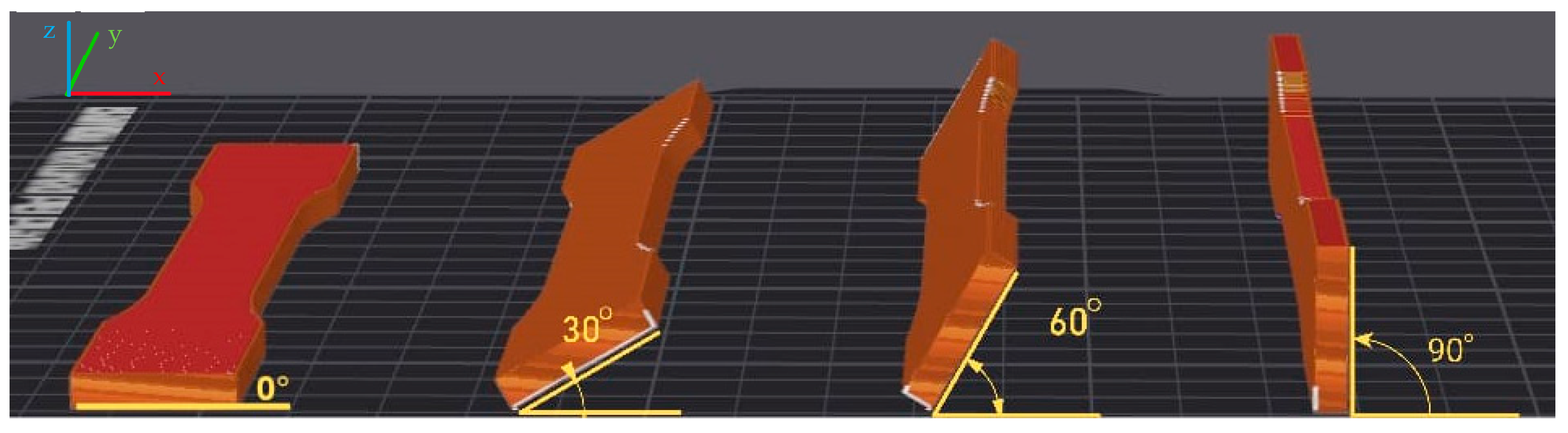

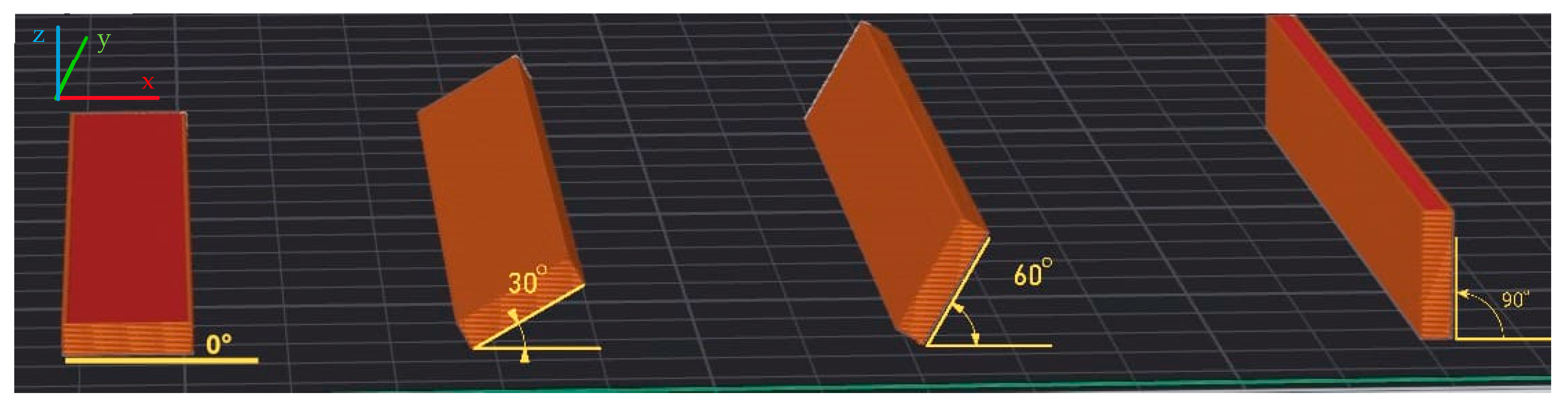

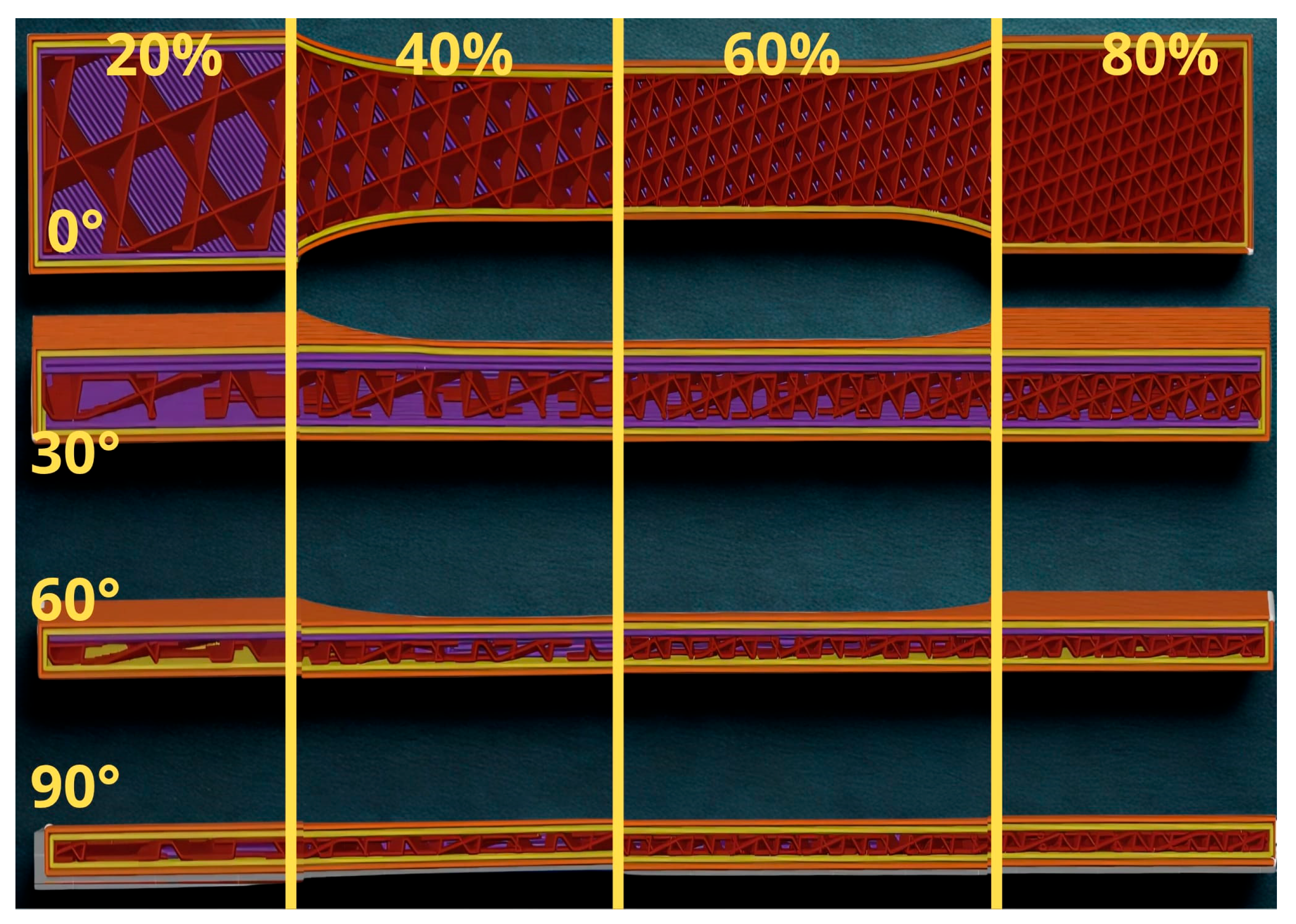

Definition of Printing Angle and Filling Variants

2.3. Conditioning and Cryogenic Treatment

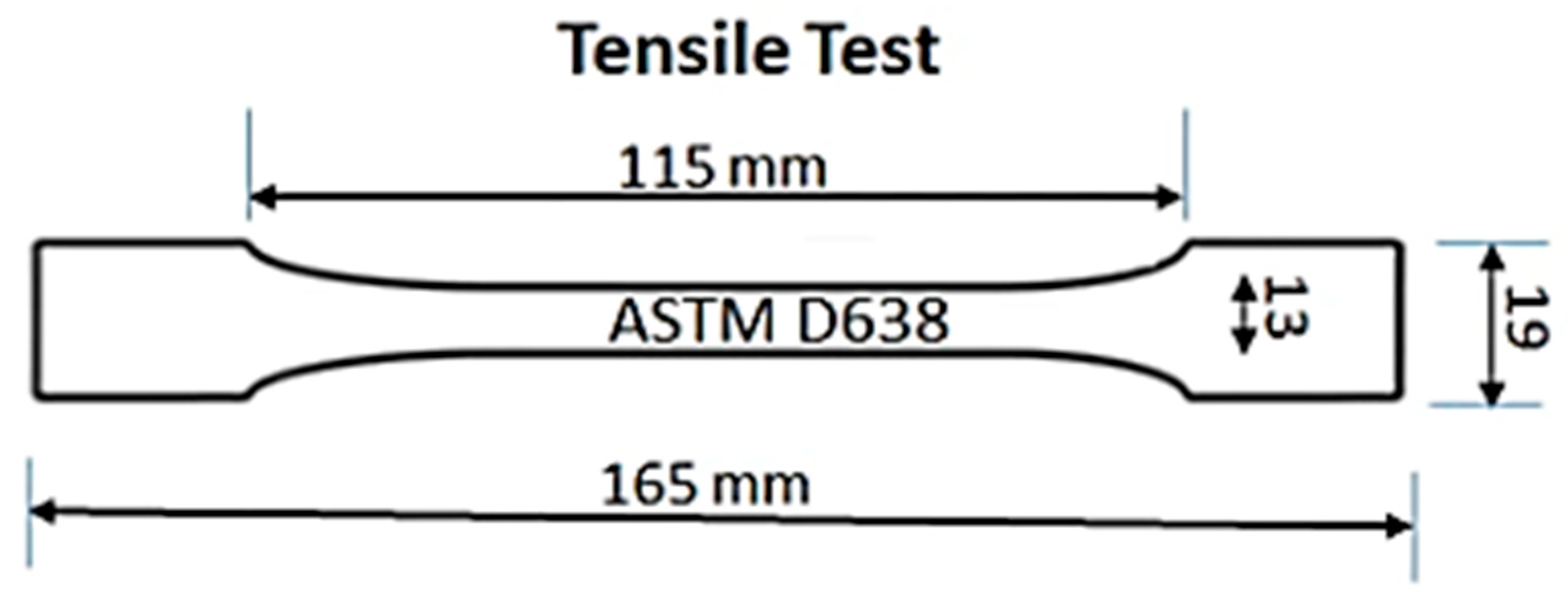

2.4. Tensile Test

2.5. Bending Test

3. Results

3.1. Tensile Test–Series of As-Printed Samples

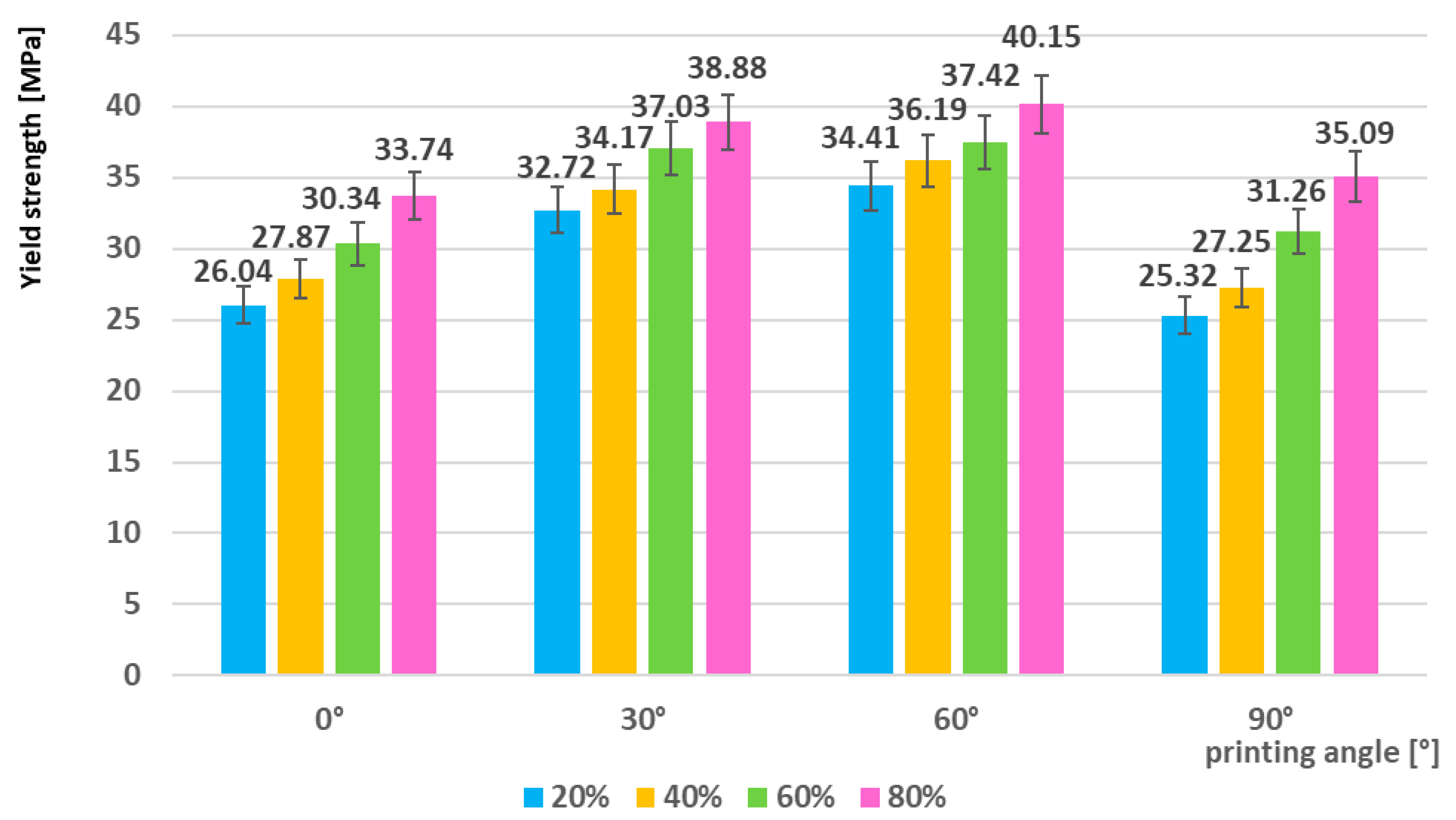

3.1.1. Yield Strength–As-Printed Samples

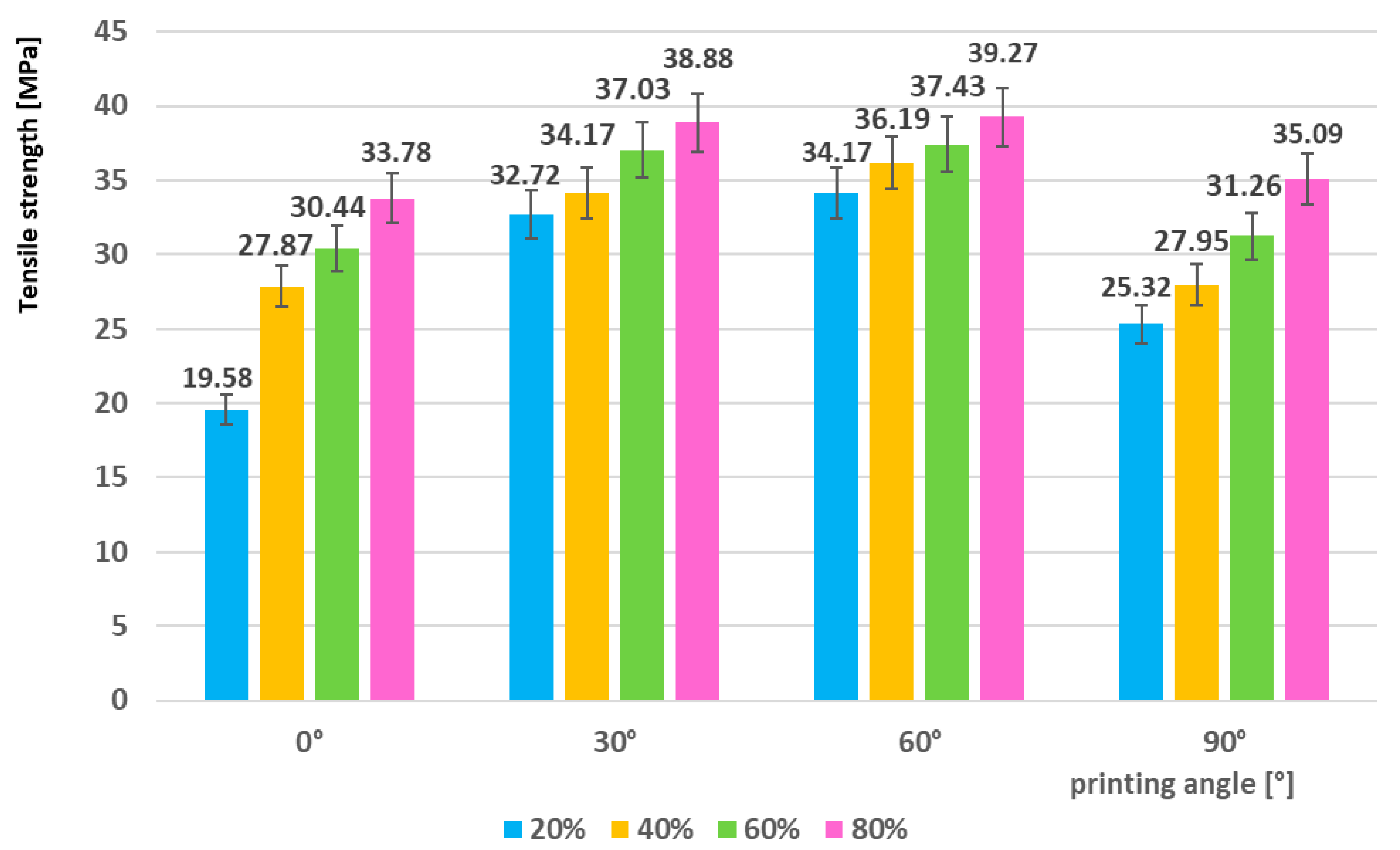

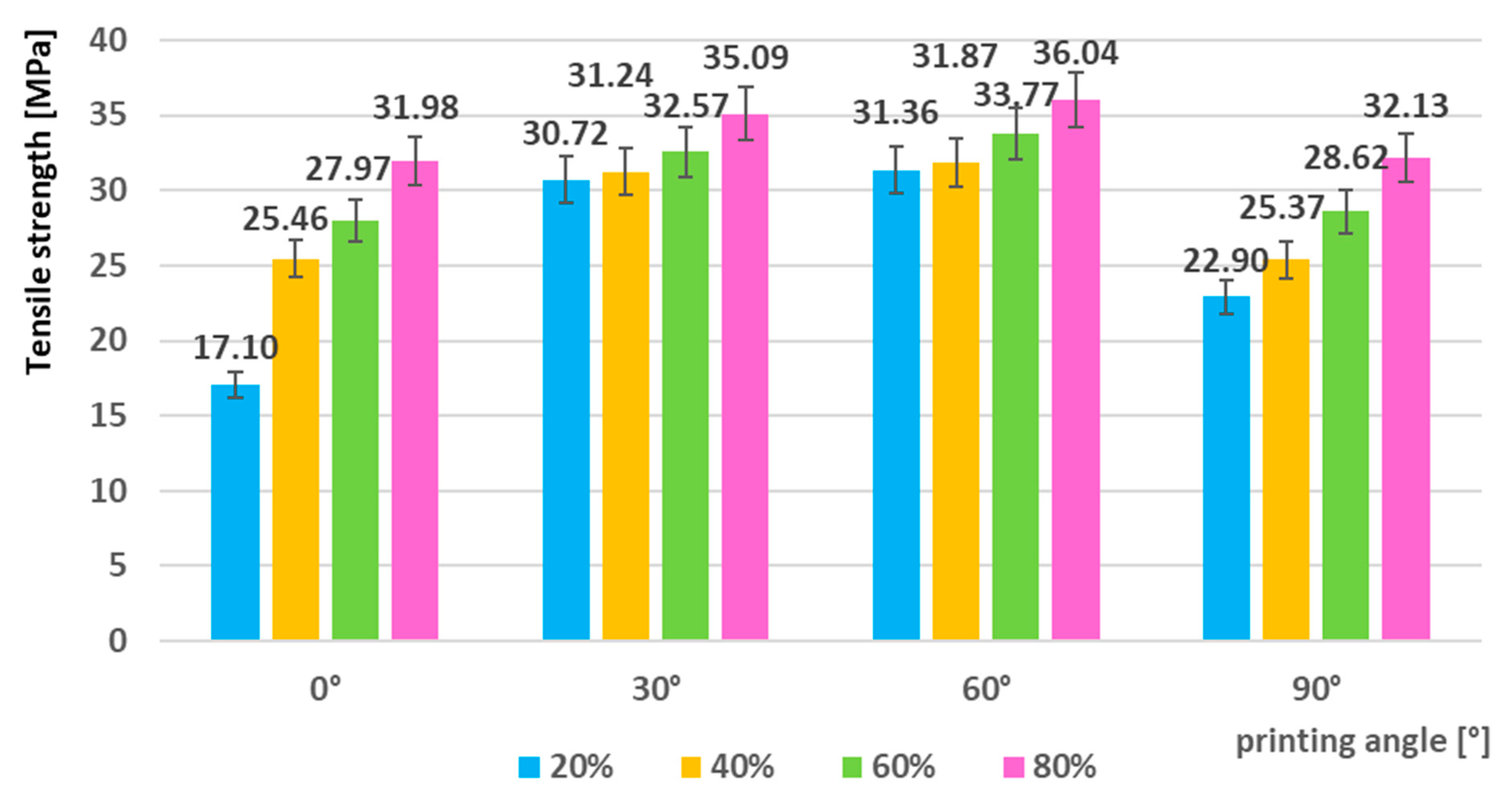

3.1.2. Tensile Strength–As-Printed Samples

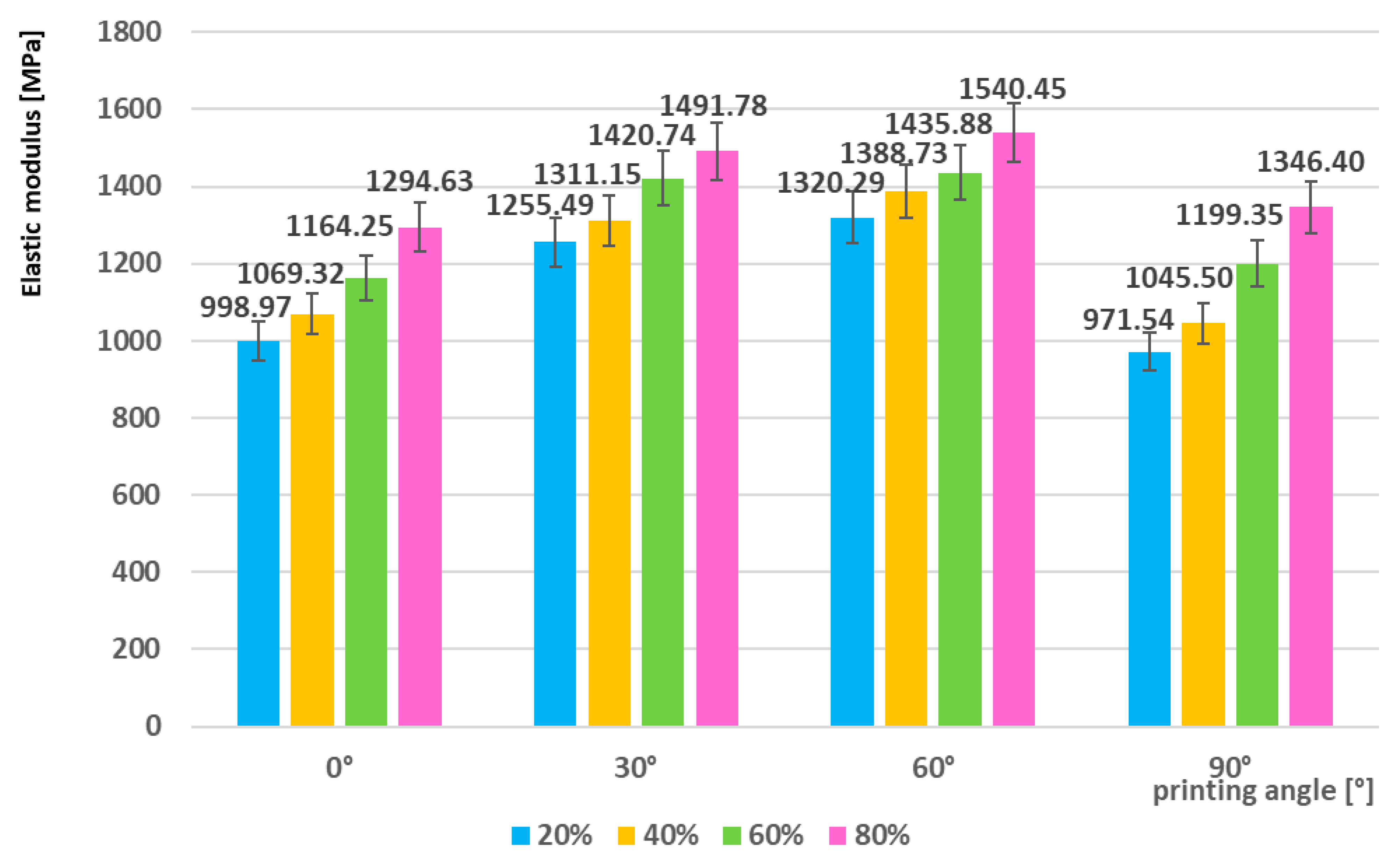

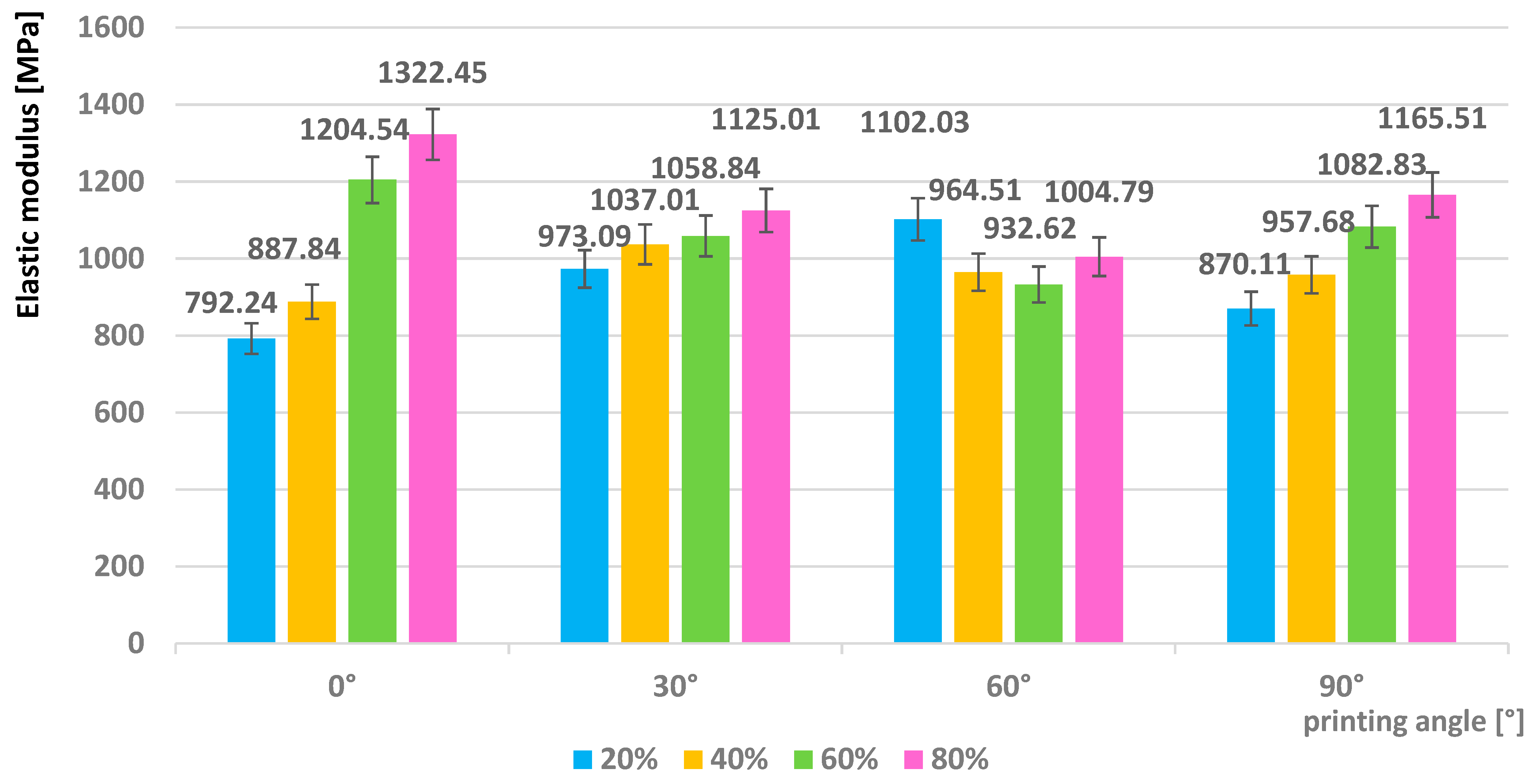

3.1.3. Elastic Modulus–As-Printed Samples

3.2. Tensile Test–Cryogenic Pre-Treated Sample Series

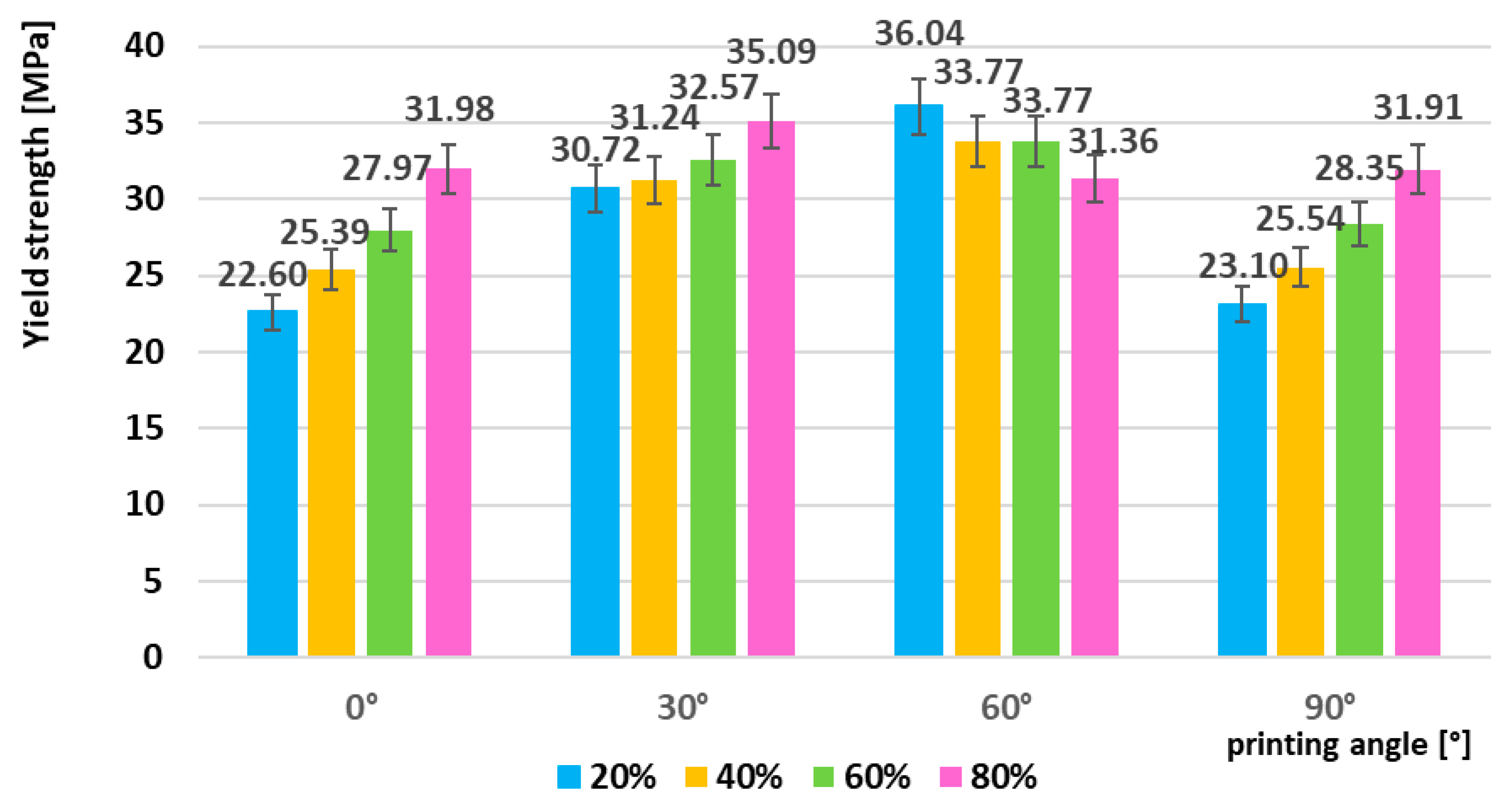

3.2.1. Yield Strength–Cryogenic Pre-Treated Sample

3.2.2. Tensile Strength–Cryogenic Pre-Treated Samples

3.2.3. Elastic Modulus–Cryogenic Pre-Treated Samples

3.3. Comparison of As-Printed and Cryogenic Pre-Treated Series

3.3.1. Yield Strength

3.3.2. Tensile Strength

3.3.3. Elastic Modulus

3.4. Bending Test–Series of As-Printed Samples

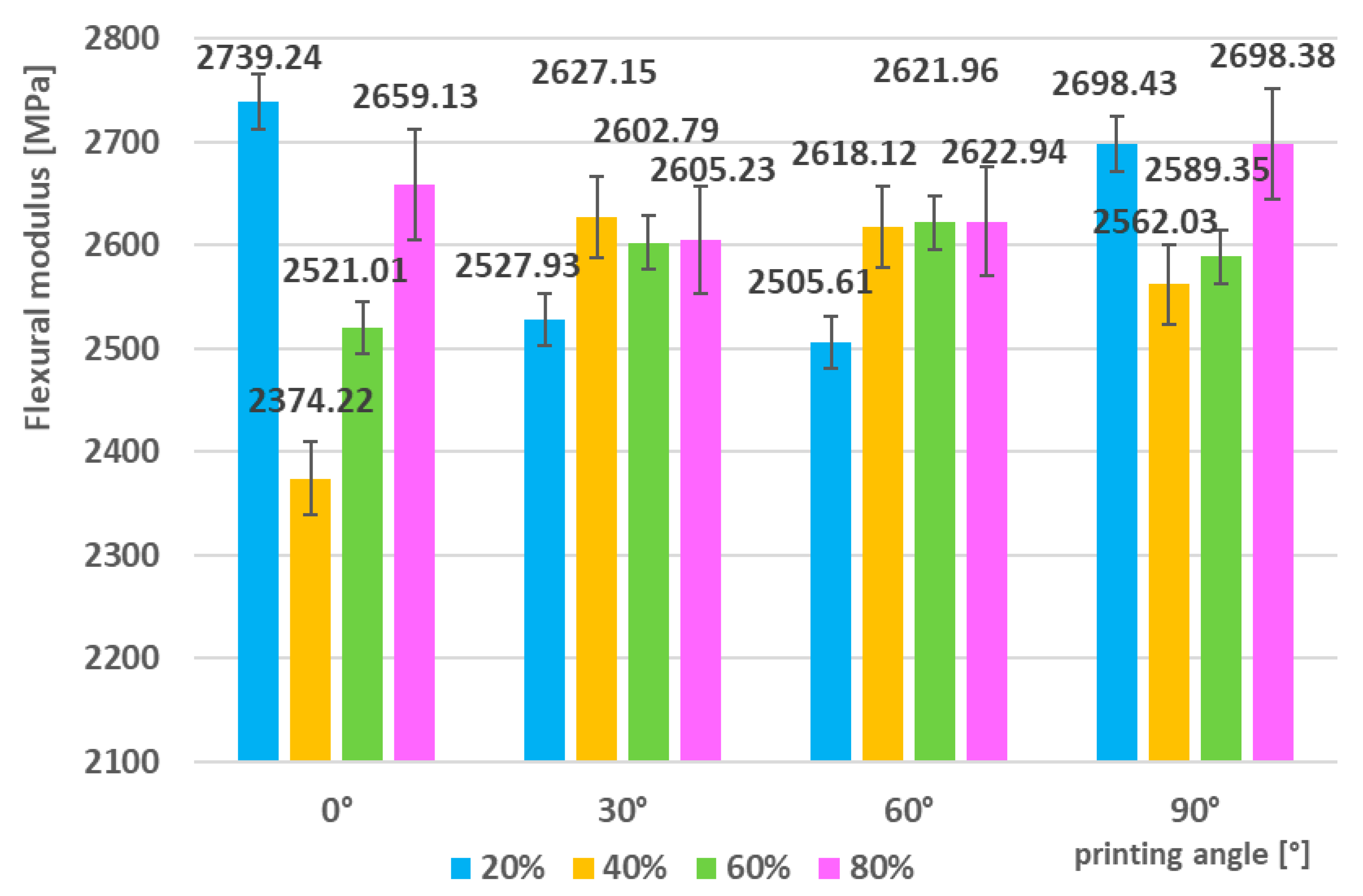

3.4.1. Flexural Modulus–As-Printed Samples

3.4.2. Flexural Strength–As-Printed Samples

3.5. Bending Test–Cryogenic Pre-Treated Sample Series

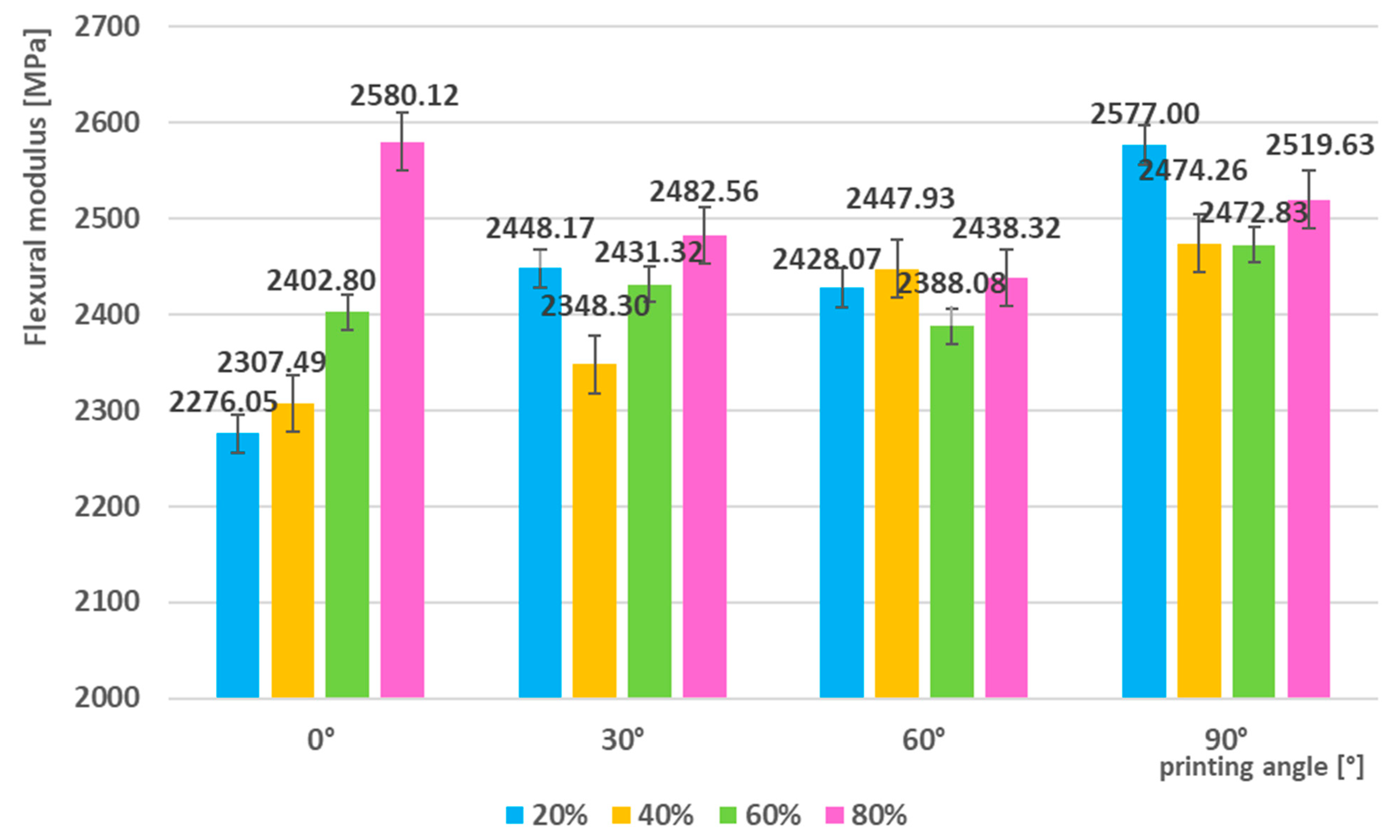

3.5.1. Flexural Modulus-Cryogenic Pre-Treated Sample

3.5.2. Flexural Strength–Cryogenic Pre-Treated Samples

3.6. Comparison of As-Printed and Cryogenic Pre-Treated Series–Bending Test

3.6.1. Flexural Modulus

3.6.2. Flexural Strength

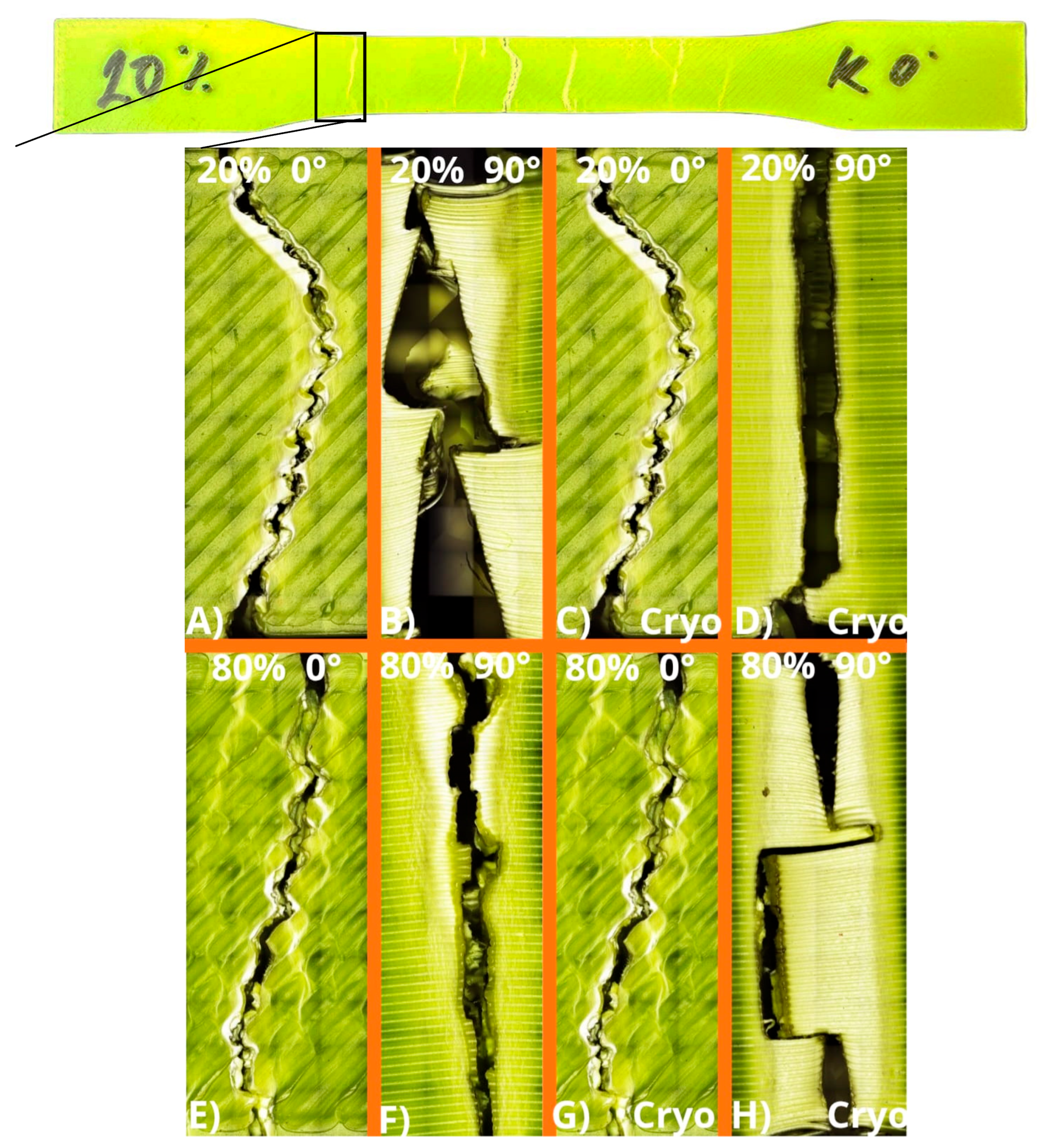

3.7. Microscopic Analysis

- a reduction in plasticity and energy absorption capacity,

- the formation of sharper and more linear fracture paths,

- decreased interlayer adhesion, and

- a shift from ductile to predominantly brittle failure behavior.

4. Discussion

5. Conclusions

- Tensile tests of the as-printed specimens demonstrated a clear dependence of mechanical performance on the filling density and printing orientation. The mechanical properties systematically increased with higher infill density, confirming the positive correlation between material compactness and load-bearing capacity. The lowest tensile strength was observed for the 0°/20% configuration (19.58 MPa), whereas the highest values were achieved at 60°/80% (tensile strength 39.27 MPa, yield strength 40.15 MPa, and elastic modulus 1540.45 MPa). This represents an improvement of approximately 100% in tensile strength and about 54% in both yield strength and modulus compared to the weakest configuration. A subsequent decline at 90° indicates that excessive fiber misalignment can reduce the overall mechanical integrity of printed parts.

- Flexural testing of the as-printed series confirmed a similar pattern. The lowest flexural strength was obtained for the 0°/20% configuration (50.01 MPa), while the highest value was recorded at 90°/80% (58.89 MPa), representing an increase of approximately 18%. The flexural modulus ranged from 2374 MPa to 2739 MPa, showing only about a 15% difference between the minimum and maximum, which suggests that the stiffness of the material is less sensitive to print orientation than its strength.

- Cryogenic pre-treatment was found to have a detrimental effect on the tensile properties of PLA specimens. After the treatment, the ultimate tensile strength decreased from 39.27 MPa to 36.04 MPa (−8%), the yield strength dropped by 10%, and the elastic modulus decreased by approximately 14%. These findings indicate that cryogenic exposure induced microstructural changes, reducing the material’s ability to withstand mechanical loads.

- Flexural performance after cryogenic treatment followed the same degradation trend. The maximum flexural strength (90°/80%) reached 51.39 MPa, which is 12.7% lower than in the as-printed condition, while the flexural modulus dropped to the 2276–2580 MPa range, approximately 6% lower than in untreated samples. This confirms that cryogenic processing adversely affects both strength and stiffness of printed PLA, with a more pronounced impact on tensile than flexural behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fekiač, J.J.; Kakošová, L.; Krbata, M.; Kohutiar, M.; Eckert, M.; Studeny, Z.; Dubec, A. Influence of Infill Geometry and Density on the Mechanical Properties of 3D-Printed Polylactic Acid Structure. J. Manuf. Mater. Process. 2025, 9, 134. [Google Scholar] [CrossRef]

- Mahović Poljaček, S.; Donevski, D.; Tomašegović, T.; Vrabič Brodnjak, U.; Leskovšek, M. Mechanical Properties of 3D-Printed PLA Structures Observed in Framework of Different Rotational Symmetry Orders in Infill Patterns. Symmetry 2025, 17, 466. [Google Scholar] [CrossRef]

- Birosz, M.T.; Ledenyák, D.; Andó, M. Effect of FDM Infill Patterns on Mechanical Properties. Polym. Test. 2022, 113, 107654. [Google Scholar] [CrossRef]

- Almonti, D.; Salvi, D.; Ucciardello, N. Optimization of Printing Parameters for Polyethylene Terephthalate Glycol Thin Honeycomb Structures with Shape-Memory Behaviors. Int. J. Adv. Manuf. Technol. 2025, 136, 4455–4469. [Google Scholar] [CrossRef]

- Agrawal, A.P.; Kumar, V.; Kumar, J.; Paramasivam, P.; Dhanasekaran, S.; Prasad, L. An Investigation of Combined Effect of Infill Pattern, Density, and Layer Thickness on Mechanical Properties of 3D Printed ABS by Fused Filament Fabrication. Heliyon 2023, 9, e16531. [Google Scholar] [CrossRef]

- Khaliq, J.; Gurrapu, D.R.; Elfakhri, F. Effects of Infill Line Multiplier and Patterns on Mechanical Properties of Lightweight and Resilient Hollow Section Products Manufactured Using Fused Filament Fabrication. Polymers 2023, 15, 2585. [Google Scholar] [CrossRef] [PubMed]

- Turaka, S.; Jagannati, V.; Pappula, B.; Makgato, S. Impact of Infill Density on Morphology and Mechanical Properties of 3D Printed ABS/CF-ABS Composites Using Design of Experiments. Heliyon 2024, 10, e29920. [Google Scholar] [CrossRef] [PubMed]

- dos Reis, M.Q.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Effect of the Infill Density on 3D-Printed Geometrically Graded Impact Attenuators. Polymers 2024, 16, 3193. [Google Scholar] [CrossRef]

- Naveed, N. Investigating the Material Properties and Microstructural Changes of Fused Filament Fabricated PLA and Tough-PLA Parts. Polymers 2021, 13, 1487. [Google Scholar] [CrossRef] [PubMed]

- Guessasma, S.; Belhabib, S. Effect of the Printing Angle on the Microstructure and Tensile Performance of Iron-Reinforced Polylactic Acid Composite Manufactured Using Fused Filament Fabrication. J. Manuf. Mater. Process. 2024, 8, 65. [Google Scholar] [CrossRef]

- Fekiač, J.J.; Krbata, M.; Kohutiar, M.; Janík, R.; Kakošová, L.; Breznická, A.; Eckert, M.; Mikuš, P. Comprehensive Review: Optimization of Epoxy Composites, Mechanical Properties, & Technological Trends. Polymers 2025, 17, 271. [Google Scholar] [CrossRef]

- Dziewit, P.; Rajkowski, K.; Płatek, P. Effects of Building Orientation and Raster Angle on the Mechanical Properties of Selected Materials Used in FFF Techniques. Materials 2024, 17, 6076. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Chung, C.-F.; Wang, S.-H.; Huang, W.-C.; Pan, C.-Y.; Zeng, Y.-S.; Hsieh, C.-H. Effect of Printing Parameters on the Tensile Properties of 3D-Printed Polylactic Acid (PLA) Based on Fused Deposition Modeling. Polymers 2021, 13, 2387. [Google Scholar] [CrossRef]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Infill Density Influence on Mechanical and Thermal Properties of Short Carbon Fiber-Reinforced Polyamide Composites Manufactured by FFF Process. Materials 2022, 15, 3706. [Google Scholar] [CrossRef]

- Qayyum, H.; Hussain, G.; Sulaiman, M.; Hassan, M.; Ali, A.; Muhammad, R.; Wei, H.; Shehbaz, T.; Aamir, M.; Altaf, K. Effect of Raster Angle and Infill Pattern on the In-Plane and Edgewise Flexural Properties of Fused Filament Fabricated Acrylonitrile–Butadiene–Styrene. Appl. Sci. 2022, 12, 12690. [Google Scholar] [CrossRef]

- Kohutiar, M.; Kakošová, L.; Krbata, M.; Janík, R.; Fekiač, J.J.; Breznická, A.; Eckert, M.; Mikuš, P.; Timárová, Ľ. Comprehensive Review: Technological Approaches, Properties, and Applications of Pure and Reinforced Polyamide 6 (PA6) and Polyamide 12 (PA12) Composite Materials. Polymers 2025, 17, 442. [Google Scholar] [CrossRef]

- Orellana-Barrasa, J.; Ferrández-Montero, A.; Ferrari, B.; Pastor, J.Y. Natural Ageing of PLA Filaments, Can It Be Frozen? Polymers 2022, 14, 3361. [Google Scholar] [CrossRef] [PubMed]

- Iyer, S.S.G.; Keles, O. Effect of Raster Angle on Mechanical Properties of 3D Printed Short Carbon Fiber Reinforced Acrylonitrile Butadiene Styrene. Compos. Commun. 2022, 32, 101163. [Google Scholar] [CrossRef]

- Algarni, M. The Influence of Raster Angle and Moisture Content on the Mechanical Properties of PLA Parts Produced by Fused Deposition Modeling. Polymers 2021, 13, 237. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Berto, F.; Ayatollahi, M.R.; Reinicke, T. Characterization of 3D-Printed PLA Parts with Different Raster Orientations and Printing Speeds. Sci. Rep. 2022, 12, 1016. [Google Scholar] [CrossRef] [PubMed]

- Karad, A.S.; Sonawwanay, P.D.; Naik, M.; Thakur, D.G. Experimental Study of Effect of Infill Density on Tensile and Flexural Strength of 3D Printed Parts. J. Eng. Appl. Sci. 2023, 70, 104. [Google Scholar] [CrossRef]

- Arslan, Y. Effects of ultra-cold temperature on thermoplastic (ASA, PLA) parts produced by 3D FDM printing technology. Sādhanā 2025, 50, 250. [Google Scholar] [CrossRef]

- Gupta, A.; Kumar, N.; Sachdeva, A.; Verma, R.; Sharma, G.K.; Kumar, M. Effect of Cryogenic Treatment on the Mechanical Properties of 3D-Printed Polylactic Acid Part. Cryogenics 2024, 145, 104000. [Google Scholar] [CrossRef]

- Cui, Y.; Yan, J.; Li, J.; Chen, D.; Wang, Z.; Yin, W.; Wu, Z. Cryogenic Mechanical Properties and Stability of Polymer Films for Liquid Oxygen Hoses. Polymers 2023, 15, 3423. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.; Tariq, M.; Abas, M.; Shakeel, M.; Hira, F.; Rashid, A.A.; Koç, M. Parametric Investigation and Optimisation of Mechanical Properties of Thick Tri-Material Based Composite of PLA-PETG-ABS 3D-Printed Using Fused Filament Fabrication. Compos. Part C Open Access 2023, 12, 100392. [Google Scholar] [CrossRef]

- Kadhum, A.H.; Al-Zubaidi, S.; Abdulkareem, S.S. Effect of the Infill Patterns on the Mechanical and Surface Characteristics of 3D Printing of PLA, PLA+ and PETG Materials. ChemEngineering 2023, 7, 46. [Google Scholar] [CrossRef]

| Category | Parameter | Value/Description |

|---|---|---|

| Material | Material name | Bambu Lab PLA Basic |

| Material type | Industrial-grade PLA | |

| Chemical composition | Poly(lactic acid) (C3H4O2)n with trace additives for color and thermal stability | |

| Filament diameter | 1.75 mm | |

| Density | 1.24 g/cm3 | |

| Glass transition temperature (Tg) | 60 °C | |

| Melting temperature | 160 °C | |

| Heat deflection temperature | 52 °C (at 0.45 MPa) | |

| Tensile strength (manufacturer data) | 35 MPa (X-Y), 31 MPa (Z) | |

| Young’s modulus (manufacturer data) | 2580 MPa (X-Y), 2060 MPa (Z) | |

| Elongation at break (manufacturer data) | 12.2 ± 1.8% (X-Y), 7.5 ± 1.3% (Z) | |

| Bending Strength | 76 ± 5 MPa (X-Y), 59 ± 6 MPa (Z) | |

| Impact strength | 26.6 ± 2.8 kJ/m2; 7.9 ± 1.2 kJ/m2 (notched) (X-Y), 13.8 ± 0.9 kJ/m2 (Z) | |

| 3D Printer | Printer model | Bambu Lab P1S |

| Slicing software | Bambu Studio version 2.2.2.56 (default PLA profile) | |

| Sample configurations | Perimeter contour count | 2 |

| Number of samples per configuration | 5 | |

| Estimated wall thickness range | 0.2 mm | |

| Sample geometry | ASTM D638 Type I (tensile testing standard) ASTM D790 (bending testing standard) | |

| Build parameters | Nozzle temperature | 240 °C |

| Bed temperature | 55 °C | |

| Nozzle diameter | 0.4 mm | |

| Layer height | 0.2 mm | |

| Infill structure | Cubic | |

| Infill density | 20%, 40%, 60%, 80% | |

| Layer orientation | Horizontal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fekiač, J.J.; Kakošová, L.; Krbata, M.; Kohutiar, M.; Studeny, Z.; Mikuš, P.; Viliš, J.; Breznická, A. Effects of Printing Angle, Infill Density and Cryogenic Pre-Treatment on the Tensile and Flexural Properties of FFF-Printed PLA. J. Manuf. Mater. Process. 2025, 9, 365. https://doi.org/10.3390/jmmp9110365

Fekiač JJ, Kakošová L, Krbata M, Kohutiar M, Studeny Z, Mikuš P, Viliš J, Breznická A. Effects of Printing Angle, Infill Density and Cryogenic Pre-Treatment on the Tensile and Flexural Properties of FFF-Printed PLA. Journal of Manufacturing and Materials Processing. 2025; 9(11):365. https://doi.org/10.3390/jmmp9110365

Chicago/Turabian StyleFekiač, Jozef Jaroslav, Lucia Kakošová, Michal Krbata, Marcel Kohutiar, Zbynek Studeny, Pavol Mikuš, Jindřich Viliš, and Alena Breznická. 2025. "Effects of Printing Angle, Infill Density and Cryogenic Pre-Treatment on the Tensile and Flexural Properties of FFF-Printed PLA" Journal of Manufacturing and Materials Processing 9, no. 11: 365. https://doi.org/10.3390/jmmp9110365

APA StyleFekiač, J. J., Kakošová, L., Krbata, M., Kohutiar, M., Studeny, Z., Mikuš, P., Viliš, J., & Breznická, A. (2025). Effects of Printing Angle, Infill Density and Cryogenic Pre-Treatment on the Tensile and Flexural Properties of FFF-Printed PLA. Journal of Manufacturing and Materials Processing, 9(11), 365. https://doi.org/10.3390/jmmp9110365