Strain-Induced Surface Roughening of Thin Sheets and Its Effects on Metal Forming and Component Properties

Abstract

1. Introduction

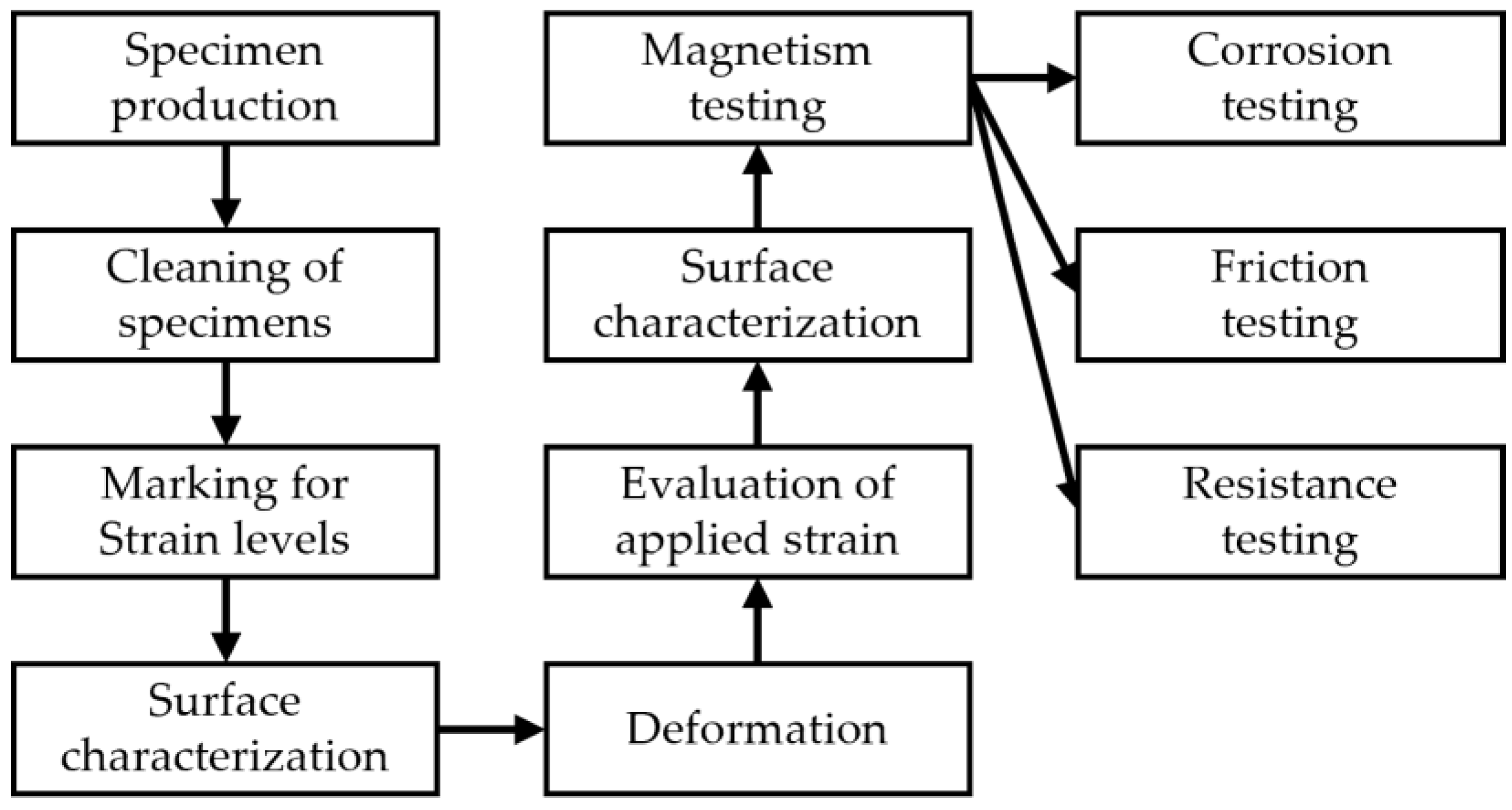

2. Materials and Methods

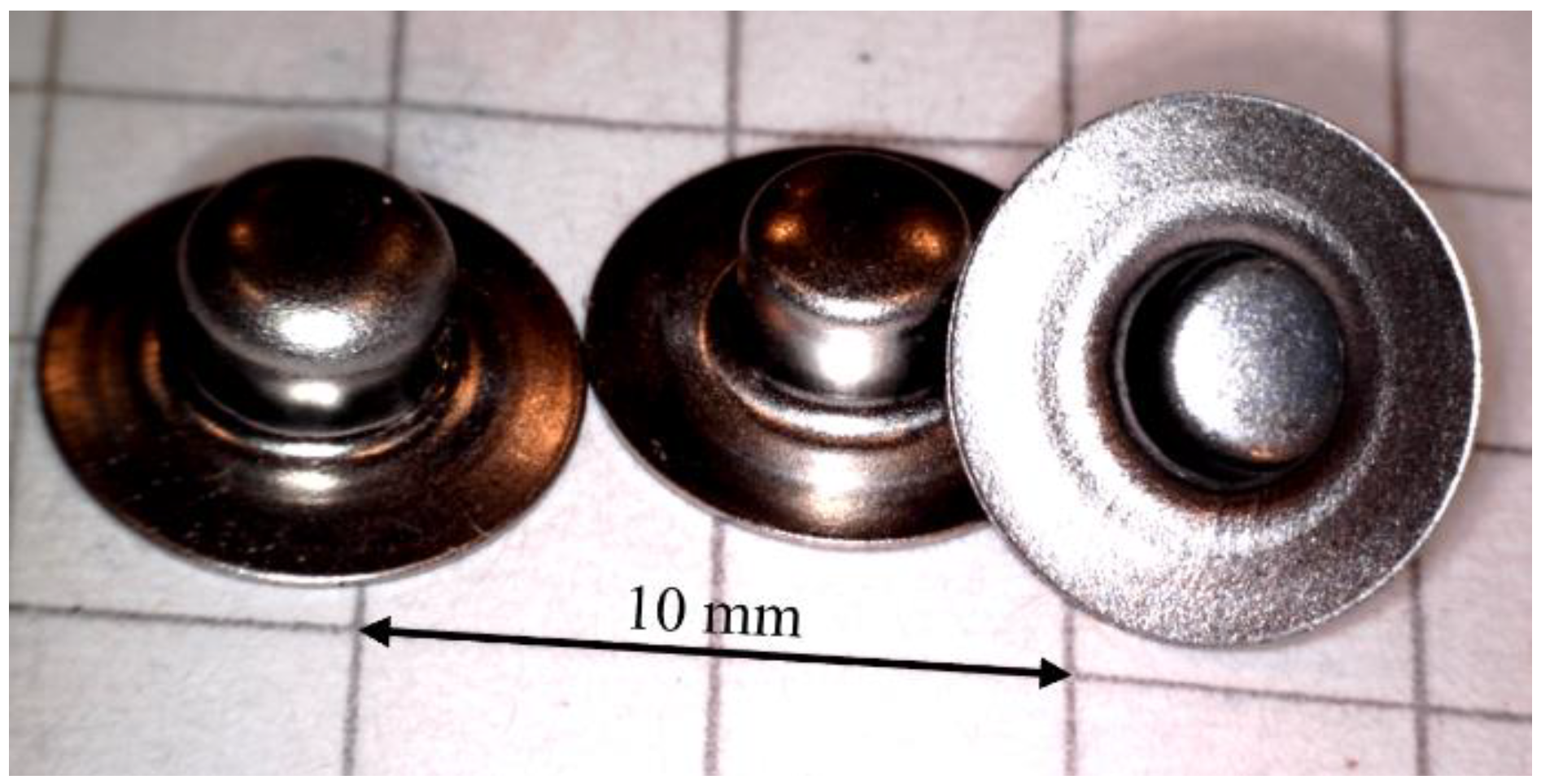

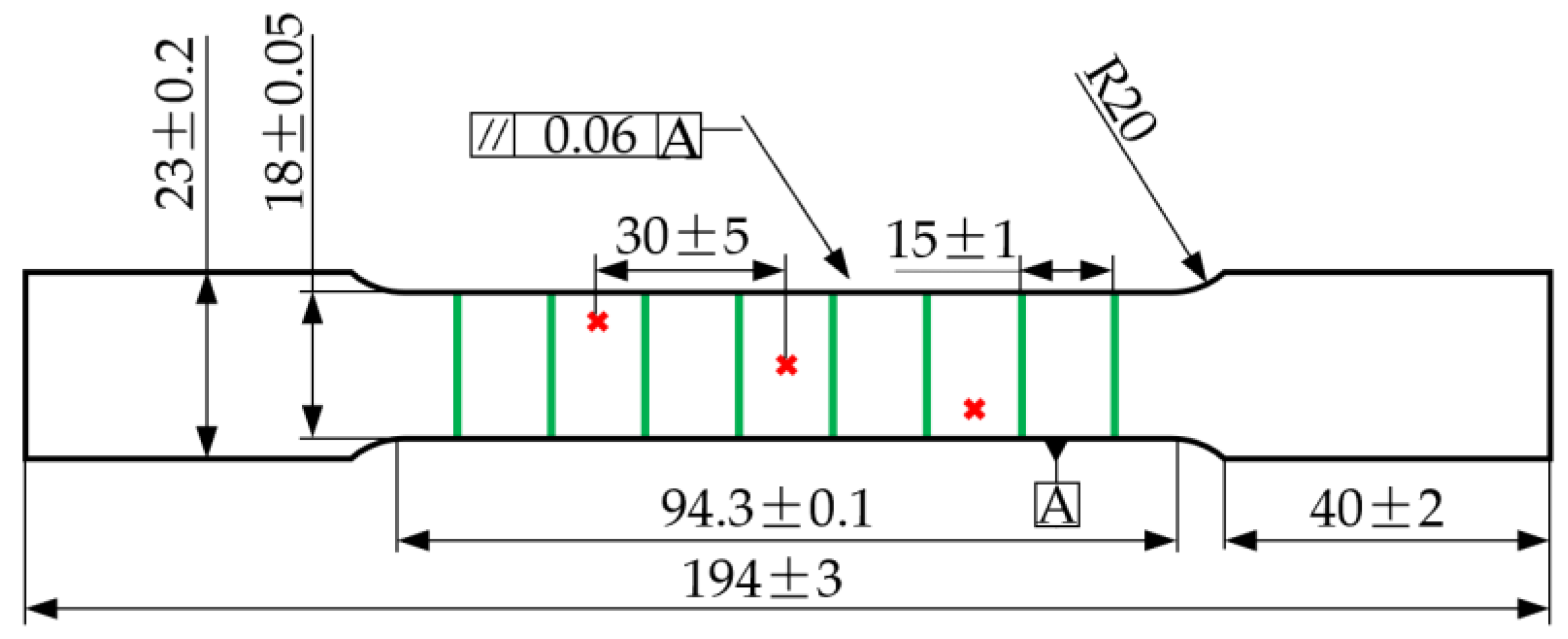

2.1. Materials and Sample Geometry

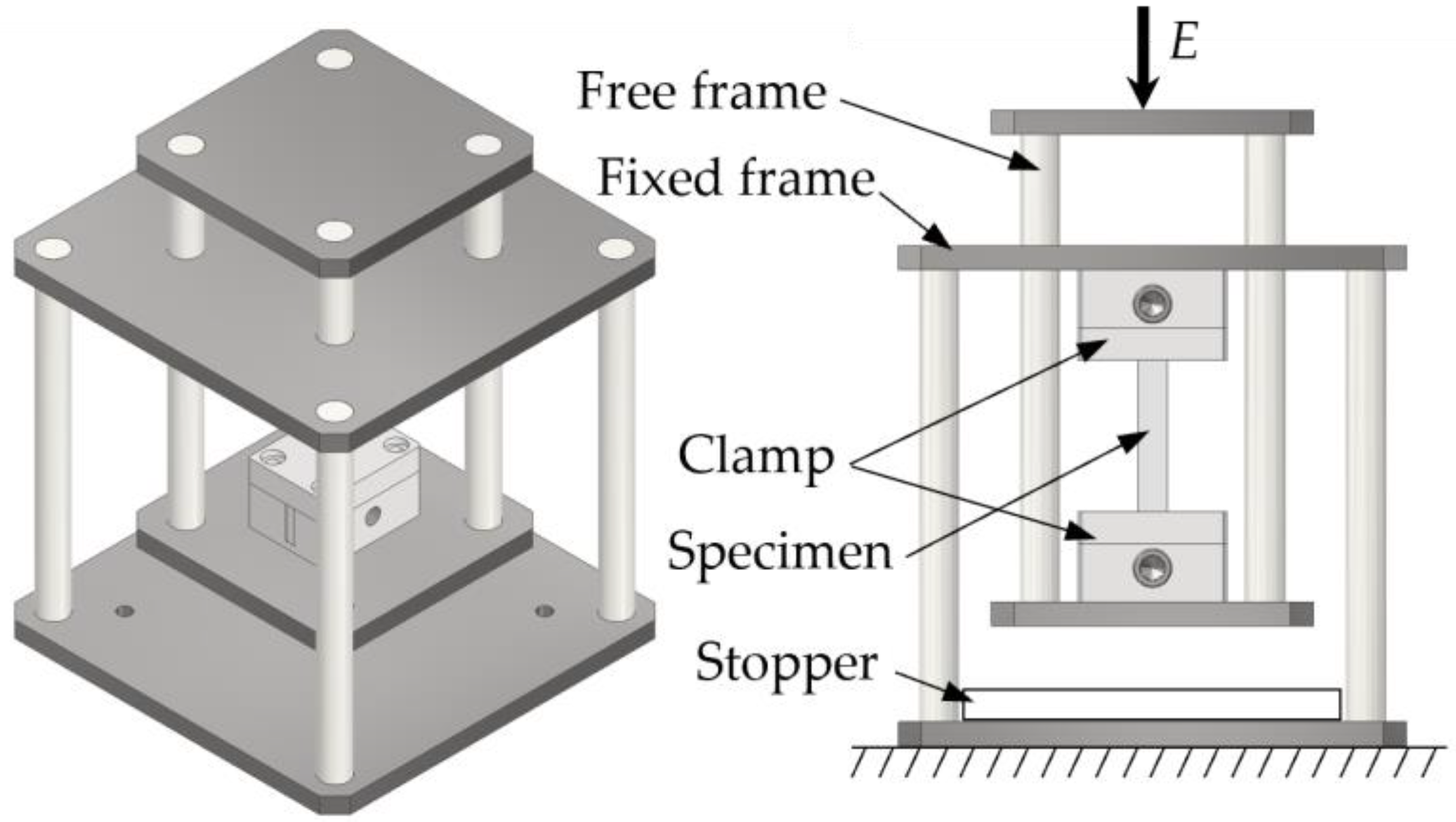

2.2. Uniaxial Tension at Different Strain-Rates

2.3. Surface Characterisation

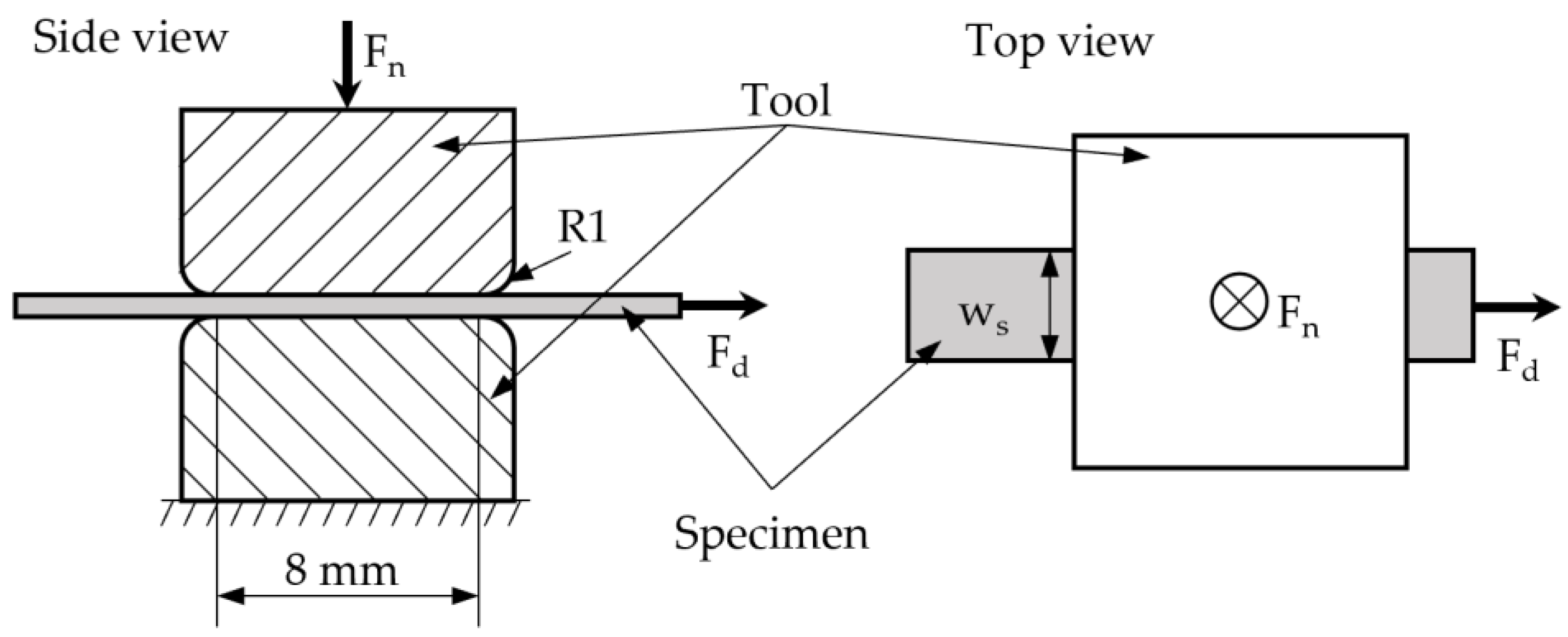

2.4. Testing of Friction

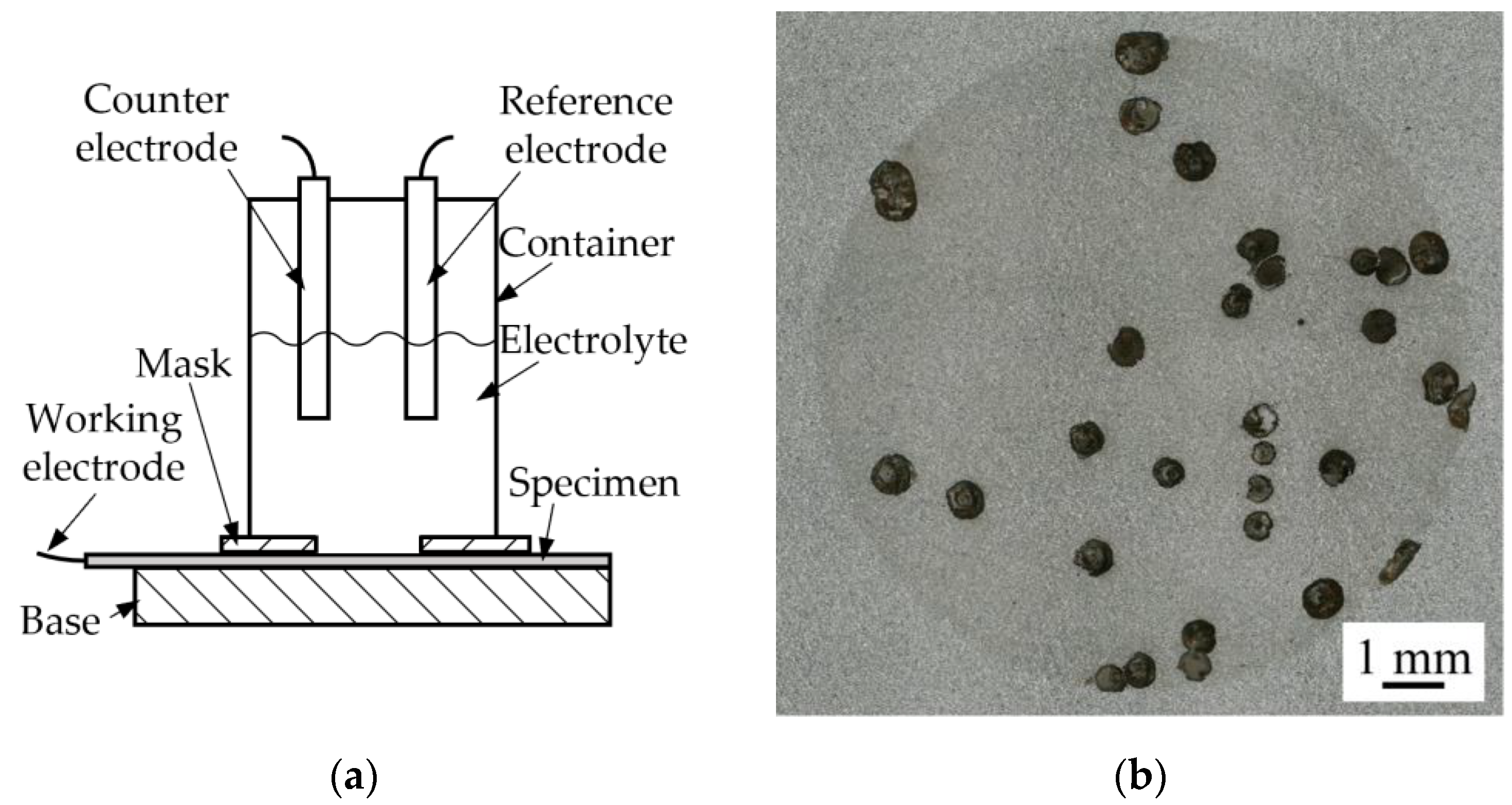

2.5. Evaluation of Corrosion Resistance

2.6. Evaluation of Phase Fractions

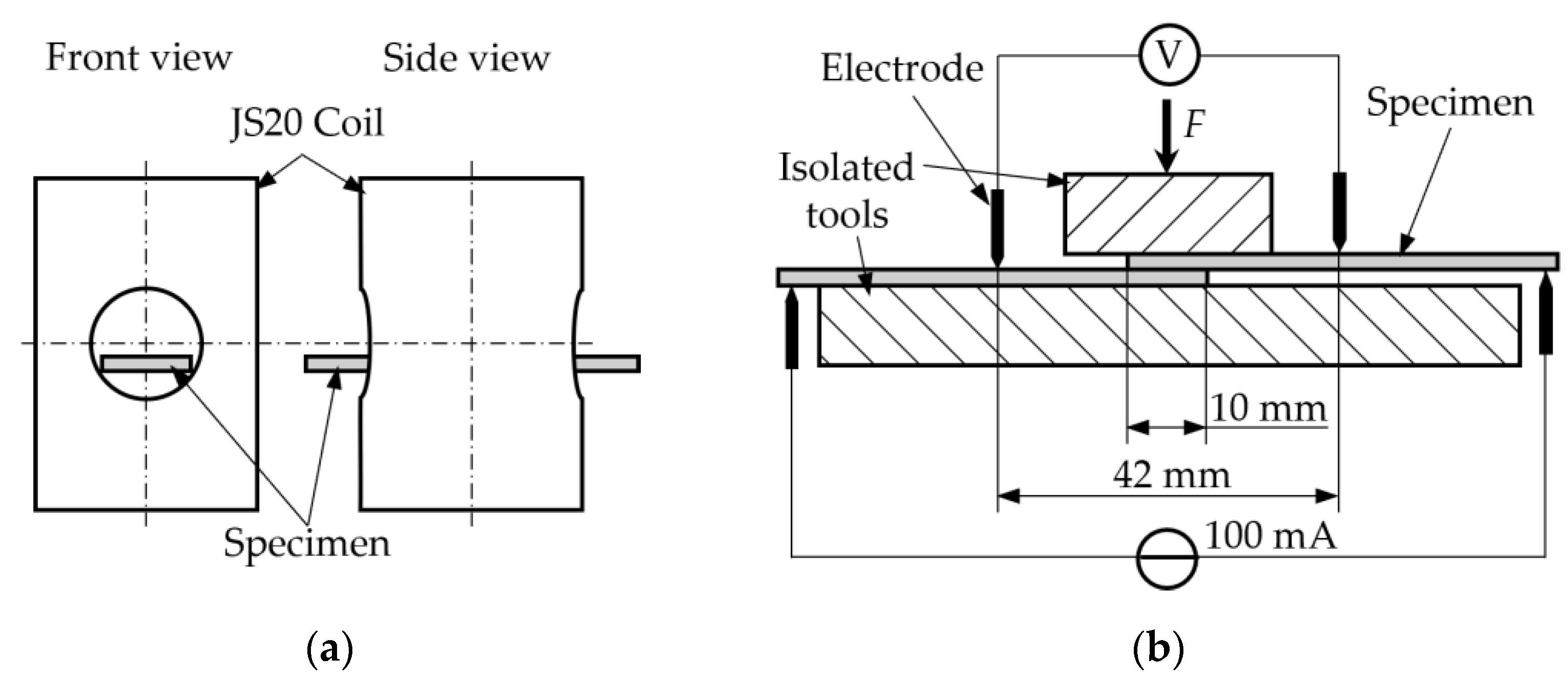

2.7. Evaluation of Electrical Contact Resistance

3. Results and Discussion

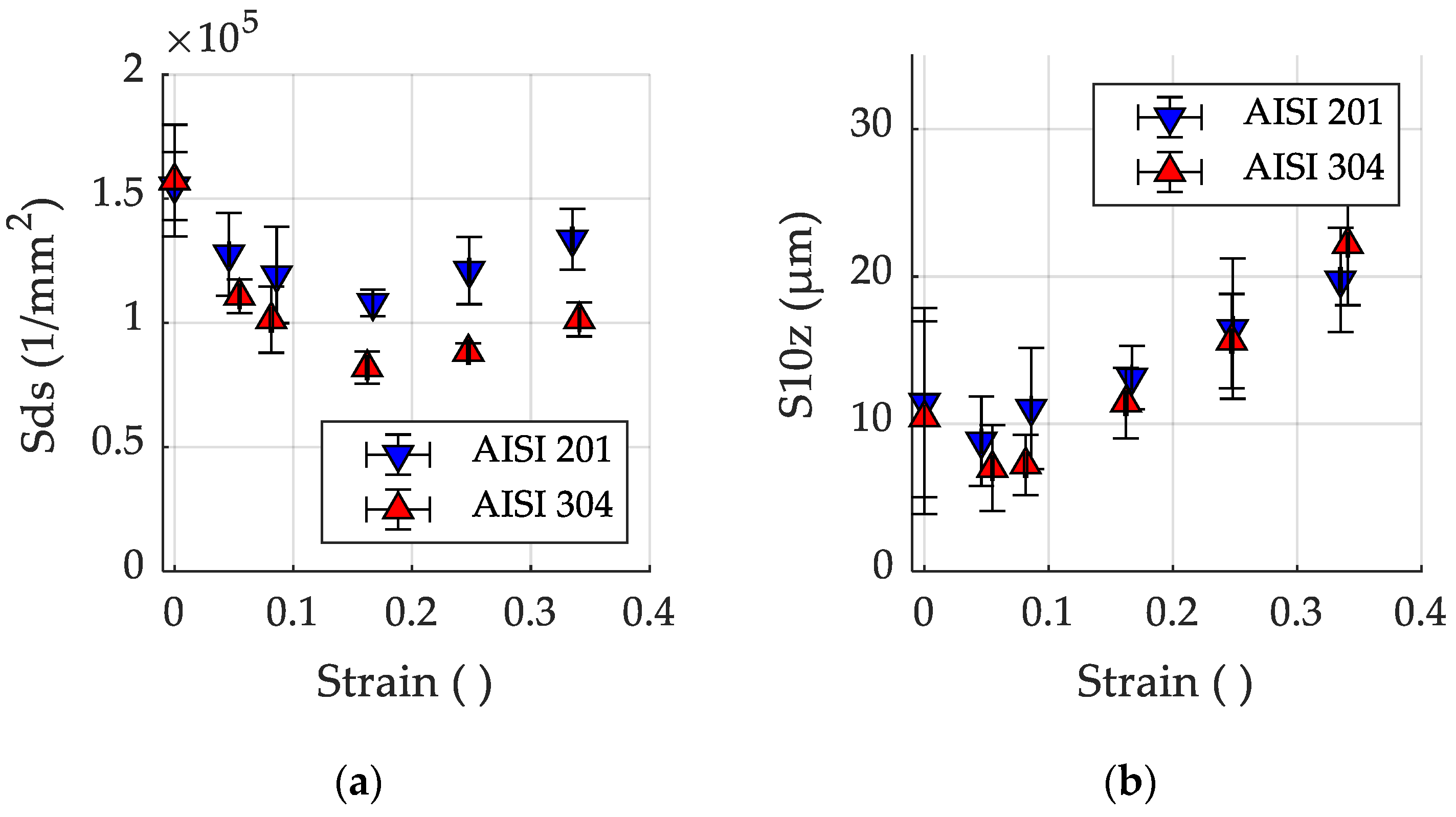

3.1. Strain-Induced Surface Development

3.2. Effect of Strain-Induced Surface Development

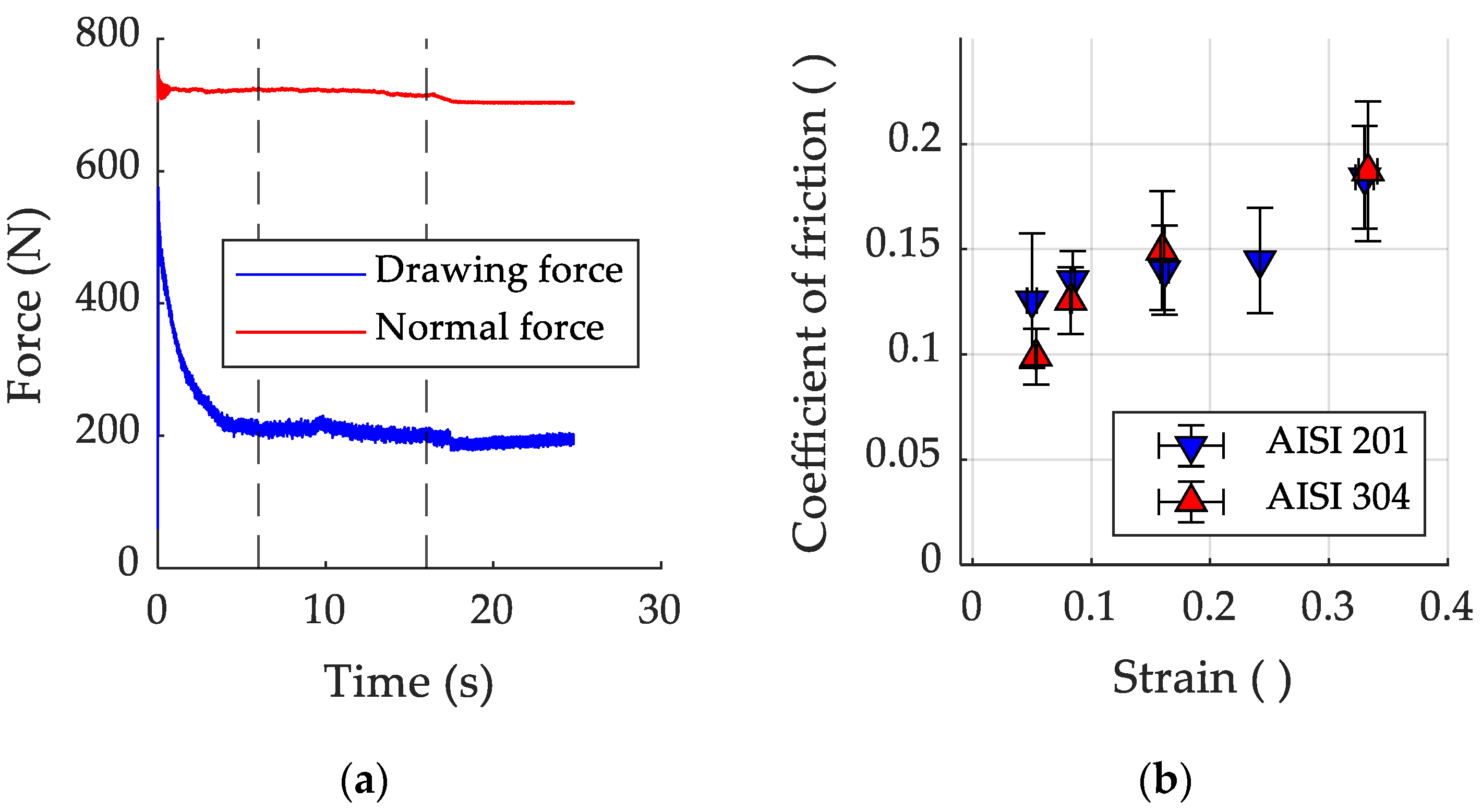

3.2.1. Friction

3.2.2. Martensite Fraction

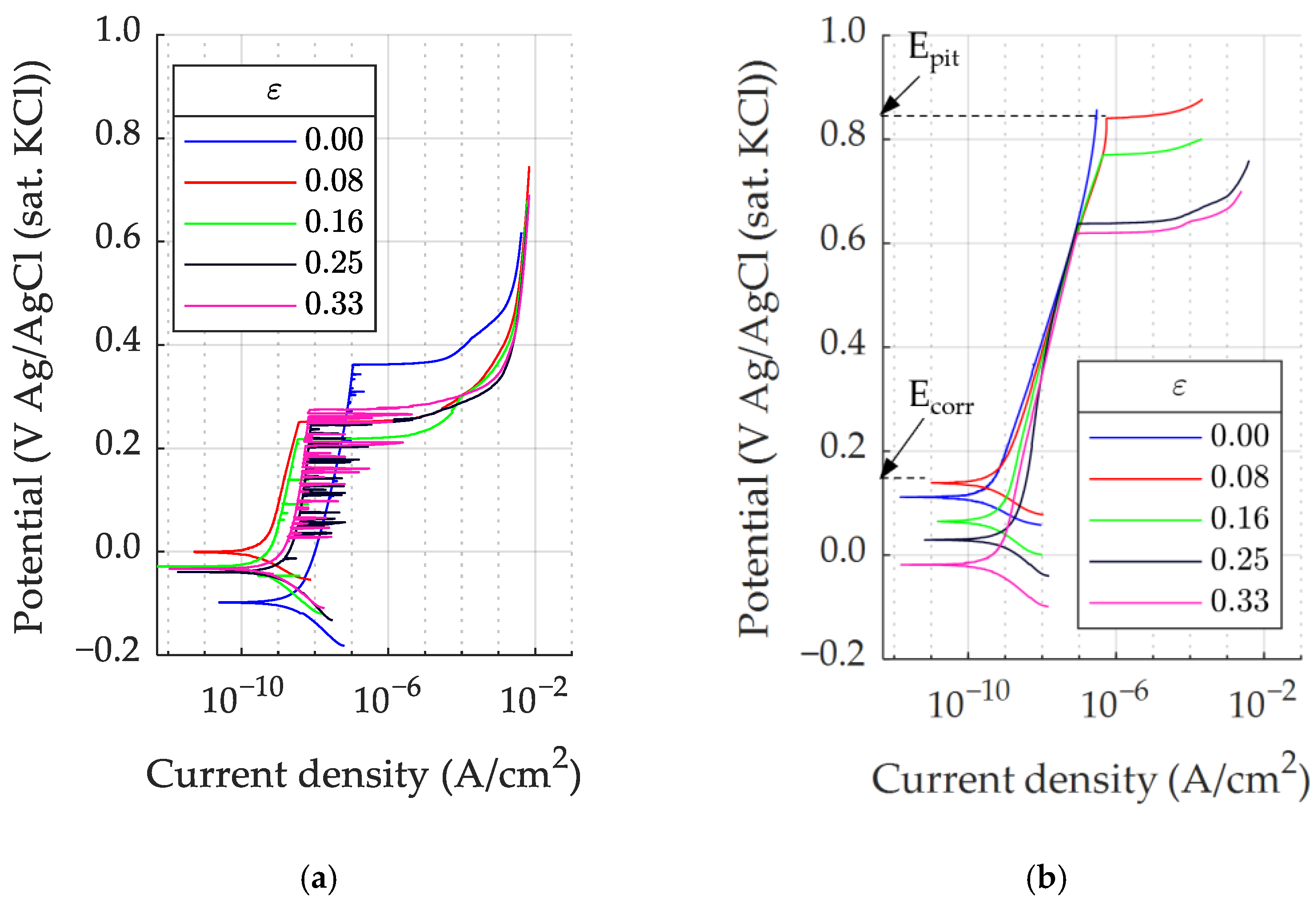

3.2.3. Corrosion Resistance

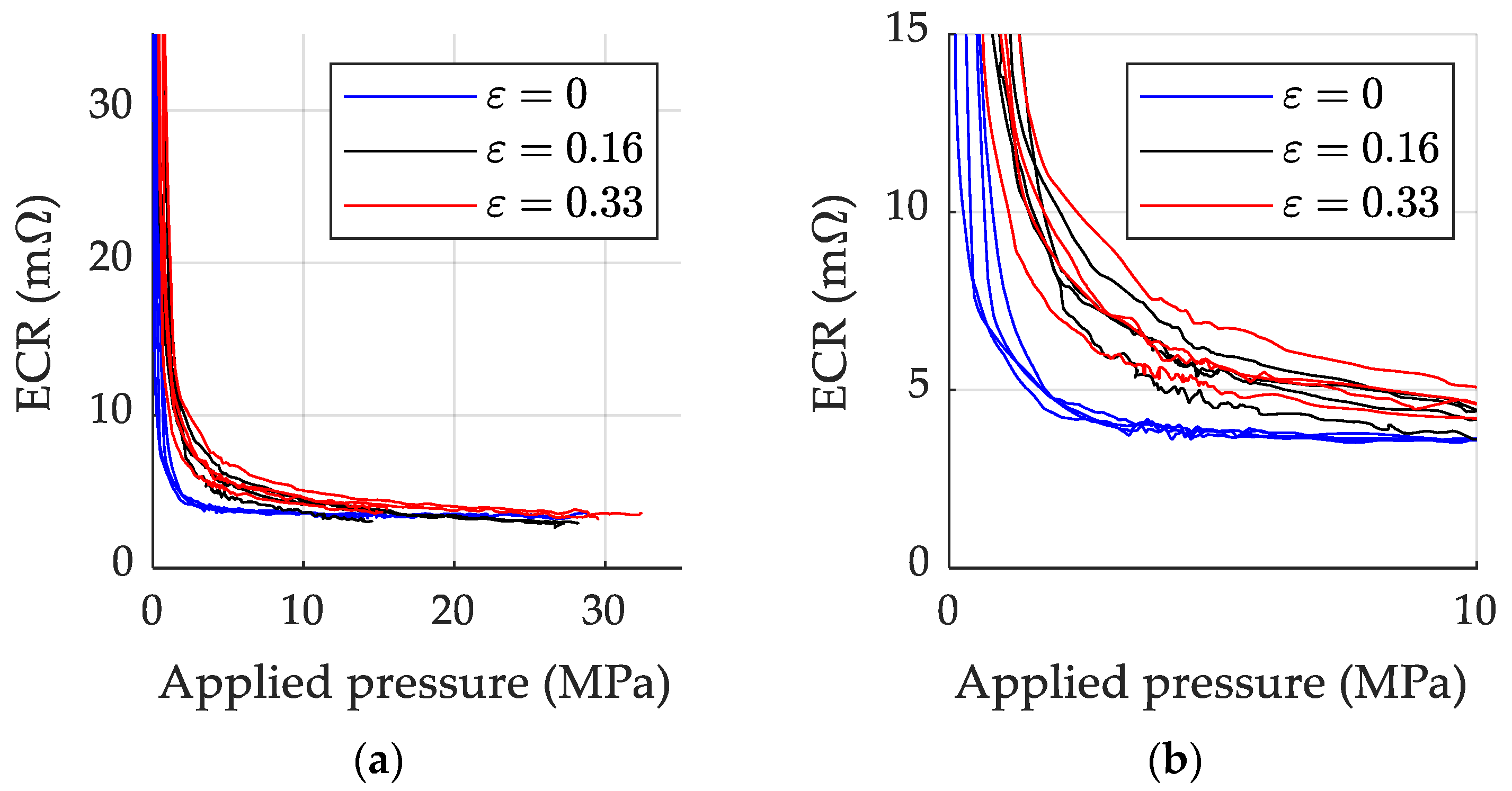

3.2.4. Electrical Contact Resistance

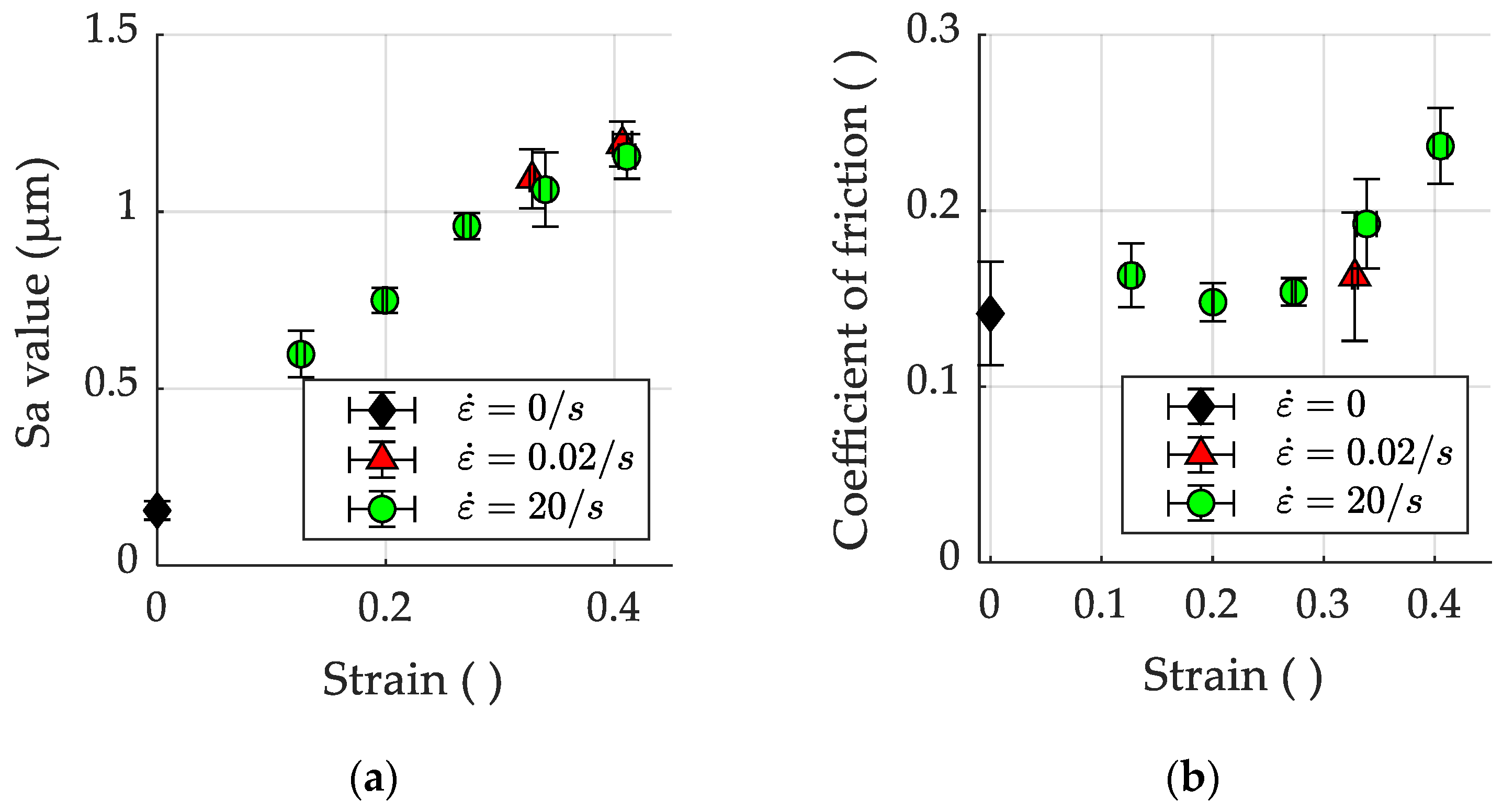

3.3. Effect of Strain-Rate

3.3.1. Surface Roughness and Friction

3.3.2. Martensite Fraction

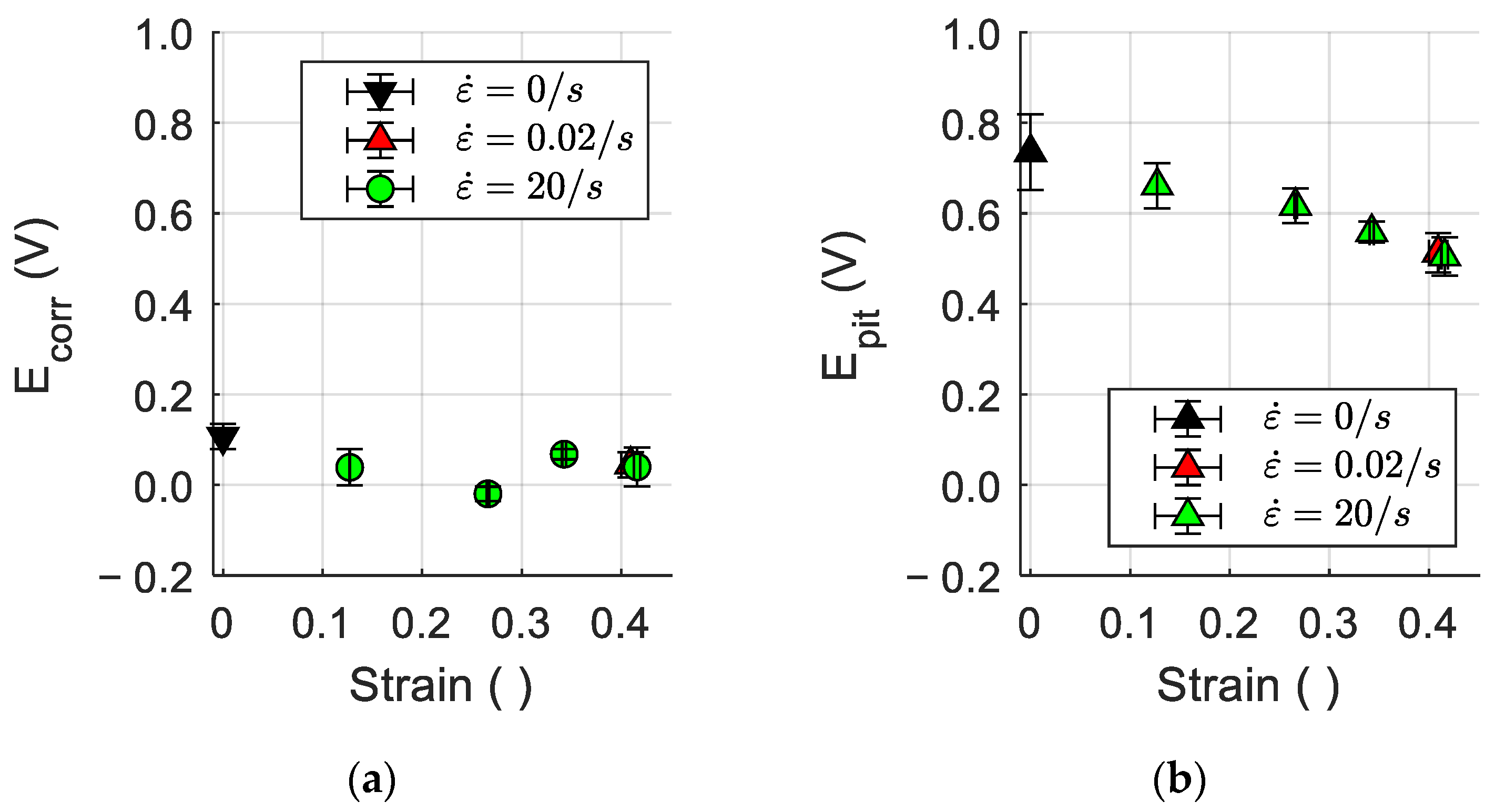

3.3.3. Corrosion Resistance

4. Conclusions

- The development of surface roughness as function of strain is not dependent on the strain-rate that is applied for the materials tested in this work, between strain-rates of 0.0002/s and 20/s.

- Friction increases with increasing strain, and hence with increasing surface roughness.

- AISI 201 is more prone to deformation-induced martensitic transformation than AISI 304. Increased strain-rate suppressed martensitic transformation, leading to low strain-rates exhibiting a higher magnetic field density after straining.

- The corrosion resistance, determined by evaluation of the pitting potential, of all materials decreased with increasing strain. No effect of strain-rate on the pitting potential could be detected and effects on corrosion potential were minimal.

- No effect from the strain-induced surface development on the contact resistance could be detected.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Osakada, K.; Oyane, M. On the roughening of free surface in deformation processes. Bull. JSME 1971, 14, 171–177. [Google Scholar] [CrossRef]

- Dai, Y.Z.; Chiang, F.P. On the mechanism of plastic deformation induced surface roughness. Trans. ASME 1992, 114, 432–438. [Google Scholar] [CrossRef]

- Shimizu, I.; Okuda, T.; Abe, T.; Tani, H. Surface roughening and deformation of grains during uniaxial tension of polycrystalline iron. JSME Int. J. Ser. A 2001, 44, 499–506. [Google Scholar] [CrossRef]

- Guangnan, C.; Huan, S.; Shiguang, H.; Baudelet, B. Roughening of the free surfaces of metallic sheets during stretch forming. Mater. Sci. Eng. A 1990, 128, 33–38. [Google Scholar] [CrossRef]

- Azushima, A.; Miyagawa, M. Effect of working factors and metallurgical factors on roughening phenomenon on free surface of sheets. J. Jpn. Soc. Technol. Plast. 1986, 27, 1261–1267. [Google Scholar]

- Mahmudi, R.; Mehdizadeh, M. Surface roughening during uniaxial and equi-biaxial stretching of 70-30 brass sheets. J. Mater. Process. Technol. 1998, 80, 707–712. [Google Scholar] [CrossRef]

- Baydogan, M.; Akoy, M.A.; Kayali, E.S.; Cimenoglu, H. Deformation induced surface roughening of austenitic stainless steels. ISIJ Int. 2003, 43, 1795–1798. [Google Scholar] [CrossRef][Green Version]

- Furushima, T.; Tsunezaki, H.; Hirose, Y. Fracture and surface roughening behaviours in micro metal forming. Procedia Manuf. 2018, 15, 1481–1486. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Mellor, P.B. Thickness and grain size dependence of limit strains in sheet metal stretching. Int. J. Mech. Sci. 1976, 18, 85–90. [Google Scholar] [CrossRef]

- Chen, J.Q.; Gao, H.T.; Hu, X.L.; Yang, L.Q.; Ke, D.W.; Liu, X.H.; Yan, S.; Lu, R.H.; Misra, R.D.K. The significant size effect on nucleation and propagation of crack during tensile deformation of copper foil: Free surface roughening and crystallography study. Mat. Sci. Eng. A 2020, 790, 139678. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Takakura, N.; Hnatani, S. Increase in forming limit of sheet metals by removal of surface roughening with plastic strain. J. Mater. Process. Technol. 1995, 48, 27–34. [Google Scholar] [CrossRef]

- Sundaram, P.A. Deformation-induced surface roughening studies in an AISI 1090 spheroidized steel. Scr. Metall. Mater. 1995, 33, 1093–1099. [Google Scholar] [CrossRef]

- Ottenklev, F.; Adell, M.; Orlov, D. Non-monotonic evolution of surface roughness in a stainless steel during cold deformation. Mater. Sci. Eng. A 2021, 799, 140150. [Google Scholar] [CrossRef]

- Kasuga, Y.; Yamaguchi, K.; Kato, K. Friction and lubrication in the deformation processing of metals—3rd report, Effect of grain-size of material on lubrication. Bull. JSME 1968, 11, 361–365. [Google Scholar] [CrossRef]

- Wu, Y.; Recklin, V.; Groche, P. Strain induced surface change in sheet metal forming: Numerical prediction, influence on friction and tool wear. J. Manuf. Mater. Process. 2021, 5, 29. [Google Scholar] [CrossRef]

- Saha, P.K.; Wilson, W.R.D. Influence of plastic strain on friction in sheet metal forming. Wear 1994, 172, 167–173. [Google Scholar] [CrossRef]

- Shi, Y.; Zhao, P.Z.; Jin, H.; Wu, P.D.; Lloyd, D.J. Analysis of surface roughening in AA6111 automotive sheet under pure bending. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 949–960. [Google Scholar] [CrossRef]

- Hansen, C.M. The Effect of Deformation on the Corrosion Properties of Stainless Steel. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2019. [Google Scholar]

- Petersen, S.R. Numerical Simulation of ECG Studs Manufactured by Multistep Forming. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2020. [Google Scholar]

- Uddeholm. Uddeholm Vanadis® 8 SuperClean. 2020. Available online: https://www.uddeholm.com/denmark/da/products/uddeholm-vanadis-8-superclean/ (accessed on 1 August 2023).

- Ceron, E. New Tribo-Systems for Sheet Metal Forming of Advanced High Strength Steels and Stainless Steels. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Tanaka, K.; Watanabe, T. An electrical resistivity study of lattice defects in deformed iron. Jpn. J. Appl. Phys. 1972, 11, 1429–1439. [Google Scholar] [CrossRef]

- Kubo, M.; Hama, T.; Tsunemi, Y.; Nakazawa, Y.; Takuda, H. Influence of strain ratio on surface roughening in biaxial stretching of IF steel sheets. ISIJ Int. 2018, 58, 704–713. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Emelianova, E.; Sinyakova, E.; Kazachenok, M. Early prediction of macroscale plastic strain localization in titanium from observation of mesoscale surface roughening. Int. J. Mech. Sci. 2019, 161–162, 105047. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Naghizadeh, M.; Mirzadeh, H. Deformation-induced martensite in austenitic stainless steels: A review. Arch. Civ. Mech. Eng. 2020, 20, 124. [Google Scholar] [CrossRef]

- Hong, T.; Nagumo, M. Effect of surface roughness on early stages of pitting corrosion of Type 301 stainless steel. Corros. Sci. 1997, 39, 1665–1672. [Google Scholar] [CrossRef]

- Chunchun, X.; Gang, H. Effect of deformation-induced martensite on the pit propagation behavior of 304 stainless steel. Anti-Corros. Methods Mater. 2004, 51, 381–388. [Google Scholar] [CrossRef]

- Monrrabal, G.; Bautista, A.; Guzman, S.; Gutierrez, C.; Velasco, F. Influence of the cold working induced martensite on the electrochemical behavior of AISI 304 stainless steel surfaces. J. Mater. Res. Technol. 2019, 8, 1335–1346. [Google Scholar] [CrossRef]

- Wanheim, T. Friction at high normal pressures. Wear 1973, 25, 225–244. [Google Scholar] [CrossRef]

| Material (wt%) | AISI 201 | AISI 304 Coil 1 | AISI 304 Coil 2 |

|---|---|---|---|

| Fe | Bal. | Bal. | Bal. |

| C | 0.098 | 0.077 | 0.065 |

| Cr | 16.33 | 18.31 | 18.25 |

| Ni | 3.660 | 8.60 | 8.64 |

| Mn | 6.640 | 1.07 | 1.23 |

| Si | 0.560 | 0.36 | 0.24 |

| P | 0.035 | 0.045 | 0.054 |

| S | 0.004 | <0.0010 | <0.0010 |

| N | 0.103 | 0.075 | 0.061 |

| Other (trace amount) | Ti, Mo, Al, Co, Cu, Nb | Ti, Mo, Al, Cu | Ti, Mo, Al, Cu |

| Material | AISI 201 | AISI 304 |

|---|---|---|

| Yield strength (MPa) | 344–345 | 273–275 |

| Tensile strength (MPa) | 736–740 | 633–636 |

| Hardness (HV1) | 210 | 150 |

| εt ( ) | t (mm) | ρ (µΩ mm) | Rideal (mΩ) |

|---|---|---|---|

| 0.00 | 0.200 | 680 | 12.6 |

| 0.167 | 0.184 | 708 | 14.2 |

| 0.334 | 0.169 | 728 | 15.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arinbjarnar, Ú.; Christiansen, R.J.; Knoll, M.; Pantleon, K.; Jellesen, M.S.; Nielsen, C.V. Strain-Induced Surface Roughening of Thin Sheets and Its Effects on Metal Forming and Component Properties. J. Manuf. Mater. Process. 2023, 7, 174. https://doi.org/10.3390/jmmp7050174

Arinbjarnar Ú, Christiansen RJ, Knoll M, Pantleon K, Jellesen MS, Nielsen CV. Strain-Induced Surface Roughening of Thin Sheets and Its Effects on Metal Forming and Component Properties. Journal of Manufacturing and Materials Processing. 2023; 7(5):174. https://doi.org/10.3390/jmmp7050174

Chicago/Turabian StyleArinbjarnar, Úlfar, Rune Juul Christiansen, Maximilian Knoll, Karen Pantleon, Morten Stendahl Jellesen, and Chris Valentin Nielsen. 2023. "Strain-Induced Surface Roughening of Thin Sheets and Its Effects on Metal Forming and Component Properties" Journal of Manufacturing and Materials Processing 7, no. 5: 174. https://doi.org/10.3390/jmmp7050174

APA StyleArinbjarnar, Ú., Christiansen, R. J., Knoll, M., Pantleon, K., Jellesen, M. S., & Nielsen, C. V. (2023). Strain-Induced Surface Roughening of Thin Sheets and Its Effects on Metal Forming and Component Properties. Journal of Manufacturing and Materials Processing, 7(5), 174. https://doi.org/10.3390/jmmp7050174