A Machine Learning Perspective to the Investigation of Surface Integrity of Al/SiC/Gr Composite on EDM

Abstract

:1. Introduction

- (i)

- To find the surface roughness values using different strategies of ML approach.

- (ii)

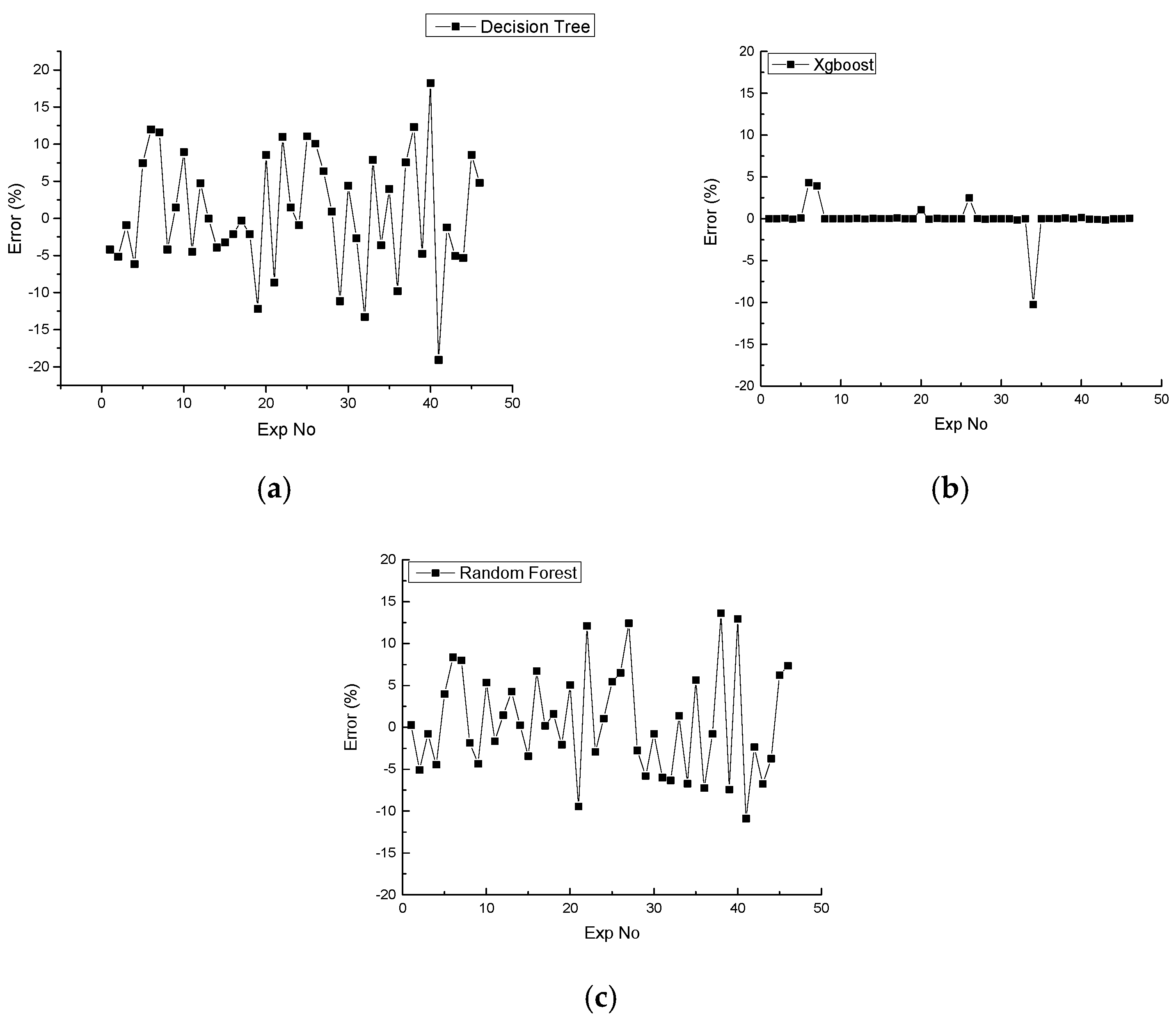

- To find out the error percentage between the predicted value by different ML strategies and experimental values.

- (iii)

- To analyze the response variables with the machining indicators using ANOVA.

- (iv)

- To optimize the best solutions predicted by the ML approach using TLBO and perform the validation experiments at the suggested setting

- (v)

- To perform the mapping of elements for different electrodes used for machining along with the morphological analysis of the machined surface of the composite.

2. Materials and Methods

2.1. Experimental Set-Up

2.2. Response Characterization

2.3. Methodology

3. Results and Discussion

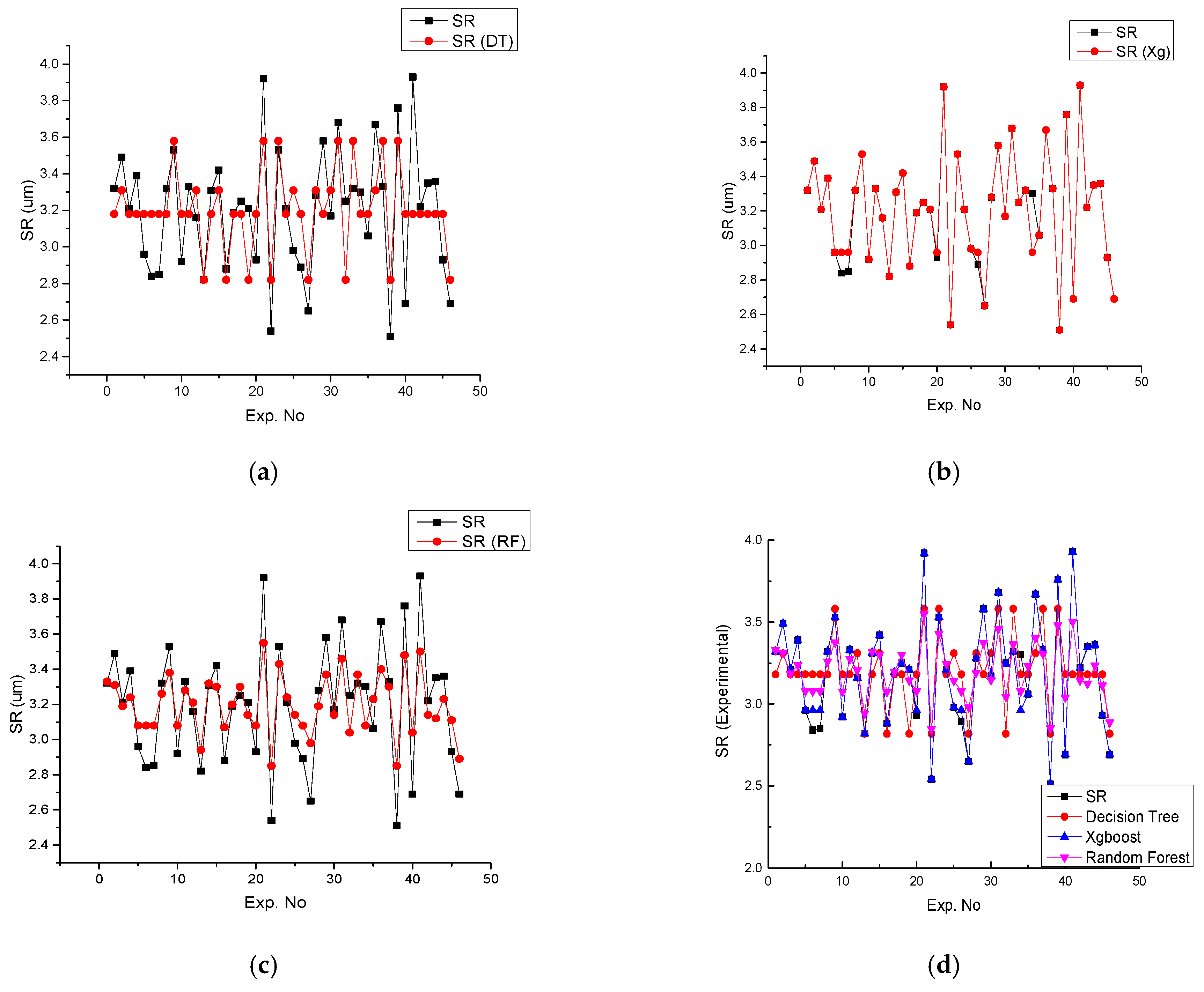

3.1. Machine Learning Perspective

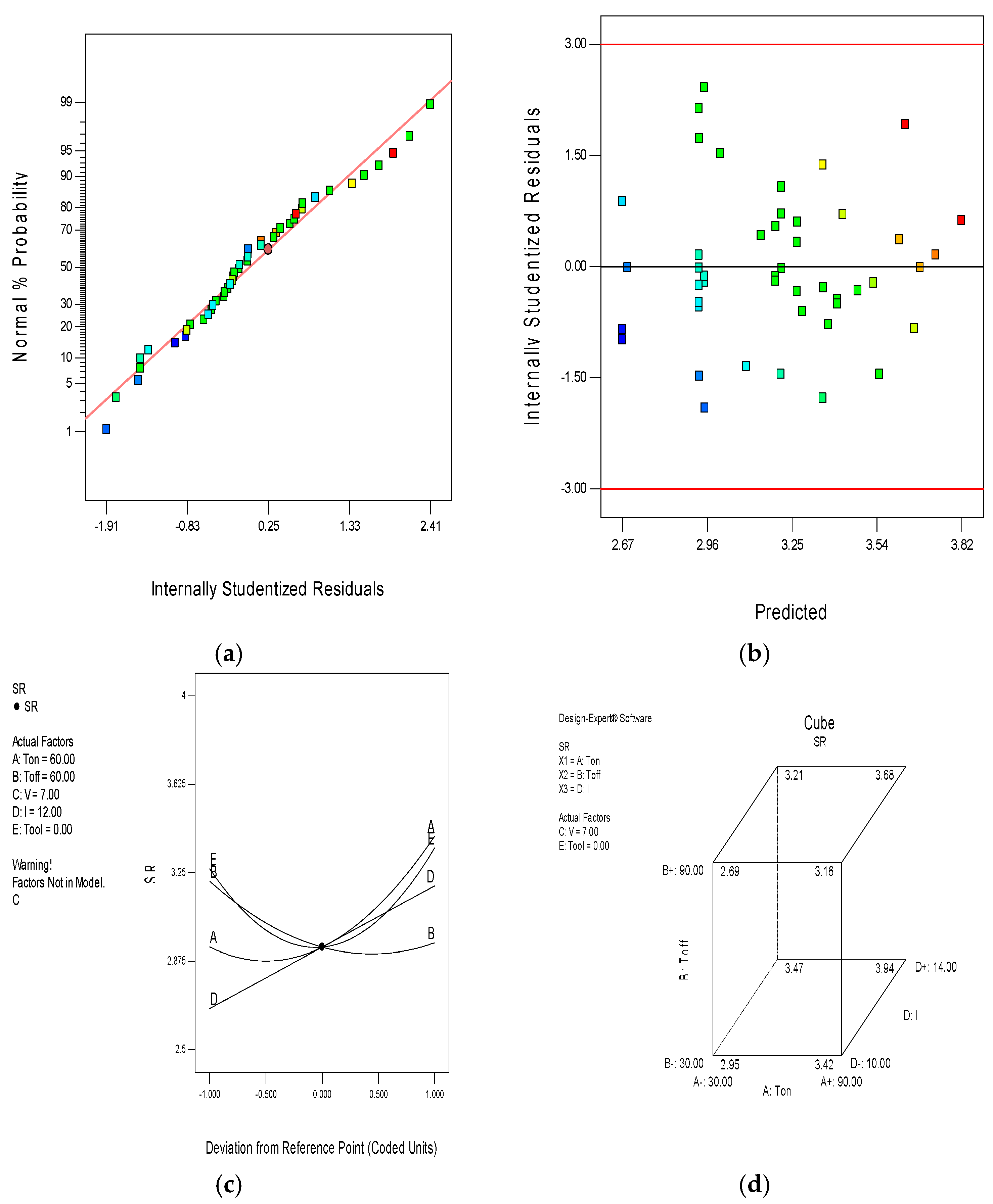

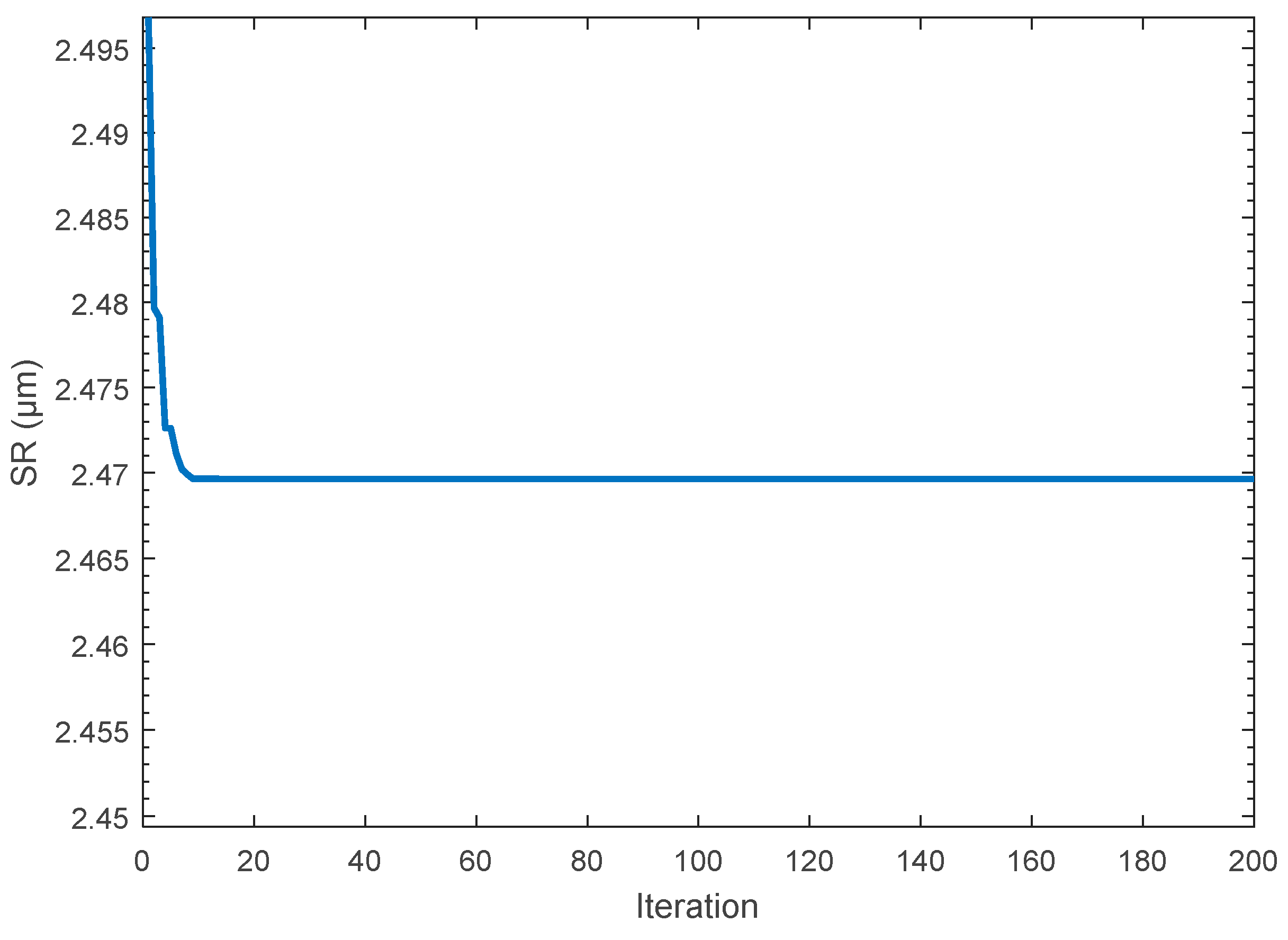

3.2. Analysis of Results Evaluated from Gradient Boost Algorithm and TLBO Implementation

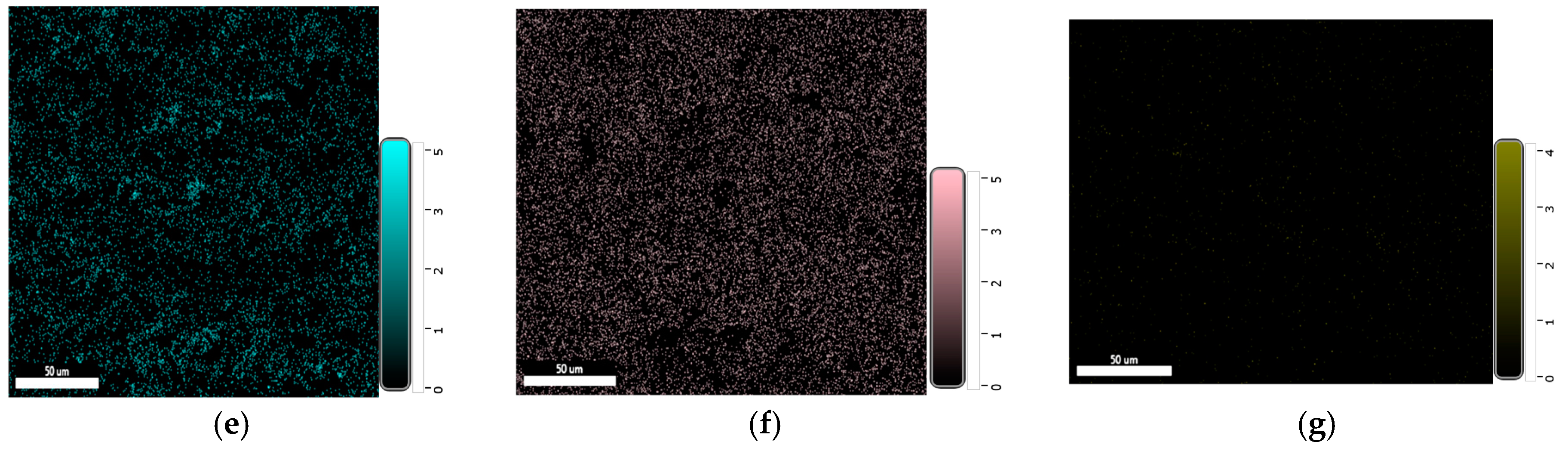

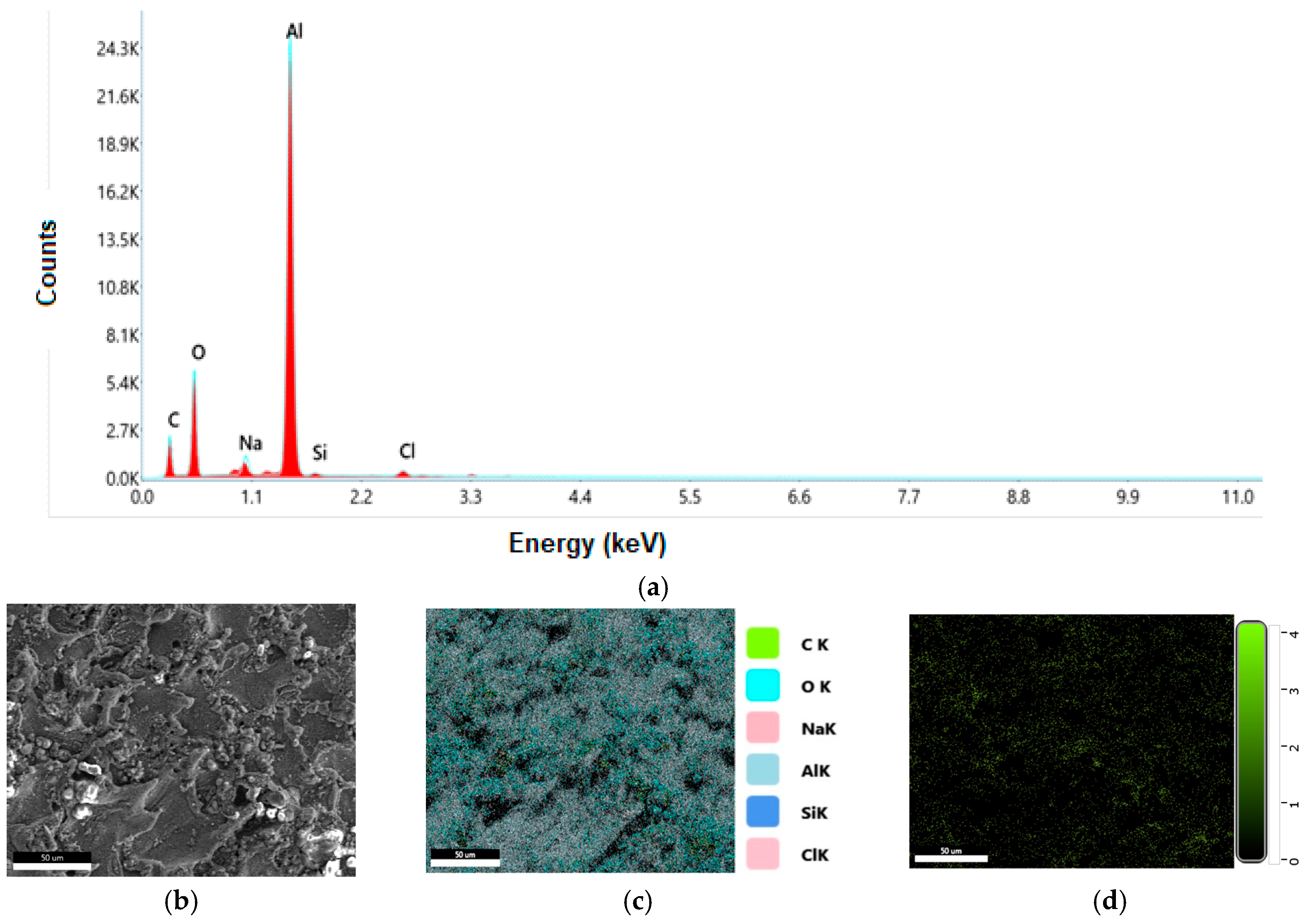

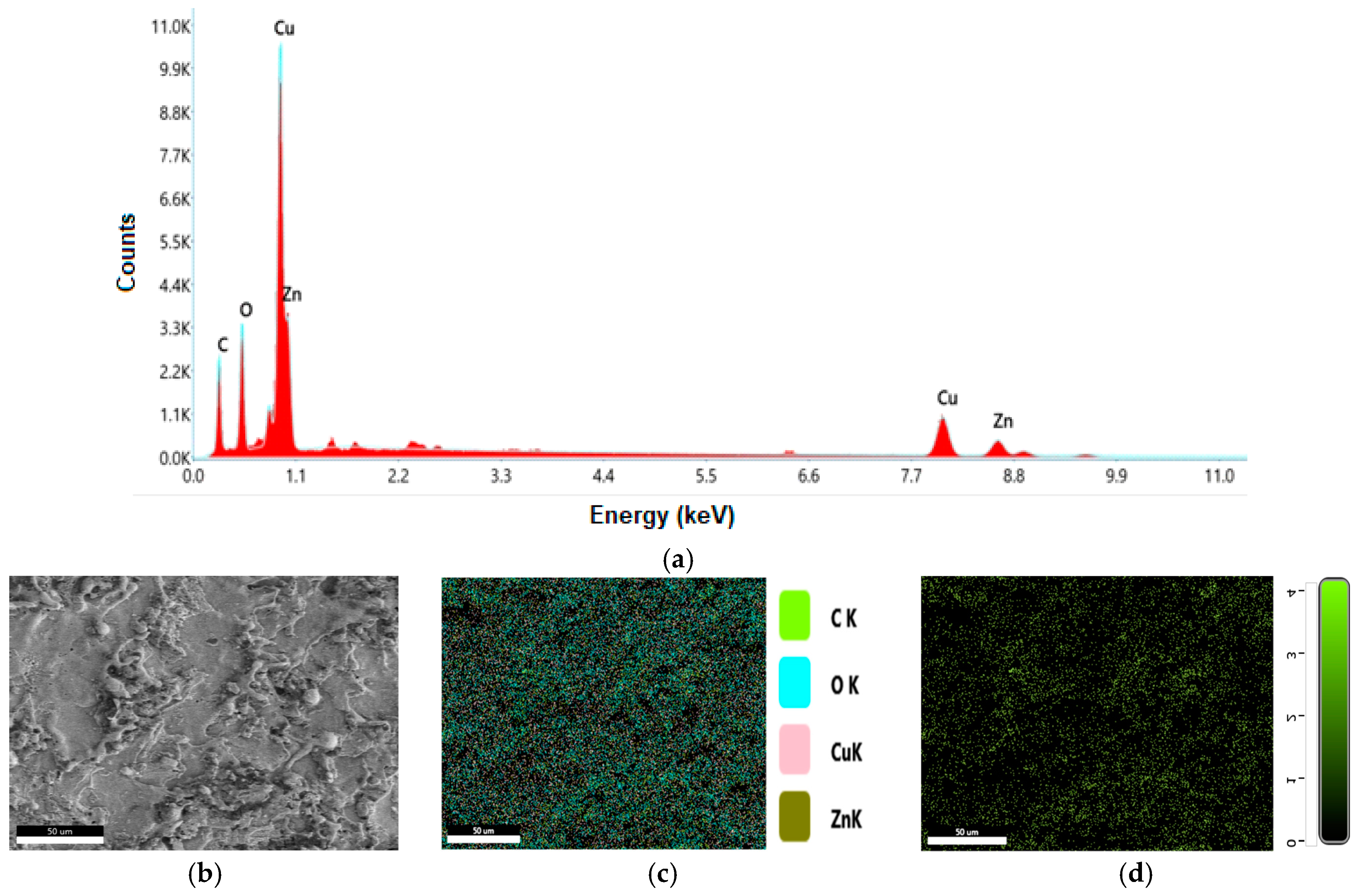

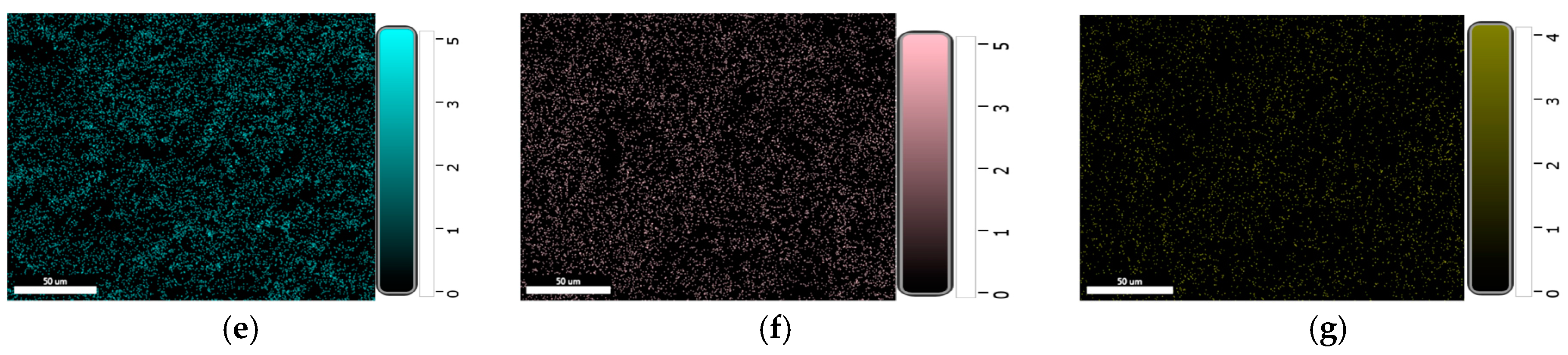

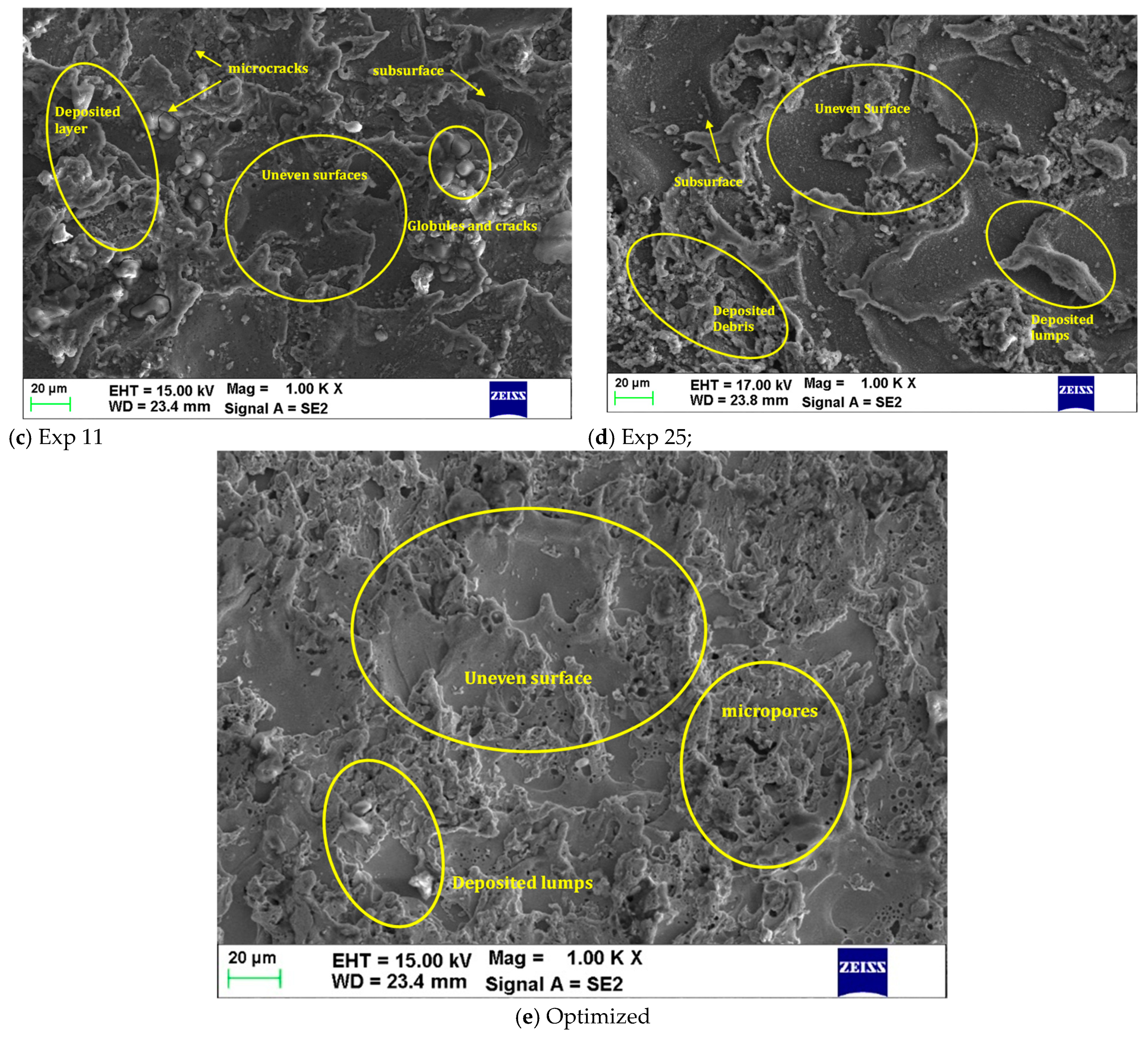

4. Morphological Study

5. Conclusions

- (i)

- The best ML strategy for the prediction of SR while processing Al/SiC/Gr hybrid composite on EDM is gradient boost, which exhibits an error percentage in the range of ±1% (except for six observations).

- (ii)

- The discharge current has a significant influence on SR, followed by Ton and Toff. However, tool material is hierarchically added in the quadratic model.

- (iii)

- The best SR value after the RSM and integrated approach of RSM-ML-TLBO are 2.51 and 2.47 µm corresponding to Ton: 45 µs; Toff: 73 µs; SV:8 V; I: 10 A; tool: brass and Ton: 47 µs; Toff: 76 µs; SV:8V; I: 10A; tool: brass, respectively.

- (iv)

- At high DE level parameters, the DE is large between the tool and workpiece, and a large number of microcracks, deposited lumps, sub-surface formation, etc., are observed. However, the deposited lumps, microcracks, and uneven surfaces are significantly reduced from the machined surface, which is processed at the optimized settings suggested by RSM-ML-TLBO.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baratzadeh, F.; Handyside, A.B.; Boldsaikhan, E.; Lankarani, H.; Carlson, B.; Burford, D. Microstructural and Mechanical Properties of Friction Stir Welding Joints of 6082-T6 with 6063-T6. In Friction Stir Welding and Processing VI; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 229–236. [Google Scholar]

- Kumar, S.; Pandey, R.; Panwar, R.S.; Pandey, O.P. Effect of Particle Size on Wear of Particulate Reinforced Aluminum Alloy Composites at Elevated Temperatures. J. Mater. Eng. Perform. 2013, 22, 3550–3560. [Google Scholar] [CrossRef]

- Kumar, N.; Ahuja, N.; Singh, S. Review of Research Work in Wire-Cut Electrical Discharge Machining (WEDM). Int. J. Eng. Studies. 2014, 6, 224–230. [Google Scholar]

- Davim, J.P.; Jain, V.K. Advanced (Non-Traditional) Machining Processes. In Machining; Fundamentals and Recent Advances; Springer: London, UK, 2008; pp. 299–327. [Google Scholar]

- Mohanty, C.P.; Satpathy, M.P.; Mahapatra, S.S.; Singh, M.R. Optimization of Cryo-Treated EDM Variables Using TOPSIS-Based TLBO Algorithm. Sādhanā 2018, 43, 51. [Google Scholar] [CrossRef]

- Mohanty, C.P.; Mahapatra, S.S.; Singh, M.R. An Intelligent Approach to Optimize the EDM Process Parameters Using Utility Concept and QPSO Algorithm. Eng. Sci. Technol. Int. J. 2017, 20, 552–562. [Google Scholar] [CrossRef]

- Lee, S.H.; Li, X.P. Study of the Effect of Machining Parameters on the Machining Characteristics in Electrical Discharge Machining of Tungsten Carbide. J. Mater. Process. Technol. 2001, 115, 344–358. [Google Scholar] [CrossRef]

- Bhaumik, M.; Maity, K. Effect of Different Tool Materials during EDM Performance of Titanium Grade 6 Alloy. Eng. Sci. Technol. Int. J. 2018, 21, 507–516. [Google Scholar] [CrossRef]

- Kanagarajan, D.; Karthikeyan, R.; Palanikumar, K.; Sivaraj, P. Influence of Process Parameters on Electric Discharge Machining of WC/30% Co Composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 807–815. [Google Scholar] [CrossRef]

- Theisen, W.; Schuermann, A. Electro Discharge Machining of Nickel–Titanium Shape Memory Alloys. Mater. Sci. Eng. A 2004, 378, 200–204. [Google Scholar] [CrossRef]

- Wang, S.M.; Wu, J.X.; Gunawan, H.; Tu, R.Q. Optimization of machining parameters for corner accuracy improvement for WEDM processing. Appl. Sci. 2022, 12, 10324. [Google Scholar] [CrossRef]

- Peta, K.; Mendak, M.; Bartkowiak, T. Discharge Energy as a Key Contributing Factor Determining Microgeometry of Aluminum Samples Created by Electrical Discharge Machining. Crystals 2021, 11, 1371. [Google Scholar] [CrossRef]

- Gostimirovic, M.; Kovac, P.; Sekulic, M.; Skoric, B. Influence of Discharge Energy on Machining Characteristics in EDM. J. Mech. Sci. Technol. 2012, 26, 173–179. [Google Scholar] [CrossRef]

- Salcedo, A.T.; Arbizu, I.P.; Pérez, C.J.L. Analytical Modelling of Energy Density and Optimization of the EDM Machining Parameters of Inconel 600. Metals 2017, 7, 166. [Google Scholar] [CrossRef]

- Singh, V.; Sharma, A.K.; Goyal, A.; Kumar Saxena, K.; Negi, P.; Rao, P.C.S. Electric Discharge Machining Performance Measures and Optimisation: A Review. Adv. Mater. Process. Technol. 2023, 1–14. [Google Scholar] [CrossRef]

- Hasan, M.M.; Saleh, T.; Sophian, A.; Rahman, M.A.; Huang, T.; Mohamed Ali, M.S. Experimental Modeling Techniques in Electrical Discharge Machining (EDM): A Review. Int. J. Adv. Manuf. Technol. 2023, 127, 2125–2150. [Google Scholar] [CrossRef]

- Ming, W.; Zhang, S.; Zhang, G.; Du, J.; Ma, J.; He, W.; Cao, C.; Liu, K. Progress in Modeling of Electrical Discharge Machining Process. Int. J. Heat Mass Transf. 2022, 187, 122563. [Google Scholar] [CrossRef]

- Channi, A.S.; Bains, H.S.; Grewal, J.S.; Chidambranathan, V.S.; Kumar, R. Tool Wear Rate during Electrical Discharge Machining for Aluminium Metal Matrix Composite Prepared by Squeeze Casting: A Prospect as a Biomaterial. J. Electrochem. Sci. Eng. 2023, 13, 149–162. [Google Scholar]

- Shanmugavel, R.; Chinthakndi, N.; Selvam, M.; Madasamy, N.; Shanmugakani, S.K.; Nair, A.; Prakash, C.; Buddhi, D.; Dixit, S. Al-Mg-MoS2 Reinforced Metal Matrix Composites: Machinability Characteristics. Materials 2022, 15, 4548. [Google Scholar] [CrossRef]

- Lin, M.-Y.; Tsao, C.; Hsu, C.; Chiou, A.; Huang, P.; Lin, Y. Optimization of Micro Milling Electrical Discharge Machining of Inconel 718 by Grey-Taguchi Method. Trans. Nonferrous Met. Soc. China 2013, 23, 661–666. [Google Scholar] [CrossRef]

- Nikalje, A.M.; Kumar, A.; Srinadh, K.V. Influence of Parameters and Optimization of EDM Performance Measures on MDN 300 Steel Using Taguchi Method. Int. J. Adv. Manuf. Technol. 2013, 69, 41–49. [Google Scholar] [CrossRef]

- Kalsi, N.S.; Sehgal, R.; Sharma, V.S. Multi-Objective Optimization Using Grey Relational Taguchi Analysis in Machining: Grey Relational Taguchi Analysis. Int. J. Organ. Collect. Intell. 2016, 6, 45–64. [Google Scholar] [CrossRef]

- Jangra, K.; Grover, S.; Aggarwal, A. Simultaneous Optimization of Material Removal Rate and Surface Roughness for WEDM of WC-Co Composite Using Grey Relational Analysis along with Taguchi Method. Int. J. Ind. Eng. Comput. 2011, 2, 479–490. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, H.; Kumar, V. Study the parametric effect of abrasive water jet machining on surface roughness of Inconel 718 using RSM-BBD techniques. Mater. Manuf. Process. 2018, 33, 1483–1490. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, R.; Gujral, R. Investigation of crack density, white layer thickness, and material characterization of biocompatible material commercially pure titanium (grade-2) through a wire electric discharge machining process using a response surface methodology. J. Process Mech. Eng. 2021, 235, 2073–2097. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, R.; Sharma, R. Investigation of machining characterization of solar material on WEDM process through response surface methodology. J. Mech. Behav. Mater. 2023, 32, 20220291. [Google Scholar] [CrossRef]

- Ahuja, N.; Batra, U.; Kumar, K. Multicharacteristics optimization of electrical discharge micro hole drilling in Mg alloy using hybrid approach of GRA–regression–PSO. Grey Sys. Theory Appl. 2021, 11, 136–151. [Google Scholar] [CrossRef]

- Khanna, R.; Kumar, A.; Garg, M.P.; Singh, A.; Sharma, N. Multiple Performance Characteristics Optimization for Al 7075 on Electric Discharge Drilling by Taguchi Grey Relational Theory. J. Ind. Eng. Int. 2015, 11, 459–472. [Google Scholar] [CrossRef]

- Selvarajan, L.; Manohar, M.; Dhinakaran, P. Modelling and Experimental Investigation of Process Parameters in EDM of Si3N4-TiN Composites Using GRA-RSM. J. Mech. Sci. Technol. 2017, 31, 111–122. [Google Scholar] [CrossRef]

- Kumar, P.; Barua, P.B.; Gaindhar, J.L. Quality Optimization (Multi-characteristics) through Taguchi’s Technique and Utility Concept. Qual. Reliab. Eng. Int. 2000, 16, 475–485. [Google Scholar] [CrossRef]

- Jangra, K.K.; Sharma, N.; Khanna, R.; Matta, D. An Experimental Investigation and Optimization of Friction Stir Welding Process for AA6082 T6 (Cryogenic Treated and Untreated) Using an Integrated Approach of Taguchi, Grey Relational Analysis and Entropy Method. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2016, 230, 454–469. [Google Scholar] [CrossRef]

- Jangra, K.; Grover, S.; Aggarwal, A. Optimization of Multi Machining Characteristics in WEDM of WC-5.3% Co Composite Using Integrated Approach of Taguchi, GRA and Entropy Method. Front. Mech. Eng. 2012, 7, 288–299. [Google Scholar] [CrossRef]

- Sharma, V.; Misra, J.P.; Singhal, S. Machine Learning Algorithms Based Advanced Optimization of Wire-EDM Parameters: An Experimental Investigation into Titanium Alloy. Int. J. Interact. Des. Manuf. 2023, 1–14. [Google Scholar] [CrossRef]

- Kalita, K.; Ghadai, R.K.; Chakraborty, S. A Comparative Study on Multi-Objective Pareto Optimization of WEDM Process Using Nature-Inspired Metaheuristic Algorithms. Int. J. Interact. Des. Manuf. 2023, 17, 499–516. [Google Scholar] [CrossRef]

- Garg, M.P.; Jain, A.; Bhushan, G. Modelling and multi-objective optimization of process parameters of wire electrical discharge machining using non-dominated sorting genetic algorithm-II. J. Eng. Manuf. 2012, 226, 1986–2001. [Google Scholar] [CrossRef]

- Saffaran, A.; Azadi Moghaddam, M.; Kolahan, F. Optimization of Backpropagation Neural Network-Based Models in EDM Process Using Particle Swarm Optimization and Simulated Annealing Algorithms. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 73. [Google Scholar] [CrossRef]

- Nain, S.S.; Garg, D.; Kumar, S. Investigation for Obtaining the Optimal Solution for Improving the Performance of WEDM of Super Alloy Udimet-L605 Using Particle Swarm Optimization. Eng. Sci. Technol. Int. J. 2018, 21, 261–273. [Google Scholar] [CrossRef]

- Singh, B.; Misra, J.P. Surface finish analysis of wire electric discharge machined specimens by RSM and ANN modeling. Measurement 2019, 137, 225–237. [Google Scholar] [CrossRef]

- Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Taha, M.A.; Soliman, M.S.; El Rayes, M.M. ANN Surface Roughness Optimization of AZ61 Magnesium Alloy Finish Turning: Minimum Machining Times at Prime Machining Costs. Materials 2018, 11, 808. [Google Scholar] [CrossRef]

- Goyal, K.K.; Sharma, N.; Gupta, R.D.; Gupta, S.; Rani, D.; Kumar, D.; Sharma, V.S. Measurement of Performance Characteristics of WEDM While Processing AZ31 Mg-Alloy Using Levy Flight MOGWO for Orthopedic Application. Int. J. Adv. Manuf. Technol. 2022, 119, 7175–7197. [Google Scholar] [CrossRef]

- Verma, A.S.; Singh, S. Multi-Objective Parametric Optimization during WEDM of Silicon through MOGWO. In Advances in Modern Machining Processes: Proceedings of AIMTDR 2021; Springer: Singapore, 2022; pp. 215–226. [Google Scholar]

- Chen, Y.; Hu, S.; Li, A.; Cao, Y.; Zhao, Y.; Ming, W. Parameters Optimization of Electrical Discharge Machining Process Using Swarm Intelligence: A Review. Metals 2023, 13, 839. [Google Scholar] [CrossRef]

- Abbas, A.T.; Sharma, N.; Alsuhaibani, Z.A.; Sharma, A.; Farooq, I.; Elkaseer, A. Multi-Objective Optimization of AISI P20 Mold Steel Machining in Dry Conditions Using Machine Learning—TOPSIS Approach. Machines 2023, 11, 748. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Liu, L.; Xu, G.; Wang, G.; Zhao, M. Effect of High-Speed Ultrasonic Vibration Cutting on the Microstructure, Surface Integrity, and Wear Behavior of Titanium Alloy. J. Mater. Res. Technol. 2023, 24, 3870–3888. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Zhang, Y.; Liu, L.; Xu, G.; Wang, G.; Zhao, M. Wear Resistance Enhancement of Inconel 718 via High-Speed Ultrasonic Vibration Cutting and Associated Surface Integrity Evaluation under High-Pressure Coolant Supply. Wear 2023, 530–531, 205027. [Google Scholar] [CrossRef]

- Abbas, A.T.; Sharma, N.; Alsuhaibani, Z.A.; Sharma, V.S.; Soliman, M.S.; Sharma, R.C. Processing of Al/SiC/Gr Hybrid Composite on EDM by Different Electrode Materials Using RSM-COPRAS Approach. Metals 2023, 13, 1125. [Google Scholar] [CrossRef]

- Box, G.E.P.; Draper, N.R. Response Surfaces, Mixtures, and Ridge Analyses; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 047007275X. [Google Scholar]

| Process Parameters | Notation (Units) | Code/Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Pulse-on time | Ton (µs) | 30 | 60 | 90 |

| Tool | - | Steel-304 | Brass | Copper |

| Voltage | V (V) | 6 | 7 | 8 |

| Pulse-off time | Toff (µs) | 30 | 60 | 90 |

| Current | I (A) | 10 | 12 | 14 |

| Run Odr | Ton (µs) | B: Toff (µs) | V (V) | I (A) | Tool | SR (µm) |

|---|---|---|---|---|---|---|

| 1 | 60 | 30 | 7 | 12 | −1 | 3.32 |

| 2 | 60 | 60 | 7 | 14 | −1 | 3.49 |

| 3 | 60 | 60 | 6 | 12 | −1 | 3.21 |

| 4 | 60 | 30 | 6 | 12 | 0 | 3.39 |

| 5 | 60 | 60 | 7 | 12 | 0 | 2.96 |

| 6 | 60 | 60 | 7 | 12 | 0 | 2.84 |

| 7 | 60 | 60 | 7 | 12 | 0 | 2.85 |

| 8 | 60 | 60 | 8 | 12 | −1 | 3.32 |

| 9 | 90 | 90 | 7 | 12 | 0 | 3.53 |

| 10 | 30 | 90 | 7 | 12 | 0 | 2.92 |

| 11 | 60 | 30 | 8 | 12 | 0 | 3.33 |

| 12 | 60 | 60 | 8 | 14 | 0 | 3.16 |

| 13 | 60 | 60 | 8 | 10 | 0 | 2.82 |

| 14 | 30 | 60 | 7 | 12 | 1 | 3.31 |

| 15 | 60 | 30 | 7 | 14 | 0 | 3.42 |

| 16 | 60 | 60 | 7 | 10 | 1 | 2.88 |

| 17 | 60 | 90 | 7 | 12 | −1 | 3.19 |

| 18 | 60 | 90 | 7 | 12 | 1 | 3.25 |

| 19 | 90 | 60 | 7 | 10 | 0 | 3.21 |

| 20 | 60 | 60 | 7 | 12 | 0 | 2.93 |

| 21 | 90 | 60 | 7 | 12 | 1 | 3.92 |

| 22 | 30 | 60 | 7 | 10 | 0 | 2.54 |

| 23 | 90 | 60 | 7 | 14 | 0 | 3.53 |

| 24 | 30 | 30 | 7 | 12 | 0 | 3.21 |

| 25 | 60 | 90 | 7 | 14 | 0 | 2.98 |

| 26 | 60 | 60 | 7 | 12 | 0 | 2.89 |

| 27 | 60 | 30 | 7 | 10 | 0 | 2.65 |

| 28 | 30 | 60 | 7 | 14 | 0 | 3.28 |

| 29 | 60 | 60 | 8 | 12 | 1 | 3.58 |

| 30 | 60 | 60 | 6 | 14 | 0 | 3.17 |

| 31 | 90 | 30 | 7 | 12 | 0 | 3.68 |

| 32 | 60 | 60 | 7 | 10 | −1 | 3.25 |

| 33 | 90 | 60 | 8 | 12 | 0 | 3.32 |

| 34 | 60 | 60 | 7 | 12 | 0 | 3.3 |

| 35 | 60 | 60 | 6 | 12 | 1 | 3.06 |

| 36 | 60 | 60 | 7 | 14 | 1 | 3.67 |

| 37 | 90 | 60 | 6 | 12 | 0 | 3.33 |

| 38 | 60 | 60 | 6 | 10 | 0 | 2.51 |

| 39 | 90 | 60 | 7 | 12 | −1 | 3.76 |

| 40 | 30 | 60 | 6 | 12 | 0 | 2.69 |

| 41 | 60 | 30 | 7 | 12 | 1 | 3.93 |

| 42 | 30 | 60 | 8 | 12 | 0 | 3.22 |

| 43 | 60 | 90 | 6 | 12 | 0 | 3.35 |

| 44 | 30 | 60 | 7 | 12 | −1 | 3.36 |

| 45 | 60 | 90 | 8 | 12 | 0 | 2.93 |

| 46 | 60 | 90 | 7 | 10 | 0 | 2.69 |

| Run Odr | SR (µm) | SR (µm) | SR (µm) | SR (µm) | Error | Error | Error |

|---|---|---|---|---|---|---|---|

| Experimental | Decision Tree | Xgboost | Random Forest | Decision Tree | Xgboost | Random Forest | |

| 1 | 3.32 | 3.18 | 3.32 | 3.33 | −4.192 | 0.009 | 0.269 |

| 2 | 3.49 | 3.31 | 3.49 | 3.31 | −5.158 | 0.002 | −5.095 |

| 3 | 3.21 | 3.18 | 3.21 | 3.19 | −0.909 | 0.063 | −0.773 |

| 4 | 3.39 | 3.18 | 3.39 | 3.24 | −6.170 | −0.056 | −4.474 |

| 5 | 2.96 | 3.18 | 2.96 | 3.08 | 7.461 | 0.072 | 3.983 |

| 6 | 2.84 | 3.18 | 2.96 | 3.08 | 12.001 | 4.300 | 8.377 |

| 7 | 2.85 | 3.18 | 2.96 | 3.08 | 11.608 | 3.934 | 7.997 |

| 8 | 3.32 | 3.18 | 3.32 | 3.26 | −4.192 | −0.014 | −1.859 |

| 9 | 3.53 | 3.58 | 3.53 | 3.38 | 1.457 | −0.003 | −4.360 |

| 10 | 2.92 | 3.18 | 2.92 | 3.08 | 8.933 | −0.006 | 5.342 |

| 11 | 3.33 | 3.18 | 3.33 | 3.28 | −4.479 | 0.000 | −1.649 |

| 12 | 3.16 | 3.31 | 3.16 | 3.21 | 4.747 | 0.046 | 1.452 |

| 13 | 2.82 | 2.82 | 2.82 | 2.94 | −0.044 | −0.035 | 4.281 |

| 14 | 3.31 | 3.18 | 3.31 | 3.32 | −3.902 | 0.049 | 0.267 |

| 15 | 3.42 | 3.31 | 3.42 | 3.30 | −3.216 | 0.019 | −3.459 |

| 16 | 2.88 | 2.82 | 2.88 | 3.07 | −2.127 | 0.018 | 6.731 |

| 17 | 3.19 | 3.18 | 3.19 | 3.20 | −0.287 | 0.072 | 0.178 |

| 18 | 3.25 | 3.18 | 3.25 | 3.30 | −2.128 | 0.007 | 1.592 |

| 19 | 3.21 | 2.82 | 3.21 | 3.14 | −12.188 | −0.003 | −2.080 |

| 20 | 2.93 | 3.18 | 2.96 | 3.08 | 8.561 | 1.097 | 5.048 |

| 21 | 3.92 | 3.58 | 3.92 | 3.55 | −8.637 | −0.043 | −9.455 |

| 22 | 2.54 | 2.82 | 2.54 | 2.85 | 10.974 | 0.030 | 12.123 |

| 23 | 3.53 | 3.58 | 3.53 | 3.43 | 1.457 | 0.011 | −2.943 |

| 24 | 3.21 | 3.18 | 3.21 | 3.24 | −0.909 | −0.001 | 1.048 |

| 25 | 2.98 | 3.31 | 2.98 | 3.14 | 11.074 | −0.023 | 5.435 |

| 26 | 2.89 | 3.18 | 2.96 | 3.08 | 10.063 | 2.496 | 6.502 |

| 27 | 2.65 | 2.82 | 2.65 | 2.98 | 6.368 | 0.017 | 12.428 |

| 28 | 3.28 | 3.31 | 3.28 | 3.19 | 0.915 | −0.042 | −2.762 |

| 29 | 3.58 | 3.18 | 3.58 | 3.37 | −11.150 | 0.012 | −5.817 |

| 30 | 3.17 | 3.31 | 3.17 | 3.14 | 4.416 | −0.009 | −0.791 |

| 31 | 3.68 | 3.58 | 3.68 | 3.46 | −2.679 | −0.001 | −5.998 |

| 32 | 3.25 | 2.82 | 3.25 | 3.04 | −13.269 | −0.143 | −6.345 |

| 33 | 3.32 | 3.58 | 3.32 | 3.37 | 7.874 | 0.009 | 1.387 |

| 34 | 3.3 | 3.18 | 2.96 | 3.08 | −3.611 | −10.239 | −6.730 |

| 35 | 3.06 | 3.18 | 3.06 | 3.23 | 3.949 | 0.003 | 5.651 |

| 36 | 3.67 | 3.31 | 3.67 | 3.40 | −9.809 | 0.018 | −7.256 |

| 37 | 3.33 | 3.58 | 3.33 | 3.30 | 7.550 | 0.005 | −0.790 |

| 38 | 2.51 | 2.82 | 2.51 | 2.85 | 12.301 | 0.090 | 13.620 |

| 39 | 3.76 | 3.58 | 3.76 | 3.48 | −4.749 | −0.029 | −7.431 |

| 40 | 2.69 | 3.18 | 2.69 | 3.04 | 18.247 | 0.137 | 12.966 |

| 41 | 3.93 | 3.18 | 3.93 | 3.50 | −19.063 | −0.040 | −10.904 |

| 42 | 3.22 | 3.18 | 3.22 | 3.14 | −1.216 | −0.080 | −2.357 |

| 43 | 3.35 | 3.18 | 3.35 | 3.12 | −5.050 | −0.142 | −6.740 |

| 44 | 3.36 | 3.18 | 3.36 | 3.23 | −5.332 | −0.009 | −3.744 |

| 45 | 2.93 | 3.18 | 2.93 | 3.11 | 8.561 | 0.011 | 6.236 |

| 46 | 2.69 | 2.82 | 2.69 | 2.89 | 4.786 | 0.050 | 7.341 |

| Source | SS | df | MS | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 3.98 | 7 | 0.57 | 17.94 | <0.0001 | significant |

| A-Ton | 0.88 | 1 | 0.88 | 27.71 | <0.0001 | |

| B-Toff | 0.27 | 1 | 0.27 | 8.61 | 0.0057 | |

| D-I | 1.08 | 1 | 1.08 | 33.93 | <0.0001 | |

| E-Tool | 0.031 | 1 | 0.031 | 0.97 | 0.332 | |

| A^2 | 0.55 | 1 | 0.55 | 17.26 | 0.0002 | |

| B^2 | 0.22 | 1 | 0.22 | 6.89 | 0.0124 | |

| E^2 | 1.4 | 1 | 1.4 | 44.09 | <0.0001 | |

| Residual | 1.21 | 38 | 0.032 | |||

| Lack of Fit | 1.06 | 33 | 0.032 | 1.08 | 0.5215 | Non-significant |

| Pure Error | 0.15 | 5 | 0.03 | |||

| Cor Total | 5.19 | 45 |

| Suggested Solutions by RSM and RSM-ML-TLBO | ||||||

|---|---|---|---|---|---|---|

| Technique | Ton | Toff | V * | I | Tool | SR |

| RSM | 45.04 | 73.23 | 7.68 | 10 | −0.06 | 2.5865 |

| RSM-ML-TLBO | 46.98 | 76.09 | - | 10 | 0.058 | 2.4696 |

| Exp No. 38 | 60 | 60 | 6 | 10 | 0 | 2.51 |

| Confirmation Experiments | ||||||

| RSM | 45 | 73 | 8 | 10 | Brass | 2.62 |

| RSM-ML-TLBO | 47 | 76 | 8 | 10 | Brass | 2.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.T.; Sharma, N.; Al-Bahkali, E.A.; Sharma, V.S.; Farooq, I.; Elkaseer, A. A Machine Learning Perspective to the Investigation of Surface Integrity of Al/SiC/Gr Composite on EDM. J. Manuf. Mater. Process. 2023, 7, 163. https://doi.org/10.3390/jmmp7050163

Abbas AT, Sharma N, Al-Bahkali EA, Sharma VS, Farooq I, Elkaseer A. A Machine Learning Perspective to the Investigation of Surface Integrity of Al/SiC/Gr Composite on EDM. Journal of Manufacturing and Materials Processing. 2023; 7(5):163. https://doi.org/10.3390/jmmp7050163

Chicago/Turabian StyleAbbas, Adel T., Neeraj Sharma, Essam A. Al-Bahkali, Vishal S. Sharma, Irfan Farooq, and Ahmed Elkaseer. 2023. "A Machine Learning Perspective to the Investigation of Surface Integrity of Al/SiC/Gr Composite on EDM" Journal of Manufacturing and Materials Processing 7, no. 5: 163. https://doi.org/10.3390/jmmp7050163

APA StyleAbbas, A. T., Sharma, N., Al-Bahkali, E. A., Sharma, V. S., Farooq, I., & Elkaseer, A. (2023). A Machine Learning Perspective to the Investigation of Surface Integrity of Al/SiC/Gr Composite on EDM. Journal of Manufacturing and Materials Processing, 7(5), 163. https://doi.org/10.3390/jmmp7050163