A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing

Abstract

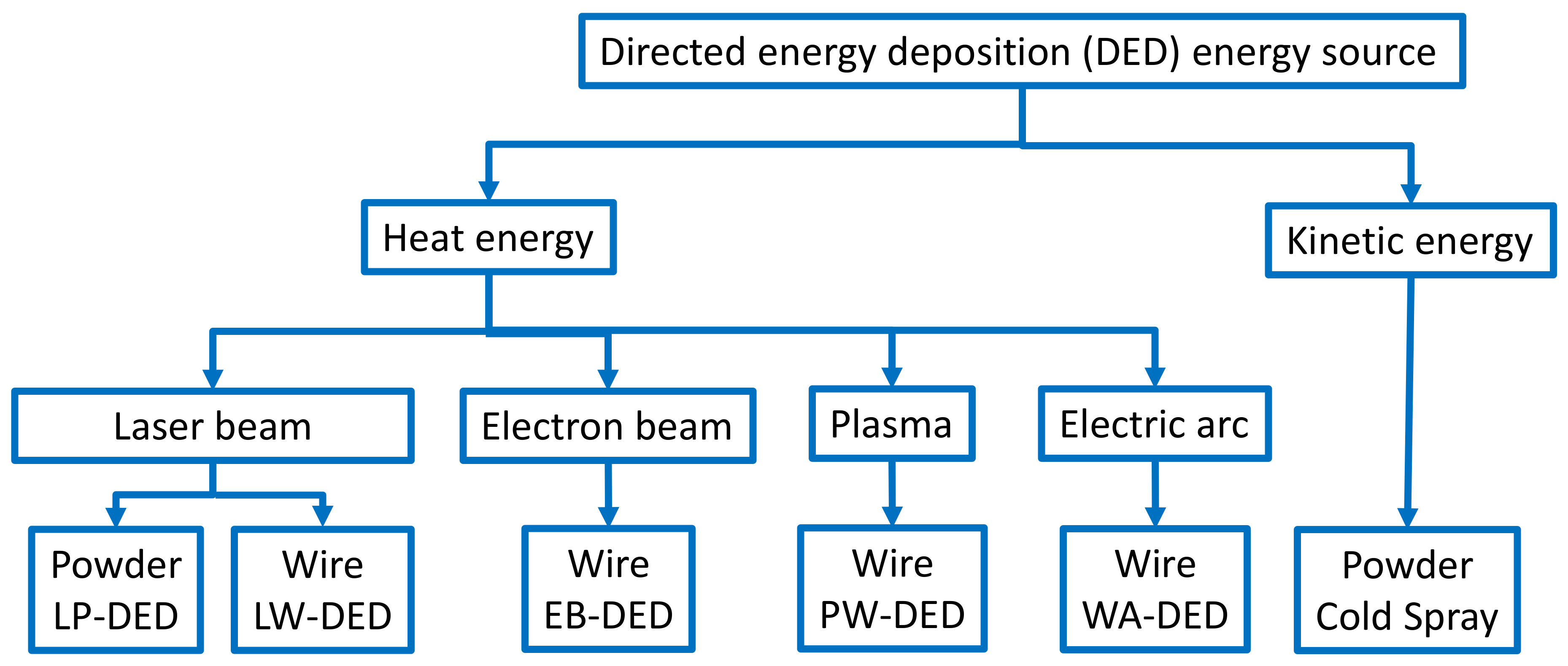

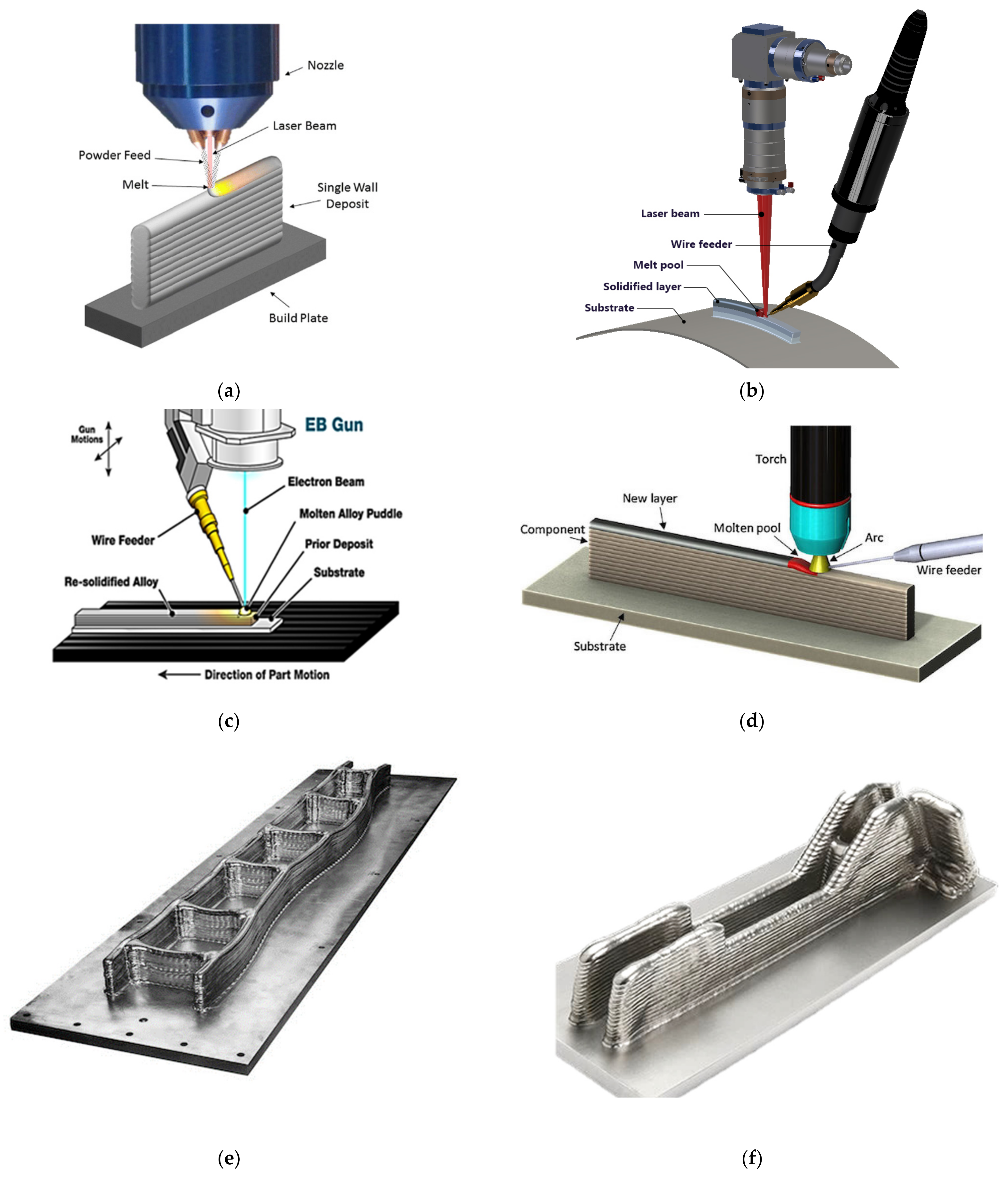

:1. Introduction

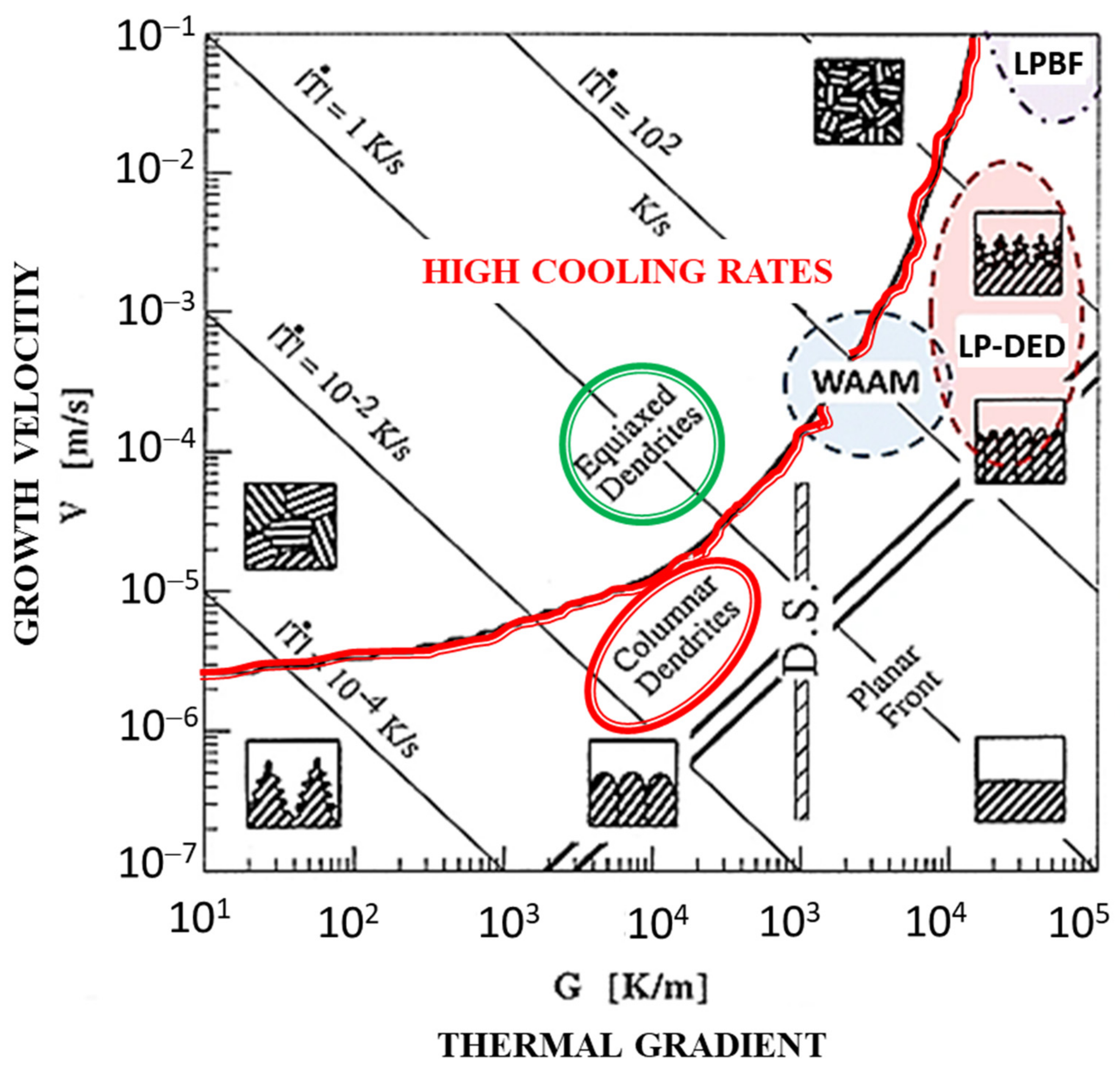

2. Grain Size and Morphology

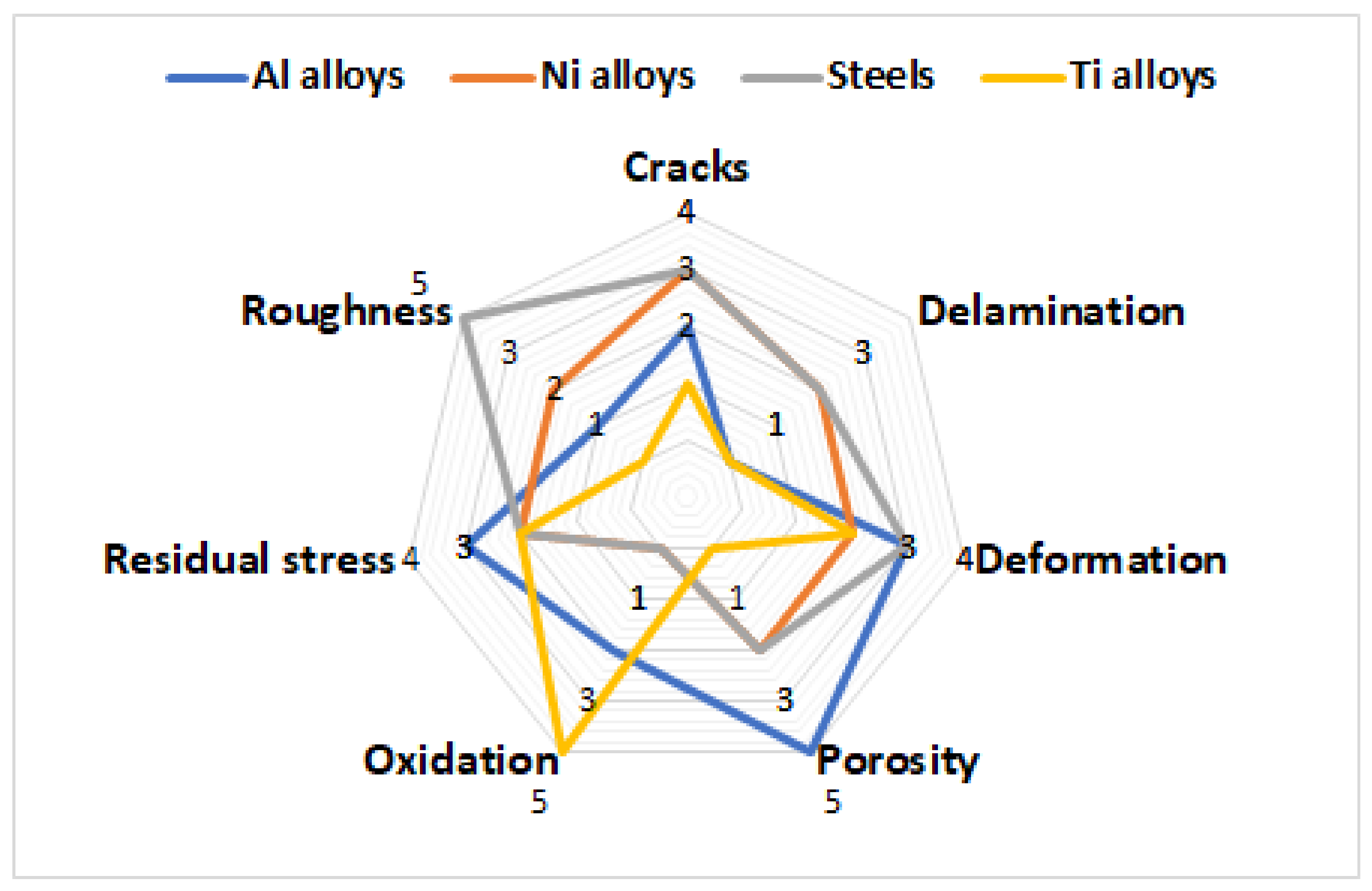

- : grain size (µm);

- : undercooling for nucleation (°C);

- : diffusion rate in the liquid (m2·s−1);

- : growth of the solid–liquid interface velocity (m·s−1);

- : growth restriction factor (Q = C0 m (k − 1));

- C0: alloy composition (%wt);

- m: slope of the liquidus;

- k: solute partition coefficient;

- : inoculant particle density added to the melt;

- : particle fraction that successfully nucleates a grain.

3. Process Parameters

4. Alloy Composition

5. Nucleant Particles for Grain Refinement

6. Post-Processing of WAAM Parts

6.1. Post-Process Heat Treatment

6.2. Interpass Cold Rolling

6.3. Interpass Cooling

6.4. Peening and Ultrasonic Impact Treatment

6.5. In-Process Ultrasonic Vibration Treatment

7. Modeling of Solidification Microstructure

7.1. Phase Field Method

7.2. Monte Carlo Method

7.3. Cellular Automata Method

8. Combined Mechanistic and Data-Driven Modeling

9. Summary and Future Outlook

10. Research Directions

- Could the research improve the properties of additively manufactured titanium alloy by grain refinement of the product using a combination of the three main optimized solutions (alloying element changing, adding nucleants, using mechanical means, and changing the process parameters)?

- Does reducing defects by controlling the process parameters and feedstock quality help the grain refinement and hence improve the properties, or does their presence during solidification help to obtain a finer microstructure?

- Is phase and microstructure refinement effective and profitable for the corrosion resistance properties of the products?

- What is the effect of the grain size, shape, and microstructure on the surface roughness and integrity?

- How can physics-based simulation modeling for solidification microstructure and grain morphology describe the optimized condition for the aforementioned process?

Author Contributions

Funding

Conflicts of Interest

References

- Fu, R.; Tang, S.; Lu, J.; Cui, Y.; Li, Z.; Zhang, H.; Xu, T.; Chen, Z.; Liu, C. Hot-wire arc additive manufacturing of aluminum alloy with reduced porosity and high deposition rate. Mater. Des. 2021, 199, 109370. [Google Scholar] [CrossRef]

- Aldalur, E.; Veiga, F.; Suárez, A.; Bilbao, J.; Lamikiz, A. High deposition wire arc additive manufacturing of mild steel: Strategies and heat input effect on microstructure and mechanical properties. J. Manuf. Process. 2020, 58, 615–626. [Google Scholar] [CrossRef]

- Taminger, K.M.; Domack, C.S. Challenges in Metal Additive Manufacturing for Large-Scale Aerospace Applications. In Women in Aerospace Materials; Women in Engineering and Science; Kinsella, M., Ed.; Springer: Cham, Switzerland, 2020; pp. 105–124. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Dugar, J.; Ikram, A.; Klobčar, D.; Pušavec, F. Sustainable Hybrid Manufacturing of AlSi5 Alloy Turbine Blade Prototype by Robotic Direct Energy Layered Deposition and Subsequent Milling: An Alternative to Selective Laser Melting? Materials 2022, 15, 8631. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Mereddy, S.; Bermingham, M.J.; StJohn, D.H.; Dargusch, M.S. Grain refinement of wire arc additively manufactured titanium by the addition of silicon. J. Alloys Compd. 2017, 695, 2097–2103. [Google Scholar] [CrossRef]

- Childerhouse, T.; Jackson, M. Near Net Shape Manufacture of Titanium Alloy Components from Powder and Wire: A Review of State-of-the-Art Process Routes. Metals 2019, 9, 689. [Google Scholar] [CrossRef]

- Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid metal additive manufacturing: A state–of–the-art review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Alonso, U.; Veiga, F.; Suárez, A.; Del Val, A.G. Characterization of Inconel 718® superalloy fabricated by wire Arc Additive Manufacturing: Effect on mechanical properties and machinability. J. Mater. Res. Technol. 2021, 14, 2665–2676. [Google Scholar] [CrossRef]

- Kindermann, R.M.; Roy, M.J.; Morana, R.; Prangnell, P.B. Process response of Inconel 718 to wire + arc additive manufacturing with cold metal transfer. Mater. Des. 2020, 195, 109031. [Google Scholar] [CrossRef]

- Artaza, T.; Bhujangrao, T.; Suárez, A.; Veiga, F.; Lamikiz, A. Influence of heat input on the formation of laves phases and hot cracking in plasma arc welding (PAW) additive manufacturing of inconel 718. Metals 2020, 10, 771. [Google Scholar] [CrossRef]

- Lopes, J.G.; Machado, C.M.; Duarte, V.R.; Rodrigues, T.A.; Santos, T.G.; Oliveira, J.P. Effect of milling parameters on HSLA steel parts produced by Wire and Arc Additive Manufacturing (WAAM). J. Manuf. Process. 2020, 59, 739–749. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, J.; Liu, C.; Ma, Y.; Han, Y.; Xu, T.; Lu, J.; Fang, H. Fabricating Pyramidal Lattice Structures of 304 L Stainless Steel by Wire Arc Additive Manufacturing. Materials 2020, 13, 3482. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Aldalur, E.; Goenaga, I.; Amondarain, J. Wire Arc Additive Manufacturing Process for Topologically Optimized Aeronautical Fixtures. 3D Print. Addit. Manuf. 2021. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A.F.Y.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys—A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Totin, A.; MacDonald, E.; Conner, B.P. Additive Manufacturing for Aerospace Maintenance and Sustainment (Postprint) Air Force Research Laboratory Materials and Manufacturing Directorate Wright-Patterson Air Force Base, Oh 45433-7750 Air Force Materiel Command United States Air Force. 2019. Available online: www.dsiac.org (accessed on 14 December 2022).

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Reichardt, A.; Dillon, R.P.; Borgonia, J.P.; Shapiro, A.A.; McEnerney, B.W.; Momose, T.; Hosemann, P. Development and characterization of Ti-6Al-4V to 304L stainless steel gradient components fabricated with laser deposition additive manufacturing. Mater. Des. 2016, 104, 404–413. [Google Scholar] [CrossRef]

- Procada, Directed Energy Deposition Additive Manufacturing. 2023. Available online: https://www.procada.se/technology.html (accessed on 14 December 2022).

- Sciaky, Additive Manufacturing. 2022. Available online: https://www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology (accessed on 14 December 2022).

- McAndrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire + arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Özel, T.; Altay, A.; Donmez, A.; Leach, R. Surface topography investigations on nickel alloy 625 fabricated via laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2018, 94, 4451–4458. [Google Scholar] [CrossRef]

- Asala, G.; Khan, A.K.; Andersson, J.; Ojo, O.A. Microstructural Analyses of ATI 718Plus® Produced by Wire-ARC Additive Manufacturing Process. Metall. Mater. Trans. A 2017, 48, 4211–4228. [Google Scholar] [CrossRef]

- Lin, J.; Lv, Y.; Liu, Y.; Sun, Z.; Wang, K.; Li, Z.; Wu, Y.; Xu, B. Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment. J. Mech. Behav. Biomed. Mater. 2016, 69, 19–29. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Zhang, D.; Prasad, A.; Bermingham, M.J.; Todaro, C.J.; Benoit, M.J.; Patel, M.N.; Qiu, D.; StJohn, D.H.; Qian, M.; Easton, M.A. Grain Refinement of Alloys in Fusion-Based Additive Manufacturing Processes. Metall. Mater. Trans. A 2020, 51, 4341–4359. [Google Scholar] [CrossRef]

- Collins, P.C.; Haden, C.V.; Ghamarian, I.; Hayes, B.J.; Ales, T.; Penso, G.; Dixit, V.; Harlow, G. Progress toward an integration of process–structure–property–performance models for “three-dimensional (3-D) printing” of titanium alloys. JOM 2014, 66, 1299–1309. [Google Scholar] [CrossRef]

- Bermingham, M.J.; StJohn, D.H.; Krynen, J.; Tedman-Jones, S.; Dargusch, M.S. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, C.; Fan, C.; Zhuo, Y.; Lin, S.; Chen, C. Grain refinement of additive manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy by the addition of La2O3. Mater. Lett. 2020, 275, 128170. [Google Scholar] [CrossRef]

- Ng, C.H.; Bermingham, M.J.; Dargusch, M.S. Controlling grain size, morphology and texture in additively manufactured β-titanium alloy with super transus hot isostatic pressing. Addit. Manuf. 2022, 59, 103176. [Google Scholar] [CrossRef]

- Yuan, D.; Shao, S.; Guo, C.; Jiang, F.; Wang, J. Grain refining of Ti-6Al-4V alloy fabricated by laser and wire additive manufacturing assisted with ultrasonic vibration. Ultrason. Sonochem. 2021, 73, 105472. [Google Scholar] [CrossRef]

- Lu, T.; Liu, C.; Li, Z.; Wu, Q.; Wang, J.; Xu, T.; Liu, J.; Wang, H.; Ma, S. Hot-wire arc additive manufacturing Ti–6.5Al–2Zr–1Mo–1V titanium alloy: Pore characterization, microstructural evolution, and mechanical properties. J. Alloys Compd. 2020, 817, 153334. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Lervåg, M.; Sørensen, C.; Robertstad, A.; Brønstad, B.M.; Nyhus, B.; Eriksson, M.; Aune, R.; Ren, X.; Akselsen, O.M.; Bunaziv, I. Additive Manufacturing with Superduplex Stainless Steel Wire by CMT Process. Metals 2020, 10, 272. [Google Scholar] [CrossRef]

- Stützer, J.; Totzauer, T.; Wittig, B.; Zinke, M.; Jüttner, S. GMAW Cold Wire Technology for Adjusting the Ferrite–Austenite Ratio of Wire and Arc Additive Manufactured Duplex Stainless Steel Components. Metals 2019, 9, 564. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Hosseini, V.; Högström, M.; Hurtig, K.; Valiente Bermejo, M.A.; Stridh, L.E.; Karlsson, L. Wire-arc additive manufacturing of a duplex stainless steel: Thermal cycle analysis and microstructure characterization. Weld. World 2019, 63, 975–987. [Google Scholar] [CrossRef]

- Bermingham, M.; StJohn, D.; Easton, M.; Yuan, L.; Dargusch, M. Revealing the Mechanisms of Grain Nucleation and Formation During Additive Manufacturing. JOM 2020, 72, 1065–1073. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- St John, D.H.; McDonald, S.D.; Bermingham, M.J.; Mereddy, S.; Prasad, A.; Dargusch, M. The challenges associated with the formation of equiaxed grains during additive manufacturing of titanium alloys. Key Eng. Mater. 2018, 770, 155–164. [Google Scholar] [CrossRef]

- StJohn, D.H.; Qian, M.; Easton, M.A.; Cao, P. The Interdependence Theory: The relationship between grain formation and nucleant selection. Acta Mater. 2011, 59, 4907–4921. [Google Scholar] [CrossRef]

- Liberini, M.; Astarita, A.; Campatelli, G.; Scippa, A.; Montevecchi, F.; Venturini, G.; Durante, M.; Boccarusso, L.; Minutolo, F.M.C.; Squillace, A. Selection of optimal process parameters for Wire Arc additive manufacturing. Procedia CIRP 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Effects of process variables and size-scale on solidification microstructure in beam-based fabrication of bulky 3D structures. Mater. Sci. Eng. A 2009, 513–514, 311–318. [Google Scholar] [CrossRef]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Erdakov, I.; Glebov, L.; Pashkeev, K.; Bykov, V.; Bryk, A.; Lezin, V.; Radionova, L. Effect of the Ti6Al4V Alloy Track Trajectories on Mechanical Properties in Direct Metal Deposition. Machines 2020, 8, 79. [Google Scholar] [CrossRef]

- Kushwaha, A.; Kumar, S.A.; Velu, R. Selective laser melting of titanium alloys: Effect of processing parameters on microstructure and mechanical properties. Int. J. Mechatron. Manuf. Syst. 2021, 14, 128–142. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Lin, X.; Tan, H.; Huang, W.D. Grain morphology control and texture characterization of laser solid formed Ti6Al2Sn2Zr3Mo1.5Cr2Nb titanium alloy. J. Mater. Process. Technol. 2016, 238, 202–211. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; bin Abdollah, M.F.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Review on effect of heat input for wire arc additive manufacturing process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar] [CrossRef]

- Kisielewicz, A.; Thalavai Pandian, K.; Sthen, D.; Hagqvist, P.; Valiente Bermejo, M.A.; Sikström, F.; Ancona, A. Hot-Wire Laser-Directed Energy Deposition: Process Characteristics and Benefits of Resistive Pre-Heating of the Feedstock Wire. Metals 2021, 11, 634. [Google Scholar] [CrossRef]

- Wang, J.; Lin, X.; Wang, J.; Yang, H.; Zhou, Y.; Wang, C.; Li, Q.; Huang, W. Grain morphology evolution and texture characterization of wire and arc additive manufactured Ti-6Al-4V. J. Alloys Compd. 2018, 768, 97–113. [Google Scholar] [CrossRef]

- Zhuo, Y.; Yang, C.; Fan, C.; Lin, S.; Chen, Y.; Chen, C.; Cai, X. Grain refinement of wire arc additive manufactured titanium alloy by the combined method of boron addition and low frequency pulse arc. Mater. Sci. Eng. A 2020, 805, 140557. [Google Scholar] [CrossRef]

- Davis, A.E.; Hönnige, J.R.; Martina, F.; Prangnell, P.B. Quantification of strain fields and grain refinement in Ti-6Al-4V inter-pass rolled wire-arc AM by EBSD misorientation analysis. Mater. Charact. 2020, 170, 110673. [Google Scholar] [CrossRef]

- Hönnige, J.; Colegrove, P.; Prangnell, P.; Ho, A.; Williams, S. The Effect of Thermal History on Microstructural Evolution, Cold-Work Refinement and α/β Growth in Ti-6Al-4V Wire + Arc AM. arXiv 2018, arXiv:1811.02903. [Google Scholar]

- Donoghue, J.; Antonysamy, A.A.; Martina, F.; Colegrove, P.A.; Williams, S.W.; Prangnell, P.B. The effectiveness of combining rolling deformation with Wire–Arc Additive Manufacture on β-grain refinement and texture modification in Ti–6Al–4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Ding, D.; Wu, B.; Pan, Z.; Qiu, Z.; Li, H. Wire arc additive manufacturing of Ti6AL4V using active interpass cooling. Mater. Manuf. Process. 2020, 35, 845–851. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Artaza, T.; Suárez, A.; Veiga, F.; Braceras, I.; Tabernero, I.; Larrañaga, O.; Lamikiz, A. Wire arc additive manufacturing Ti6Al4V aeronautical parts using plasma arc welding: Analysis of heat-treatment processes in different atmospheres. J. Mater. Res. Technol. 2020, 9, 15454–15466. [Google Scholar] [CrossRef]

- Martina, F.; Colegrove, P.A.; Williams, S.W.; Meyer, J. Microstructure of Interpass Rolled Wire + Arc Additive Manufacturing Ti-6Al-4V Components. Metall. Mater. Trans. A 2015, 46, 6103–6118. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S.; StJohn, D.H. Grain-refinement mechanisms in titanium alloys. J. Mater. Res. 2008, 23, 97–104. [Google Scholar] [CrossRef]

- Wang, F.; Mei, J.; Wu, X. Microstructure study of direct laser fabricated Ti alloys using powder and wire. Appl. Surf. Sci. 2006, 253, 1424–1430. [Google Scholar] [CrossRef]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef]

- Mok, S.H.; Bi, G.; Folkes, J.; Pashby, I.; Segal, J. Deposition of Ti-6Al-4V using a high power diode laser and wire, Part II: Investigation on the mechanical properties. Surf. Coat. Technol. 2008, 202, 4613–4619. [Google Scholar] [CrossRef]

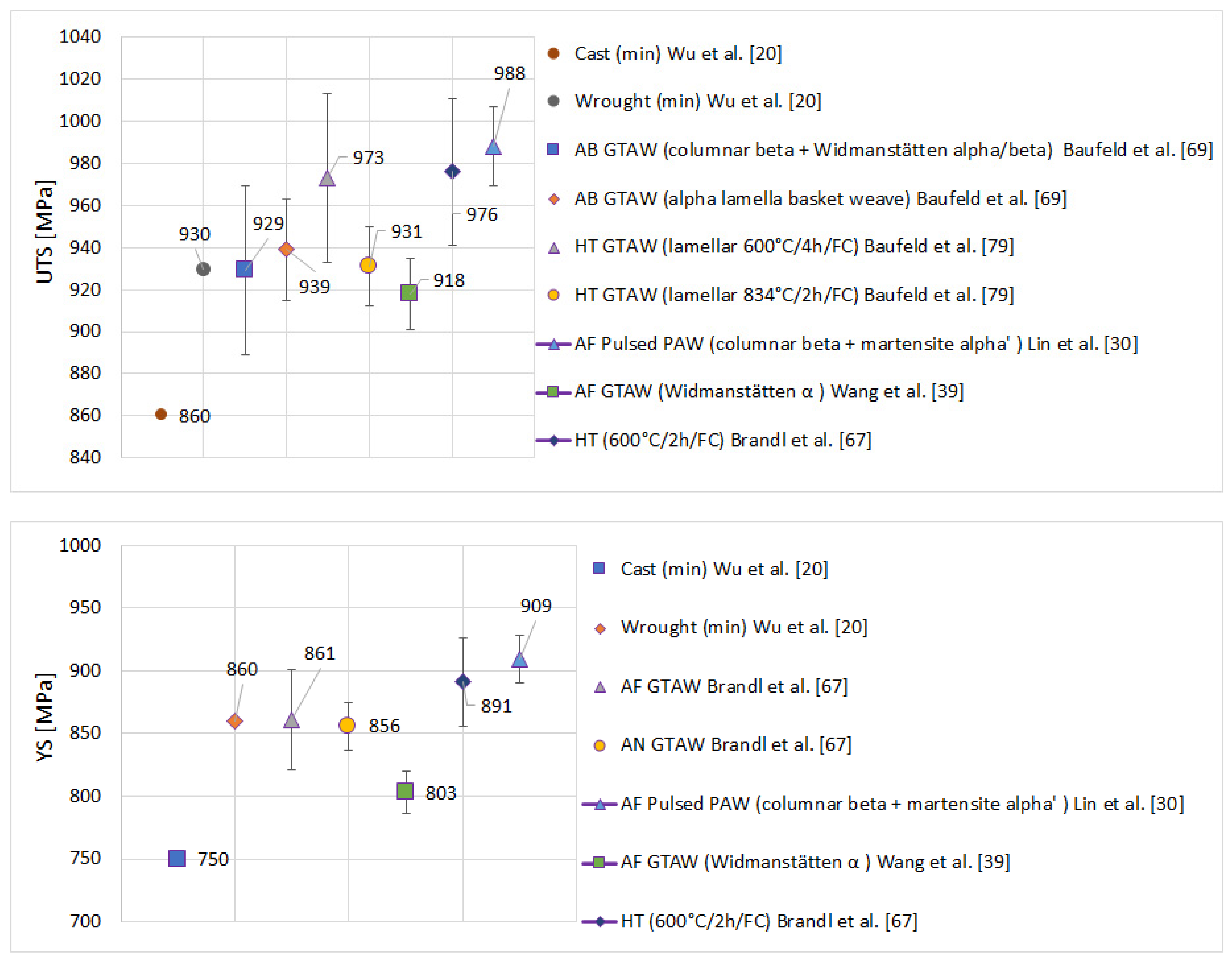

- Baufeld, B.; Van der Biest, O.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification; Trans Tech Publications: Aedermannsdorf, Switzerland, 1989. [Google Scholar]

- Ştefănescu, D.M. Equilibrium and non-equilibrium during solidification. In Science and Engineering of Casting Solidification, 2nd ed.; Springer: Boston, MA, USA, 2009; pp. 1–20. [Google Scholar]

- Fredriksson, H.; Åkerlind, U. Nucleation. In Solidification and Crystallization Processing in Metals and Alloys; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 166–200. [Google Scholar]

- Tedman-Jones, S.N.; McDonald, S.D.; Bermingham, M.J.; StJohn, D.H.; Dargusch, M.S. A new approach to nuclei identification and grain refinement in titanium alloys. J. Alloys Compd. 2019, 794, 268–284. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Kent, D.; Zhan, H.; StJohn, D.H.; Dargusch, M.S. Controlling the microstructure and properties of wire arc additive manufactured Ti–6Al–4V with trace boron additions. Acta Mater. 2015, 91, 289–303. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S. Effect of trace lanthanum hexaboride and boron additions on microstructure, tensile properties and anisotropy of Ti-6Al-4V produced by additive manufacturing. Mater. Sci. Eng. A 2018, 719, 1–11. [Google Scholar] [CrossRef]

- Kennedy, J.R.; Davis, A.E.; Caballero, A.E.; Williams, S.; Pickering, E.J.; Prangnell, P.B. The potential for grain refinement of Wire-Arc Additive Manufactured (WAAM) Ti-6Al-4V by ZrN and TiN inoculation. Addit. Manuf. 2021, 40, 101928. [Google Scholar] [CrossRef]

- Mereddy, S.; Bermingham, M.J.; Kent, D.; Dehghan-Manshadi, A.; StJohn, D.H.; Dargusch, M.S. Trace carbon addition to refine microstructure and enhance properties of additive-manufactured Ti-6Al-4V. JOM 2018, 70, 1670–1676. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Baufeld, B.; Brandl, E.; Van Der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Coules, H.E.; Fairman, J.; Martina, F.; Kashoob, T.; Mamash, H.; Cozzolino, L.D. Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling. J. Mater. Process. Technol. 2013, 213, 1782–1791. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Fei, Z. The effects of forced interpass cooling on the material properties of wire arc additively manufactured Ti6Al4V alloy. J. Mater. Process. Technol. 2018, 258, 97–105. [Google Scholar] [CrossRef]

- Li, G.; Qu, S.; Xie, M.X.; Li, X. Effect of ultrasonic surface rolling at low temperatures on surface layer microstructure and properties of HIP Ti-6Al-4V alloy. Surf. Coat. Technol. 2017, 316, 75–84. [Google Scholar] [CrossRef]

- Xiaogang, J. The Effect of Ultrasonic Vibration on the Solidification of Light Alloys. Ph.D. Thesis, University of Tennessee, Knoxville, TN, USA, 2005. [Google Scholar]

- Kumar, S.; Wu, C.S.; Padhy, G.K.; Ding, W. Application of ultrasonic vibrations in welding and metal processing: A status review. J. Manuf. Process. 2017, 26, 295–322. [Google Scholar] [CrossRef]

- Ning, F.; Hu, Y.; Liu, Z.; Cong, W.; Li, Y.; Wang, X. Ultrasonic Vibration-Assisted Laser Engineered Net Shaping of Inconel 718 Parts: A Feasibility Study. Procedia Manuf. 2017, 10, 771–778. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Ning, F.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: Effects of ultrasonic frequency on microstructural and mechanical properties. J. Mater. Process. Technol. 2019, 276, 116395. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain structure control during metal 3D printing by high-intensity ultrasound. Nat. Commun. 2020, 11, 142. [Google Scholar] [CrossRef]

- Criales, L.E.; Arisoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Laser powder bed fusion of nickel alloy 625: Experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int. J. Mach. Tools Manuf. 2017, 121, 22–36. [Google Scholar] [CrossRef]

- Criales, L.E.; Özel, T. Temperature profile and melt depth in laser powder bed fusion of Ti-6Al-4V titanium alloy. Prog. Addit. Manuf. 2017, 2, 169–177. [Google Scholar] [CrossRef]

- Criales, L.E.; Arısoy, Y.M.; Lane, B.; Moylan, S.; Donmez, A.; Özel, T. Predictive modeling and optimization of multi-track processing for laser powder bed fusion of nickel alloy 625. Addit. Manuf. 2017, 13, 14–36. [Google Scholar] [CrossRef]

- Yang, L.; Özel, T. Physics-based simulation models for digital twin development in laser powder bed fusion. Int. J. Mechatron. Manuf. Syst. 2021, 14, 143–162. [Google Scholar] [CrossRef]

- DebRoy, T.; Mukherjee, T.; Wei, H.L.; Elmer, J.W.; Milewski, J.O. Metallurgy, mechanistic models and machine learning in metal printing. Nat. Rev. Mater. 2021, 6, 48–68. [Google Scholar] [CrossRef]

- Lee, J.L.; Bhadeshia, H.K.D.H. A methodology for the prediction of time-temperature-transformation diagrams. Mater. Sci. Eng. A 1993, 171, 223–230. [Google Scholar] [CrossRef]

- Maynier, P.H.; Dollet, J.; Bastien, P. Prediction of Microstructure via Empirical Formulas based on CCT Diagrams. Metall. Soc. AIME 1978, 163–178. [Google Scholar]

- Kumar, A.; Mishra, S.; Debroy, T.; Elmer, J.W. Optimization of the Johnson-Mehl-Avarami equation parameters for α-ferrite to γ-austenite transformation in steel welds using a genetic algorithm. Metall. Mater. Trans. A 2005, 36, 15–22. [Google Scholar] [CrossRef]

- Liu, J.; Jalalahmadi, B.; Guo, Y.B.; Sealy, M.P.; Bolander, N. A review of computational modeling in powder-based additive manufacturing for metallic part qualification. Rapid Prototyp. J. 2018, 24, 1245–1264. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Z.; Yao, X.; Hu, C.; Ge, P.; Wan, Z.; Li, J.; Wu, Q. Numerical methods for microstructural evolutions in laser additive manufacturing. Comput. Math. Appl. 2019, 78, 2296–2307. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, F.; Zhang, H.; Cui, Z. Review on modeling and simulation of microstructure evolution during dynamic recrystallization using cellular automaton method. Sci. China Technol. Sci. 2019, 63, 357–396. [Google Scholar] [CrossRef]

- Gatsos, T.; Eslayed, K.A.; Zhai, Y.; Lados, D.A. Review on Computational Modeling of Process–Microstructure–Property Relationships in Metal Additive Manufacturing. JOM 2020, 72, 403–419. [Google Scholar] [CrossRef]

- Arısoy, Y.M.; Criales, L.E.; Özel, T. Modeling and simulation of thermal field and solidification in laser powder bed fusion of nickel alloy IN625. Opt. Laser Technol. 2019, 109, 278–292. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Zhan, M. A review on the modeling and simulations of solid-state diffusional phase transformations in metals and alloys. Manuf. Rev. 2018, 5, 10. [Google Scholar] [CrossRef]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V. Three-dimensional modeling of the microstructure evolution during metal additive manufacturing. Comput. Mater. Sci. 2018, 141, 207–220. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V. Simulation of metal additive manufacturing microstructures using kinetic Monte Carlo. Comput. Mater. Sci. 2017, 135, 78–89. [Google Scholar] [CrossRef]

- Lian, Y.; Gan, Z.; Yu, C.; Kats, D.; Liu, W.K.; Wagner, G.J. A cellular automaton finite volume method for microstructure evolution during additive manufacturing. Mater. Des. 2019, 169, 107672. [Google Scholar] [CrossRef]

- Benakis, M.; Costanzo, D.; Patran, A. Current mode effects on weld bead geometry and heat affected zone in pulsed wire arc additive manufacturing of Ti-6-4 and Inconel 718. J. Manuf. Process. 2020, 60, 61–74. [Google Scholar] [CrossRef]

- Wan, H.; Chen, G.; Li, C.; Qi, X.; Zhang, G. Data-Driven evaluation of fatigue performance of additive manufactured parts using miniature specimens. J. Mater. Sci. Technol. 2019, 35, 1137–1146. [Google Scholar] [CrossRef]

- Popova, E.; Rodgers, T.M.; Gong, X.; Cecen, A.; Madison, J.D.; Kalidindi, S.R. Process-Structure linkages using a data science approach: Application to simulated additive manufacturing data. Integr. Mater. Manuf. Innov. 2017, 6, 54–68. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report 2021: 3D Printing and Additive Manufacturing State of the Industry; Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2021. [Google Scholar]

| Material Feedstock | Titanium Ti-6Al4V | Tantalum | Inconel 625 |

|---|---|---|---|

| Wire (0.9 mm diameter) | ~USD120/kg | ~USD1100/kg | ~USD55/kg |

| Wire (1.1 mm diameter) | ~USD110/kg | ~USD1100/kg | ~USD55/kg |

| Wire (1.6 mm diameter) | ~USD100/kg | ~USD1000/kg | ~USD55/kg |

| Wire (2.4 mm diameter) | ~USD97/kg | ~USD950/kg | ~USD50/kg |

| Wire (3.2 mm diameter) | ~USD95/kg | ~USD900/kg | ~USD50/kg |

| Wire (4.0 mm diameter) | ~USD92/kg | ~USD900/kg | N/A |

| Powder AM grade | ~USD250/kg | ~USD1100/kg | ~USD100/kg |

| Factors That Minimize the Size of the Nucleation-Free Zone | Factors That Minimize xsd |

|---|---|

| Minimize D: this will encourage a narrow solute pile up and faster generation of ΔTCS | Increase the particle density: more particles per volume of melt increases the probability of their presence at the end of the nucleation-free zone |

| Minimize ΔTn: this will allow nucleation sooner (less ΔTCS is required) | Increase the potency of the particles: a low ΔTn will require less thermal or constitutional supercooling |

| Minimize z: the newly nucleated equiaxed grain will not need to grow as much and instead requires only an incremental contribution to ‘top up’ the net ΔTCS. z is a product of the temperature gradient G and is small when G is small | Particle size has also been associated with potency |

| Maximize Q: solutes with high Q will rapidly develop ΔTCS | Create a homogeneous size and spatial distribution of particles within the melt |

| Maximize V: this will encourage a narrow solute pile up and ΔTCS | Maximize chemical stability of the particles in the liquid metal |

| Material | Process | Defect or Feature | |||||

|---|---|---|---|---|---|---|---|

| Porosity | Cracking | Delamination | Oxidation | Substrate Adherence | Surface Finish | ||

| Ti6Al4V | TIG | No | No | No | Light | Good | Smooth |

| Plasma | No | No | No | No | Good | Smooth | |

| CMT | No | No | No | Light | Good | Smooth | |

| DCEP-GMAW | No | No | No | Light | Medium | Poor | |

| H08Mn2Si steel | DE-GMAW | Low | No | No | No | Good | Waviness |

| Copper-coated steel | GMAW | No | No | No | Light | Good | Medium-rough |

| ER4043 Al alloy | CMT | High | No | No | Light | Good | Smooth |

| VP-GTAW | No | No | No | No | Good | Medium-rough | |

| AA2319 Al alloy | CMT | High | No | No | No | Good | Smooth |

| CMT-PADV | No | No | No | No | Good | Smooth | |

| 5356 Al alloy | VP-GTAW | No | Yes | No | No | Good | Smooth |

| Inconel 625 | PPAD | High | Yes | No | No | Good | Smooth |

| GTAW | No | No | No | No | Good | Smooth | |

| Inconel 718 | GMAW | Medium | Yes | Yes | No | Good | Smooth |

| AZ31 Mg alloy | PMIG | No | No | No | Light | Medium | Medium-rough |

| Nickel-Al-Cu | CMT | No | No | No | No | Good | Smooth |

| Steel–bronze bimetal | GMAW | No | No | No | No | Good | Smooth |

| Steel- nickel bimetal | GMAW | No | No | No | No | Good | Medium-rough |

| Intermetallic Fe/Al | GTAW | High | Yes | No | Serious | Medium | Medium-poor |

| Intermetallic Al/Ti | GTAW | Low | Yes | No | No | Good | Rough |

| Intermetallic Al/Cu | GTAW | No | No | Yes | Light | Poor | Rough |

| Aim | Model | Highlights | Outcomes |

|---|---|---|---|

| Heat transfer numerical analysis | Heat conduction model [89,90] | 3D heat conduction equation is solved numerically using FEM/FDM methods | Thermal field, geometry of fusion zone, heating/cooling rates |

| Heat conduction–convection model | 3D transient solution for conservation of mass, momentum, and energy | Thermal and velocity fields, geometry of fusion zone, lack of fusion, heating/cooling rates | |

| Volumetric fluid flow model | Free surface of fusion zone movement | Thermal and velocity fields, heating/cooling rates | |

| Microstructure, nucleation, grain growth | Time-temperature-transformation [93], Continuous cooling transformation [93], Johnson–Mehrl–Avrami model [94] | Kinetics of phase transformation during cooling | Solid-state phase transformation kinetics |

| Phase field method [95,96,97,98,99] | Calculation of an order parameter based on free energy to represent the state of entire microstructure | Evolution of phases, nucleation, grain growth, solid-state phase transformation | |

| Monte Carlo method [100,101,102] | Probabilistic method for grain orientation change | Solidification microstructure, grain growth, texture | |

| Cellular automata [100,101,102,103] | Element birth and death for calculating grain growth and subgrain structure | Solidification microstructure, grain growth, texture |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özel, T.; Shokri, H.; Loizeau, R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. J. Manuf. Mater. Process. 2023, 7, 45. https://doi.org/10.3390/jmmp7010045

Özel T, Shokri H, Loizeau R. A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2023; 7(1):45. https://doi.org/10.3390/jmmp7010045

Chicago/Turabian StyleÖzel, Tuğrul, Hamed Shokri, and Raphaël Loizeau. 2023. "A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing" Journal of Manufacturing and Materials Processing 7, no. 1: 45. https://doi.org/10.3390/jmmp7010045

APA StyleÖzel, T., Shokri, H., & Loizeau, R. (2023). A Review on Wire-Fed Directed Energy Deposition Based Metal Additive Manufacturing. Journal of Manufacturing and Materials Processing, 7(1), 45. https://doi.org/10.3390/jmmp7010045