Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate and Surface Materials

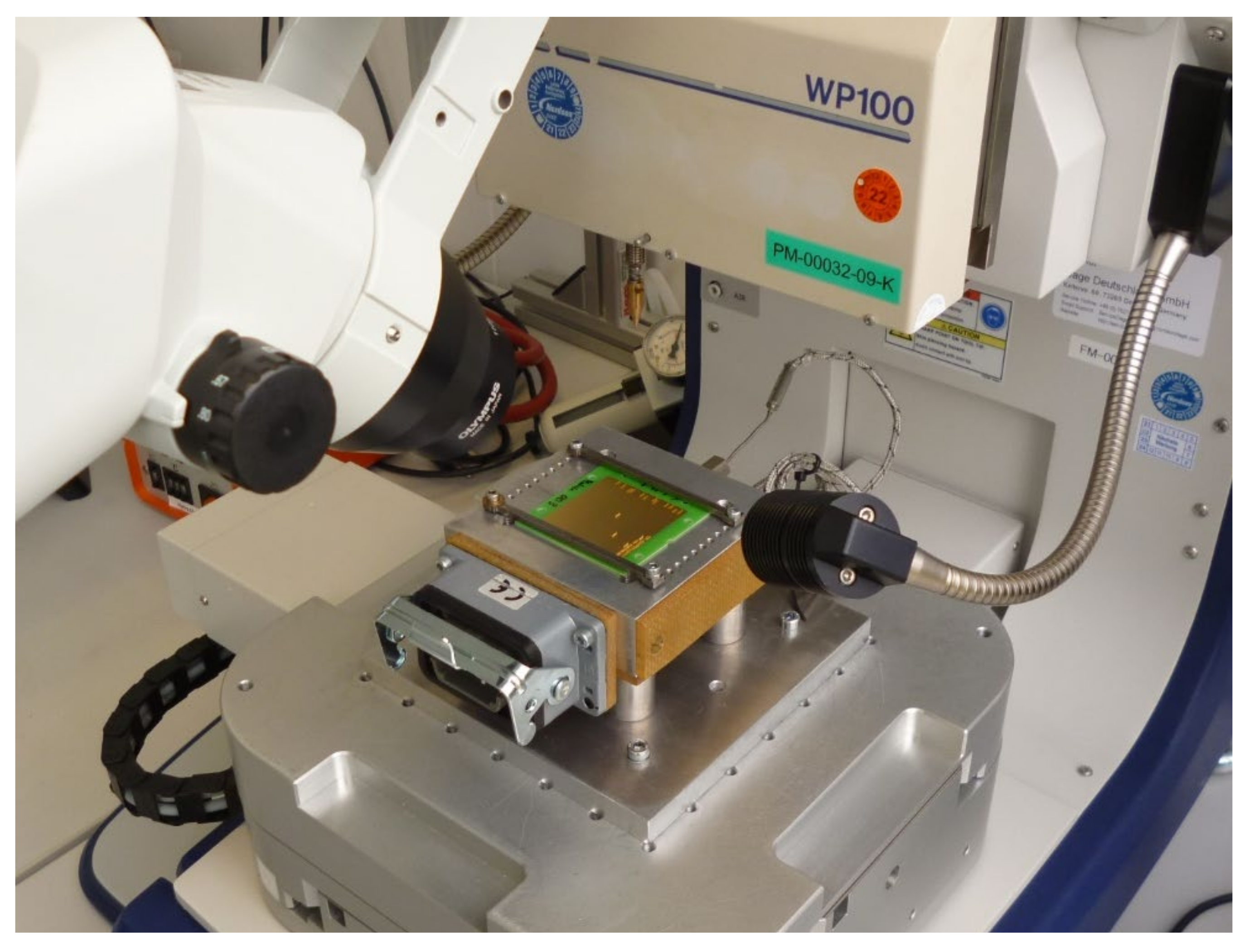

2.2. Wire Bond Process

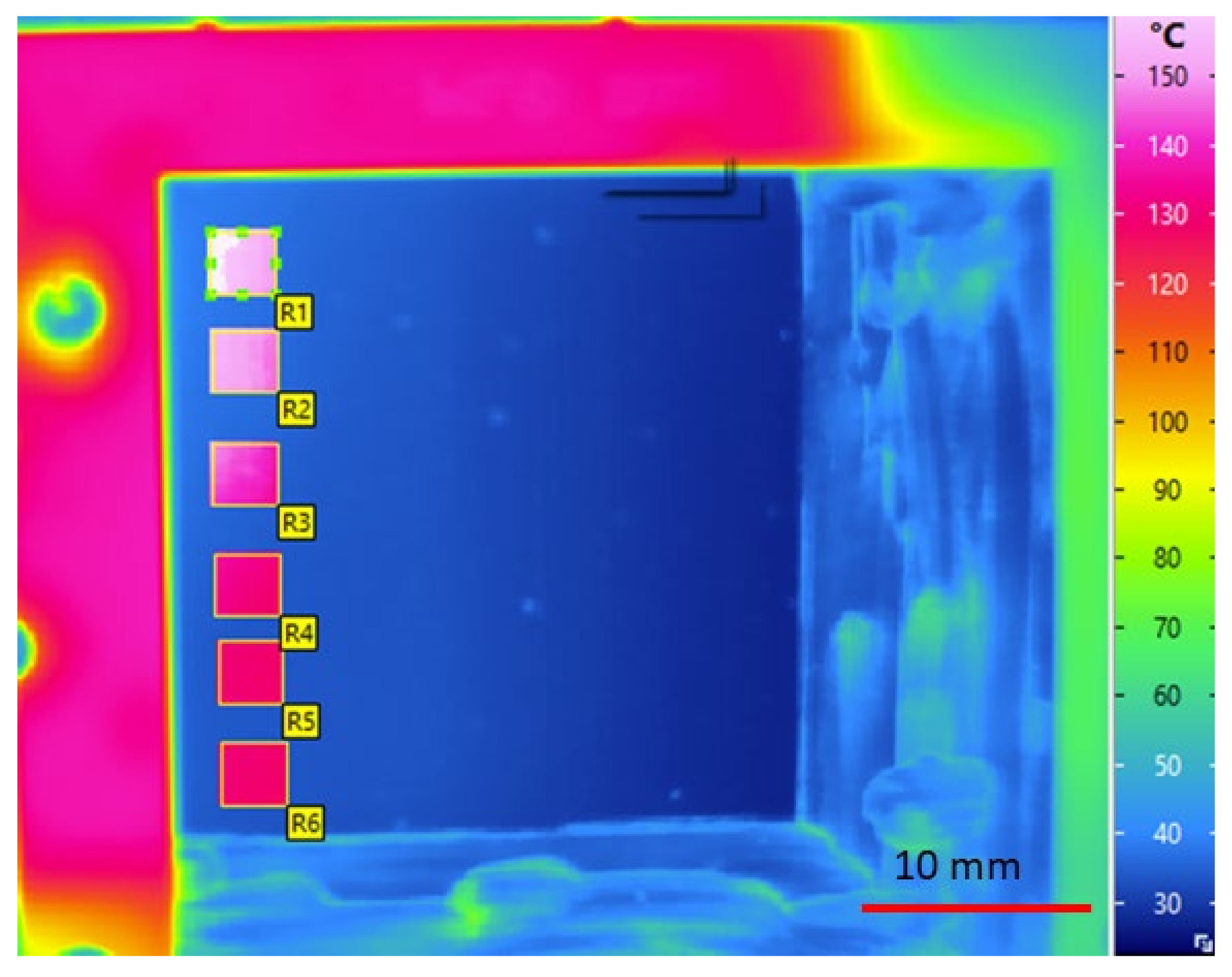

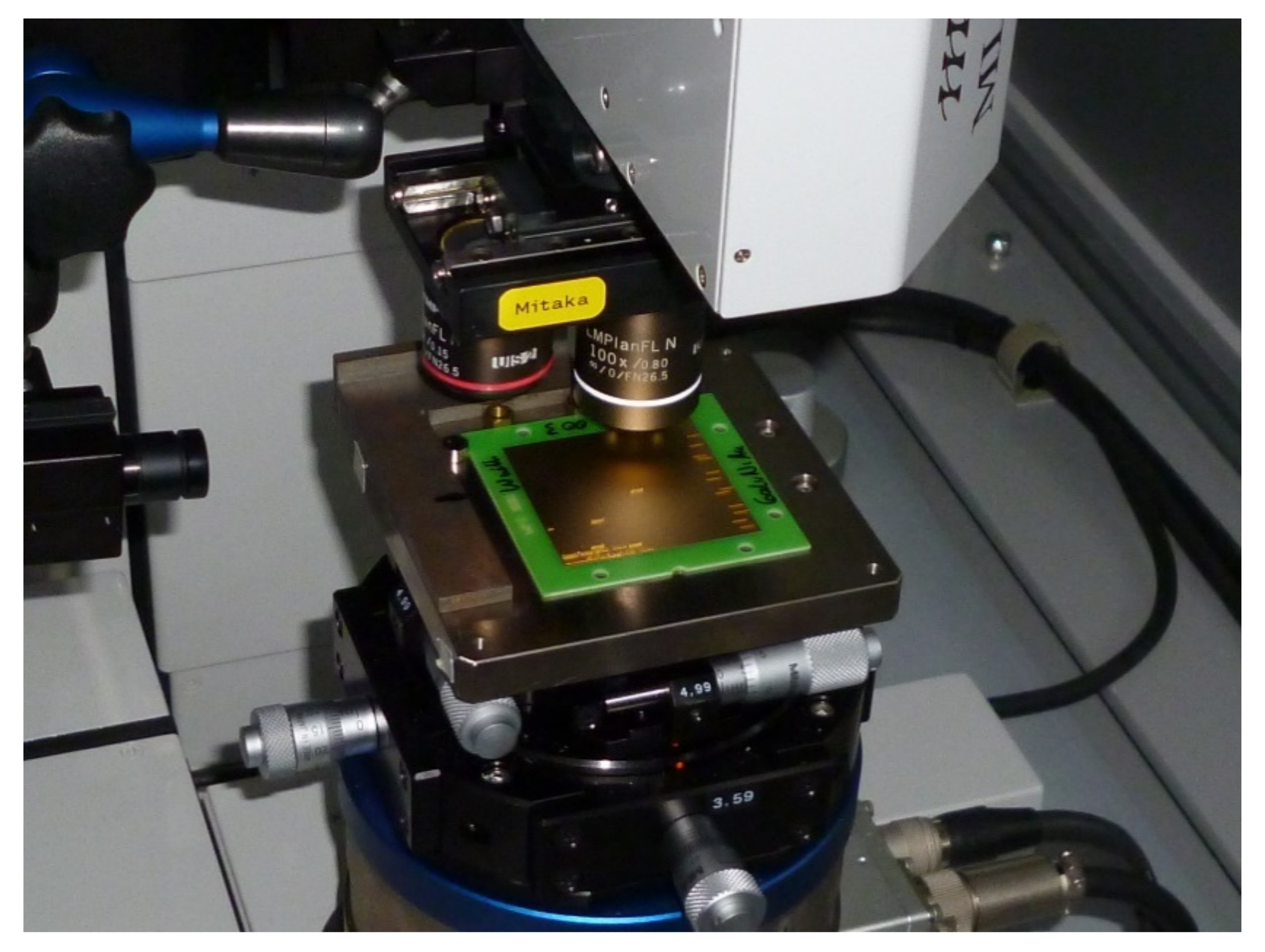

2.3. Thermal Observation of the Bond Surface

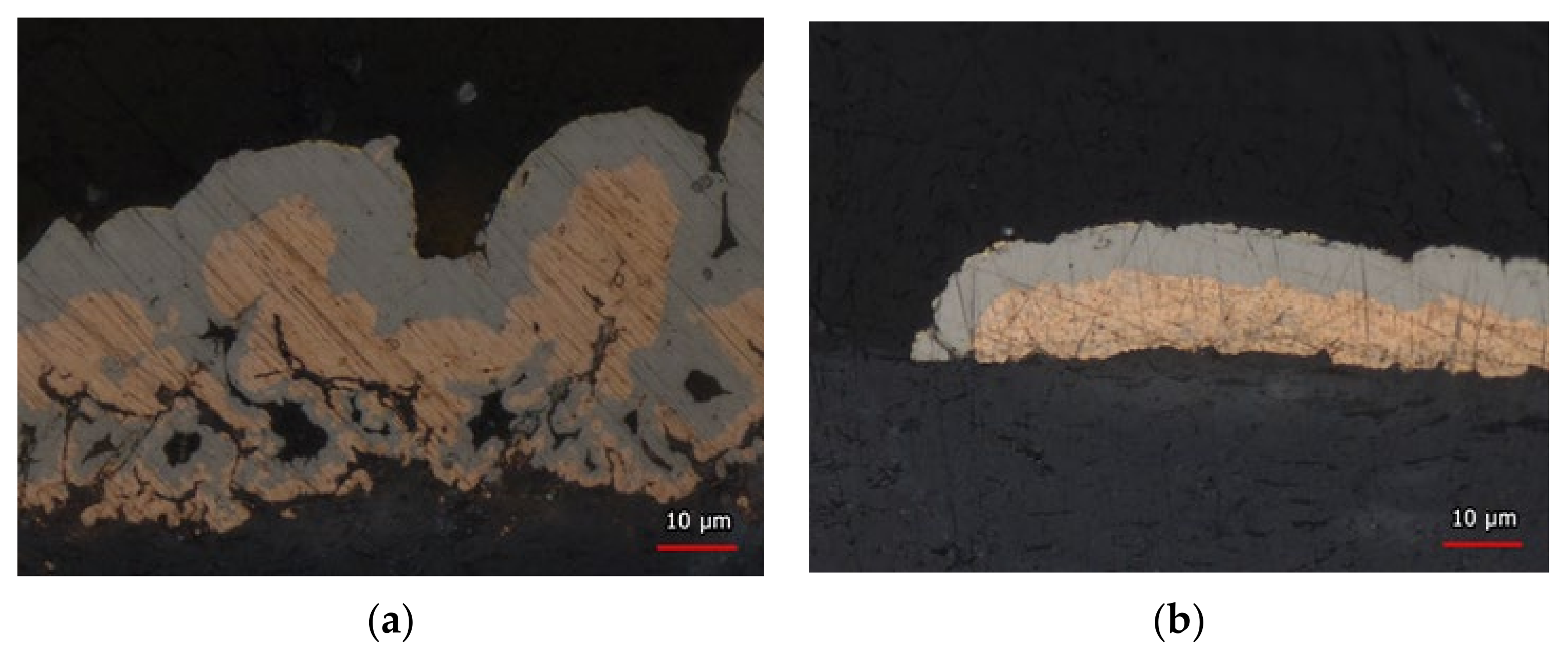

2.4. Bond Pad Surface Characterization

- Sa—Arithmetical mean height of the surface;

- Sz—Maximum height of the surface;

- Sq—Root mean square height of the surface;

- Ra—Arithmetical mean deviation of the assessed profile;

- Rq—Root mean squared;

- Rz—Average Rz value over assessment length.

2.5. Characterization of Bond Strength in Means of Pull Tests

3. Results

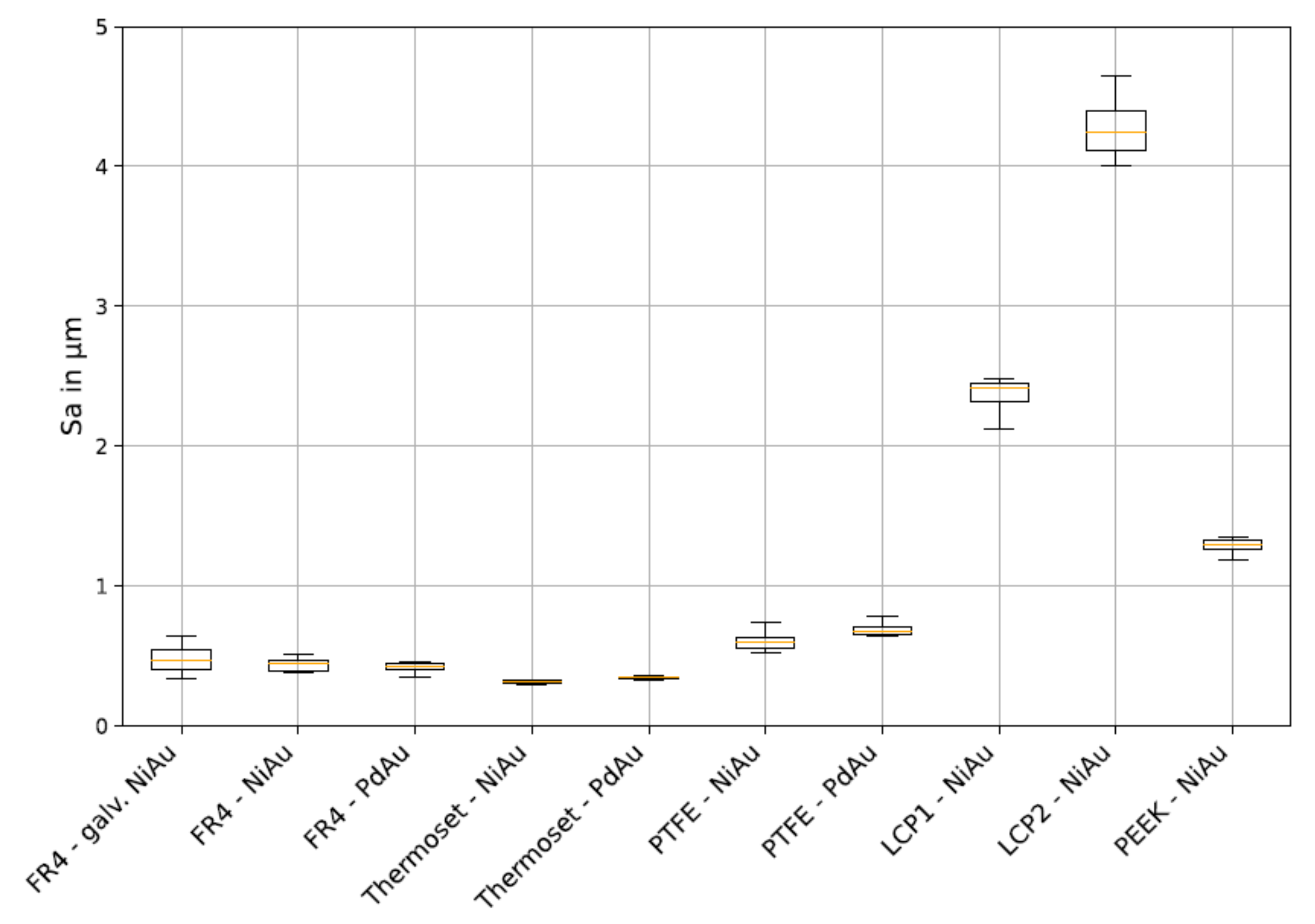

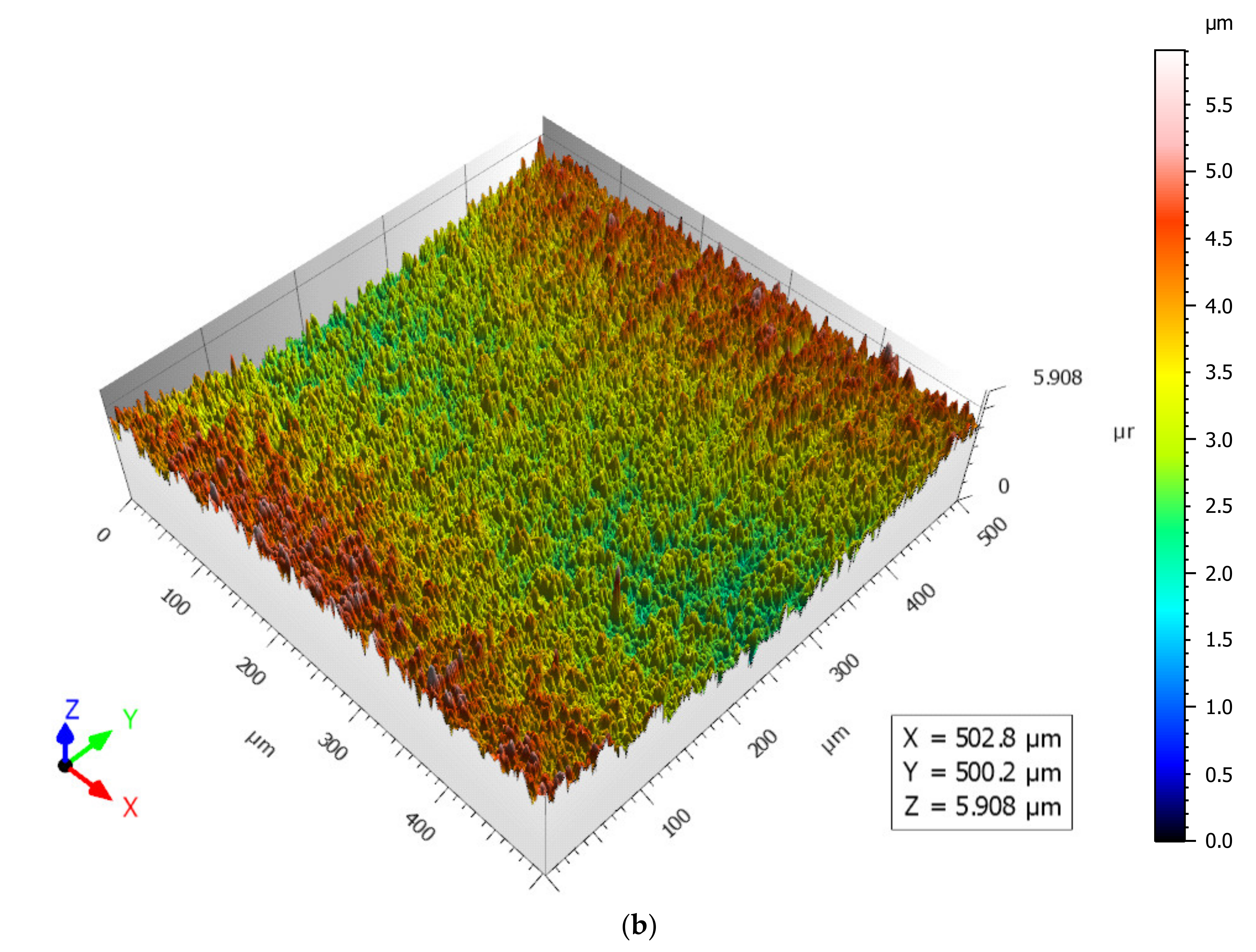

3.1. Surface Roughness of Bond Pad Surface Characterization

3.2. Controlling of the Thermal Factor and Epsilon Determination

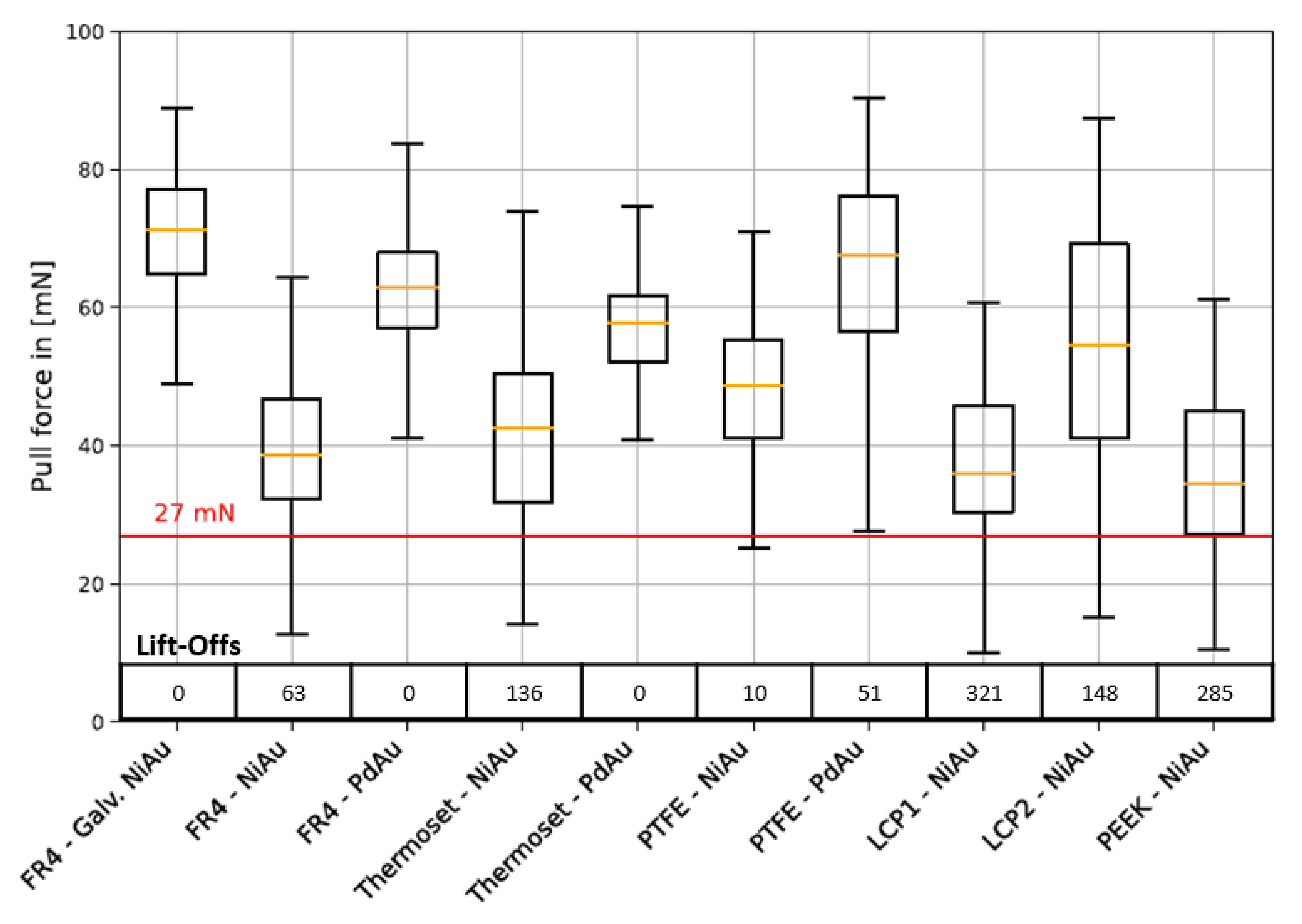

3.3. Characterization by Pull Tests

3.4. Substrate-Dependent Measurement of Roughness and Pull Force on LCP-MID

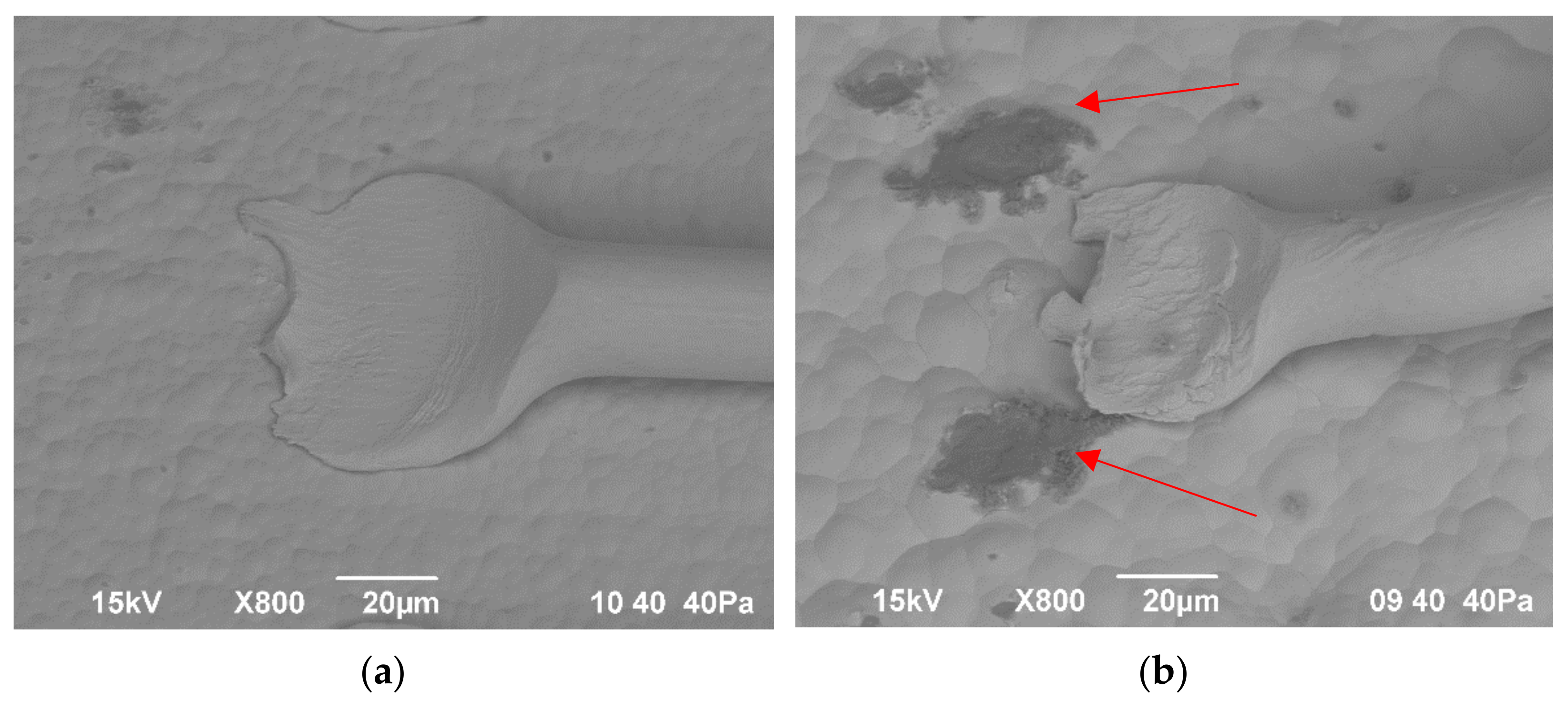

3.5. Improving Bondability by Means of Stitch-on-Ball Method

4. Discussion

5. Summary

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bogatin, E. Roadmaps of Packaging Technology; Addie Rose Press: Longmont, CO, USA, 2018. [Google Scholar]

- Tummala, R.R. Fundamentals of Microsystems Packaging, 1st ed.; McGraw-Hill Education: New York, NY, USA, 2001. [Google Scholar]

- Hall, E.; Lyons, A.M.; Weld, J.D. Gold wire bonding onto flexible polymeric substrates. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1996, 19, 12–17. [Google Scholar] [CrossRef]

- Cullen, D.; Kline, B.; Moderhock, G.; Gatewood, L. Effects of surface finish on high frequency signal loss using various substrate materials. CIRCUITREE-CAMPBELL 2001, 14, 80. [Google Scholar]

- Franke, J. Räumliche Elektronische Baugruppen (3D-MID)—Werkstoffe, Herstellung, Montage und Anwendungen für Spritzgegossene Schaltungsträger, 1st ed.; Carl Hanser Verlag: Munich, Germany, 2013. [Google Scholar]

- Geneiß, V.; Lüke, T.; Hedayat, C.; Wolf, M.; Janek, J.; Meißner, T.; Barth, M.; Eberhardt, W.; Zimmermann, A.; Otto, T. Impedance-Controlled Design and Connection Technology for Micromounting and Hybrid Integration of High-Frequency and Mixed-Signal Systems with MID Technology. In Proceedings of the 2018 Smart Systems Integration, Dresden, Germany, 11–12 April 2018. [Google Scholar]

- Friedrich, A.; Fengler, M.; Geck, B. LDS Molded Interconnect Devices Fit for mmWave. Microw. J. 2016, 59, 116–128. [Google Scholar]

- Buckmüller, P.; Eberhardt, W.; Kessler, U.; Willeck, H.; Kück, H. Aluminium wedge-wedge wire bonding on thermoplastic substrates made by LPKF-LDS® technology. In Proceedings of the 3rd Electronics System Integration Technology Conference ESTC, Berlin, Germany, 13–16 September 2010; pp. 1–5. [Google Scholar]

- Kanthamneni, A.; Brose, A.; Majcherek, S.; Brinkhues, S.; Aman, A.; Schmidt, B. Characterization of Ultrasonic Wire Bonding for LDS MID Prototyping. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 1703–1710. [Google Scholar] [CrossRef]

- Scholz, U. Untersuchungen zur Eignung des Ultraschallbondens für Die Chipmontage auf MID-Substraten. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2003. [Google Scholar]

- Lai, Z.; Liu, J. The Nordic Electronics Packaging Guideline. Microelectron. Int. 2000, 17. [Google Scholar] [CrossRef]

- Kologe, J. High Reliability Wire Bond Technique for MIDs. Available online: https://www.3d-mid.de/wp-content/uploads/2019/10/Kologe_J._-_High_Reliability_Wire_Bond_Technique_for_MIDs.pdf (accessed on 10 November 2021).

- Wu, Y.; Long, Z.; Han, L.; Zhong, J. Temperature effect in thermosonic wire bonding. Trans. Nonferrous Met. Soc. China 2006, 16, 618–622. [Google Scholar] [CrossRef]

- Liang, Z.N.; Kuper, F.G.; Chen, M.S. A concept to relate wire bonding parameters to bondability and ball bond reliability. Micro-Electron. J. 1998, 38, 1278–1291. [Google Scholar] [CrossRef]

- Charles, H.K. Advanced Wire Bonding Technology: Materials, Methods, and Testing. In Materials for Advanced Packaging; Lu, D., Wong, C.P., Eds.; Springer: New York, NY, USA, 2017. [Google Scholar]

- Test Procedures for Wire Bonded Joints; Technical Bulletin DVS 2811; DVS Media GmbH: Düsseldorf, Germany, 2017.

- Cosemi—Wire-Bonding-Guidelines; Application Note AN1002; Cosemi: Irvine, CA, USA, 2016.

- Sedlmair, J.; Nacke, U. Technische Notiz 2015/02; F&K Delvotec Bondtechnik GmbH: Ottobrunn, Germany, 2015; Available online: https://www.fkdelvotec.com/fileadmin/media_fuk/dokumente/160809D_TN_15_01_Frequenz.pdf (accessed on 10 November 2021).

| Identification | Substrate Material | Metallization | Suitability (3D/HF) |

|---|---|---|---|

| FR4-Galv. NiAu | FR4 | NiAu | - |

| FR4-NiAu | FR4 | NiAu | - |

| FR4-PdAu | FR4 | PdAu | - |

| Thermoset-NiAu | Rogers RO4350b | NiAu | HF |

| Thermoset-PdAu | Rogers RO4350b | PdAu | HF |

| PTFE-NiAu | TSM-DS3 | NiAu | HF |

| PTFE-PdAu | TSM-DS3 | PdAu | HF |

| LCP1-NiAu | Tecacomp LCP LDS black 4107 | Autocatalytic NiAu | 3D/HF |

| LCP2-NiAu | Vectra E840i LDS | Autocatalytic NiAu | 3D/HF |

| PEEK-NiAu | Tecacomp PEEK LDS black 1047045 | Autocatalytic NiAu | 3D/HF |

| Bonding Parameter | Ball | Wedge |

|---|---|---|

| Ultrasonic Time—UT | 80 ms | 80 ms |

| Ultrasonic Power—UP | 120 digits | 120 digits |

| Bond Force—BF | 25 cN | 15 cN |

| Temperature of Bond surface | 140 °C | 140 °C |

| Substrate | SA in µm | SQ in µm | SZ in µm | RA in µm | RQ in µm | RZ in µm |

|---|---|---|---|---|---|---|

| FR4-Galv. NiAu | 0.48 ± 0.1 | 0.58 ± 0.11 | 6.74 ± 2.64 | 0.27 ± 0.04 | 0.34 ± 0.04 | 1.82 ± 0.32 |

| FR4-NiAu | 0.44 ± 0.05 | 0.55 ± 0.06 | 6.89 ± 1.8 | 0.30 ± 0.06 | 0.39 ± 0.13 | 2.22 ± 1.07 |

| FR4-PdAu | 0.41 ± 0.04 | 0.52 ± 0.04 | 6.79 ± 3.15 | 0.25 ± 0.03 | 0.32 ± 0.03 | 1.65 ± 0.16 |

| Thermoset-NiAu | 0.31 ± 0.02 | 0.42 ± 0.02 | 8.23 ± 4.76 | 0.25 ± 0.04 | 0.31 ± 0.05 | 1.68 ± 0.20 |

| Thermoset-PdAu | 0.34 ± 0.02 | 0.45 ± 0.03 | 7.70 ± 3.17 | 0.28 ± 0.06 | 0.35 ± 0.08 | 1.93 ± 0.43 |

| PTFE-NiAu | 0.60 ± 0.06 | 0.76 ± 0.08 | 9.37 ± 2.97 | 0.46 ± 0.07 | 0.59 ± 0.09 | 3.37 ± 0.75 |

| PTFE-PdAu | 0.69 ± 0.05 | 0.87 ± 0.06 | 10.36 ± 2.22 | 0.53 ± 0.06 | 0.70 ± 0.17 | 4.10 ± 1.81 |

| LCP1-NiAu | 2.38 ± 0.15 | 3.35 ± 0.19 | 70.15 ± 21.97 | 1.94 ± 0.54 | 2.50 ± 0.63 | 12.90 ± 2.30 |

| LCP2-NiAu | 4.27 ± 0.21 | 5.63 ± 0.27 | 60.42 ± 6.30 | 3.96 ± 0.71 | 5.10 ± 0.93 | 25.03 ± 4.78 |

| PEEK-NiAu | 1.38 ± 0.34 | 2.23 ± 1.27 | 47.15 ± 19.10 | 1.12 ± 0.23 | 1.51 ± 0.35 | 8.31 ± 2.11 |

| Substrate | FR4 Galv. NiAu | FR4 NiAu1 | FR4 PdAu | Thermoset NiAu | Thermoset PdAu | PTFE NiAu | PTFE PdAu | LCP 1 NiAu | LCP 2 NiAu | PEEK NiAu |

|---|---|---|---|---|---|---|---|---|---|---|

| Emissivity ε | 0.069 | 0.103 | 0.100 | 0.106 | 0.104 | 0.095 | 0.095 | 0.056 | 0.060 | 0.062 |

| ε-St.Dev.-R6 | 0.013 | 0.009 | 0.008 | 0.010 | 0.008 | 0.007 | 0.004 | 0.001 | 0.002 | 0.003 |

| Calibration T of Heating Plate Temperature/°C | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 | 145 |

| Adapted bonding T of HP | 180 °C | 178 | 171 | 170 | 170 | 158 | 162 | 161 | 160 | 158 |

| Substrate | Sa in µm | Sz in µm | Ra in µm | Rq in µm | Rz in µm | Pull Mean in mN | Lift-Offs |

|---|---|---|---|---|---|---|---|

| LCP1 | 2.38 ± 0.15 | 70.15 ± 21.97 | 1.94 ± 0.54 | 2.50 ± 0.63 | 12.90 ± 2.3 | 41.7 ± 9.8 | 321 |

| LCP2 | 4.27 ± 0.21 | 60.42 ± 6.3 | 3.96 ± 0.71 | 5.10 ± 0.93 | 25.03 ± 4.78 | 59.8 ± 16.2 | 148 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guenther, T.; Werum, K.; Müller, E.; Wolf, M.; Zimmermann, A. Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications. J. Manuf. Mater. Process. 2022, 6, 9. https://doi.org/10.3390/jmmp6010009

Guenther T, Werum K, Müller E, Wolf M, Zimmermann A. Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications. Journal of Manufacturing and Materials Processing. 2022; 6(1):9. https://doi.org/10.3390/jmmp6010009

Chicago/Turabian StyleGuenther, Thomas, Kai Werum, Ernst Müller, Marius Wolf, and André Zimmermann. 2022. "Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications" Journal of Manufacturing and Materials Processing 6, no. 1: 9. https://doi.org/10.3390/jmmp6010009

APA StyleGuenther, T., Werum, K., Müller, E., Wolf, M., & Zimmermann, A. (2022). Characterization of Wire-Bonding on LDS Materials and HF-PCBs for High-Frequency Applications. Journal of Manufacturing and Materials Processing, 6(1), 9. https://doi.org/10.3390/jmmp6010009