Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges

Abstract

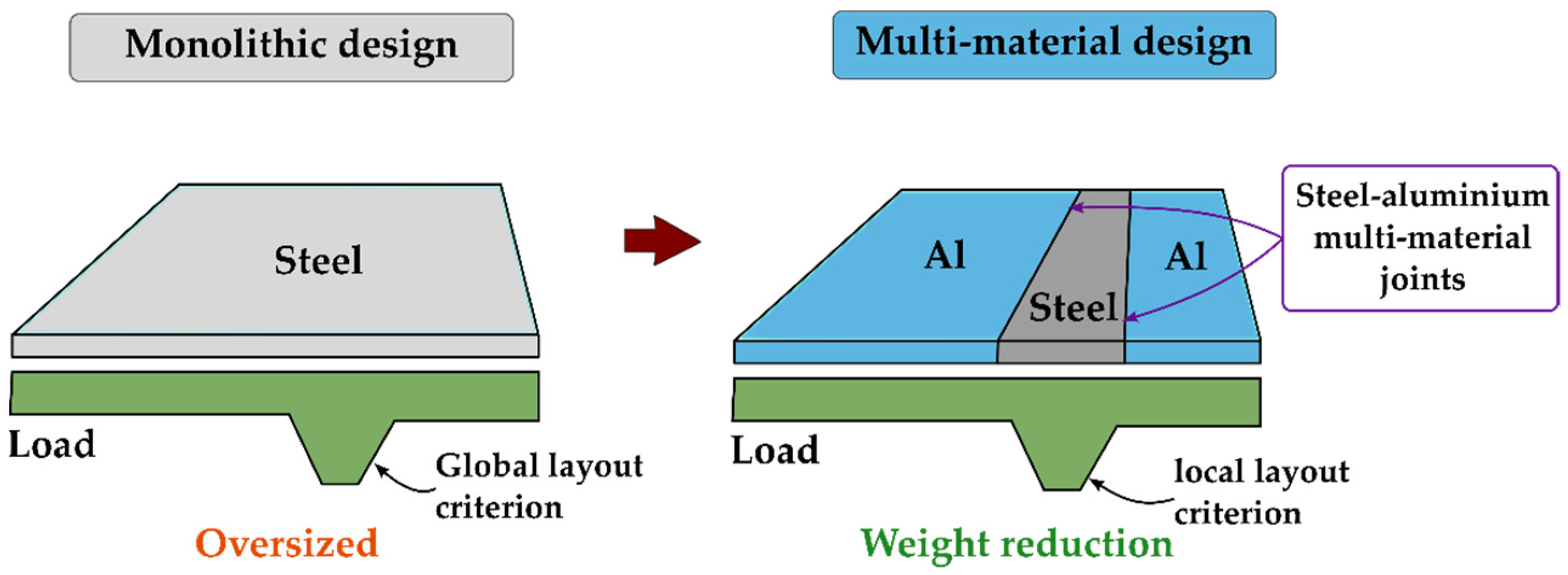

1. Introduction

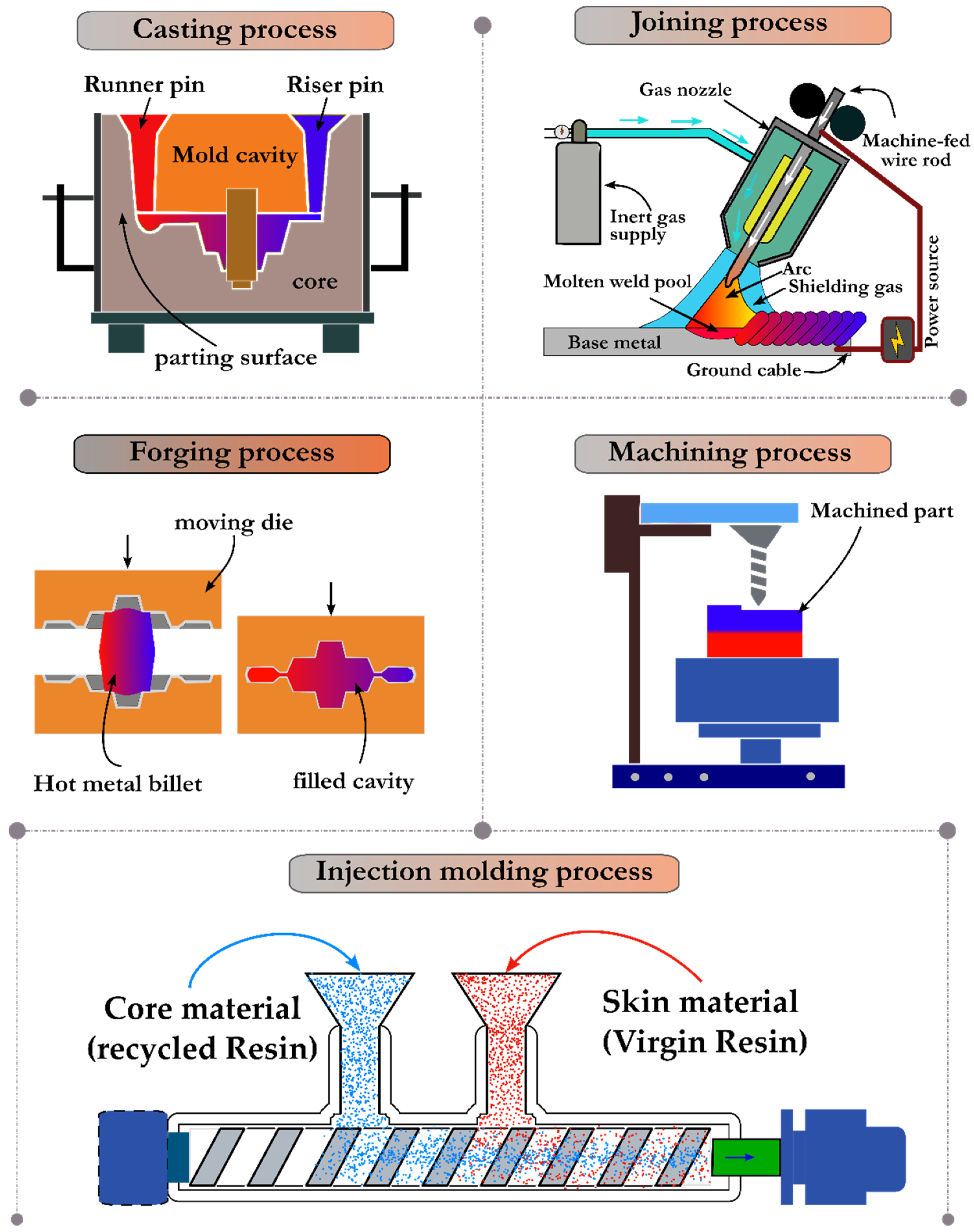

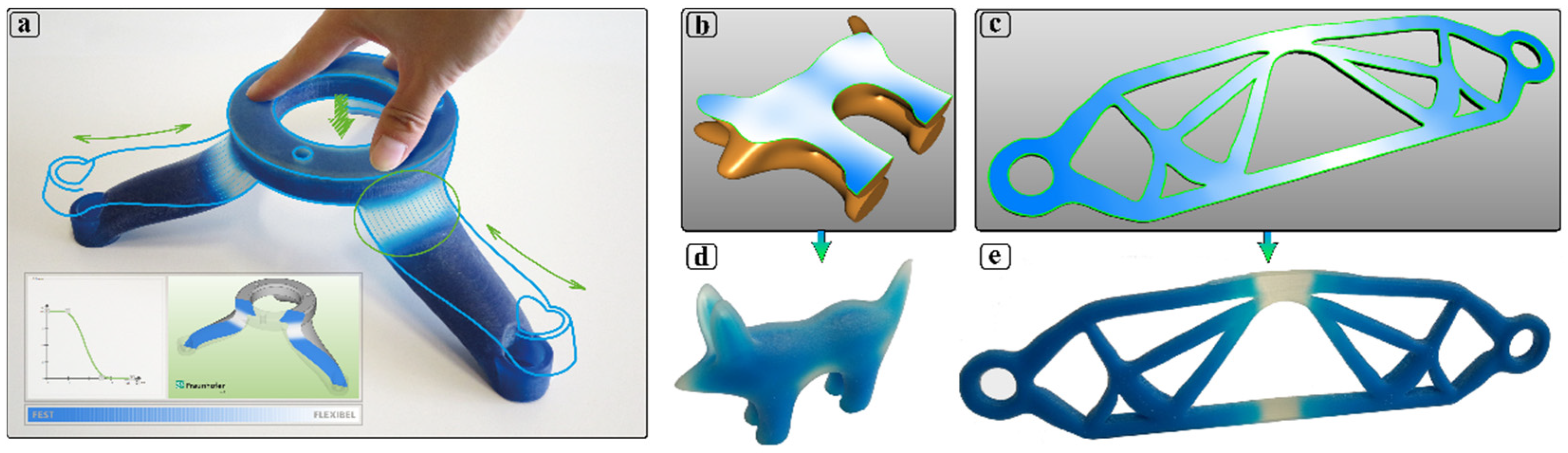

2. Conventional Methods of Fabricating Multi-Material Parts

2.1. Casting Process

2.2. Joining Process

2.3. Forging Process

2.4. Machining Process

2.5. Limitations of Conventional Manufacturing of Fabricating Multi-Material Parts

3. Current Multi-Material Additive Manufacturing Processes

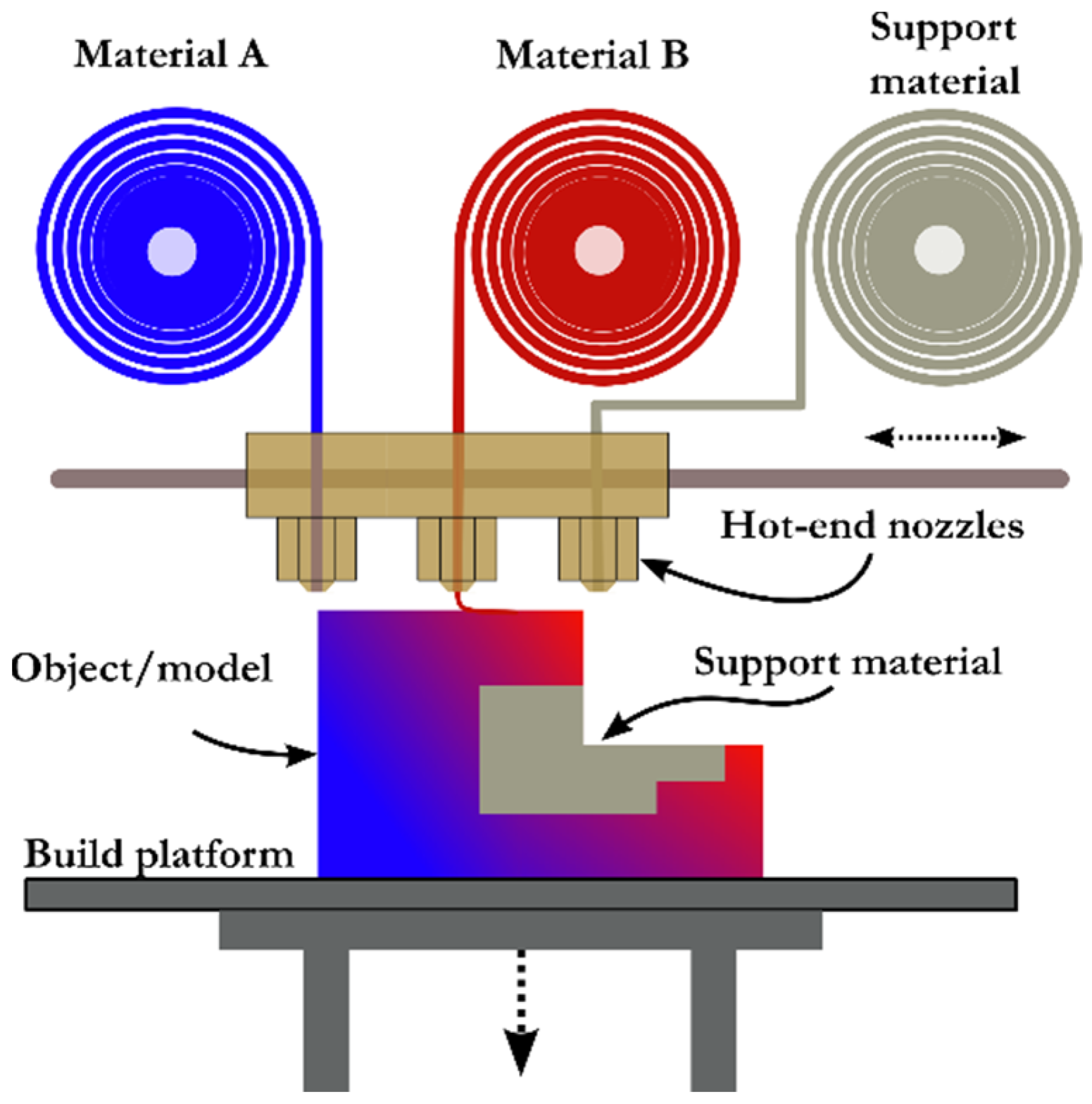

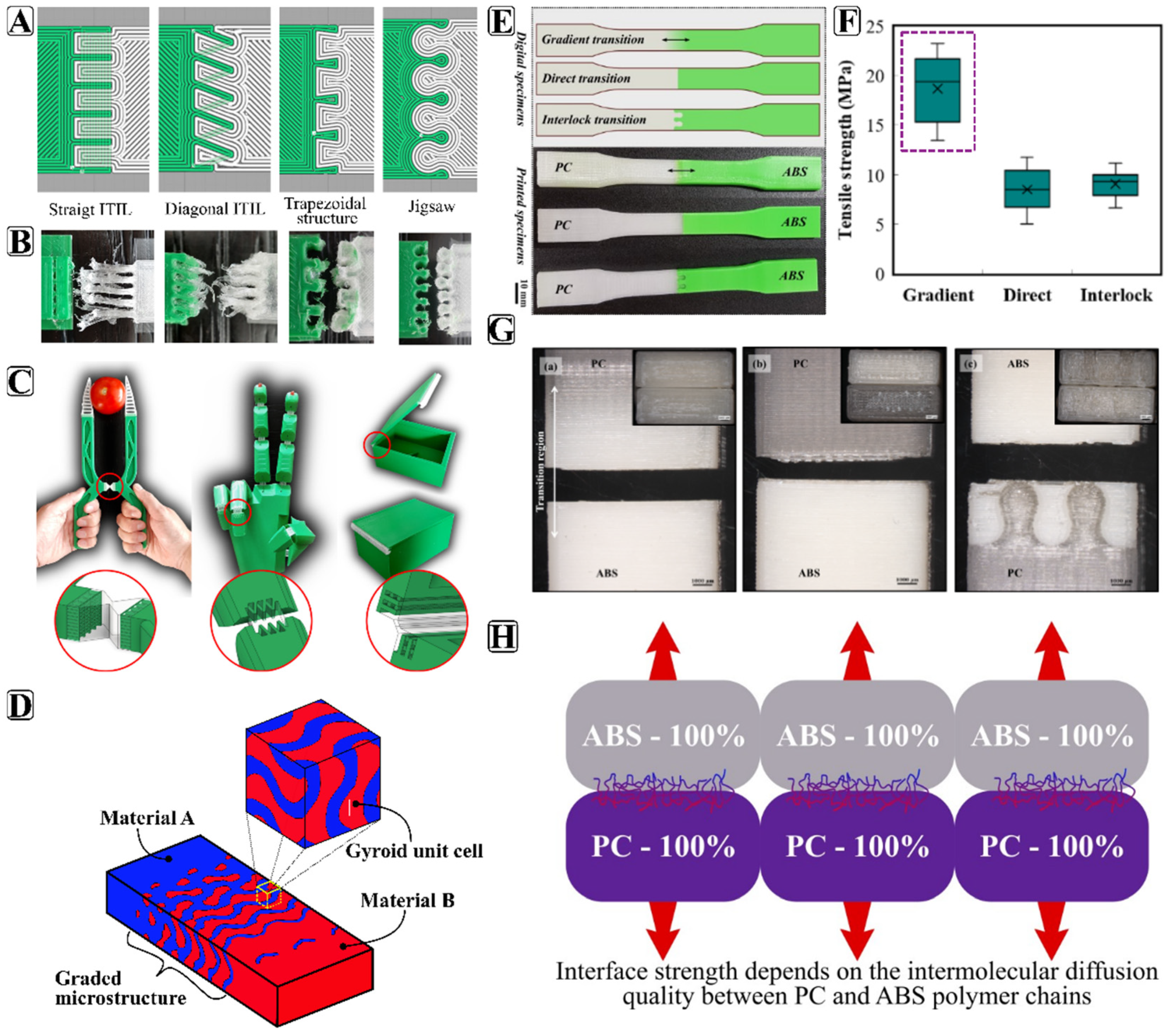

3.1. Material Extrusion (ME)

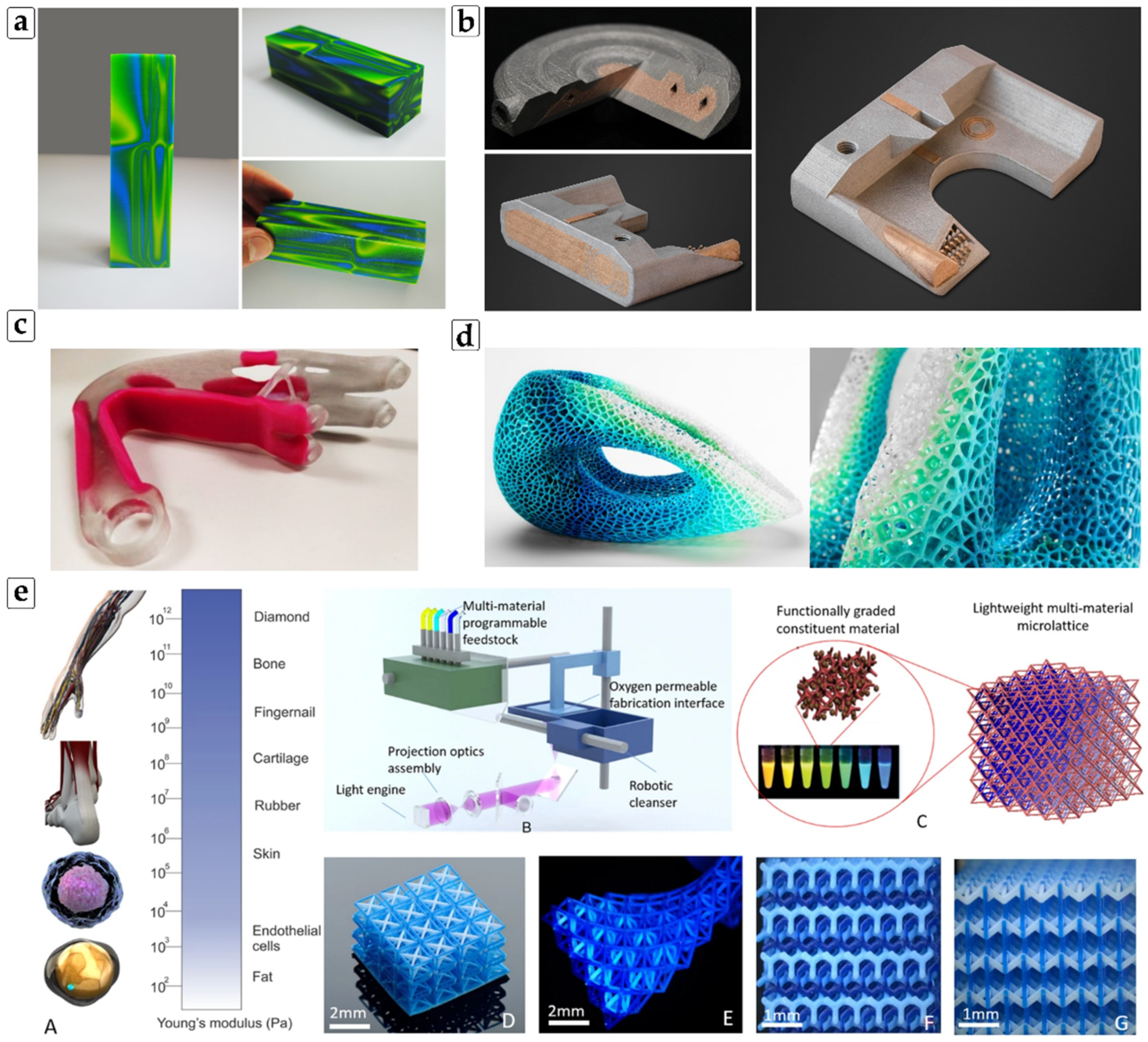

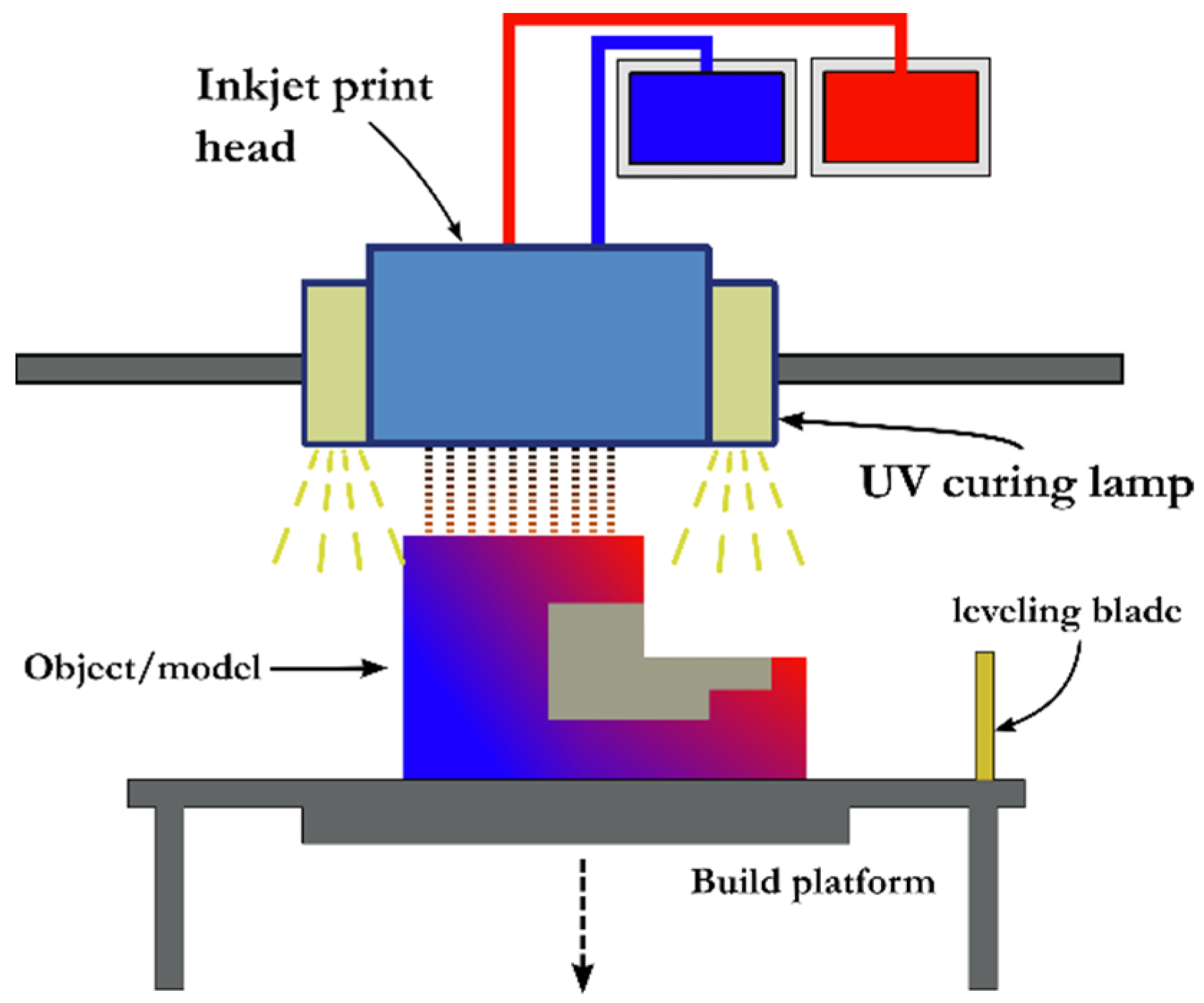

3.2. Material Jetting (MJ)

3.3. Direct Ink Writing (DIW)

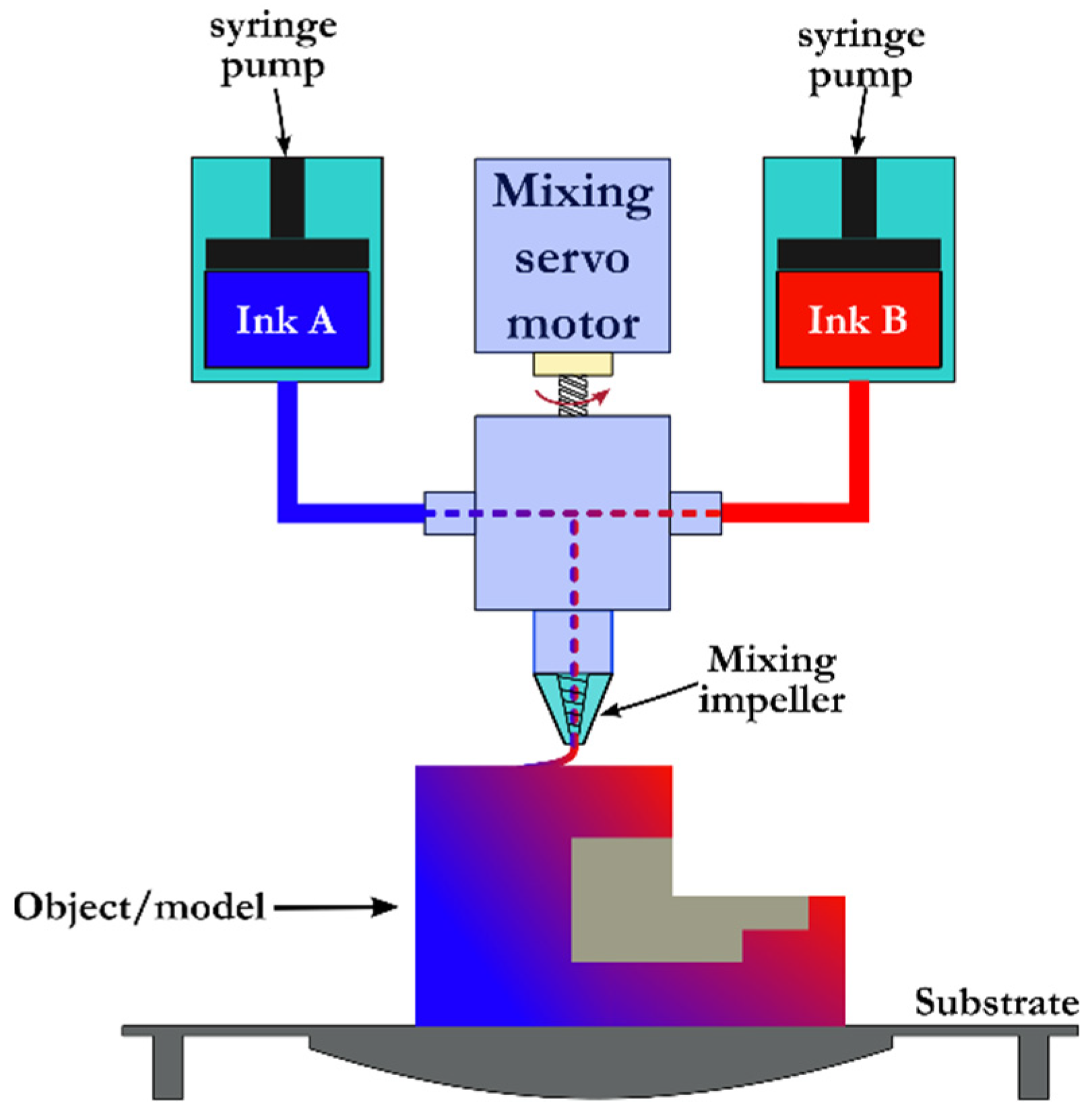

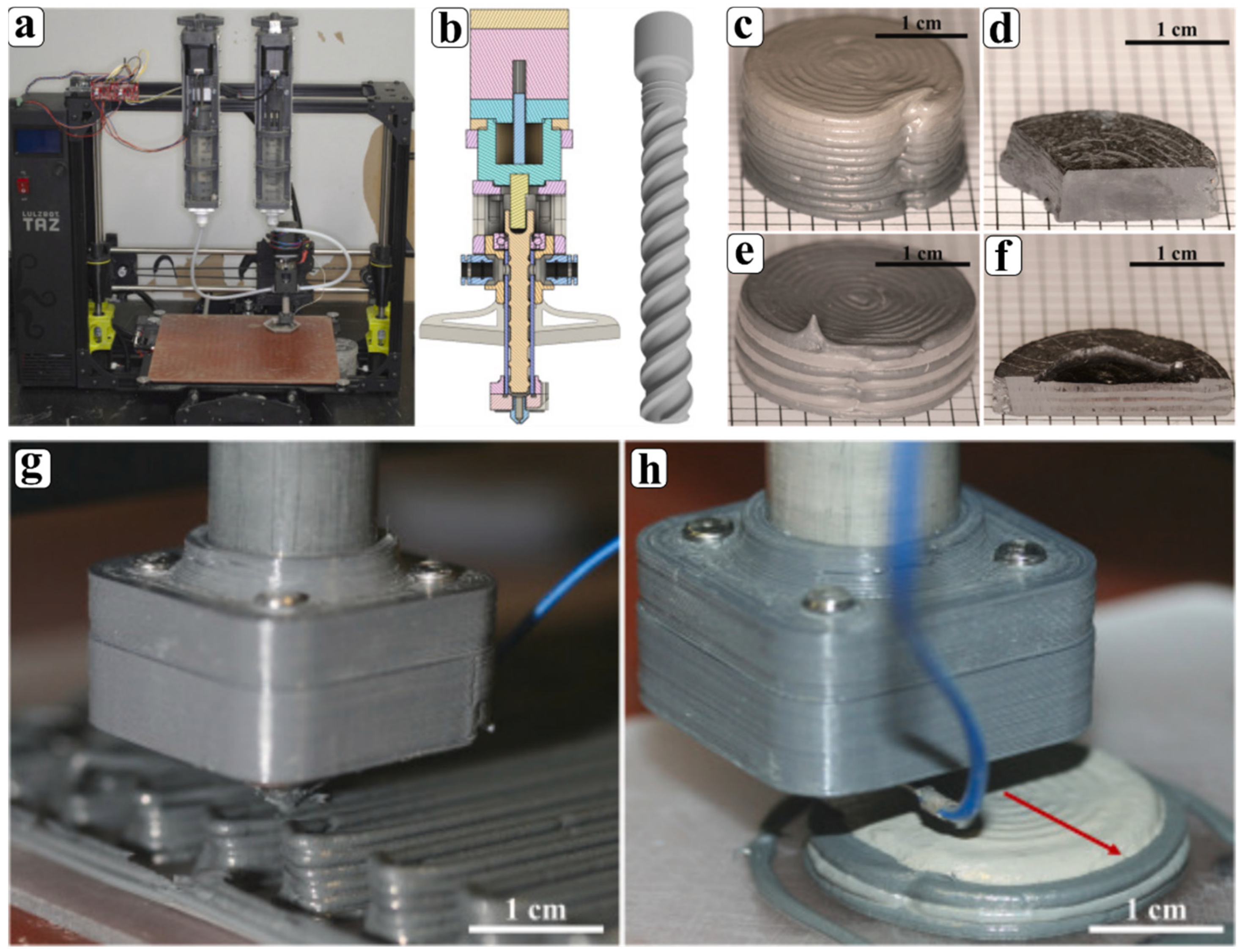

3.4. Vat Photopolimerization (VAT)

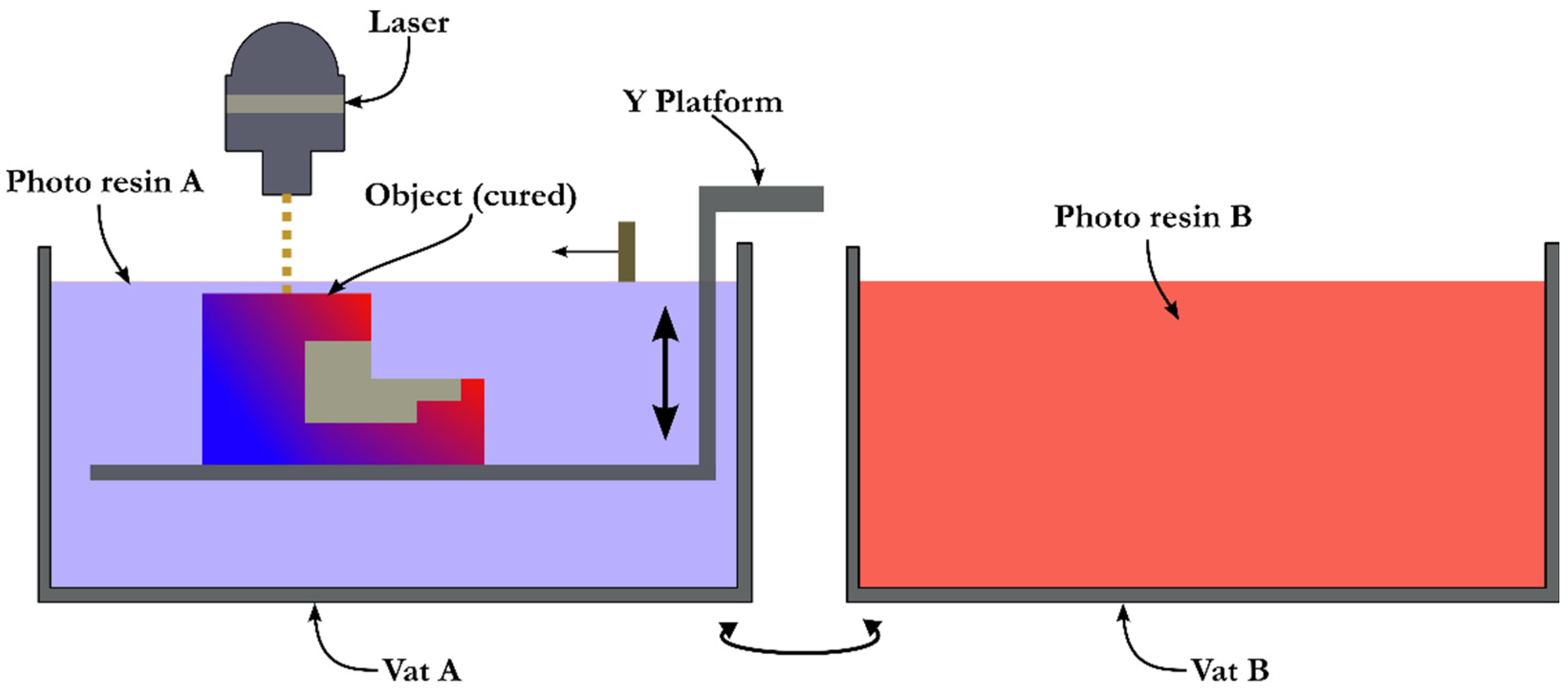

3.5. Direct Energy Deposition (DED)

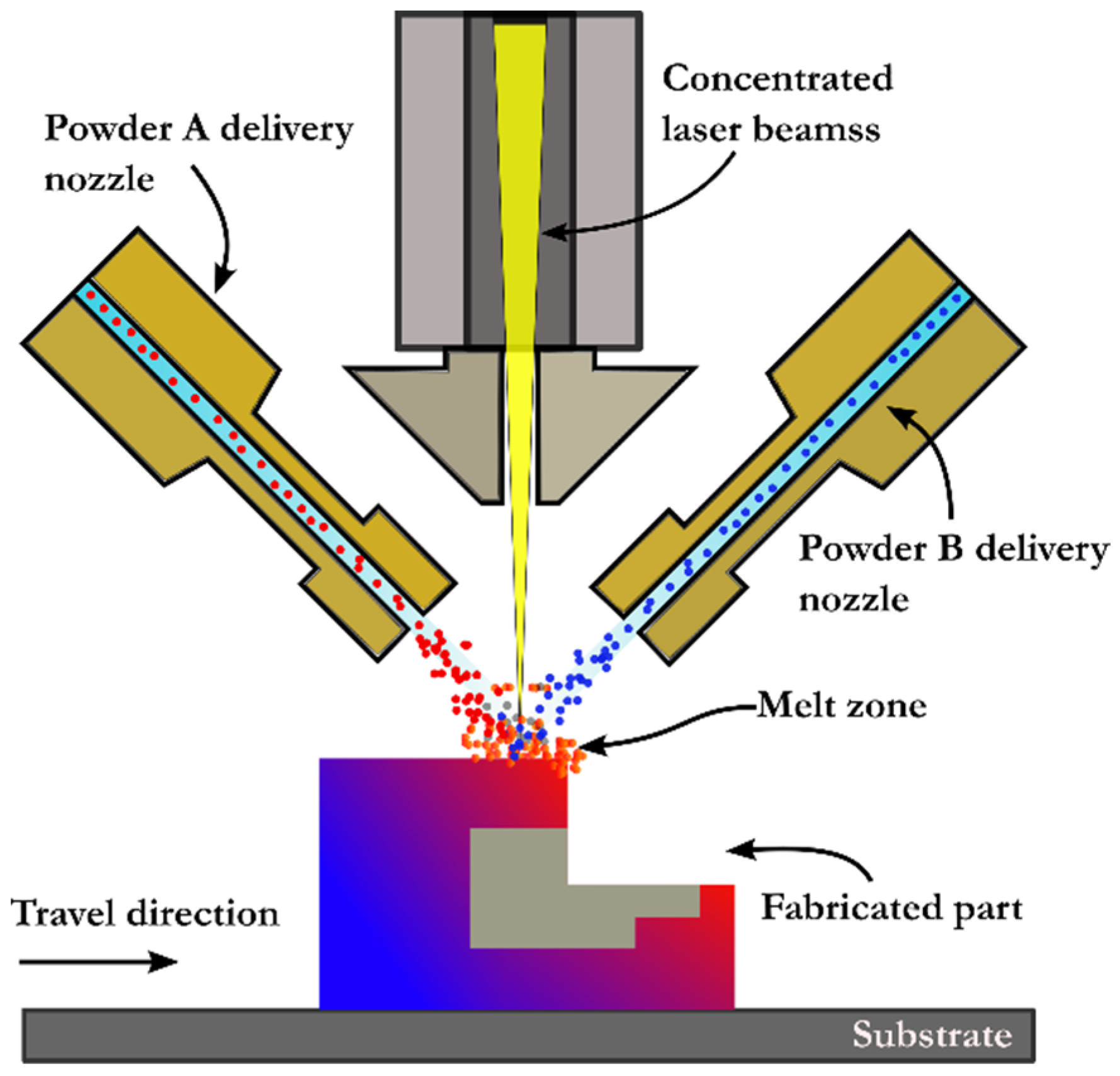

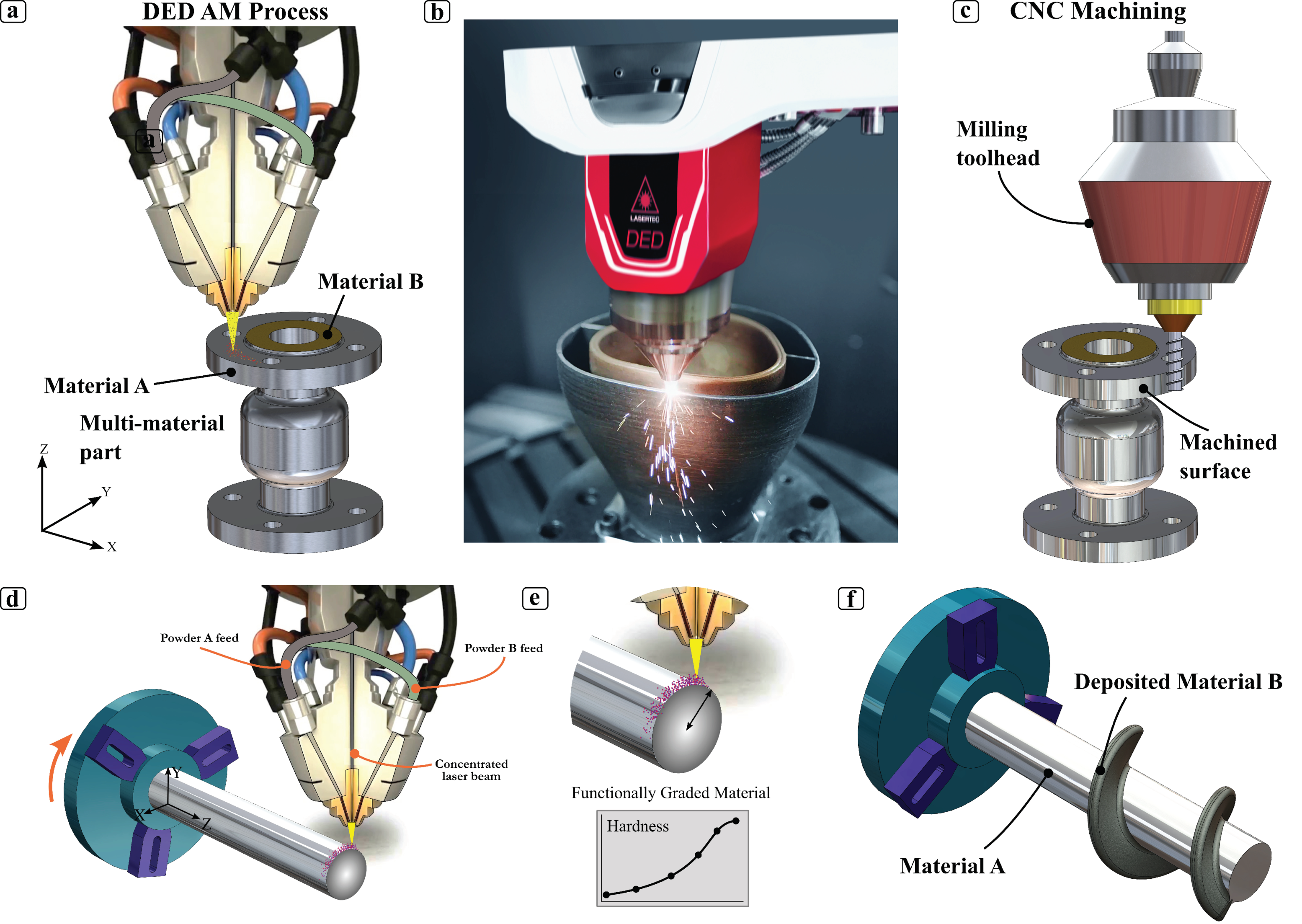

3.6. Hybrid Additive Manufacturing

3.7. Functionally Graded Additive Manufacturing (FGAM)

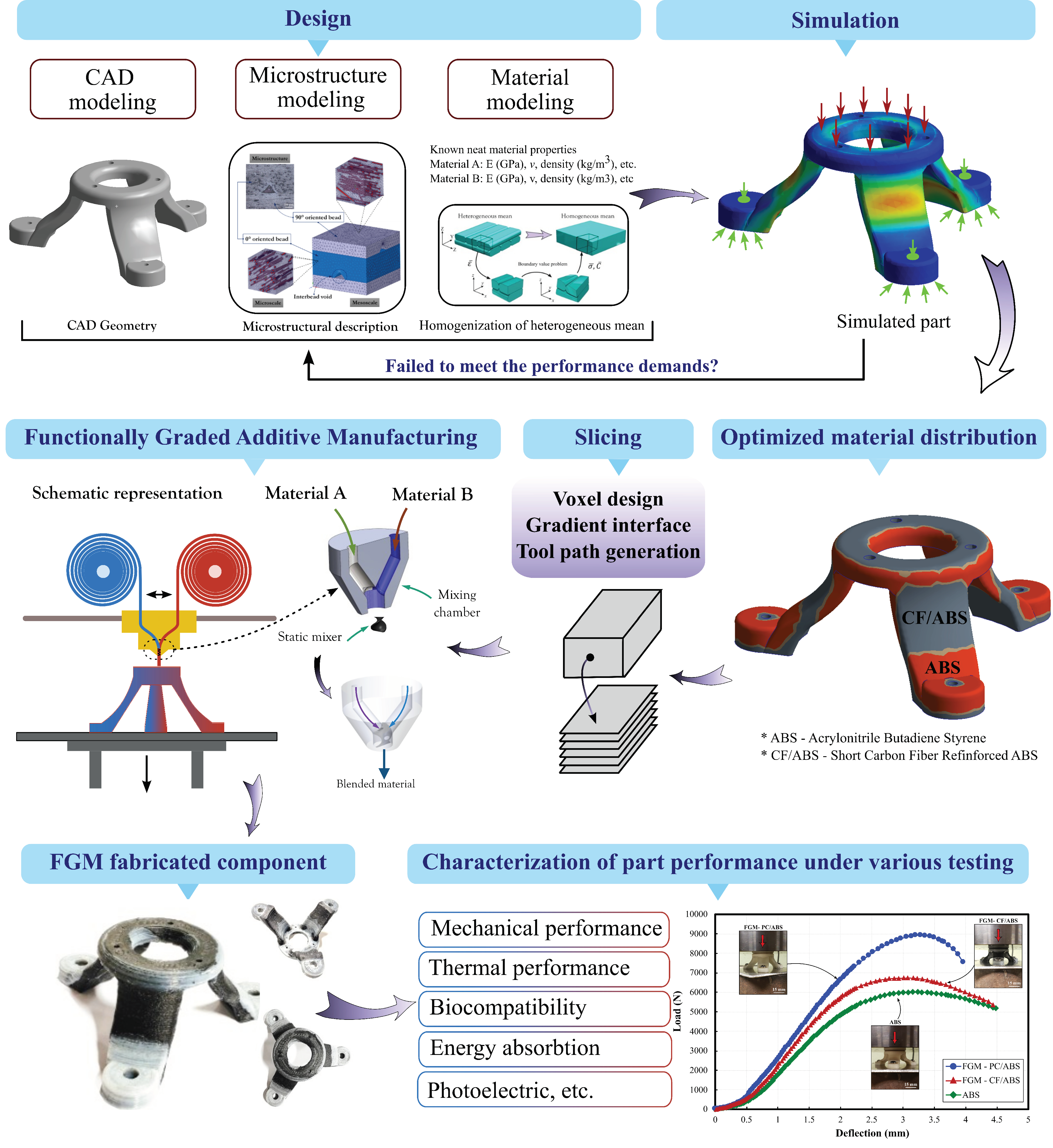

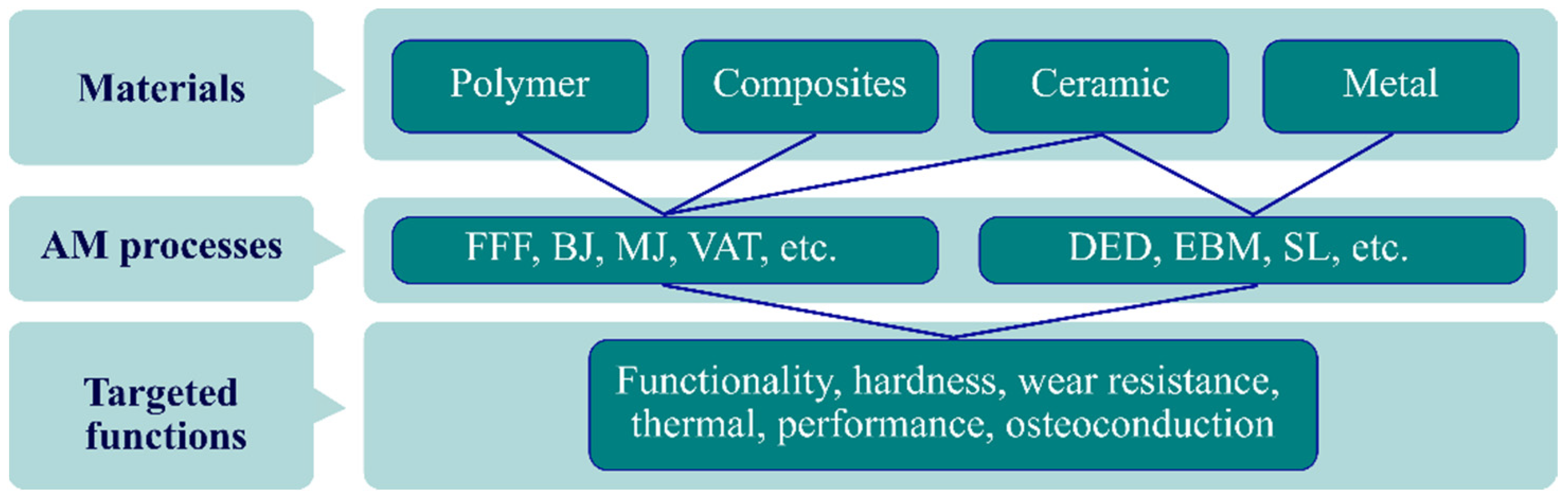

4. Materials used to Fabricate Multi-Material Parts with AM Technologies

4.1. Thermoplastic Polymers and Composites

4.2. Metal–Ceramic Materials

4.3. Metals and Alloys

5. Applications of MMAM

6. Critical Issues and Challenges Associated with MMAM

7. Future Trends

7.1. Improving Software Capabilities

7.2. Thermo-Mechanical Characterization of Material Interfaces

7.3. Incorporating Big Area Additive Manufacturing (BAAM) into MMAM

7.4. New Extruder Designs for Better Material Mixing for ME Process

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fidan, I.; Imeri, A.; Gupta, A.; Hasanov, S.; Nasirov, A.; Elliott, A.; Alifui-Segbaya, F.; Nanami, N. The trends and challenges of fiber reinforced additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 1801–1818. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Buchanan, C.; Matilainen, V.P.; Salminen, A.; Gardner, L. Structural performance of additive manufactured metallic material and cross-sections. J. Constr. Steel Res. 2017, 136, 35–48. [Google Scholar] [CrossRef]

- Ford, S.L.N. Additive Manufacturing Technology: Potential Implications for US Manufacturing Competitiveness. J. Int’l Com. Econ. 2014, 6, 40. [Google Scholar]

- Alifui-Segbaya, F. Biomedical photopolymers in 3D printing. Rapid Prototyp. J. 2019, 26, 437–444. [Google Scholar] [CrossRef]

- Xu, Z.; Ha, C.S.; Kadam, R.; Lindahl, J.; Kim, S.; Wu, H.F.; Kunc, V.; Zheng, X. Additive manufacturing of two-phase lightweight, stiff and high damping carbon fiber reinforced polymer microlattices. Addit. Manuf. 2020, 32, 101106. [Google Scholar] [CrossRef]

- Alifui-Segbaya, F.; Bowman, J.; White, A.R.; George, R.; Fidan, I.; Love, R.M. Chemical characterization of additively manufactured methacrylates for dental devices. Addit. Manuf. 2020, 31, 100944. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-material additive manufacturing of sustainable innovative materials and structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J. Manuf. Process. 2020, 58, 923–935. [Google Scholar] [CrossRef]

- Putra, N.E.; Mirzaali, M.J.; Apachitei, I.; Zhou, J.; Zadpoor, A.A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20. [Google Scholar] [CrossRef]

- Guessasma, S.; Nouri, H.; Roger, F. Microstructural and mechanical implications of microscaled assembly in droplet-based multi-material additive manufacturing. Polymers 2017, 9, 372. [Google Scholar] [CrossRef]

- Mirzaali, M.J.; de la Nava, A.H.; Gunashekar, D.; Nouri-Goushki, M.; Doubrovski, E.L.; Zadpoor, A.A. Fracture behavior of bio-inspired functionally graded soft-hard composites made by multi-material 3D printing: The case of colinear cracks. Materials 2019, 12, 2735. [Google Scholar] [CrossRef]

- Sheydaeian, E. Systems, Materials, and Methodologies for Multi-Material Hybrid Additive Manufacturing Functionally Graded Structures. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, October 2017. [Google Scholar]

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple material additive manufacturing - Part 1: A review: This review paper covers a decade of research on multiple material additive manufacturing technologies which can produce complex geometry parts with different materials. Virtual Phys. Prototyp. 2013, 8, 19–50. [Google Scholar] [CrossRef]

- Toursangsaraki, M. A Review of Multi-Material and Composite Parts Production by Modified Additive Manufacturing Methods. arXiv 2018, arXiv:1808.01861. [Google Scholar]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Ahankari, S.S.; Kar, K.K. Functionally graded composites: Processing and applications. In Composite Materials: Processing, Applications, Characterizations; Springer: Berlin/Heidelberg, Germany, 2016; pp. 119–168. ISBN 9783662495148. [Google Scholar]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Ahsan, M.R.U.; Tanvir, A.N.M.; Ross, T.; Elsawy, A.; Oh, M.S.; Kim, D.B. Fabrication of bimetallic additively manufactured structure (BAMS) of low carbon steel and 316L austenitic stainless steel with wire + arc additive manufacturing. Rapid Prototyp. J. 2019, 26, 519–530. [Google Scholar] [CrossRef]

- Ahsan, M.R.U.; Tanvir, A.N.M.; Seo, G.J.; Bates, B.; Hawkins, W.; Lee, C.; Liaw, P.K.; Noakes, M.; Nycz, A.; Kim, D.B. Heat-treatment effects on a bimetallic additively-manufactured structure (BAMS) of the low-carbon steel and austenitic-stainless steel. Addit. Manuf. 2020, 32, 101036. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Laser metal deposition of functionally graded Ti6Al4V/TiC. Mater. Des. 2015, 84, 402–410. [Google Scholar] [CrossRef]

- Jeong, J.-S.; Shin, K.-H. Fabrication of Functionally Graded Materials Between P21 Tool Steel and Cu by Using Laser-Aided Layered Manufacturing. Trans. Korean Soc. Mech. Eng. A 2013, 37, 61–66. [Google Scholar] [CrossRef]

- Doubrovski, E.L.; Tsai, E.Y.; Dikovsky, D.; Geraedts, J.M.P.; Herr, H.; Oxman, N. Voxel-based fabrication through material property mapping: A design method for bitmap printing. CAD Comput. Aided Des. 2015, 60, 3–13. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 2019, 575, 330–335. [Google Scholar] [CrossRef]

- Kaweesa, D.V.; Meisel, N.A. Material Property Changes in Custom-Designed Digital Composite Structures Due to Voxel Size. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018; pp. 1499–1510. [Google Scholar]

- Ituarte, I.F.; Boddeti, N.; Hassani, V.; Dunn, M.L.; Rosen, D.W. Design and additive manufacture of functionally graded structures based on digital materials. Addit. Manuf. 2019, 30, 100839. [Google Scholar] [CrossRef]

- Garland, A.; Fadel, G. Design and Manufacturing Functionally Gradient Material Objects with an off the Shelf Three-Dimensional Printer: Challenges and Solutions. J. Mech. Des. Trans. ASME 2015, 137, 111407. [Google Scholar] [CrossRef]

- Brischetto, S.; Ferro, C.G.; Torre, R.; Maggiore, P. 3D FDM production and mechanical behavior of polymeric sandwich specimens embedding classical and honeycomb cores. Curved Layer. Struct. 2018, 5, 80–94. [Google Scholar] [CrossRef]

- Lopez, D.M.B.; Ahmad, R. Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef]

- Chueh, Y.-H.; Zhang, X.; Wei, C.; Sun, Z.; Li, L. Additive Manufacturing of Polymer-Metal/Ceramic Functionally Graded Composite Components via Multiple Material Laser Powder Bed Fusion. J. Manuf. Sci. Eng. 2020, 142, 051003. [Google Scholar] [CrossRef]

- Chueh, Y.H.; Wei, C.; Zhang, X.; Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Addit. Manuf. 2020, 31, 100928. [Google Scholar] [CrossRef]

- Richards, D.; Abram, T.; Rennie, A. Designing Digital Materials with Volumetric Gradients. In Proceedings of the 15th Rapid Design, Prototyping & Manufacturing Conference (RDPM2017), Northumbria University, Newcastle, UK, 27–28 April 2017. [Google Scholar]

- Multi Material 3D Printing by Aerosint’s Selective Powder Deposition. Available online: https://aerosint.com/how-to-make-cheap-scalable-multi-material-3d-printing-a-reality/ (accessed on 5 November 2021).

- ParaMatters | Technology. Available online: https://paramatters.com/technology/ (accessed on 5 November 2021).

- Gallery of Synthesis Design + Architecture Utilizes Gradient 3-D Printing in “Durotaxis Chair”. Available online: https://www.archdaily.com/610939/synthesis-design-architecture-utilizes-gradient-3-d-printing-in-durotaxis-chair/550985aae58eceb0fa00003d-durotaxis_down_2-jpg?next_project=no (accessed on 17 November 2021).

- Chen, D.; Zheng, X. Multi-material Additive Manufacturing of Metamaterials with Giant, Tailorable Negative Poisson’s Ratios. Sci. Rep. 2018, 8, 9139. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Chastel, Y.; Passemard, L. Joining Technologies for Future Automobile Multi-material Modules. Procedia Eng. 2014, 81, 2104–2110. [Google Scholar] [CrossRef]

- Smithy Secrets: An Intro to Forging Methods | Metal Casting Resources. Available online: https://www.reliance-foundry.com/blog/forging (accessed on 2 November 2021).

- Black, J.T.; Kohser, R.A. DeGarmo’s Materials and Processes in Manufacturing, 13th ed.; Black, J.T., Kohser, R.A., Eds.; Willey: Hoboken, NJ, USA, 2019; ISBN 978-1-119-49282-5. [Google Scholar]

- Priyadarshi, A.K.; Gupta, S.K.; Gouker, R.; Krebs, F.; Shroeder, M.; Warth, S. Manufacturing multi-material articulated plastic products using in-mold assembly. Int. J. Adv. Manuf. Technol. 2007, 32, 350–365. [Google Scholar] [CrossRef][Green Version]

- Gouker, R.M.; Gupta, S.K.; Bruck, H.A.; Holzschuh, T. Manufacturing of multi-material compliant mechanisms using multi-material molding. Int. J. Adv. Manuf. Technol. 2006, 30, 1049–1075. [Google Scholar] [CrossRef]

- Meschut, G.; Hahn, O.; Janzen, V.; Olfermann, T. Innovative joining technologies for multi-material structures. Weld. World 2014, 58, 65–75. [Google Scholar] [CrossRef]

- Friction Element Welding Innovations for Hybrid Body Parts Dr. Uwe Alber (AUDI AG) April, 19th 2012. Available online: https://businessdocbox.com/Metals/70595739-Friction-element-welding-innovations-for-hybrid-body-parts-dr-uwe-alber-audi-ag-april-19-th-2012.html (accessed on 2 November 2021).

- Wohletz, S.; Groche, P. Temperature Influence on Bond Formation in Multi-Material Joining by Forging. Procedia Eng. 2014, 81, 2000–2005. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Chugreev, A.; Matthias, T.; Poll, G.; Pape, F.; Coors, T.; Hassel, T.; Maier, H.J.; Mildebrath, M. Manufacturing and Evaluation of Multi-Material Axial-Bearing Washers by Tailored Forming. Metals 2019, 9, 232. [Google Scholar] [CrossRef]

- Understanding The History of Machining Tools and Their Uses. Available online: https://thewerkscandc.com/understanding-the-history-of-machining-tools-and-their-uses/ (accessed on 2 November 2021).

- Fidan, I. Benchmarking Studies for 3D Printing Process. In Proceedings of the SME’s First Annual Manufacturing Technology Summit, Dearborn, MI, USA, 4 May 2004. [Google Scholar]

- Numerical Control—Wikipedia. Available online: https://en.wikipedia.org/wiki/Numerical_control (accessed on 2 November 2021).

- Halbig, M.C.; Singh, M.; Singh, M. Additive Manufacturing of Multi-Material Systems for Aerospace Applications. Available online: https://ntrs.nasa.gov/citations/20190032205 (accessed on 2 November 2021).

- Nasirov, A.; Hasanov, S.; Fidan, I.; Technology, E. Prediction of Mechanical Properties of Fused Deposition Modeling Made Parts using Multiscale Modeling and Classical Laminate Theory. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; pp. 1373–1382. [Google Scholar]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Fidan, I.; Hasanov, S.; Nasirov, A. Processing, mechanical characterization, and micrography of 3D-printed short carbon fiber reinforced polycarbonate polymer matrix composite material. Int. J. Adv. Manuf. Technol. 2020, 107, 3185–3205. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Fidan, I.; Zhang, Z. Homogenized modeling approach for effective property prediction of 3D-printed short fibers reinforced polymer matrix composite material. Int. J. Adv. Manuf. Technol. 2021, 1–18. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Fidan, I. Processing and characterization of 3d-printed polymer matrix composites reinforced with discontinuous fibers. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; pp. 1054–1066. [Google Scholar]

- Hasanov, S.; Fidan, I. Additive Manufacturing of Magnetic Materials. MatEDU Resour. Cent. 2020. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Lu, H.; Fidan, I.; Tantawi, K.; Gupta, A.; Hasanov, S.; Zhang, Z.; Alifui-Segbaya, F.; Rennie, A. Mechanical and Thermal Analyses of Metal-PLA Components Fabricated by Metal Material Extrusion. Inventions 2020, 5, 44. [Google Scholar] [CrossRef]

- Hasanov, S. Manufacturing of Soft Magnets using the Fused Filament Fabrication Process. MatEDU Resour. Cent. 2021, 1–13. [Google Scholar] [CrossRef]

- Yin, J.; Lu, C.; Fu, J.; Huang, Y.; Zheng, Y. Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion. Mater. Des. 2018, 150, 104–112. [Google Scholar] [CrossRef]

- Sanders, E.D.; Aguiló, M.A.; Paulino, G.H. Multi-material continuum topology optimization with arbitrary volume and mass constraints. Comput. Methods Appl. Mech. Eng. 2018, 340, 798–823. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Asad, A.; Sameoto, D. Printing with mechanically interlocked extrudates using a custom bi-extruder for fused deposition modelling. Rapid Prototyp. J. 2018, 24, 921–934. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Christ, J.F. Printing polymer blends through in situ active mixing during fused filament fabrication. Addit. Manuf. 2020, 36, 101233. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Material Jetting (PolyJet) 3D Printing: Everything You Need to Know. Available online: https://3dsourced.com/guides/polyjet/ (accessed on 11 November 2020).

- Vu, I.Q.; Bass, L.B.; Williams, C.B.; Dillard, D.A. Characterizing the effect of print orientation on interface integrity of multi-material jetting additive manufacturing. Addit. Manuf. 2018, 22, 447–461. [Google Scholar] [CrossRef]

- Vu, I.; Bass, L.; Meisel, N.; Orler, B.; Williams, C.B.; Dillard, D.A. Characterization of mutli-material interfaces in polyjet additive manufacturing. In Proceedings of the 2015 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; pp. 959–982. [Google Scholar]

- Pugalendhi, A.; Ranganathan, R.; Ganesan, S. Impact of process parameters on mechanical behaviour in multi-material jetting. Mater. Today Proc. 2021, 46, 9139–9144. [Google Scholar] [CrossRef]

- The Complete Guide to Material Jetting (PolyJet) in 3D Printing—3D Natives. Available online: https://www.3dnatives.com/en/polyjet100420174/#! (accessed on 5 November 2021).

- Rocha, V.G.; Saiz, E.; Tirichenko, I.S.; García-Tuñón, E. Direct ink writing advances in multi-material structures for a sustainable future. J. Mater. Chem. A 2020, 8, 15646–15657. [Google Scholar] [CrossRef]

- Joung, D.; Truong, V.; Neitzke, C.C.; Guo, S.Z.; Walsh, P.J.; Monat, J.R.; Meng, F.; Park, S.H.; Dutton, J.R.; Parr, A.M.; et al. 3D Printed Stem-Cell Derived Neural Progenitors Generate Spinal Cord Scaffolds. Adv. Funct. Mater. 2018, 28, 1801850. [Google Scholar] [CrossRef]

- Kolesky, D.B.; Truby, R.L.; Gladman, A.S.; Busbee, T.A.; Homan, K.A.; Lewis, J.A. 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv. Mater. 2014, 26, 3124–3130. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Michael Cue, J.; Stefan, M.C.; Ravi Shankar, M.; et al. Molecularly-engineered, 4D-Printed liquid crystal elastomer actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Hyun Park, S.; Su, R.; Jeong, J.; Guo, S.-Z.; Qiu, K.; Joung, D.; Meng, F.; McAlpine, M.C.; Park, S.H.; Su, R.; et al. 3D printed polymer photodetectors. Adv. Mater. 2018, 30, 1803980. [Google Scholar] [CrossRef]

- Wei, T.-S.; Ahn, B.Y.; Grotto, J.; Lewis, J.A.; Lewis, A.; Wei, T.-S.; Ahn, B.Y.; Grotto, J.; Paulson, J.A. 3D printing of customized Li-ion batteries with thick electrodes. Adv. Mater. 2018, 30, 1703027. [Google Scholar] [CrossRef]

- Kokkinis, D.; Bouville, F.; Studart, A.R. 3D Printing of Materials with Tunable Failure via Bioinspired Mechanical Gradients. Adv. Mater. 2018, 30, 1705808. [Google Scholar] [CrossRef]

- Hardin, J.O.; Ober, T.J.; Valentine, A.D.; Lewis, J.A. Microfluidic printheads for multimaterial 3D printing of viscoelastic inks. Adv. Mater. 2015, 27, 3279–3284. [Google Scholar] [CrossRef]

- Pelz, J.S.; Ku, N.; Shoulders, W.T.; Meyers, M.A.; Vargas-Gonzalez, L.R. Multi-material additive manufacturing of functionally graded carbide ceramics via active, in-line mixing. Addit. Manuf. 2021, 37, 101647. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Gibson, I.; Rosen, D.; Stucker, B. Vat Photopolymerization Processes. In Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 63–106. [Google Scholar]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Chan, V.; Jeong, J.H.; Bajaj, P.; Collens, M.; Saif, T.; Kong, H.; Bashir, R. Multi-material bio-fabrication of hydrogel cantilevers and actuators with stereolithography. Lab Chip 2012, 12, 88–98. [Google Scholar] [CrossRef]

- Choi, J.W.; Kim, H.C.; Wicker, R. Multi-material stereolithography. J. Mater. Process. Technol. 2011, 211, 318–328. [Google Scholar] [CrossRef]

- Yan, J.; Masoudi, N.; Battiato, I.; Fadel, G. Optimization of Process Parameters in Laser Engineered Net Shaping (LENS) Deposition of Multi-Materials. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; p. V01AT02A034. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An overview of additive manufacturing of titanium components by directed energy deposition: Microstructure and mechanical properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Ke, D.; Vu, A.A.; Bandyopadhyay, A.; Bose, S. Compositionally graded doped hydroxyapatite coating on titanium using laser and plasma spray deposition for bone implants. Acta Biomater. 2019, 84, 414–423. [Google Scholar] [CrossRef]

- Fousová, M.; Vojtěch, D.; Kubásek, J.; Jablonská, E.; Fojt, J. Promising characteristics of gradient porosity Ti-6Al-4V alloy prepared by SLM process. J. Mech. Behav. Biomed. Mater. 2017, 69, 368–376. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.N.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 131, 112–120. [Google Scholar] [CrossRef]

- del Val, J.; Arias-González, F.; Barro, O.; Riveiro, A.; Comesaña, R.; Penide, J.; Lusquiños, F.; Bountinguiza, M.; Quintero, F.; Pou, J. Functionally graded 3D structures produced by laser cladding. Procedia Manuf. 2017, 13, 169–176. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid metal additive manufacturing: A state–of–the-art review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Lasertec 125: DMG Mori Releases New 3D Hybrid System for Maintaining & Repairing Parts. Available online: https://3dprint.com/260887/lasertec-125-dmg-mori-releases-new-3d-hybrid-system-maintaining-repairing-parts/ (accessed on 12 November 2021).

- Hybrid Metal Manufacturing—A Core Application for Optomec Additive Manufacturing Solutions. Available online: http://optomec.com/3d-printed-metals/lens-core-applications/hybrid-manufacturing/ (accessed on 19 November 2021).

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid additive and subtractive machine tools–Research and industrial developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E. Building a Conceptual Understanding of Functionally Graded Additive Manufacturing (FGAM) and Its Limitations. In Proceedings of the 15th Rapid Design, Prototyping & Manufacturing Conference (RDPM 2017), Newcastle, UK, 27–28 April 2017. [Google Scholar]

- Li, J.; Stachowski, M.; Zhang, Z. Application of responsive polymers in implantable medical devices and biosensors. In Switchable and Responsive Surfaces and Materials for Biomedical Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 259–298. ISBN 9780857097170. [Google Scholar]

- Hasanov, S. Numerical Modeling and Experimental Characterization of Functionally Fraded Materials Manufactured by the Fused Filament Fabrication Process. Ph.D. Thesis, Tennessee Technological University, Cookeville, TN, USA, 2021. [Google Scholar]

- Hasanov, S.; Gupta, A.; Alifui-Segbaya, F.; Fidan, I. Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Compos. Struct. 2021, 275, 114488. [Google Scholar] [CrossRef]

- Nasirov, A.; Gupta, A.; Hasanov, S.; Fidan, I. Three-scale asymptotic homogenization of short fiber reinforced additively manufactured polymer composites. Compos. Part B Eng. 2020, 202, 108269. [Google Scholar] [CrossRef]

- GraMMaCAD—Graded Multi-Material CAD. Available online: https://www.igd.fraunhofer.de/en/projects/grammacad-graded-multi-material-cad (accessed on 7 November 2021).

- Luu, T.H.; Altenhofen, C.; Ewald, T.; Stork, A.; Fellner, D. Efficient slicing of Catmull–Clark solids for 3D printed objects with functionally graded material. Comput. Graph. 2019, 82, 295–303. [Google Scholar] [CrossRef]

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, M. Multi-material 3D printed PLA/PA6-TiO2 composite matrix: Rheological, thermal, tensile, morphological and 4D capabilities. Adv. Mater. Process. Technol. 2021, 1–19. [Google Scholar] [CrossRef]

- PC-ABS: A Heat Resistant 3D Printing Material. Available online: https://www.stratasys.com/materials/search/pc-abs (accessed on 17 November 2020).

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Sa’ude, N.; Masood, S.H.; Nikzad, M.; Ibrahim, M. Dynamic Mechanical Properties of Copper-ABS Composites for FDM Feedstock. Int. J. Eng. Res. Appl. 2013, 3, 1257–1263. [Google Scholar]

- Rohde, S.; Cantrell, J.; Jerez, A.; Kroese, C.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Steinbach, D.; et al. Experimental Characterization of the Shear Properties of 3D–Printed ABS and Polycarbonate Parts. Exp. Mech. 2018, 58, 871–884. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Farina, I. On the 3D printing of recycled ABS, PLA and HIPS thermoplastics for structural applications. PSU Res. Rev. 2018, 2, 115–137. [Google Scholar] [CrossRef]

- Afshar, A.; Wood, R. Development of Weather-Resistant 3D Printed Structures by Multi-Material Additive Manufacturing. J. Compos. Sci. 2020, 4, 94. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Kravcov, A.; Grzelak, K.; Svoboda, P.; Szachogłuchowicz, I.; Franek, O.; Morozov, N.; Torzewski, J.; Kubeček, P. The Examination of Restrained Joints Created in the Process of Multi-Material FFF Additive Manufacturing Technology. Materials 2020, 13, 903. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.A.; Huang, J.-L.; Okle, P.; Paik, J.; Spolenak, R. Hinges for origami-inspired structures by multimaterial additive manufacturing. Mater. Des. 2020, 191, 108643. [Google Scholar] [CrossRef]

- Otepbergenov, T.; Smagulov, Z.; Abilgaziyev, A.; Kurokawa, S.; Ali, M.H. Numerical and experimental analysis of the 3D printed multi-material ankle-foot orthosis. J. Phys. Conf. Ser. 2020, 1510, 012012. [Google Scholar] [CrossRef]

- Dey, A.; Roan Eagle, I.N.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications — A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Polyetheretherketone (PEEK). Available online: https://www.makeitfrom.com/material-properties/Polyetheretherketone-PEEK (accessed on 2 November 2021).

- Jiang, S.; Liao, G.; Xu, D.; Liu, F.; Li, W.; Cheng, Y.; Li, Z.; Xu, G. Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling. High Perform. Polym. 2018, 31, 97–106. [Google Scholar] [CrossRef]

- Polyamide (PA, Nylon) 11. Available online: https://www.makeitfrom.com/material-properties/Polyamide-PA-Nylon-11 (accessed on 2 November 2021).

- Kim, D.K.; Woo, W.; Kim, E.Y.; Choi, S.H. Microstructure and mechanical characteristics of multi-layered materials composed of 316L stainless steel and ferritic steel produced by direct energy deposition. J. Alloys Compd. 2019, 774, 896–907. [Google Scholar] [CrossRef]

- Udupa, G.; Rao, S.S.; Gangadharan, K.V. Functionally Graded Composite Materials: An Overview. Procedia Mater. Sci. 2014, 5, 1291–1299. [Google Scholar] [CrossRef]

- Zhuang, Y.; Song, W.; Ning, G.; Sun, X.; Sun, Z.; Xu, G.; Zhang, B.; Chen, Y.; Tao, S. 3D–printing of materials with anisotropic heat distribution using conductive polylactic acid composites. Mater. Des. 2017, 126, 135–140. [Google Scholar] [CrossRef]

- Nasirov, A.; Fidan, I. Prediction of mechanical properties of fused filament fabricated structures via asymptotic homogenization. Mech. Mater. 2020, 145, 103372. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Gupta, A.; Fidan, I. Mechanical benchmarking of additively manufactured continuous and short carbon fiber reinforced nylon. J. Compos. Mater. 2021. [Google Scholar] [CrossRef]

- Christ, J.; Aliheidari, N.; Pötschke, P.; Ameli, A. Bidirectional and Stretchable Piezoresistive Sensors Enabled by Multimaterial 3D Printing of Carbon Nanotube/Thermoplastic Polyurethane Nanocomposites. Polymers 2018, 11, 11. [Google Scholar] [CrossRef] [PubMed]

- García-Macías, E.; Rodríguez-Tembleque, L.; Castro-Triguero, R.; Sáez, A. Eshelby-Mori-Tanaka approach for post-buckling analysis of axially compressed functionally graded CNT/polymer composite cylindrical panels. Compos. Part B Eng. 2017, 128, 208–224. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, G.; Chen, Z.; Liu, C.; Wang, D.; Lao, C. Multiple metals doped polymer-derived SiOC ceramics for 3D printing. Ceram. Int. 2018, 44, 11030–11038. [Google Scholar] [CrossRef]

- Gualtieri, T.; Bandyopadhyay, A. Additive manufacturing of compositionally gradient metal-ceramic structures: Stainless steel to vanadium carbide. Mater. Des. 2018, 139, 419–428. [Google Scholar] [CrossRef]

- Krella, A.; Czyzniewski, A. Cavitation erosion resistance of Cr-N coating deposited on stainless steel. Wear 2006, 260, 1324–1332. [Google Scholar] [CrossRef]

- Zhang, Y.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of Ti-Si-N ceramic coatings on titanium. Appl. Surf. Sci. 2015, 346, 428–437. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W. Experimental characterization of laser cladding of CPM 9V on H13 tool steel for die repair applications. J. Manuf. Process. 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Ceramic Matrix Composites. Available online: https://www.library.ucdavis.edu/wp-content/uploads/2016/12/HDBK17-5.pdf (accessed on 20 November 2021).

- Pavlov, M.; Novichenko, D.; Doubenskaia, M. Optical Diagnostics of Deposition of Metal Matrix Composites by Laser Cladding. Phys. Procedia 2011, 12, 674–682. [Google Scholar] [CrossRef]

- Zhang, D.; Jonhson, W.; Herng, T.S.; Xu, X.; Liu, X.; Pan, L.; He, H.; Ding, J. High Temperature Co-firing of 3D-Printed Al-ZnO/Al2O3 Multi-Material Two-Phase Flow Sensor. J. Mater. 2021. [Google Scholar] [CrossRef]

- Gheisari, R.; Chamberlain, H.; Chi-Tangyie, G.; Zhang, S.; Goulas, A.; Lee, C.-K.; Whittaker, T.; Wang, D.; Ketharam, A.; Ghosh, A.; et al. Multi-material additive manufacturing of low sintering temperature Bi 2 Mo 2 O 9 ceramics with Ag floating electrodes by selective laser burnout. Virtual Phys. Prototyp. 2020, 15, 133–147. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Heer, B.; Bandyopadhyay, A. Compositionally graded magnetic-nonmagnetic bimetallic structure using laser engineered net shaping. Mater. Lett. 2018, 216, 16–19. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Zhao, X.; Yang, S.; Gao, N. Interfacial characterisation of multi-material 316L stainless steel/Inconel 718 fabricated by laser powder bed fusion. Mater. Lett. 2021, 284, 128928. [Google Scholar] [CrossRef]

- Tan, C.; Wang, D.; Ma, W.; Zhou, K. Ultra-strong bond interface in additively manufactured iron-based multi-materials. Mater. Sci. Eng. A 2021, 802, 140642. [Google Scholar] [CrossRef]

- Sing, S.L.L.; Lam, L.P.P.; Zhang, D.Q.Q.; Liu, Z.H.H.; Chua, C.K.K. Interfacial characterization of SLM parts in multi-material processing: Intermetallic phase formation between AlSi10Mg and C18400 copper alloy. Mater. Charact. 2015, 107, 220–227. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Multi-material selective laser melting of Fe/Al-12Si components. Manuf. Lett. 2017, 11, 8–11. [Google Scholar] [CrossRef]

- Singh, S.; Singh, R. Development of functionally graded material by fused deposition modelling assisted investment casting. J. Manuf. Process. 2016, 24, 38–45. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, T. Selective laser melting of tungsten-copper functionally graded material. Mater. Lett. 2019, 237, 328–331. [Google Scholar] [CrossRef]

- Xiang, W.; Xuliang, M.; Xinlin, L.; Lihua, D.; Mingjia, W. Effect of boron addition on microstructure and mechanical properties of TiC/Ti6Al4V composites. Mater. Des. 2012, 36, 41–46. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Lin, P.; Liu, H. Microstructure and mechanical properties of functionally graded TiCp/Ti6Al4V composite fabricated by laser melting deposition. Ceram. Int. 2017, 43, 16638–16651. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.B.; Fang, Y.L.; Liu, D.; Wang, H.M. Microstructure evolution of sub-critical annealed laser deposited Ti–6Al–4V alloy. Mater. Des. 2012, 37, 56–63. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Bocklund, B.; Otis, R.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; McEnerney, B.; Liu, Z.K.; Beese, A.M. Characterization of a functionally graded material of Ti-6Al-4V to 304L stainless steel with an intermediate V section. J. Alloys Compd. 2018, 742, 1031–1036. [Google Scholar] [CrossRef]

- Bobbio, L.D.; Otis, R.A.; Borgonia, J.P.; Dillon, R.P.; Shapiro, A.A.; Liu, Z.K.; Beese, A.M. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: Experimental characterization and thermodynamic calculations. Acta Mater. 2017, 127, 133–142. [Google Scholar] [CrossRef]

- Schneider-Maunoury, C.; Weiss, L.; Acquier, P.; Boisselier, D.; Laheurte, P. Functionally graded Ti6Al4V-Mo alloy manufactured with DED-CLAD® process. Addit. Manuf. 2017, 17, 55–66. [Google Scholar] [CrossRef]

- Zhang, Y.; Bandyopadhyay, A. Direct fabrication of compositionally graded Ti-Al2O3 multi-material structures using Laser Engineered Net Shaping. Addit. Manuf. 2018, 21, 104–111. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Brenne, F.; Tröster, T.; Richard, H.A.; Schwarze, D. Functionally Graded Alloys Obtained by Additive Manufacturing. Adv. Eng. Mater. 2014, 16, 857–861. [Google Scholar] [CrossRef]

- Yakovlev, A.; Trunova, E.; Grevey, D.; Pilloz, M.; Smurov, I. Laser-assisted direct manufacturing of functionally graded 3D objects. Surf. Coat. Technol. 2005, 190, 15–24. [Google Scholar] [CrossRef]

- Woo, W.; Kim, D.K.; Kingston, E.J.; Luzin, V.; Salvemini, F.; Hill, M.R. Effect of interlayers and scanning strategies on through-thickness residual stress distributions in additive manufactured ferritic-austenitic steel structure. Mater. Sci. Eng. A 2019, 744, 618–629. [Google Scholar] [CrossRef]

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- JZ, G.; M, S.; MM, R.; GU, S.; I, S.; KH, K.; JW, L.; KH, C. 3D printing for soft robotics - a review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D printing of soft robotic systems. Nat. Rev. Mater. 2018, 3, 84–100. [Google Scholar] [CrossRef]

- Venumbaka, S.A.; Covarubias, M.; Cesaro, G.; Ronca, A.; De Capitani, C.; Ambrosio, L.; Sorrentino, A. Application of Multi Materials Additive Manufacturing Technique in the Design and Manufacturing of Hand Orthoses. In Proceedings of the International Conference on Computers Helping People with Special Needs LNCS, Lecco, Italy, 9–11 September 2020; pp. 461–468. [Google Scholar] [CrossRef]

- 3D Printing Applications for Medical Education. Available online: https://www.stratasys.com/explore/whitepaper/3d-printing-clinical-simulation (accessed on 2 November 2021).

- Lithoz Shows Off Multi-Material Ceramics 3D Printing on CeraFab Multi 2M30. Available online: https://www.3dprintingmedia.network/multi-material-ceramics-3d-printing-on-cerafab-multi-2m30/ (accessed on 6 November 2021).

- Anatomical Model Parts on Demand with 3D Printing. Available online: https://www.stratasysdirect.com/applications/anatomical-models (accessed on 20 November 2021).

- 3D Design Futures: An Interview with Dr. Daniel Richards, Part 2. Available online: https://www.fabbaloo.com/2018/01/3d-design-futures-an-interview-with-dr-daniel-richards-part-2 (accessed on 6 November 2021).

- Cámara-Torres, M.; Duarte, S.; Sinha, R.; Egizabal, A.; Álvarez, N.; Bastianini, M.; Sisani, M.; Scopece, P.; Scatto, M.; Bonetto, A.; et al. 3D additive manufactured composite scaffolds with antibiotic-loaded lamellar fillers for bone infection prevention and tissue regeneration. Bioact. Mater. 2021, 6, 1073. [Google Scholar] [CrossRef]

- Fanfoni, L.; Marsich, E.; Turco, G.; Breschi, L.; Cadenaro, M. Development of di-methacrylate quaternary ammonium monomers with antibacterial activity. Acta Biomater. 2021, 129, 138–147. [Google Scholar] [CrossRef]

- Bishop, E.S.; Mostafa, S.; Pakvasa, M.; Luu, H.H.; Lee, M.J.; Wolf, J.M.; Ameer, G.A.; He, T.C.; Reid, R.R. 3-D bioprinting technologies in tissue engineering and regenerative medicine: Current and future trends. Genes Dis. 2017, 4, 185–195. [Google Scholar] [CrossRef] [PubMed]

- Lind, J.U.; Busbee, T.A.; Valentine, A.D.; Pasqualini, F.S.; Yuan, H.; Yadid, M.; Park, S.J.; Kotikian, A.; Nesmith, A.P.; Campbell, P.H.; et al. Instrumented cardiac microphysiological devices via multimaterial three-dimensional printing. Nat. Mater. 2017, 16, 303–308. [Google Scholar] [CrossRef]

- Tan, Y.J.N.; Yong, W.P.; Low, H.R.; Kochhar, J.S.; Khanolkar, J.; Lim, T.S.E.; Sun, Y.; Wong, J.Z.E.; Soh, S. Customizable drug tablets with constant release profiles via 3D printing technology. Int. J. Pharm. 2021, 598. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Kumar Thakur, V.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Lumpe, T.S.; Mueller, J.; Shea, K. Tensile properties of multi-material interfaces in 3D printed parts. Mater. Des. 2019, 162, 1–9. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef]

- Brackett, J.; Yan, Y.; Cauthen, D.; Kishore, V.; Lindahl, J.; Smith, T.; Sudbury, Z.; Ning, H.; Kunc, V.; Duty, C. Characterizing material transitions in large-scale Additive Manufacturing. Addit. Manuf. 2021, 38, 101750. [Google Scholar] [CrossRef]

- Sudbury, Z.; Duty, C.; Kunc, V. Expanding material property space maps with functionally graded materials for large scale additive manufacturing. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; Volume 5, pp. 459–469. [Google Scholar]

- Hofmann, D.C.; Roberts, S.; Otis, R.; Kolodziejska, J.; Dillon, R.P.; Suh, J.O.; Shapiro, A.A.; Liu, Z.K.; Borgonia, J.P. Developing gradient metal alloys through radial deposition additive manufacturing. Sci. Rep. 2014, 4, 5357. [Google Scholar] [CrossRef]

- Freund, R.; Watschke, H.; Heubach, J.; Vietor, T. Determination of Influencing Factors on Interface Strength of Additively Manufactured Multi-Material Parts by Material Extrusion. Appl. Sci. 2019, 9, 1782. [Google Scholar] [CrossRef]

- Ezair, B.; Dikovsky, D.; Elber, G. Fabricating Functionally Graded Material Objects Using Trimmed Trivariate Volumetric Representations. In Proceedings of the Shape Modeling International (SMI-2017) Symposium, Berkeley, CA, USA, 21–23 June 2017. [Google Scholar]

- Kuipers, T.; Su, R.; Wu, J.; Wang, C.C.L. ITIL: Interlaced Topologically Interlocking Lattice for continuous dual-material extrusion. Addit. Manuf. 2022, 50, 102495. [Google Scholar] [CrossRef]

- Stoner, B.; Bartolai, J.; Kaweesa, D.V.; Meisel, N.A.; Simpson, T.W. Achieving Functionally Graded Material Composition Through Bicontinuous Mesostructural Geometry in Material Extrusion Additive Manufacturing. JOM 2018, 70, 413–418. [Google Scholar] [CrossRef]

- Muller, P.; Mognol, P.; Hascoet, J.Y. Functionally Graded Material (FGM) Parts: From Design to the Manufacturing Simulation. In Proceedings of the ASME 2012 11th Biennial Conference on Engineering Systems Design and Analysis, Nantes, France, 2–4 July 2012; pp. 123–131. [Google Scholar] [CrossRef]

- Ponche, R.; Hascoët, J.-Y.; Kerbrat, O.; Mognol, P. A new global approach to design for additive manufacturing: A method to obtain a design that meets specifications while optimizing a given additive manufacturing. Virtual Phys. Prototyp. 2012, 7, 93–105. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Kim, H.; Park, E.; Kim, S.; Park, B.; Kim, N.; Lee, S. Experimental Study on Mechanical Properties of Single- and Dual-material 3D Printed Products. Procedia Manuf. 2017, 10, 887–897. [Google Scholar] [CrossRef]

- Roger, F.; Krawczak, P. 3D-printing of thermoplastic structures by FDM using heterogeneous infill and multi-materials: An integrated design-advanced manufacturing approach for factories of the future. Abstr. Struct. Multidiscip. Optim. 2015, 50, 1–7. [Google Scholar] [CrossRef]

- Brackett, J.; Yan, Y.; Cauthen, D.; Kishore, V.; Lindahl, J. Development of Functionally Graded Material Capabilities in Large-scale Extrusion Deposition Additive Manufacturing. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; pp. 1793–1803. [Google Scholar]

- Lopes, L.R.; Silva, A.F.; Carneiro, O.S. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Mueller, J.; Courty, D.; Spielhofer, M.; Spolenak, R.; Shea, K. Mechanical Properties of Interfaces in Inkjet 3D Printed Single- and Multi-Material Parts. 3D Print. Addit. Manuf. 2017, 4, 193–199. [Google Scholar] [CrossRef]

- Sundaram, S.; Skouras, M.; Kim, D.S.; van den Heuvel, L.; Matusik, W. Topology optimization and 3D printing of multimaterial magnetic actuators and displays. Sci. Adv. 2019, 5, eaaw1160. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

| Easy fabrication of complex geometries | Limited selection of materials |

| Faster printing time of multiple materials | Expensive process |

| High dimensional accuracy | Higher material cost |

| Parts can be built in a variety of materials with multiple inkjet nozzles | Poor mechanical properties of the materials |

| Multiple materials can be fabricated with higher resolution | MJ materials are photosensitive and mechanical properties degrade overtime |

| Parts have homogeneous mechanical and thermal properties | Most parts still require support materials |

| Low material waste due to accurate jetting | Mainly used for non-functional prototypes |

| CNC Machining | Direct Energy Deposition | ||

|---|---|---|---|

| Repeatable |  | Less material waste |  |

| Precise |  | Geometry freedom |  |

| Good surface finish |  | Material Combos |  |

| High productivity |  | Longer cycle-times |  |

| Wasteful |  | Poor Surface Finish |  |

| Material | Density (g/cm3) | Youngs Modulus (GPA) | Tensile Strength (MPA) | Glass Transition Temperature (°C) | Melting Temperature (°C) | Printing Temperature Range |

|---|---|---|---|---|---|---|

| ABS | 2.28 | 43 | 200–250 | 210–250 [118] | ||

| PLA | 1.21–1.25 [119] | 21–60 [119] | 45–60 [119] | 150–162 [119] | 190–230 [118] | |

| PC | 1.21 [55] | 2.57 [55] | - | 140 [55] | 270 [55] | 260–310 [118] |

| PEEK | 1.32 [120] | 90–100 [120] | 143 [120] | 343 [120] | 360–420 [118] | |

| PEI | 1.27 [121] | 217 [121] | 340–380 [118] | |||

| Nylon | 1.15 [122] | 190–350 [122] | 240–270 [118] | |||

| HIPS | 220–250 [118] | |||||

| Polyester Vinyl ester | 1.2–1.5 [123] 1.12–1.32 [123] | 40–90 [123] 73–81 [123] |

| Material | AM Technology | Yield Strength MPa | Hardness HV |

|---|---|---|---|

| Ti6Al4V/TiC (From 0% to 50% Ti [147] | LMD | 380–737 | |

| TA15/TiC (From 0% to 50% TiC) [148] | LMD | 806–925 | |

| Ti6Al4V/TiC (From 0% to 30% Ti) [149] | DED | 300–600 | |

| Ti6Al4V/SS304 L/V [150] | DED | 220–850 | |

| TiAl4V/Invar (From Ti6Al4V to pure Invar with 3% increment) [151] | DED | 350–858 | |

| Ti6Al4V/Mo (From Ti6Al4V to pure Mo with 25% increment) [152] | DED | 250–450 | |

| Ti6Al4V/Al2O3 [153] | LENS | 350–2365 | |

| SS AISI316L [154] | SLM | 150–220 | |

| SS 316L/Stellite12 with few millimeter transition zone [155] | LDM | 200–650 | |

| SS 316L/P21 with 25/50/75% graded layers [156] | DED | 200–440 | |

| SS 316L/P21 + 316L SS/P21 [123] | DED | 210–330 | |

| SS430 + SS316 [140] | LENS | 266 ± 4, −174 ± 3 | |

| AlSi10Mg + C18400 [143] | SLM | 119.06 ± 9.1, −71 ± 7.45 | |

| 316L SS + IN 718 [141] | L-PBF | 304, 223 | |

| CS 45 and CS/MS [142] | L-PBF | 562 ± 22,596 | |

| SS 304 [142] | L-PBF | 514 ± 16 | |

| Fe/Al-12Si [144] | SLM | 450–550 |

| Authors/Reference | Methods (AM Technique) | Investigated Properties |

|---|---|---|

| Garland et al. [28] | Bi-level topology optimization (FFF) | Flexural behavior, Optimization of material distribution |

| Hasanov et al. [9,101,102] | Tensile, flexural, compression (FFF) | Numerical and experimental investigation of FGM parts |

| Brischetto et al. [29] | External layer ABS, while internal layer with PLA sandwich structure (FFF) | Bending properties |

| Lopez et al. [30] | Tensile specimen of sandwich structures (FFF) | Tensile behavior of various material combinations of sandwich structures |

| Kim et al. [184] | Tensile test (FFF) | Tensile behavior |

| Roger et al. [185] | Topology Optimization (TO), FEA (FFF) | Selectively material placement based on FEA results |

| Singh et al. [145] | Tensile tests (FFF) | Tensile behavior of specimens with different printing speed and infill density |

| Sudbury et al. [175] | Development of BAAM system for FGM fabrication (BAAM) | Cost, weight analysis |

| Bracket et al. [186] | Repeatability of mixing and printing process (BAAM) | Fabrication of FGM sandwich structure |

| Zheng et al. [6] | Compression test, Dynamic Material Analysis (SLA) | Energy dissipation characterizations, damping |

| Ituarte et al. [27] | Tensile test, FEA, TO (MJ) | Tensile behavior |

| Dorcas et al. [26] | Tensile test (MJ) | Tensile behavior |

| Doubrovski et al. [24] | Voxel-based design, bitmap printing (MJ) | Generation of FGM distribution on prosthetic socket |

| Freund et al. [177] | Peel test, plasma treatment (FFF) | Peel resistance |

| Lopes et a. [187] | Tensile test (FFF) | Interface strength of zebra-like patterns |

| Guessasma et al. [11] | Tensile test, DIC (BJ) | Strength of different interface patterns, porosity analysis using CT scan |

| Vu et al. [68] | Interface characterization, tension test (MJ) | Fracture resistance |

| Bartlett et al. [173] | FEA simulation, experiments (MJ) | Fabrication of robotic rigid-flex legs for jumping applications |

| Lumpe et al. [172] | Tensile test (MJ) | Tensile properties of interfaces |

| Mueller et al. [188] | Hardness test (MJ) | Stiffness properties of various concentrations of rigid–soft composites |

| Mirzaali et al. [12] | Tensile test (MJ) | Fracture resistance properties |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. J. Manuf. Mater. Process. 2022, 6, 4. https://doi.org/10.3390/jmmp6010004

Hasanov S, Alkunte S, Rajeshirke M, Gupta A, Huseynov O, Fidan I, Alifui-Segbaya F, Rennie A. Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. Journal of Manufacturing and Materials Processing. 2022; 6(1):4. https://doi.org/10.3390/jmmp6010004

Chicago/Turabian StyleHasanov, Seymur, Suhas Alkunte, Mithila Rajeshirke, Ankit Gupta, Orkhan Huseynov, Ismail Fidan, Frank Alifui-Segbaya, and Allan Rennie. 2022. "Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges" Journal of Manufacturing and Materials Processing 6, no. 1: 4. https://doi.org/10.3390/jmmp6010004

APA StyleHasanov, S., Alkunte, S., Rajeshirke, M., Gupta, A., Huseynov, O., Fidan, I., Alifui-Segbaya, F., & Rennie, A. (2022). Review on Additive Manufacturing of Multi-Material Parts: Progress and Challenges. Journal of Manufacturing and Materials Processing, 6(1), 4. https://doi.org/10.3390/jmmp6010004