Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences

Abstract

:1. Introduction

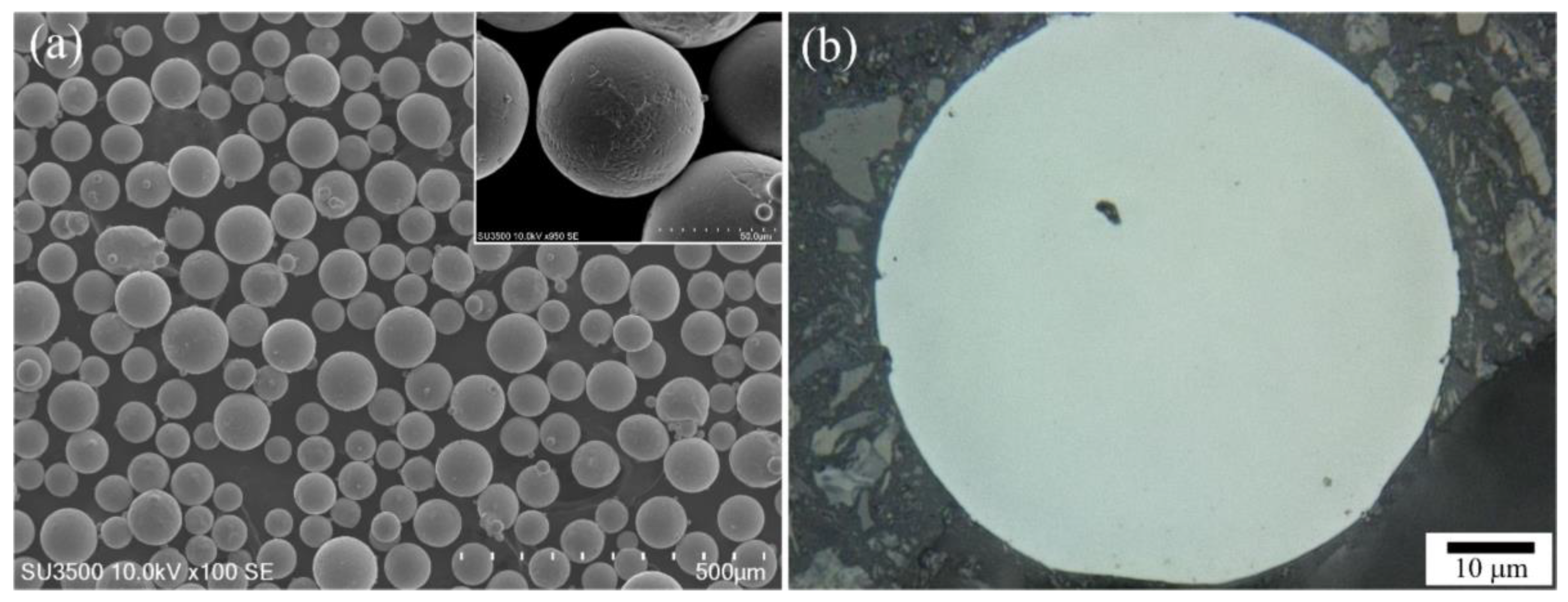

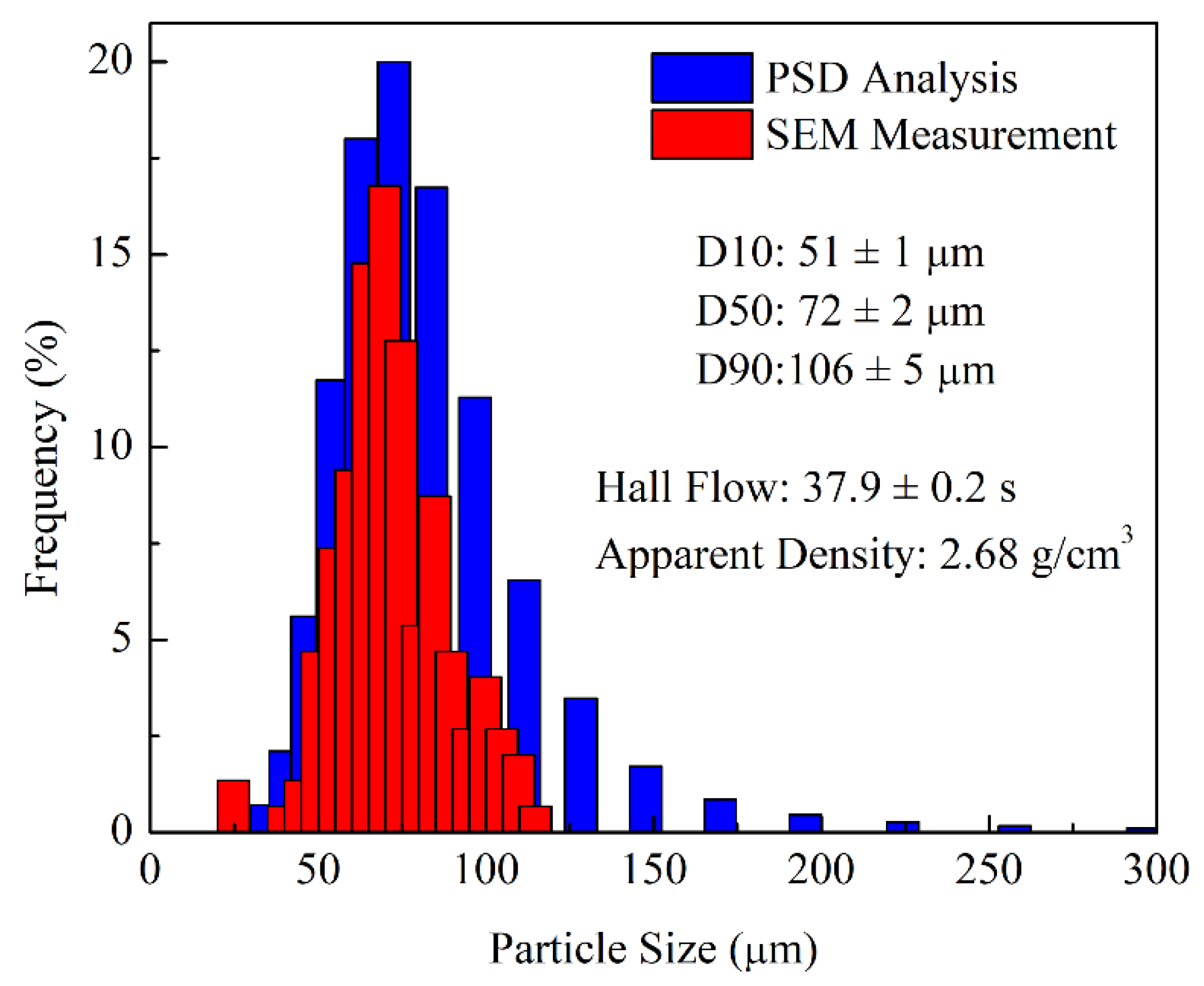

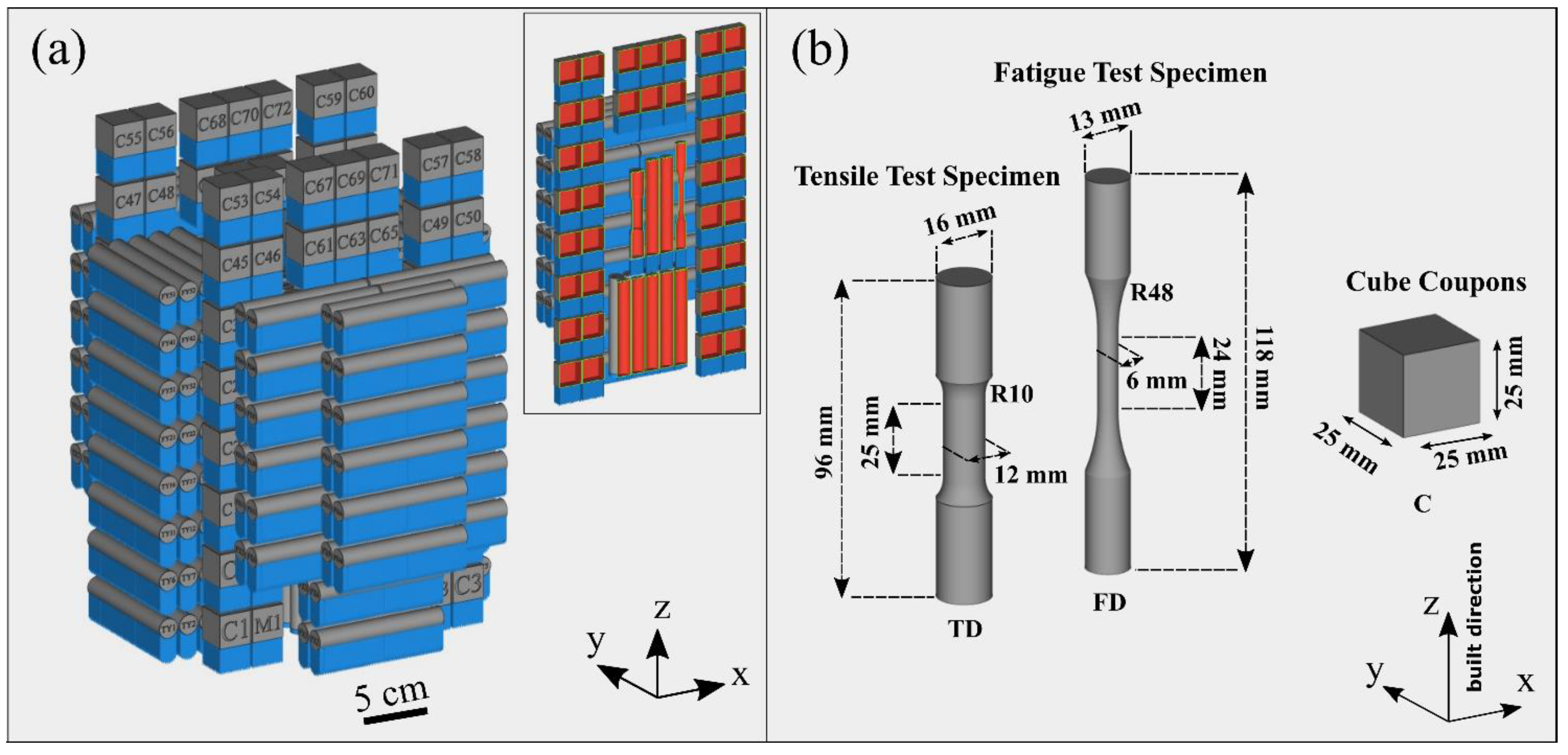

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Analysis Post-Fabrication

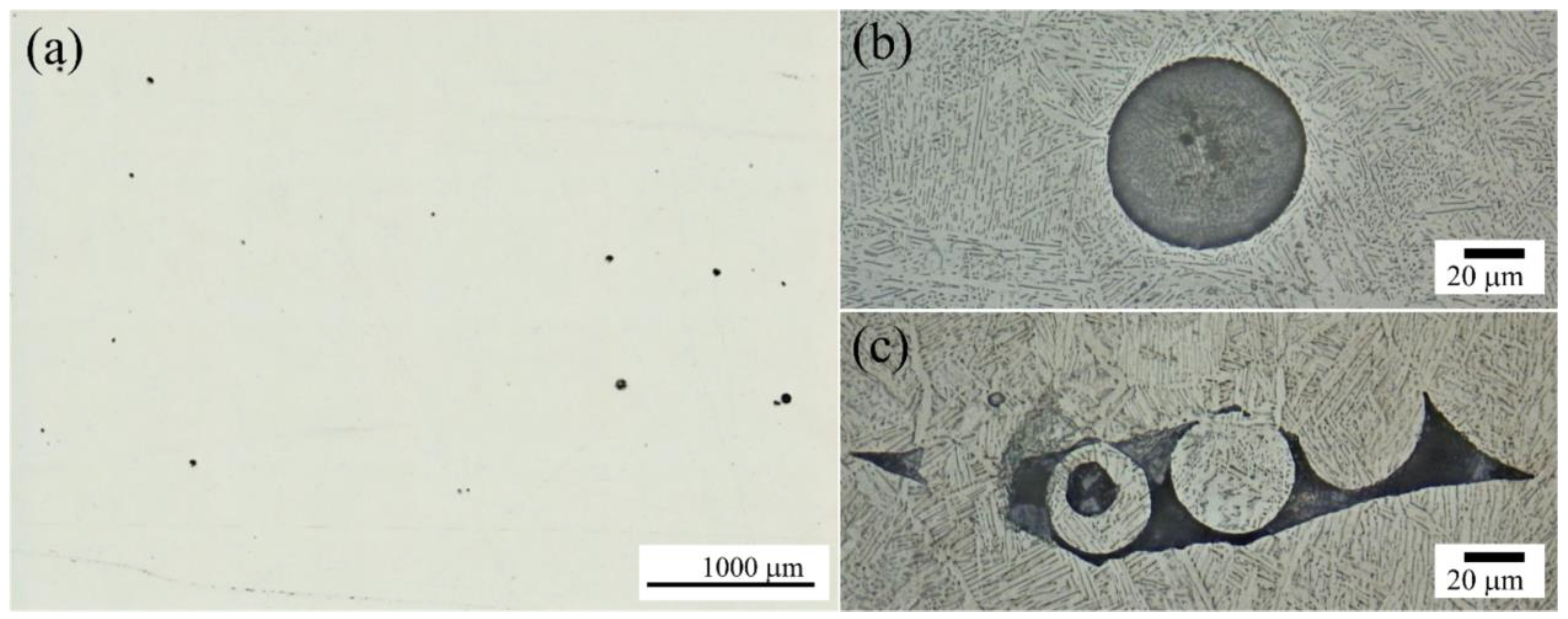

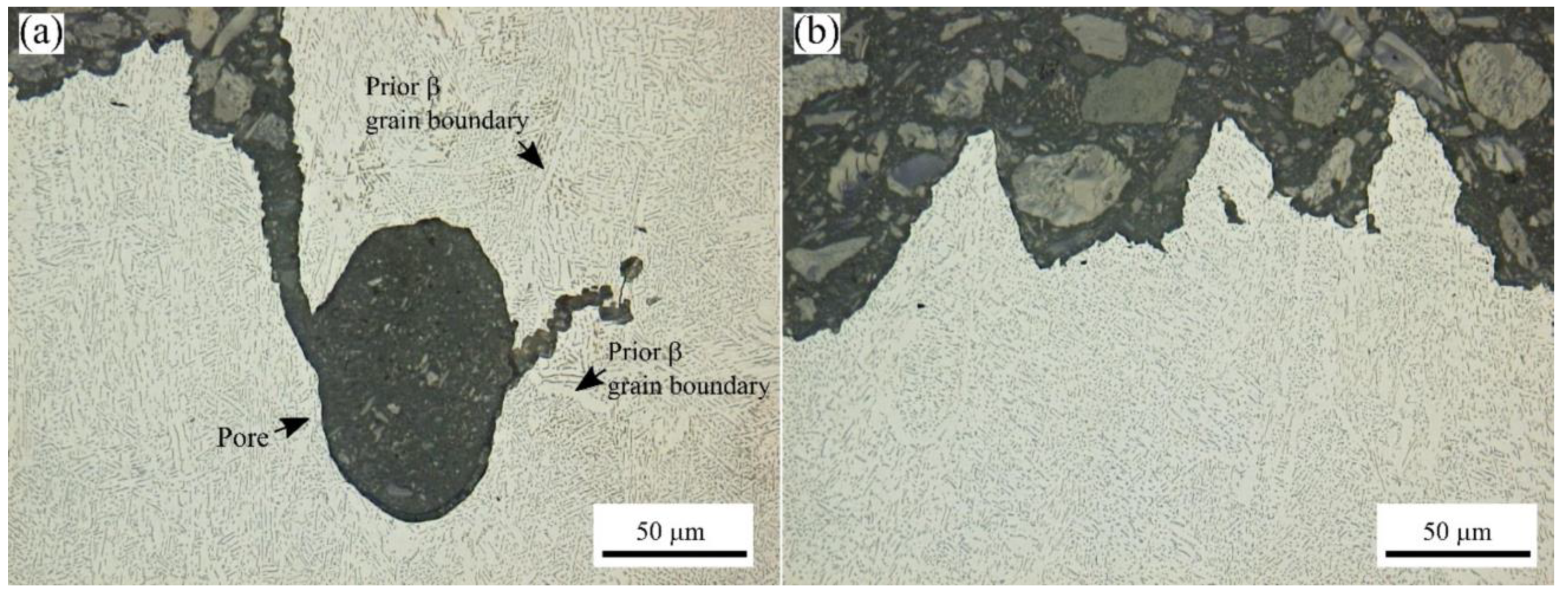

3.2. Density in as-Built Condition

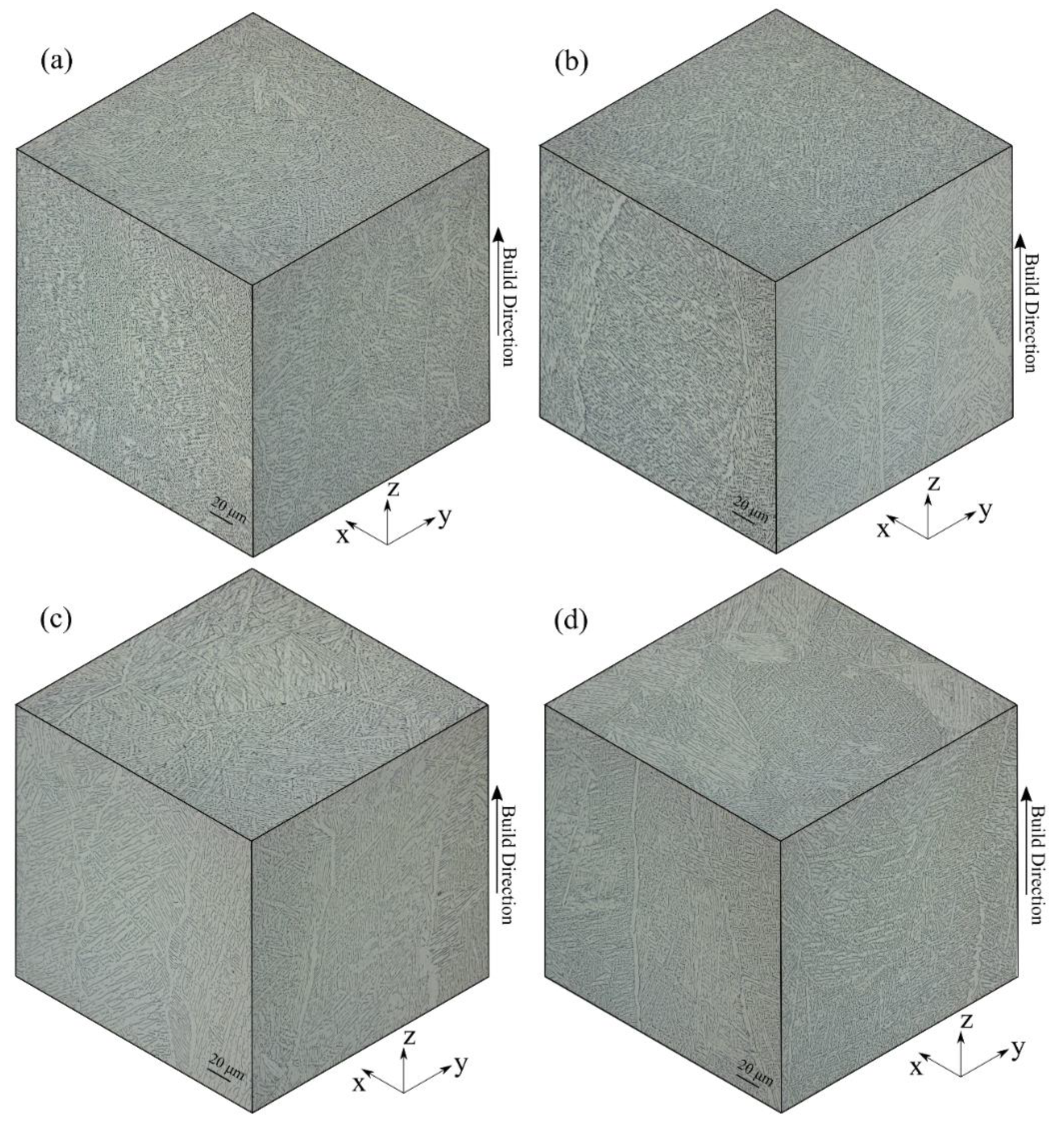

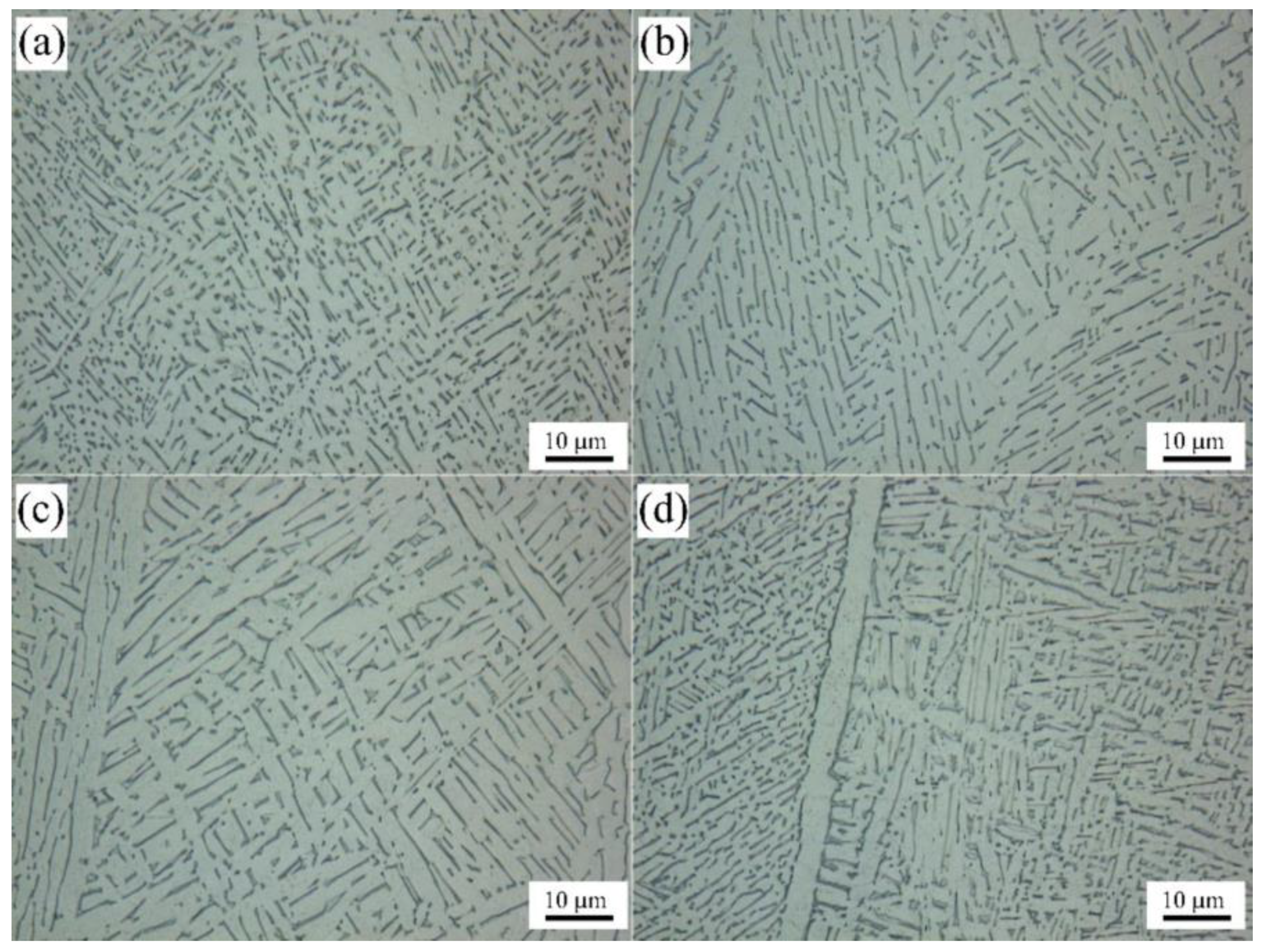

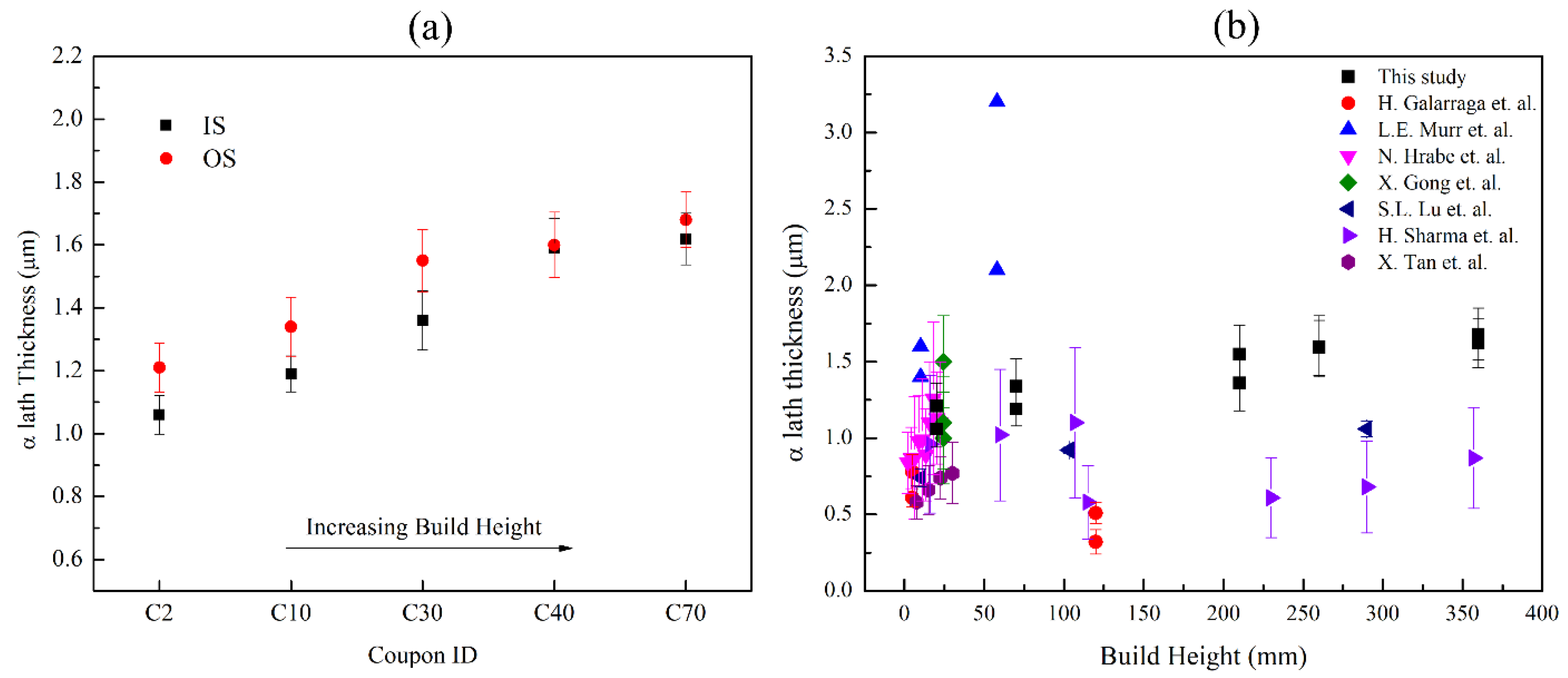

3.3. Microstructural Analysis

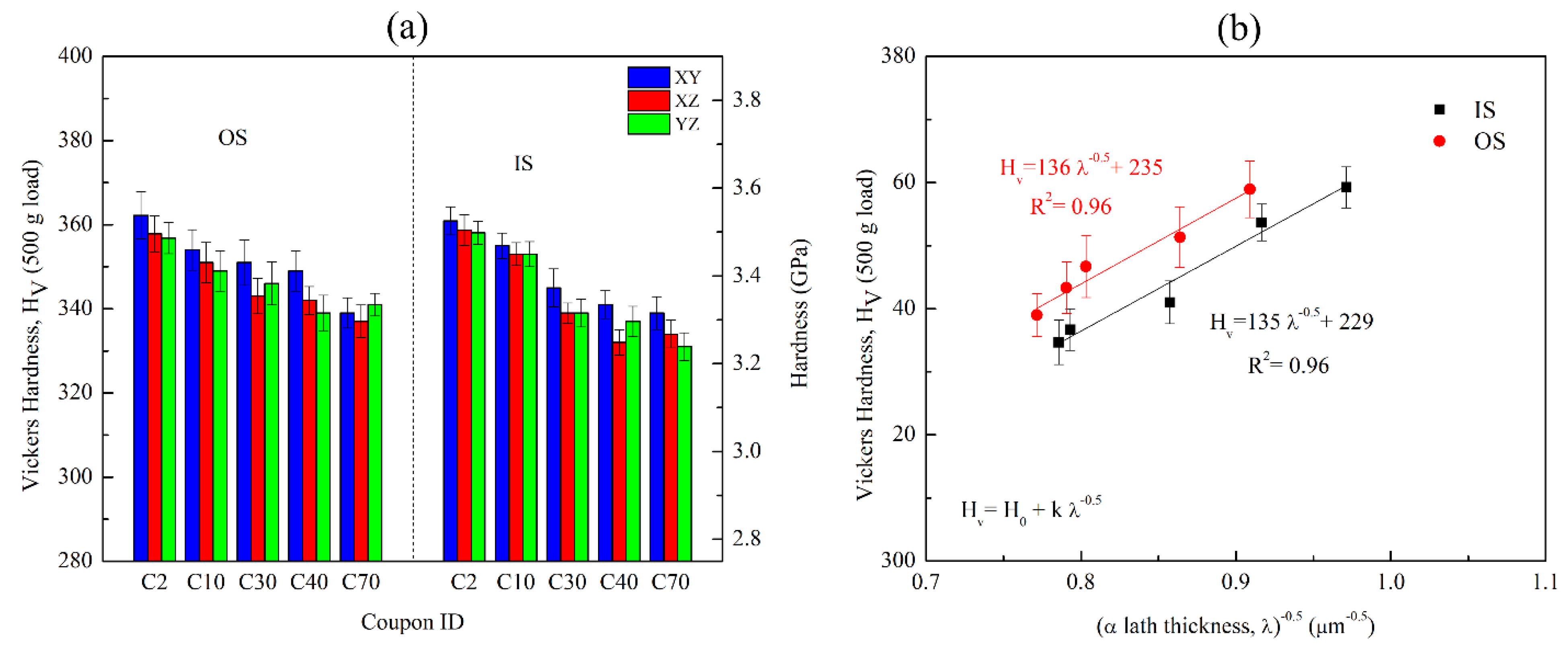

3.4. Relationship between α Lath Size and Hardness

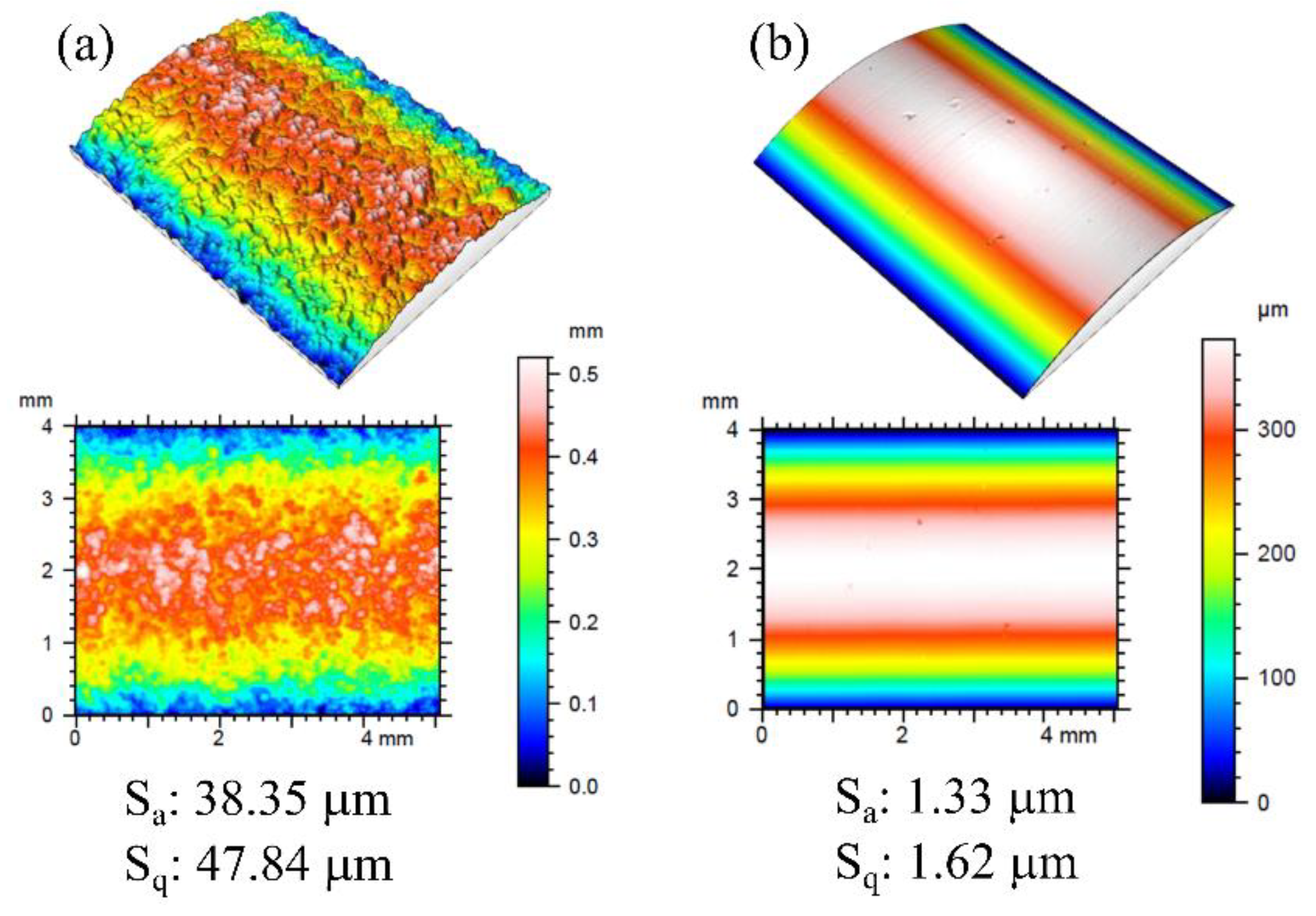

3.5. Surface Analysis

3.6. Tensile Testing

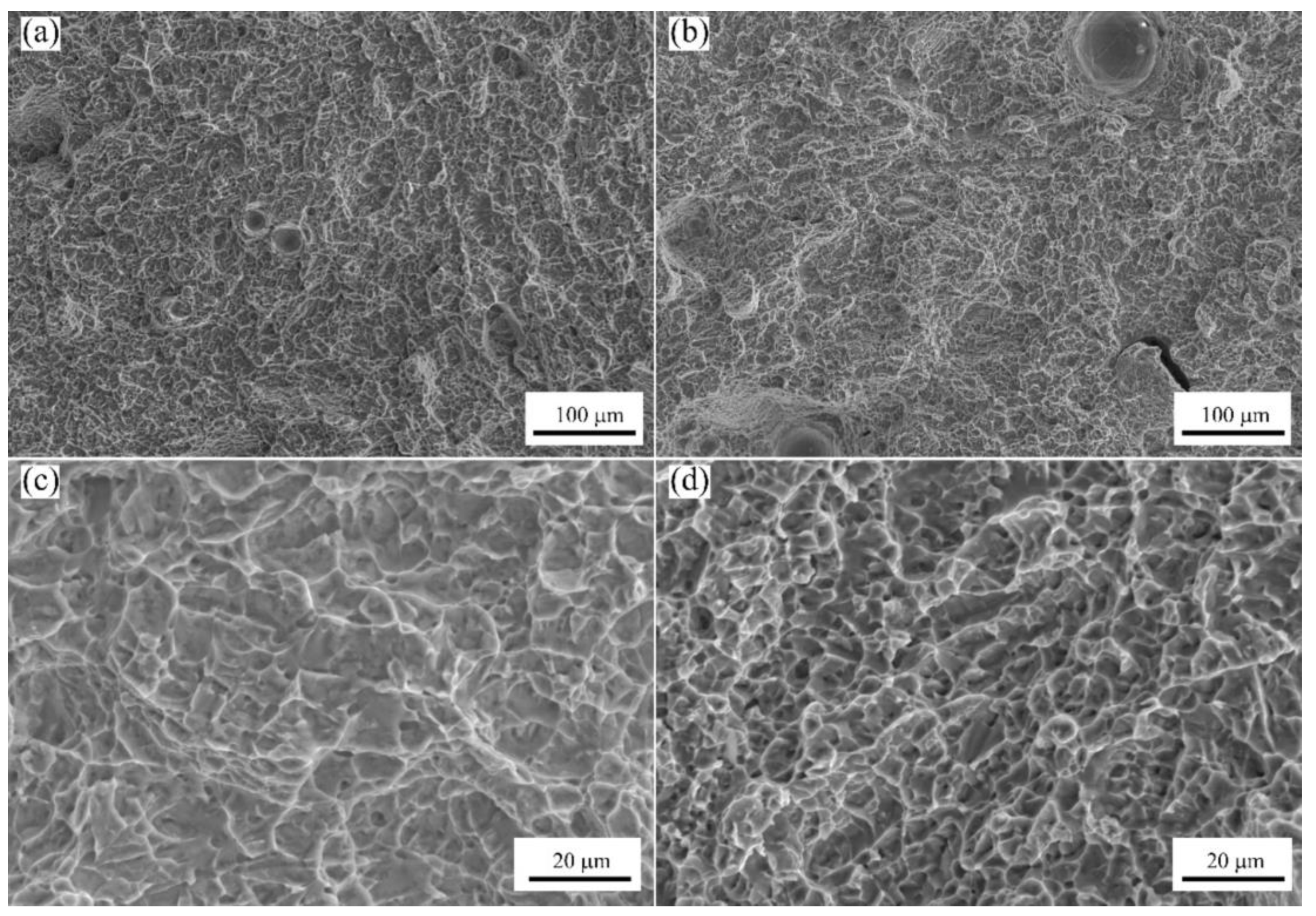

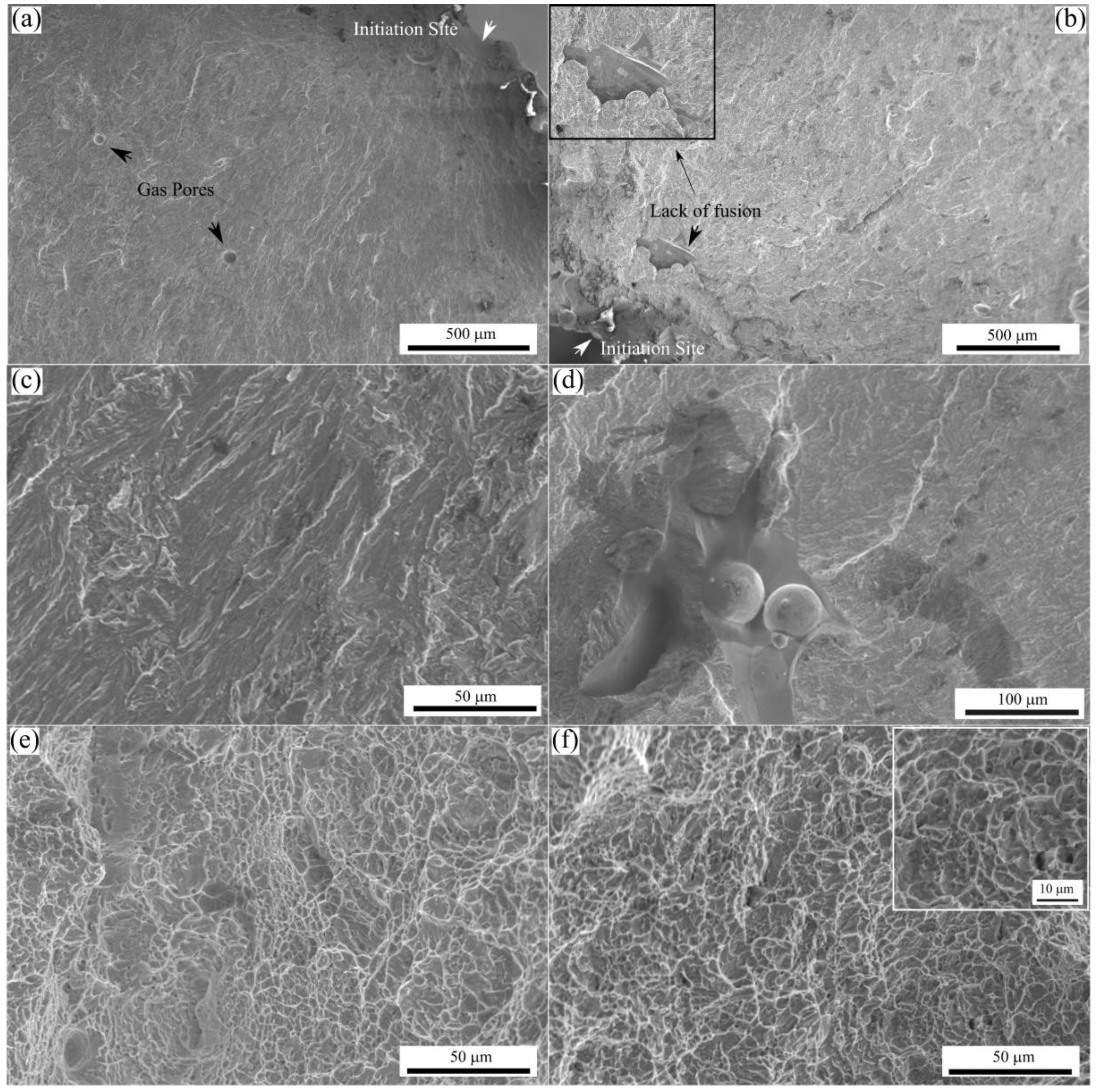

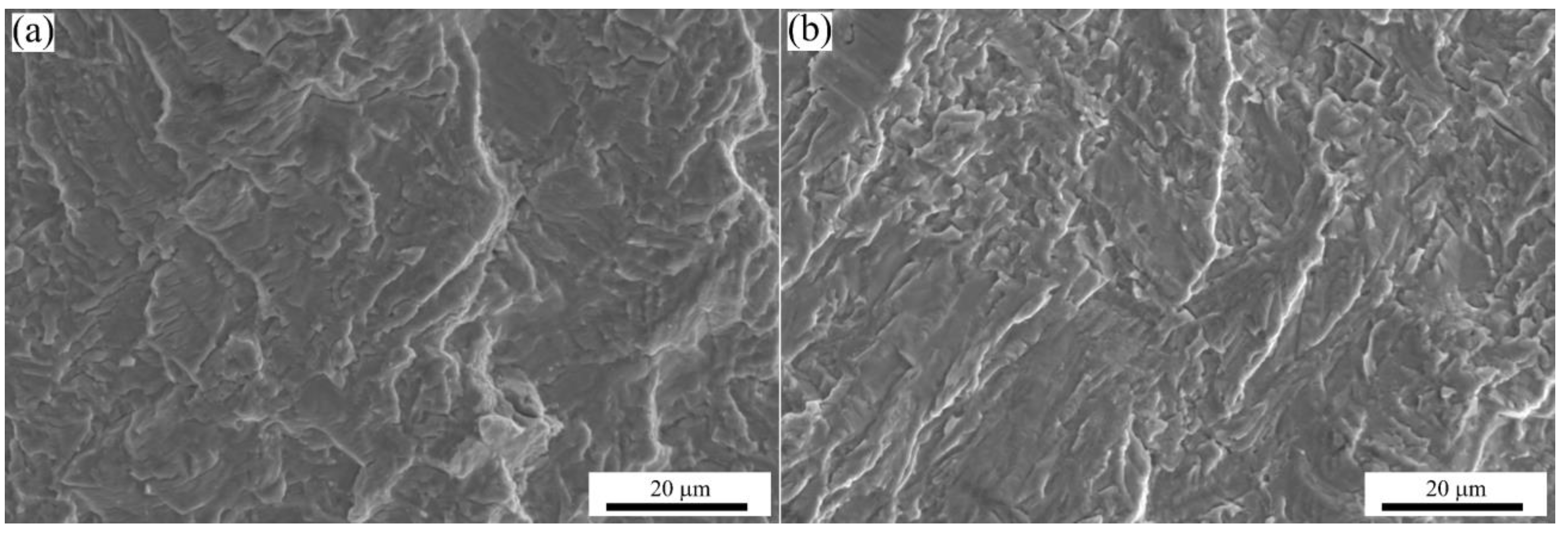

3.7. Fractography of the Tensile Test Specimens

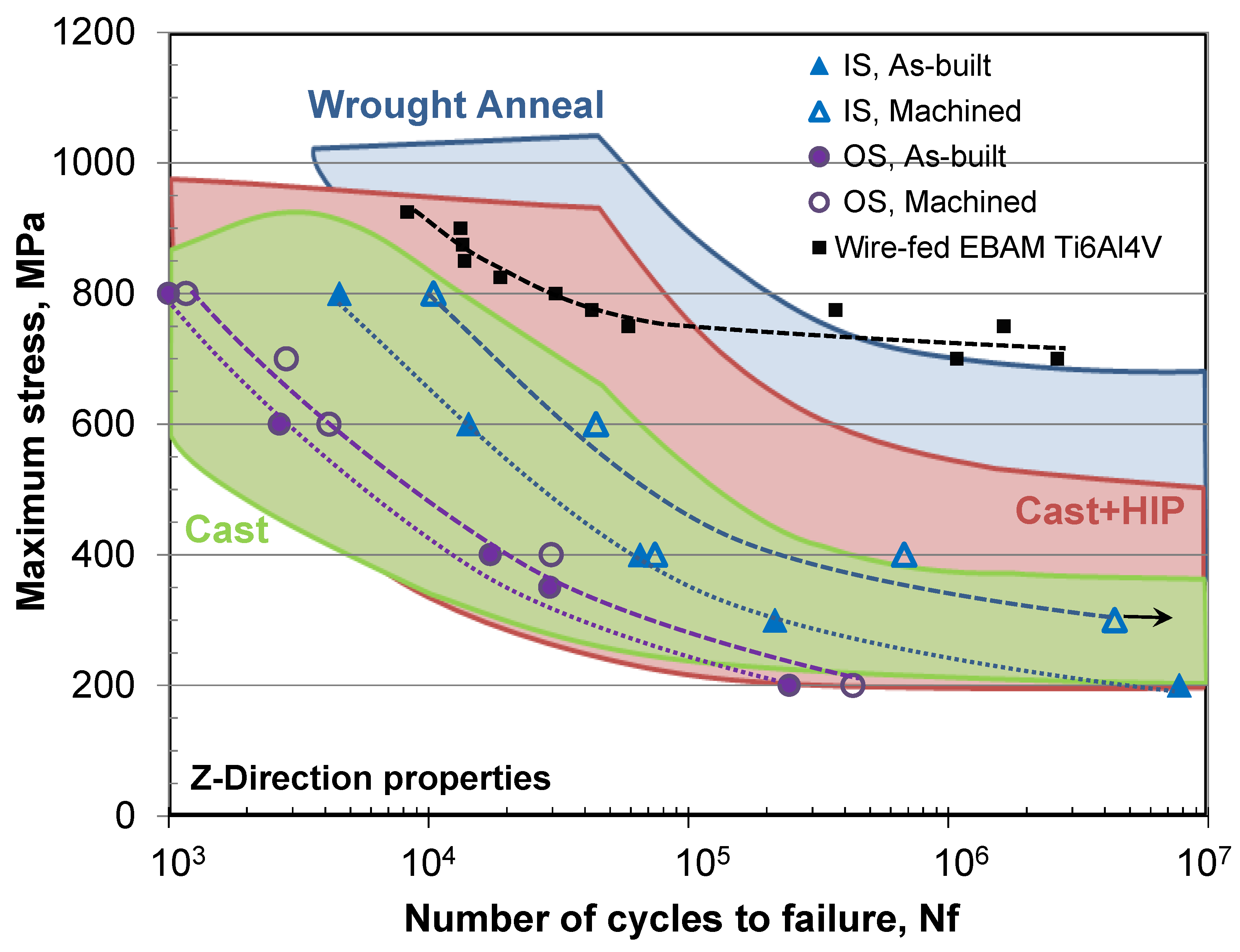

3.8. Fatigue Testing

4. Conclusions

- A build layout design that incorporated nesting/stacking of different coupon types with low density block-design supports was deliberated for the entire build volume of an Arcam Q20+ system. A printing operation of 225 h and 49 min without interruptions or print failure was shown to be possible and provides evidence for the robustness and maturity of the technology.

- The Ti-6Al-4V material produced reached 99.8% of its theoretical density. Spherical gas porosity was the main defect, but irregularly shaped lack of fusion cavities was also observed, especially in the OS powder lot and in the rough surface layer (~350 μm in depth).

- The coarse average powder size (71.5 μm) and high layer thickness (90 µm) generated a rough surface due to partially melted powder particles adhering to the solidified surfaces of the coupon/part. After machining, the average roughness and root mean square roughness were more than an order of magnitude lower than the as-built condition.

- The as-built microstructure exhibited typical solidification features of wavy columnar prior-β grains—that were delineated by a thin grain boundary α layer—and transformed α-β laths arranged in either a colony or Widmanstätten morphology. The α lath width increased with build height by 32% and 41% for the OS and IS material, respectively, from the bottom (20 mm) to the top (360 mm) of the build.

- This graded α-β microstructure along the build height resulted in a graded microhardness, and strong Hall-Petch correlations were established between the hardness and the average α lath width. In comparison, the influence of orientation on microhardness was relatively minor.

- The tensile properties of the IS Ti-6Al-4V material in the as-built and machined states fully met the requirements of ASTM F2924-14 for PBF Ti-6Al-4V. By contrast, the OS Ti-6Al-4V material exhibited acceptable yield and ultimate strengths, but the ductility values were below the limit accepted by the ASTM standard. Removal of the rough surface layer by machining increased the consistency and performance of the IS and OS Ti-6Al-4V materials.

- Tensile fracture of the OS and IS Ti-6Al-4V materials showed transgranular ductile dimple tearing, characterized by microvoid formation, growth, and coalescence of voids with a tortuous crack path propagating through the porosity in the microstructure, as well as the α colony structure.

- The fatigue behaviour of the EBM Ti-6Al-4V material in the Z-direction was in the range of properties produced by casting. Due to the strong influence of both the surface finish and oxygen content on the fatigue strength, the IS Ti-6Al-4V material exhibited the highest performance, with results in the range of parts processed by casting plus hot isostatic pressing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Bourell, D.L. Perspectives on Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- Milewski, J. Additive Manufacturing of Metals; Springer: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M. Additive Manufacturing of Composite Materials: An Overview. In Proceedings of the 6th International Conference on Virtual Machining Process Technology (VMPT), Montreal, QC, Canada, 29 May–2 June 2017. [Google Scholar]

- Bandyopadhyay, A.; Traxel, K.D. Invited review article: Metal-additive manufacturing—Modeling strategies for application-optimized designs. Addit. Manuf. 2018, 22, 758–774. [Google Scholar] [CrossRef]

- Singamneni, S.; Lv, Y.; Hewitt, A.; Chalk, R.; Thomas, W.; Jordison, D. Additive Manufacturing for the Aircraft Industry: A Review. J. Aeronaut. Aerosp. Eng. 2019, 8, 1. [Google Scholar] [CrossRef] [Green Version]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The impact of metal additive manufacturing on the aerospace industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef] [Green Version]

- Weston, N.S.; Jackson, M. FAST-forge of titanium alloy swarf: A solid-state closed-loop recycling approach for aerospace machining waste. Metals 2020, 10, 296. [Google Scholar] [CrossRef] [Green Version]

- Dutta, B.; Froes, F.H. Additive manufacturing of titanium alloys. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 263–270. [Google Scholar] [CrossRef]

- Dutta, B.; (Sam) Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Wanjara, P.; Watanabe, K.; De Formanoir, C.; Yang, Q.; Bescond, C.; Godet, S.; Brochu, M.; Nezaki, K.; Gholipour, J.; Patnaik, P. Titanium Alloy Repair with Wire-Feed Electron Beam Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2019, 2019, 3979471. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Sikan, F.; Wanjara, P.; Gholipour, J.; Kumar, A.; Brochu, M. Thermo-mechanical modeling of wire-fed electron beam additive manufacturing. Materials 2021, 14, 911. [Google Scholar] [CrossRef] [PubMed]

- Aliprandi, P.; Giudice, F.; Guglielmino, E.; Sili, A. Tensile and creep properties improvement of Ti-6Al-4V alloy specimens produced by electron beam powder bed fusion additive manufacturing. Metals 2019, 9, 1207. [Google Scholar] [CrossRef] [Green Version]

- Cardon, A.; Mareau, C.; Ayed, Y.; Van Der Veen, S.; Santo, P.D. Creep behaviour of Ti-6Al-4V produced by SLM. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; Volume 2113. [Google Scholar] [CrossRef]

- Wanjara, P.; Gholipour, J.; Watanabe, E.; Watanabe, K.; Sugino, T.; Patnaik, P.; Sikan, F.; Brochu, M. High Frequency Vibration Fatigue Behavior of Ti6Al4V Fabricated by Wire-Fed Electron Beam Additive Manufacturing Technology. Adv. Mater. Sci. Eng. 2020, 2020, 1902567. [Google Scholar] [CrossRef]

- Ellyson, B.; Brochu, M.; Brochu, M. Characterization of bending vibration fatigue of SLM fabricated Ti-6Al-4V. Int. J. Fatigue 2017, 99, 25–34. [Google Scholar] [CrossRef]

- Jesus, J.S.; Borrego, L.P.; Ferreira, J.A.; Costa, J.D.; Capela, C. Fatigue crack growth behaviour in Ti6Al4V alloy specimens produced by selective laser melting. Int. J. Fract. 2020, 223, 123–133. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion (F2924); ASTM International Standards: West Conshohocken, PA, USA, 2012; pp. 1–9. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Microindentation Hardness of Materials (E384); ASTM International Standards: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ISO. Geometrical Product Specifications (GPS)—Surface Texture: Areal (ISO 25178); ISO: Geneva, Switzerland, 2012. [Google Scholar]

- ASTM International. Standard Test Methods for Tension Testing of Metallic Materials (E8/E8M); ASTM International Standards: West Conshohocken, PA, USA, 2010; pp. 1–27. [Google Scholar] [CrossRef]

- ASTM International. Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials (E466); ASTM International Standards: West Conshohocken, PA, USA, 2002; Volume 3, pp. 4–8. [Google Scholar] [CrossRef]

- Lu, S.L.; Tang, H.P.; Ning, Y.P.; Liu, N.; StJohn, D.H.; Qian, M. Microstructure and Mechanical Properties of Long Ti-6Al-4V Rods Additively Manufactured by Selective Electron Beam Melting Out of a Deep Powder Bed and the Effect of Subsequent Hot Isostatic Pressing. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 3824–3834. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti6Al4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.Y.; Snis, A.; Lai, Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 2012, 65, 8–15. [Google Scholar] [CrossRef]

- De Formanoir, C.; Michotte, S.; Rigo, O.; Germain, L.; Godet, S. Electron beam melted Ti-6Al-4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater. Sci. Eng. A 2016, 652, 105–119. [Google Scholar] [CrossRef]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, M. Microstructure and Mechanical Properties of High Strength Two-Phase Titanium Alloys. In Titanium Alloys-Advances in Properties Control; IntechOpen: London, UK, 2013; pp. 1–15. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, T.; Rack, H.J. Phase transformations during cooling in α + β titanium alloys. Mater. Sci. Eng. A 2002, 243, 206–211. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International: Materials Park, OH, USA, 1994; pp. 483–633. [Google Scholar]

- Cheng, B.; Price, S.; Lydon, J.; Cooper, K.; Chou, K. On Process Temperature in Powder-Bed Electron Beam Additive Manufacturing: Model Development and Validation. J. Manuf. Sci. Eng. Trans. ASME 2014, 136, 1–12. [Google Scholar] [CrossRef]

- Smith, C.J.; Tammas-Williams, S.; Hernandez-Nava, E.; Todd, I. Tailoring the thermal conductivity of the powder bed in Electron Beam Melting (EBM) Additive Manufacturing. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Martinez, J.L.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Galarraga, H.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef] [Green Version]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 1: Distance from build plate and part size. Mater. Sci. Eng. A 2013, 573, 264–270. [Google Scholar] [CrossRef]

- Gong, X.; Lydon, J.; Cooper, K.; Chou, K. Beam speed effects on Ti-6Al-4V microstructures in electron beam additive manufacturing. J. Mater. Res. 2014, 29, 1951–1959. [Google Scholar] [CrossRef]

- Sharma, H.; Parfitt, D.; Syed, A.K.; Wimpenny, D.; Muzangaza, E.; Baxter, G.; Chen, B. A critical evaluation of the microstructural gradient along the build direction in electron beam melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2019, 744, 182–194. [Google Scholar] [CrossRef]

- Wanjara, P.; Brochu, M.; Jahazi, M. Thin Gauge Titanium Manufacturing using Multiple-Pass Electron Beam Welding. Mater. Manuf. Process. 2006, 21, 439–451. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Atabaki, M.M.; Zahiri, M.; Kelly, S.; Sadek, A.; Kovacevic, R. Microstructural modification of Ti-6Al-4V by using an in-situ printed heat sink in Electron Beam Melting® (EBM). J. Mater. Process. Technol. 2015, 226, 264–271. [Google Scholar] [CrossRef] [Green Version]

- Zuback, J.S.; DebRoy, T. The hardness of additively manufactured alloys. Materials 2018, 11, 2070. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, M.; Xu, W.; Dargusch, M.S.; Tang, H.P.; Brandt, M.; Qian, M. Review of effect of oxygen on room temperature ductility of titanium and titanium alloys. Powder Metall. 2014, 57, 251–257. [Google Scholar] [CrossRef]

- Tiferet, E.; Ganor, M.; Zolotaryov, D.; Garkun, A.; Hadjadj, A.; Chonin, M.; Ganor, Y.; Noiman, D.; Halevy, I.; Tevet, O.; et al. Mapping the tray of electron beam melting of Ti-6Al-4V: Properties and microstructure. Materials 2019, 12, 1470. [Google Scholar] [CrossRef] [Green Version]

- Sidambe, A.T. Three dimensional surface topography characterization of the electron beam melted Ti6Al4V. Met. Powder Rep. 2017, 72, 200–205. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants (F1108); ASTM International Standards: West Conshohocken, PA, USA, 2010; Volume 4, pp. 1–4. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Titanium and Titanium Alloy Bars and Billets (B348/B348M); ASTM International Standards: West Conshohocken, PA, USA, 2013. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate (B265); ASTM International Standards: West Conshohocken, PA, USA, 2010; Volume 3, pp. 1–9. [Google Scholar] [CrossRef]

- Persenot, T.; Martin, G.; Dendievel, R.; Buffiére, J.Y.; Maire, E. Enhancing the tensile properties of EBM as-built thin parts: Effect of HIP and chemical etching. Mater. Charact. 2018, 143, 82–93. [Google Scholar] [CrossRef]

- Donachie, M.J. Titanium: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2000; p. 57. [Google Scholar]

- Polmear, I.; StJohn, D.; Nie, J.-F.; Qian, M. (Eds.) 1—The Light Metals. In Light Alloys: Metallurgy of the Light Metals; Butterworth-Heinemann: Boston, MA, USA, 2017; pp. 1–29. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Khalid Rafi, H.; Karthik, N.V.; Starr, T.L.; Stucker, B.E. Mechanical property evaluation of Ti-6Al-4V parts made using Electron Beam Melting. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference (SFF 2012), Austin, TX, USA, 6–8 August 2012; pp. 526–535. [Google Scholar]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron beam additive manufacturing of titanium components: Properties and performance. J. Manuf. Sci. Eng. Trans. ASME 2013, 135, 1–7. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- Syed, A.K.; Awd, M.; Walther, F.; Zhang, X. Microstructure and mechanical properties of as-built and heat-treated electron beam melted Ti–6Al–4V. Mater. Sci. Technol. 2019, 35, 653–660. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies-electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Zhai, Y.; Galarraga, H.; Lados, D.A. Microstructure, static properties, and fatigue crack growth mechanisms in Ti-6Al-4V fabricated by additive manufacturing: LENS and EBM. Eng. Fail. Anal. 2016, 69, 3–14. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Święszkowski, W. Laser and electron beam additive manufacturing methods of fabricating titanium bone implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Feng, X.; Qiu, J.; Ma, Y.; Lei, J.; Cui, Y.; Wu, X.; Yang, R. Influence of Processing Conditions on Microstructure and Mechanical Properties of Large Thin-Wall Centrifugal Ti-6Al-4V Casting. J. Mater. Sci. Technol. 2016, 32, 362–371. [Google Scholar] [CrossRef]

- Eylon, D.; Newman, J.R.; Thorne, J.K. Titanium and Titanium Alloy Castings. In ASM Handbook Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Materials Park, OH, USA, 1990; p. 642. [Google Scholar]

- Muzangaza, E. The Effects of Titanium Ti-6Al-4V Powders Manufactured Using Electron Beam Melting (EBM)—Additive Manufacturing on Metallurgical Evaluation. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2018. [Google Scholar]

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Charkaluk, E.; Chastand, V. Fatigue of Additive Manufacturing Specimens: A Comparison with Casting Processes. Proceedings 2018, 2, 474. [Google Scholar] [CrossRef] [Green Version]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–783. [Google Scholar] [CrossRef] [Green Version]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The Influence of Porosity on Fatigue Crack Initiation in Additively Manufactured Titanium Components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef] [PubMed]

| Material | Al | V | Fe | C | N | O | H | Ti |

|---|---|---|---|---|---|---|---|---|

| OS Powder | 6.54 | 4.02 | 0.20 | 0.016 | 0.016 | 0.27 | 0.0035 | Bal. |

| IS Powder | 6.44 | 3.97 | 0.21 | 0.014 | 0.018 | 0.18 | 0.0031 | Bal. |

| ASTM F2924 | ||||||||

| Min | 5.50 | 3.50 | - | - | - | - | - | - |

| Max | 6.75 | 4.50 | 0.30 | 0.08 | 0.05 | 0.20 | 0.015 | Bal. |

| Material | Al | V | Fe | C | N | O | H | Ti |

|---|---|---|---|---|---|---|---|---|

| OS Coupons | 5.66 | 4.22 | 0.19 | 0.017 | 0.015 | 0.29 | 0.00350 | Bal. |

| IS Coupons | 5.60 | 4.16 | 0.21 | 0.014 | 0.017 | 0.19 | 0.00312 | Bal. |

| Material Type | OS | IS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Coupon ID | C2 | C10 | C30 | C40 | C70 | C2 | C10 | C30 | C40 | C70 |

| Relative Density (%) | 99.92 | 99.83 | 99.88 | 99.93 | 99.88 | 99.91 | 99.89 | 99.87 | 99.88 | 99.89 |

| Standard Deviation | 0.04 | 0.02 | 0.02 | 0.05 | 0.03 | 0.02 | 0.01 | 0.01 | 0.02 | 0.03 |

| Material | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|

| OS As-built | 913 ± 18 | 981 ± 26 | 4.7 ± 2.0 |

| OS Machined | 973 ± 20 | 1045 ± 12 | 7.8 ± 2.1 |

| IS As-built | 930 ± 9 | 1015 ± 5 | 13.4 ± 1.7 |

| IS Machined | 973 ± 15 | 1053 ± 3 | 13.4 ± 0.9 |

| ASTM F2924-14 PBF Ti-6Al-4V | 825 | 895 | 10 |

| ASTM F1108-14 Cast Ti-6Al-4V | 758 | 860 | 8 |

| ASTM B348-19 or B265-05 grade 5 Wrought Ti-6Al-4V | 828 | 895 | 10 |

| Reference | Machine | Preheat (°C) | Surface | Geometry *, Orientation | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|---|---|---|

| Present work (IS) | Q20+ | 326–556 | As-built | Round, V | 930.0 | 1015.2 | 11.9 |

| Machined | 939.8 | 1058.9 | 13.4 | ||||

| Edwards et al. [58] | A1 | 700 | As-built | Flat, V | 812 | 851 | 3.6 |

| Rafi et al. [56,57] | S400 | 700 | As-built | Round, V | 782 | 842 | 9.9 |

| Machined | 869 | 928 | 9.9 | ||||

| Chastand et al. [59] | A2 | 680 | Machined | Round, V | 970 | 1045 | 10.9 |

| Syed et al. [60] | A2 | NA | Machined | Flat, H + V | 905 | 990 | 4 |

| Koike et al. [61] | A2 | 700 | As-built | Round, NA | 740 | 790 | 2.2 |

| Zhai et al. [62] | A2 | 650–750 | Machined | Flat and Round, V | 1001 | 1073 | 11 |

| Q10 | 1051 | 1116 | 15 | ||||

| de Formanoir et al. [32] | A2 | 850 | As-built | Flat, V | 832 | 850 | 3.6 |

| Polished | 1055 | 1100 | 4.6 | ||||

| Wysocki et al. [63] | S12 | 700 | Machined | Flat, Non-std, V | 845 | 972 | 14.2 |

| Hrabe et al. [41,64] | S12 | NA | Machined | Flat, I, V | 984.1 | 1032.9 | 9.0 |

| Flat, E, V | 961.0 | 1008.6 | 7.1 | ||||

| Bermani et al. [30] | S12 | 626 | Machined | Round, NA | 938.5 | 1029.1 | 13.2 |

| 644 | 928.8 | 1028.9 | 13 | ||||

| 678 | 932.4 | 1031.9 | 11.6 | ||||

| 700 | 883.7 | 993.9 | 13.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the National Research Council Canada. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wanjara, P.; Backman, D.; Sikan, F.; Gholipour, J.; Amos, R.; Patnaik, P.; Brochu, M. Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences. J. Manuf. Mater. Process. 2022, 6, 21. https://doi.org/10.3390/jmmp6010021

Wanjara P, Backman D, Sikan F, Gholipour J, Amos R, Patnaik P, Brochu M. Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences. Journal of Manufacturing and Materials Processing. 2022; 6(1):21. https://doi.org/10.3390/jmmp6010021

Chicago/Turabian StyleWanjara, Priti, David Backman, Fatih Sikan, Javad Gholipour, Robert Amos, Prakash Patnaik, and Mathieu Brochu. 2022. "Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences" Journal of Manufacturing and Materials Processing 6, no. 1: 21. https://doi.org/10.3390/jmmp6010021

APA StyleWanjara, P., Backman, D., Sikan, F., Gholipour, J., Amos, R., Patnaik, P., & Brochu, M. (2022). Microstructure and Mechanical Properties of Ti-6Al-4V Additively Manufactured by Electron Beam Melting with 3D Part Nesting and Powder Reuse Influences. Journal of Manufacturing and Materials Processing, 6(1), 21. https://doi.org/10.3390/jmmp6010021