Friction Stir Processing on the Tribological, Corrosion, and Erosion Properties of Steel: A Review

Abstract

1. Introduction

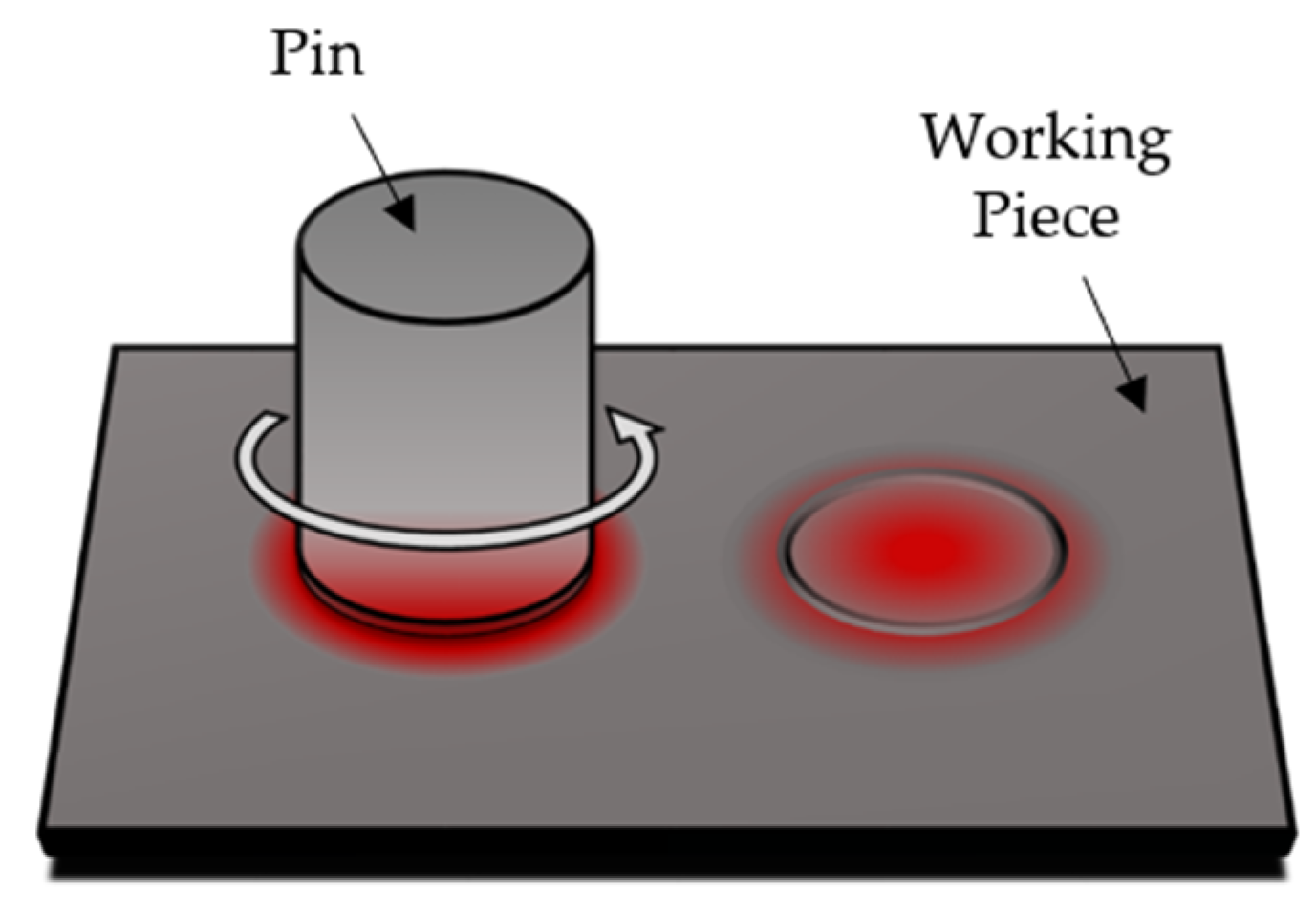

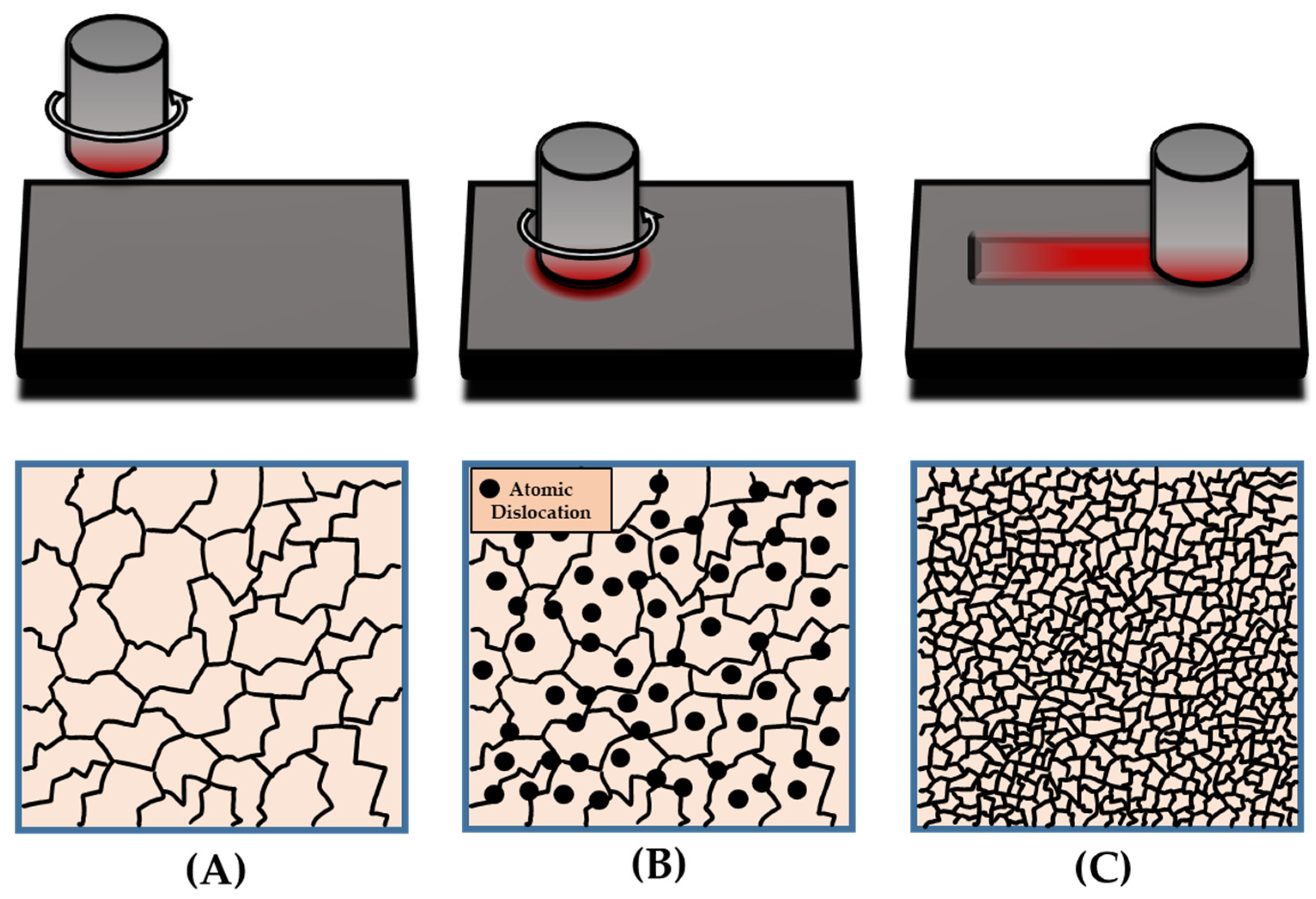

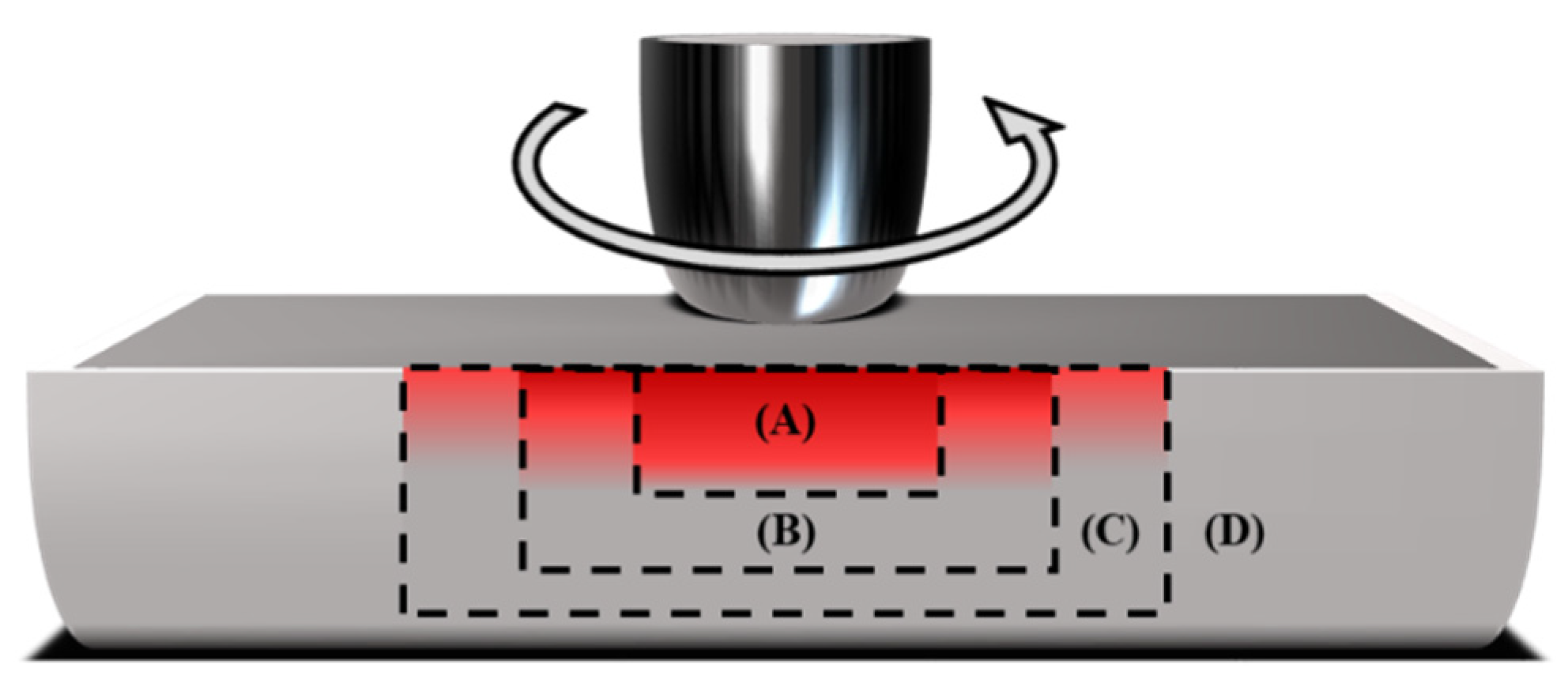

2. Microstructural Mechanisms of Friction Stir Processing

3. Mechanical and Tribological Enhancements

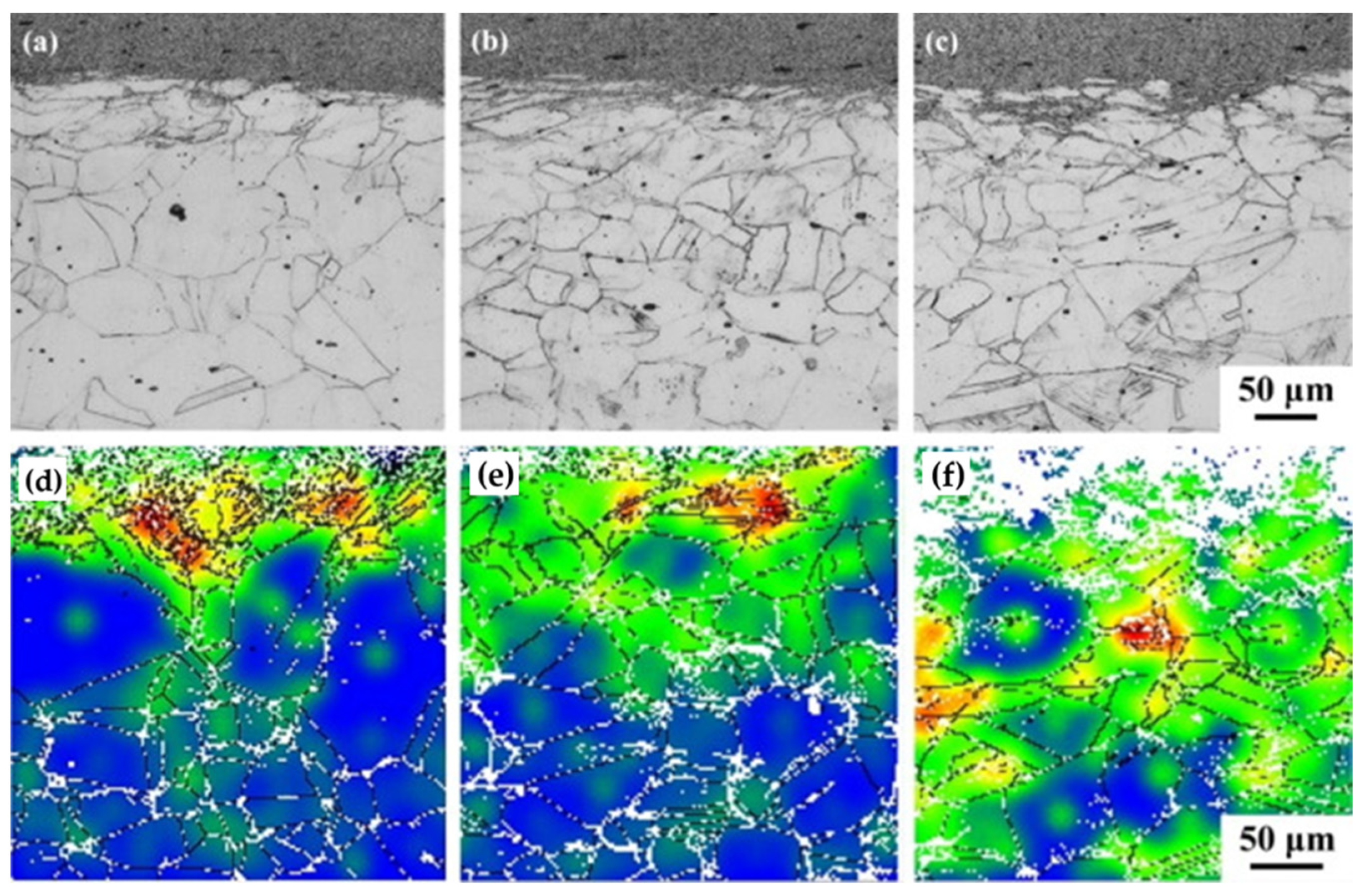

3.1. Microstructural Changes

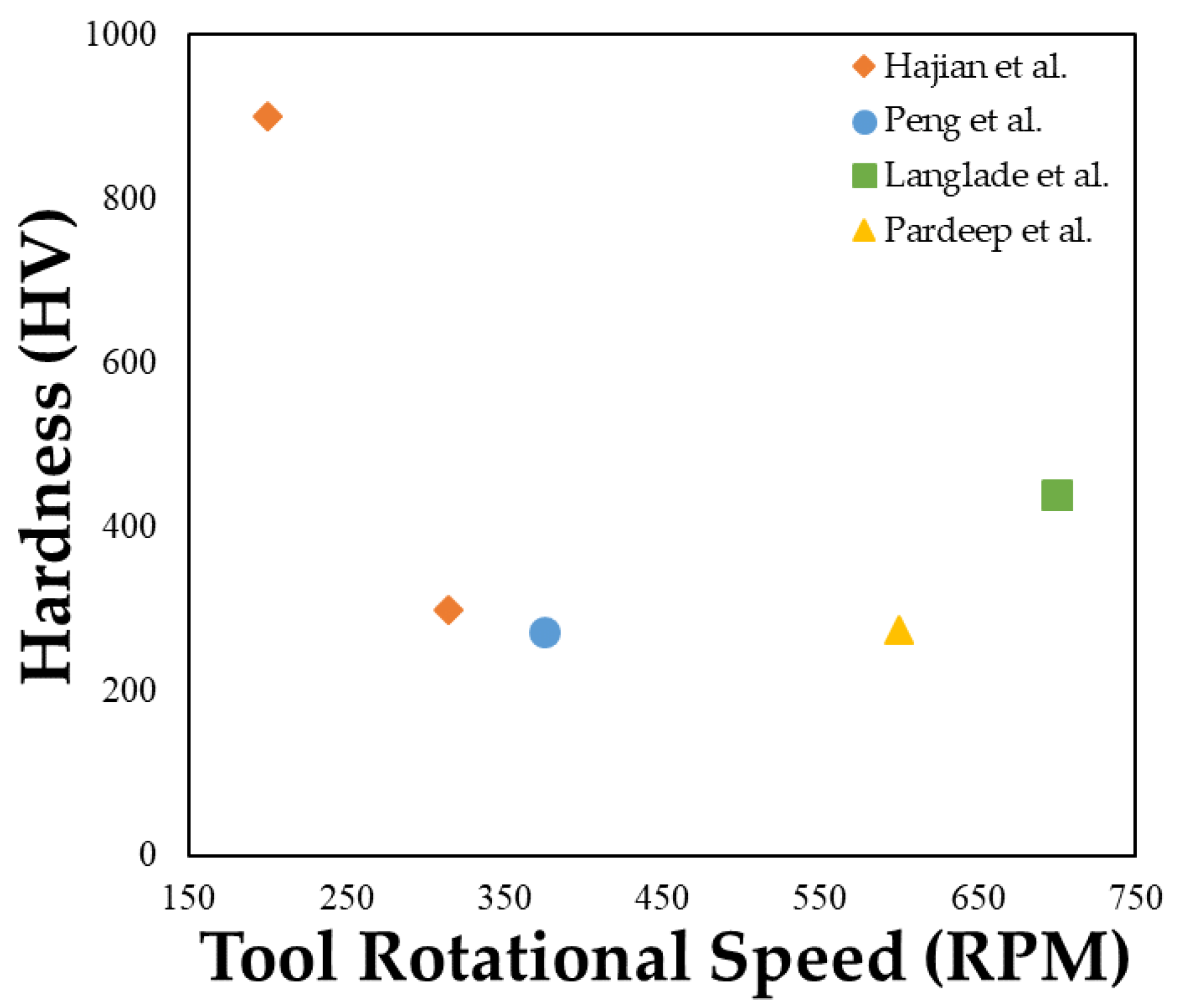

3.2. Mechanical Properties

3.3. Tribological Properties

4. Effects on Corrosion-Erosion Properties

5. Applications of FSP Steel

6. Summary and Future Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Liu, X.; Zhao, Y. Research Status and Prospect of Friction Stir Processing Technology. Coatings 2019, 9, 129. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction Stir Processing Technology: A Review. Met. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Metall. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Chiteka, K. Friction Stir Welding/Processing Tool Materials and Selection. Int. J. Eng. Res. 2013, 2, 11. [Google Scholar]

- Emamian, S.; Awang, M.; Yusof, F.; Hussain, P.; Mehrpouya, M.; Kakooei, S.; Moayedfar, M.; Zafar, A. A Review of Friction Stir Welding Pin Profile. In Proceedings of the 2nd International Conference on Mechanical, Manufacturing and Process Plant Engineering; Kuala Lumpur, Kuala Lumpur, Malaylsia, 30 April 2017; Awang, M., Ed.; Springer: Singapore, 2017; pp. 1–18. [Google Scholar]

- Investigation of the Mechanical Properties of Friction Stir Welded 6061 Al Plates. Available online: http://www.jeaconf.org/UploadedFiles/Document/97626981-7e64-4048-8a70-6a0e1f6f9847.pdf (accessed on 25 March 2020).

- MuhsinJ, J.; Tolephih, M. Effect of Friction Stir Welding Parameters (Rotation and Transverse) Speed on the Transient Temperature Distribution in Friction Stir Welding of AA 7020-T53. Available online: https://www.semanticscholar.org/paper/EFFECT-OF-FRICTION-STIR-WELDING-PARAMETERS-AND-ON-MuhsinJ.-Tolephih/451174f3bc07db6cd07a18c468f634957f6aced2 (accessed on 29 June 2021).

- McNelley, T.R. Procesado por fricción batida (FSP): Afino de la microestructura y mejora de propiedades. Rev. Metal. 2010, 46, 149–156. [Google Scholar] [CrossRef]

- Sharma, V.; Prakash, U.; Kumar, B.V.M. Surface composites by friction stir processing: A review. J. Mater. Process. Technol. 2015, 224, 117–134. [Google Scholar] [CrossRef]

- Bajakke, P.A.; Jambagi, S.C.; Malik, V.R.; Deshpande, A.S. Friction Stir Processing: An Emerging Surface Engineering Technique. In Surface Engineering of Modern Materials; Gupta, K., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–31. ISBN 978-3-030-43232-4. [Google Scholar]

- Ralls, A.; Kumar, P.; Misra, M.; Menezes, P.L. Material Design and Surface Engineering for Bio-implants. JOM 2020, 72, 684–696. [Google Scholar] [CrossRef]

- Miranda, R.M.; Gandra, J.; Vilaça, P. Chapter 1 Surface Modification by Friction Based Processes; IntechOpen Limited: London, UK, 2017. [Google Scholar]

- El-Danaf, E.A.; El-Rayes, M.M.; Soliman, M.S. Friction stir processing: An effective technique to refine grain structure and enhance ductility. Mater. Des. 2010, 31, 1231–1236. [Google Scholar] [CrossRef]

- Liu, F.; Li, Y.; Sun, Z.; Ji, Y. Corrosion resistance and tribological behavior of particles reinforced AZ31 magnesium matrix composites developed by friction stir processing. J. Mater. Res. Technol. 2021, 11, 1019–1030. [Google Scholar] [CrossRef]

- Moeini, G.; Sajadifar, S.V.; Engler, T.; Heider, B.; Niendorf, T.; Oechsner, M.; Böhm, S. Effect of Friction Stir Processing on Microstructural, Mechanical, and Corrosion Properties of Al-Si12 Additive Manufactured Components. Metals 2020, 10, 85. [Google Scholar] [CrossRef]

- Ralls, A.M.; Kumar, P.; Menezes, P.L. Tribological Properties of Additive Manufactured Materials for Energy Applications: A Review. Processes 2021, 9, 31. [Google Scholar] [CrossRef]

- Mondal, M.; Das, H.; Hong, S.-T.; Jeong, B.-S.; Han, H.N. Local enhancement of the material properties of aluminium sheets by a combination of additive manufacturing and friction stir processing. CIRP Ann. 2019, 68, 289–292. [Google Scholar] [CrossRef]

- Perard, T.; Sova, A.; Robe, H.; Robin, V.; Zedan, Y.; Bocher, P.; Feulvarch, E. Friction stir processing of austenitic stainless steel cold spray coating deposited on 304L stainless steel substrate: Feasibility study. Int. J. Adv. Manuf. Technol. 2021, 115, 2379–2393. [Google Scholar] [CrossRef]

- Rubino, F.; Scherillo, F.; Franchitti, S.; Squillace, A.; Astarita, A.; Carlone, P. Microstructure and surface analysis of friction stir processed Ti-6Al-4V plates manufactured by electron beam melting. J. Manuf. Process. 2019, 37, 392–401. [Google Scholar] [CrossRef]

- Kumar Srivastava, A.; Kumar, N.; Rai Dixit, A. Friction stir additive manufacturing—An innovative tool to enhance mechanical and microstructural properties. Mater. Sci. Eng. B 2021, 263, 114832. [Google Scholar] [CrossRef]

- Palanivel, S.; Nelaturu, P.; Glass, B.; Mishra, R.S. Friction stir additive manufacturing for high structural performance through microstructural control in an Mg based WE43 alloy. Mater. Des. 2015, 65, 934–952. [Google Scholar] [CrossRef]

- Lu, I. Friction Stir Additive Manufacturing(FSAM) of 2050 Al-Cu-Li Alloy. Master’s Thesis, University of South Carolina, Columbia, SC, USA, 2019. [Google Scholar]

- Akinlabi, E.T.; Mahamood, R.M.; Akinlabi, S.A.; Ogunmuyiwa, E. Processing Parameters Influence on Wear Resistance Behaviour of Friction Stir Processed Al-TiC Composites. Available online: https://www.hindawi.com/journals/amse/2014/724590/ (accessed on 25 March 2020).

- Smith, C.B.; Ajayi, O. Friction Stir Processing for Efficient Manufacturing; Friction Stir Link, Inc.: Brookfield, NY, USA, 2012. [Google Scholar]

- Carter, B. Introduction to Friction Stir Welding (FSW). p. 25. Available online: https://core.ac.uk/download/pdf/42710093.pdf (accessed on 19 August 2021).

- Wang, J.; Lu, X.; Cheng, C.; Li, B.; Ma, Z. Improve the quality of 1060Al/Q235 explosive composite plate by friction stir processing. J. Mater. Res. Technol. 2020, 9, 42–51. [Google Scholar] [CrossRef]

- Kaya, Y.; Kahraman, N. An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel. Mater. Des. 2013, 52, 367–372. [Google Scholar] [CrossRef]

- Friction Stir Processing—Google Scholar. Available online: https://scholar.google.com/scholar?q=friction+stir+processing&hl=en&as_sdt=0%2C29&as_ylo=&as_yhi= (accessed on 24 March 2020).

- SciELO—Brazil—The Role of Friction Stir Processing (FSP) Parameters on TiC Reinforced Surface Al7075-T651 Aluminum Alloy The Role of Friction Stir Processing (FSP) Parameters on TiC Reinforced Surface Al7075-T651 Aluminum Alloy. Available online: https://www.scielo.br/j/si/a/5pDddMwYdyBfDbX5X5fgqvr/?lang=en (accessed on 29 June 2021).

- Friction Stir Processing as a Novel Technique to Achieve Superplasticity in Aluminum Alloys: Process Variables, Variants, and Applications | SpringerLink. Available online: https://link.springer.com/article/10.1007/s13632-016-0285-x (accessed on 24 March 2020).

- Gupta, M.K. Friction stir process: A green fabrication technique for surface composites—A review paper. SN Appl. Sci. 2020, 2, 532. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W.; McFaden, S.X.; Mara, N.A.; Mukherjee, A.K. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42. [Google Scholar] [CrossRef]

- Ramesh Babu, S.; Kumar, V.S.S.; Reddy, G.M.; Karunamoorthy, L. Microstructural Changes and Mechanical Properties of Friction Stir Processed Extruded AZ31B Alloy. Procedia Eng. 2012, 38, 2956–2966. [Google Scholar] [CrossRef][Green Version]

- Mechanical Properties, Corrosion Resistance, and Microstructural Changes during Friction Stir Processing of 5083 Aluminum Rolled Plates. Available online: https://www.researchgate.net/publication/254343154_Mechanical_Properties_Corrosion_Resistance_and_Microstructural_Changes_during_Friction_Stir_Processing_of_5083_Aluminum_Rolled_Plates (accessed on 24 March 2020).

- Janbozorgi, M.; Shamanian, M.; Sadeghian, M.; Sepehrinia, P. Improving tribological behavior of friction stir processed A413/SiC p surface composite using MoS 2 lubricant particles. Trans. Nonferrous Met. Soc. China 2017, 27, 298–304. [Google Scholar] [CrossRef]

- A Review on Friction Stir Processing of Titanium Alloy: Characterization, Method, Microstructure, Properties | SpringerLink. Available online: https://link.springer.com/article/10.1007/s11663-019-01634-9 (accessed on 24 March 2020).

- Huang, Y.; Wang, Y.; Meng, X.; Wan, L.; Cao, J.; Zhou, L.; Feng, J. Dynamic recrystallization and mechanical properties of friction stir processed Mg-Zn-Y-Zr alloys. J. Mater. Process. Technol. 2017, 249, 331–338. [Google Scholar] [CrossRef]

- EBSD Study of a Hot Deformed Nickel-Based Superalloy—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0925838815009494 (accessed on 25 March 2020).

- Mathematical and Physical Modelling of the Flat Rolling Process—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/B9780080994185000056 (accessed on 24 March 2020).

- A Review of Dynamic Recrystallization Phenomena in Metallic Materials—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0264127516311753 (accessed on 24 March 2020).

- Characterization for Dynamic Recrystallization Kinetics Based on Stress-Strain Curves | IntechOpen. Available online: https://www.intechopen.com/books/recent-developments-in-the-study-of-recrystallization/characterization-for-dynamic-recrystallization-kinetics-based-on-stress-strain-curves (accessed on 24 March 2020).

- Arora, H.S.; Ayyagari, A.; Saini, J.; Selvam, K.; Riyadh, S.; Pole, M.; Grewal, H.S.; Mukherjee, S. High Tensile Ductility and Strength in Dual-phase Bimodal Steel through Stationary Friction Stir Processing. Sci. Rep. 2019, 9, 1972. [Google Scholar] [CrossRef]

- Hajian, M.; Abdollah-zadeh, A.; Rezaei-Nejad, S.S.; Assadi, H.; Hadavi, S.M.M.; Chung, K.; Shokouhimehr, M. Microstructure and mechanical properties of friction stir processed AISI 316L stainless steel. Mater. Des. 2015, 67, 82–94. [Google Scholar] [CrossRef]

- Twinning Behaviors and Grain Refinement Mechanisms during Friction Stir Processing of Zr Alloy—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1044580319329213 (accessed on 25 March 2020).

- Microstructure Evolution and Texture Development in a Friction Stir-Processed AISI D2 Tool Steel—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0169433213024112 (accessed on 25 March 2020).

- Microstructural Evolutions of the Al Strip Prepared by Cold Rolling and Continuous Equal Channel Angular Pressing—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1359645402002008 (accessed on 25 March 2020).

- Friction Stir Processing of Particle Reinforced Composite Materials. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5525169/ (accessed on 25 March 2020).

- A Review on Friction Stir Processing on Aluminum Based Materilas. Available online: https://www.researchgate.net/publication/305481261_A_review_on_friction_stir_processing_on_aluminum_based_materilas (accessed on 25 March 2020).

- Sun, N.; Apelian, D. Friction stir processing of aluminum cast alloys for high performance applications. JOM 2011, 63, 44–50. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Kuriachen, B. Friction stir processing of alloys with secondary phase particles: An overview. Mater. Manuf. Process. 2019, 34, 1429–1457. [Google Scholar] [CrossRef]

- Valdez, B.; Schorr, M.; Zlatev, R.; Carrillo, M.; Stoytcheva, M.; Alvarez, L.; Eliezer, A.; Rosas, N. Corrosion Control in Industry. Environ. Ind. Corros. Pract. Theor. Asp. 2012. [Google Scholar] [CrossRef]

- López-Ortega, A.; Arana, J.L.; Bayón, R. Tribocorrosion of Passive Materials: A Review on Test Procedures and Standards. Available online: https://www.hindawi.com/journals/ijc/2018/7345346/ (accessed on 26 March 2020).

- Sodhi, G.P.S.; Singh, H. Development of corrosion resistant surfaces via friction stir processing for bio implant applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 284, 012026. [Google Scholar] [CrossRef]

- Hegelmann, E.; Hengst, P.; Hollmann, P.; Thronicke, J.; Buchwalder, A.; Schimpf, C.; Hunger, R.; Zenker, R. Improvement of Wear and Corrosion Resistance of Austenitic Stainless Steel by Combined Treatment Using Electron Beam Cladding and Subsequent Gas Nitrocarburizing. Adv. Eng. Mater. 2019, 21, 1900365. [Google Scholar] [CrossRef]

- The Cost of Corrosion. Available online: https://www.zerust.com/blog/2019/10/02/the-cost-of-corrosion/ (accessed on 27 March 2020).

- The Global Impact of Corrosion. Available online: http://impact.nace.org/executive-summary.aspx (accessed on 27 March 2020).

- Bjorhovde, R. Development and use of high performance steel. J. Constr. Steel Res. 2004, 60, 393–400. [Google Scholar] [CrossRef]

- Venkatesh, K.M.; Arivarsu, M.; Manikandan, M.; Arivazhagan, N. Review on friction stir welding of steels. Mater. Today Proc. 2018, 5, 13227–13235. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Boccaccini, A.R. 3—Ceramics. In Biomaterials, Artificial Organs and Tissue Engineering; Hench, L.L., Jones, J.R., Eds.; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Sawston, UK, 2005; pp. 26–36. ISBN 978-1-85573-737-2. [Google Scholar]

- Patel, V.; Li, W.; Vairis, A.; Badheka, V. Recent Development in Friction Stir Processing as a Solid-State Grain Refinement Technique: Microstructural Evolution and Property Enhancement. Crit. Rev. Solid State Mater. Sci. 2019, 44, 378–426. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Kashani-Bozorg, S.F. Microstructure and mechanical properties of steel/TiC nano-composite surface layer produced by friction stir processing. Surf. Coat. Technol. 2012, 209, 15–22. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S.; Scheu, C. Microstructure and Properties of Engineering Materials. In Neutrons and Synchrotron Radiation in Engineering Materials Science; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; pp. 1–20. ISBN 978-3-527-68448-9. [Google Scholar]

- Mishra, M.K.; Rao, A.G.; Balasundar, I.; Kashyap, B.P.; Prabhu, N. On the microstructure evolution in friction stir processed 2507 super duplex stainless steel and its effect on tensile behaviour at ambient and elevated temperatures. Mater. Sci. Eng. A 2018, 719, 82–92. [Google Scholar] [CrossRef]

- Peng, P.; Wang, K.; Wang, W.; Han, P.; Zhang, T.; Liu, Q.; Zhang, S.; Wang, H.; Qiao, K.; Liu, J. Relationship between microstructure and mechanical properties of friction stir processed AISI 316L steel produced by selective laser melting. Mater. Charact. 2020, 163, 110283. [Google Scholar] [CrossRef]

- Zhang, H.; Xue, P.; Wang, D.; Wu, L.H.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. A novel approach to achieve high yield strength high nitrogen stainless steel with superior ductility and corrosion resistance. Mater. Lett. 2019, 242, 91–94. [Google Scholar] [CrossRef]

- Xue, P.; Li, W.D.; Wang, D.; Wang, W.G.; Xiao, B.L.; Ma, Z.Y. Enhanced mechanical properties of medium carbon steel casting via friction stir processing and subsequent annealing. Mater. Sci. Eng. A 2016, 670, 153–158. [Google Scholar] [CrossRef]

- Chen, Y.C.; Fujii, H.; Tsumura, T.; Kitagawa, Y.; Nakata, K.; Ikeuchi, K.; Matsubayashi, K.; Michishita, Y.; Fujiya, Y.; Katoh, J. Friction stir processing of 316L stainless steel plate. Sci. Technol. Weld. Join. 2009, 14, 197–201. [Google Scholar] [CrossRef]

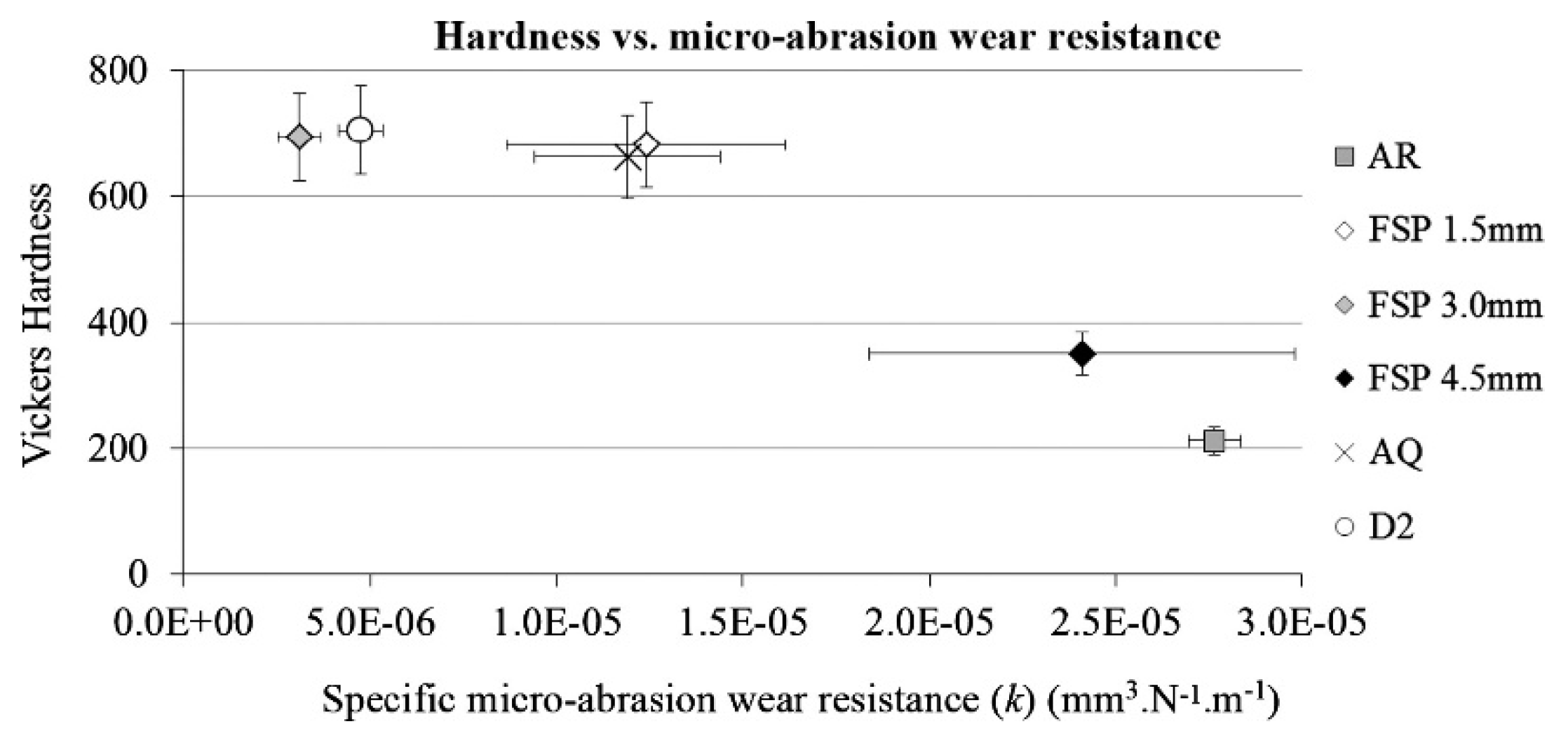

- Dodds, S.; Jones, A.H.; Cater, S. Tribological enhancement of AISI 420 martensitic stainless steel through friction-stir processing. Wear 2013, 302, 863–877. [Google Scholar] [CrossRef]

- Amirafshar, A.; Pouraliakbar, H. Effect of tool pin design on the microstructural evolutions and tribological characteristics of friction stir processed structural steel. Measurement 2015, 68, 111–116. [Google Scholar] [CrossRef]

- Aldajah, S.H.; Ajayi, O.O.; Fenske, G.R.; David, S. Effect of friction stir processing on the tribological performance of high carbon steel. Wear 2009, 267, 350–355. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.O. Rapid surface hardening and enhanced tribological performance of 4140 steel by friction stir processing. Wear 2015, 332–333, 962–970. [Google Scholar] [CrossRef]

- Sarlak, H.; Atapour, M.; Esmailzadeh, M. Corrosion behavior of friction stir welded lean duplex stainless steel. Mater. Des. 2015, 66, 209–216. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-zadeh, A.; Assadi, H.; Malek Ghaini, F. Effect of friction stir welding speed on the microstructure and mechanical properties of a duplex stainless steel. Mater. Sci. Eng. A 2008, 496, 262–268. [Google Scholar] [CrossRef]

- Cui, H.B.; Xie, G.M.; Luo, Z.A.; Ma, J.; Wang, G.D.; Misra, R.D.K. Microstructural evolution and mechanical properties of the stir zone in friction stir processed AISI201 stainless steel. Mater. Des. 2016, 106, 463–475. [Google Scholar] [CrossRef]

- Evaluation of Microstructure and Mechanical Properties in Friction Stir Processed SKD61 Tool Steel—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1044580309002514 (accessed on 1 April 2020).

- Material Hardness Review—Engineers Edge. Available online: https://www.engineersedge.com/material_science/hardness.htm (accessed on 1 April 2020).

- Top 3 Industries for Steel Applications | MSP Group. Available online: https://mspsteel.com/top-3-industries-for-steel-applications (accessed on 1 April 2020).

- Langlade, C.; Roman, A.; Schlegel, D.; Gete, E.; Folea, M. Study of stirred layers on 316L steel created by friction stir processing. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012007. [Google Scholar] [CrossRef]

- Pankaj, P.; Tiwari, A.; Biswas, P.; Rao, A.G.; Pal, S. Experimental studies on controlling of process parameters in dissimilar friction stir welding of DH36 shipbuilding steel–AISI 1008 steel. Weld World 2020, 64, 963–986. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S. Mechanical properties of dissimilar thickness aluminium alloy weld by single/double pass FSW. J. Mater. Process. Technol. 2017, 243, 442–455. [Google Scholar] [CrossRef]

- Material Flow Analysis of Similar and Dissimilar Friction Stir Welding. Available online: http://gyan.iitg.ernet.in/handle/123456789/1215 (accessed on 30 June 2021).

- Buffa, G.; Hua, J.; Shivpuri, R.; Fratini, L. A continuum based fem model for friction stir welding—Model development. Mater. Sci. Eng. A 2006, 419, 389–396. [Google Scholar] [CrossRef]

- Cartigueyen, S.; Sukesh, O.P.; Mahadevan, K. Numerical and Experimental Investigations of Heat Generation during Friction Stir Processing of Copper. Procedia Eng. 2014, 97, 1069–1078. [Google Scholar] [CrossRef][Green Version]

- Al-moussawi, M.; Smith, A.J.; Young, A.; Cater, S.; Faraji, M. Modelling of friction stir welding of DH36 steel. Int. J. Adv. Manuf. Technol. 2017, 92, 341–360. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of Multi-Pass Friction Stir Processing on Mechanical Properties for AA2024/Al2O3 Nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef]

- El-Rayes, M.M.; El-Danaf, E.A. The influence of multi-pass friction stir processing on the microstructural and mechanical properties of Aluminum Alloy 6082. J. Mater. Process. Technol. 2012, 212, 1157–1168. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Meng, X.; Wan, L.; Feng, J. Microstructural evolution and mechanical properties of MgZnYZr alloy during friction stir processing. J. Alloys Compd. 2017, 696, 875–883. [Google Scholar] [CrossRef]

- Xu, N.; Bao, Y. Enhanced mechanical properties of tungsten inert gas welded AZ31 magnesium alloy joint using two-pass friction stir processing with rapid cooling. Mater. Sci. Eng. A 2016, 655, 292–299. [Google Scholar] [CrossRef]

- What Are the Top 10 Strongest Metals on Earth? Available online: https://sciencing.com/top-10-strongest-metals-earth-2595.html (accessed on 13 April 2020).

- What is Tensile Testing? The Theory and Applications. Available online: https://www.azom.com/article.aspx?ArticleID=5551 (accessed on 13 April 2020).

- Marshall. The Applications of Advanced High-Strength Steel. National Material Company—Steel Processing Facilities. 2017. Available online: http://www.nationalmaterial.com/applications-advanced-high-strength-steel/ (accessed on 13 April 2020).

- The Application of Friction Stir Processing to the Fabrication of Magnesium-Based Foams. Available online: https://www.researchgate.net/publication/321697379_The_Application_of_Friction_Stir_Processing_to_the_Fabrication_of_Magnesium-Based_Foams (accessed on 20 April 2020).

- Hangai, Y.; Utsunomiya, T.; Hasegawa, M. Effect of tool rotating rate on foaming properties of porous aluminum fabricated by using friction stir processing. J. Mater. Process. Technol. 2010, 210, 288–292. [Google Scholar] [CrossRef]

- Hangai, Y.; Utsunomiya, T. Fabrication of Porous Aluminum by Friction Stir Processing. Met. Mater. Trans. A 2009, 40, 275–277. [Google Scholar] [CrossRef]

- Kumar, M.; Prasanth, R.; Selvakumar, B.; Ranjith, V. A review on friction stir processing of Al6061 surface composites. AIP Conf. Proc. 2019, 2128, 020031. [Google Scholar]

- Jost, H.P. The Economic Importance of Tribology in the Conservation of Energy. In Tribologie Reibung · Verschleiß · Schmierung; Bunk, W., Hansen, J., Geyer, M., Eds.; Dokumentation zum Forschungs- und Entwicklungsprogramm des Bundesministeriums für Forschung und Technologie (BMFT); Springer: Berlin/Heidelberg, Germany, 1981; pp. 9–38. ISBN 978-3-642-52220-8. [Google Scholar]

- Tribology for Scientists and Engineers—From Basics to Advanced Concepts | Pradeep Menezes | Springer. Available online: https://www.springer.com/gp/book/9781461419440 (accessed on 21 November 2019).

- Ciulli, E. Tribology and Industry: From the Origins to 4.0. Front. Mech. Eng. 2019, 5. [Google Scholar] [CrossRef]

- Rezaei-Nejad, S.S.; Abdollah-zadeh, A.; Hajian, M.; Kargar, F.; Seraj, R. Formation of Nanostructure in AISI 316L Austenitic Stainless Steel by Friction Stir Processing. Procedia Mater. Sci. 2015, 11, 397–402. [Google Scholar] [CrossRef]

- Selvam, K.; Ayyagari, A.; Grewal, H.S.; Mukherjee, S.; Arora, H.S. Enhancing the erosion-corrosion resistance of steel through friction stir processing. Wear 2017, 386–387, 129–138. [Google Scholar] [CrossRef]

- Lotfollahi, M.; Shamanian, M.; Saatchi, A. Effect of friction stir processing on erosion–corrosion behavior of nickel–aluminum bronze. Mater. Des. 2014, 62, 282–287. [Google Scholar] [CrossRef]

- Snell, R.; Tammas-Williams, S.; Chechik, L.; Lyle, A.; Hernández-Nava, E.; Boig, C.; Panoutsos, G.; Todd, I. Methods for Rapid Pore Classification in Metal Additive Manufacturing. JOM 2020, 72, 101–109. [Google Scholar] [CrossRef]

- Zhao, Y.; Dong, C.; Jia, Z.; You, J.; Tan, J.; Miao, S.; Yi, Y. Microstructure Characteristics and Corrosion Resistance of Friction Stir Welded 2205 Duplex Stainless Steel. Adv. Mater. Sci. Eng. 2021, 2021, e8890274. [Google Scholar] [CrossRef]

- Lü, A.Q.; Zhang, Y.; Li, Y.; Liu, G.; Zang, Q.H.; Liu, C.M. Effect of Nanocrystalline and Twin Boundaries on Corrosion Behavior of 316l Stainless Steel Using Smat. Acta Metall. Sin. (Engl. Lett.) 2006, 19, 183–189. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of Grain Size on Corrosion: A Review. Corrosion 2010, 66, 075005. [Google Scholar] [CrossRef]

- Wang, W.; Xu, R.; Hao, Y.; Wang, Q.; Yu, L.; Che, Q.; Cai, J.; Wang, K.; Ma, Z. Corrosion fatigue behavior of friction stir processed interstitial free steel. J. Mater. Sci. Technol. 2018, 34, 148–156. [Google Scholar] [CrossRef]

- Ultrasonic Cavitation Erosion-Corrosion Behavior of Friction Stir Processed Stainless Steel—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S135041771830302X (accessed on 31 March 2020).

- Microstructure, Mechanical and Corrosion Properties of Friction Stir Welded High Nitrogen Nickel-Free Austenitic Stainless Steel—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0264127515004530 (accessed on 31 March 2020).

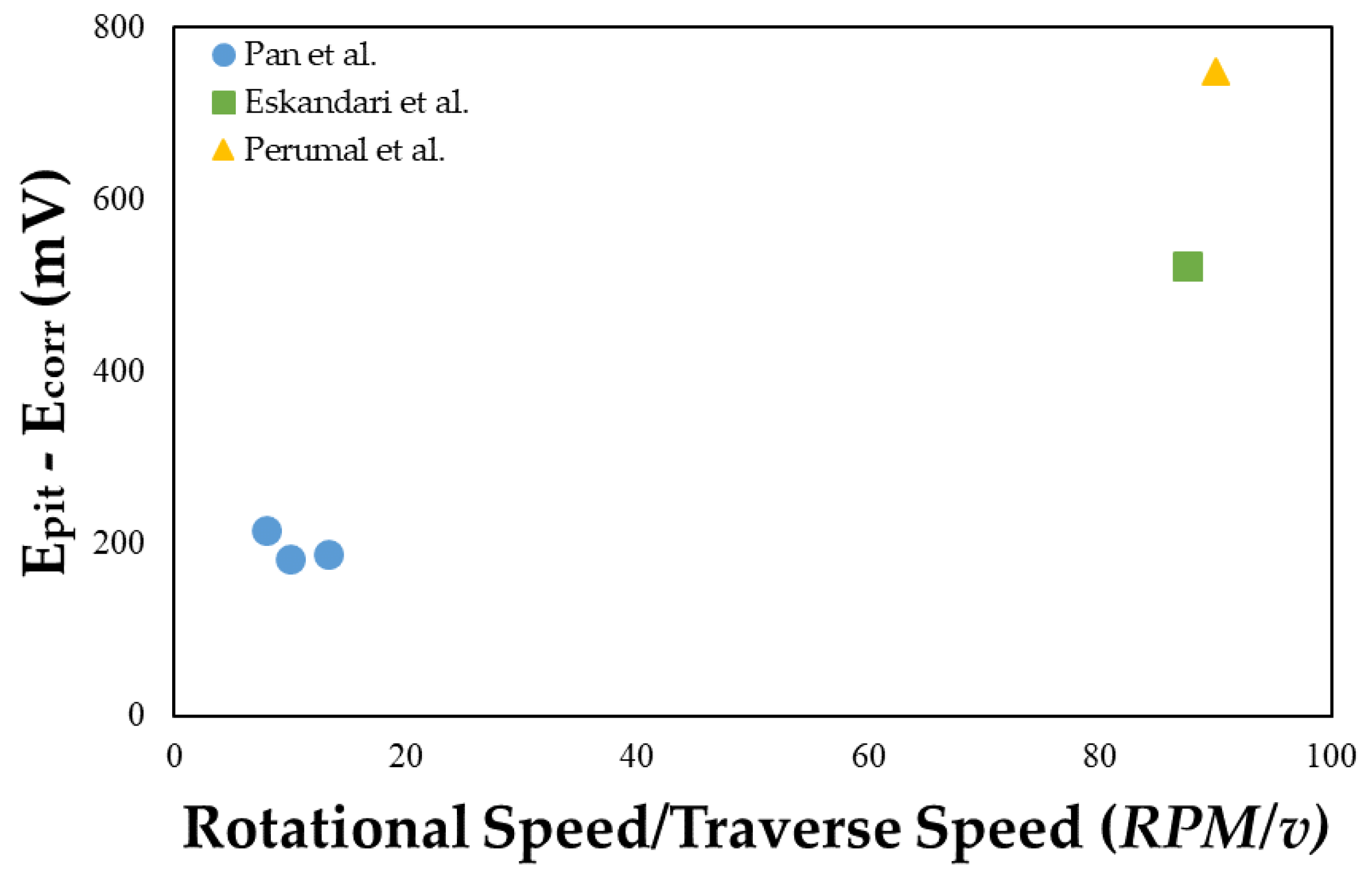

- Pan, L.; Kwok, C.T.; Lo, K.H. Enhancement in hardness and corrosion resistance of AISI 420 martensitic stainless steel via friction stir processing. Surf. Coat. Technol. 2019, 357, 339–347. [Google Scholar] [CrossRef]

- Mishra, M.K.; Gunasekaran, G.; Rao, A.G.; Kashyap, B.P.; Prabhu, N. Effect of Multipass Friction Stir Processing on Mechanical and Corrosion Behavior of 2507 Super Duplex Stainless Steel. J. Mater. Eng. Perform. 2017, 26, 849–860. [Google Scholar] [CrossRef]

- Eskandari, F.; Atapour, M.; Golozar, M.A.; Sadeghi, B.; Cavaliere, P. Corrosion behavior of friction stir processed AISI 430 ferritic stainless steel. Mater. Res. Express 2019, 6, 086532. [Google Scholar] [CrossRef]

- Perumal, G.; Ayyagari, A.; Chakrabarti, A.; Kannan, D.; Pati, S.; Grewal, H.S.; Mukherjee, S.; Singh, S.; Arora, H.S. Friction Stir Processing of Stainless Steel for Ascertaining Its Superlative Performance in Bioimplant Applications. ACS Appl. Mater. Interfaces 2017, 9, 36615–36631. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Kwok, C.T.; Lo, K.H. Friction-stir processing of AISI 440C high-carbon martensitic stainless steel for improving hardness and corrosion resistance. J. Mater. Process. Technol. 2020, 277, 116448. [Google Scholar] [CrossRef]

- Hajian, M.; Abdollah-zadeh, A.; Rezaei-Nejad, S.S.; Assadi, H.; Hadavi, S.M.M.; Chung, K.; Shokouhimehr, M. Improvement in cavitation erosion resistance of AISI 316L stainless steel by friction stir processing. Appl. Surf. Sci. 2014, 308, 184–192. [Google Scholar] [CrossRef]

- Escobar, J.D.; Velásquez, E.; Santos, T.F.A.; Ramirez, A.J.; López, D. Improvement of cavitation erosion resistance of a duplex stainless steel through friction stir processing (FSP). Wear 2013, 297, 998–1005. [Google Scholar] [CrossRef]

- Davis, J.R. Corrosion of Weldments; ASM International: Sawston, UK, 2006; ISBN 978-1-61503-051-4. [Google Scholar]

- Hong, T.; Ogushi, T.; Nagumo, M. The effect of chromium enrichment in the film formed by surface treatments on the corrosion resistance of type 430 stainless steel. Corros. Sci. 1996, 38, 881–888. [Google Scholar] [CrossRef]

- Chen, Y.C.; Fujii, H.; Tsumura, T.; Kitagawa, Y.; Nakata, K.; Ikeuchi, K.; Matsubayashi, K.; Michishita, Y.; Fujiya, Y.; Katoh, J. Banded structure and its distribution in friction stir processing of 316L austenitic stainless steel. J. Nucl. Mater. 2012, 420, 497–500. [Google Scholar] [CrossRef]

- Boggs, R.S.; Joseph, M.W.; Hall, J.F. Experience with Detection and Disposition of PWSCC Flaws in PWR Pressurizer and Reactor Coolant System Loop Alloy 600 Penetrations. 1996. Available online: https://www.osti.gov/biblio/403317-experience-detection-disposition-pwscc-flaws-pwr-pressurizer-reactor-coolant-system-loop-alloy-penetrations (accessed on 28 July 2021).

- Dunn, D.S. Example AMP for Localized Corrosion and Stress Corrosion Cracking of Welded Stainless Steel Dry Storage Canisters; U.S. NRC: Rockville, MD, USA, 2015; p. 27. [Google Scholar]

- Stress Corrosion Cracking. Available online: https://sanonofresafety.org/tag/stress-corrosion-cracking/ (accessed on 28 July 2021).

- Grewal, H.S.; Arora, H.S.; Singh, H.; Agrawal, A. Surface modification of hydroturbine steel using friction stir processing. Appl. Surf. Sci. 2013, 268, 547–555. [Google Scholar] [CrossRef]

| Article Name | Summarization | Reference |

|---|---|---|

| Microstructure and Mechanical Properties of Friction Stir Processed AISI 316L Stainless Steel |

| [44] |

| On the Microstructure Evolution in Friction Stir Processed 2507 Super Duplex Stainless Steel and its Effect on Tensile Behaviour at Ambient and Elevated Temperatures |

| [65] |

| Relationship between microstructure and mechanical properties of friction stir processed AISI 316L steel produced by selective laser melting |

| [66] |

| A novel approach to achieve high yield strength high nitrogen stainless steel with superior ductility and corrosion resistance |

| [67] |

| High Tensile Ductility and Strength in Dual-phase Bimodal Steel through Stationary Friction Stir Processing |

| [43] |

| Enhanced mechanical properties of medium carbon steel casting via friction stir processing and subsequent annealing |

| [68] |

| Friction stir processing of 316L stainless steel plate |

| [69] |

| Tribological enhancement of AISI 420 martensitic stainless steel through friction-stir processing |

| [70] |

| Effect of tool pin design on the microstructural evolutions and tribological characteristics of friction stir processed structural steel |

| [71] |

| Effect of friction stir processing on the tribological performance of high carbon steel |

| [72] |

| Rapid surface hardening and enhanced tribological performance of 4140 steel by friction stir processing |

| [73] |

| Article Name | Summarization | Reference |

|---|---|---|

| Enhancing the erosion-corrosion resistance of steel through friction stir processing |

| [102] |

| Enhancement in hardness and corrosion resistance of AISI 420 martensitic stainless steel via friction stir processing |

| [111] |

| Corrosion behavior of friction stir processed AISI 430 ferritic stainless steel |

| [113] |

| Friction Stir Processing of Stainless Steel for Ascertaining Its Superlative Performance in Bioimplant Applications |

| [114] |

| Friction-stir processing of AISI 440C high-carbon martensitic stainless steel for improving hardness and corrosion resistance |

| [115] |

| Improvement in cavitation erosion resistance of AISI 316L stainless steel by friction stir processing |

| [116] |

| Improvement of cavitation erosion resistance of a duplex stainless steel through friction stir processing (FSP) |

| [117] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ralls, A.M.; Kasar, A.K.; Menezes, P.L. Friction Stir Processing on the Tribological, Corrosion, and Erosion Properties of Steel: A Review. J. Manuf. Mater. Process. 2021, 5, 97. https://doi.org/10.3390/jmmp5030097

Ralls AM, Kasar AK, Menezes PL. Friction Stir Processing on the Tribological, Corrosion, and Erosion Properties of Steel: A Review. Journal of Manufacturing and Materials Processing. 2021; 5(3):97. https://doi.org/10.3390/jmmp5030097

Chicago/Turabian StyleRalls, Alessandro M., Ashish K. Kasar, and Pradeep L. Menezes. 2021. "Friction Stir Processing on the Tribological, Corrosion, and Erosion Properties of Steel: A Review" Journal of Manufacturing and Materials Processing 5, no. 3: 97. https://doi.org/10.3390/jmmp5030097

APA StyleRalls, A. M., Kasar, A. K., & Menezes, P. L. (2021). Friction Stir Processing on the Tribological, Corrosion, and Erosion Properties of Steel: A Review. Journal of Manufacturing and Materials Processing, 5(3), 97. https://doi.org/10.3390/jmmp5030097