1. Introduction

While additive manufacturing (AM) has demonstrated its potential to be a disruptive technology it still suffers from many drawbacks with regard to the creation of functional part surfaces, low dimensional accuracy, and defects from the deposition process. To counter these disadvantages, modern subtractive manufacturing (SM) machine tools are incorporating AM technology to create hybrid machine tools [

1]. These machine tools have the ability to deposit material and remove material to manufacture a part with the production speed and material efficiency of AM and the dimensional accuracy of SM. Of the many deposition processes available, a popular one is wire feedstock-directed energy deposition (DED). This process uses a focused heat source, such as a laser or an electrical arc, to melt inexpensive welding wire and deposit it on to a substrate. However, this process can also have unpredictable results that can cause defects and irregular part surfaces which can in turn adversely affect the SM process [

2,

3].

The irregular geometric surfaces caused by wire-based DED pose substantial challenges and provide singular opportunities for optimization of subtractive manufacturing toolpaths. The gains provided from such optimization are especially applicable in the context of a hybrid machine tool where additive and subtractive manufacturing capabilities exist on the same machine. There have been a variety of methods utilized for generating SM toolpaths for hybrid manufactured parts, however, many have not taken into account the geometric discrepancies that can arise from deposition. Liou et al. [

4] were one of the first to investigate 5-axis hybrid manufacturing machine tools using powder feedstock DED, and their process generated the additive and subtractive toolpaths prior to the actual production process, such that the SM toolpath did not account for AM geometric defects. More recently, Chen et al. [

5] used the aforementioned toolpath generation approach, but this did not consider the actual as-built geometry in determination of SM toolpaths. Rodrigues et al. [

6] also investigated wire DED and applied traditional 3-axis SM facing operations to the top surfaces of as-built AM parts without using online measuring equipment to adjust the SM toolpath. Another approach taken by Fuchs et al. [

7] involved characterization of surface waviness of AM part surfaces to determine a suitable machining tolerance for deposition geometries. Similarly, Zhang et al. [

8] simulated the effect of different steps over distances between beads in the construction of planar parts and used additional deposition toolpaths to correct perimeter defects. While these methods have made strides in advancing hybrid AM/SM approaches, they are either inefficient due to lack of utilization of as-built AM geometry in SM toolpath generation or they require extensive characterization experiments to implement. Since parts manufactured by hybrid manufacturing machine tools may need to undergo multiple AM and SM process steps, it is therefore desirable to optimize the subtractive operation toolpath in a manner that incorporates measurements of the as-built AM part surface and can be achieved without the use of prior characterization experiments.

Current methods of traditional SM toolpath optimization are not well suited to this task as they have not incorporated the surface waviness and geometric process defects inherent to the AM process. However, certain foundational aspects of these methods can be brought in to the SM toolpath optimization for as-built AM parts. Maiyar et al. [

9] and Shaik et al. [

10] optimized the machining parameters for Inconel 718 and Al-6061 alloys, respectively, with a focus on achieving high surface quality and material removal rate. It should be noted that superalloys like Inconel 718 can retain their mechanical properties at high temperatures, which makes them difficult to machine due to higher tool wear, thus requiring a more in depth analysis of machining considerations [

11]. While the present work is not focused on nickel superalloy machining, this illustrates how subtractive manufacturing optimization has been used on a material-specific basis in past work. Corso et al. [

12] performed a similar optimization study with a focus on implementing different optimization algorithms. An et al. [

13] conducted a study specific to face milling operations that varied parameters to minimize production cost and machining time with surface roughness and cutting force as constraints. Yan et al. [

14] conducted an in-depth multi-objective study that focused on optimizing cutting energy, surface roughness, and machining time. These studies regarding subtractive toolpath optimization focus on optimizing machining parameters without considering the toolpath or the part geometry. Castelino et al. [

15] explored optimizing the order of different toolpath segments in order to reduce the overall travel time between segments by utilizing approaches to the classical traveling salesman problem. This study generated an algorithm that can be applied to different part geometries. Lazoglu et al. [

16] varied the XY plane orientation angle of the subtractive toolpath in a ball milling operation to determine the orientation that yielded the lowest cutting force. Ali et al. [

17] tested different face-milling toolpath strategies (e.g., raster, zig zag) to determine the strategy that optimized surface finish and material removal rate. Hernandez et al. [

18] developed on optimization algorithm for continuous machining operations, independent of workpiece geometry, where optimal cutting parameters were chosen to maximize tool life and material removal rate.

As mentioned previously, it is desirable to incorporate as much information as possible about the part surface’s geometry to achieve an effective toolpath optimization. This need illustrates a unique challenge of hybrid manufacturing since subtractive operations must be performed in between deposition operations, and so part surface geometry must likewise be gathered iteratively. This differs from considerations used in machining of forged or cast parts as in those situations the part dimensions are much more controlled through the use of molds and the well understood mechanics of the casting and forging processes. Heralic et al. [

19] utilized a laser profilometer to incorporate geometric data about each deposition bead into a closed loop control algorithm to minimize variations in the layer height but this approach is not suitable for commercial hybrid machines as those controller architectures lack flexible configurability. Additionally, the cost of laser profilometers may be prohibitive to manufacturers. It is here where the technological advances achieved in Industry 4.0 should be leveraged to facilitate and improve the hybrid manufacturing process [

20]. A common method of determining the geometry of part features is to use an on-machine touch probe to digitize the part’s surface as it is an efficient use of existing equipment and most modern machine tools already have one. Both Praniewicz et al. [

21] and Kim et al. [

22] used an on-machine touch probe to digitize the geometry of turbine blades and use that geometry to formulate toolpaths for component repair workflows. An added benefit of using these on-machine probes is that modern machine tool controllers come equipped with capabilities that allow probe data to read from the controller and be transmitted to the user and incorporated into a digital representation of the part. Stavropoulos et al. [

23] also investigated hybrid manufacturing processes for turbine blade repair but used a 3D scanner to inspect the blade geometry.

Special consideration must be given to the process workflow of hybrid manufacturing and where online inspection and SM toolpath optimization could be best applied. The hybrid manufacturing process as described by Davila et al. [

24] consists of repeated cycles of DED and SM operations until the final part geometry is achieved. This simplistic workflow can be expanded to accompany both component repair and new component manufacturing operations. The most common hybrid manufacturing workflow for repair or remanufacturing of components is one whereby damaged components are scanned, defects are machined, and then material is added and remachined to the final shape. This workflow process is utilized heavily in turbine blade repair [

21,

22]. Stavropoulos et al. [

23] generated multiple hybrid manufacturing workflows and assessed each according to a variety of KPIs. For manufacturing new components, Chen at al. [

5] proposed a unique workflow where conventional stock material was partially machined and only certain features were deposited with AM and then subsequently machined. Zheng et al. [

25] developed a complex method involving feature extraction of the desired CAD geometry and the formulation of AM and SM toolpaths for remanufacturing components. Davila et al. [

24] proposed a workflow for manufacturing components from a substrate wherein the DED and SM steps are repeated such that only the part geometry from roughing SM operations is achieved, after which the finishing SM operation is conducted to bring the part within final dimensions and tolerances. The present work is focused on applying an SM toolpath optimization for the surface qualification facing operation, which is the point in the hybrid manufacturing workflow where the top surface of an as-built DED part is being prepared for the next deposition process step. Since such an operation would happen frequently in the hybrid manufacturing process, it would be ideal to use an on-machine touch probe to gather geometric data about the part surface [

20]. However, one drawback to using the touch probe in this case is that there is an inherent process time problem since using more probe points to gather information about the part surface inevitably results in large increases in process time. This effect is compounded when considering the fact that the surface qualification of the part may need to happen multiple times throughout the part’s build. Therefore, it is desirable to approximate the surface of wire-based DED components using geometries that require a low number of probe points per deposited bead of material. However, this surface approximation must be robust enough such that collisions are avoided and feed rates for non-cutting movements can be increased safely [

20]. The present work is focused on examining how such geometric approximations can be incorporated into an optimization of the SM toolpath of the hybrid manufacturing process and how different geometric surface approximations affect the results of that optimization.

2. Background

One of the most common defects that is especially detrimental in all metal AM processes is the build-up of deposited material that occurs during the start and stop points and the corners of a deposition track. This defect occurs due to the fact that the material deposition rate is constant through the AM process, while the traverse rate of the deposition head accelerates when starting, stopping, or rounding a corner, as characterized by Cajella et al. [

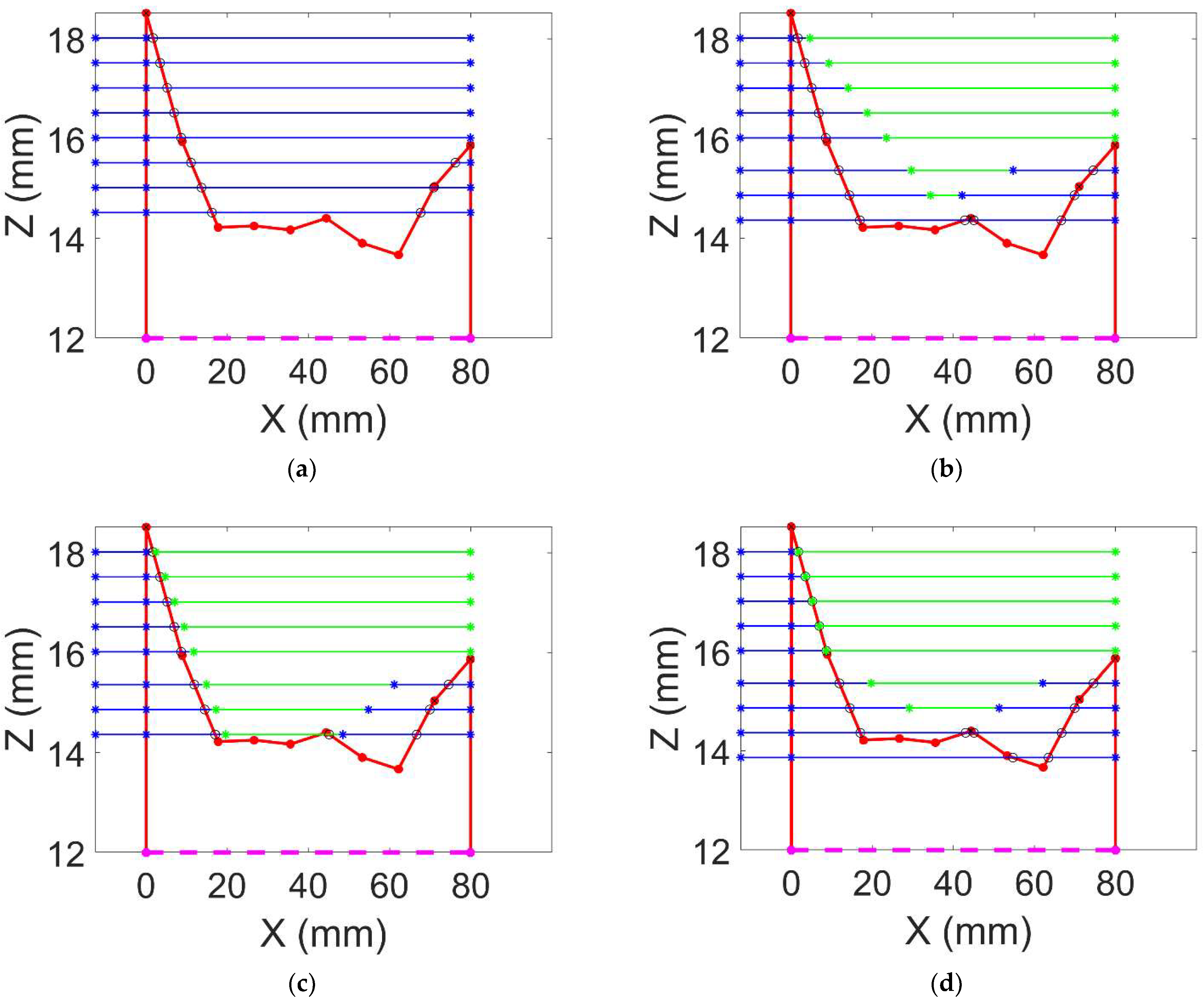

26]. In the case of a simple wall specimen, the overbuilding at the deposition start and stop points results in a part surface that has a cup-shaped geometry with tall wall ends and a low middle portion of the wall. An approximation of this geometry can be seen in

Figure 1 below.

There are two main manufacturing issues that arise due to this cup-shaped geometry defect. First, there is the issue of increased air cutting. Air cutting is when a cutting tool is traversing over a part at a cutting feed rate but not actually engaging with the part. The cup-shaped geometry defect produces many regions where air cutting occurs, as illustrated in

Figure 1a below. The many air cutting sections needlessly increase production time since the cutting tool moves at a cutting feed rate when not in contact with the workpiece. Therefore, it is desirable to incorporate the geometric information gained from probing so that appropriate increases to the feed rate can be applied to the toolpath during these air-cutting sections. This approach is similar to the technique of feed rate scheduling, wherein the feed rate is adjusted depending on predetermined cutting forces [

27]. In this case, the feed rate is increased to the rapid feed rate during sections of no tool load, i.e., air cutting. The other prominent issue is the irregular tool loading due to the changing slopes of the cup-shaped geometry.

Figure 1b below shows that when the cutting tool engages with a section of the part geometry that has a positive slope, there is an increase in the tool’s axial depth of cut which causes there to be irregular tool loading along a given toolpath. This irregular tool loading is undesirable for a number of reasons. It has been shown in multiple studies that having a constant engagement of the tool with the workpiece, and therefore constant cutting force, can improve tool wear by minimizing cutting force spikes and improve machining accuracy by minimizing the variations of the tool’s deflection during cutting [

28,

29]. This would be beneficial in decreasing chatter as well, since Chuangwen et al. [

30] found that increased tool wear and cutting depth led to increased amplitude of cutting vibrations that can lead to regenerative chatter [

31]. To minimize the cutting force and make the engagement of the cutting tool more uniform, adaptive toolpaths must be created that conform to the cup-shaped geometry, as shown in

Figure 1c.

An SM toolpath optimization methodology must be utilized to counter both of the issues previously described. This can be achieved by varying the axial depth of cut and the cutting feed rate to achieve toolpaths that minimize the cutting force and machining time, as illustrated in

Figure 1d below. For each selection of an axial depth of cut and cutting feed rate for the adaptively layered toolpaths, the feed rate of the air cutting sections of each toolpath segment, shown in green in

Figure 1d, is increased to the rapid traverse feed rate of the machine. Lastly, in addition to minimizing the machining time and the cutting force, the surface roughness must also be minimized. This is done to avoid regenerative chatter and to achieve the desired surface finish for the part [

31].

Currently, there is a knowledge gap in applying SM toolpath optimization to the facing of irregular part surfaces, as well as a method of efficiently gathering enough geometric data about the part’s surface so that a proper toolpath optimization can be applied. The purpose of this work was to examine different geometric approximations of a wire-based DED part surface that use minimal probe points and to then use those geometric approximations as the basis for optimization of the surface qualification facing operation. The optimization results for the different geometric surface approximations were evaluated to determine if there was an optimal geometric surface approximation for the cup-shaped geometry.

An overview of the experimental process is described here. The first stage of the experimental methodology used in this work was to probe each bead of the deposited part to generate a height profile for each bead. Then, the height profiles for each bead were consolidated into one height profile that was used for the entire top surface of the part. To generate this singular height profile, the highest height value from among the individual beads’ height profiles at each successive probe location along the length of the wall was used. Next, a digitized part surface was created from the consolidated probe height profile by connecting the individual probe points. Finally, the SM toolpath was optimized using an optimization methodology.

5. Discussion

The numerical comparison of the non-optimized and optimized objective values can be found in

Table 3,

Table 4,

Table 5 and

Table 6 below. The numerical results for each prioritization scenario are given as a percentage change in the parameter of interest from the non-optimized cutting condition. The equal prioritization scenario, where all of the the objective function weights Wt, Wr, and Wf were set to 0.33 was analyzed first and the results can be seen in

Table 3 below. Overall there was a significant improvement over the non-optimized cutting condition, with the smallest magnitude percent change being ~30%. The hybrid and trapezoidal surface approximations yielded comparable percent changes in machining time of 44.00% and 45.32%, respectively, which should be expected since those surface approximations were less conservative that the triangular surface approximation. Similarly, the percent change in machining time and cutting force for the hybrid and trapezoidal surface approximations only varied by 5%. The triangular surface approximation performed the worst out of the three, with the smallest magnitude percent changes in machining time, surface roughness, and cutting force.

The previous section focused on optimization results where each optimization objective was prioritized equally. However, this is seldom the case in an actual production environment. Depending on the component produced, the material being used, or the production schedule, different optimization objectives may need to be prioritized above others. To understand the relationship between prioritization of optimization objectives and different geometric approximations used, several scenarios were tested where each optimization objective was prioritized above the others. To establish prioritization of different objectives, the weight of the prioritized objective was set 0.8, and the other two weights were set at 0.1 so that all weights summed to 1.

The first objective that was prioritized was the machining time. From the results in

Table 4 it can be seen that although there was a substantial decrease in machining time of 57–68% across all surface approximations, the surface roughness parameter actually increased from the non-optimized condition by as much as 20% for the triangular surface approximation. The cutting force, however, experienced only a slight decrease in the percent change from the non-optimized cutting condition of a maximum magnitude of 2.75% which may be acceptable in a production environment. The trapezoidal and hybrid surface approximations again had very similar results and the maximum difference between them was 2.6%.

The next objective that was prioritized was the cutting force. From the results in

Table 5 it can be seen that there was a substantial decrease in cutting force of 74–83% across all surface approximations and there was a substantial decrease in surface roughness of 68–80% across all surface approximations. There was only marginal improvement in the machining time from the non-optimized cutting condition of a maximum magnitude of 2.75%. The similar range of improvement between the cutting force and surface roughness can be explained by the fact that they are both directly proportional to the feed rate. The trapezoidal and hybrid surface approximations again had very similar results and the maximum difference between them was 3.3%.

The last objective that was prioritized was the surface roughness. From the results in

Table 6 it can be seen that there was again a substantial decrease in cutting force of 65–70% across all surface approximations and there was a substantial decrease in surface roughness of 57–67% across all surface approximations. The triangular surface approximation yielded a lower magnitude reduction in the range of 21–40%. The similar range of improvement between the cutting force and surface roughness can be explained by the fact that they are both directly proportional to the feed rate. The trapezoidal and hybrid surface approximations again had very similar results and the maximum difference between them was 3.68%.

From inspection of the numerical values of the percent changes in the objective prioritization scenarios, it would appear that the trapezoidal approximation would be the ideal approach since it resulted in the highest percent decreases. However, the trapezoidal approximation was also the approach most at risk for crashing the tool into unexpected peaks in the actual part height profile. If the wire DED process is not well understood and the outcome of the deposition is not well controlled, the risk of crashing could be even higher. The hybrid approximation had percent decreases in the equal prioritization and surface roughness prioritization scenarios that were lower than those of the trapezoidal approximation, but only by a few percentage points as mentioned earlier. Additionally, the hybrid approximation has the added benefit of being less susceptible to undetected peaks in the height profile.

Up to this point, the probing operation process time has not yet been taken into account when considering the overall optimization process time, while the probe process uses minimal points so that probing time must be accounted for when comparing the optimization process to the non-optimized toolpath. As such,

Figure 7a below shows a comparison of the non-optimized machining time to the different total optimization process times using the hybrid geometric approximation for each of the four objective prioritization scenarios. It can be seen that the total optimization process time exceeded the non-optimized process time for each of the four objective prioritization scenarios, with the lowest and highest total process times for the optimized conditions being 2.36 min and 3.69 min compared to the non-optimized condition’s total process time of 1.95 min. The process time data can be found in

Supplementary Table S4.

It is important to note that this comparison was for a part that is three beads wide and assumed to be machined using a single facing pass per layer. Therefore, it is desirable to determine the effect of the number of beads being probed per part and the number of facing passes being taken per layer.

Figure 7b shows that when the number of beads is reduced to one, the total optimization process time was lower than the non-optimized process time of 1.95 min for every objective prioritization scenario except the cutting force prioritization. The lowest total process time was 1.20 min for the machining time prioritization optimization scenario.

Figure 7c shows that when the number of facing passes was increased to two, the total optimization process time was lower than the non-optimized process time of 3.89 min for every objective prioritization scenario, with the lowest total process time being 2.36 min. This serves as a guidance on how to select which hybrid machine tool, in terms of its bead width capability, to use for certain parts. It also can be inferred that this optimization process is most useful for parts constructed of fewer, thicker beads as that drastically reduces the probing time and thus the overall optimization process time.

6. Conclusions

In this work an optimization strategy for facing the surfaces of wire-based DED parts was presented. Geometrics gathered about wire-based DED part surfaces via an on-machine touch probe were used to construct a digitized part surface using different geometric surface approximations and then different optimization scenarios were conducted in which individual optimization objectives of minimizing machining time, cutting force, and surface roughness were prioritized.

The hybrid approximation was the preferred approximation option as the resultant toolpath provided a low risk of crashing the tool into unknown geometry and yielded significant improvements in machining time, surface roughness or cutting force, depending on the prioritization scenario, which lagged only slightly behind those of the trapezoidal approximation by around 3%. An analysis of the different optimization prioritization scenarios concluded that the prioritization scenarios where machining time and cutting force were prioritized resulted in poor improvements in the other two optimization objectives of around 0.1–3.8%, with the machining time prioritization actually resulting in an increase in surface roughness for all geometric surface approximations. While some production scenarios may wish to prioritize machining time or cutting force, it is important to realize the performance trade-offs in the other optimization objectives.

When the overall optimization process time, which considers probing and optimized machining, was compared to the non-optimized process time for different numbers of facing passes and beads per part it was shown that the optimized process time was substantially lower than the non-optimized process time when the number of beads per part was decreased and when the machining operation was conducted with multiple facing passes. This means that this optimization process is well suited for parts constructed of a few thick beads rather than many thinner ones. Finally, the optimization strategy utilized in this work lends itself to covering a multiplicity of different optimization objectives. The objective function can be easily expanded to include additional terms that represent different optimization objectives and thus can be tailored to fit a variety of production scenarios.

There were several limitations to this study that can be improved upon in future work. First, the present analysis of cutting forces and surface roughness are theoretical, and as such do not take into account real-world uncertainties that affect the surface roughness and cutting force calculations. Furthermore, the effects of tool wear have not been included in the surface roughness calculations. While the wall artifact used in this study is small enough that tool wear may not be significant, this would not be the case for larger components or full-scale production. Additionally, the repeatability of the probing operation results should be investigated since variance in the present probing results would affect both the final surface approximation and the overall process time. Future research could investigate the use of other algorithms (e.g., pattern search or genetic optimization) to address the optimization problem.