Influence of a Discontinuous Process Strategy on Microstructure and Microhardness in Drilling Inconel 718

Abstract

1. Introduction and Preliminary Investigations

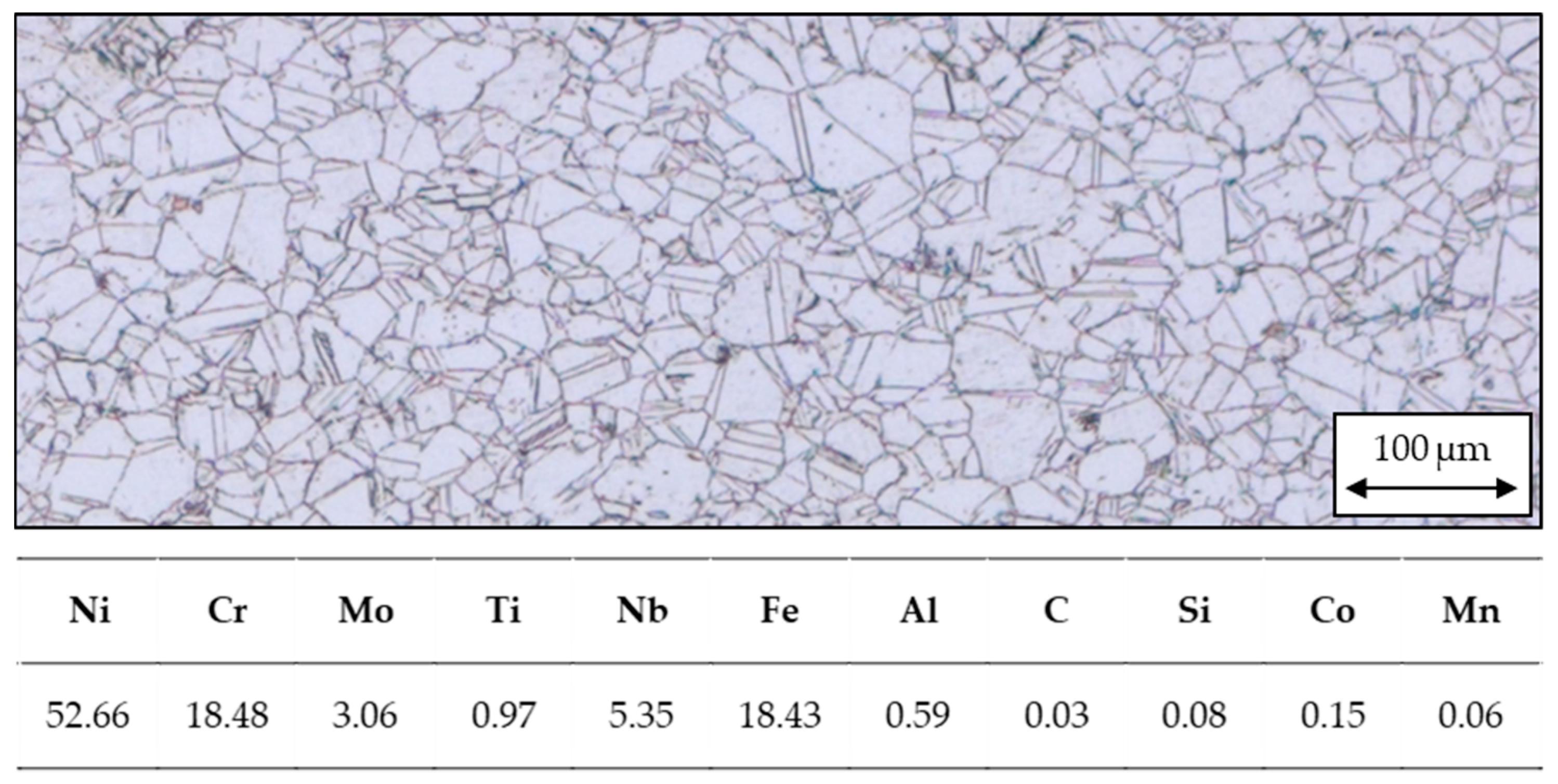

1.1. The Nickel-Base Alloy Inconel 718

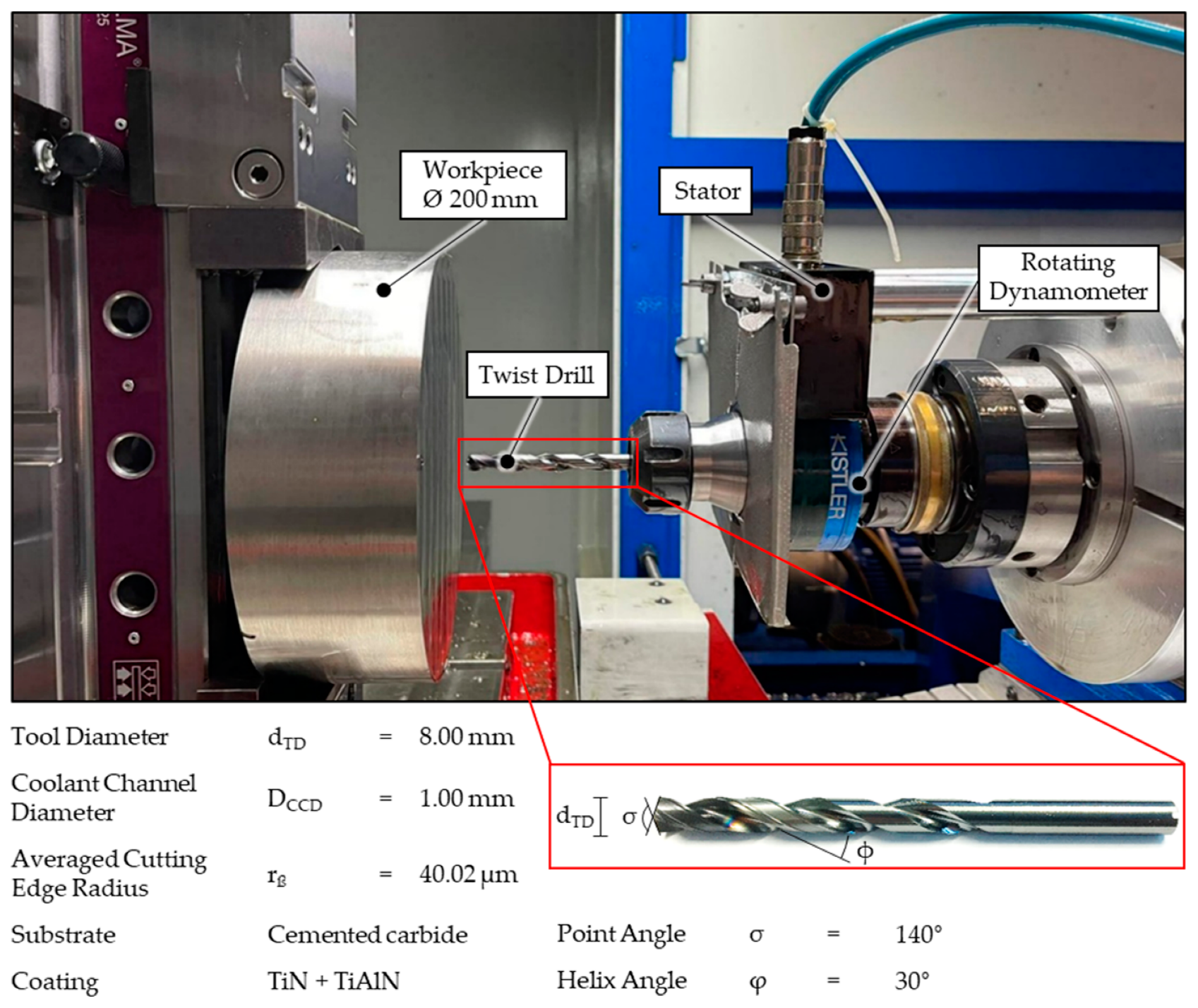

1.2. Characteristic Challenges and New Approaches to Drilling Inconel 718

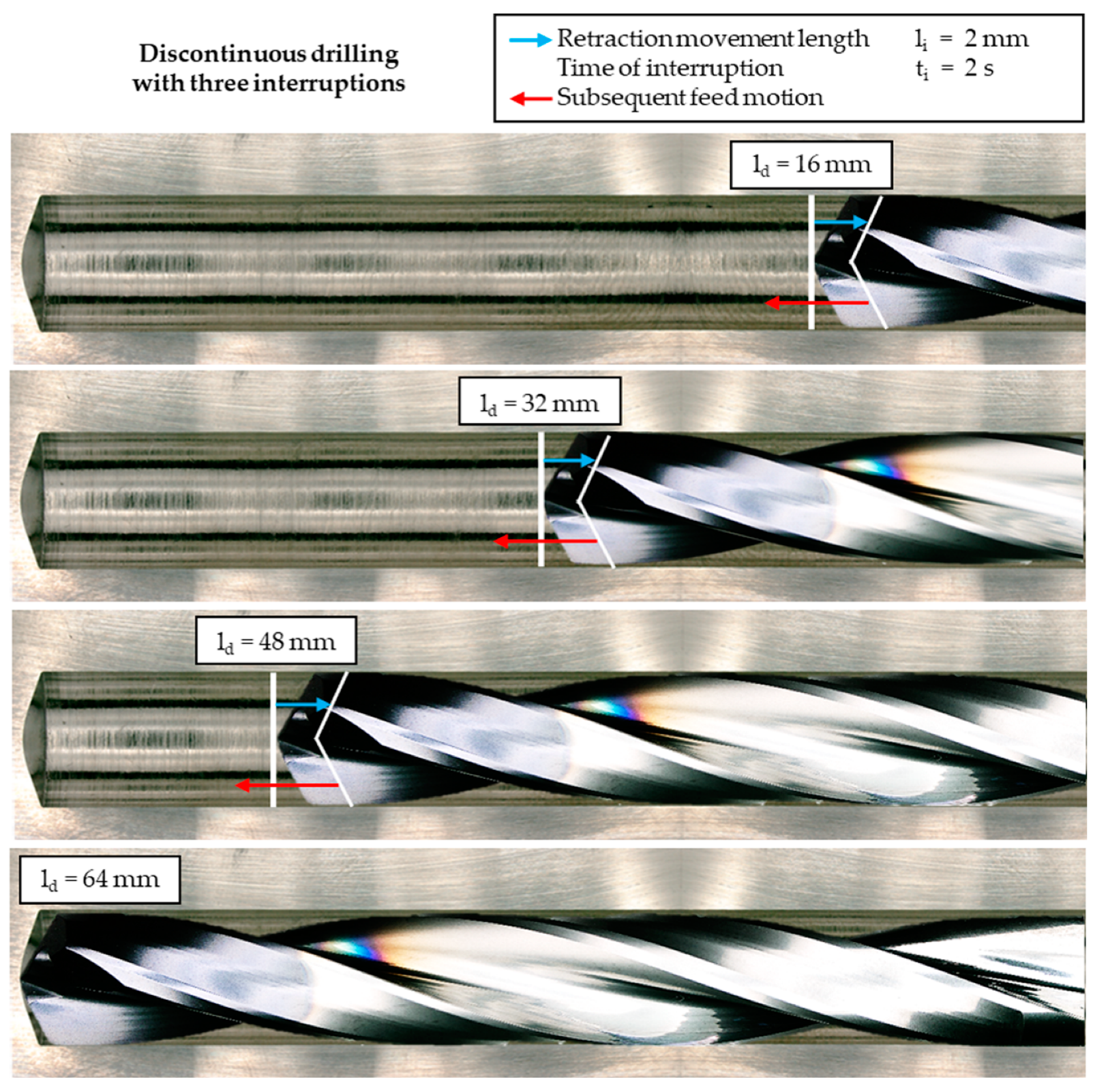

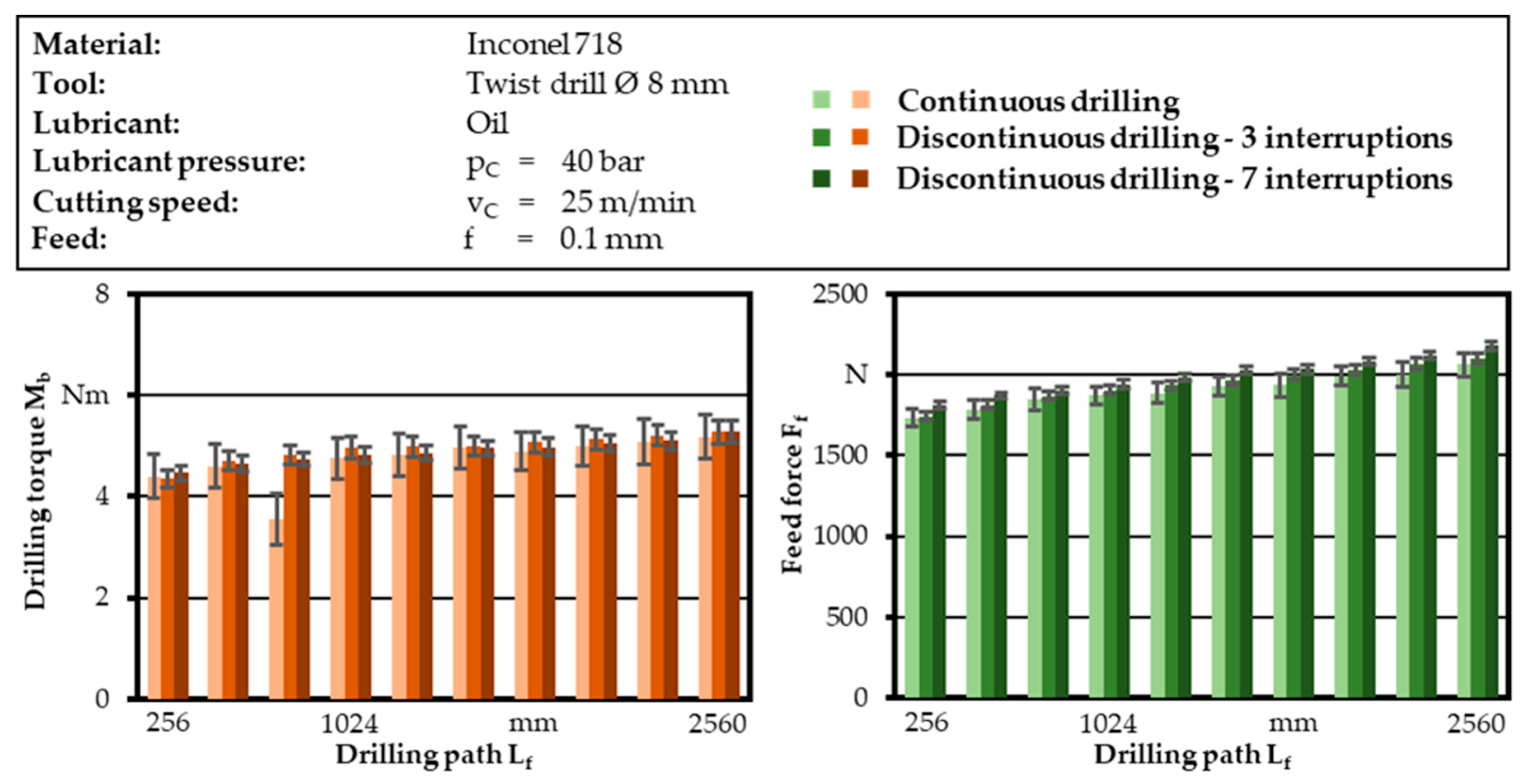

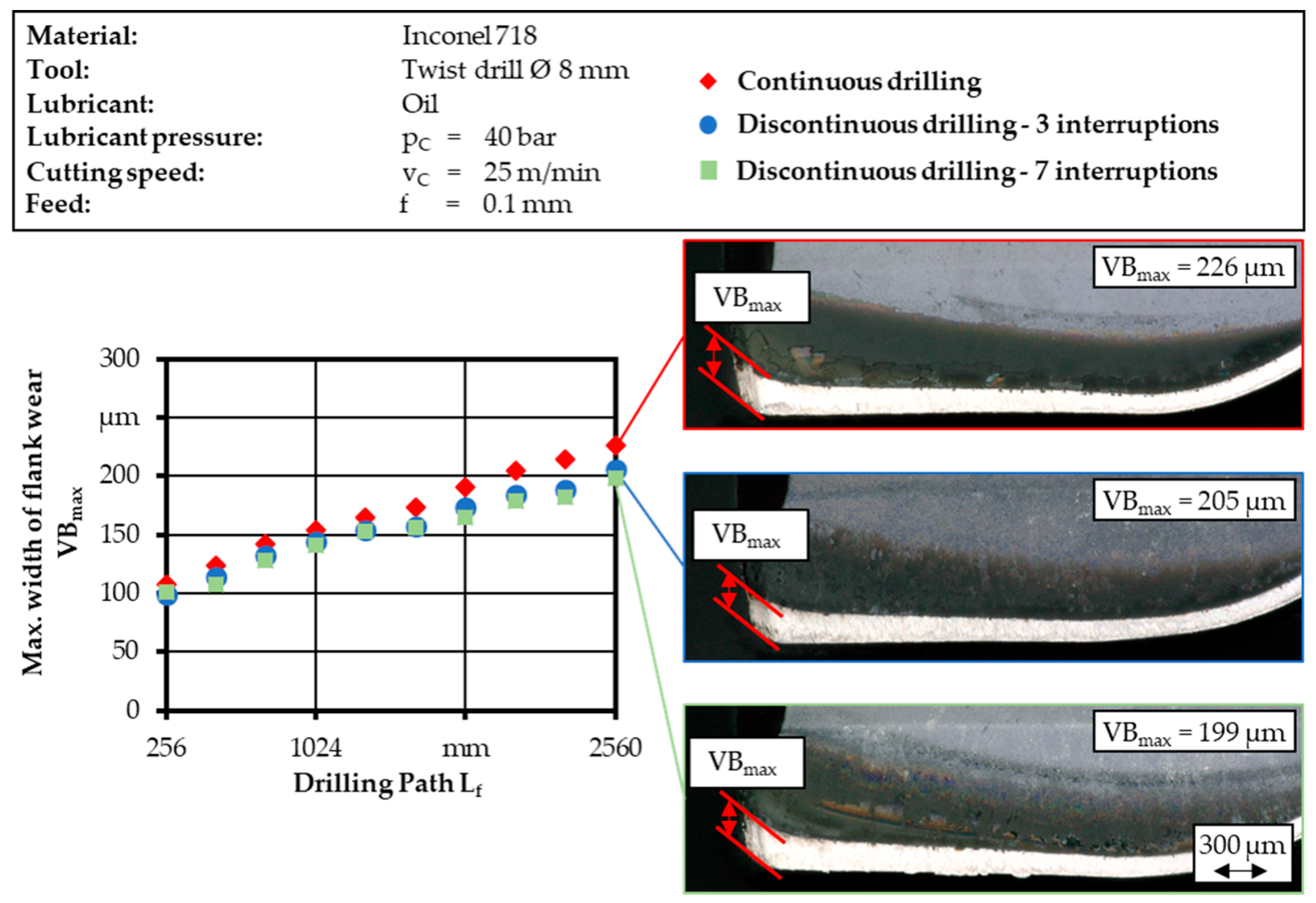

1.3. Further Development of the Conventional Process towards Discontinuous Drilling

2. Metallographic Analysis of Microstructure and Microhardness

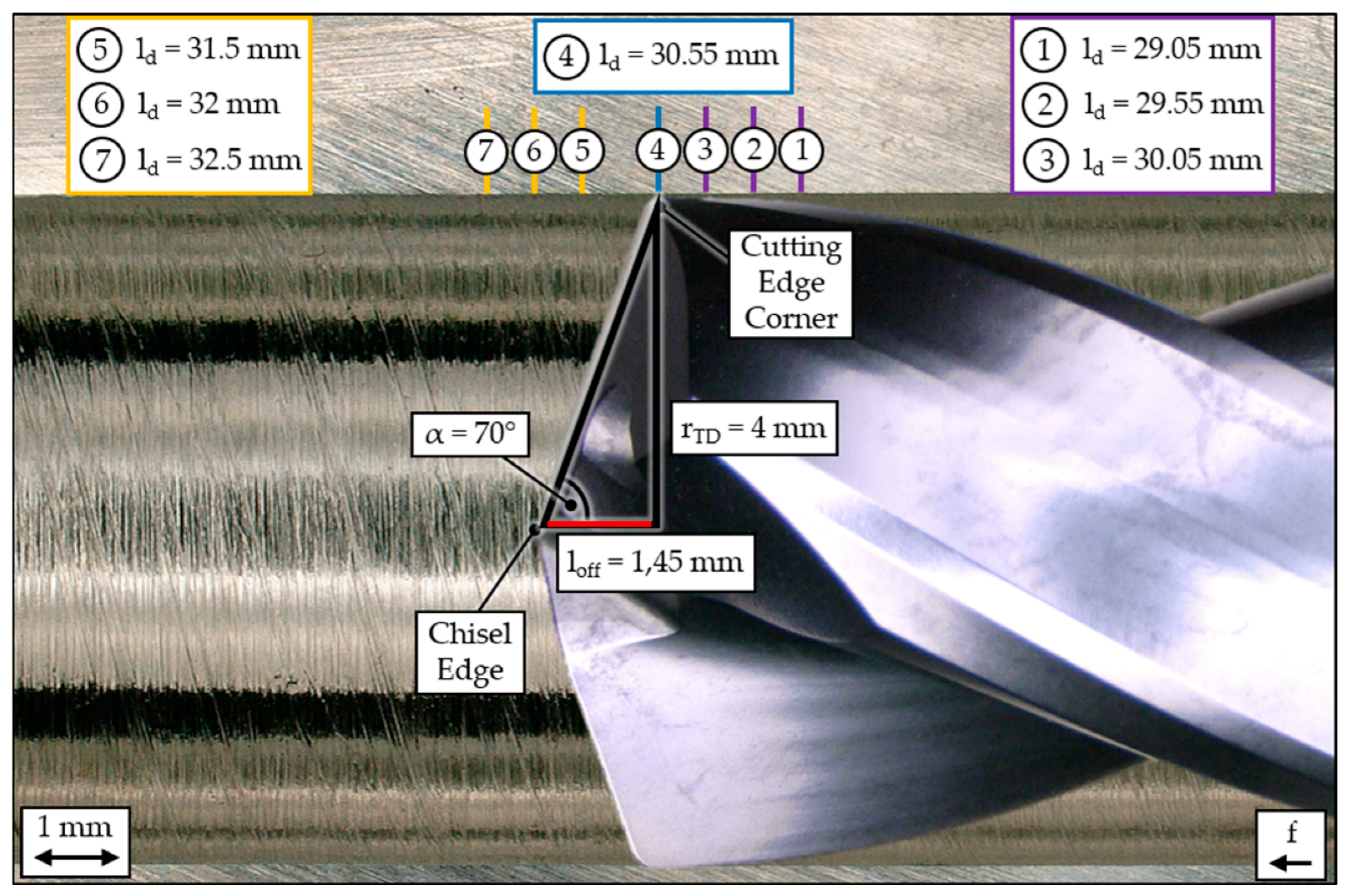

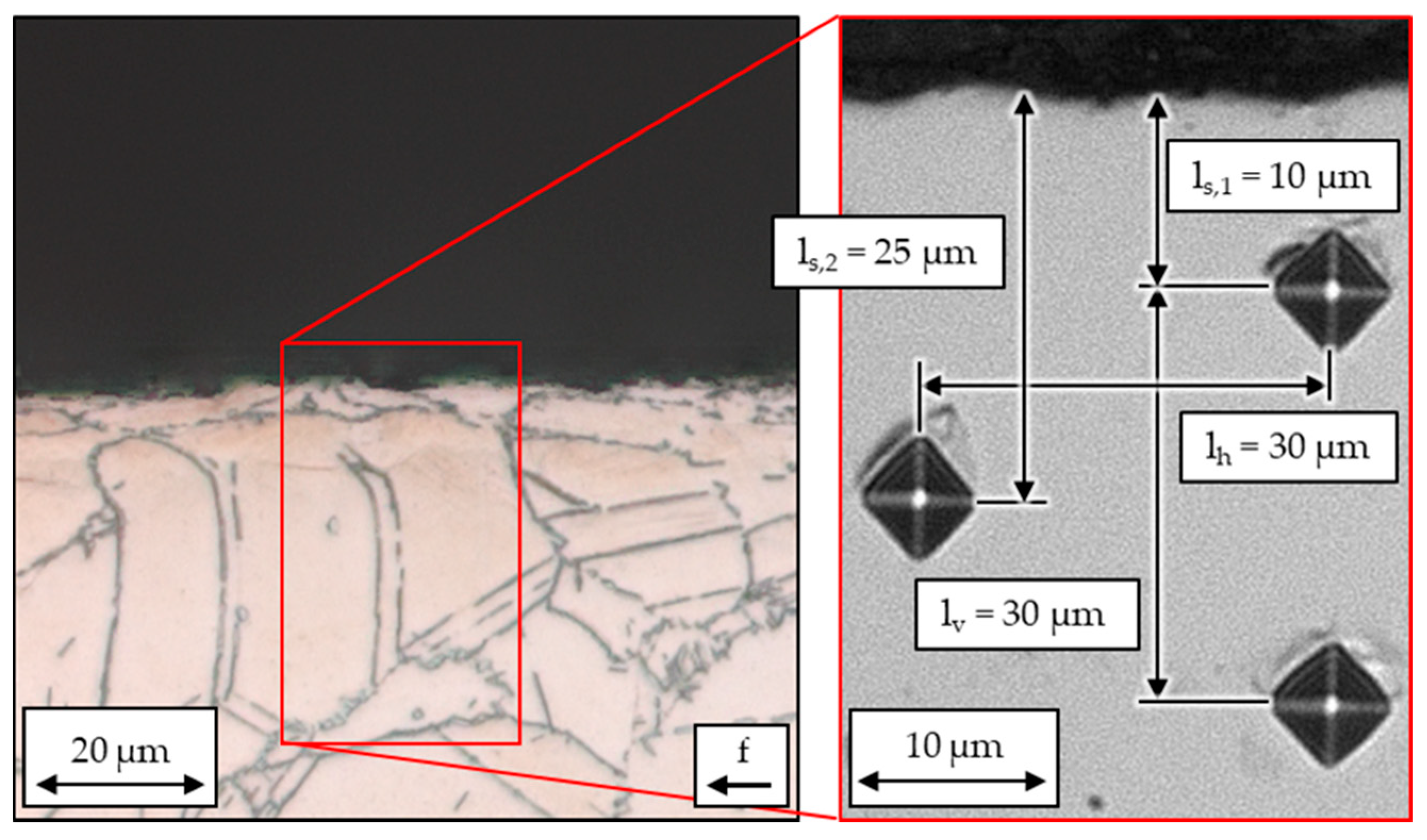

Preparation in Favor of Metallographic Analysis

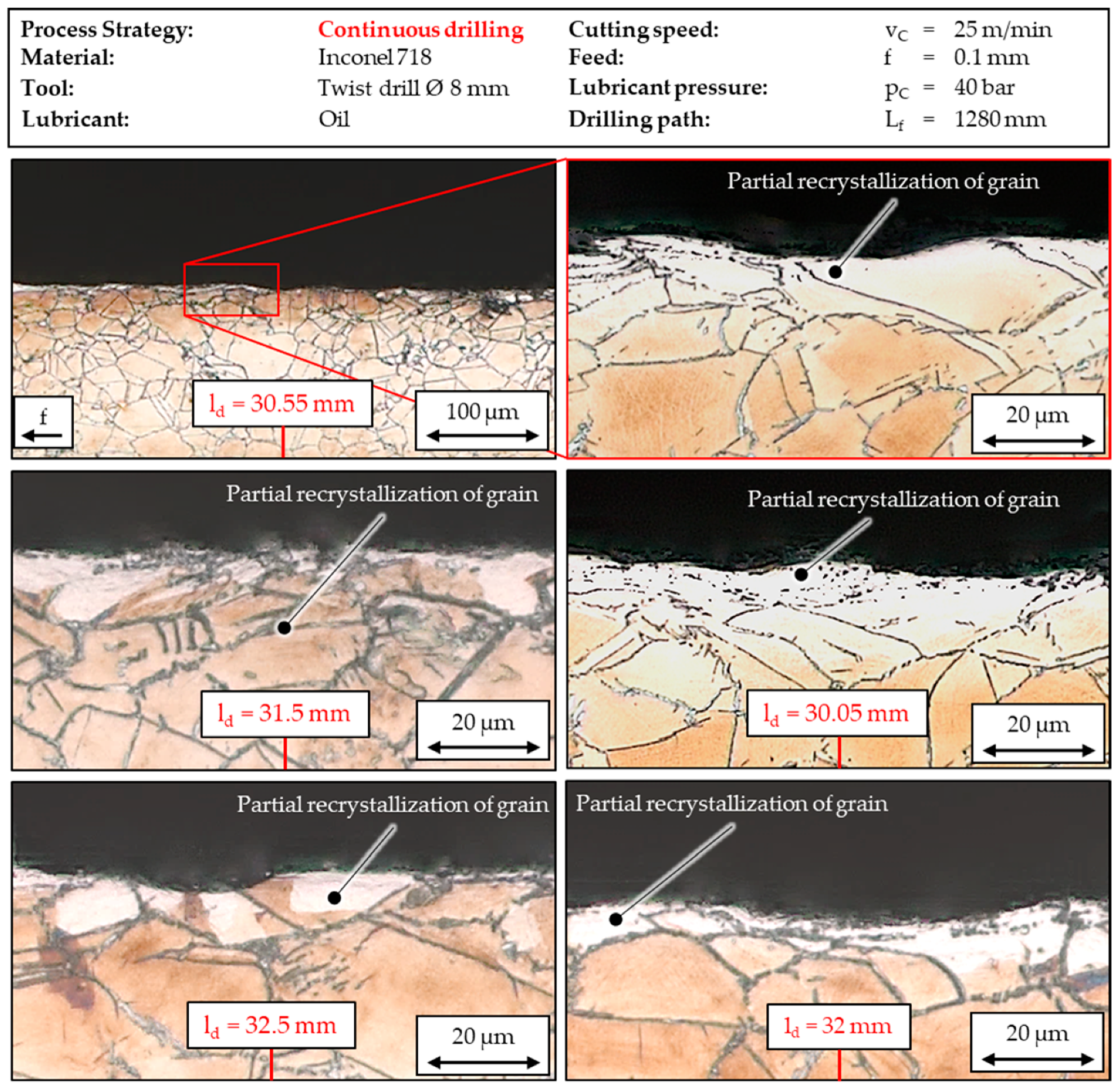

3. Results of Metallographic Analysis

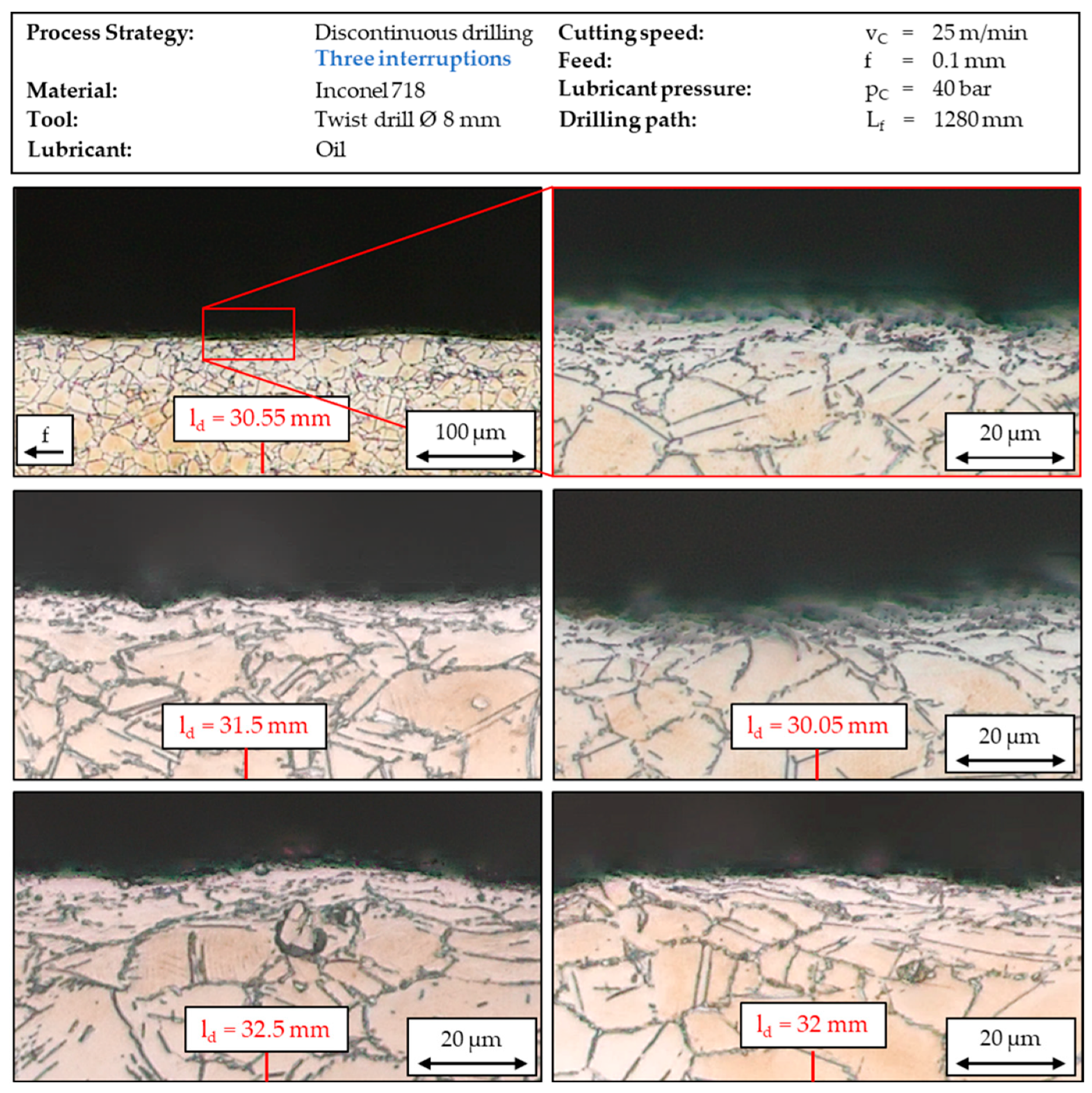

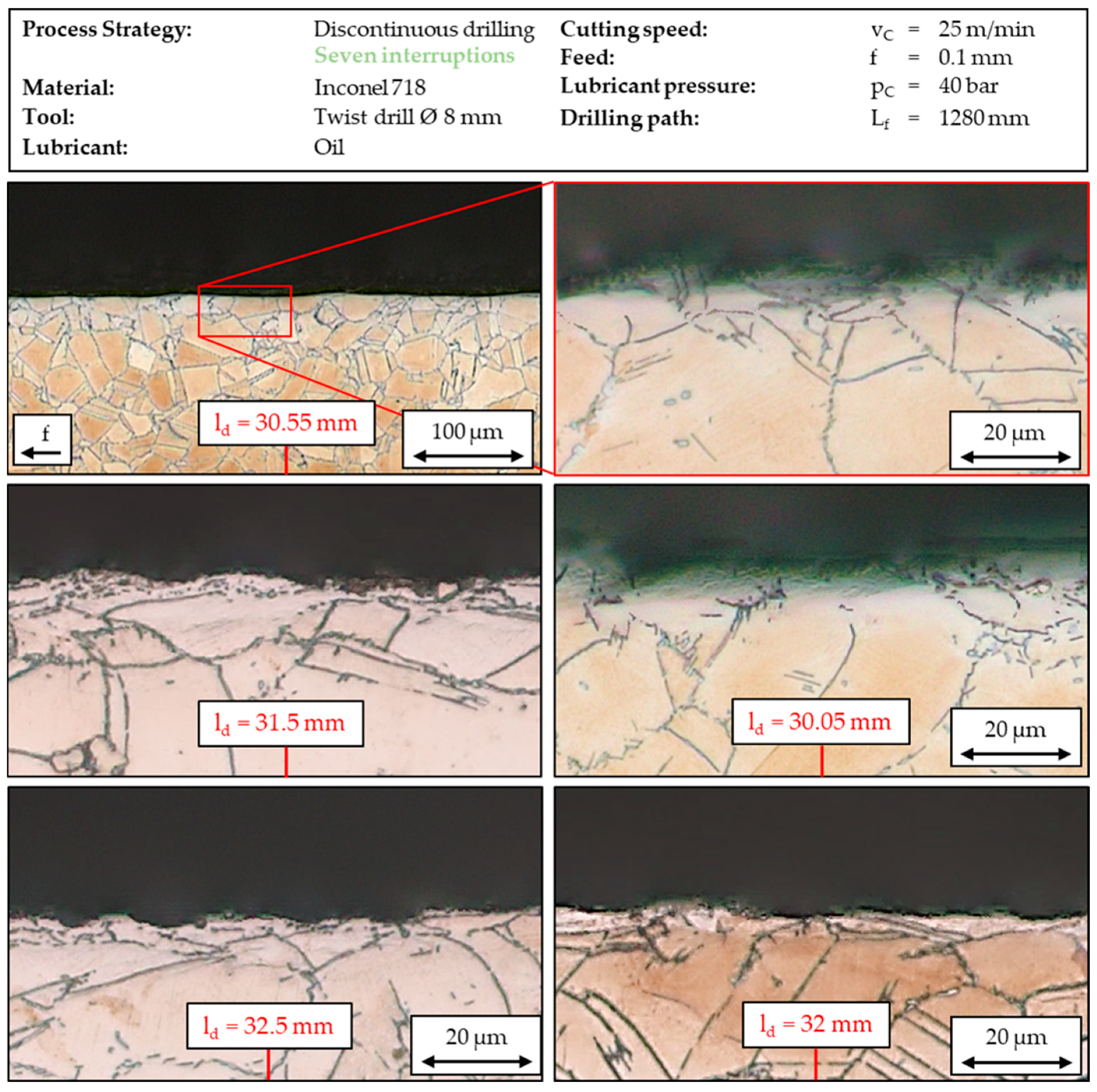

3.1. Analysis of Process-Related Microstructure

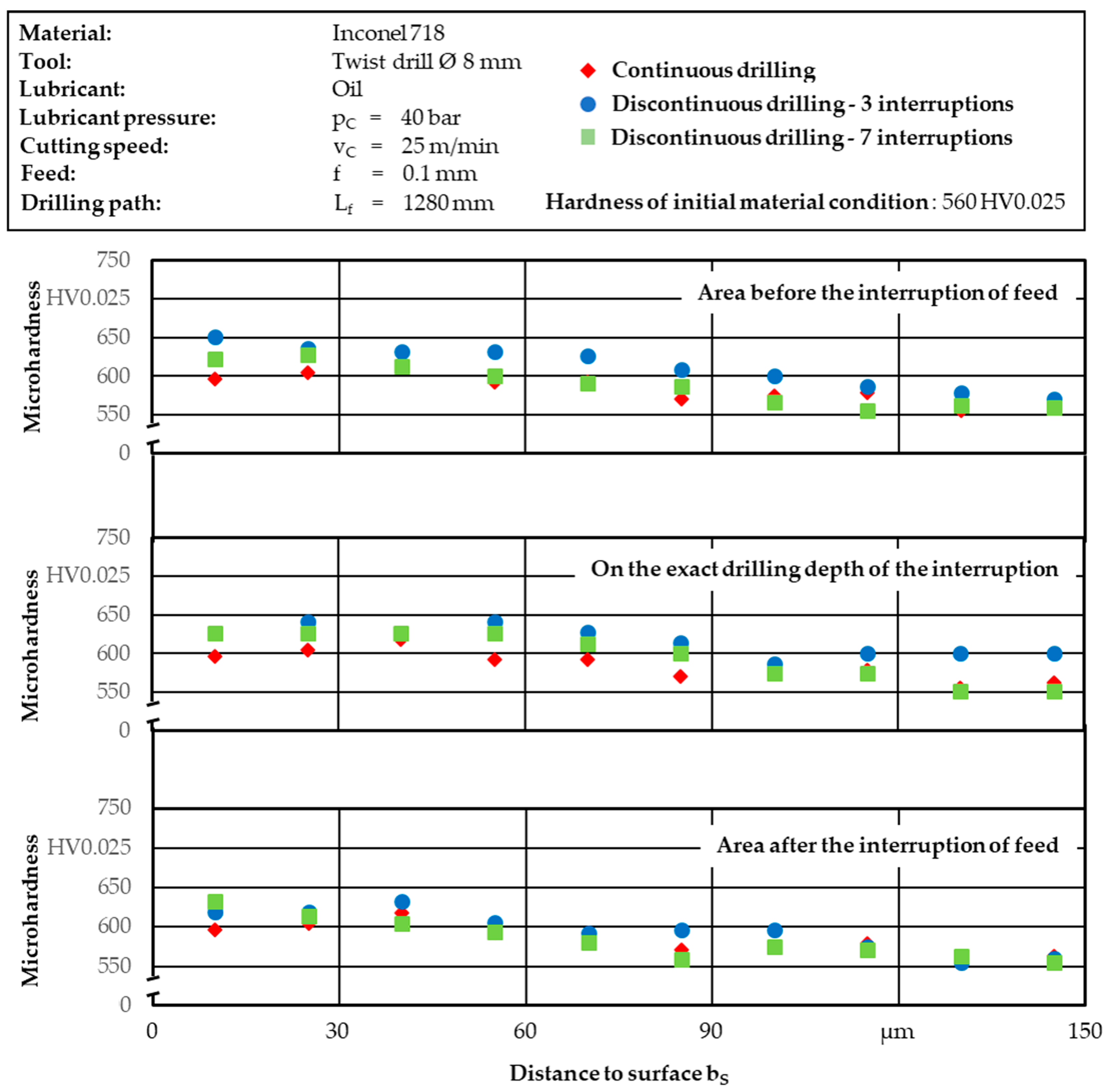

3.2. Analysis of Process-Related Microhardness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Donachie, M.J.; Donachie, S.J. Superalloys—A Technical Guide, 2nd ed.; ASM: Geauga County, OH, USA, 2008. [Google Scholar]

- Heubner, U. Nickelwerkstoffe und Hochlegierte Sonderedelstähle, 5th ed.; Expert Verlag: Renningen, Germany, 2012. [Google Scholar]

- Bürgel, R.; Maier, H.-J.; Niendorf, T. Handbuch Hochtemperatur-Werkstofftechnik, 4th ed.; Vieweg-Teubner Verlag: Wiesbaden, Germany, 2011. [Google Scholar]

- Steffens, K.; Wilhelm, H. Werkstoffe, Oberflächentechnik und Fertigungsverfahren für die nächste Generation von Flugtriebwerken; Deutscher Luft-und Raumfahrtkongress: Hamburg, Germany, 2000. [Google Scholar]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel base super alloys. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Wessels, T. Bohren in Ph.D. Titan-und Nickelbasislegierungen; TU Braunschweig: Braunschweig, Germany, 2007. [Google Scholar]

- Günther, C.; Böttger, H.; Köhler, S. Hochgeschwindigkeitsbearbeitung von Nickelbasislegierungen. MM-Masch. Das Ind. 1998, 104, 44–49. [Google Scholar]

- Veselovac, D. Process and Product Monitoring in the Drilling of Critical Aero Engine Components. Ph.D. Dissertation, RWTH Aachen, Aachen, Germany, 2013. [Google Scholar]

- Rasti, A.; Sadeghi, M.H.; Farshi, S.S. An investigation into the effect of surface integrity on the fatigue failure of AISI 4340 steel in different drilling strategies. Eng. Fail. Anal. 2019, 95, 66–81. [Google Scholar] [CrossRef]

- Mütze, H. Beitrag zur Zerspanbarkeit hochwarmester Werkstoffe. Ph.D. Dissertation, Technische Hochschule Aachen, Aachen, Germany, 1967. [Google Scholar]

- Klocke, F.; Sangermann, H.; Krämer, A.; Lung, D. Influence of a high-pressure lubricoolant supply on thermo-mechanical tool load and tool wear behaviour in the turning of aerospace materials. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 52–61. [Google Scholar] [CrossRef]

- Zhang, L.; Wagner, T.; Biermann, D. Optimization of cutting parameters for drilling Nickel-based alloys using statistical experimental design techniques. In Proceedings of the 37th International MATADOR Conference, Manchester, UK, 25–27 July 2012. [Google Scholar]

- Oezkaya, E.; Bücker, M.; Strodick, S.; Biermann, D. A thermomechanical analysis leading to a novel flank face design providing longer tool lives for tools used in the drilling of Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 102, 2977–2992. [Google Scholar] [CrossRef]

- Oezkaya, E.; Bücker, M.; Biermann, D. Simulative analyses focused on the changes in cutting fluid supply of twist drills with a modified flank face geometry. Int. J. Mech. Sci. 2020, 180, 105650. [Google Scholar] [CrossRef]

- Bücker, M.; Oezkaya, E.; Hensler, U.; Biermann, D. A new flank face design leading to an improved process performance when drilling high-temperature nickel-base alloys. In Proceedings of the 20th Machining Innovations Conference for Aerospace Industry 2020 (MIC 2020), Hannover, Germany, 2 December 2020. [Google Scholar]

- Brinksmeier, E.; Pecat, O.; Rentsch, R. Quantitative analysis of chip extraction in drilling of Ti6Al4V. CIRP Ann. Manuf. Technol. 2015, 64, 93–96. [Google Scholar] [CrossRef]

- Deyuan, Z.; Lijiang, W. Investigation of chip in vibration drilling. Int. J. Mach. Tools Manuf. 1998, 38, 165–176. [Google Scholar] [CrossRef]

- Paulsen, T.; Pecat, O.; Brinksmeier, E. Influence of Different Machining Conditions on the Surface Properties of Drilles TiAl6V4. Procedia CIRP 2016, 46, 472–475. [Google Scholar] [CrossRef]

- Beer, N. Systematische Untersuchung von Vollhartmetall-Wendelbohrern zum Bearbeiten von Inconel 718; Vulkan-Verlag GmbH: Dortmund, Germany, 2015. [Google Scholar]

- Wolf, T.; Iovkov, I.; Biermann, D. Discontinuous Drilling of Inconel 718. In Proceedings of the 2nd International Conference on Thermal Issues in Machine Tools, ICTIMT 2021, Praque, Czech Republic, 20 April 2021. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolf, T.; Iovkov, I.; Biermann, D. Influence of a Discontinuous Process Strategy on Microstructure and Microhardness in Drilling Inconel 718. J. Manuf. Mater. Process. 2021, 5, 43. https://doi.org/10.3390/jmmp5020043

Wolf T, Iovkov I, Biermann D. Influence of a Discontinuous Process Strategy on Microstructure and Microhardness in Drilling Inconel 718. Journal of Manufacturing and Materials Processing. 2021; 5(2):43. https://doi.org/10.3390/jmmp5020043

Chicago/Turabian StyleWolf, Tobias, Ivan Iovkov, and Dirk Biermann. 2021. "Influence of a Discontinuous Process Strategy on Microstructure and Microhardness in Drilling Inconel 718" Journal of Manufacturing and Materials Processing 5, no. 2: 43. https://doi.org/10.3390/jmmp5020043

APA StyleWolf, T., Iovkov, I., & Biermann, D. (2021). Influence of a Discontinuous Process Strategy on Microstructure and Microhardness in Drilling Inconel 718. Journal of Manufacturing and Materials Processing, 5(2), 43. https://doi.org/10.3390/jmmp5020043