Edge Grinding Characteristics of Display Glass Substrate

Abstract

1. Introduction

2. Theoretical Analysis

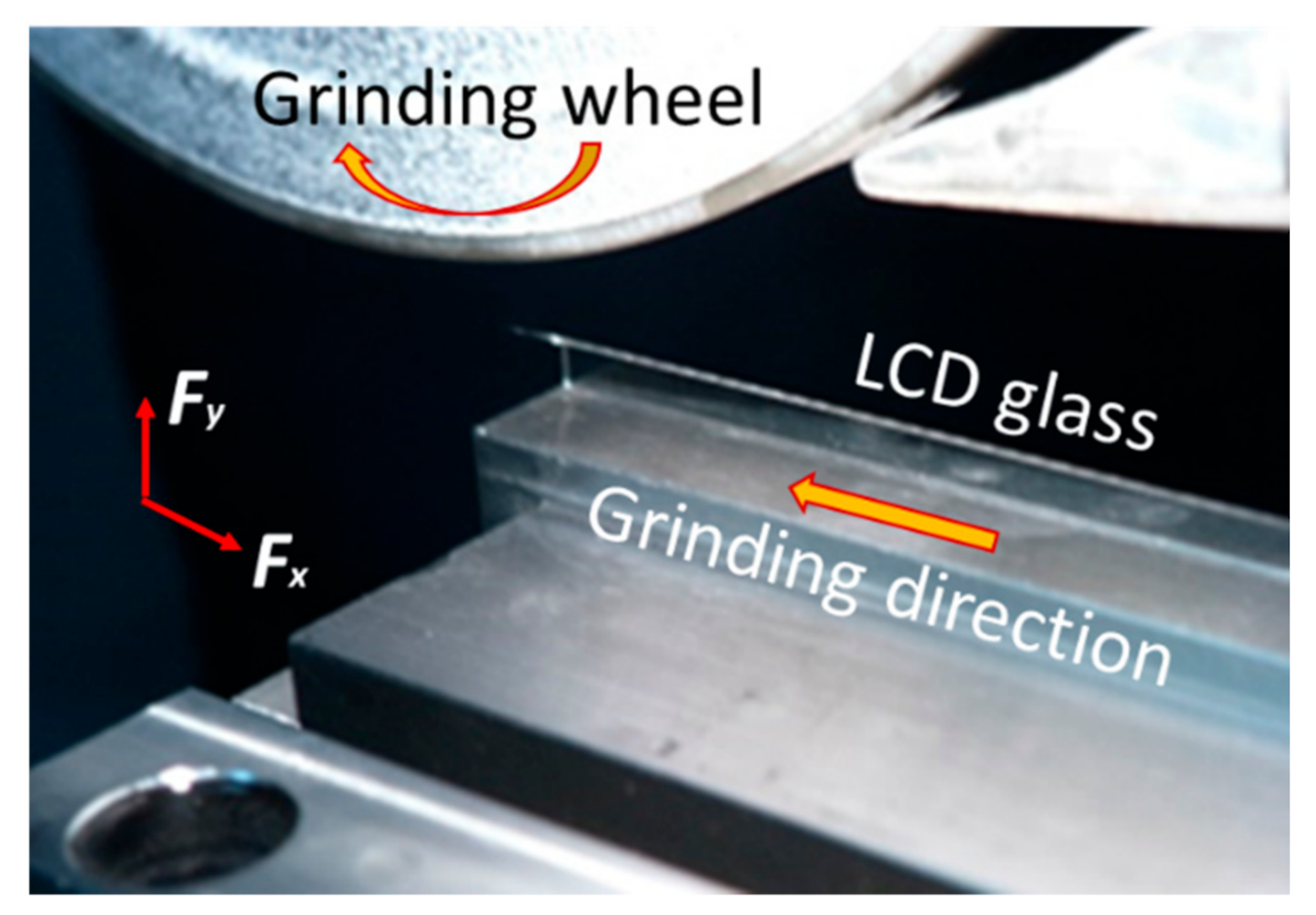

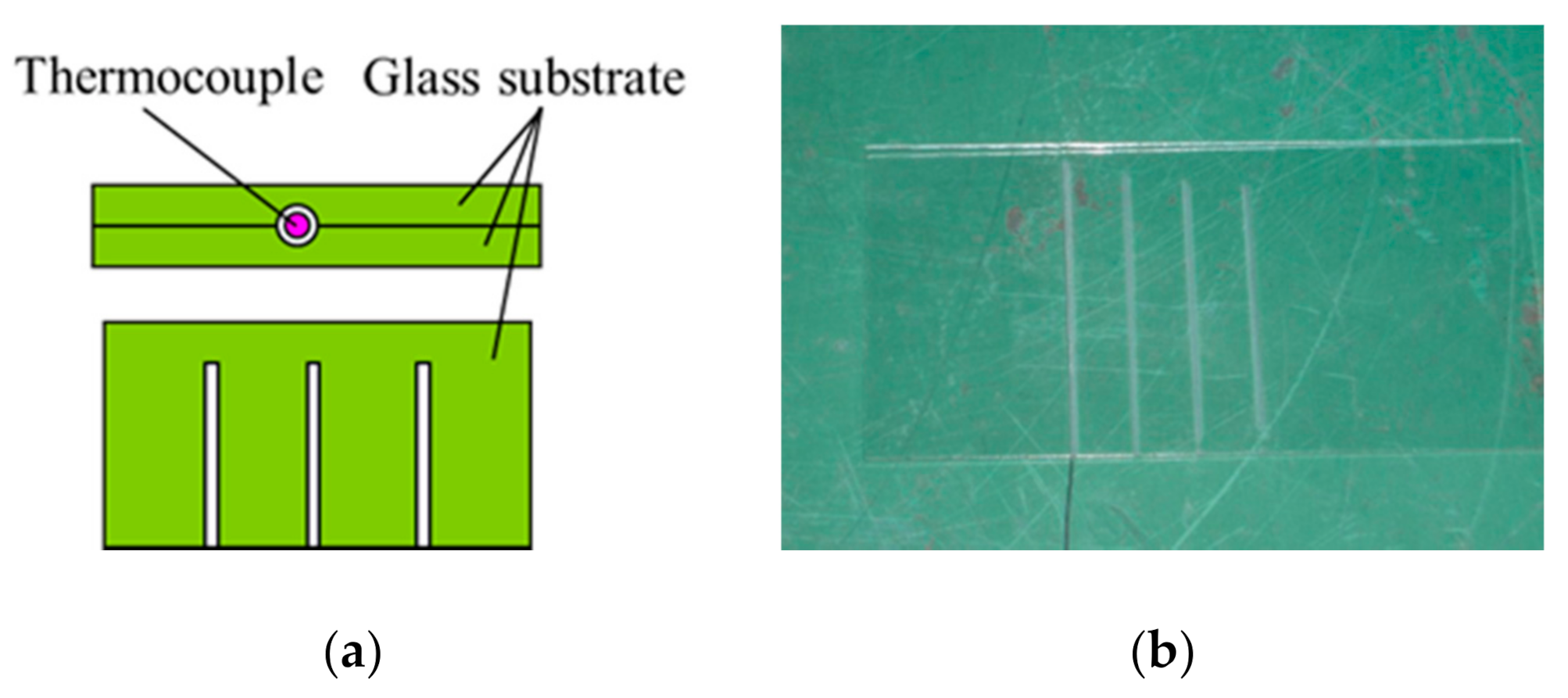

3. Experiment Details

4. Experimental Results

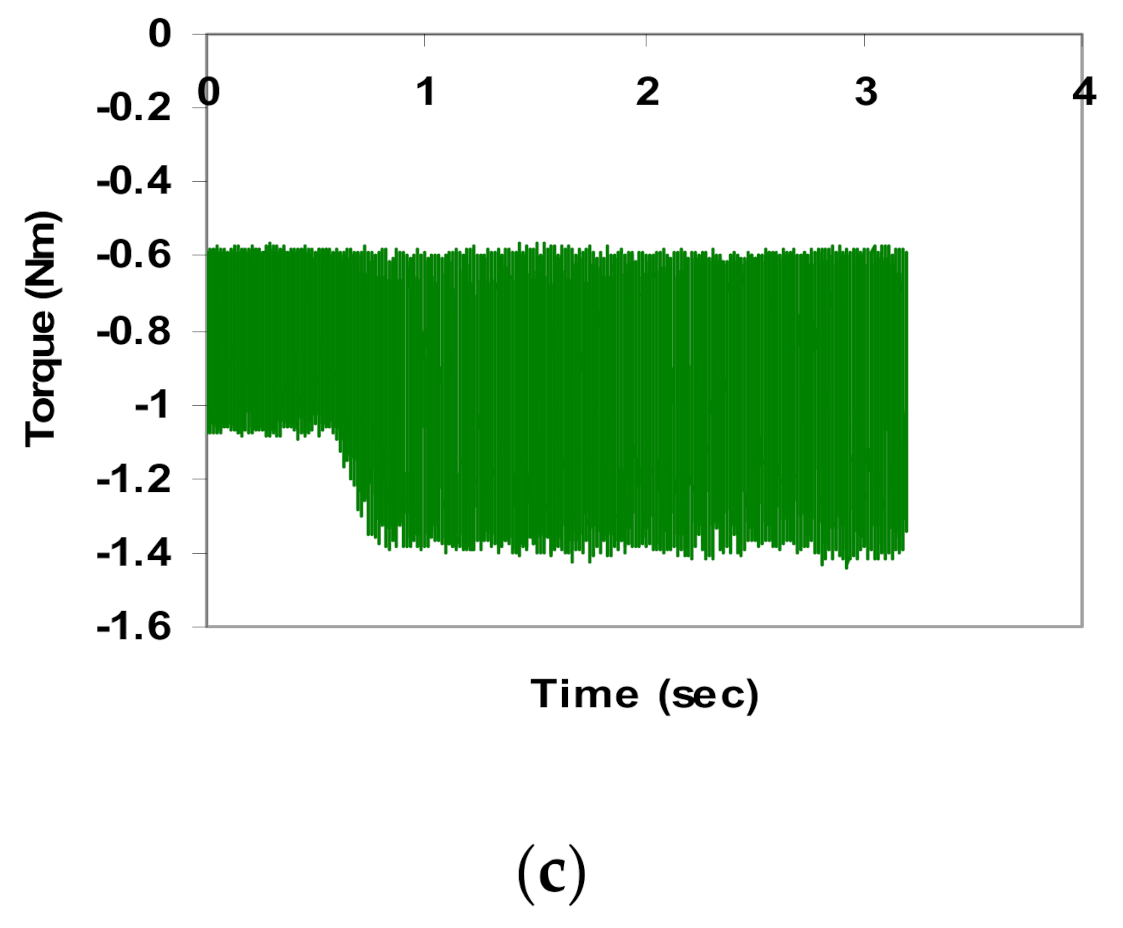

4.1. Grinding Force and Torque

4.2. Grinding Temperature

4.3. Ground Surface Topography

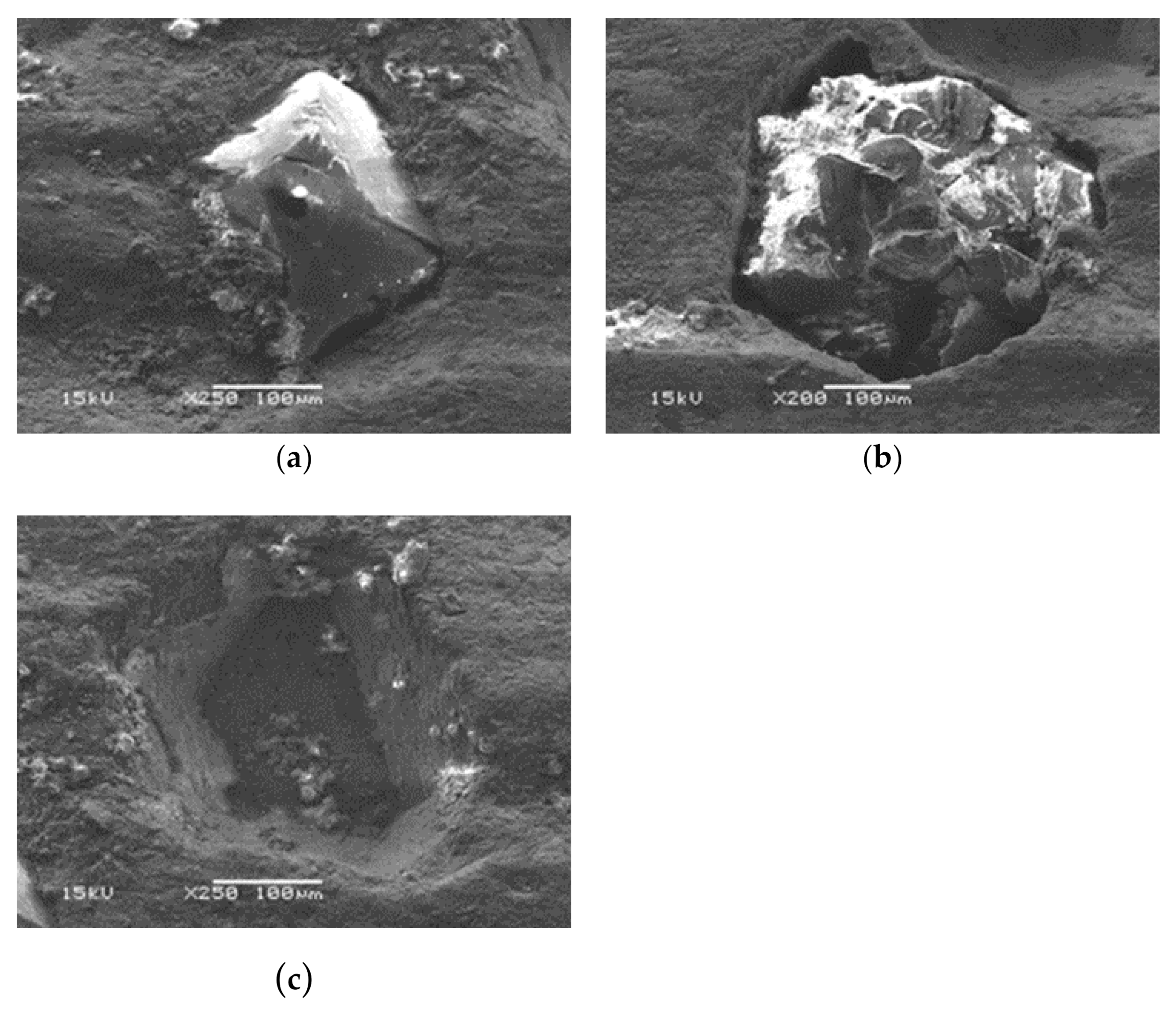

4.4. Diamond Wheel Wear

5. Discussion

6. Conclusions

- Grinding force (Fy) in the vertical direction obtained in the test conditions was much larger than grinding force (Fx) in the horizontal direction, causing a large compressive stress acting on the grinding glass edge.

- Grinding force (Fx) was almost constant, while grinding force (Fy) tended to increase when increasing the grinding distance up to 200 m. Grinding torque was slightly increased with the increase of grinding speed.

- Grinding temperature rising was slightly increased with the increase of grinding depth from 0.1 to 0.4 mm when applying high-pressure coolant, and it was increased much faster when a higher feed rate was used. Grinding temperature was measured as over 1100 °C under dry grinding.

- Ground surface topography analysis indicated that the grinding of glass substrate edge in the test conditions was performed under brittle mode machining, and fractured surface was obtained in the production.

- It was found that grinding of glass substrate edge was performed partially under ductile mode machining in the experimental conditions, which can be attributed to and contributed by those micro cutting edges generated by the fractured diamond grit on the grinding wheel surface.

- Ductile mode machining of glass substrate and smooth surface can be achieved under certain conditions when the critical undeformed chip thickness was less than 40 nm. However, the productivity for ductile mode machining conditions is extremely low, and thus subsequent polishing process is essential for display glass panel production.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huet, R.; Ming, W. LCD display strength: Why edge preparation matters. In Proceedings of the IEEE International Conference on Portable Information Devices, Orlando, FL, USA, 25–29 May 2007. [Google Scholar]

- Minami, H.; Mori, J.; Iwai, S.; Moriya, H.; Watanabe, N. Manufacturing and inspection equipment for efficient production of large LCDs. Hitachi Rev. 2011, 60, 228–232. [Google Scholar]

- Liu, K.; Wang, H.; Zhang, X.Q. Ductile mode cutting of glass. In Ductile Mode Cutting of Brittle Materials; Springer Nature: Singapore, 2020; pp. 135–148. [Google Scholar]

- Antwi, E.K.; Liu, K.; Wang, H. A review on ductile mode cutting of brittle materials. Front. Mech. Eng. 2018, 13, 251–263. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.P.; Liang, S.Y.; Liu, X.D. Nanometer scale ductile mode cutting of soda-lime glass. J. Manuf. Proc. 2005, 7, 95–101. [Google Scholar] [CrossRef]

- Huerta, M.; Malkin, S. Grinding of glass: The mechanics of the process. ASME T J. Eng. Ind. 1976, 98, 459–467. [Google Scholar] [CrossRef]

- Huerta, M.; Malkin, S. Grinding of glass: Surface strength and fracture strength. ASME T J. Eng. Ind. 1976, 98, 468–473. [Google Scholar] [CrossRef]

- Fang, F.Z.; Chen, L.J. Ultra-precision cutting for ZKN7 glass. Ann. CIRP 2000, 49, 17–20. [Google Scholar] [CrossRef]

- Fang, F.Z.; Xu, F.F. Recent advances in micro/nano-cutting: Effect of tool edge and material properties. Nanomanuf. Metrol. 2018, 1, 4–31. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, X.J.; Ngoi, B.K. Brittle ductile transition in the diamond cutting of glasses with the aid of ultrasonic vibration. J. Mater. Proc. Tech. 2002, 121, 243–251. [Google Scholar] [CrossRef]

- Moriwaki, T.; Shmoto, E.; Inoue, K. Ultraprecision ductile cutting of glass by applying ultrasonic vibration. Ann. CIRP 1992, 41, 141–144. [Google Scholar] [CrossRef]

- Arefin, S.; Zhang, X.Q.; Kumar, A.S.; Liu, K.; Neo, W.K. An analytical model for determining the shear angle in 1D vibration-assisted micro machining. Nanomanuf. Metrol. 2019, 2, 199–214. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Matuszak, M.; Powałka, B.; Madajewski, M.; Maruda, R.W.; Krolczyk, G.M. Prediction of cutting forces during micro end milling considering chip thickness accumulation. I J. Mach. Tool Manuf. 2019, 147, 103466. [Google Scholar] [CrossRef]

- Liao, Y.S.; Yang, G.M.; Hsu, Y.S. Vibration assisted scribing process on LCD glass substrate. I J. Mach. Tool Manuf. 2010, 50, 532–537. [Google Scholar] [CrossRef]

- Zhong, Z.W.; Tian, Y.B.; Xie, T.G. Investigation of subsurface damage of ground glass edges. I J. Adv. Manuf. Tech. 2016, 87, 3261–3269. [Google Scholar] [CrossRef]

- Zhou, L.; Shiina, T.; Qiu, Z.; Shimizu, J.; Yamamoto, T.; Tashiro, T. Research on chemo-mechanical grinding of large size quartz glass substrate. Prec. Eng. 2009, 33, 499–504. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-regime grinding: A new technology for machining brittle materials. ASME T J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Ewalds, H.L.; Wanhill, R.J.H. Fracture Mechanics; Edward Arnold: London, UK, 1986; pp. 15–68. [Google Scholar]

- Malkin, S.; Guo, C.S. Grinding Technology: Theory and Applications of Machining with Abrasives; Industrial Press Inc.: New York, NY, USA, 2008; pp. 43–79. [Google Scholar]

- Liu, K.; Wang, H.; Zhang, X.Q. Ductile mode cutting mechanisms. In Ductile Mode Cutting of Brittle Materials; Springer Nature: Singapore, 2020; pp. 17–37. [Google Scholar]

- Fang, F.Z.; Liu, K.; Kurfess, T.R.; Lim, G.C. Tool-based micro machining and applications in MEMS. In MEMS/NEMS Handbook: Techniques and Applications; Leondes, C.T., Ed.; Springer: Boston, MA, USA, 2006; Volume 3, pp. 678–840. [Google Scholar]

- O’Hara, J.; Fang, F.Z. Advances in micro cutting tool design and fabrication. I J. Extrem. Manuf. 2019, 1, 032003. [Google Scholar] [CrossRef]

- Liu, K.; Zuo, D.W.; Li, X.P.; Rahman, M. Nanometric ductile cutting characteristics of silicon wafer using single crystal diamond tools. J. Vacu. Sci. Tech. B 2009, 27, 1361–1366. [Google Scholar] [CrossRef]

- Khatri1, N.; Barkachary, B.M.; Muneeswaran, B.; Al-Sayegh, R.; Luo, X.C.; Goel, S. Surface defects incorporated diamond machining of silicon. I J. Extrem. Manuf. 2020, 2, 045102. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.P.; Liang, S.Y. The mechanism of ductile chip formation in cutting of brittle materials. I J. Adv. Manuf. Tech. 2007, 33, 875–884. [Google Scholar] [CrossRef]

| Generation | Year | Size (mm) |

|---|---|---|

| 1 | 1988 | 300 × 400 |

| 2 | 1993 | 360 × 465 |

| 3 | 1995 | 550 × 650 |

| 4 | 2000 | 730 × 920 |

| 5 | 2002 | 1100 × 1300 |

| 6 | 2003 | 1500 × 1850 |

| 7 | 2005 | 1870 × 2200 |

| 8 | 2008 | 2200 × 2500 |

| 9 | 2009 | 2400 × 2800 |

| 10 | 2010 | 2880 × 3130 |

| 10.5 | 2019 | 2940 × 3370 |

| Material Properties | Display Glass |

|---|---|

| Specific gravity (g/cm)3 | 2.49 |

| Young’s modulus (GPa) | 70.9 |

| Modulus of rigidity | 28.3 |

| Modulus of volume elasticity | 45.2 |

| Knoop hardness (GPa) | 5.2 |

| Fracture toughness (MPa·m0.5) | 0.7 |

| Poisson’s ratio | 0.24 |

| Strain point (°C) | 661 |

| Annealing point (°C) | 715 |

| Softening point (°C) | 895 |

| Roughness (RMS, nm) 1 × 1 µm size | 0.324 |

| Refractive index (Nd) | 1.513 |

| Dielectric constant (S/m) | 4.7 |

| Grinding Parameters | Grinding Conditions |

|---|---|

| Spindle speed (rpm) | 250, 500, 750, 1000, 2000, 3000 |

| Feed rate (mm/min) | 7000, 10,000 |

| Grinding depth (mm) | 0.1, 0.15, 0.2, 0.4 |

| High-pressure coolant | Water-based |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wee Keong Neo, D.; Liu, K.; Huang, R.; Wu, H. Edge Grinding Characteristics of Display Glass Substrate. J. Manuf. Mater. Process. 2021, 5, 20. https://doi.org/10.3390/jmmp5010020

Wee Keong Neo D, Liu K, Huang R, Wu H. Edge Grinding Characteristics of Display Glass Substrate. Journal of Manufacturing and Materials Processing. 2021; 5(1):20. https://doi.org/10.3390/jmmp5010020

Chicago/Turabian StyleWee Keong Neo, Dennis, Kui Liu, Rui Huang, and Hu Wu. 2021. "Edge Grinding Characteristics of Display Glass Substrate" Journal of Manufacturing and Materials Processing 5, no. 1: 20. https://doi.org/10.3390/jmmp5010020

APA StyleWee Keong Neo, D., Liu, K., Huang, R., & Wu, H. (2021). Edge Grinding Characteristics of Display Glass Substrate. Journal of Manufacturing and Materials Processing, 5(1), 20. https://doi.org/10.3390/jmmp5010020