Micromechanism of Damage of the Graphite Spheroid in the Nodular Cast Iron During Static Tensile Test

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials for Examination

2.2. Examinations

3. Results

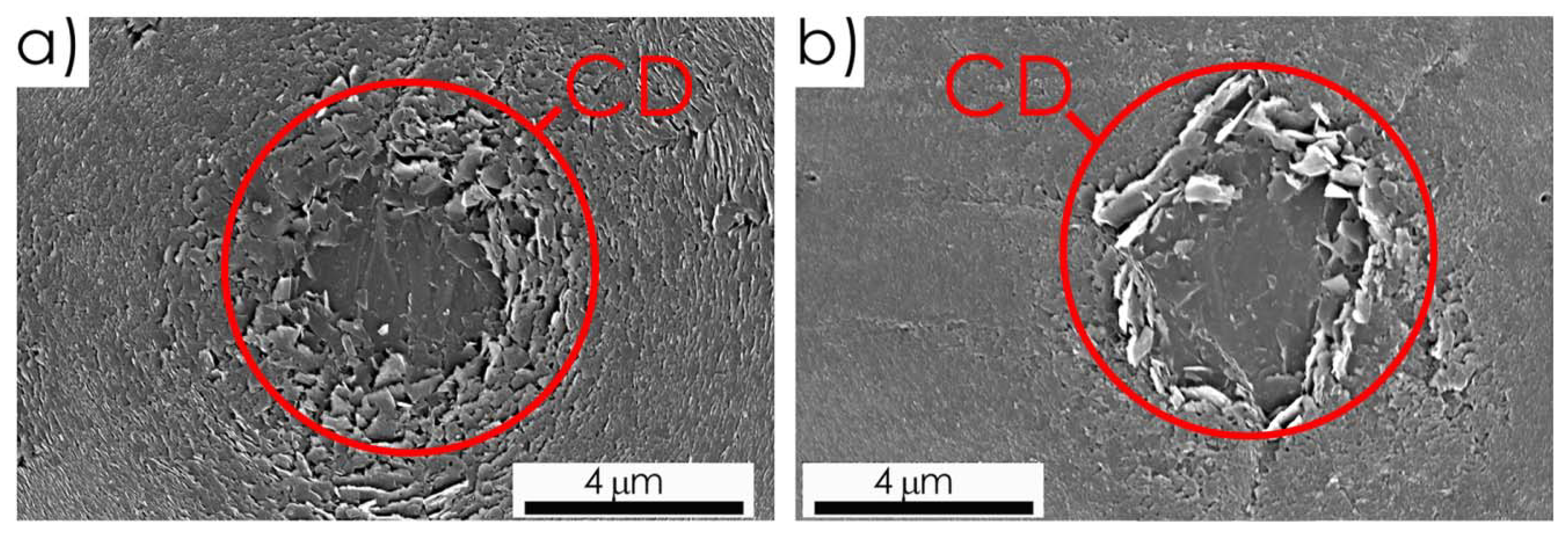

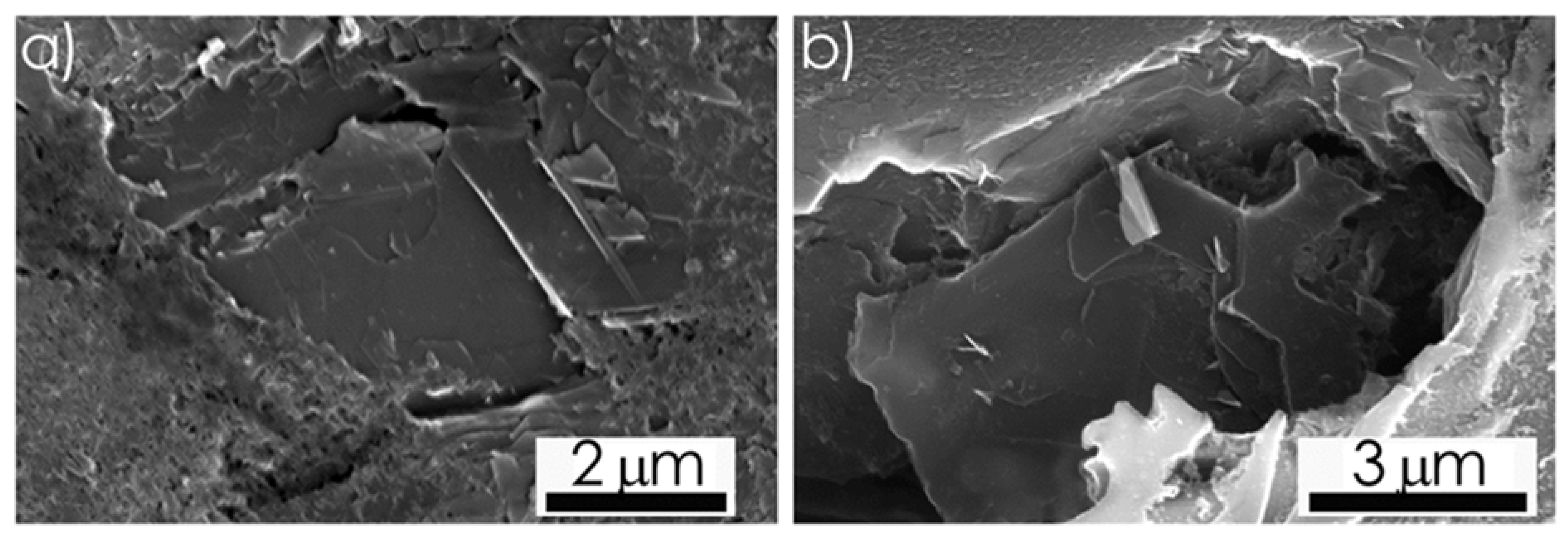

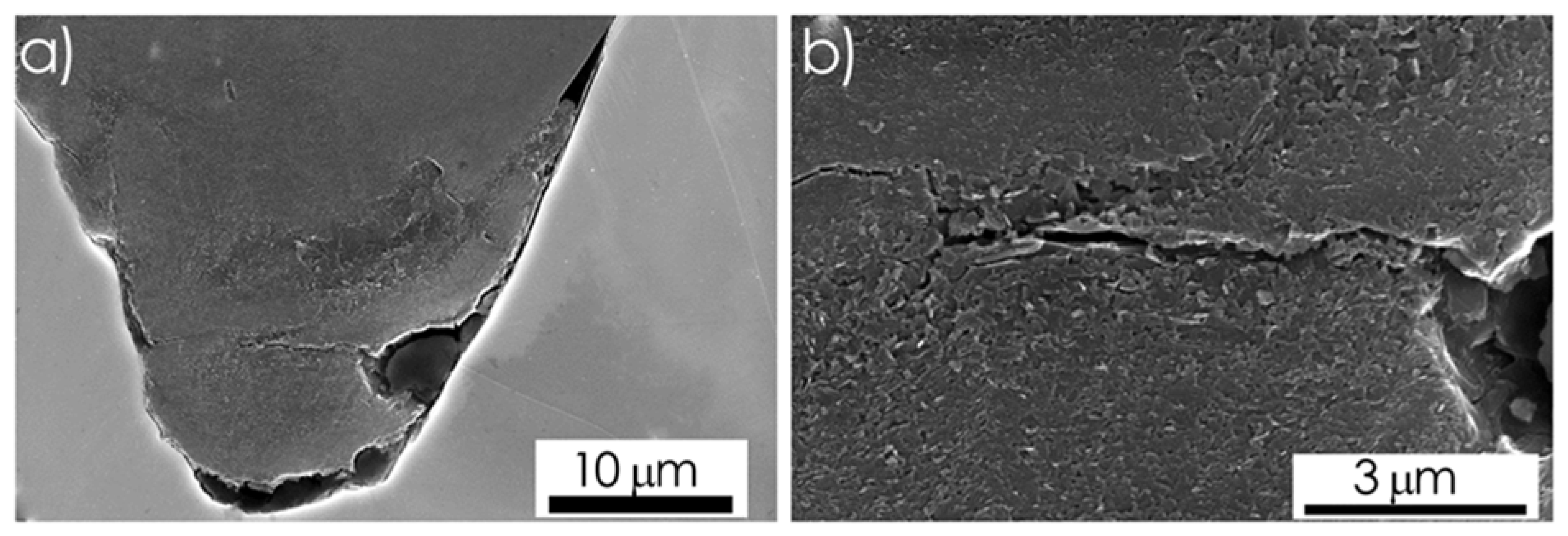

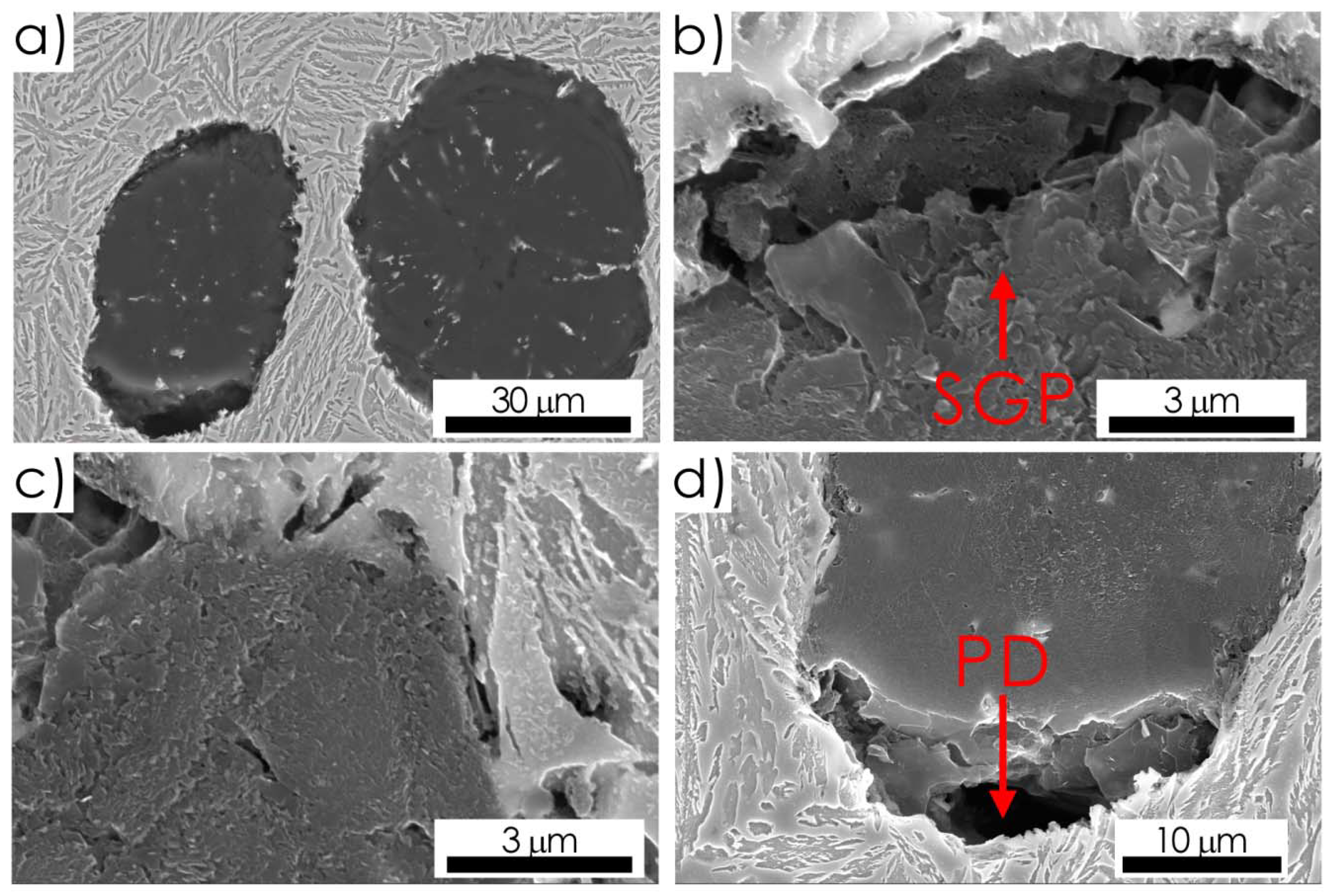

3.1. Internal Destruction Inside Graphite Nodule

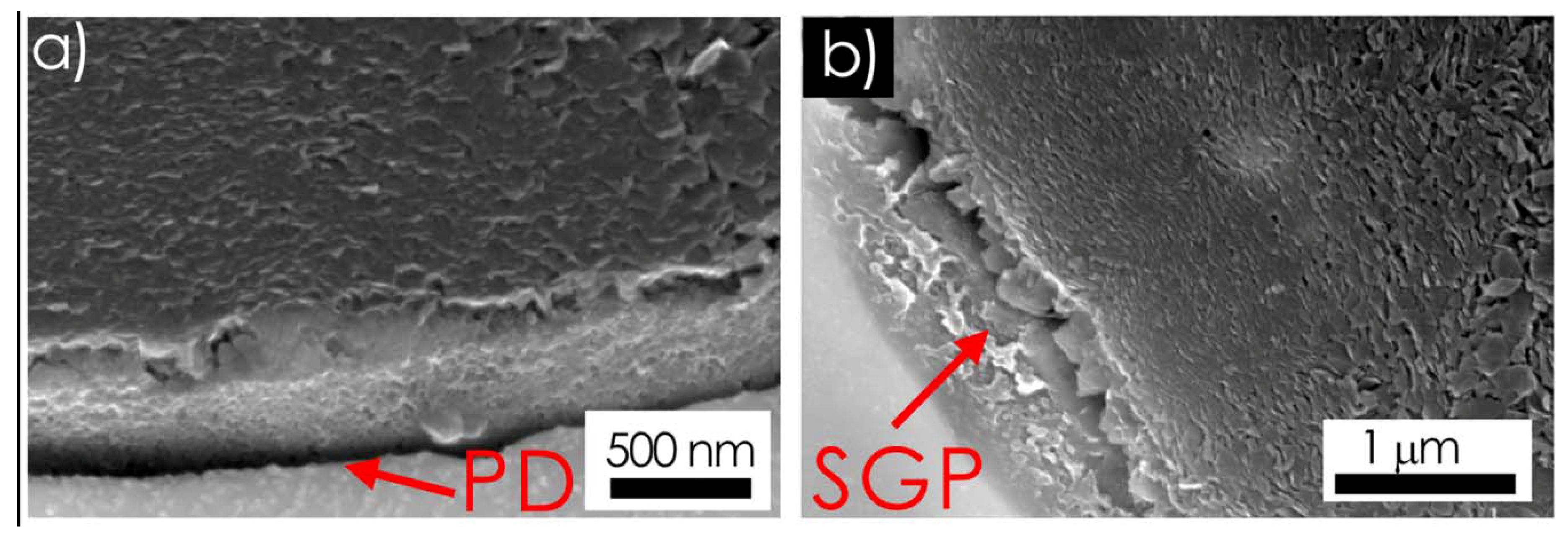

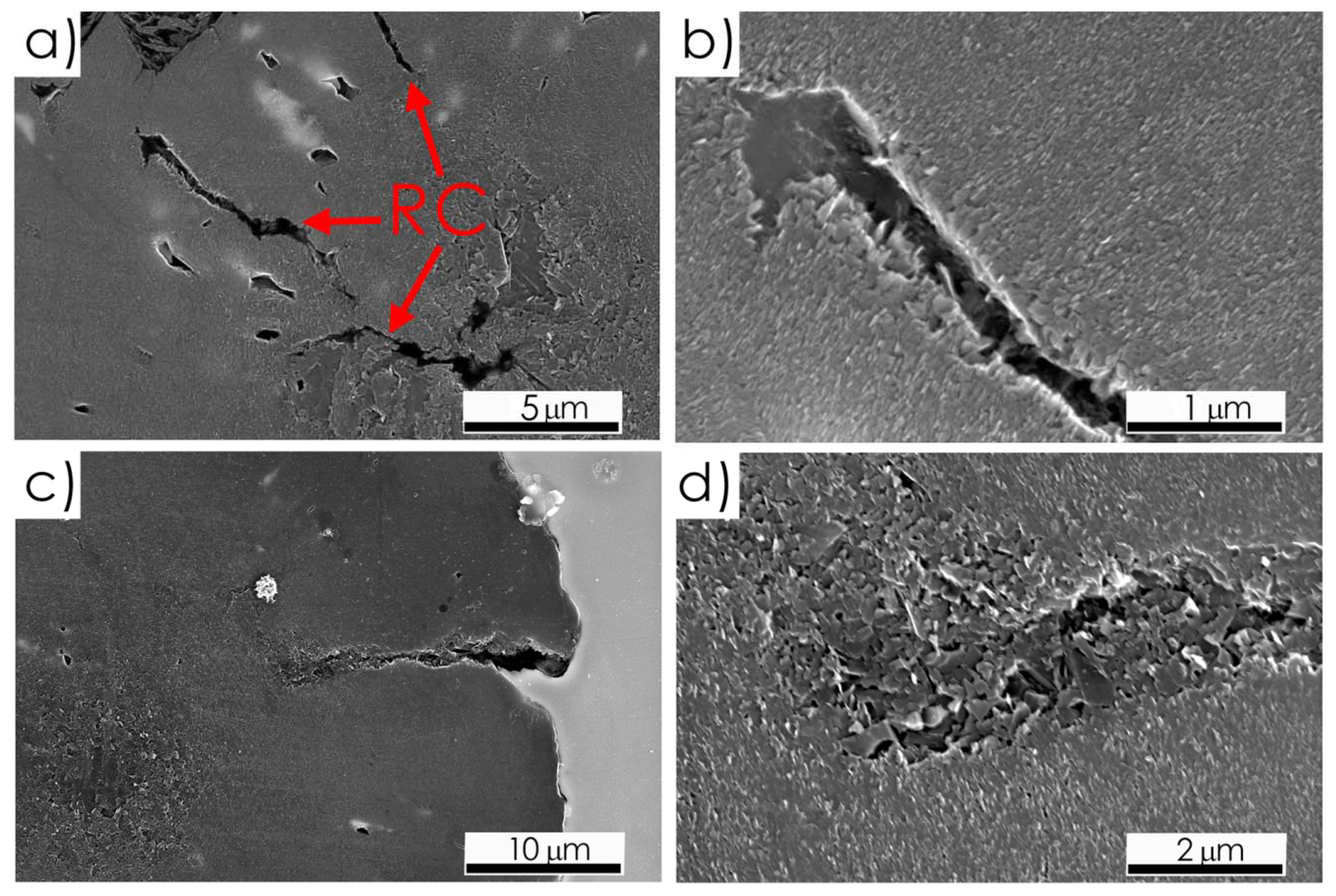

3.2. Graphite-Metal Matrix Debonding

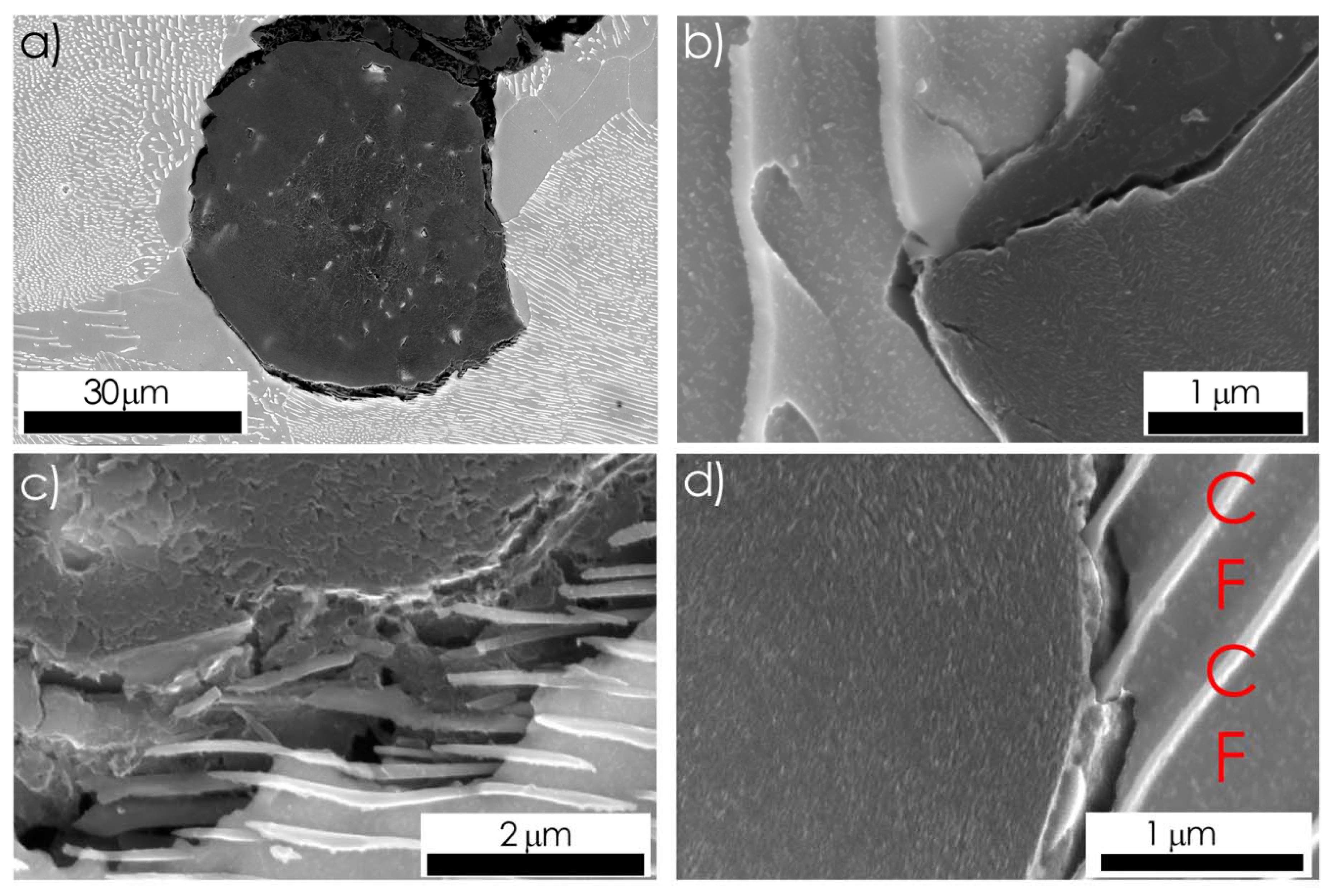

3.2.1. Debonding at Graphite/Ferrite Interface

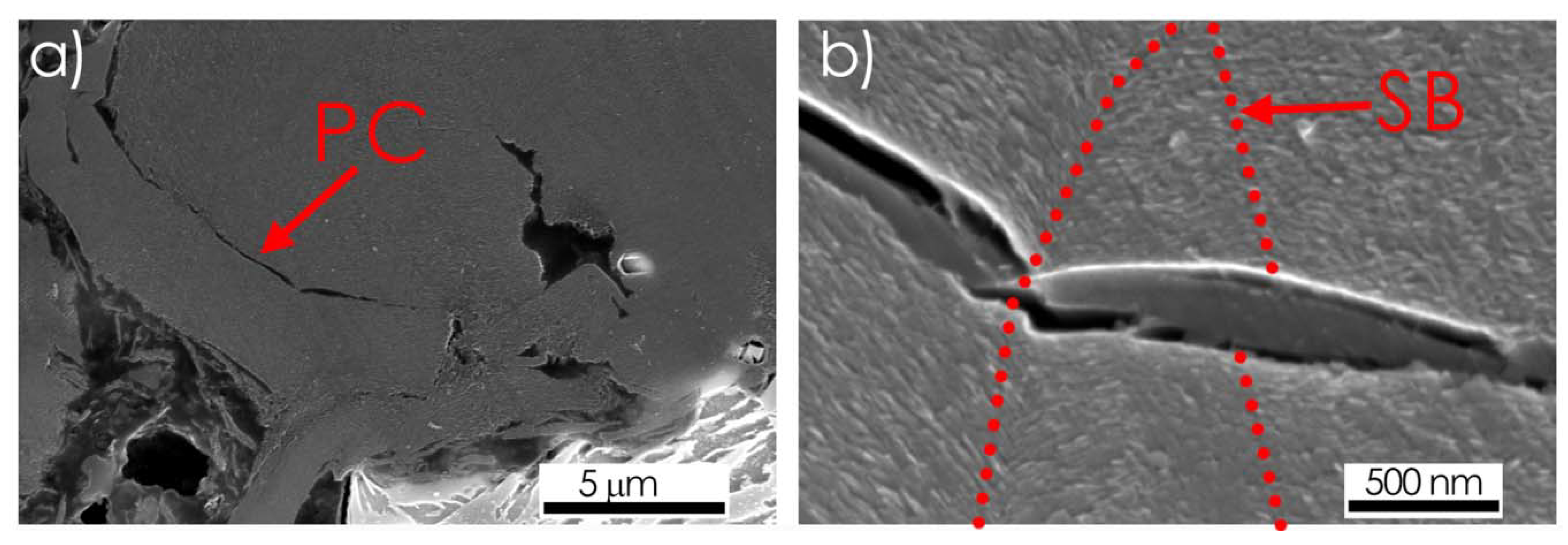

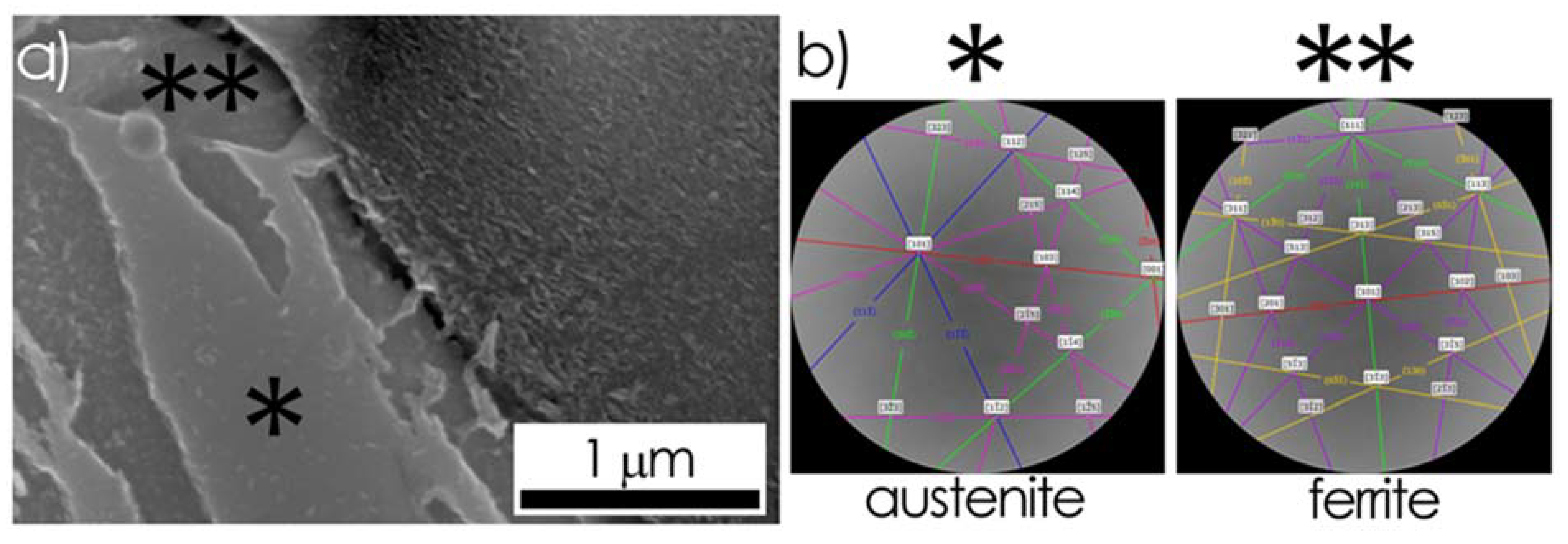

3.2.2. Debonding at Graphite/Ferrite Interface

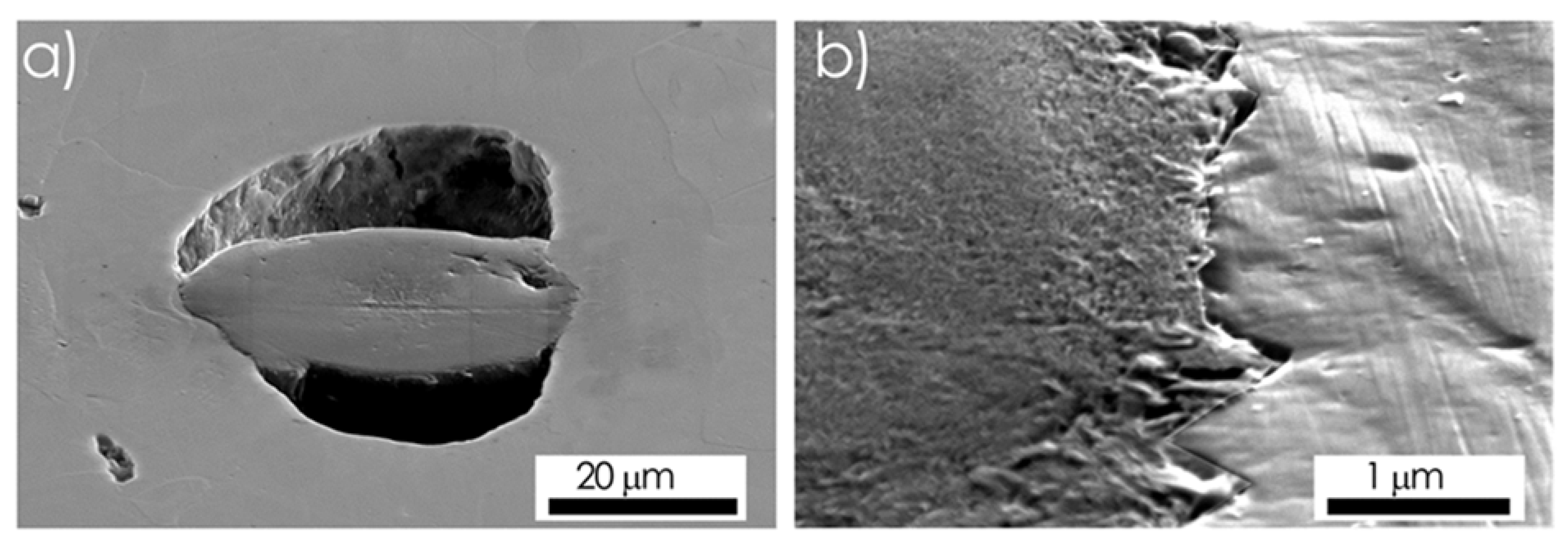

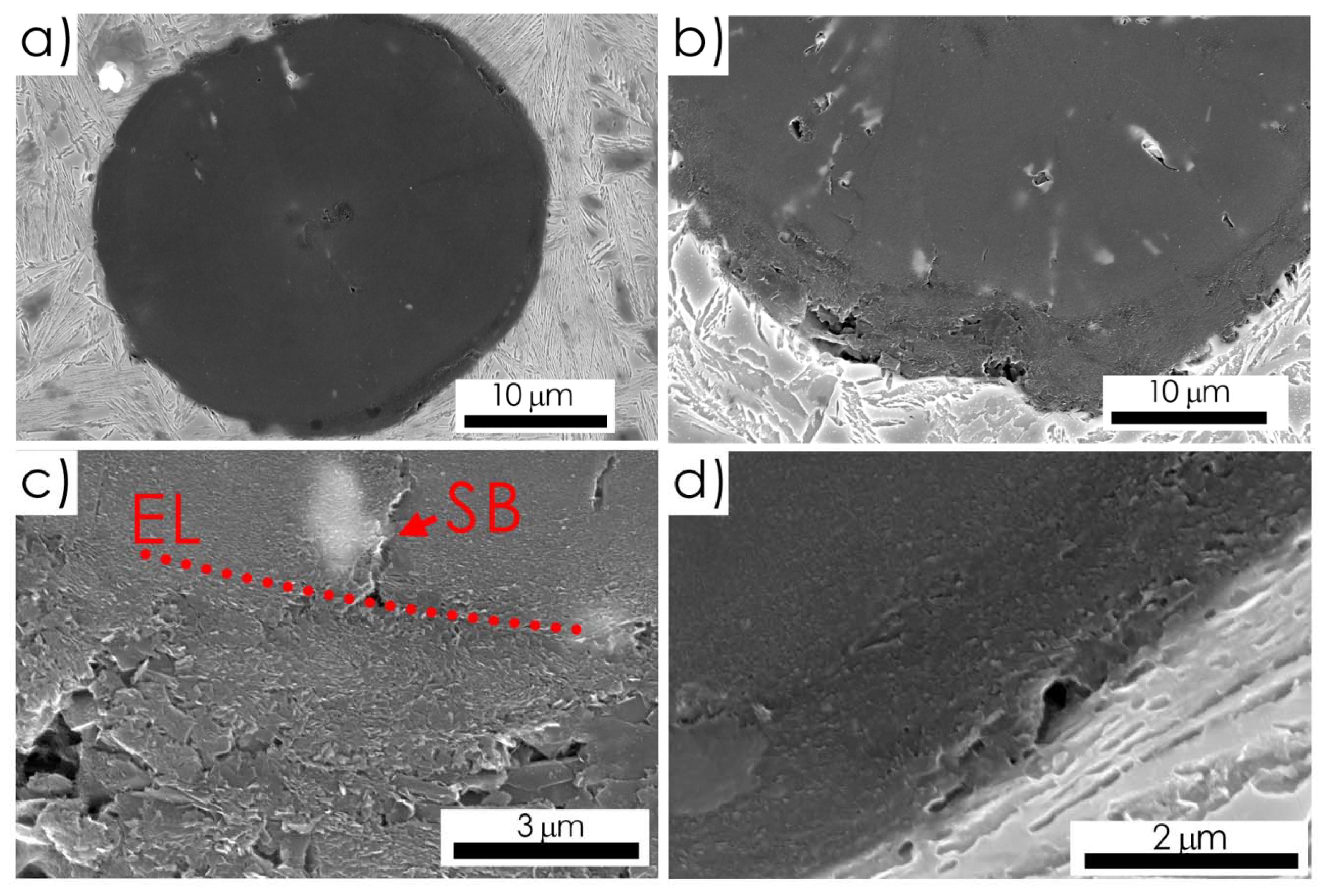

3.2.3. Debonding at Graphite/Ausferrite Interface

4. Discussion of the Results

5. Summary Conclusions

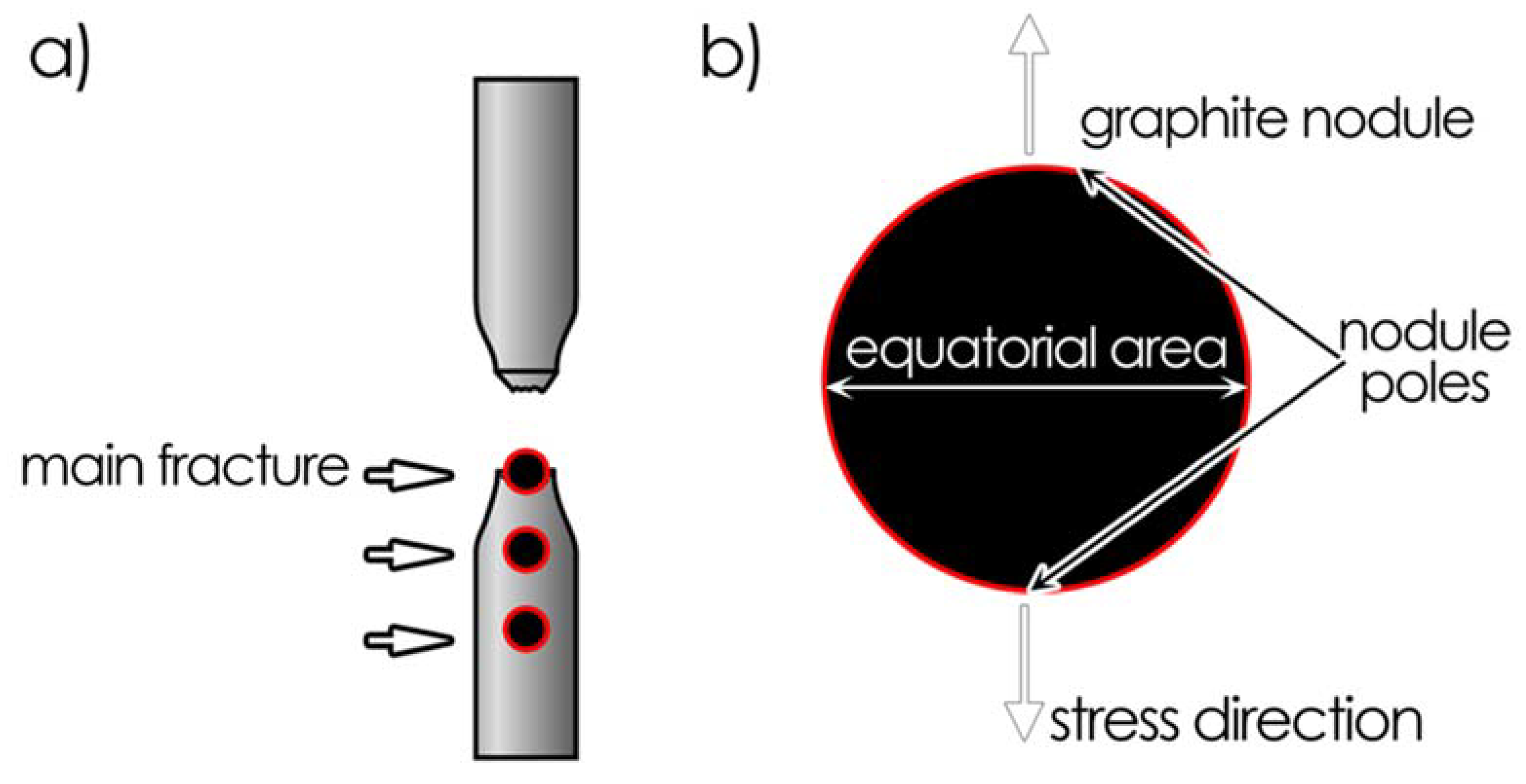

- In alloys with a ferritic ductile matrix, on the cross-section of the specimen near the main crack, i.e., in an area with a relatively high matrix ductility, at the pole area of the graphite/ferrite interface, the dominant damage mechanism was a pure GM debonding, preceded by a slight shift of graphene plates in the surface spheroid layers.

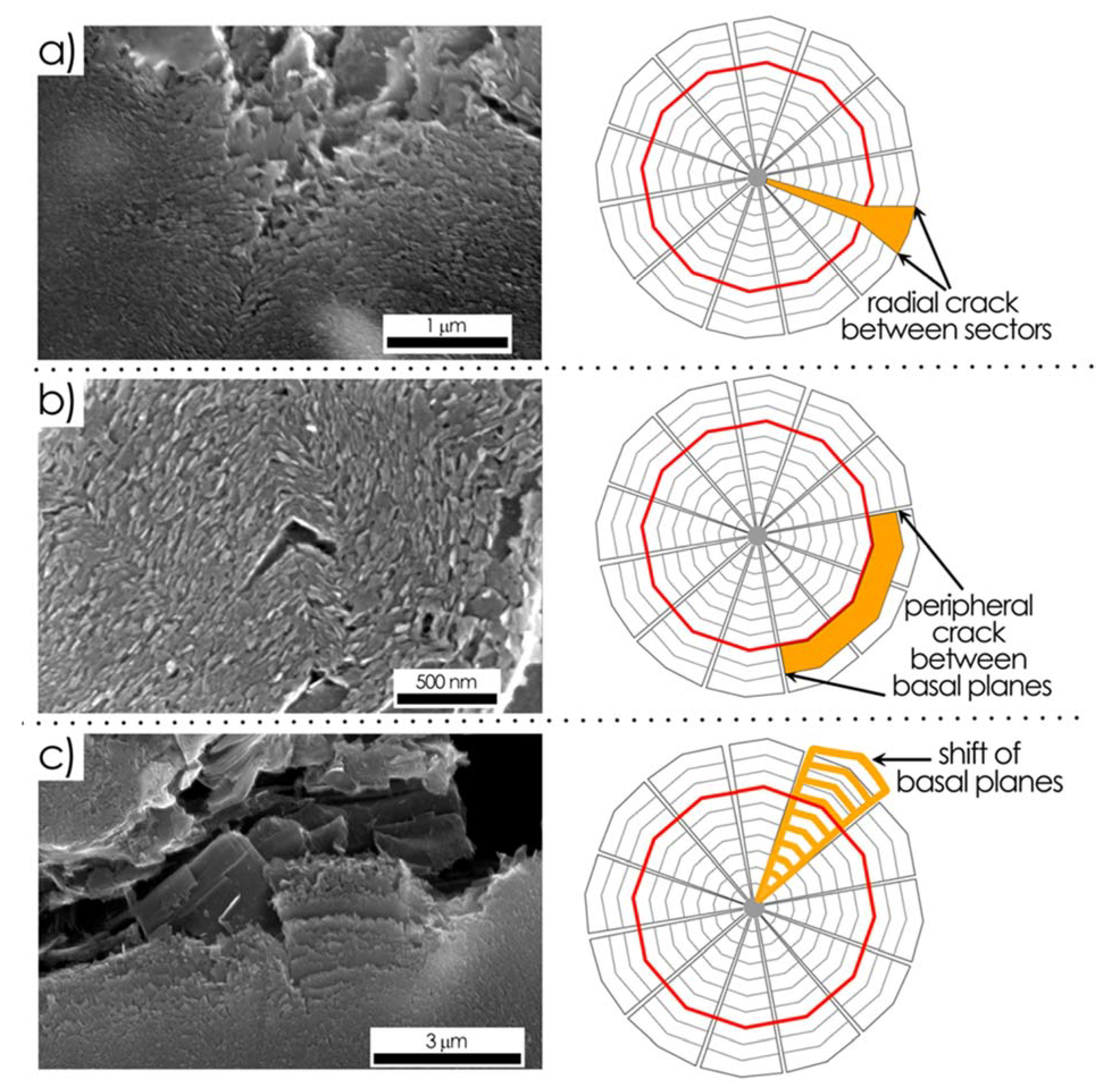

- The displacement of graphene plates in individual sectors of the outer shell at the spheroid poles, observed in ferrite and ausferrite matrix alloys, seems to be an intermediate stage of damage preceding the pure G-M debonding and onion-like cracks.

- The effect of apparent elongation of the spheroid, observed near the main fracture surface, can be attributed to the displacement of crushed graphene plates that fill the empty spaces formed at poles of spheroid, developing as the matrix deforms. It can be assumed that such a mechanism of internal spheroid destruction results from the local interaction between the actual tensile stress, the strain rate in the matrix adjacent to the spheroid pole, the G-M boundary strength and the stress necessary to displace the graphene blocks in the microcrystalline outer layer.

- In multiphase alloys the G-M debonding may be blocked by some phase components of matrix, as indicated by the presence of close phase contact still observed on the graphite/austenite and graphite/cementite interfaces, even when local separation at the graphite/ferrite interface was already occurred. This local delay of irreversible process of the G-M debonding can be considered one of the microstructural factors determining the actual value of the ultimate tensile strength/elongation ratio for the ductile cast iron with a multi-phase matrix.

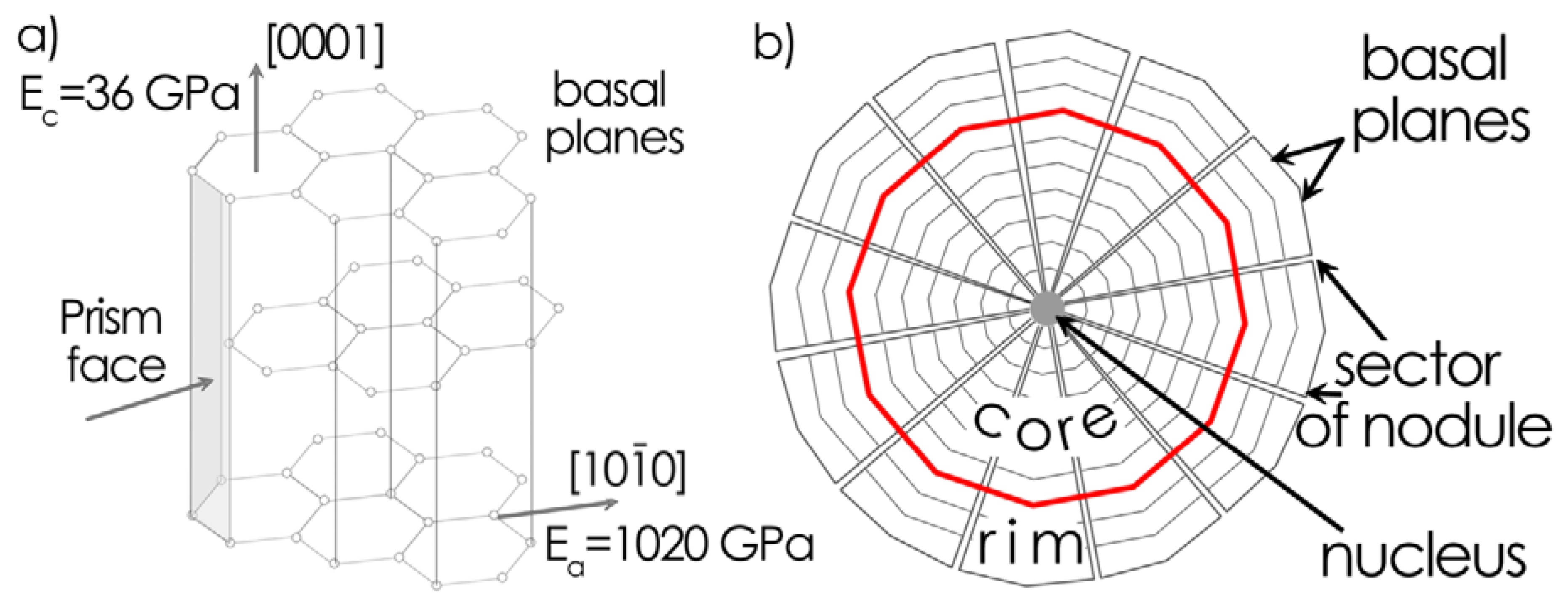

- The results of microscopic observations suggest that internal cracks in the graphite spheroid passed through areas of weakened cohesion, radial cracks across sector boundaries, and peripheral cracks between graphene layers. Thus, the actual state of the sectoral and layered structure of the graphite spheroid and anisotropy of interatomic bonds in the graphite crystal lattice may be factors determining its destruction during a tensile test.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hughes, C.H. Ductile Iron; ASM Handbook; ASM Casting ASM International: Materials Park, OH, USA, 2004; p. V15. [Google Scholar]

- Petrus, Ł.; Bulanowski, A.; Kołakowski, J.; Brzeżański, M.; Urbanowicz, M.; Sobieraj, J.; Matuszkiewicz, G.; Szwalbe, L.; Janerka, K. The influence of selected melting parameters on the physical and chemical properties of cast iron. Arch. Foundry Eng. 2020, 20, 105–110. [Google Scholar]

- Nofal, A.A. Advances in metallurgy and applications of ADI. J. Metall. Eng. 2013, 2, 1–18. [Google Scholar]

- Gazda, A.; Warmuzek, M.; Bitka, A. Optimization of mechanical properties of complex, two-stage heat treatment of Cu–Ni (Mn, Mo) austempered ductile iron. J. Therm. Anal. Calorim. 2018, 132, 813–822. [Google Scholar] [CrossRef]

- Putatunda, S.K. Development of austempered ductile cast iron (ADI) with simultaneous high yield strength and fracture toughness by a novel two-step austempering process. Mater. Sci. Eng. A 2001, 315, 70–80. [Google Scholar] [CrossRef]

- Fatahalla, N.; Hussein, O. Microstructure, mechanical properties, toughness, wear characteristics and fracture phenomena of austenitised and austempered low-alloyed ductile iron. Open Access Libr. J. 2015, 2, 1–16. [Google Scholar] [CrossRef]

- Marques, E.S.V.; Silva, F.J.G.; Paiva, O.C.; Pereira, A.B. Improving the mechanical strength of ductile cast iron welded joints using different heat treatments. Materials 2019, 226, 2263. [Google Scholar] [CrossRef] [PubMed]

- Cooper, C.A.; Elliott, R.; Young, R.J. Investigation of elastic property relationships for flake and spheroidal cast irons using Raman spectroscopy. Acta Mater. 2002, 50, 4037–4046. [Google Scholar] [CrossRef]

- He, Z.R.; Lin, G.X.; Ji, S. Deformation and fracture of cast iron with an optimized microstructure. Mater. Charact. 1997, 38, 251–258. [Google Scholar] [CrossRef]

- Dong, M.J.; Prioul, C.; François, D. Damage effect on the fracture toughness of nodular cast iron: Part I. Damage characterization and plastic flow modeling. Metall. Mater. Trans. A 1997, 28, 2245–2254. [Google Scholar] [CrossRef]

- Dai, P.Q.; He, Z.R.; Zheng, C.M.; Mao, Z.Y. In-situ SEM observation on the fracture of austempered ductile iron. Mater. Sci. Eng. A 2001, 319–321, 531–534. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, D.; Iacoviello, F.; Rossi, A. Graphite nodules influence on DCIs mechnical properties: Experimental and numerical investigation. Procedia Eng. 2015, 109, 135–143. [Google Scholar] [CrossRef]

- Fragassa, C.; Radovic, N.; Pavlovic, A.; Minak, G. Comparison of mechanical properties in compacted and spheroidal graphite irons. Tribol. Ind. 2016, 38, 49–59. [Google Scholar] [CrossRef][Green Version]

- Pachla, W.; Mazur, A.; Skiba, J.; Kulczyk, M.; Przybysz, S. Effect of hydrostatic extrusion with back pressure on mechanical properties of grey and nodular cast irons. Arch. Metall. Mater. 2011, 56, 945–953. [Google Scholar] [CrossRef][Green Version]

- Mohammed, A.D.; Kachi, M. Effects of Features of Graphite Nodules on Stress Concentration in Nodular Graphite Cast Iron Material under Multi-Axial Loading. Int. J. Appl. Eng. Res. 2017, 12, 656–663. [Google Scholar]

- Gaudig, W.; Mellert, R.; Weber, U.; Schmauder, S. Self-consistent one-particle 3D unit cell model for simulation of the effect of graphite aspect ratio on Young’s modulus of cast-iron. Comput. Mater. Sci. 2003, 28, 654–662. [Google Scholar] [CrossRef]

- Seetharamu, S.; Srinivasan, N.; Mangalgir, P.D. Effect of graphite size and spacing in spheroidal cast iron: An analytical on the elastic constants of analytical approach. J. Indian Inst. Sci. 1981, 63, 213–226. [Google Scholar]

- Bonora, N.; Ruggiero, A. Micromechanical modeling of ductile cast iron incorporating damage. Part I: Ferritic ductile cast iron. Int. J. Solids Struct. 2005, 42, 1401–1424. [Google Scholar] [CrossRef]

- Fukumasu, N.K.; Pelegrino, P.L.; Cueva, G.; Souza, R.M.; Sinatora, A. Numerical analysis of the stresses developed during the sliding of a cylinder over compact graphite iron. Wear 2005, 259, 1400–1407. [Google Scholar] [CrossRef]

- Andriollo, T.; Thorborg, J.; Tiedje, N.S.; Hattel, J. Modeling of damage in ductile cast iron – The effect of including plasticity in the graphite nodules. IOP Conf. Ser. Mater. Sci. Eng. 2015, 84. [Google Scholar] [CrossRef]

- Andriollo, T.; Hattel, J. On the isotropic constants of graphite nodules in ductile cast iron: Analitycal and micromechanical investigations. Mech. Mater. 2016, 96, 138–150. [Google Scholar] [CrossRef]

- Tsai, J.-L.; Tu, J.-F. Characterizing mechanical properties of graphite using molecular dynamics simulation. Mater. Des. 2010, 31, 194–199. [Google Scholar] [CrossRef]

- Pina, J.C.; Kouznetsova, V.G.; Geers, M.G.D. Thermo-mechanical analyses of heterogeneous materials with a strongly anisotropic phase: The case of cast iron. Int. J. Solids Struct. 2015, 63, 153–166. [Google Scholar] [CrossRef]

- Stefanescu, D.M.; Alonso, G.; Larranaga, P.; De la Fuente, E.; Suarez, R. On the crystallization of graphite from liquid irone-carbone-silicon melts. Acta Mater. 2016, 107, 102–126. [Google Scholar] [CrossRef]

- Qing, J.; Richards, V.L.; Van Aken, D.C. Growth stages and hexagonalrhombohedral structural arrangementsin spheroidal graphite observed in ductile iron. Carbon 2017, 116, 456–469. [Google Scholar] [CrossRef]

- Hervas, I.; Thuault, A.; Hug, E. Damage analysis of a ferritic simo ductile cast iron submitted to tension and compression loadings in temperature. Metals 2015, 5, 2351–2369. [Google Scholar] [CrossRef]

- Andriollo, T.; Thorborg, J.; Tiedje, N.; Hattel, J. A micro-mechanical analysis of thermo-elastic properties and local residual stresses in ductile iron based on a new anisotropic model for the graphite nodules. Modelling Simul. Mater. Sci. Eng. 2016, 24. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Cavallini, M. Damaging micromechanisms characterization of a ferritic ductile cast iron. Eng. Fract. Mech. 2010, 77, 2016–2023. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Rossi, A.; Iacoviello, D. Macro- and microscopical approach to the damaging micromechanisms analysis in a ferritic ductile cast iron. Theor. Appl. Fract. Mech. 2013, 69, 26–33. [Google Scholar] [CrossRef]

- Iacoviello, F.; Di Cocco, V.; Rossi, A. Pearlitic ductile cast iron: Damaging micromechanisms at crack tip. Frat. Integrita Strut. 2013, 25, 102–108. [Google Scholar] [CrossRef]

- Warmuzek, M.; Polkowska, A.; Gazda, A. Microscopic approach to micromechanism of damage in spheroidal cast iron. Article in press. Microsc. Res. Tech. 2020, 1–9. [Google Scholar] [CrossRef]

- Gouveia, R.M.; Silva, F.J.G.; Paiva, O.C.; Andrade, M.F.; Silva, L.; Moselli, P.C.; Papis, K.J.M. Study of the heat-treatments effect on high strength ductile cast iron welded joints. Metals 2017, 7, 382. [Google Scholar] [CrossRef]

- Velichko, A.; Holzapfel, C.; Mücklich, F. 3D Characterization of Graphite Morphologies in Cast Iron. Adv. Eng. 2007, 9, 39–45. [Google Scholar] [CrossRef]

- Lacaze, J.; Theuwissen, K.; Laffont, L.; Véron, M. Misorientations in spheroidal graphite: Some new insights about spheroidal graphite growth in cast irons. IOP Conf. Ser. Mater. Sci. Eng. 2016, 117, 1–6. [Google Scholar] [CrossRef]

- Theuwissen, K.; Lacaze, J.; Laffont, L. Structure of graphite precipitates in cast iron. Carbon 2016, 96, 1120–1128. [Google Scholar] [CrossRef]

- Monchoux, J.P.; Verdu, C.; Thollet, G.; Fougères, R.; Reynaud, A. Morphological changes of graphite spheroids during heat treatment of ductile cast irons. Acta Mater. 2001, 49, 4355–4362. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Andriollo, T.; Fæster, S.; Liu, W.; Hattel, J.; Barabash, R. 3D local residual stress and orientation gradients near graphite nodules in ductile cast iron. Acta Mater. 2016, 121, 173–180. [Google Scholar] [CrossRef]

- Lopez-Covaleda, E.A.; Sepideh-Ghodrat, I.D.; Kestens, L.A.I.; Sacre, C.H.; Pardoen, T. Proposal of characterization procedure of metal–graphite interface strength in compacted graphite iron. Materials 2018, 11, 1159. [Google Scholar] [CrossRef]

| Material | Serie des. | C | Si | Mg | Mn | Cu | Mo | Ni | Cr |

|---|---|---|---|---|---|---|---|---|---|

| SCI | SNi9 | 3.38 | 4.02 | 0.056 | 0.19 | 0.05 | - | 0.92 | - |

| SNi11 | 3.25 | 3.99 | 0.072 | 0.19 | 0.06 | - | 1.80 | - | |

| ADI | ADI | 3.66 | 2.38 | 0.070 | 0.21 | 0.53 | 0.16 | 0.85 | 0.05 |

| Material | Specimen Designation | Matrix Microstructure | Tensile Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation to Fracture, % |

|---|---|---|---|---|---|

| SCI | SNi9 (as cast) | Ferrite + 10% perlite | 510 | 631 | 17.8 |

| SNi11(as cast) | Ferrite + 20% perlite | 550 | 694 | 12.0 | |

| ADI | ADI (as cast) | Ferrite + 90% perlite | 524 | 772 | 2.7 |

| ADI310 (austempered at 310 °C) | Ausferrite (austenite) | 1324 | 1424 | 3.5 | |

| ADI390 (austempered at 390 °C) | Ausferrite (austenite) | 710 | 1025 | 8.4 |

| Distance from Fracture | >3 mm | >1 mm | Near Fracture | |

|---|---|---|---|---|

| Matrix | Damage Mode | |||

| Monophase | Ferritic | Pure G-M debonding | Lens -like pole voids at G/M interface | Total debonding: -Pure at G-M interface -onion-like at core-external rim interface |

| Graphene layers shift at G/M interface | Lens-like pole voids filled with crushed graphene layers at G-M interface | |||

| Peripheral cracks at core-external rim interface | ||||

| Radial cracks | Radial cracks | |||

| Polyphase | Pearlitic | Local G-M debonding F-G crack C-G contact | Elliptical pole voids at G-M interface | Total debonding: At G-M interface |

| Radial cracks | Radial cracks | |||

| Ausferritic | Local G-M debonding F-G crack A-G contact | Lens -like areas partially filled with crushed graphene layers at G-M interface | Total debonding: -Onion like: -peripheral cracks at core-external rim interface | |

| Peripheral cracks at core-external rim boundaries and inside external layer of secondary particles | ||||

| Total debonding: -Onion like: -Peripheral cracks inside external layer of secondary graphite | ||||

| Radial cracks | Radial cracks | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warmuzek, M.; Polkowska, A. Micromechanism of Damage of the Graphite Spheroid in the Nodular Cast Iron During Static Tensile Test. J. Manuf. Mater. Process. 2020, 4, 22. https://doi.org/10.3390/jmmp4010022

Warmuzek M, Polkowska A. Micromechanism of Damage of the Graphite Spheroid in the Nodular Cast Iron During Static Tensile Test. Journal of Manufacturing and Materials Processing. 2020; 4(1):22. https://doi.org/10.3390/jmmp4010022

Chicago/Turabian StyleWarmuzek, Małgorzata, and Adelajda Polkowska. 2020. "Micromechanism of Damage of the Graphite Spheroid in the Nodular Cast Iron During Static Tensile Test" Journal of Manufacturing and Materials Processing 4, no. 1: 22. https://doi.org/10.3390/jmmp4010022

APA StyleWarmuzek, M., & Polkowska, A. (2020). Micromechanism of Damage of the Graphite Spheroid in the Nodular Cast Iron During Static Tensile Test. Journal of Manufacturing and Materials Processing, 4(1), 22. https://doi.org/10.3390/jmmp4010022