A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites

Abstract

1. Introduction

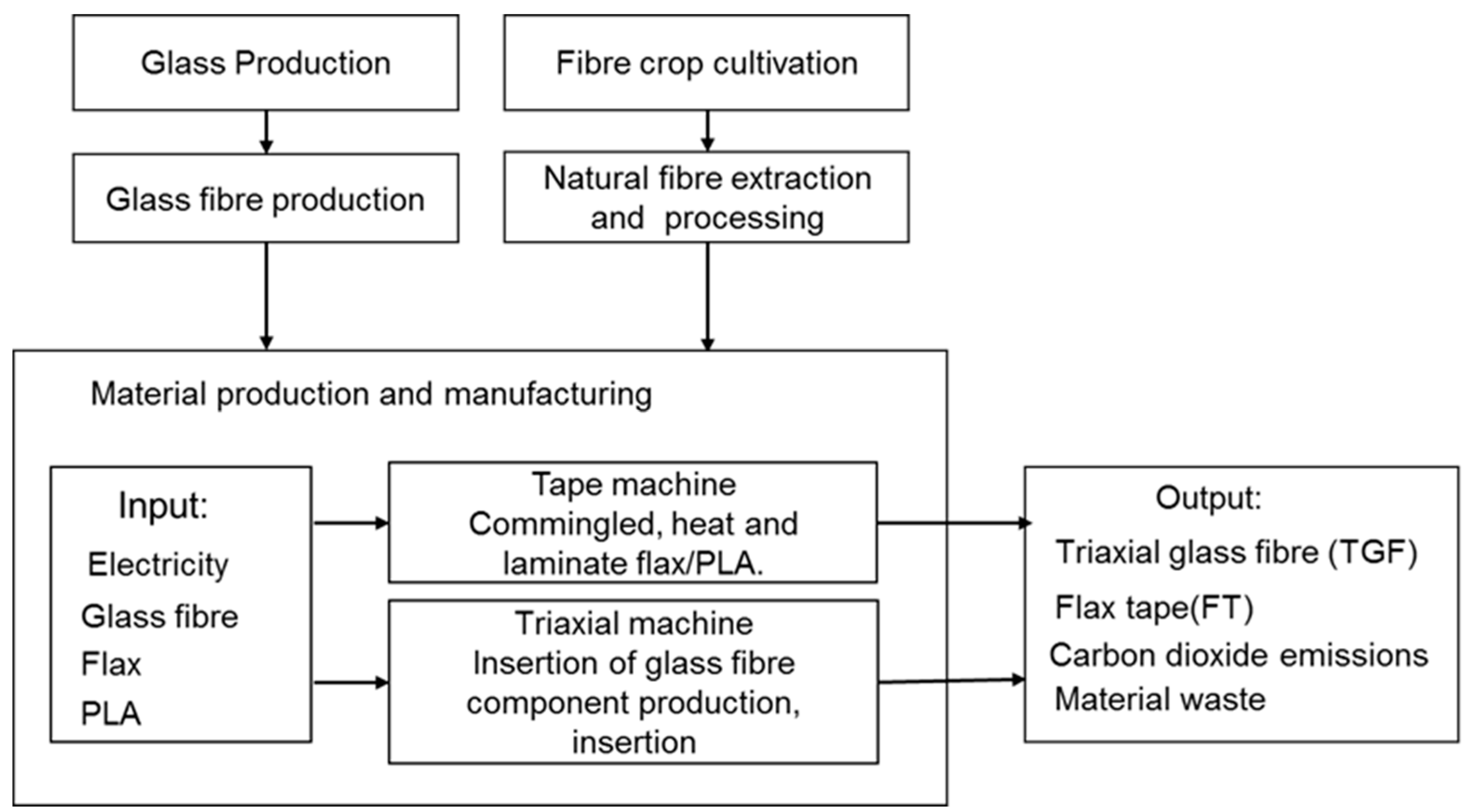

2. Materials and Methods

2.1. Materials

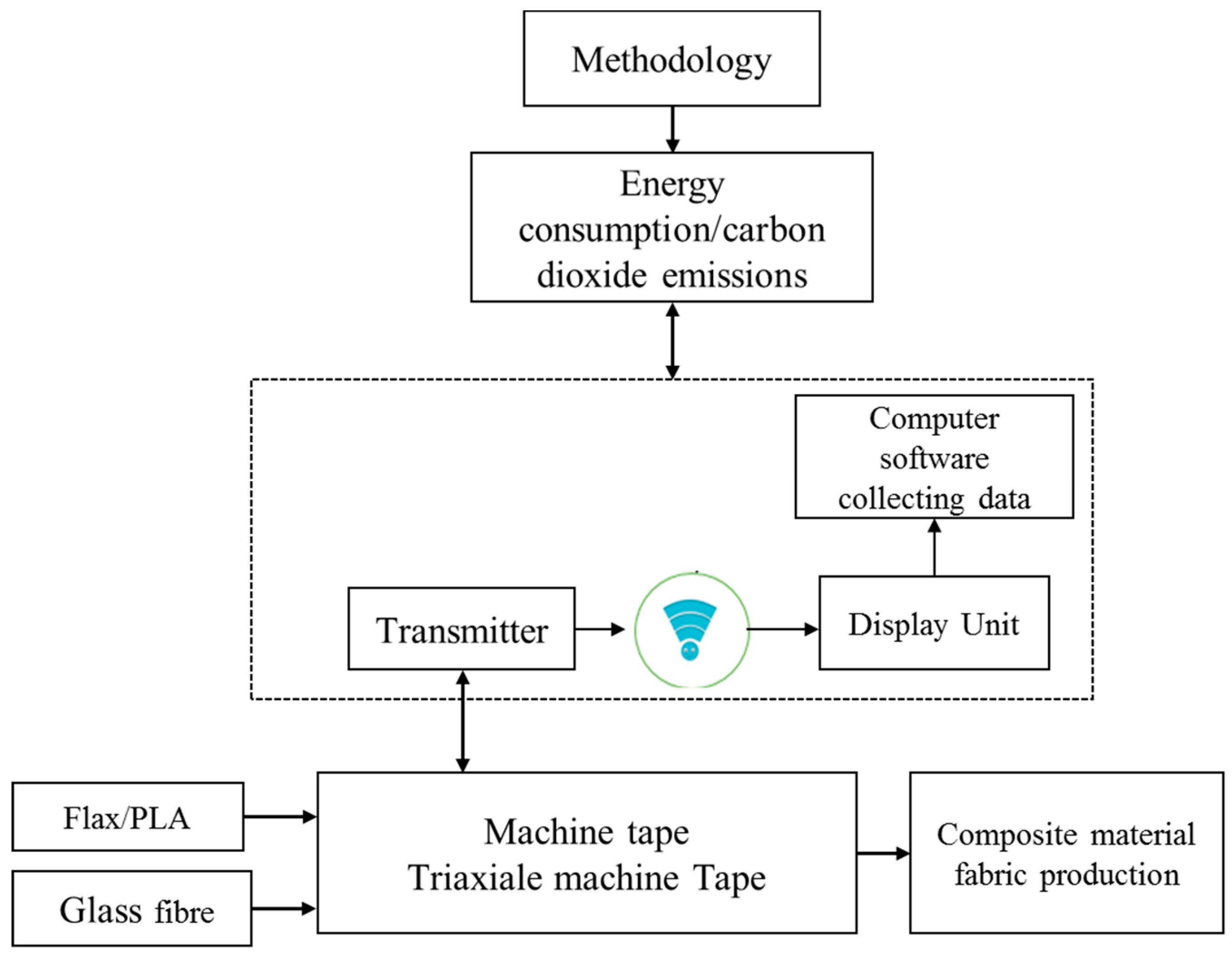

2.2. Methods

2.2.1. Prediction Method to Calculate the Energy Consumption and Environment Impact

2.2.2. Calculation Method for Life Cycle Energy Consumption

2.3. Manufacturing Process

2.3.1. Manufacturing Flax/PLA Tape

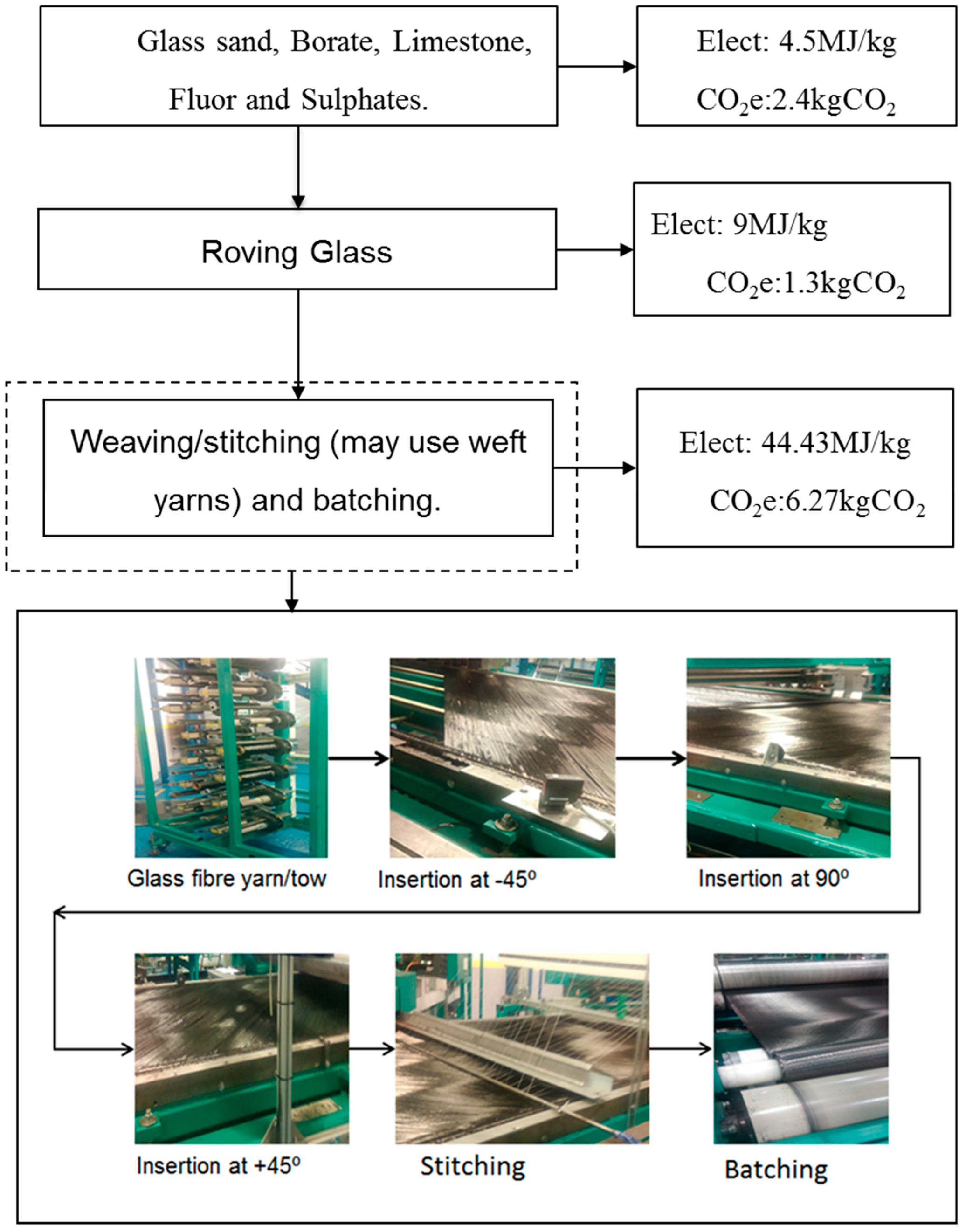

2.3.2. Manufacturing Triaxial Glass Fibre

3. Results and Discussion

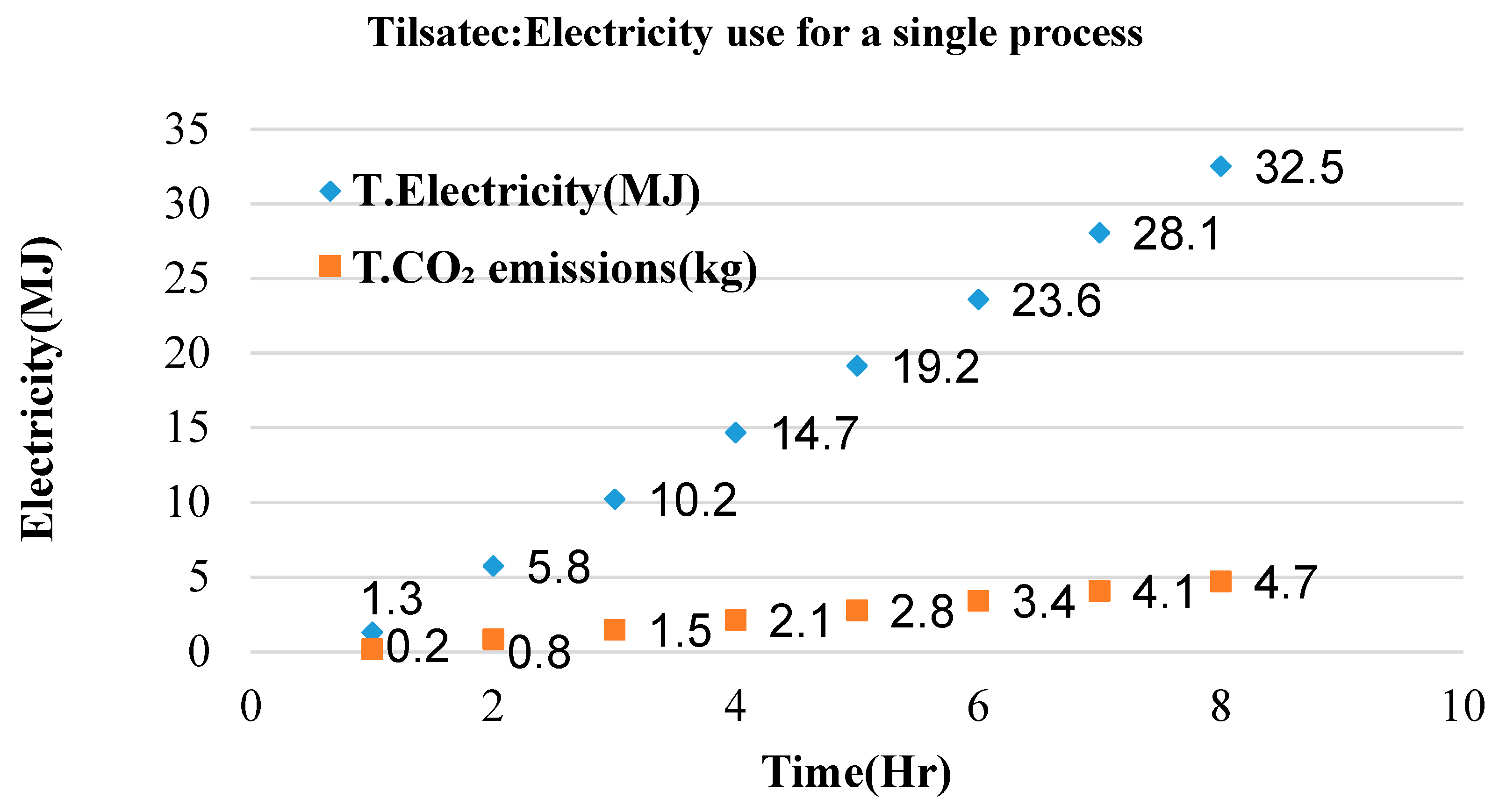

3.1. Energy Consumption Profile

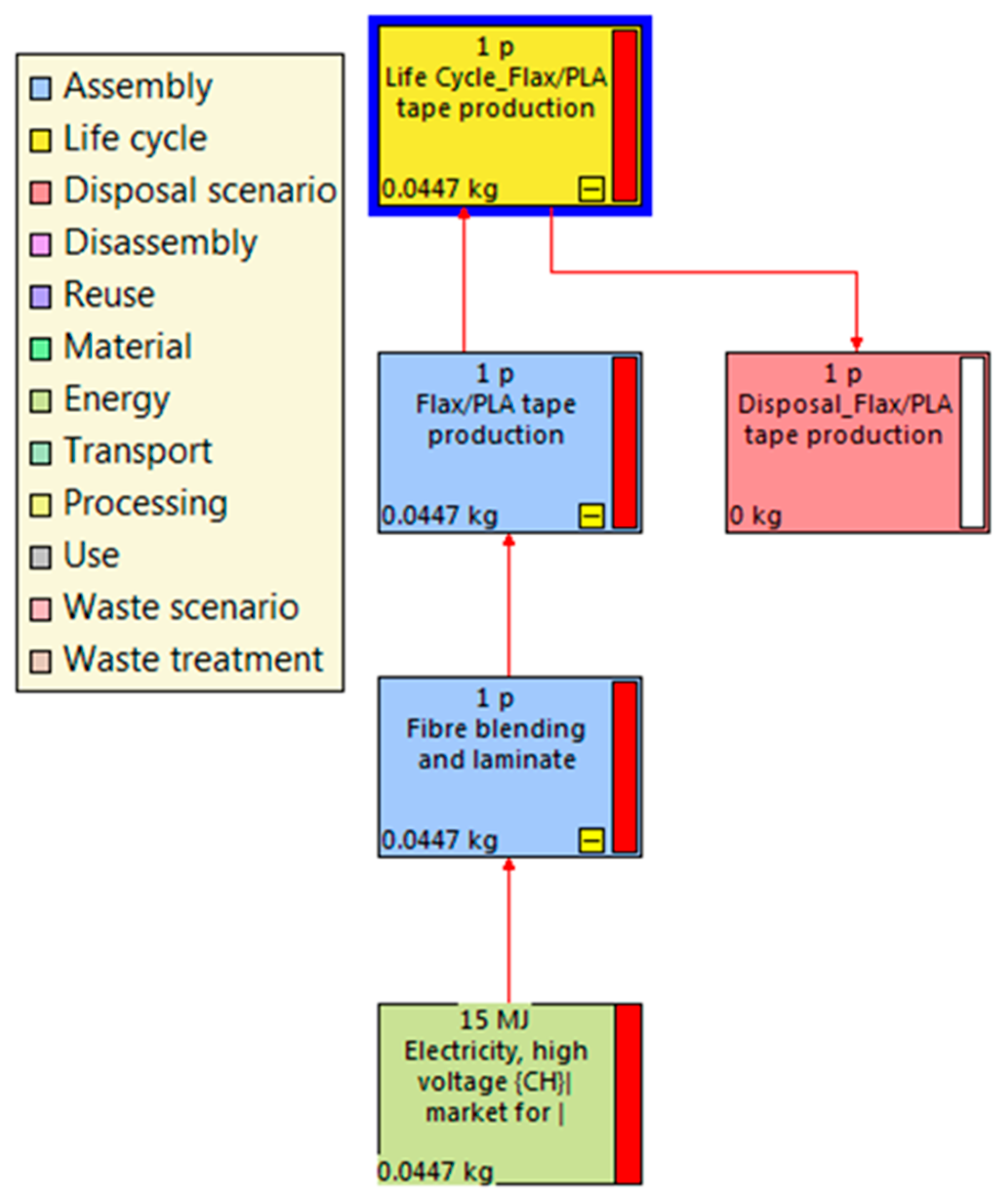

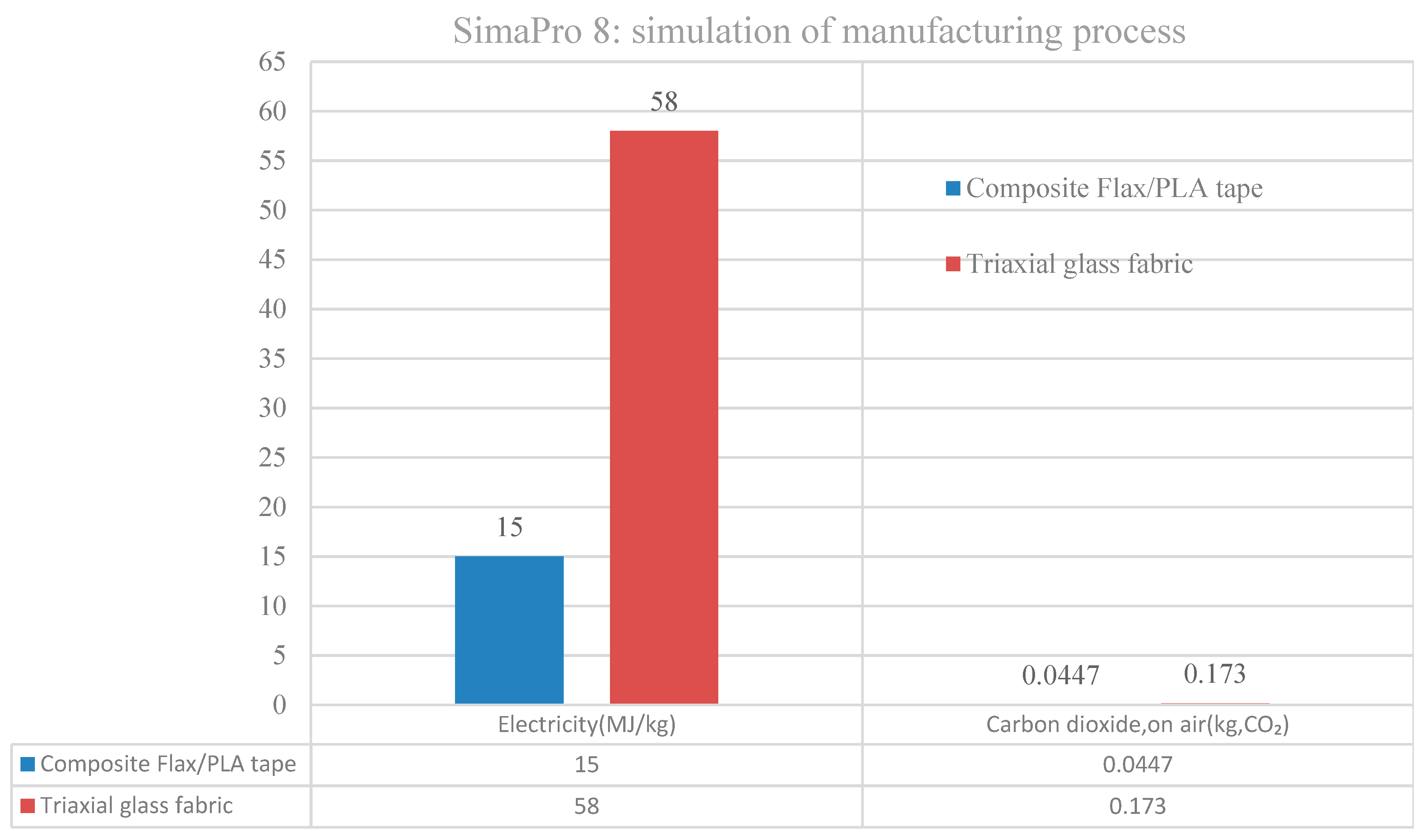

3.1.1. Energy Consumption during Production of Flax/PLA Tape

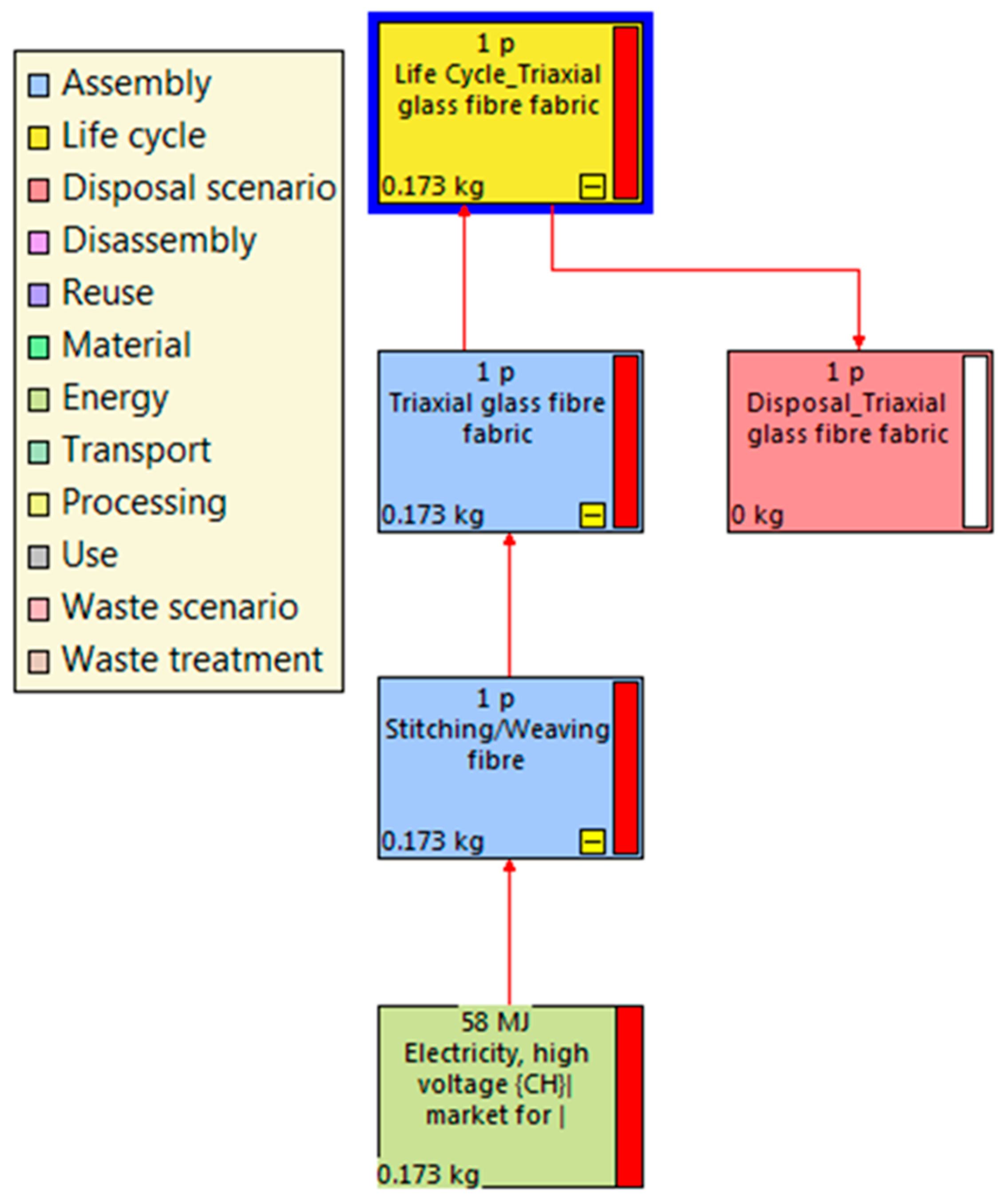

3.1.2. Energy Consumption during the Production of Triaxial Glass Fabrics

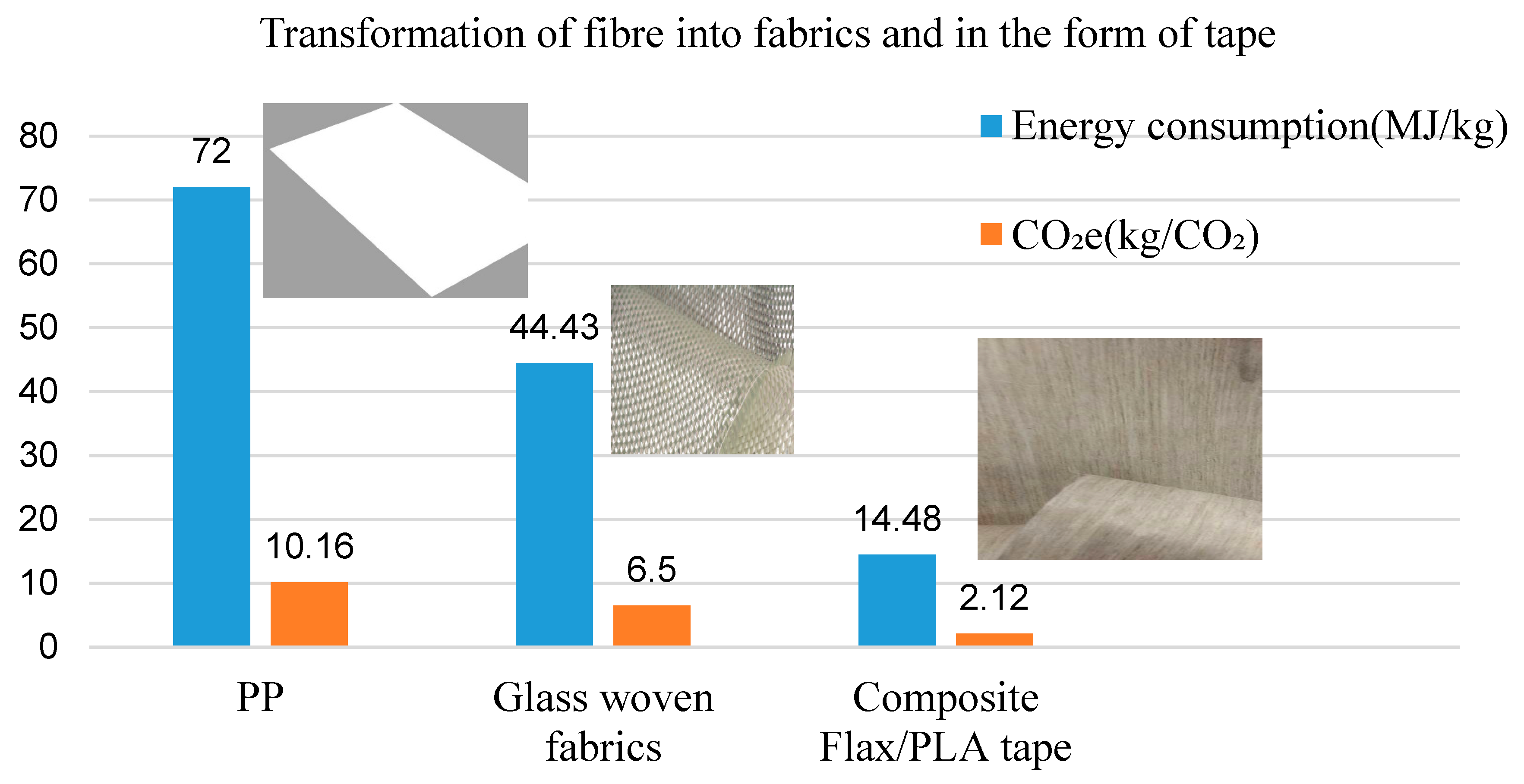

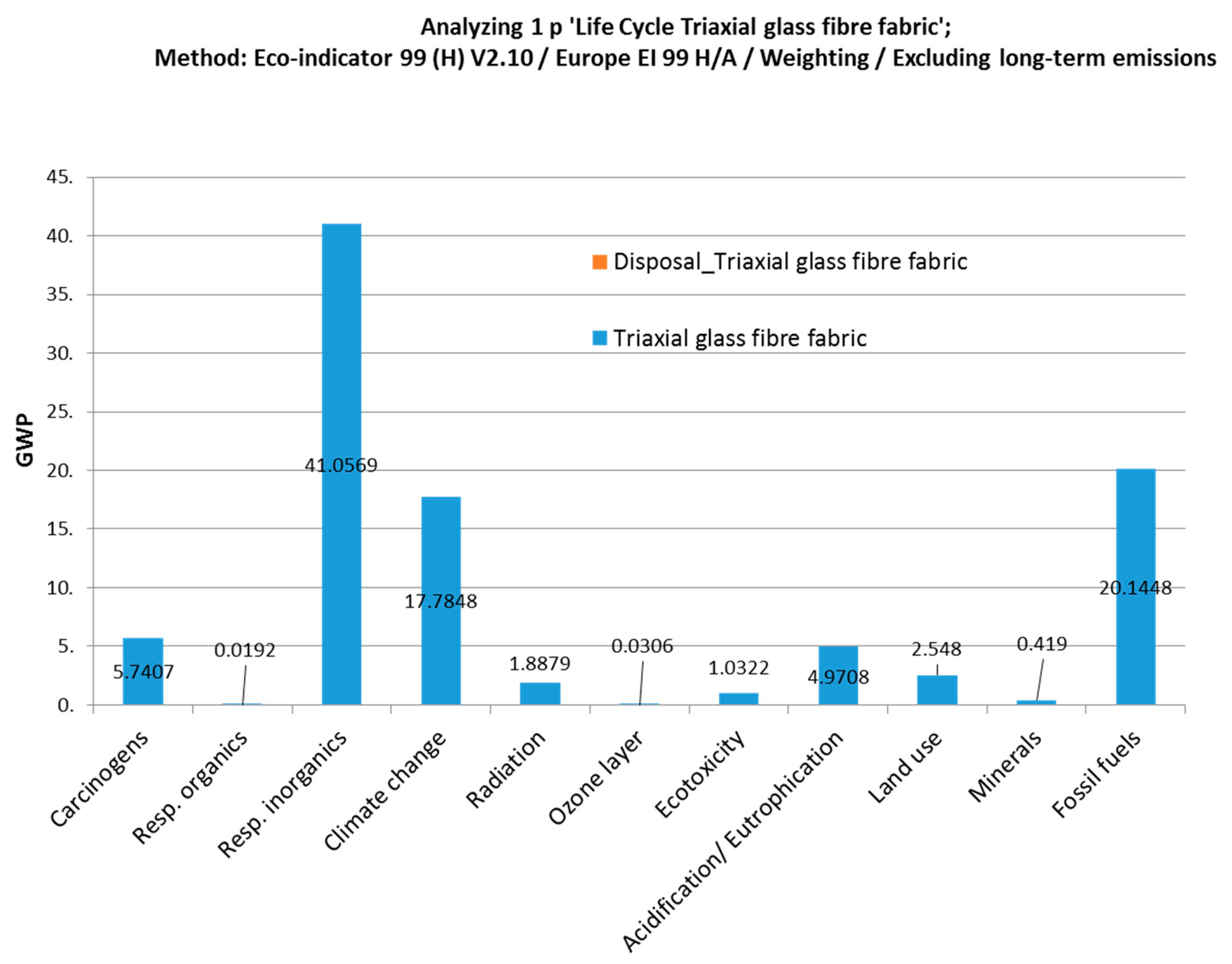

3.1.3. Environment Impact of the Production of Composite Fabrics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Van de Velde, K.; Baetens, E. Thermal and mechanical properties of flax fibres as potential composite reinforcement. Macromol. Mater. Eng. 2001, 286, 342–349. [Google Scholar] [CrossRef]

- Garcia, M.; Hidalgo, J.; Garmendia, I.; García-Jaca, J. Wood–plastics composites with better fire retardancy and durability performance. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1772–1776. [Google Scholar] [CrossRef]

- Schirp, A.; Stender, J. Properties of extruded wood-plastic composites based on refiner wood fibres (TMP fibres) and hemp fibres. Eur. J. Wood Prod. 2010, 68, 219–231. [Google Scholar] [CrossRef]

- Sykacek, E.; Hrabalova, M.; Frech, H.; Mundigler, N. Extrusion of five biopolymers reinforced with increasing wood flour concentration on a production machine, injection moulding and mechanical performance. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1272–1282. [Google Scholar] [CrossRef]

- Rajendran, S.; Hodzic, A.; Soutis, C.; MariamAl-Maadeed, A. Review of life cycle assessment on polyolefins and related materials. Plast. Rubber Compos. 2012, 41, 159–168. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-based renewable green composites from agricultural residues and their hybrids. Biomacromolecules 2010, 11, 1654–1660. [Google Scholar] [CrossRef]

- Huda, M.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced poly (lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sawpan, M.A.; Jayaraman, J.; Fernyhough, A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1148–1156. [Google Scholar] [CrossRef]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Corbière-Nicollier, T.; Laban, B.G.; Lundquist, L.; Leterrier, Y.; Månson, J.A.; Jolliet, O. Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour. Conserv. Recycl. 2001, 33, 267–287. [Google Scholar] [CrossRef]

- Schmidt, W.-P.; Beyer, H.-M. Life Cycle Study on a Natural Fibre Reinforced Component. Sae Trans. 1998, 107, 2095–2102. [Google Scholar]

- Diener, J.; Siehler, U. Ökologischer Vergleich von NMT-und GMT-Bauteilen. Die Angew. Makromol. Chem. 1999, 272, 1–4. [Google Scholar] [CrossRef]

- Wötzel, K.; Wirth, R.; Flake, M. Life cycle studies on hemp fibre reinforced components and ABS for automotive parts. Die Angew. Makromol. Chem. 1999, 272, 121–127. [Google Scholar] [CrossRef]

- Boustead, I. Ecoprofiles of Plastics and Related Intermediates; Association of Plastics Manufacturers in Europe: Brussels, Belgium, 1999. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-Indicator 95; PRé Consultants: Amersfoort, The Netherlands, 1995. [Google Scholar]

- Guinée, J.G.; Heijungs, M.; Huppes, R.; Kleijn, G.; Wegener Sleeswijk, R.; Udo de Haes, A.; de Bruijn, H.A.; van Duin, J.A.; Huijbregts, R.; Huijbregts, M.A.J. Environmental Life Cycle Assessment, An Operational Guide to the ISO Standard; Draft Version; Centre of Environmental Science (CML), Leiden University: Leiden, The Netherlands, 2000; in prepare. [Google Scholar]

- Jang, B.Z.; Ma, E.; Wang, C.J. Apparatus and Process for Producing Fiber Reinforced Composite Objects. U.S. Patent 5,936,861, 10 August 1999. [Google Scholar]

- Duflou, J.R.; Kellens, K.; Guo, Y.; Dewulf, W. Critical comparison of methods to determine the energy input for discrete manufacturing processes. Cirp Ann. Manuf. Technol. 2012, 61, 63–66. [Google Scholar] [CrossRef]

- Ribeiro, I.; Peças, P.; Henriques, E. Modelling the energy consumption in the injection moulding process. Int. J. Sustain. Manuf. 2015, 3, 289–309. [Google Scholar] [CrossRef]

- Gutowski, T.G. The Efficiency and Eco-Efficiency of Manufacturing. Int. J. Nanomanufacturing 2010, 6, 38–45. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Analysis of thermal cycling efficiency and optimal design of heating/cooling systems for rapid heat cycle injection molding process. Mater. Des. 2010, 31, 3426–3441. [Google Scholar]

- Scacchi, C.C.O.; González-García, S.; Caserini, S.; Rigamonti, L. Greenhouse gases emissions and energy use of wheat grain-based bioethanol fuel blends. Sci. Total Env. 2010, 408, 5010–5018. [Google Scholar] [CrossRef]

- China, S.; Mazzoleni, C.; Gorkowski, K.; Aiken, A.C.; Dubey, M.K. Morphology and mixing state of individual freshly emitted wildfire carbonaceous particles. Nat. Commun. 2013, 4, 2122. [Google Scholar] [CrossRef]

- Dissanayake, N.P.; Summerscales, J.; Grove, S.M.; Singh, M.M. Energy use in the production of flax fiber for the reinforcement of composites. J. Nat. Fibers 2009, 6, 331–346. [Google Scholar] [CrossRef]

- Ren, G.; Patel, H.; Hapuarachchi, D.; Crowther, S.; Fan, M.; Hogg, P.J. Development of natural HEMP fibre sheet mould composites (NF-SMC). In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in life cycle assessment. J. Env. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- ISO 14040:2006—Environmental Management–Life Cycle Assessment–Principles and Framework; British Standards Institution: London, UK, 2006.

- Pimentel, D.; Pleasant, A.; Barron, J.; Gaudioso, J.; Pollock, N.; Chae, E.; Kim, Y.; Lassiter, A.; Schiavoni, C.; Jackson, A.; et al. US energy conservation and efficiency: Benefits and costs. Env. Dev. Sustain. 2004, 6, 279–305. [Google Scholar] [CrossRef]

- Stiller, H. Material Intensity of Advanced Composite Materials: Results of Asudy for the Verbundwerkstofflabor Bremen Ev; Wuppertal Papers; EconStor: Kiel, Germany, 1999. [Google Scholar]

- Xu, X.; Jayaraman, K.; Morin, C.; Pecqueux, N. Life cycle assessment of wood-fibre-reinforced polypropylene composites. J. Mater. Process. Technol. 2008, 198, 168–177. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- Qiang, T.; Yu, D.; Zhang, A.; Gao, H.; Li, Z.; Liu, Z.; Chen, W.; Han, Z. Life cycle assessment on polylactide-based wood plastic composites toughened with polyhydroxyalkanoates. J. Clean. Prod. 2014, 66, 139–145. [Google Scholar] [CrossRef]

- Vink, E.T.; Glassner, D.A.; Kolstad, J.J.; Wooley, R.J.; O’Connor, R.P. The eco-profiles for current and near-future NatureWorks® polylactide (PLA) production. Ind. Biotechnol. 2007, 3, 58–81. [Google Scholar] [CrossRef]

- Alves, C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Scharnhorst, W.; Althaus, H.J.; Classen, M.; Jolliet, O.; Hilty, L.M. The end of life treatment of second generation mobile phone networks: Strategies to reduce the environmental impact. Env. Impact Assess. Rev. 2005, 25, 540–566. [Google Scholar] [CrossRef]

- Baumann, H.; Boons, F.; Bragd, A. Mapping the green product development field: Engineering, policy and business perspectives. J. Clean. Prod. 2002, 10, 409–425. [Google Scholar] [CrossRef]

- Specification, P.A. Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. Bsi Br. Stand. Isbn 2008, 978, 580. [Google Scholar]

- Wagner, B.; Svensson, G. A framework to navigate sustainability in business networks: The transformative business sustainability (TBS) model. Eur. Bus. Rev. 2014, 26, 340–367. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Baas, L.W.; Boons, F.A. An industrial ecology project in practice: Exploring the boundaries of decision-making levels in regional industrial systems. J. Clean. Prod. 2004, 12, 1073–1085. [Google Scholar] [CrossRef]

- Pietrini, M.; Roes, L.; Patel, M.K.; Chiellini, E. Comparative life cycle studies on poly (3-hydroxybutyrate)-based composites as potential replacement for conventional petrochemical plastics. Biomacromolecules 2007, 8, 2210–2218. [Google Scholar] [CrossRef]

- Vidal, R.; Martínez, P.; Garraín, D. Life cycle assessment of composite materials made of recycled thermoplastics combined with rice husks and cotton linters. Int. J. Life Cycle Assess. 2009, 14, 73–82. [Google Scholar] [CrossRef]

- Bolin, C.A.; Smith, S. Life cycle assessment of ACQ-treated lumber with comparison to wood plastic composite decking. J. Clean. Prod. 2011, 19, 620–629. [Google Scholar] [CrossRef]

- Curran, M.A. Life-Cycle Assessment. In Encyclopedia of Ecology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 4. [Google Scholar] [CrossRef]

- Norgate, T.; Rajakumar, V.; Trang, S. Titanium and Other Light Metals: Technology Pathways to Sustainable Development. In Proceedings of the Green Processing 2004. 2nd International Conference on the Sustainable Processing of Minerals, Fremantle, WA, USA, 10–12 May 2004. [Google Scholar]

| Materials | Energy Intensity (MJ/kg) | CO2 Emissions (kg CO2) | References |

|---|---|---|---|

| Glass fibres | 13–32 | 1.8–4.6 | [28] |

| China reed fibres | 3.6 | 0.5 | [28] |

| Flax fibres | 6.5 | 0.9 | |

| Process analysis | |||

| Fibre production | 12.24 | 1.7 | [28] |

| Fabric production | 0.772 | 0.1 | [31] |

| Prepreg production | 40.0 | 5.8 | [31] |

| Resin production | 34.2 | 4.9 | [31] |

| Flax tape fabric | 12.25 | 1.7 | Source: Tilsatec |

| Triaxial glass fabric | 29.04 | 4.2 | Source: Formax |

| Glass fabrics manufacturing | 30.84 | 4.5 | [31] |

| Prepreg material production | |||

| Prepreg flax tape component | 64.49 | 9.3 | Source: Tilsatec [31] |

| China reed fibre-epoxy | 56.61 | 8.2 | [41] |

| Glass fibre-epoxy | 83.84 | 12.18 | [41] |

| Triaxial glass fabric-Epoxy | 82.04 | 12 | Source: Formax [41] |

| Environmental | Glass Fibre Pallet/PP | Triaxial Glass Fabric-Epoxy | Natural Fibre Reed /PP | Flax/PLA Tape |

|---|---|---|---|---|

| Total energy use (MJ/kg) | 70 | 82.04 | 35.7 | 15 |

| Carbon dioxide emissions (kg) | 3.65 | 4.27 | 2.1 | 1.38 |

| Carbon monoxide (g) | 3.71 | 4.34 | 2.73 | 0.0447 |

| NOx (oxides of nitrogen) air emissions (g) | 25.65 | 30 | 17.45 | NE |

| Sulphur oxides (SOx) air emissions (g) | 14.45 | 17 | 8.15 | NE |

| Water emission—BOD (mg) | 20.7 | 24.35 | 13.3 | 1.32 |

| Water emissions—nitrates (g) | 0.086 | 0.1011 | 7.65 | NE |

| Water emissions—phosphates (g) | 0.029 | 0.0341 | 0.08 | NE |

| CML—Greenhouse effect (kg CO2 eq.) | 3.76 | 4.42 | 2.02 | NE |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tchana Toffe, G.; Oluwarotimi Ismail, S.; Montalvão, D.; Knight, J.; Ren, G. A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites. J. Manuf. Mater. Process. 2019, 3, 92. https://doi.org/10.3390/jmmp3040092

Tchana Toffe G, Oluwarotimi Ismail S, Montalvão D, Knight J, Ren G. A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites. Journal of Manufacturing and Materials Processing. 2019; 3(4):92. https://doi.org/10.3390/jmmp3040092

Chicago/Turabian StyleTchana Toffe, Gilles, Sikiru Oluwarotimi Ismail, Diogo Montalvão, Jason Knight, and Guogang Ren. 2019. "A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites" Journal of Manufacturing and Materials Processing 3, no. 4: 92. https://doi.org/10.3390/jmmp3040092

APA StyleTchana Toffe, G., Oluwarotimi Ismail, S., Montalvão, D., Knight, J., & Ren, G. (2019). A Scale-up of Energy-Cycle Analysis on Processing Non-Woven Flax/PLA Tape and Triaxial Glass Fibre Fabric for Composites. Journal of Manufacturing and Materials Processing, 3(4), 92. https://doi.org/10.3390/jmmp3040092